Effect of Extrusion Compression Ratio and Particle Size of Rice on the Sectional Expansion Index of Third-Generation Snacks †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of Rice Flour and Rice Grits in 3G Extruded Pellets

2.3. Particle Size

2.4. Microwave Expansion

Microwave Expansion Kinetics

2.5. Statistical Analysis

3. Results and Discussion

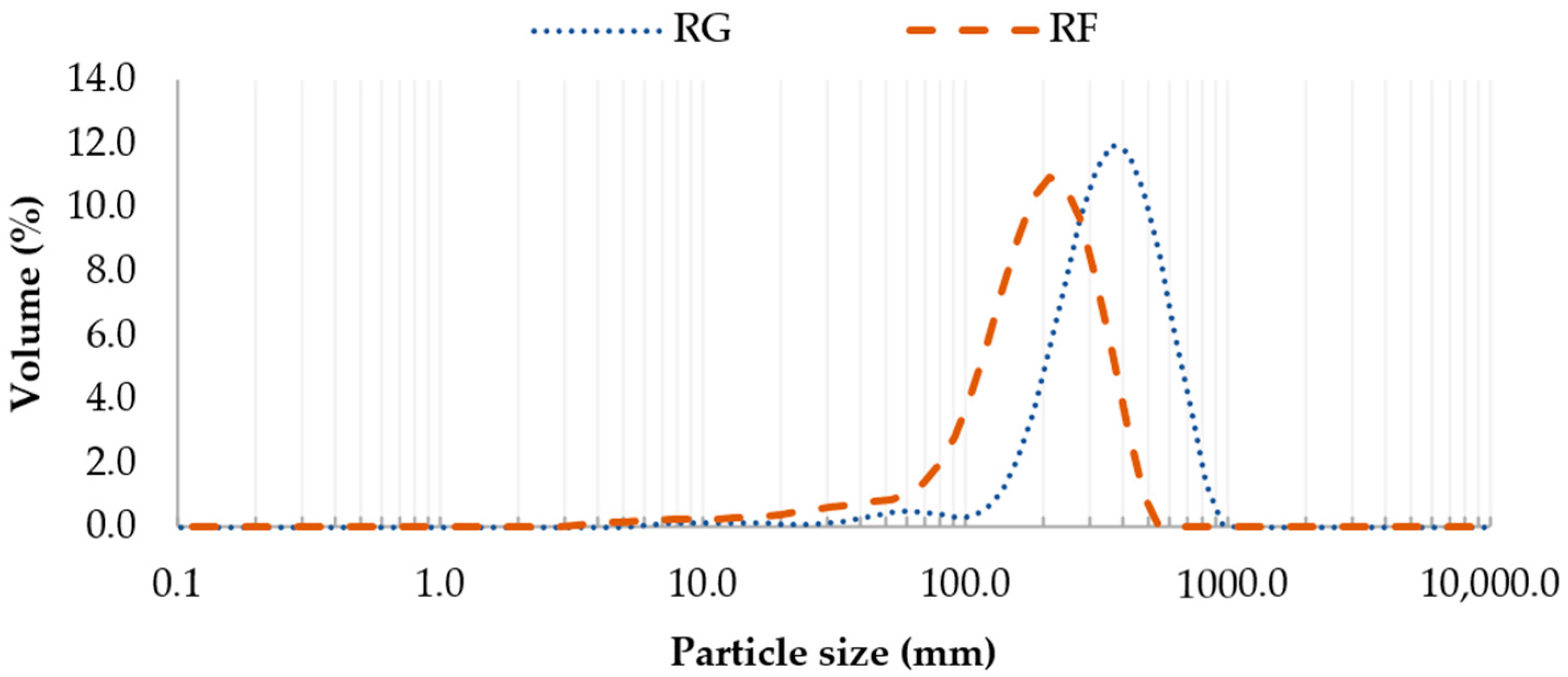

3.1. Particle Size

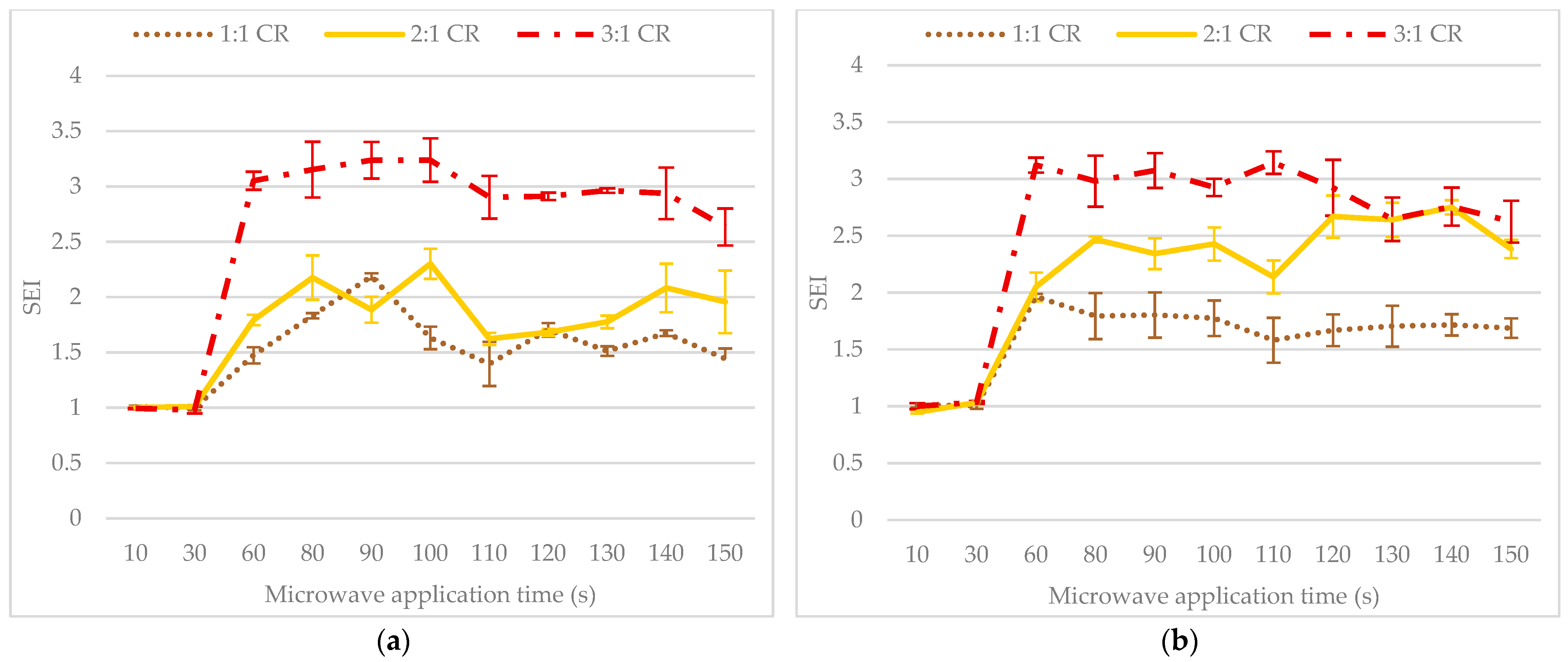

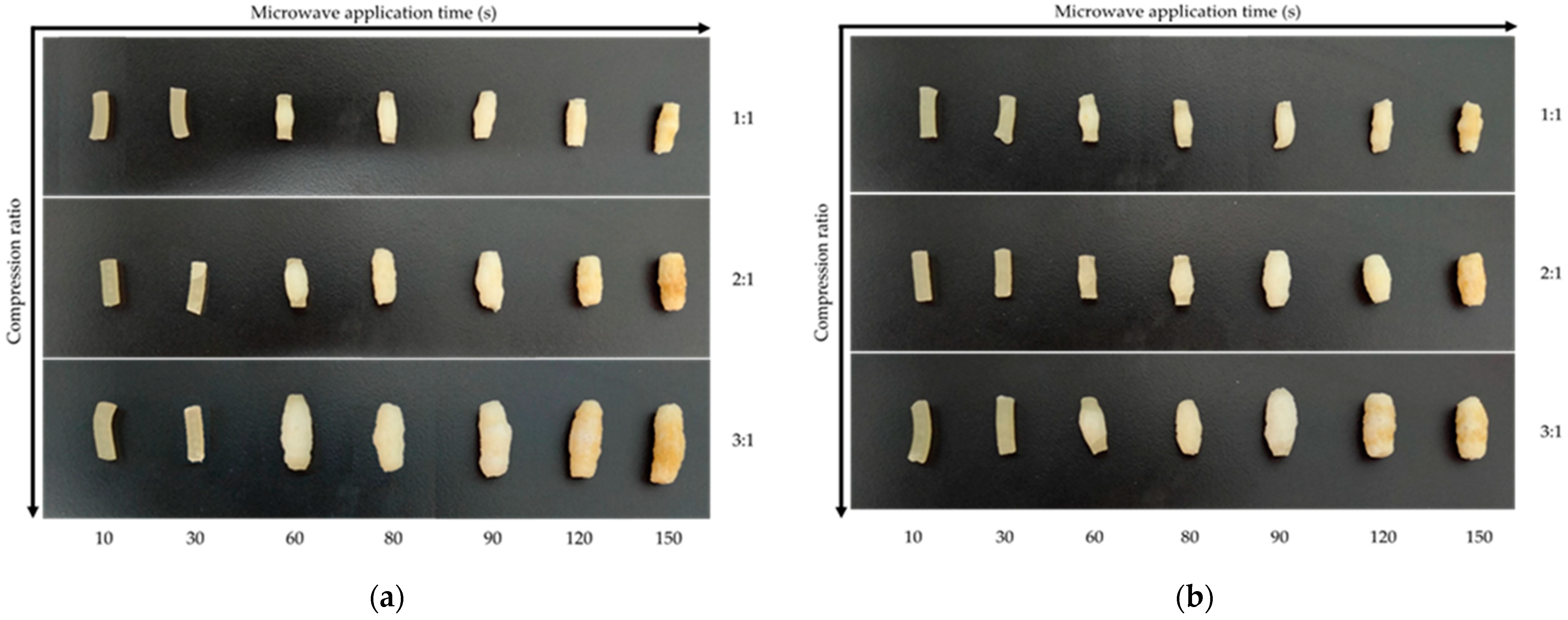

3.2. Microwaving Expansion Kinetics and Sectional Expansion Index (SEI)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Panak Balentic, J.; Babic, J.; Jozinovic, A.; Ackar, D.; Milicevic, B.; Muhamedbegovic, B.; Subaric, D. Production of Third-Generation Snacks. Croat. J. Food Sci. Technol. 2018, 10, 98–105. [Google Scholar] [CrossRef]

- Kantrong, H.; Klongdee, S.; Jantapirak, S.; Limsangouan, N.; Pengpinit, W. Effects of Extrusion Temperature and Puffing Technique on Physical and Functional Properties of Purpled Third-Generation Snack after Heat Treatment. J. Food Sci. Technol. 2022, 59, 2209–2219. [Google Scholar] [CrossRef] [PubMed]

- Yousouf, M.; Hussain, S.Z.; Kanojia, V.; Qadri, T.; Naseer, B.; Shafi, F.; Jabeen, A. Development of Third Generation Protein Rich Snacks from Lentil and Egg Powder through Microwave Assisted Extrusion Cooking. Nutr. Food Sci. 2023, 53, 285–300. [Google Scholar] [CrossRef]

- Igual, M.; Moreau, F.; García-Segovia, P.; Martínez-Monzó, J. Valorization of Beetroot by-Products for Producing Value-Added Third Generation Snacks. Foods 2023, 12, 176. [Google Scholar] [CrossRef] [PubMed]

- Neder-Suárez, D.; Quintero-Ramos, A.; Meléndez-Pizarro, C.O.; de Jesús Zazueta-Morales, J.; Paraguay-Delgado, F.; Ruiz-Gutiérrez, M.G. Evaluation of the Physicochemical Properties of Third-Generation Snacks Made from Blue Corn, Black Beans, and Sweet Chard Produced by Extrusion. LWT 2021, 146, 111414. [Google Scholar] [CrossRef]

- Acurio, L.; Salazar, D.; García-Segovia, P.; Martínez-Monzó, J.; Igual, M. Third-Generation Snacks Manufactured from Andean Tubers and Tuberous Root Flours: Microwave Expansion Kinetics and Characterization. Foods 2023, 12, 2168. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.S.; Kaur, J.; Khaira, H.; Gupta, K. Extrusion and Extruded Products: Changes in Quality Attributes as Affected by Extrusion Process Parameters: A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 445–473. [Google Scholar] [CrossRef] [PubMed]

- ISO 13320; Particle size analysis-laser diffraction methods. ISO Standard International: Geneva, Switzerland, 2020.

- Patil, R.T.; Berrios, J.D.J.; Tang, D.J.; Swanson, B.G. Swanson Evaluation of Methods for Expansion Properties of Legume Extrudates. Appl. Eng. Agric. 2007, 23, 777–783. [Google Scholar] [CrossRef]

- Desrumaux, A.; Bouvier, J.M.; Burri, J. Corn Grits Particle Size and Distribution Effects on the Characteristics of Expanded Extrudates. J. Food Sci. 1998, 63, 857–863. [Google Scholar] [CrossRef]

- Alam, S.A.; Järvinen, J.; Kirjoranta, S.; Jouppila, K.; Poutanen, K.; Sozer, N. Influence of Particle Size Reduction on Structural and Mechanical Properties of Extruded Rye Bran. Food Bioproc Tech. 2014, 7, 2121–2133. [Google Scholar] [CrossRef]

- Petrova, T.; Penov, N.; Ruskova, M.; Bakalov, I.; Kalcheva–Karadzhova, K. Optimization of Extrusion Process for Production of Lentil Extrudates. In Proceedings of the Food, Technologies & Health, Plovdiv, Bulgaria, 20 November 2015; pp. 101–105. [Google Scholar]

- Lee, E.Y.; Lim, K.I.; Lim, J.K.; Lim, S.T. Effects of Gelatinization and Moisture Content of Extruded Starch Pellets on Morphology and Physical Properties of Microwave-Expanded Products. Cereal Chem. 2000, 77, 769–773. [Google Scholar] [CrossRef]

- Gat, Y.; Ananthanarayan, L. Effect of Extrusion Process Parameters and Pregelatinized Rice Flour on Physicochemical Properties of Ready-to-Eat Expanded Snacks. J. Food Sci. Technol. 2015, 52, 2634–2645. [Google Scholar] [CrossRef] [PubMed]

- Acurio, L.; Moreau, F.; García-Segovia, P.; Martínez-Monzó, J.; Igual, M. Microwave Expansion Kinetics of Third-Generation Extruded Corn Pellets under Different Moisture Contents. Foods 2022, 12, 51. [Google Scholar] [CrossRef]

- Beck, S.M.; Knoerzer, K.; Foerster, M.; Mayo, S.; Philipp, C.; Arcot, J. Low Moisture Extrusion of Pea Protein and Pea Fibre Fortified Rice Starch Blends. J. Food Eng. 2018, 231, 61–71. [Google Scholar] [CrossRef]

| Chemical Composition | Average Values per 100 g of RF | Average Values per 100 g of RG |

|---|---|---|

| Carbohydrates | 79.5 g | 78.0 g |

| Proteins | 6.5 g | 6.5 g |

| Fat | 0.6 g | 0.3 g |

| Fiber | 2.1 g | 1.9 g |

| Sample | D[4,3] | d(0.1) | d(0.5) | d(0.9) |

|---|---|---|---|---|

| RF | 186.2 (0.4) b | 67.9 (0.6) b | 178.9 (0.4) b | 313.9 (0.7) b |

| RG | 348 (2) a | 170 (2) a | 331 (2) a | 563 (2) a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vicente-Jurado, D.; García-Segovia, P.; Gutiérrez-Cano, J.D.; Martínez-Monzó, J.; Catalá-Civera, J.M.; Igual-Ramo, M. Effect of Extrusion Compression Ratio and Particle Size of Rice on the Sectional Expansion Index of Third-Generation Snacks. Biol. Life Sci. Forum 2023, 26, 69. https://doi.org/10.3390/Foods2023-15121

Vicente-Jurado D, García-Segovia P, Gutiérrez-Cano JD, Martínez-Monzó J, Catalá-Civera JM, Igual-Ramo M. Effect of Extrusion Compression Ratio and Particle Size of Rice on the Sectional Expansion Index of Third-Generation Snacks. Biology and Life Sciences Forum. 2023; 26(1):69. https://doi.org/10.3390/Foods2023-15121

Chicago/Turabian StyleVicente-Jurado, Diana, Purificación García-Segovia, José Daniel Gutiérrez-Cano, Javier Martínez-Monzó, José Manuel Catalá-Civera, and Marta Igual-Ramo. 2023. "Effect of Extrusion Compression Ratio and Particle Size of Rice on the Sectional Expansion Index of Third-Generation Snacks" Biology and Life Sciences Forum 26, no. 1: 69. https://doi.org/10.3390/Foods2023-15121

APA StyleVicente-Jurado, D., García-Segovia, P., Gutiérrez-Cano, J. D., Martínez-Monzó, J., Catalá-Civera, J. M., & Igual-Ramo, M. (2023). Effect of Extrusion Compression Ratio and Particle Size of Rice on the Sectional Expansion Index of Third-Generation Snacks. Biology and Life Sciences Forum, 26(1), 69. https://doi.org/10.3390/Foods2023-15121