Supply Chain Disruption versus Optimization: A Review on Artificial Intelligence and Blockchain

Abstract

:1. Introduction

2. Supply Chain Disruptions

3. AI and Blockchain in Supply Chain

4. Methodology

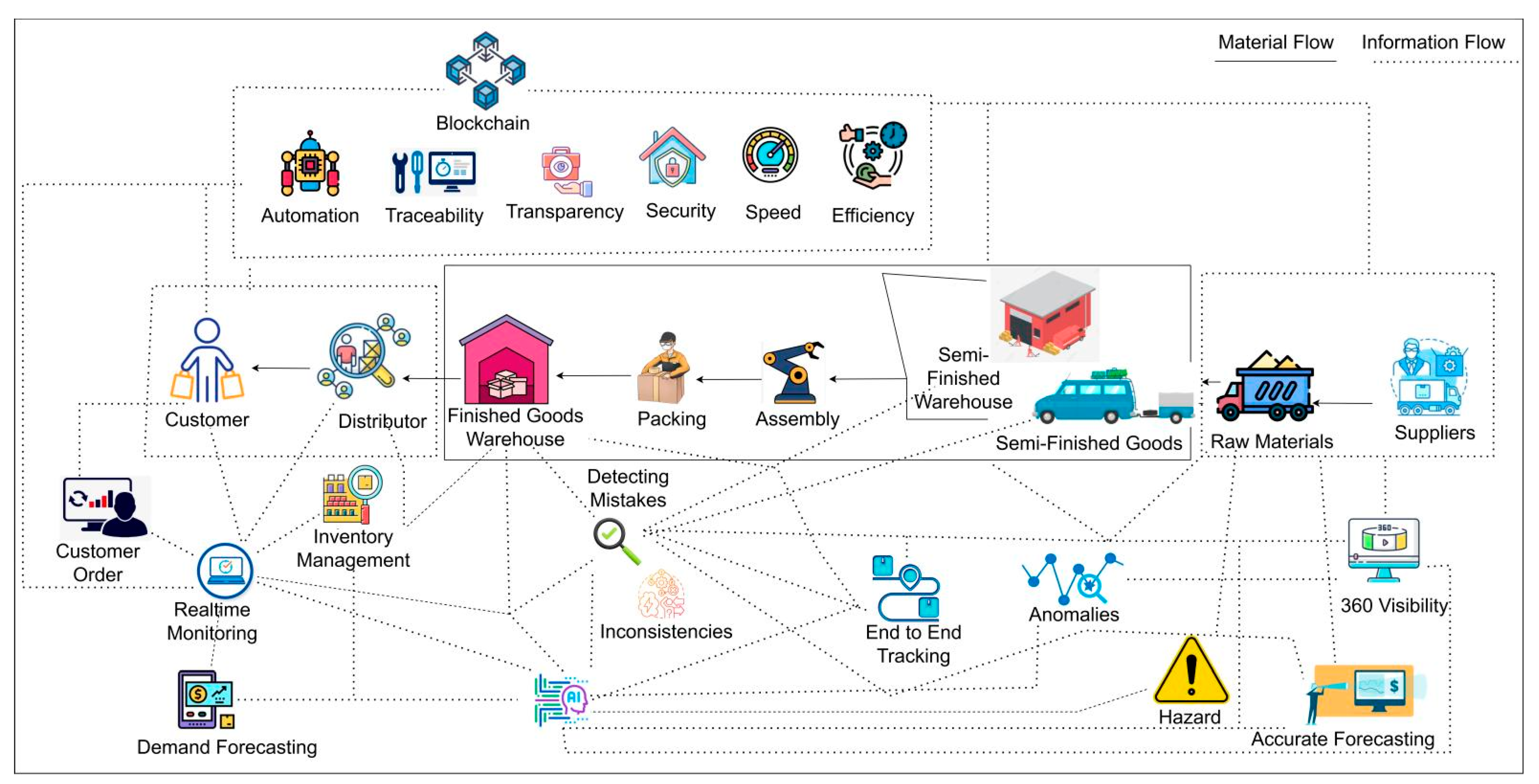

5. AI and Blockchain Incorporated Supply Chain Framework

6. Intelligence in Supply Chain

7. Theoretical and Managerial Implications

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

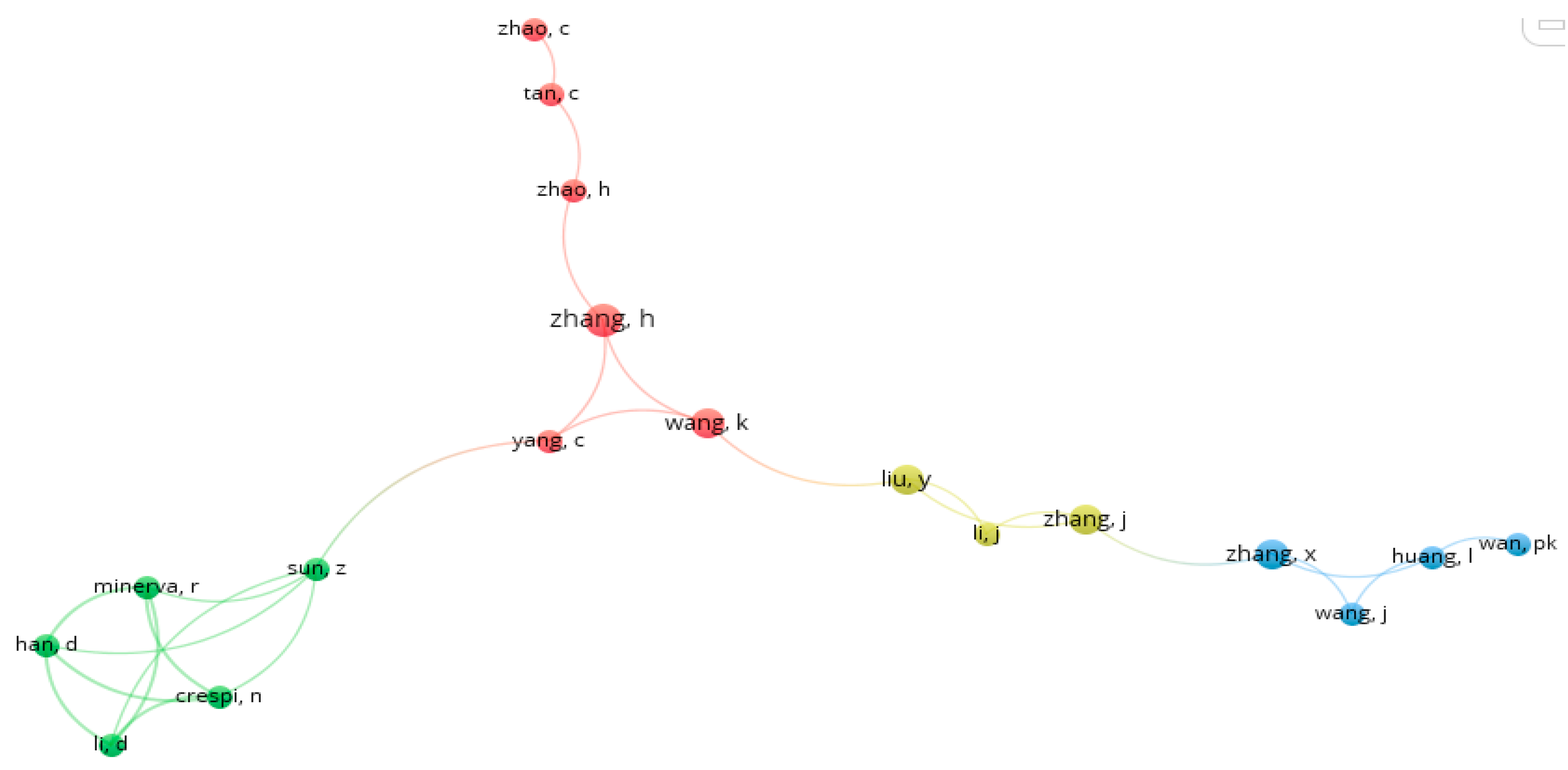

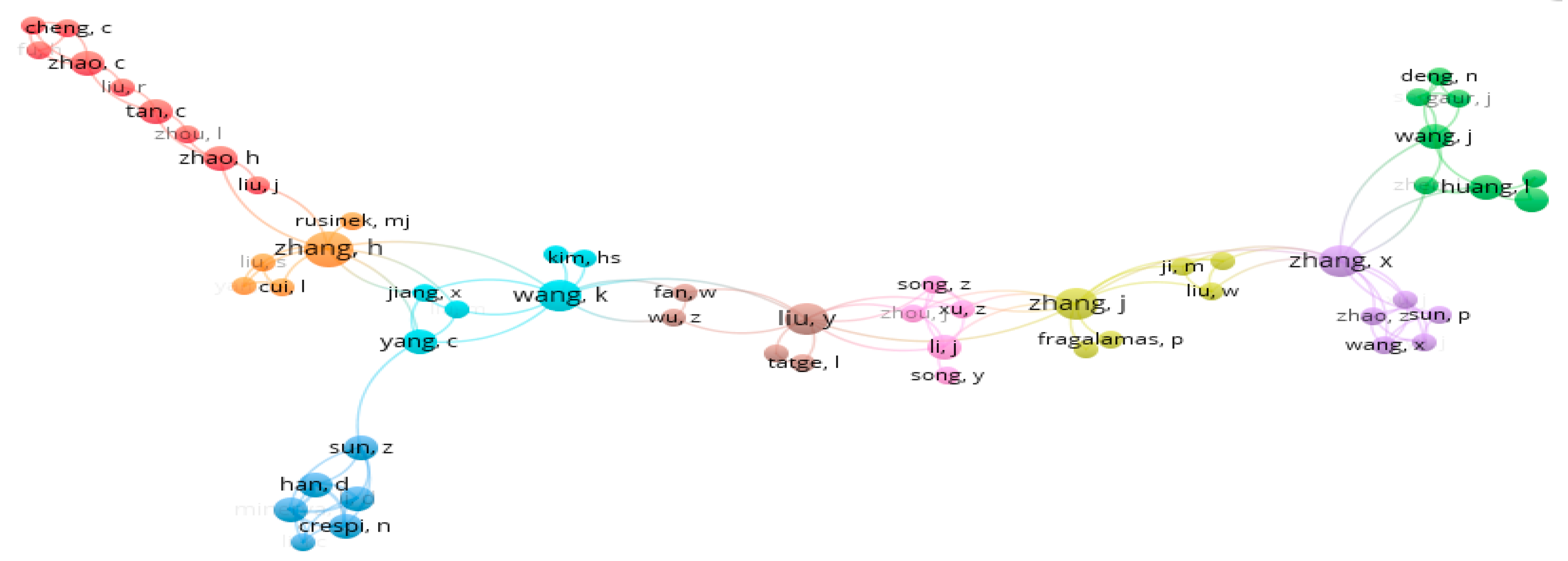

| Min. No. of Documents of an Author | Total Authors in the List | No. of Authors Meet the Criteria | No. of Authors Selected | No. of Items (No. of Clusters) |

|---|---|---|---|---|

| 4 | 1142 | 4 | 4 | 4 (4) |

| 3 | 1142 | 21 | 21 | 5 (3) |

| 2 | 1142 | 115 | 115 | 18 (4) |

| 1 | 1142 | 1142 | 1000 | 56 (9) |

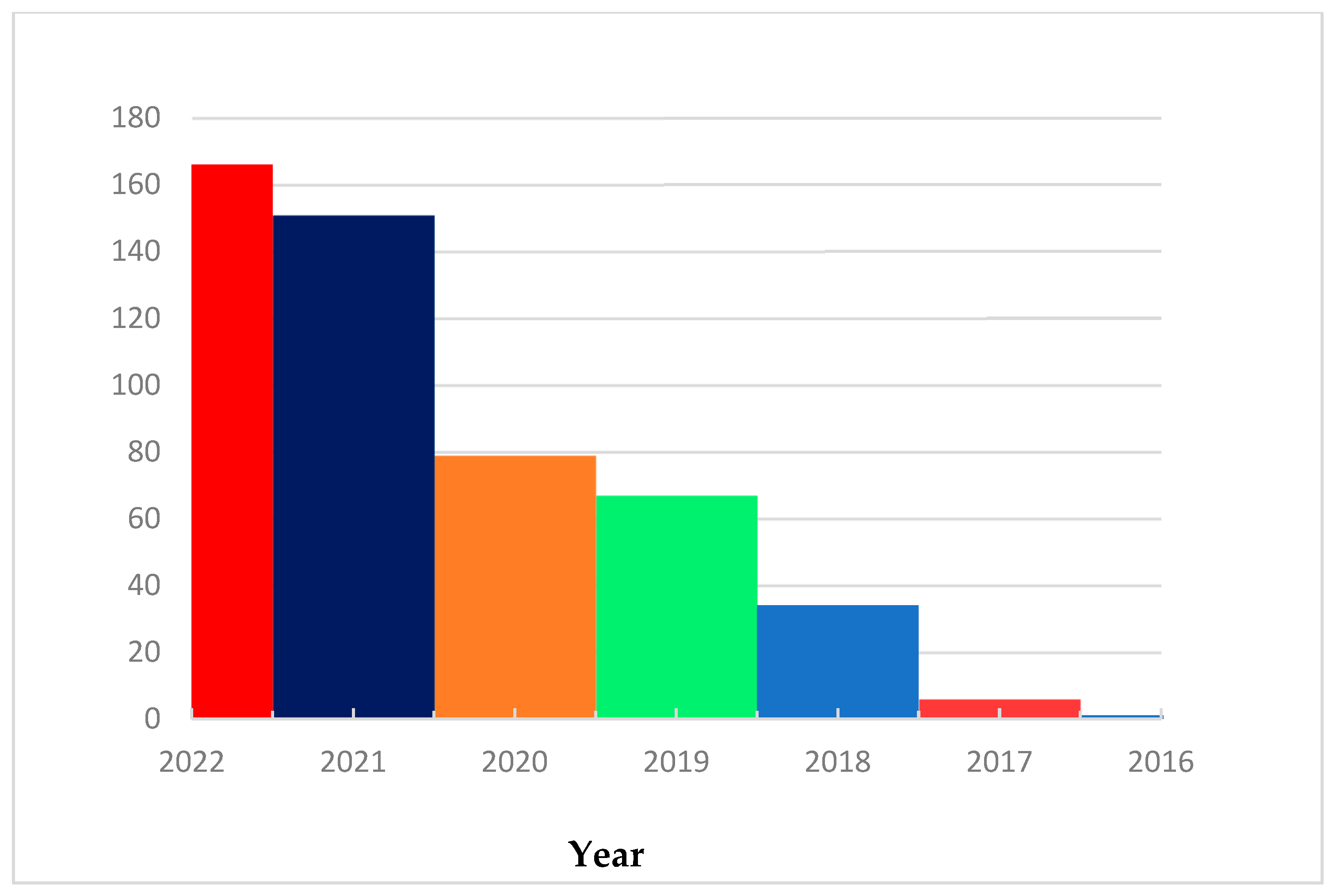

| Year | Number of Papers |

|---|---|

| 2016 | 1 |

| 2017 | 6 |

| 2018 | 34 |

| 2019 | 67 |

| 2020 | 79 |

| 2021 | 151 |

| 2022 | 166 |

| Rank | Cites | Authors | Year | GS Rank | ECC | Cites Per Year | Cites Per Author |

|---|---|---|---|---|---|---|---|

| 1 | 686 | K Francisco, D Swanson | 2018 | 190 | 686 | 171.5 | 343 |

| 2 | 432 | SS Kamble, A Gunasekaran, R Sharma | 2020 | 216 | 432 | 216 | 144 |

| 3 | 369 | M Kouhizadeh, S Saberi, J Sarkis | 2021 | 414 | 369 | 369 | 123 |

| 4 | 356 | K Salah, N Nizamuddin, R Jayaraman, M Omar | 2019 | 35 | 356 | 118.67 | 89 |

| 5 | 310 | LW Wong, LY Leong, JJ Hew, GWH Tan | 2020 | 496 | 310 | 155 | 62 |

| 6 | 267 | DE O’Leary | 2017 | 126 | 267 | 53.4 | 267 |

| 7 | 264 | C Bai, J Sarkis | 2020 | 241 | 264 | 132 | 132 |

| 8 | 214 | JH Tseng, YC Liao, B Chong, S Liao | 2018 | 87 | 214 | 53.5 | 54 |

| 9 | 210 | J Chod, N Trichakis, G Tsoukalas… | 2020 | 43 | 210 | 105 | 53 |

| 10 | 192 | F Longo, L Nicoletti, A Padovano, G d’Atri… | 2019 | 329 | 192 | 64 | 38 |

| 11 | 188 | A Di Vaio, L Varriale | 2020 | 338 | 188 | 94 | 94 |

| 12 | 186 | KA Clauson, EA Breeden… | 2018 | 129 | 186 | 46.5 | 62 |

| 13 | 184 | TM Fernández-Caramés, O Blanco-Novoa… | 2019 | 351 | 184 | 61.33 | 61 |

| 14 | 178 | D Mao, F Wang, Z Hao, H Li | 2018 | 306 | 178 | 44.5 | 45 |

| 15 | 176 | KS Hald, A Kinra | 2019 | 486 | 176 | 58.67 | 88 |

| 16 | 171 | A Banerjee | 2018 | 488 | 171 | 42.75 | 171 |

| 17 | 167 | SF Wamba, MM Queiroz, L Trinchera | 2020 | 74 | 167 | 83.5 | 56 |

| 18 | 155 | J Duan, C Zhang, Y Gong, S Brown, Z Li | 2020 | 206 | 155 | 77.5 | 31 |

| 19 | 132 | R van Hoek | 2019 | 291 | 132 | 44 | 132 |

| 20 | 127 | A, J Johny | 2019 | 281 | 127 | 42.33 | 64 |

| Name of the Publisher | No. of Top Cited Papers (Out of 504) |

|---|---|

| ieeexplore.ieee.org | 54 |

| Springer | 48 |

| Elsevier | 45 |

| mdpi.com | 41 |

| emerald.com | 18 |

| researchgate.net | 18 |

| Taylor & Francis | 18 |

| papers.ssrn.com | 11 |

| Wiley Online Library | 10 |

| academia.edu | 7 |

| hindawi.com | 7 |

| igi-global.com | 7 |

| arxiv.org | 6 |

| iopscience.iop.org | 4 |

| journal.oscm-forum.org | 3 |

| lup.lub.lu.se | 3 |

| politesi.polimi.it | 3 |

| ntnuopen.ntnu.no | 2 |

| preprints.org | 2 |

| core.ac.uk | 2 |

| Rank | Title of the Journal | Rank | Title of the Journal |

|---|---|---|---|

| 1 | Logistics | 11 | Sensors |

| 2 | International Journal of Information Management | 12 | International Journal of Physical Distribution & Logistics Management. |

| 3 | International Journal of Production Economics | 13 | Advances in computers |

| 4 | IEEE Access | 14 | International Journal of Operations & Production Management. |

| 5 | Intelligent Systems in Accounting, Finance and Management | 15 | Robotics and Computer-Integrated Manufacturing |

| 6 | International Journal of Production Research | 16 | Journal of cleaner production |

| 7 | International journal of environmental research and public health | 17 | IEEE Transactions on Engineering Management |

| 8 | Management Science | 18 | Supply Chain Management: An International Journal |

| 9 | Computers & Industrial Engineering | 19 | Sustainability |

| 10 | Blockchain in healthcare today | 20 | Journal of Business Logistics |

References

- Abbas, K.; Afaq, M.; Ahmed Khan, T.; Song, W.C. A blockchain and machine learning-based drug supply chain management and recommendation system for smart pharmaceutical industry. Electronics 2020, 9, 852. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Khan, S.; Suman, R. Blockchain technology applications for Industry 4.0: A literature-based review. Blockchain Res. Appl. 2021, 2, 100027. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Kumar, V.; Belhadi, A.; Foropon, C. A machine learning based approach for predicting blockchain adoption in the supply Chain. Technol. Forecast. Soc. Chang. 2021, 163, 120465. [Google Scholar] [CrossRef]

- Makridakis, S.; Polemitis, A.; Giaglis, G.; Louca, S. Blockchain: The next breakthrough in the rapid progress of AI. Artif. Intell.-Emerg. Trends Appl. 2018, 2, 73–84. [Google Scholar]

- Wang, M.; Wu, Y.; Chen, B.; Evans, M. Blockchain and supply chain management: A new paradigm for supply chain integration and collaboration. Oper. Supply Chain Manag. Int. J. 2020, 14, 111–122. [Google Scholar] [CrossRef]

- Koh, L.; Dolgui, A.; Sarkis, J. Blockchain in transport and logistics—Paradigms and transitions. Int. J. Prod. Res. 2020, 58, 2054–2062. [Google Scholar] [CrossRef]

- Olan, F.; Arakpogun, E.O.; Jayawickrama, U.; Suklan, J.; Liu, S. Sustainable supply chain finance and supply networks: The role of artificial intelligence. IEEE Trans. Eng. Manag. 2022, 1. Available online: https://hdl.handle.net/2134/17929241.v1 (accessed on 16 January 2023). [CrossRef]

- Pimenidis, E.; Patsavellas, J.; Tonkin, M. Blockchain and Artificial Intelligence Managing a Secure and Sustainable Supply Chain. In Cybersecurity, Privacy and Freedom Protection in the Connected World; Springer: Berlin/Heidelberg, Germany, 2021; pp. 367–377. [Google Scholar]

- Anthony Kendall, A.D.; Bruce Nagy, A.G. Blockchain Data Management Benefits by Increasing Confidence in Datasets Supporting Artificial Intelligence (AI) and Analytical Tools Using Supply Chain Examples; Acquisition Research Program: Monterey, CA, USA, 2021. [Google Scholar]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Liu, K.S.; Lin, M.H. Performance Assessment on the Application of Artificial Intelligence to Sustainable Supply Chain Management in the Construction Material Industry. Sustainability 2021, 13, 12767. [Google Scholar] [CrossRef]

- Toorajipour, R.; Sohrabpour, V.; Nazarpour, A.; Oghazi, P.; Fischl, M. Artificial intelligence in supply chain management: A systematic literature review. J. Bus. Res. 2021, 122, 502–517. [Google Scholar] [CrossRef]

- Vyas, N.; Beije, A.; Krishnamachari, B. Blockchain and the Supply Chain: Concepts, Strategies and Practical Applications; Kogan Page Publishers: London, UK, 2019. [Google Scholar]

- Younis, H.; Sundarakani, B.; Alsharairi, M. Applications of artificial intelligence and machine learning within supply chains: Systematic review and future research directions. J. Model. Manag. 2021, 17, 916–940. [Google Scholar] [CrossRef]

- Belhadi, A.; Mani, V.; Kamble, S.S.; Khan, S.A.R.; Verma, S. Artificial intelligence-driven innovation for enhancing supply chain resilience and performance under the effect of supply chain dynamism: An empirical investigation. Ann. Oper. Res. 2021, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Nayal, K.; Raut, R.; Priyadarshinee, P.; Narkhede, B.E.; Kazancoglu, Y.; Narwane, V. Exploring the role of artificial intelligence in managing agricultural supply chain risk to counter the impacts of the COVID-19 pandemic. Int. J. Logist. Manag. 2021, 29, covidwho-1309707. [Google Scholar] [CrossRef]

- Arunmozhi, M.; Venkatesh, V.G.; Arisian, S.; Shi, Y.; Sreedharan, V.R. Application of blockchain and smart contracts in autonomous vehicle supply chains: An experimental design. Transp. Res. Part E Logist. Transp. Rev. 2022, 165, 102864. [Google Scholar] [CrossRef]

- Mamoshina, P.; Ojomoko, L.; Yanovich, Y.; Ostrovski, A.; Botezatu, A.; Prikhodko, P.; Izumchenko, E.; Aliper, A.; Romantsov, K.; Zhavoronkov, A. Converging blockchain and next-generation artificial intelligence technologies to decentralize and accelerate biomedical research and healthcare. Oncotarget 2018, 9, 5665. [Google Scholar] [CrossRef]

- Rodríguez-Espíndola, O.; Chowdhury, S.; Beltagui, A.; Albores, P. The potential of emergent disruptive technologies for humanitarian supply chains: The integration of blockchain, Artificial Intelligence and 3D printing. Int. J. Prod. Res. 2020, 58, 4610–4630. [Google Scholar] [CrossRef]

- Sharma, R.; Shishodia, A.; Gunasekaran, A.; Min, H.; Munim, Z.H. The role of artificial intelligence in supply chain management: Mapping the territory. Int. J. Prod. Res. 2022, 60, 7527–7550. [Google Scholar] [CrossRef]

- Singh, S.K.; Rathore, S.; Park, J.H. Blockiotintelligence: A blockchain-enabled intelligent IoT architecture with artificial intelligence. Future Gener. Comput. Syst. 2020, 110, 721–743. [Google Scholar] [CrossRef]

- Ekramifard, A.; Amintoosi, H.; Seno, A.H.; Dehghantanha, A.; Parizi, R.M. A systematic literature review of integration of blockchain and artificial intelligence. Blockchain Cybersecur. Trust Priv. 2020, 79, 147–160. [Google Scholar]

- Helo, P.; Hao, Y. Artificial intelligence in operations management and supply chain management: An exploratory case study. Prod. Plan. Control 2021, 33, 1573–1590. [Google Scholar] [CrossRef]

- Singh, S.; Sharma, P.K.; Yoon, B.; Shojafar, M.; Cho, G.H.; Ra, I.H. Convergence of blockchain and artificial intelligence in IoT network for the sustainable smart city. Sustain. Cities Soc. 2020, 63, 102364. [Google Scholar] [CrossRef]

- Hussain, A.A.; Al-Turjman, F. Artificial intelligence and blockchain: A review. Trans. Emerg. Telecommun. Technol. 2021, 32, e4268. [Google Scholar] [CrossRef]

- Sgantzos, K.; Grigg, I. Artificial intelligence implementations on the blockchain. Use cases and future applications. Future Internet 2019, 11, 170. [Google Scholar] [CrossRef]

- Shamsuddoha, M.; Kashem, M.A. A Revolutionary Paradigm Shift in Supply Chain Management: The Blockchain Mechanism. In Exploring the Latest Trends in Management Literature; Emerald Publishing Limited: Bingley, UK, 2022; pp. 15–34. ISSN 2754-5865. [Google Scholar] [CrossRef]

- Hassija, V.; Chamola, V.; Gupta, V.; Jain, S.; Guizani, N. A survey on supply chain security: Application areas, security threats, and solution architectures. IEEE Internet Things J. 2020, 8, 6222–6246. [Google Scholar] [CrossRef]

- Kranz, M. Success with the internet of things requires more than chasing the cool factor. Harv. Bus. Rev. 2017, H03SWU. [Google Scholar]

- Min, S.; Zacharia, Z.G.; Smith, C.D. Defining supply chain management: In the past, present, and future. J. Bus. Logist. 2019, 40, 44–55. [Google Scholar] [CrossRef]

- Iansiti, M.; Lakhani, K.R. The Truth about Blockchain. Harv. Bus. Rev. 2017, 95, 118–127. [Google Scholar]

- Swan, M. Blockchain for business: Next-generation enterprise artificial intelligence systems. Adv. Comput. 2018, 111, 121–162. [Google Scholar]

- Lücker, F.; Seifert, R.W.; Biçer, I. Roles of inventory and reserve capacity in mitigating supply chain disruption risk. Int. J. Prod. Res. 2019, 57, 1238–1249. [Google Scholar] [CrossRef]

- Alam, M.A.; Ahad, A.; Zafar, S.; Tripathi, G. A neoteric smart and sustainable farming environment incorporating blockchain-based artificial intelligence approach. In Cryptocurrencies Blockchain Technology Applications; Wiley: Hoboken, NJ, USA, 2020; pp. 197–213. [Google Scholar]

- Blanchard, D. Supply Chain Management Best Practices; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Nozari, H.; Szmelter-Jarosz, A.; Ghahremani-Nahr, J. Analysis of the Challenges of Artificial Intelligence of Things (AIoT) for the Smart Supply Chain (Case Study: FMCG Industries). Sensors 2022, 22, 2931. [Google Scholar] [CrossRef] [PubMed]

- Gohil, D.; Thakker, S.V. Blockchain-integrated technologies for solving supply chain challenges. Mod. Supply Chain Res. Appl. 2021, 3, 78–97. [Google Scholar] [CrossRef]

- Kashem, M.A.; Shamsuddoha, M.; Nasir, T.; Chowdhury, A.A. The Role of Artificial Intelligence and Blockchain Technologies in Sustainable Tourism in the Middle East. In Worldwide Hospitality and Tourism Themes; Emerald Publishing Limited: Bingley, UK, 2022; pp. 1755–4225. ISSN 1755-4217. [Google Scholar]

- Zhang, Z.; Song, X.; Liu, L.; Yin, J.; Wang, Y.; Lan, D. Recent advances in blockchain and artificial intelligence integration: Feasibility analysis, research issues, applications, challenges, and future work. Secur. Commun. Netw. 2021, 2021, 9991535. [Google Scholar] [CrossRef]

- Reddy, K.R.K.; Gunasekaran, A.; Kalpana, P.; Sreedharan, V.R.; Kumar, S.A. Developing a blockchain framework for the automotive supply chain: A systematic review. Comput. Ind. Eng. 2021, 157, 107334. [Google Scholar] [CrossRef]

- Korpela, K.; Hallikas, J.; Dahlberg, T. Digital supply chain transformation toward blockchain integration. In Proceedings of the 50th Hawaii International Conference on System Sciences, Waikoloa Village, HI, USA, 4–7 January 2017. [Google Scholar]

- Thwin, T.T.; Vasupongayya, S. Blockchain based secret-data sharing model for personal health record system. In Proceedings of the 5th International Conference on Advanced Informatics: Concept Theory and Applications (ICAICTA), Krabi, Thailand, 14–17 August 2018; pp. 196–201. [Google Scholar]

- Wang, Y.; Han, J.H.; Beynon-Davies, P. Understanding blockchain technology for future supply chains: A systematic literature review and research agenda. Supply Chain Manag. Int. J. 2018, 24, 62–84. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Patel, C.; McGaughey, R.E. A framework for supply chain performance measurement. Int. J. Prod. Econ. 2004, 87, 333–347. [Google Scholar] [CrossRef]

- Dash, R.; McMurtrey, M.; Rebman, C.; Kar, U.K. Application of artificial intelligence in automation of supply chain management. J. Strateg. Innov. Sustain. 2019, 14, 43–53. [Google Scholar]

- Vassakis, K.; Petrakis, E.; Kopanakis, I. Big data analytics: Applications, prospects and challenges. In Mobile Big Data; Springer: Berlin/Heidelberg, Germany, 2018; pp. 3–20. [Google Scholar]

- Niu, B.; Zou, Z. Better demand signal, better decisions? Evaluation of big data in a licensed remanufacturing supply chain with environmental risk considerations. Risk Anal. 2017, 37, 1550–1565. [Google Scholar] [CrossRef]

- Feizabadi, J. Machine learning demand forecasting and supply chain performance. Int. J. Logist. Res. Appl. 2022, 25, 119–142. [Google Scholar] [CrossRef]

- Merlino, M.; Sproģe, I. The augmented supply chain. Procedia Eng. 2017, 178, 308–318. [Google Scholar] [CrossRef]

- Gorane, S.; Kant, R. Supply chain practices and organizational performance: An empirical investigation of Indian manufacturing organizations. Int. J. Logist. Manag. 2017, 28, 75–101. [Google Scholar] [CrossRef]

- Cao, L. Artificial intelligence in retail: Applications and value creation logics. Int. J. Retail. Distrib. Manag. Commun. 2021, 49, 100521. [Google Scholar] [CrossRef]

- Mahroof, K. A human-centric perspective exploring the readiness towards smart warehousing: The case of a large retail distribution warehouse. Int. J. Inf. Manag. 2019, 45, 176–190. [Google Scholar] [CrossRef]

- Sohrabpour, V.; Oghazi, P.; Toorajipour, R.; Nazarpour, A. Export sales forecasting using artificial intelligence. Technol. Forecast. Soc. Chang. 2021, 163, 120480. [Google Scholar] [CrossRef]

- Kumar, S.; Lim, W.M.; Sivarajah, U.; Kaur, J. Artificial intelligence and blockchain integration in business: Trends from a bibliometric-content analysis. Inf. Syst. Front. 2022, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Rejeb, A.; Rejeb, K.; Abdollahi, A.; Treiblmaier, H. The big picture on Instagram research: Insights from a bibliometric analysis. Telemat. Inform. 2022, 73, 101876. [Google Scholar] [CrossRef]

- Wamba, S.F.; Mishra, D. Big data integration with business processes: A literature review. Bus. Process Manag. J. 2017, 23, 477–492. [Google Scholar] [CrossRef]

- Mengist, W.; Soromessa, T.; Legese, G. Method for conducting systematic literature review and meta-analysis for environmental science research. MethodsX 2020, 7, 100777. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Text mining and visualization using VOSviewer. arXiv 2011, arXiv:1109.2058. [Google Scholar]

- Rejeb, A.; Simske, S.; Rejeb, K.; Treiblmaier, H.; Zailani, S. Internet of Things research in supply chain management and logistics: A bibliometric analysis. Internet Things 2020, 12, 100318. [Google Scholar] [CrossRef]

- Shamsuddoha, M. Knowledge management in the intelligent organization. Pak. J. Soc. Sci. 2004, 3, 216–224. [Google Scholar]

- Wetzstein, A.; Feisel, E.; Hartmann, E.; Benton, W.C., Jr. Uncovering the supplier selection knowledge structure: A systematic citation network analysis from 1991 to 2017. J. Purch. Supply Manag. 2019, 25, 100519. [Google Scholar] [CrossRef]

- Francisco, K.; Swanson, D. The supply chain has no clothes: Technology adoption of blockchain for supply chain transparency. Logistics 2018, 2, 2. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Modeling the blockchain enabled traceability in agriculture supply chain. Int. J. Inf. Manag. 2020, 52, 101967. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Saberi, S.; Sarkis, J. Blockchain technology and the sustainable supply chain: Theoretically exploring adoption barriers. Int. J. Prod. Econ. 2021, 231, 107831. [Google Scholar] [CrossRef]

- Salah, K.; Nizamuddin, N.; Jayaraman, R.; Omar, M. Blockchain-based soybean traceability in agricultural supply chain. IEEE Access 2019, 7, 73295–73305. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, X.; Pan, W. Big Data Logistics Service Supply Chain Innovation Model Based on Artificial Intelligence and Blockchain. Mob. Inf. Syst. 2022, 2022, 4794190. [Google Scholar] [CrossRef]

- Martinčević, I.; Sesar, V.; Žunac, A.G. Artificial Intelligence and Blockchain—New Challenges for Digital Supply Chain Management. In Proceedings of the 21st International Scientific Conference on Business Logistics in Modern Management, Osijek, Croatia, 7–8 October 2021. [Google Scholar]

- Karadgi, S.; Kulkarni, V.; Doddamani, S. Traceable and Intelligent Supply Chain based on Blockchain and Artificial Intelligence. J. Phys. Conf. Ser. 2021, 2070, 012158. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, F.; Xie, Y.; Fan, X.; Gu, H. The impact of artificial intelligence and blockchain on the accounting profession. IEEE Access 2020, 8, 110461–110477. [Google Scholar] [CrossRef]

- Wang, Z.; Li, M.; Lu, J.; Cheng, X. Business Innovation based on artificial intelligence and Blockchain technology. Inf. Process. Manag. 2022, 59, 102759. [Google Scholar] [CrossRef]

- De Giovanni, P. Smart Supply Chains with vendor managed inventory, coordination, and environmental performance. Eur. J. Oper. Res. 2021, 292, 515–531. [Google Scholar] [CrossRef]

- Firouzi, F.; Farahani, B.; Weinberger, M.; DePace, G.; Aliee, F.S. Iot fundamentals: Definitions, architectures, challenges, and promises. In Intelligent Internet of Things; Springer: Cham, Switzerland, 2020; pp. 3–50. [Google Scholar]

- Singh, P.; Elmi, Z.; Lau, Y.Y.; Borowska-Stefańska, M.; Wiśniewski, S.; Dulebenets, M.A. Blockchain and AI technology convergence: Applications in transportation systems. Veh. Commun. 2022, 2022, 100521. [Google Scholar] [CrossRef]

- Tagde, P.; Tagde, S.; Bhattacharya, T.; Tagde, P.; Chopra, H.; Akter, R.; Kaushik, D.; Rahman, M. Blockchain and artificial intelligence technology in e-Health. Environ. Sci. Pollut. Res. 2021, 28, 52810–52831. [Google Scholar] [CrossRef] [PubMed]

- Hartley, J.L.; Sawaya, W.J. Tortoise, not the hare: Digital transformation of supply chain business processes. Bus. Horiz. 2019, 62, 707–715. [Google Scholar] [CrossRef]

- Wamba, S.F.; Queiroz, M.M. Blockchain in the operations and supply chain management: Benefits, challenges and future research opportunities. Int. J. Inf. Manag. 2020, 52, 102064. [Google Scholar] [CrossRef]

- Lopes, V.; Alexandre, L.A. An overview of blockchain integration with robotics and artificial intelligence. arXiv 2018, arXiv:1810.00329. [Google Scholar] [CrossRef]

- Baryannis, G.; Validi, S.; Dani, S.; Antoniou, G. Supply chain risk management and artificial intelligence: State of the art and future research directions. Int. J. Prod. Res. 2019, 57, 2179–2202. [Google Scholar] [CrossRef]

- Dhar Dwivedi, A.; Singh, R.; Kaushik, K.; Rao Mukkamala, R.; Alnumay, W.S. Blockchain and artificial intelligence for 5G-enabled internet of things: Challenges, opportunities, and solutions. Trans. Emerg. Telecommun. Technol. 2021, 2021, e4329. [Google Scholar] [CrossRef]

- Naz, F.; Kumar, A.; Majumdar, A.; Agrawal, R. Is artificial intelligence an enabler of supply chain resiliency post COVID-19? An exploratory state-of-the-art review for future research. Oper. Manag. Res. 2021, 15, 378–398. [Google Scholar] [CrossRef]

- Sobb, T.; Turnbull, B.; Moustafa, N. Supply chain 4.0: A survey of cyber security challenges, solutions and future directions. Electronics 2020, 9, 1864. [Google Scholar] [CrossRef]

- Mithas, S.; Chen, Z.L.; Saldanha, T.; de Oliveira Silveira, A. How will artificial intelligence and industry 4.0 emerging technologies transform operations management? Prod. Oper. Manag. 2022, 31, 4475–4487. [Google Scholar] [CrossRef]

- Bublitz, M.F.; Oetomo, A.; Sahu, K.S.; Kuang, A.; Fadrique, L.X.; Velmovitsky, P.E.; Nobrega, R.M.; Morita, P. Disruptive technologies for environment and health research: An overview of artificial intelligence, blockchain, and internet of things. Int. J. Environ. Res. Public Health 2019, 16, 3847. [Google Scholar] [CrossRef] [PubMed]

| Research Gap | Research Question(s) | Research Contribution |

|---|---|---|

| Existing literature on AI-blockchain integrated supply chains and their commercial applications is lacking | RQ1. What is the throughput of AI and blockchain-integrated scientific manuscripts in the field of the supply chain? RQ2. What are the most noteworthy articles on using AI and blockchain in supply chain optimization? | Insights into publication distribution by year and analysis of highly cited research papers |

| There is a lack of research in many areas of supply chain optimization that benefit from using AI-integrated blockchain systems | RQ3. What are the most potential operational platforms for supply chain operations combining AI and blockchain? | Incorporate the most manuscripts combining these two technologies simultaneously in the supply chain context and draw a dummy model for adding value to the supply chain process and optimization |

| Keywords/Search String | Search Engine | No. of Papers | Inclusion and Exclusion Parameters |

| supply chain blockchain artificial intelligence | Google Scholar | 49,400 (incorporating citations) | Anywhere in the articles |

| “supply chain artificial intelligence blockchain” OR “supply chain blockchain” OR “supply chain artificial intelligence” | Google Scholar | 17,100 | Anywhere in the articles Year: (2016–2022) |

| “supply chain artificial intelligence blockchain” OR “supply chain blockchain” OR “supply chain artificial intelligence” | Google Scholar Google Scholar | 504 | Title of the article Year: (2016–2022) |

| “supply chain artificial intelligence blockchain” | Google Scholar | 5 | Title of the article |

| Publication Year | Citation Year | Papers | Citations | Cites/Per Year | Cites/Per Author | Author/Paper | h-Index | g-Index |

|---|---|---|---|---|---|---|---|---|

| 2016–2022 | 2016–2022 | 504 | 9263 | 1543.83 | 18.38 | 2.80 | 45 | 90 |

| Broad Areas | Specific Areas of Changes |

|---|---|

| Primary potential benefits | Improving supply chains by enabling faster and cheaper product delivery, enhancing product transparency, improving partner cooperation, and making finance more accessible [32,75] |

| Enhancing resource supply chain tracking to ensure compliance with corporate needs [76] | |

| Decreasing losses as a result of black trade [28] | |

| Improving insight and adherence in the context of outsourcing manufacturing and distribution [77] | |

| Minimizing of paperwork costs [28] | |

| Secondary potential benefits | Boosting of the company’s image by providing information on the materials used in its products [78] |

| Enhancing the authenticity and public confidence in the data provided [71] | |

| Lowering the likelihood of supply chain mistakes causing public relations damage [79] | |

| The including of stakeholders [80] |

| Broad Areas | Specific Areas of Changes |

|---|---|

| Sales and Distribution Inventory | Communicate with the supply chain and sales teams on stock-out [15] |

| Track Real-Time Performance | Track forecasted sell-in and sell-through to balance channel inventories [32] |

| Schedule exact restocking and ordering with important distributors and suppliers [68] | |

| Provide sound guidance and recommendations in addition to analysis of the company’s influence [23] | |

| Smart Reporting | Generate and publish reports on sales and operational performance data such as order cycle time, and channel inventory automatically [81] |

| 360° Visibility for the AI-Driven Supply Chain | Transform heterogeneous data into workforce warnings and suggestions [36] |

| Provide answers to complicated business issues [82] | |

| Flag anomalies and hazards proactively before they become costly blunders [79] | |

| Accessible Insights for Al | Responding in seconds using a single search box for queries related to product order, etc. [83] |

| True Estimation | Achieving goods prediction and planning to minimize excess inventory in outlets that take up valuable space despite fluctuations in demand and periodic requirements [70] |

| Accelerate Growth and Minimize Disruption | Detecting mistakes and inconsistencies early, avoiding costly interruptions, and gaining particular insights from dispersed data systems [84] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kashem, M.A.; Shamsuddoha, M.; Nasir, T.; Chowdhury, A.A. Supply Chain Disruption versus Optimization: A Review on Artificial Intelligence and Blockchain. Knowledge 2023, 3, 80-96. https://doi.org/10.3390/knowledge3010007

Kashem MA, Shamsuddoha M, Nasir T, Chowdhury AA. Supply Chain Disruption versus Optimization: A Review on Artificial Intelligence and Blockchain. Knowledge. 2023; 3(1):80-96. https://doi.org/10.3390/knowledge3010007

Chicago/Turabian StyleKashem, Mohammad Abul, Mohammad Shamsuddoha, Tasnuba Nasir, and Asma Akter Chowdhury. 2023. "Supply Chain Disruption versus Optimization: A Review on Artificial Intelligence and Blockchain" Knowledge 3, no. 1: 80-96. https://doi.org/10.3390/knowledge3010007

APA StyleKashem, M. A., Shamsuddoha, M., Nasir, T., & Chowdhury, A. A. (2023). Supply Chain Disruption versus Optimization: A Review on Artificial Intelligence and Blockchain. Knowledge, 3(1), 80-96. https://doi.org/10.3390/knowledge3010007