Impact of Mixed Rations on Rumen Fermentation, Microbial Activity and Animal Performance: Enhancing Livestock Health and Productivity—Invited Review

Simple Summary

Abstract

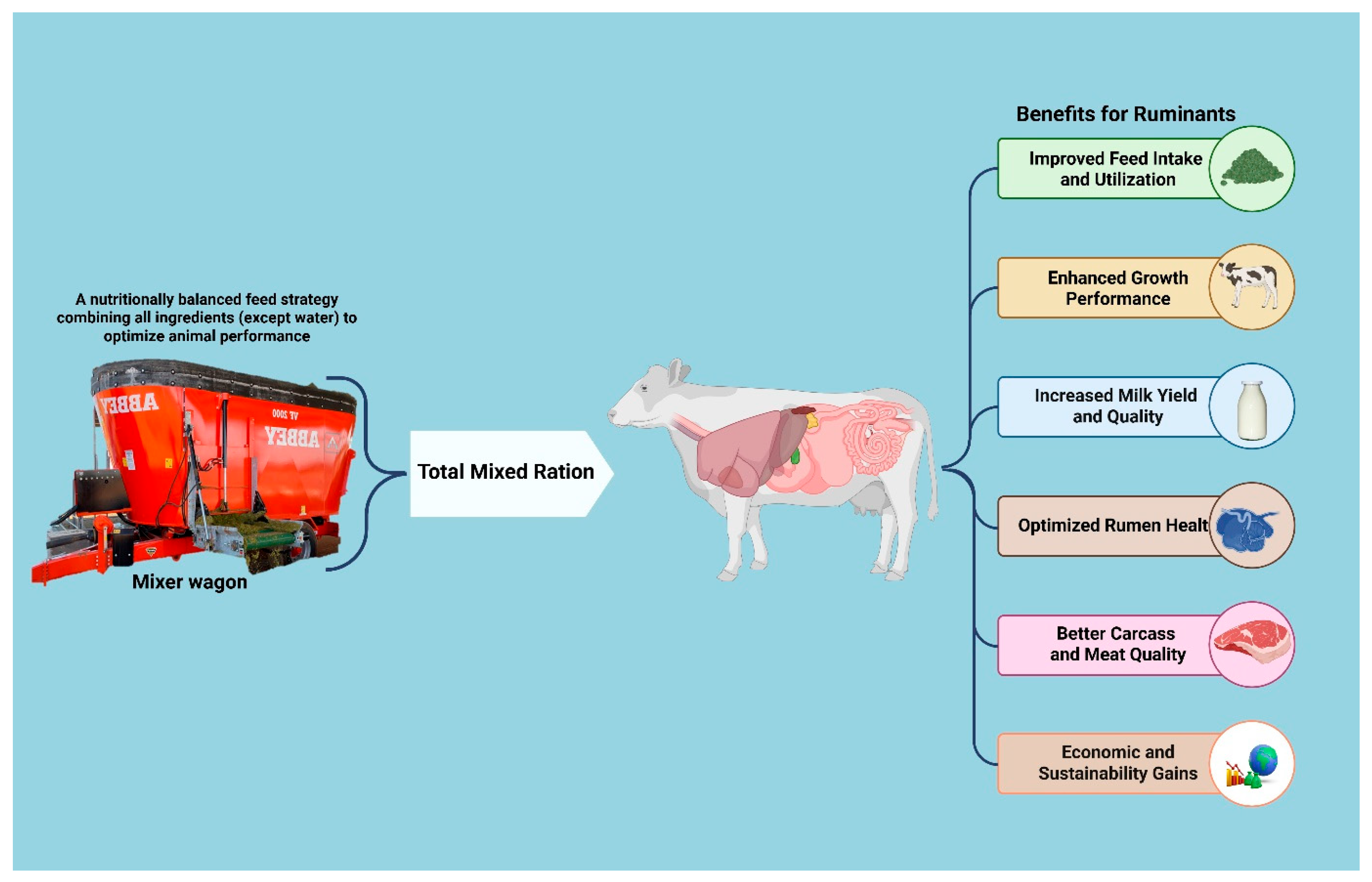

1. Introduction

2. Methodology

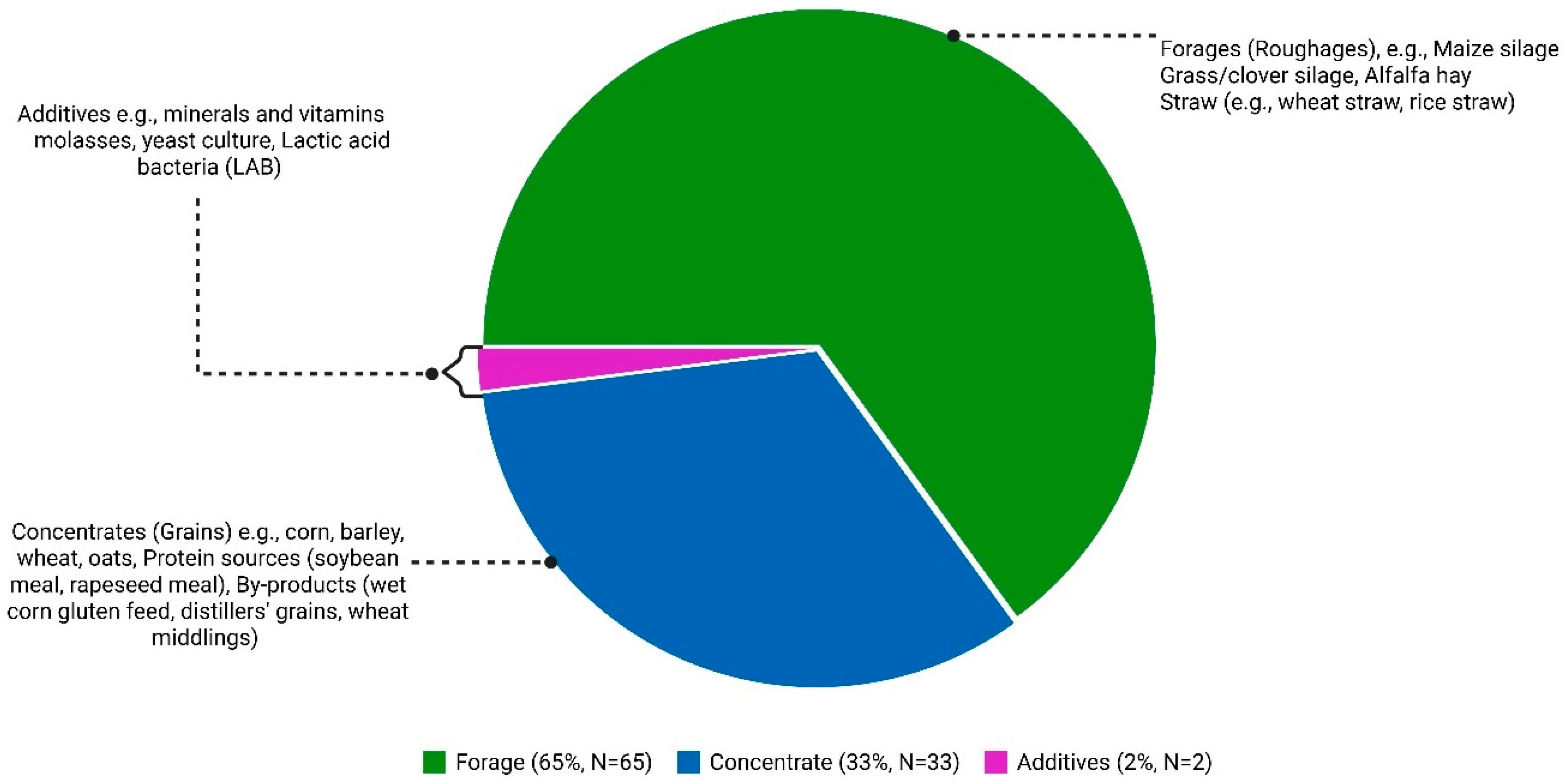

3. Total Mixed Ration: Composition, Advantages, and Fermentation Technologies

3.1. Typical Composition and Formulation

3.2. Forage Components

3.3. Concentrate Components

3.4. Key Advantages and Innovations

3.5. Fermentation Quality and Implications

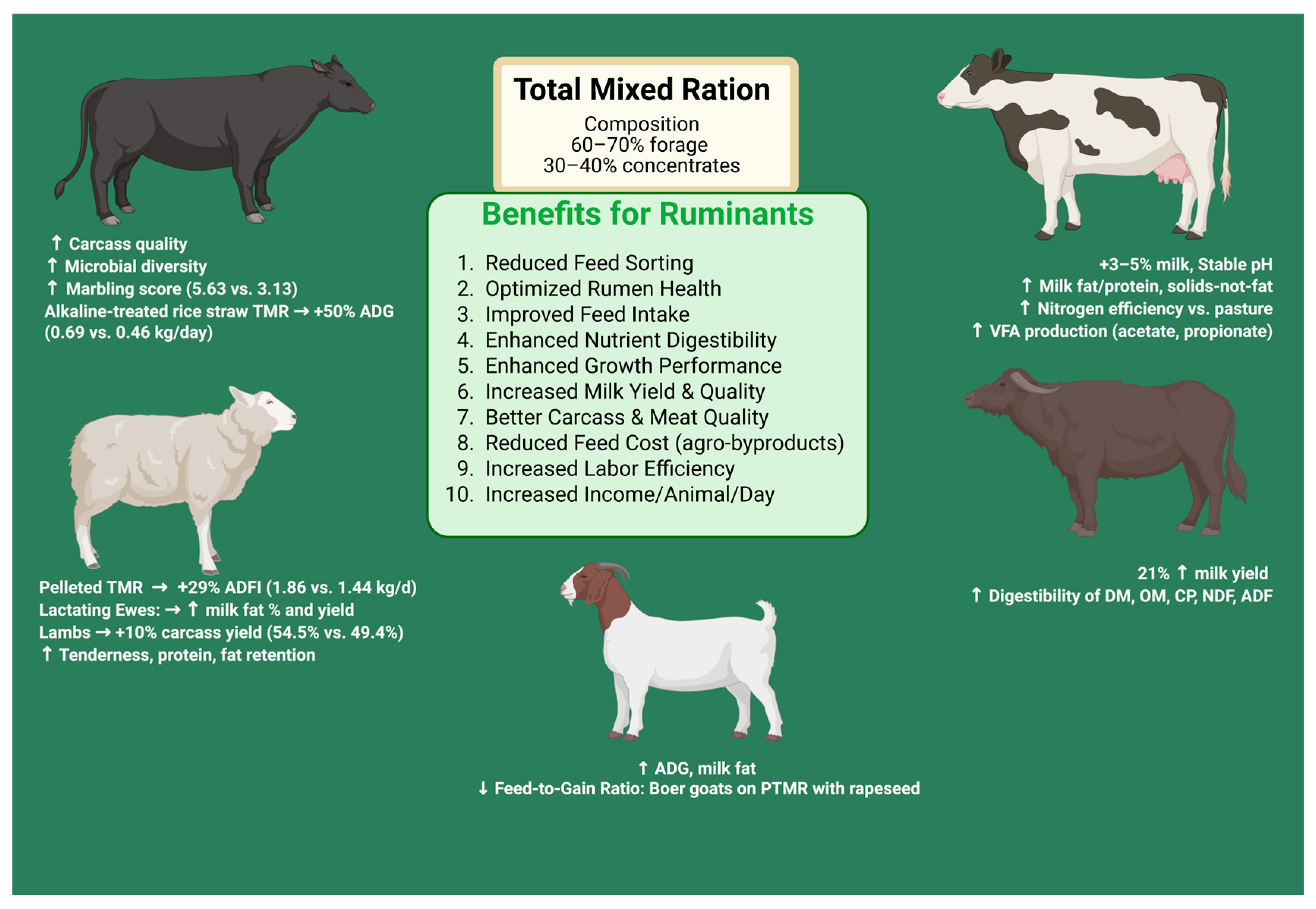

4. Effects of Total Mixed Ration on Ruminant Diets

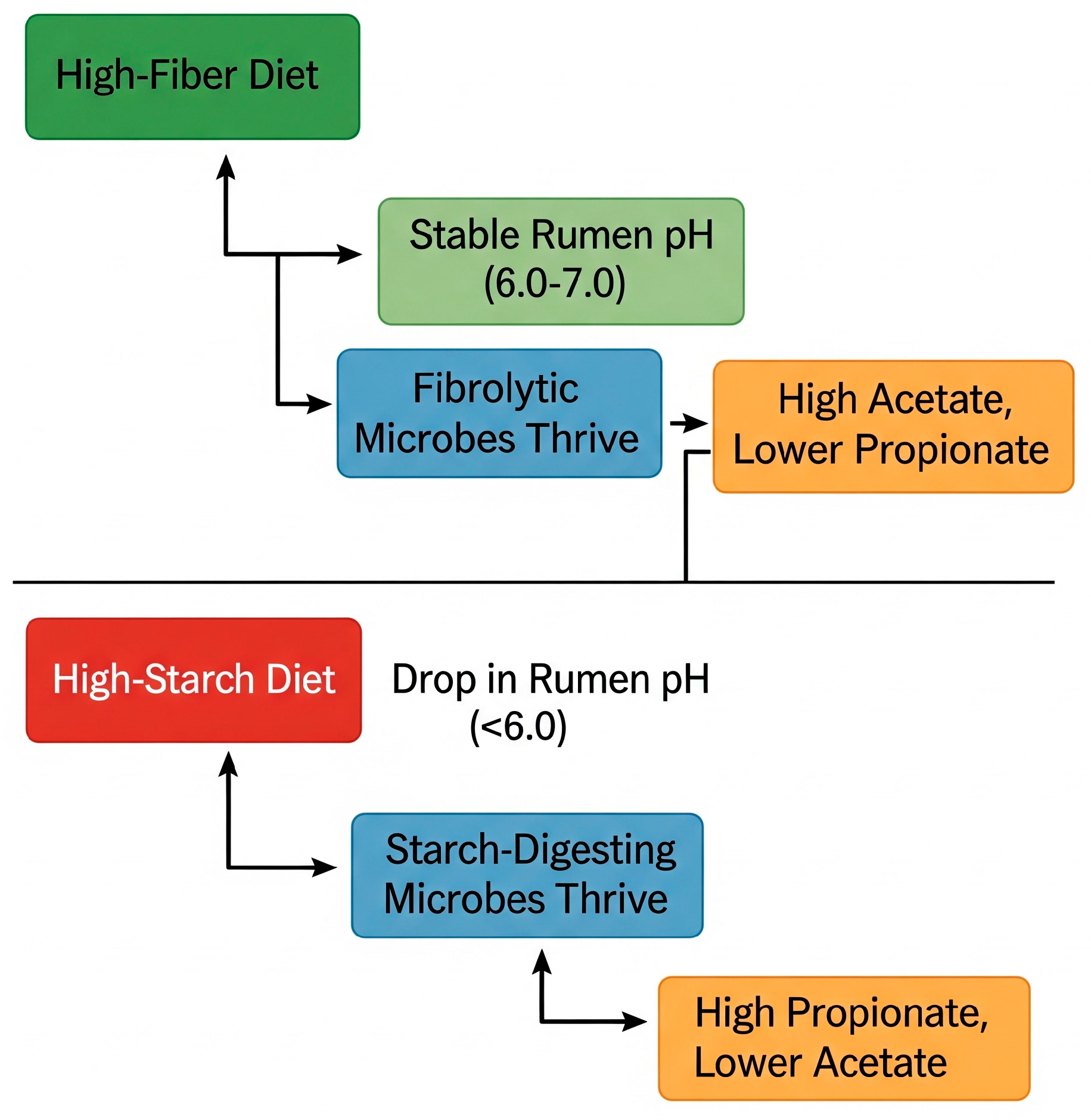

4.1. Effects of Total Mixed Ration on Rumen Fermentation

| Species/Breed | TMR Type/Modification | Summary of Results | Reference |

|---|---|---|---|

| Holstein calves | WPCS-based TMR (CTMR) | Higher rumen pH, total VFA, and propionate vs. CSCS (15% WPCS) | [56] |

| Crossbred lambs | Pelleted TMR (PTMR) | Higher acetate (49.8 vs. 45.7 mmol/L), propionate (24.8 vs. 21.4 mmol/L) | [48] |

| Hu sheep lambs | High-grain pelleted TMR | Lower pH, Increased lactate, Reduced Fibrobacteres | [26] |

| Mixed ruminal microbes | TMR + ryegrass pasture | ↑ Butyrate/valerate, ↓ Methane, ↑ Microbial biomass N | [57] |

| Holstein dairy cows | TMR + FF | Stable pH/VFA; ↓ N-NH3 in 50% FF | [58] |

| Red Chittagong Cows | Maize stover-based TMR | ↑ TVFA/NH3-N; stable rumen pH | [16] |

| Dairy cows (in vitro) | Varied TMR compositions | CP fermentation: 25–60%; CPM synthesis: 677–1778 mg/day | [59] |

| Red Chittagong cows | Maize stover-based TMR | ↑ TVFA and NH3-N | [16] |

| Buffalo (in vitro) | HFA-supplemented TMR | ↑ VFAs, ↓ methane (Shatavari @ 3% most effective) | [60] |

| Dairy cows (in vitro) | 100% TMR (69:31 forage/concentrate) | ↑ Total VFA (+16.6 mmol/L), ↑ Acetate/propionate ratio | [33] |

| German Holstein cows | Pasture transition (from TMR to pasture) | Lower pH in the pasture group (SARA risk in wk 9–10). No adverse LPS effects. | [11] |

| Holstein-Zebu steers | Fermented TMR (FTMR; pH 3.5) | Stable ruminal pH despite low TMR pH. No acidosis observed. | [61] |

| Angus beef cattle | High-concentrate TMR | Significantly decreased rumen pH | [18] |

| Wethers (Sheep) | Pelleted TMR + 1% yeast culture | Higher mean pH, reduced time below pH 5.8. | [24] |

| Simmental bulls | Multi-silage TMR (MS) | Improved rumen pH stability linked to higher VFA production. | [5] |

| German Holstein cows | Pasture transition | ↓ Acetate (C2%), ↑ butyrate (C4%), ↓ C2/C3 ratio | [11] |

| Cattle (Bulls) | 60:40 Roughage/Concentrate | Highest TVFA production (optimal fermentation) | [62] |

| Holstein-Zebu steers | FTMR (pH 3.5) | ↑ Acetic/butyric acid; ↓ propionate. | [61] |

| Crossbred lambs | Pelleted TMR (PTMR) | ↑ Acetate (49.8 vs. 45.7 mmol/L) and propionate (24.8 vs. 21.4 mmol/L). | [48] |

| Wethers (Sheep) | Pelleted TMR + 1% yeast | ↑ Total VFA, propionate, and n-butyrate. | [24] |

| Simmental bulls | Multi-silage TMR (MS) | ↑ TVFA (62.49 vs. 56.09 mmol/L) and acetate. | [63] |

| German Holstein cows | Pasture transition | ↓ Rumen papillae surface area (recovered by wk 10). | [11] |

| Angus beef cattle | High-concentrate TMR | ↑ Starch-degraders (Bacteroidota), ↓ fiber-degraders (Ruminococcus). | [18] |

| Crossbred lambs | Pelleted TMR (PTMR) | ↑ Prevotellaceae (rumen), ↓ Ruminococcaceae. | [48] |

| Holstein cows | Fermented TMR (FTMR) | ↑ Unclassified_Bacteroidales, ↓ Candida (fungi). | [64] |

| Wethers (Sheep) | Pelleted TMR + 1% yeast | ↑ Fibrolytic bacteria (NK4A214, FD2005). | [24] |

| Yellow cattle (in vitro) | Fermented TMR (FTMR) | ↓ Methane production, ↓ Methanobrevibacter abundance. | [46] |

| Holstein cows | Fermented TMR (FTMR) | ↑ Methanobrevibacter (due to higher H2 availability). | [64] |

| Holstein (Dairy) | Pelleted TMR | Lower rumen pH (6.10 vs. 6.48), higher propionate | [65] |

| Cattle (Bulls) | 60:40 Roughage/Concentrate | Optimal TVFA, stable pH | [62] |

| Hanwoo Heifers | Italian Ryegrass TMR | Increased propionate, enriched Ruminococcus bromii | [66] |

| Holstein dairy cows | Grass silage + concentrate + hay | Higher early GP (2–4 h) with particle-associated inocula (PAL). Declined later. | [67] |

| Brown Swiss cows | TMR + Saccharomyces cerevisiae (CE/LC) | CE improved asymptotic GP more than LC; low/intermediate doses are most effective. | [68] |

| Suffolk sheep | Fermented TMR (FTMR) | Higher GP due to enhanced microbial activity from lactic acid fermentation. | [44] |

| Hanwoo steers | TMR with fermented feed (TMRF) | Improved GP linked to higher acetate/propionate production. | [13] |

| Holstein cows | TMR with varying particle sizes (5.5–25 mm) | Smaller particles ↑ SCFA in dorsal rumen; ↓ acetate/propionate ratio. | [69] |

| Suffolk sheep | Fermented TMR (FTMR) | ↑ Propionate (392.4 mmol/mol), ↓ butyrate (86.6 mmol/mol). | [30] |

| Nellore bulls | TMR with pefNDF | Optimal SCFA at 20.5 g pefNDF/kg DM; higher fiber ↑ butyrate. | [70] |

| Holstein steers | TMR vs. separate feeding | Higher total VFA and propionate at 1.5 h post-feeding. | [9] |

| Holstein cows | TMR (5.5–25 mm particle size) | 5.5 mm: ↓ rumen pH; 11 mm: maintained pH and ↑ protozoa. | [69] |

| Montbéliarde cattle | TMR (high concentrate) | Lower rumen pH (5.58 vs. 5.87 in control), higher acidosis risk. | [17] |

| Suffolk sheep | FTMR in varying pH media | Lower pH (5.62–5.66) ↓ CH4 and ↑ propionate. | [44] |

| Nellore steers | High-concentrate TMR | Faster microbial adaptation in preconditioned cattle. | [71] |

4.2. Effects of Total Mixed Ration on Nutrient Digestibility

4.3. Effects of Total Mixed Ration on Growth Performance

| Species/Breed | TMR Type/Modification | Summary of Results | Reference |

|---|---|---|---|

| Holstein dairy calves | WPCS-based TMR (CTMR) | No difference in BW, ADG, or feed efficiency vs. starter (CONS) | [56] |

| Karakul sheep | 40% SS-AF silage TMR | Highest BW, ADG, and DMI | [5] |

| Fattening lambs | Pelleted TMR + LY (0.8 g/kg) | 11% higher ADG (+36 g/d) | [72] |

| Jersey cows | 60% grass hay + 40% concentrate | Higher DMI (12.82 vs. 10.55 kg/day; ↓ FCR (1.36 vs. 1.72) | [82] |

| Red Chittagong cows | Maize stover-based TMR (50:50) | Higher DMI in block form (T1) vs. mash (T2) | [16] |

| Holstein cows | MS or IRS TMR + grazing | Night grazing ↑ grass intake (8.53 vs. 5.65 kg DM/d) | [83] |

| Finnish Ayrshire cows | Grass silage + concentrate (FF1 vs. FF5) | FF1 ↑ DMI (20.9 vs. 19.9 kg/d) in multiparous cows | [84] |

| Holstein-Friesian cows | High-starch (27.7% DM) TMR | Starch content ↑ DMI and milk yield | [85] |

| Holstein dairy cows | 100% TMR vs. TMR + fresh forage (FF) | No DMI reduction with ≤29% FF; 8% decrease at 47% FF | [58] |

| Red Chittagong Cows | Maize stover-based TMR (50:50) | Higher DMI vs. conventional feeding | [16] |

| Korean native goats | TMR with varying peNDF (grinding speeds) | No DMI differences despite reduced peNDF | [76] |

| Crossbred lambs | Pelleted TMR (PTMR) | Higher ADG (341 vs. 265 g/d) and ADFI (1.86 vs. 1.44 kg/d) | [48] |

| Comisana lambs | Wheat middlings (WM)-based TMR | Higher final BW (23.5 vs. 21.9 kg) and daily gain (199 vs. 174 g/d) | [73] |

| Hu sheep lambs | High-grain pelleted TMR (70% concentrate) | No ADG difference vs. high-grain non-pelleted; lower rumen pH | [26] |

| Aberdeen Angus cattle | 60% grass silage + barley (MC TMR) | Highest carcass gain (967 g/d); Best feed conversion (11.1 kg DM/kg gain) | [34] |

| Crossbred lambs | FTMR with varying oat/alfalfa ratios | AH-300: Higher DMI, ADG, and total weight gain vs. CK and AH-400 | [45] |

| Dorper lambs | Cactus pear + cottonseed cake (20–30%) | No effect on WG/ADG; all treatments met target ADG (200 g/day) | [7] |

| Beef steers | Hedge lucerne/leucaena TMR | Higher ADG and FCR vs. control (fresh grass + concentrate) | [86] |

| Dairy cattle (fattening) | Whole crop rice TMR | Higher BW and ADG in mid/late fattening stages | [87] |

| Goats (barn-fed) | TMR vs. mountainous pasture | ADG doubled in the TMR group | [88] |

| Sheep | Pelleted vs. unpelleted TMR | Higher feed intake and ADG with pelleted TMR | [46] |

| Crossbred lambs | Pelleted TMR (PTMR) | ↑ ADG (341 vs. 265 g/d) and carcass yield (54.5% vs. 49.4%). | [48] |

| Holstein-Zebu steers | Grass silage-TMR (STMR) | ↑ Early-phase ADG; better FCR in FTMR later. | [61] |

| Simmental bulls | Multi-silage TMR (MS) | ↑ ADG (1.56 vs. 1.30 kg/day); ↓ FCR (10.96 vs. 12.36). | [63] |

| Angus beef cattle | High-concentrate TMR | ↑ DMI but no improvement in ADG or feed efficiency. | [18] |

| Hanwoo Steers | T70 (70:30 forage/concentrate) | Compensatory growth in late fattening stage; slower initial growth | [66] |

| Hanwoo Steers | Fermented TMR | Higher DMI (7.17 kg) Increased BW (615.20 kg), improved ADG (0.56 kg) | [89] |

| Yak | High-energy TMR | Higher ADG (0.87 kg/day vs. −0.17 kg/day in grazing) | [6] |

| Karakul Sheep | 40%SS–60%AF silage TMR | Higher BW, ADG, and DMI (p < 0.05) | [90] |

| Naemi Lambs | TMR + alfalfa hay (300 g/3 days) | Increased BW and feed conversion ratio | [10] |

| Boer Goats | TMR + 7.5% intact rapeseed | Reduced feed-to-gain ratio (improved efficiency) | [42] |

| Sindhi Crossbred | Alkaline-treated straw TMR | Higher ADG (0.69 vs. 0.46 kg/day) & BW (278.8 vs. 258.2 kg) | [14] |

| Dorper Lambs | Creep feed (18% CP TMR) | Higher weight gain (22.17 vs. 17.83 kg pre-weaning) | [22] |

| Hanwoo Steers | TMR + Medicinal Plants (30 g/kg) | Improved ADG & feed efficiency | [27] |

| Simmental Heifers | TMR vs. Free choice | No difference in ADG | [19] |

| Holstein (Dairy) | pTMR | Balanced nutrient intake, reduced purchased feeds | [91] |

| Hanwoo Heifers | Italian Ryegrass TMR | No difference in DMI/FCR; improved nitrogen efficiency | [66] |

| Dairy cows | Apple pomace TMR | Increased LWG | [15] |

| Sheep | TMR blocks vs. mash | Higher B:C ratio in TMR blocks | [92] |

| Hanwoo steers | TMRF (fermented feed) | ↑ Weight gain (308 kg vs. 284 kg) and feed efficiency (0.16 vs. 0.12). | [13] |

| Holstein-Friesian | TMR (maize silage + concentrate) | ↑ BW gain (0.54 kg/d vs. loss in control). | [93] |

4.4. Effects of Total Mixed Ration on Milk Yield and Composition

| Species/Breed | TMR Type/Intervention | Summary of Results | Reference |

|---|---|---|---|

| Lactating Holstein cows | Hay-based TMR (DM-adjusted) | Increased milk yield (26.99 → 27.29 kg/d) | [23] |

| Jersey cows | 60% grass hay + 40% concentrate | ↑ Milk yield (9.57 vs. 6.23 kg/day | [82] |

| Red Chittagong cows | Maize stover-based TMR | ↑ Milk yield (T1: 3.6 L/d; T2: 3.49 L/d vs. T0: 3.35 L/d) | [16] |

| Holstein cows | TMR vs. separate feeding | TMR ↑ milk yield (34.4 vs. 32.7 kg/d in R2X/R4X) | [95] |

| Finnish Ayrshire cows | Once vs. 5× daily feeding | No difference (32.8 kg/d ECM FF1 vs. 32.5 kg/d FF5) | [84] |

| Jersey cows | 60% grass hay + 40% concentrate | No difference in fat %; No difference in protein % | [82] |

| Red Chittagong cows | Maize stover-based TMR | ↑ Fat % in T1/T2 | [16] |

| Holstein cows | TMR vs. separate feeding | Separate feeding ↓ fat % (2.14–2.31% vs. 3.31%) | [95] |

| Dairy ewes | Wheat middling-based TMR | ↑ Fat % and yield | [73] |

| Holstein (Dairy) | Confinement TMR | Highest yield (10,000 kg/cow) | [91] |

| Holstein (Dairy) | Pasture + Concentrate (PC) | Lowest yield (7500 kg/cow) | [91] |

| Holstein (Dairy) | Full TMR (confinement) | 38.1 kg/day > pTMR (32.0 kg/day) > PC (28.5 kg/day) | [12] |

| Danish Black/White | Multi-group TMR | Higher yield at high feed levels vs. single-group TMR | [96] |

| Dairy cows | Apple pomace TMR | Increased milk yield | [15] |

| Holstein (Dairy) | Pelleted TMR | Higher milk protein (3.38% vs. 3.16%), lower fat | [65] |

| Holstein-Friesian | TMR (maize silage + concentrate) | ↑ Milk yield (29.5 kg/d vs. 21.1 kg/d) | [93] |

| Crossbred cows | FTMR with 25% peNDF | ↑ Milk fat % due to ↑ acetate | [75] |

| Aosta Red Pied cows | TMR vs. separate feeding | No difference in protein % | [97] |

| Holstein cows | TMR + night grazing | ↑ PUFA (CLA, VA, ALA) in milk | [98] |

| Holstein dairy cows | 100% TMR vs. TMR + FF | 8.5% higher yield in 100% TMR; ↑ UFA in 50% FF | [58] |

| Red Chittagong Cows | Maize stover-based TMR | Higher milk yield, fat, and SNF vs. control | [16] |

| Holstein cows | Cracked cottonseed in FTMR | ↑ C18:2 (linoleic acid) in milk | [99] |

| Dairy cows | Pasture vs. TMR (maize silage + concentrates) | TMR: 33% higher milk yield; No difference in fat/SCC | [100] |

| Buffaloes | Brewers’ grain + rice straw TMR | Higher milk yield at 1.2% supplement No difference in composition | [101] |

| Dairy cows | Apple pomace TMR | Increased milk yield and protein; reduced lactose | [15] |

4.5. Carcass Traits and Meat Quality in Livestock Fed Total Mixed Ration

| Species/Breed | TMR Type/Modification | Summary of Results | Reference |

|---|---|---|---|

| Beef steers | Hedge lucerne TMR | No difference in dressing %; Higher chilled carcass weight | [86] |

| Aberdeen Angus cattle | MC TMR (60% grass silage) | Best carcass gain (967 g/d) and conformation | [34] |

| Beef cattle | Whole crop rice TMR | Higher marbling score; No difference in carcass weight/rib eye area | [87] |

| Karakul sheep | 40% SS-AF silage TMR | ↑ Carcass weight, subcutaneous fat; Improved WHC, CP, EE, and shear force | [90] |

| Crossbred lambs | Pelleted TMR (PTMR) | Higher carcass yield (54.5% vs. 49.4%) | [48] |

| Comisana lambs | WM-based TMR | Higher cold-carcass dressing (10.5 vs. 9.7 kg) | [73] |

| Crossbred lambs | FTMR (AH-300) | Higher backfat thickness, intramuscular fat; Lower shear force | [45] |

| Hanwoo Steers | T50 (50:50 forage/concentrate) | Comparable carcass weight to control; higher IMF | [66] |

| Hanwoo Steers | FTMR | Higher marbling score (5.63 vs. 3.13), fat thickness (13.25 mm) | [89] |

| Yak | High-energy TMR | Increased carcass weight (106.43%), dressing percentage (57.52%) | [6] |

| Karakul Sheep | 40%SS–60%AF silage TMR | Higher carcass weight and subcutaneous fat thickness. | [90] |

| Beef Cattle | TMR (pre-mixed) | Higher carcass weight (279.5 kg vs. 268.6 kg in control) | [29] |

| Hanwoo Steers | FTMR | Improved tenderness, juiciness, crude fat (18.39%); no pH/cooking loss differences | [89] |

| Yak | High-energy TMR | Improved tenderness (↓ shear force), reduced cooking loss (↓ 7.28%) | [6] |

| Karakul Sheep | 40%SS–60%AF silage TMR | Improved WHC, CP, EE; reduced shear force | [90] |

| Naemi Lambs | TMR + alfalfa hay | Improved meat color (L*, a*, b*); reduced shear force | [10] |

| Beef Cattle (Retinta) | Maize silage TMR | Higher PUFA (18.8% vs. 14.3%) and n-3 PUFA (0.47% vs. 0.35%) | [20] |

| Boer Goats | TMR + 7.5% intact rapeseed | ↑ Linolenic acid, eicosenoic acid; ↓ palmitic acid | [42] |

| Beef Cattle | High-concentrate TMR | Higher 18:1, lower 18:3; increased n-6/n-3 ratio (3.83 vs. 2.72) | [29] |

| Hanwoo Steers | TMR + Medicinal Plants | Improved meat quality grade | [27] |

| Simmental Heifers | TMR | No difference in meat tenderness | [19] |

5. Methane Emission and Environmental Impact

5.1. Enteric Methane Emissions

5.2. Role of Rumen Inoculum and Microbial Populations

5.3. Impact of Dietary Composition

5.4. Feed Utilisation

6. Mycotoxin Contamination and Mitigation Costs

6.1. Mycotoxins in Total Mixed Ration

| Species/Breed | TMR Type/Intervention | Summary of Results | Reference |

|---|---|---|---|

| Dairy cattle | Mycotoxin-contaminated TMR | 100% AFB1 (30 ng/g, exceeding EU limits); 100% OTA (48.5 ng/g); 50% ZON (700 ng/g) | [112] |

| Holstein cows | Grass silage-based TMR | No mycotoxins detected | [109] |

| Holstein cows | Maize silage-based TMR | 90% of samples had DON/ZON | [109] |

| Dairy cows | Maize silage TMR | Fumonisins (74%), DON (42.5%), ZEN (39.1%) prevalent | [110] |

| Dairy cows | Fusarium-contaminated TMR | 58% samples contaminated (FBs 34%, DON 17%, ZEN 16%) | [111] |

| Dairy cattle (Pakistan) | Commercial TMR | 33.3% AFB1 positive (mean 21.97 ppb) | [113] |

| Holstein cows | Grass silage TMR | Higher enterobacteria in TMR vs. silage; linked to SCC | [109] |

| Dairy cows | Maize/grass silage TMR | Highest endotoxins in TMR (293.44 EU/mL) | [114] |

| Holstein cows | Maize silage TMR | Enterobacteriaceae: 3.93 log10 CFU/g in maize silage | [114] |

| Dairy cows | Maize silage-based TMR | Maize silage = primary source of DON/ZEA; co-occurrence increases health risks | [25] |

| Aflatoxin Carryover to Milk | |||

| Holstein cows | AFB1-contaminated TMR + sequestering agent | 47% reduction in AFM1 with optimal SA inclusion | [115] |

| High-yielding cows | AFB1-contaminated TMR | 75% milk samples exceeded EU AFM1 limits (50 ng/L) | [116] |

| Dairy cows (Portugal) | Mycotoxin-contaminated TMR | RC/BEA/enniatins showed 2–10% carryover to milk | [110] |

| Mitigation Strategies | |||

| Holstein cows | Pelletized SA in TMR | Most effective (0.013 AFM1 excretion) | [115] |

| Dairy cows | Mycotoxin adsorbents in TMR | Reduced toxin bioavailability | [117] |

| Dairy cows | Inoculant additives in grass silage TMR | Improved ME content and milk yield | [109] |

6.2. Mycotoxin Mitigation Costs

7. Implications of Total Mixed Ration for Animal Health

7.1. Blood Metabolites as Health Indicators

7.1.1. Glucose Metabolism

7.1.2. Nitrogen Utilization

7.1.3. Lipid Metabolism

7.1.4. Oxidative Stress

7.1.5. Synthesis for Animal Health

7.2. Economic Sustainability and Operational Costs of Total Mixed Ration

7.2.1. Feed Efficiency and Economic Gains

7.2.2. Labor and Operational Cost Savings

7.2.3. Productivity and Quality Premiums

7.2.4. Economic Considerations and Barriers

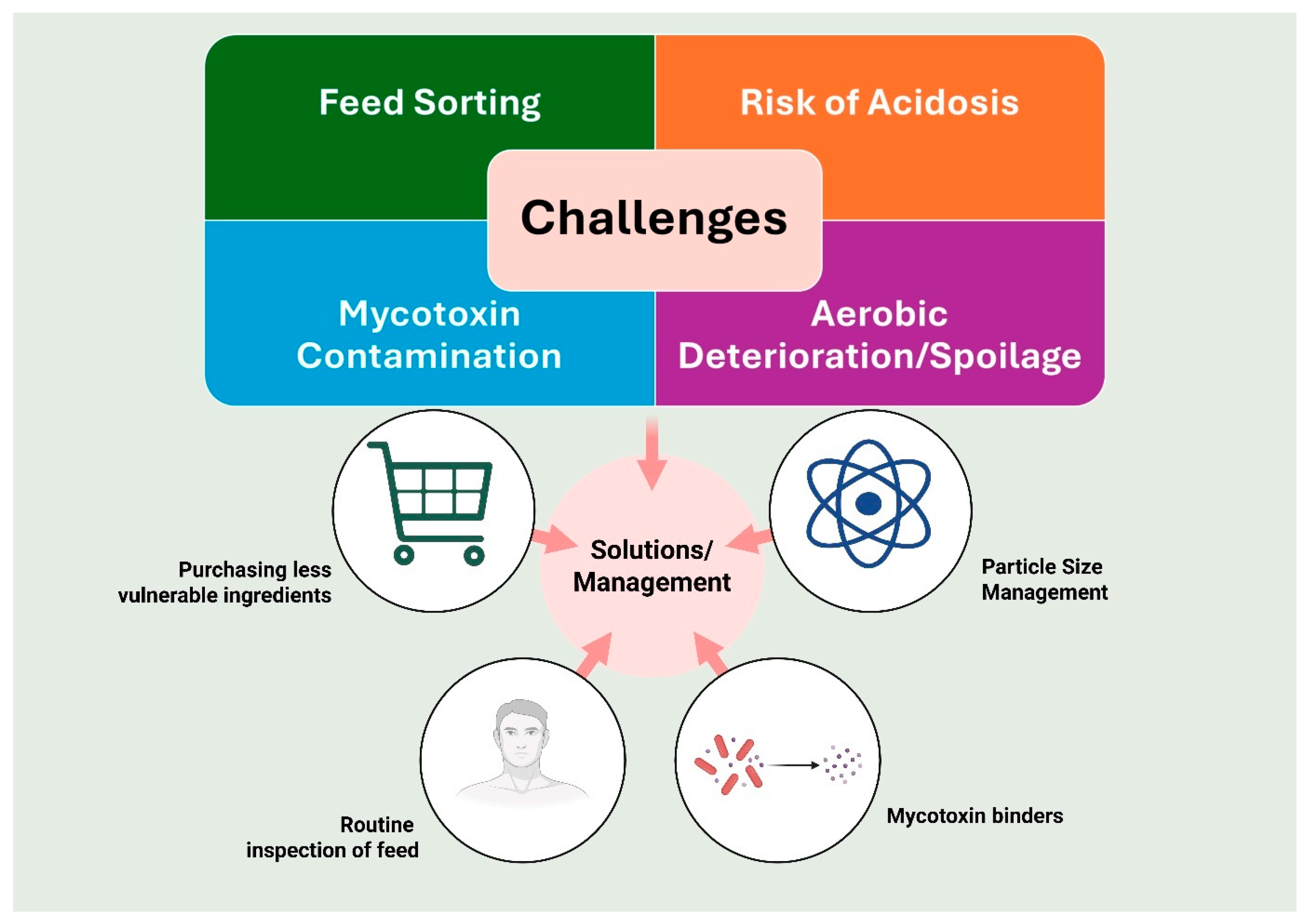

8. Challenges in Feeding Total Mixed Ration to Ruminants

9. Conclusions and Gaps Identified

10. Future Research Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ponnampalam, E.N.; Kerr, M.G.; Butler, K.L.; Cottrell, J.J.; Dunshea, F.R.; Jacobs, J.L. Filling the out of Season Gaps for Lamb and Hogget Production: Diet and Genetic Influence on Carcass Yield, Carcass Composition and Retail Value of Meat. Meat Sci. 2019, 148, 156–163. [Google Scholar] [CrossRef]

- Gadzama, I.U. Evaluation of Fresh Microalgae in Ruminant Nutrition: Impact on Rumen Fermentation, Productive Performance and Meat Quality. Master’s Thesis, The University of Queensland, Brisbane, Australia, 2024. [Google Scholar] [CrossRef]

- Gadzama, I.U.; Ray, S.; Méité, R.; Mugweru, I.M.; Gondo, T.; Rahman, M.A.; Redoy, M.R.A.; Rohani, M.F.; Kholif, A.E.; Salahuddin, M.; et al. Chlorella vulgaris as a Livestock Supplement and Animal Feed: A Comprehensive Review. Animals 2025, 15, 879. [Google Scholar] [CrossRef]

- Ponnampalam, E.N.; Butler, K.L.; McDonagh, M.B.; Jacobs, J.L.; Hopkins, D.L. Relationship between Muscle Antioxidant Status, Forms of Iron, Polyunsaturated Fatty Acids and Functionality (Retail Colour) of Meat in Lambs. Meat Sci. 2012, 90, 297–303. [Google Scholar] [CrossRef]

- Jing, H.; Liu, P.; Zheng, S.; Cao, K.; Li, X. Total mixed ration enhances nutrient digestibility, blood biochemical parameters and faecal microbial diversity in horses. BMC Vet. Res. 2025, 21, 483. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.-X.; Ma, X.-M.; Xiong, L.; Wu, X.-Y.; Liang, C.-N.; Bao, P.-J.; Yu, Q.-L.; Yan, P. Effects of Intensive Fattening With Total Mixed Rations on Carcass Characteristics, Meat Quality, and Meat Chemical Composition of Yak and Mechanism Based on Serum and Transcriptomic Profiles. Front. Vet. Sci. 2021, 7, 599418. [Google Scholar] [CrossRef]

- Pereira, D.M.; De Oliveira, J.S.; Ramos, J.P.D.F.; Cavalcante, I.T.R.; Santos, F.N.D.S.; Da Silva, E.D.S.; Perazzo, A.F.; Macêdo, A.J.D.S.; Tôrres Júnior, P.D.C.; Santos, E.M. Total Mixed Ration Silage Based on Cactus Pear and Cottonseed Cake in the Feeding of Feedlot Finished Lambs. Trop. Anim. Health Prod. 2025, 57, 50. [Google Scholar] [CrossRef] [PubMed]

- Rooney, M.; O’Connor, A.; Gollogly, C.; Mills, A.; Dunne, S.; Chonnacháin, C.N.; Timlin, M.; Brodkorb, A.; O’Callaghan, T.F.; Magan, J.B.; et al. The Impact of Pasture-Fed versus Total Mixed Ration Derived Whole Milk Powder (WMP) on Circulating Fatty Acid Concentrations and Cardiometabolic Health in Healthy Adults: Results from a Randomized Controlled Crossover Trial. J. Nutr. Biochem. 2025, 145, 110004. [Google Scholar] [CrossRef] [PubMed]

- Bharanidharan, R.; Arokiyaraj, S.; Kim, E.B.; Lee, C.H.; Woo, Y.W.; Na, Y.; Kim, D.; Kim, K.H. Ruminal Methane Emissions, Metabolic, and Microbial Profile of Holstein Steers Fed Forage and Concentrate, Separately or as a Total Mixed Ration. PLoS ONE 2018, 13, e0202446. [Google Scholar] [CrossRef]

- Alhidary, I.A.; Abdelrahman, M.M.; Alyemni, A.H.; Khan, R.U.; Al-Saiady, M.Y.; Amran, R.A.; Alshamiry, F.A. Effect of Alfalfa Hay on Growth Performance, Carcass Characteristics, and Meat Quality of Growing Lambs with Ad Libitum Access to Total Mixed Rations. Rev. Bras. Zootec. 2016, 45, 302–308. [Google Scholar] [CrossRef]

- Schären, M.; Seyfang, G.M.; Steingass, H.; Dieho, K.; Dijkstra, J.; Hüther, L.; Frahm, J.; Beineke, A.; Von Soosten, D.; Meyer, U.; et al. The Effects of a Ration Change from a Total Mixed Ration to Pasture on Rumen Fermentation, Volatile Fatty Acid Absorption Characteristics, and Morphology of Dairy Cows. J. Dairy Sci. 2016, 99, 3549–3565. [Google Scholar] [CrossRef]

- Tozer, P.R.; Bargo, F.; Muller, L.D. Economic Analyses of Feeding Systems Combining Pasture and Total Mixed Ration. J. Dairy Sci. 2003, 86, 808–818. [Google Scholar] [CrossRef]

- Kim, S.H.; Alam, M.J.; Gu, M.J.; Park, K.W.; Jeon, C.O.; Ha, J.K.; Cho, K.K.; Lee, S.S. Effect of Total Mixed Ration with Fermented Feed on Ruminal In Vitro Fermentation, Growth Performance and Blood Characteristics of Hanwoo Steers. Asian Australas. J. Anim. Sci. 2011, 25, 213–223. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Nguyen, T.Q.; Le, P.B.T.; Do, D.T.; Nguyen, T.N.; Duong, K.N. Total Mixed Ration (TMR) Based on Alkaline-Treated Rice Straw Improves Growth Rate and Feed Intake of Sindhi Crossbred Cattle. IOP Conf. Ser. Earth Environ. Sci. 2025, 1465, 012023. [Google Scholar] [CrossRef]

- Bae, D.; Shin, C.; Ko, K. Effect of total mixed ration including apple pomace for lactating cows. Korean J. Dairy Sci. 1994, 16, 295–302. [Google Scholar]

- Sarker, N.R.; Yeasmin, D.; Habib, M.A.; Tabassum, F. Feeding Effect of Total Mixed Ration on Milk Yield, Nutrient Intake, Digestibility and Rumen Environment in Red Chittagong Cows. Asian J. Med. Biol. Res. 2019, 5, 71–77. [Google Scholar] [CrossRef]

- Arbaoui, A.; Gonzalo, G.; Belanche, A.; De Vega, A. Unmixed Diet Versus Total Mixed Ration in Beef Cattle Fed High-Concentrate Diets: Effects on Methane Emissions, Animal Performance, and Rumen Fermentation. Animals 2025, 15, 723. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Ye, B.; Wu, B.; Yi, X.; Li, X.; A, R.; Cui, X.; Zhou, Z.; Cheng, Y.; Zhu, X.; et al. Effect of Total Mixed Ration on Growth Performance, Rumen Fermentation, Nutrient Digestion, and Rumen Microbiome in Angus Beef Cattle during the Growing and Fattening Phases. Fermentation 2024, 10, 205. [Google Scholar] [CrossRef]

- Iraira, S.P.; Madruga, A.; Pérez-Juan, M.; Ruíz-de-la-Torre, J.L.; Rodríguez-Prado, M.; Calsamiglia, S.; Manteca, X.; Ferret, A. Performance, Behaviour and Meat Quality of Beef Heifers Fed Concentrate and Straw Offered as Total Mixed Ration or Free-Choice. Span. J. Agric. Res. 2015, 13, e0610. [Google Scholar] [CrossRef]

- Horcada, A.; Polvillo, O.; Juárez, M.; Avilés, C.; Martínez, A.L.; Peña, F. Influence of Feeding System (Concentrate and Total Mixed Ration) on Fatty Acid Profiles of Beef from Three Lean Cattle Breeds. J. Food Compos. Anal. 2016, 49, 110–116. [Google Scholar] [CrossRef]

- Ferrari, V.B.; Bondurant, R.G.; Erickson, G.E.; Wilke, K.H.; MacDonald, J.C. Effects of Displacing Modified Distillers Grains with Dry-Rolled Corn in a Totally Mixed Ration on Performance of Growing Beef Steers Consuming Cornstalk Residue from Different Harvest Methods. Appl. Anim. Sci. 2024, 40, 717–724. [Google Scholar] [CrossRef]

- Panadi, M.; Mat, K.; Rusli, N.D.; Darmansah, N.F. Cost-Effectiveness of Total Mixed Ration with Varying Crude Protein Levels for Feeding Dorper Lambs for Human Consumption. HumEnTech 2022, 1, 17–25. [Google Scholar] [CrossRef]

- Chen, Y.-H.; Chen, Y.-M.; Tu, P.-A.; Chen, C.-Y.; Wang, H.-T. Stabilizing Total Mixed Ration Dry Matter to Mitigate Environmental-Relative-Humidity Effects on Lactating Cow Performance. Animals 2025, 15, 1137. [Google Scholar] [CrossRef]

- Wang, X.; Li, F.; Zhang, N.; Ungerfeld, E.; Guo, L.; Zhang, X.; Wang, M.; Ma, Z. Effects of Supplementing a Yeast Culture in a Pelleted Total Mixed Ration on Fiber Degradation, Fermentation Parameters, and the Bacterial Community in the Rumen of Sheep. Anim. Feed Sci. Technol. 2023, 296, 115565. [Google Scholar] [CrossRef]

- Martins, D.; Lemos, A.; Silva, J.; Rodrigues, M.; Simões, J. Mycotoxins Evaluation of Total Mixed Ration (TMR) in Bovine Dairy Farms: An Update. Heliyon 2024, 10, e25693. [Google Scholar] [CrossRef] [PubMed]

- Bo Trabi, E.; Seddik, H.; Xie, F.; Lin, L.; Mao, S. Comparison of the Rumen Bacterial Community, Rumen Fermentation and Growth Performance of Fattening Lambs Fed Low-Grain, Pelleted or Non-Pelleted High Grain Total Mixed Ration. Anim. Feed Sci. Technol. 2019, 253, 1–12. [Google Scholar] [CrossRef]

- Lee, S.J.; Kim, D.H.; Guan, L.L.; Ahn, S.K.; Cho, K.W.; Lee, S.S. Effect of Medicinal Plant By-Products Supplementation to Total Mixed Ration on Growth Performance, Carcass Characteristics and Economic Efficacy in the Late Fattening Period of Hanwoo Steers. Asian Australas. J. Anim. Sci. 2015, 28, 1729–1735. [Google Scholar] [CrossRef][Green Version]

- Cheng, Y.; Wu, Z.; Bi, K.; Wang, X.; Yu, H.; Tian, P. Impact of Inoculating Various Lactic Acid Bacteria on Vitamin A Levels in Total Mixed Ration Silage. Sci. Rep. 2025, 15, 7343. [Google Scholar] [CrossRef]

- Cooke, D.W.I.; Monahan, F.J.; Brophy, P.O.; Boland, M.R. Comparison of Concentrates or Concentrates Plus Forages in a Total Mixed Ration or Discrete Ingredient Format: Effects on Beef Production Parameters and on Beef Composition, Colour, Texture and Fatty Acid Profile. Ir. J. Agric. Food Res. 2004, 43, 201–216. [Google Scholar][Green Version]

- Cao, Y.; Takahashi, T.; Horiguchi, K.; Yoshida, N.; Cai, Y. Methane Emissions from Sheep Fed Fermented or Non-Fermented Total Mixed Ration Containing Whole-Crop Rice and Rice Bran. Anim. Feed Sci. Technol. 2010, 157, 72–78. [Google Scholar] [CrossRef]

- Kronqvist, C.; Petters, F.; Robertsson, U.; Lindberg, M. Evaluation of Production Parameters, Feed Sorting Behaviour and Social Interactions in Dairy Cows: Comparison of Two Total Mixed Rations with Different Particle Size and Water Content. Livest. Sci. 2021, 251, 104662. [Google Scholar] [CrossRef]

- Liu, W.; Li, E.; Xu, C.; Chen, L.; Wang, X. Nutritional Strategies for Nile Tilapia: Protein and Carbohydrate Balances in Saline-Alkaline Aquaculture. J. Anim. Sci. Biotechnol. 2025, 16, 86. [Google Scholar] [CrossRef]

- Soder, K.J.; Brito, A.F.; Rubano, M.D. Effect of Supplementing Orchardgrass Herbage with a Total Mixed Ration or Flaxseed on Fermentation Profile and Bacterial Protein Synthesis in Continuous Culture. J. Dairy Sci. 2013, 96, 3228–3237. [Google Scholar] [CrossRef]

- Huuskonen, A.; Hietala, S.; Hyvönen, J.; Leinonen, I.; Manni, K. Environmental Impacts and Animal Performance of Finishing Bulls Fed Different Silage-Based Total Mixed Rations. Livest. Sci. 2023, 268, 105166. [Google Scholar] [CrossRef]

- Sant’Anna, M.A.C.; Carlis, M.S.D.P.; Polizel, D.M.; Ferreira, E.M.; Andrighetto, C.; Luz, P.A.D.; Araujo, L.C.D. Megathyrsus Maximus Addition in Total Mixed Ration on Performance, Metabolism, and Quality of Lamb Carcasses. Cienc. Rural 2025, 55, e20240594. [Google Scholar] [CrossRef]

- Schingoethe, D.J. A 100-Year Review: Total Mixed Ration Feeding of Dairy Cows. J. Dairy Sci. 2017, 100, 10143–10150. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Li, Y.; Fang, X.; Cai, Y.; Zhang, Y. Lactation Performance, Nitrogen Utilization, and Profitability in Dairy Cows Fed Fermented Total Mixed Ration Containing Wet Corn Gluten Feed and Corn Stover in Combination Replacing a Portion of Alfalfa Hay. Anim. Feed Sci. Technol. 2020, 269, 114687. [Google Scholar] [CrossRef]

- Du, E.; Mao, N.; Liu, S.; Zhang, H.; Fan, M.; Sun, H.; Zheng, Y.; Cheng, Q.; Wang, C.; Li, P.; et al. Effects of Different Wet Distillers’ Grains Ratios on Fermentation Quality, Nitrogen Fractions and Bacterial Communities of Total Mixed Ration Silage. BMC Microbiol. 2025, 25, 31. [Google Scholar] [CrossRef]

- Kondo, M.; Shimizu, K.; Jayanegara, A.; Mishima, T.; Matsui, H.; Karita, S.; Goto, M.; Fujihara, T. Changes in Nutrient Composition and in Vitro Ruminal Fermentation of Total Mixed Ration Silage Stored at Different Temperatures and Periods. J. Sci. Food Agric. 2016, 96, 1175–1180. [Google Scholar] [CrossRef]

- Brambilla, M.; Lazzari, A.; Giovinazzo, S.; Tangorra, F.; Calcante, A.; Bisaglia, C. Operational Evaluation of an Optical Sensor for the Automatic In-Line Estimation of Total Mixed Ration Fibre Length and Particle Size in a Mixing Wagon. J. Agric. Eng. 2025, 56, 1730.1–1730.6. [Google Scholar] [CrossRef]

- Gheller, L.S.; Ghizzi, L.G.; Marques, J.A.; Takiya, C.S.; Grigoletto, N.T.S.; Dias, M.S.S.; Silva, T.B.P.; Nunes, A.T.; Da Silva, G.G.; Fernandes, L.G.X.; et al. Effects of Organic Acid-Based Products Added to Total Mixed Ration on Performance and Ruminal Fermentation of Dairy Cows. Anim. Feed Sci. Technol. 2020, 261, 114406. [Google Scholar] [CrossRef]

- Chen, F.; Wei, J.; Yang, X.; Zhao, N.; Zhang, W.; Huang, S.; Yan, N.; Guo, W. Effect of Pelleted Total Mixed Rations with Different Levels of Intact Rapeseed on Performance, Carcass Traits, Serum Biochemical Indices and Meat Quality of Boer Goats. Anim. Prod. Sci. 2019, 59, 82. [Google Scholar] [CrossRef]

- Miguel, M.; Mamuad, L.; Ramos, S.; Ku, M.J.; Jeong, C.D.; Kim, S.H.; Cho, Y.I.; Lee, S.S. Effects of Using Different Roughages in the Total Mixed Ration Inoculated with or without Coculture of Lactobacillus Acidophilus and Bacillus Subtilis on in Vitro Rumen Fermentation and Microbial Population. Anim. Biosci. 2020, 34, 642. [Google Scholar] [CrossRef]

- Cao, Y.; Takahashi, T.; Horiguchi, K.; Yoshida, N.; Zhou, D. In Vitro Ruminal Dry Matter Digestibility and Methane Production of Fermented Total Mixed Ration Containing Whole-crop Rice and Rice Bran. Grassl. Sci. 2012, 58, 133–139. [Google Scholar] [CrossRef]

- Liu, M.J.; Wang, Y.; Li, Y.Y.; Si, Q.; Bao, J.; Ge, G.T.; Wang, Z.J.; Jia, Y.S.; Du, S. Effects of Alfalfa and Oat Supplementation in Fermented Total Mixed Rations on Growth Performances, Carcass Characteristics, and Meat Quality in Lambs. Small Rumin. Res. 2023, 218, 106877. [Google Scholar] [CrossRef]

- Li, Y.; Lv, J.; Wang, J.; Zhou, S.; Zhang, G.; Wei, B.; Sun, Y.; Lan, Y.; Dou, X.; Zhang, Y. Changes in Carbohydrate Composition in Fermented Total Mixed Ration and Its Effects on in Vitro Methane Production and Microbiome. Front. Microbiol. 2021, 12, 738334. [Google Scholar] [CrossRef] [PubMed]

- Supapong, C.; Cherdthong, A. Can Dietary Fermented Total Mixed Ration Additives Biological and Chemical Improve Digestibility, Performance, and Rumen Fermentation in Ruminants? Anim. Biotechnol. 2023, 34, 5113–5123. [Google Scholar] [CrossRef]

- Zhang, C.; Li, M.M.; Al-Marashdeh, O.; Gan, L.P.; Zhang, C.Y.; Zhang, G.G. Performance, Rumen Fermentation, and Gastrointestinal Microflora of Lambs Fed Pelleted or Unpelleted Total Mixed Ration. Anim. Feed Sci. Technol. 2019, 253, 22–31. [Google Scholar] [CrossRef]

- Ahammed, B.; Alam, J.; Shubho, A.; Ali Biswas, A. Effect of the Fermented Total Mixed Ration on In-Vitro Gas Production and Digestibility in Cattle. Bangladesh J. Vet. Anim. Sci. 2021, 9, 23–32. [Google Scholar] [CrossRef]

- Wang, H.; ur Rehman, K.; Feng, W.; Yang, D.; ur Rehman, R.; Cai, M.; Zhang, J.; Yu, Z.; Zheng, L. Physicochemical Structure of Chitin in the Developing Stages of Black Soldier Fly. Int. J. Biol. Macromol. 2020, 149, 901–907. [Google Scholar] [CrossRef]

- Jairath, G.; Verma, A.K.; Rani, D.; Marappan, G.; Bs, Y.; Singh, B.; Mal, G.; Gopinath, D.; Sharma, R.; Katoch, S.; et al. Self-Fermented Agro-Wastes as Antioxidant Enriched Maize Grain Replacer for Sustainable Animal Feeding. J. Clean. Prod. 2023, 427, 139223. [Google Scholar] [CrossRef]

- Paul, O.; Urmi, S.; Biswas, M. Effect of TMR and Fermented TMR on Ruminal in Vitro Digestion and Gas Production Adv. Anim. Vet. Sci. 2023, 11, 586–594. [Google Scholar]

- Hamidan, M.F.R.; Nadzir, M.N.H.M.; Bakar, M.F.A.; Shohaimi, S.; Bidin, H.; Samat, N. Effect of Azolla Filiculoides Meal Inclusion in the Napier Silage Total Mixed Ration on the in Vitro Cumulative Gas Production and Digestibility. Pertanika J. Trop. Agric. Sci. 2022, 45, 452–467. [Google Scholar] [CrossRef]

- Marchesini, G.; Cortese, M.; Ughelini, N.; Ricci, R.; Chinello, M.; Contiero, B.; Andrighetto, I. Effect of Total Mixed Ration Processing Time on Ration Consistency and Beef Cattle Performance during the Early Fattening Period. Anim. Feed Sci. Technol. 2020, 262, 114421. [Google Scholar] [CrossRef]

- Gadzama, I.U.; Hoffman, L.C.; Holman, B.W.B.; Chaves, A.V.; Meale, S.J. Effects of Supplementing a Feedlot Diet with Microalgae (Chlorella vulgaris) on the Performance, Carcass Traits and Meat Quality of Lambs. Livest. Sci. 2024, 288, 105552. [Google Scholar] [CrossRef]

- Zhang, J.; Shang, J.; Hao, Y.; Wang, Y.; Cao, Z.; Yang, H.; Wang, W.; Li, S. Growth Performance, Blood Metabolites, Ruminal Fermentation, and Bacterial Community in Preweaning Dairy Calves Fed Corn Silage-Included Starter and Total Mixed Ration. J. Dairy Sci. 2023, 106, 4545–4558. [Google Scholar] [CrossRef] [PubMed]

- Vibart, R.E.; Burns, J.C.; Fellner, V. Effect of Replacing Total Mixed Ration with Pasture on Ruminal Fermentation. Prof. Anim. Sci. 2010, 26, 435–442. [Google Scholar] [CrossRef]

- Pastorini, M.; Pomiés, N.; Repetto, J.L.; Mendoza, A.; Cajarville, C. Productive Performance and Digestive Response of Dairy Cows Fed Different Diets Combining a Total Mixed Ration and Fresh Forage. J. Dairy Sci. 2019, 102, 4118–4130. [Google Scholar] [CrossRef] [PubMed]

- Boguhn, J.; Kluth, H.; Rodehutscord, M. Effect of Total Mixed Ration Composition on Fermentation and Efficiency of Ruminal Microbial Crude Protein Synthesis In Vitro. J. Dairy Sci. 2006, 89, 1580–1591. [Google Scholar] [CrossRef]

- Bakshi, M.P.S.; Singh, A.S.; Wadhwa, M. Impact of Type and Level of Herbs Supplemented to Total Mixed Ration on the Fermentation Pattern and In Vitro Methane Emission. Indian J. Anim. Nutr. 2022, 39, 264–271. [Google Scholar] [CrossRef]

- Meenongyai, W.; Pattarajinda, V.; Stelzleni, A.M.; Sethakul, J.; Duangjinda, M. Effects of Forage Ensiling and Ration Fermentation on Total Mixed Ration pH, Ruminal Fermentation and Performance of Growing Holstein-Zebu Cross Steers. Anim. Sci. J. 2017, 88, 1372–1379. [Google Scholar] [CrossRef]

- Jahan, R.; Amin, M.; Sarker, N.; Kamal, M. Feeding Effects of Total Mixed Ration on Rumen Metabolic Profile in Cattle. Bang. J. Anim. Sci. 2018, 47, 35–39. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Guo, X. Effects of Total Mixed Ration with Various Silage on Growth Performance, Serum Parameters, Ruminal Fermentation, and Bacteria Community Profile in Beef Cattle. Food Sci. Nutr. 2021, 9, 5959–5970. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Ma, Y.; Zhang, H.; Wang, L.; Zhang, Y.; Zhang, G. Fermented Total Mixed Ration Alters Rumen Fermentation Parameters and Microbiota in Dairy Cows. Animals 2023, 13, 1062. [Google Scholar] [CrossRef] [PubMed]

- Zhong, R.; Zhao, C.; Feng, P.; Wang, Y.; Zhao, X.; Luo, D.; Cheng, L.; Liu, D.; Fang, Y. Effects of Feeding Ground versus Pelleted Total Mixed Ration on Digestion, Rumen Function and Milk Production Performance of Dairy Cows. Int. J. Dairy Tech. 2020, 73, 22–30. [Google Scholar] [CrossRef]

- Ku, M.-J.; Miguel, M.A.; Kim, S.-H.; Jeong, C.-D.; Ramos, S.C.; Son, A.-R.; Cho, Y.-I.; Lee, S.-S.; Lee, S.-S. Effects of Italian Ryegrass Silage-Based Total Mixed Ration on Rumen Fermentation, Growth Performance, Blood Metabolites, and Bacterial Communities of Growing Hanwoo Heifers. J. Anim. Sci. Technol. 2023, 65, 951–970. [Google Scholar] [CrossRef]

- Metzler-Zebeli, B.U.; Scherr, C.; Sallaku, E.; Drochner, W.; Zebeli, Q. Evaluation of Associative Effects of Total Mixed Ration for Dairy Cattle Using in Vitro Gas Production and Different Rumen Inocula. J. Sci. Food Agric. 2012, 92, 2479–2485. [Google Scholar] [CrossRef]

- Rodriguez, M.P.; Mariezcurrena, M.D.; Mariezcurrena, M.A.; Lagunas, B.C.; Elghandour, M.M.M.Y.; Kholif, A.M.; Kholif, A.E.; Almaráz, E.M.; Salem, A.Z.M. Influence of live cells or cells extract of Saccharomyces Cerevisiae on in vitro gas production of a total mixed ration. Ital. J. Anim. Sci. 2015, 14, 3713. [Google Scholar] [CrossRef]

- Tafaj, M.; Zebeli, Q.; Junck, B.; Steingass, H.; Drochner, W. Effects of Particle Size of a Total Mixed Ration on in Vivo Ruminal Fermentation Patterns and Inocula Characteristics Used for in Vitro Gas Production. Anim. Feed Sci. Technol. 2005, 123–124, 139–154. [Google Scholar] [CrossRef]

- Alhadas, H.; Valadares, S.; Souza, C.; Rocha, L.; Pacheco, M.; Silva, B.; Costa, D.; Mantovani, H. PSX-18 Inclusion of Physically Effective Fiber from Forage on Whole Corn Based Diets for Beef Cattle and Its Effects on the Intake and Digestibilities of Dry Matter, Starch and Neutral Detergent Fiber. J. Anim. Sci. 2018, 96 (Suppl. 3), 414. [Google Scholar] [CrossRef]

- Felizari, L.; Millen, D.; Perina Bertoldi, G.; Squizatti, M.; Silvestre, A.; Pavão Coffani Nunes, A.; Garcia Mesquita, L.; Millen, D. PSX-26 Ruminal Bacteria and Protozoa Profile during Adaptation and Finishing Periods of Nellore Cattle Previously Submitted to Either Nutritional Restriction or Intake Concentrate Feedstuffs. J. Anim. Sci. 2018, 96 (Suppl. 3), 415–416. [Google Scholar] [CrossRef]

- Sun, X.; Wang, H.; You, P.; Pacheco, D.; Wang, M.; Wu, T.; Song, B.; Kang, K.; Li, Y.; Li, B.; et al. Agglomerated Live Yeast (Saccharomyces cerevisiae) Supplemented to Pelleted Total Mixed Rations Improves the Growth Performance of Fattening Lambs. Livest. Sci. 2022, 258, 104855. [Google Scholar] [CrossRef]

- Tufarelli, V.; Khan, R.U.; Laudadio, V. Feeding of Wheat Middlings in Lamb Total Mixed Rations: Effects on Growth Performance and Carcass Traits. Anim. Feed Sci. Technol. 2011, 170, 130–135. [Google Scholar] [CrossRef]

- Nkosi, B.D.; Meeske, R. Effects of Ensiling Totally Mixed Potato Hash Ration with or without a Heterofermentative Bacterial Inoculant on Silage Fermentation, Aerobic Stability, Growth Performance and Digestibility in Lambs. Anim. Feed Sci. Technol. 2010, 161, 38–48. [Google Scholar] [CrossRef]

- Nha, B.; Pattarajinda, V. Effect of Physically Effective Neutral Detergent Fibre and Moisture Content in Fermented Total Mixed Ration on Lactating Cow Performance. Indian J. Anim. Res. 2019, 53, 913–917. [Google Scholar]

- Jang, S.Y.; Kim, E.K.; Park, J.H.; Oh, M.R.; Tang, Y.J.; Ding, Y.L.; Seong, H.J.; Kim, W.H.; Yun, Y.S.; Moon, S.H. Effects of Physically Effective Neutral Detergent Fiber Content on Dry Matter Intake, Digestibility, and Chewing Activity in Korean Native Goats (Capra hircus coreanae) Fed with Total Mixed Ration. Asian-Australas J. Anim. Sci. 2017, 30, 1405–1409. [Google Scholar] [CrossRef]

- Kumar, V.; Tyagi, A.; Thakur, S.; Singh, N.P.; Chaudhary, J. Effect of Different Feeding Systems on Performance of Lactating Murrah Buffaloes. Indian J. Dairy Sci. 2015, 68, 61–64. [Google Scholar]

- Lakhani, N.; Tyagi, N. Comparative Evaluation of in Vitro Techniques for Predicting Metabolizable Energy Content of Total Mixed Ration for Murrah Buffaloes. Indian J. Anim. Sci. 2021, 91, 220–224. [Google Scholar] [CrossRef]

- Sunarso; Christiyanto, M.; Nuswantara, L.K. Feeding of Total Mixed Ration on the Productivity of Friesian Holstein Cross-Grade Cattle. IOP Conf. Ser. Earth Environ. Sci. 2018, 119, 012024. [Google Scholar] [CrossRef]

- Lailer, P.; Dahiya, S.; Chauhan, T. Complete Feed for Livestock Concept, Present Status and Future Trend: A Review. Indian J. Anim. Sci. 2005, 75, 84–91. [Google Scholar]

- Koch, C.; Schönleben, M.; Mentschel, J.; Göres, N.; Fissore, P.; Cohrs, I.; Sauerwein, H.; Ghaffari, M.H. Growth Performance and Economic Impact of Simmental Fattening Bulls Fed Dry or Corn Silage-Based Total Mixed Rations. Animal 2023, 17, 100762. [Google Scholar] [CrossRef]

- Teshome, D.; Fita, L.; Feyissa, F.; Kitaw, G.; Wondatir, Z. Effect of Total Mixed Ration on Dry Matter Intake, Milk Yield and Composition of Early Lactating Jersey Cows. J. Biol. 2017, 7, 19–24. [Google Scholar]

- Hernández-Ortega, M.; Martínez-Fernández, A.; Soldado, A.; González, A.; Arriaga-Jordán, C.M.; Argamentería, A.; De La Roza-Delgado, B.; Vicente, F. Effect of Total Mixed Ration Composition and Daily Grazing Pattern on Milk Production, Composition and Fatty Acids Profile of Dairy Cows. J. Dairy Res. 2014, 81, 471–478. [Google Scholar] [CrossRef]

- Mäntysaari, P.; Khalili, H.; Sariola, J. Effect of Feeding Frequency of a Total Mixed Ration on the Performance of High-Yielding Dairy Cows. J. Dairy Sci. 2006, 89, 4312–4320. [Google Scholar] [CrossRef] [PubMed]

- Caccamo, M.; Veerkamp, R.F.; Licitra, G.; Petriglieri, R.; La Terra, F.; Pozzebon, A.; Ferguson, J.D. Association of Total-Mixed-Ration Chemical Composition with Milk, Fat, and Protein Yield Lactation Curves at the Individual Level. J. Dairy Sci. 2012, 95, 6171–6183. [Google Scholar] [CrossRef] [PubMed]

- Khy, V.; Prucsasri, P.; Kanthapanit, C.; Chtwachirawong, P. A Comparison of Growth, Feed Efficiency and Carcass Characteristics of Kamphaengsaen Steers Fed Two TMR Fiber Sources During Two Different Feeding Period. Agric. Nat. Resour. 2000, 34, 216–226. [Google Scholar]

- Kim, J.G.; Cheong, E.C.; Li, Y.F.; Kim, H.J.; Farhad, A.; Kim, M.J. Effect of TMR Feed Mixed with Whole Crop Rice on Growth Performance and Meat Quality of Hanwoo Steers. J. Korean Soc. Grassl. Forage Sci. 2021, 41, 267–272. [Google Scholar] [CrossRef]

- Yun, Y.-S.; Seong, H.-J.; Zhang, Q.-M.; Chung, S.-U.; Lee, G.-E.; Jang, S.-Y.; Lee, J.; Lee, S.-H.; Moon, S.-H. Changes in Goat Productivity and Economical Efficiency at Feeding Systems by Castrated Growing Korean Native Goat (Capra hircus coreanae). J. Korean Soc. Grassl. Forage Sci. 2018, 38, 150–155. [Google Scholar] [CrossRef]

- Kim, T.; Mayakrishnan, V.; Lim, D.; Yeon, J.; Baek, K. Effect of Fermented Total Mixed Rations on the Growth Performance, Carcass and Meat Quality Characteristics of Hanwoo Steers. Anim. Sci. J. 2018, 89, 606–615. [Google Scholar] [CrossRef]

- Wang, J.; Yang, B.Y.; Zhang, S.J.; Amar, A.; Chaudhry, A.S.; Cheng, L.; Abbasi, I.H.R.; Al-Mamun, M.; Guo, X.F.; Shan, A.S. Using Mixed Silages of Sweet Sorghum and Alfalfa in Total Mixed Rations to Improve Growth Performance, Nutrient Digestibility, Carcass Traits and Meat Quality of Sheep. Animal 2021, 15, 100246. [Google Scholar] [CrossRef]

- Soder, K.J.; Rotz, C.A. Economic and Environmental Impact of Utilizing a Total Mixed Ration in Pennsylvania Grazing Dairy Herds. Prof. Anim. Sci. 2003, 19, 304–311. [Google Scholar] [CrossRef]

- Pankaj, P.K.; Ramana, D.; Nirmala, G.; Maruthi, V.; Shankar, K.S.; Prasad, T.; Singh, V.K. Enhancing Dryland Sheep Productivity with Densified Crop Residue Total Mixed Rations. Indian J. Dryland Agric. Res. Dev. 2023, 38, 49–53. [Google Scholar] [CrossRef]

- O’Neill, B.F.; Deighton, M.H.; O’Loughlin, B.M.; Mulligan, F.J.; Boland, T.M.; O’Donovan, M.; Lewis, E. Effects of a Perennial Ryegrass Diet or Total Mixed Ration Diet Offered to Spring-Calving Holstein-Friesian Dairy Cows on Methane Emissions, Dry Matter Intake, and Milk Production. J. Dairy Sci. 2011, 94, 1941–1951. [Google Scholar] [CrossRef]

- Griinari, J.M.; Dwyer, D.A.; McGuire, M.A.; Bauman, D.E.; Palmquist, D.L.; Nurmela, K.V. Trans-Octadecenoic Acids and Milk Fat Depression in Lactating Dairy Cows. J. Dairy Sci. 1998, 81, 1251–1261. [Google Scholar] [CrossRef]

- Mohammad, M.; Gorgulu, M.; Goncu, S. The Effects of Total Mixed Ration and Separate Feeding on Lactational Performance of Dairy Cows. Asian Res. J. Agric. 2017, 5, 1–7. [Google Scholar] [CrossRef]

- Østergaard, S.; Sørensen, J.T.; Hindhede, J.; Kristensen, A.R. Technical and Economic Effects of Feeding One vs. Multiple Total Mixed Rations Estimated by Stochastic Simulation under Different Dairy Herd and Management Characteristics. Livest. Prod. Sci. 1996, 45, 23–33. [Google Scholar] [CrossRef]

- Renna, M.; Cornale, P.; Lussiana, C.; Battaglini, L.M.; Turille, G.; Mimosi, A. Milk Yield, Gross Composition and Fatty Acid Profile of Dual-purpose AOsta REd PIed Cows Fed Separate Concentrate-forage versus Total Mixed Ration. Anim. Sci. J. 2014, 85, 37–45. [Google Scholar] [CrossRef] [PubMed]

- Mendoza, A.; Cajarville, C.; Repetto, J.L. Digestive Response of Dairy Cows Fed Diets Combining Fresh Forage with a Total Mixed Ration. J. Dairy Sci. 2016, 99, 8779–8789. [Google Scholar] [CrossRef]

- Wongnen, C.; Wachirapakorn, C.; Patipan, C.; Panpong, D.; Kongweha, K.; Namsaen, N.; Gunun, P.; Yuangklang, C. Effects of Fermented Total Mixed Ration and Cracked Cottonseed on Milk Yield and Milk Composition in Dairy Cows. Asian Australas. J. Anim. Sci. 2009, 22, 1625–1632. [Google Scholar] [CrossRef]

- Kolver, E.; Muller, L. Performance and Nutrient Intake of High Producing Holstein Cows Consuming Pasture or a Total Mixed Ration. J. Dairy Sci. 1998, 81, 1403–1411. [Google Scholar] [CrossRef]

- Sakai, T.; Devkota, N.R.; Oishi, K.; Hirooka, H.; Kumagai, H. Evaluation of Total Mixed Ration Silage with Brewers Grains for Dairy Buffalo in Tarai, Nepal. Anim. Sci. J. 2015, 86, 884–890. [Google Scholar] [CrossRef] [PubMed]

- Ponnampalam, E.; Priyashantha, H.; Vidanarachchi, J.; Kiani, A.; Holman, B. Effects of Nutritional Factors on Fat Content, Fatty Acid Composition, and Sensorial Properties of Meat and Milk from Domesticated Ruminants: An Overview. Animals 2024, 14, 840. [Google Scholar] [CrossRef] [PubMed]

- Ponnampalam, E.N.; Norng, S.; Burnett, V.F.; Dunshea, F.R.; Jacobs, J.L.; Hopkins, D.L. The Synergism of Biochemical Components Controlling Lipid Oxidation in Lamb Muscle. Lipids 2014, 49, 757–766. [Google Scholar] [CrossRef]

- Santos-Silva, J.; Alves, S.P.; Francisco, A.; Portugal, A.P.; Dentinho, M.T.; Almeida, J.; da Silva, J.L.R.; Fialho, L.; Cachucho, L.; Jerónimo, E.; et al. Forage Based Diet as an Alternative to a High Concentrate Diet for Finishing Young Bulls—Effects on Growth Performance, Greenhouse Gas Emissions and Meat Quality. Meat Sci. 2023, 198, 109098. [Google Scholar] [CrossRef]

- Alves, S.P.; Vahmani, P.; Mapiye, C.; McAllister, T.A.; Bessa, R.J.B.; Dugan, M.E.R. Trans-10 18:1 in Ruminant Meats: A Review. Lipids 2021, 56, 539–562. [Google Scholar] [CrossRef]

- Johnson, K.A.; Johnson, D.E. Methane Emissions from Cattle. J. Anim. Sci. 1995, 73, 2483–2492. [Google Scholar] [CrossRef]

- Koenig, K.; Beauchemin, K.; McGinn, S. PSX-22 Feeding Condensed and Hydrolysable Tannins in High Protein Finishing Diets to Beef Cattle to Reduce Ammonia Emissions from Manure. J. Anim. Sci. 2018, 96 (Suppl. 3), 415. [Google Scholar] [CrossRef]

- Tangorra, F.M.; Calcante, A. Potential Economic and Environmental Benefits of Automating Milking and Total Mixed Ration (TMR) Feeding on a Dairy Farm; Springer: Berlin/Heidelberg, Germany, 2024; pp. 935–943. [Google Scholar]

- Cogan, T.; Hawkey, R.; Higgie, E.; Lee, M.R.F.; Mee, E.; Parfitt, D.; Raj, J.; Roderick, S.; Walker, N.; Ward, P.; et al. Silage and Total Mixed Ration Hygienic Quality on Commercial Farms: Implications for Animal Production. Grass Forage Sci. 2017, 72, 601–613. [Google Scholar] [CrossRef]

- González-Jartín, J.M.; Rodríguez-Cañás, I.; Alvariño, R.; Alfonso, A.; Sainz, M.J.; Vieytes, M.R.; Gomes, A.; Ramos, I.; Botana, L.M. Occurrence of Mycotoxins in Total Mixed Ration of Dairy Farms in Portugal and Carry-over to Milk. Food Control 2024, 165, 110682. [Google Scholar] [CrossRef]

- Rodríguez-Blanco, M.; Marín, S.; Sanchis, V.; Ramos, A.J. Fusarium Mycotoxins in Total Mixed Rations for Dairy Cows. Mycotoxin Res. 2020, 36, 277–286. [Google Scholar] [CrossRef]

- Sultana, N.; Rashid, A.; Tahira, I.; Hanif, H.; Hanif, N. Distribution of Various Mycotoxins in Compound Feed, Total Mix Ration and Silage. Pak. Vet. J. 2013, 33, 200–204. [Google Scholar]

- Chohan, K.A.; Awan, F.; Ali, M.M.; Iqbal, U.; Ijaz, M. Assessment of Aflatoxin in Dairy Concentrate Feeds, Total Mixed Rations, Silage and Various Feed Ingredients in Pakistan. Pak. J. Zool. 2016, 48, 277–280. [Google Scholar] [CrossRef]

- Vaičiulienė, G.; Bakutis, B.; Jovaišienė, J.; Falkauskas, R.; Gerulis, G.; Kerzienė, S.; Baliukonienė, V. Prevalence of Mycotoxins and Endotoxins in Total Mixed Rations and Different Types of Ensiled Forages for Dairy Cows in Lithuania. Toxins 2021, 13, 890. [Google Scholar] [CrossRef] [PubMed]

- Masoero, F.; Gallo, A.; Diaz, D.; Piva, G.; Moschini, M. Effects of the Procedure of Inclusion of a Sequestering Agent in the Total Mixed Ration on Proportional Aflatoxin M1 Excretion into Milk of Lactating Dairy Cows. Anim. Feed Sci. Technol. 2009, 150, 34–45. [Google Scholar] [CrossRef]

- Mohammadi Shad, Z.; Ghavami, M.; Atungulu, G.G. Occurrence of Aflatoxin in Dairy Cow Feed Ingredients and Total Mixed Ration. Appl. Eng. Agric. 2019, 35, 679–686. [Google Scholar] [CrossRef]

- Gallo, A.; Minuti, A.; Bani, P.; Bertuzzi, T.; Cappelli, F.P.; Doupovec, B.; Faas, J.; Schatzmayr, D.; Trevisi, E. A Mycotoxin-Deactivating Feed Additive Counteracts the Adverse Effects of Regular Levels of Fusarium Mycotoxins in Dairy Cows. J. Dairy Sci. 2020, 103, 11314–11331. [Google Scholar] [CrossRef]

- Hu, Z.; Zuo, M.; Ding, S.; Zhong, Y.; Xue, M.; Zheng, H. Integrating Metabolomics and Genomics to Uncover the Impact of Fermented Total Mixed Ration on Heifer Growth Performance Through Host-Dependent Metabolic Pathways. Animals 2025, 15, 173. [Google Scholar] [CrossRef]

- Mansfield, H.; Endres, M.; Stern, M. Comparison of Microbial Fermentation in the Rumen of Dairy Cows and Dual Flow Continuous Culture. Anim. Feed Sci. Technol. 1995, 55, 47–66. [Google Scholar] [CrossRef]

| Species/Breed | TMR Type/Modification | Summary of Results | Reference |

|---|---|---|---|

| Holstein calves | WPCS-based TMR (CTMR) | Lower in vitro DM/CP/NDF digestibility vs. starter (CONS) | [56] |

| Karakul sheep | 40% SS-AF silage TMR | Higher DM, CP, and NDF digestibility | [5] |

| Fattening lambs | Pelleted TMR + LY | Increased DM (38 g/kg), OM (41 g/kg), and NDF (193 g/kg) digestibility | [72] |

| Comisana lambs | WM-based TMR | Higher aNDF/ADF digestibility No difference in DM/OM/CP | [73] |

| Red Chittagong cows | Maize stover-based TMR | ↑ DM/CP/NDF digestibility | [16] |

| Dorper lambs | LB-inoculated PH-TMR | Higher DM intake and nutrient digestibility vs. untreated PH-TMR | [74] |

| Dairy ewes | Wheat middling-based TMR | ↑ NDF digestibility | [73] |

| Dorper lambs | Cactus pear + cottonseed cake | ↑ DMD, OMD, EED in 20–30% cottonseed TMR ↓ Rumination time | [7] |

| Crossbred cows | FTMR with 25% peNDF | Improved nutrient digestibility (CP, NDF, ADF) | [75] |

| Red Chittagong Cows | Maize stover-based TMR | ↑ Digestibility of DM, CP, OM | [16] |

| Korean native goats | TMR with varying peNDF | No difference in DM, CF, or other nutrient digestibility | [76] |

| Dairy cows (in vitro) | 16 TMR formulations | OM fermentation: 35–47%; NDF fermentation: 3–28% | [59] |

| Buffaloes | TMR vs. conventional | ↑ DM, OM, NDF digestibility | [77] |

| Holstein dairy cows | TMR + FF | ↑ Nitrogen efficiency in 50% FF ↓ urinary N excretion | [58] |

| Korean native goats | TMR with varying peNDF | No difference in Nitrogen balance | [76] |

| Holstein-Zebu steers | FTMR (pH 3.5) | ↑ Crude protein digestibility ↓ fat digestibility in silage-TMR. | [61] |

| Angus beef cattle | High-concentrate TMR | ↓ DM, CP, and NDF digestibility | [18] |

| Yellow cattle (in vitro) | Fermented TMR (FTMR) | ↓ NDF/ADF; ↑ lactic acid and soluble carbohydrates. | [46] |

| Simmental bulls | Multi-silage TMR (MS) | Improved fiber degradation linked to ↑ Prevotella-1. | [63] |

| Murrah buffaloes | TMR (maize silage/concentrate ratios) | Highest DMI (14.35 kg/d) at 50:50 ratio; ME content ↓ with ↑ silage. | [78] |

| Hanwoo steers | TMR with fermented feed (TMRF) | Higher DM disappearance (3–12 h) and weight gain (308 kg vs. 284 kg control). | [13] |

| Suffolk sheep | Fermented TMR (FTMR) | ↑ CP, EE, ADF, and GE digestibility vs. non-fermented TMR. | [30] |

| Montbéliarde cattle | TMR (90% concentrate) | No difference in DMI or digestibility vs. separate feeding. | [17] |

| Nellore bulls | TMR with pefNDF | Optimal fiber digestion at 20.5 g pefNDF/kg DM. | [70] |

| Species/Breed | TMR Type/Modification | Summary of Results | Reference |

|---|---|---|---|

| Brown Swiss cows | TMR + Saccharomyces cerevisiae (CE) | CE (0.6 mg/g DM) increased CH4; LC had no effect. | [68] |

| Suffolk sheep | Fermented TMR (FTMR) | 25% lower CH4 compared to the control due to a propionate shift. | [30,44] |

| Holstein steers | High-concentrate TMR | Higher CH4 (138.5 L/day) vs. separate feeding (118.2 L/day). | [9] |

| Holstein-Friesian | TMR (maize silage + concentrate) | Higher CH4 (397 g/d) vs. grass diet (251 g/d). | [93] |

| Holstein (Dairy) | pTMR | Lower N leaching (21 kg/ha) but higher volatilization (98 kg/ha) | [91] |

| Holstein (Dairy) | Automatic TMR (AFS) | 67.5% lower CO2e emissions | [108] |

| Holstein (Dairy) | Pasture + Concentrate | Highest N volatilization (116 kg/ha) | [91] |

| Aberdeen Angus | MC TMR (60% grass silage) | Lowest GWP (19.1 kg CO2 eq/kg beef); best feed conversion | [34] |

| Species/Breed | TMR Type/Intervention | Findings vs. Control | Reference |

|---|---|---|---|

| Simmental bulls | Dry TMR (straw-based) | Higher feed costs but similar carcass yield vs. conventional TMR | [81] |

| Crossbred lambs | FTMR (AH-300) | Improved net income due to better feed efficiency | [45] |

| Dorper Lambs | 16% CP Growing TMR | Lowest feed cost/kg gain (RM 8.94 vs. RM 22.92 control) | [22] |

| Holstein (Dairy) | Confinement TMR | Highest net return ($738/cow) but greatest risk | [91] |

| Holstein (Dairy) | Automatic TMR (AFS) | 75% lower labor costs, 91% energy reduction | [108] |

| Hanwoo Steers | TMR + Medicinal Plants | Reduced feed costs, increased carcass price | [27] |

| Sindhi Crossbred | Alkaline-treated TMR | 17.75% higher economic benefit/kg gain | [14] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dey, M.C.; Jairath, G.; Gadzama, I.U.; Alves, S.P.; Ponnampalam, E.N. Impact of Mixed Rations on Rumen Fermentation, Microbial Activity and Animal Performance: Enhancing Livestock Health and Productivity—Invited Review. Ruminants 2025, 5, 42. https://doi.org/10.3390/ruminants5030042

Dey MC, Jairath G, Gadzama IU, Alves SP, Ponnampalam EN. Impact of Mixed Rations on Rumen Fermentation, Microbial Activity and Animal Performance: Enhancing Livestock Health and Productivity—Invited Review. Ruminants. 2025; 5(3):42. https://doi.org/10.3390/ruminants5030042

Chicago/Turabian StyleDey, Methun C., Gauri Jairath, Ishaya U. Gadzama, Susana P. Alves, and Eric N. Ponnampalam. 2025. "Impact of Mixed Rations on Rumen Fermentation, Microbial Activity and Animal Performance: Enhancing Livestock Health and Productivity—Invited Review" Ruminants 5, no. 3: 42. https://doi.org/10.3390/ruminants5030042

APA StyleDey, M. C., Jairath, G., Gadzama, I. U., Alves, S. P., & Ponnampalam, E. N. (2025). Impact of Mixed Rations on Rumen Fermentation, Microbial Activity and Animal Performance: Enhancing Livestock Health and Productivity—Invited Review. Ruminants, 5(3), 42. https://doi.org/10.3390/ruminants5030042