1. Introduction

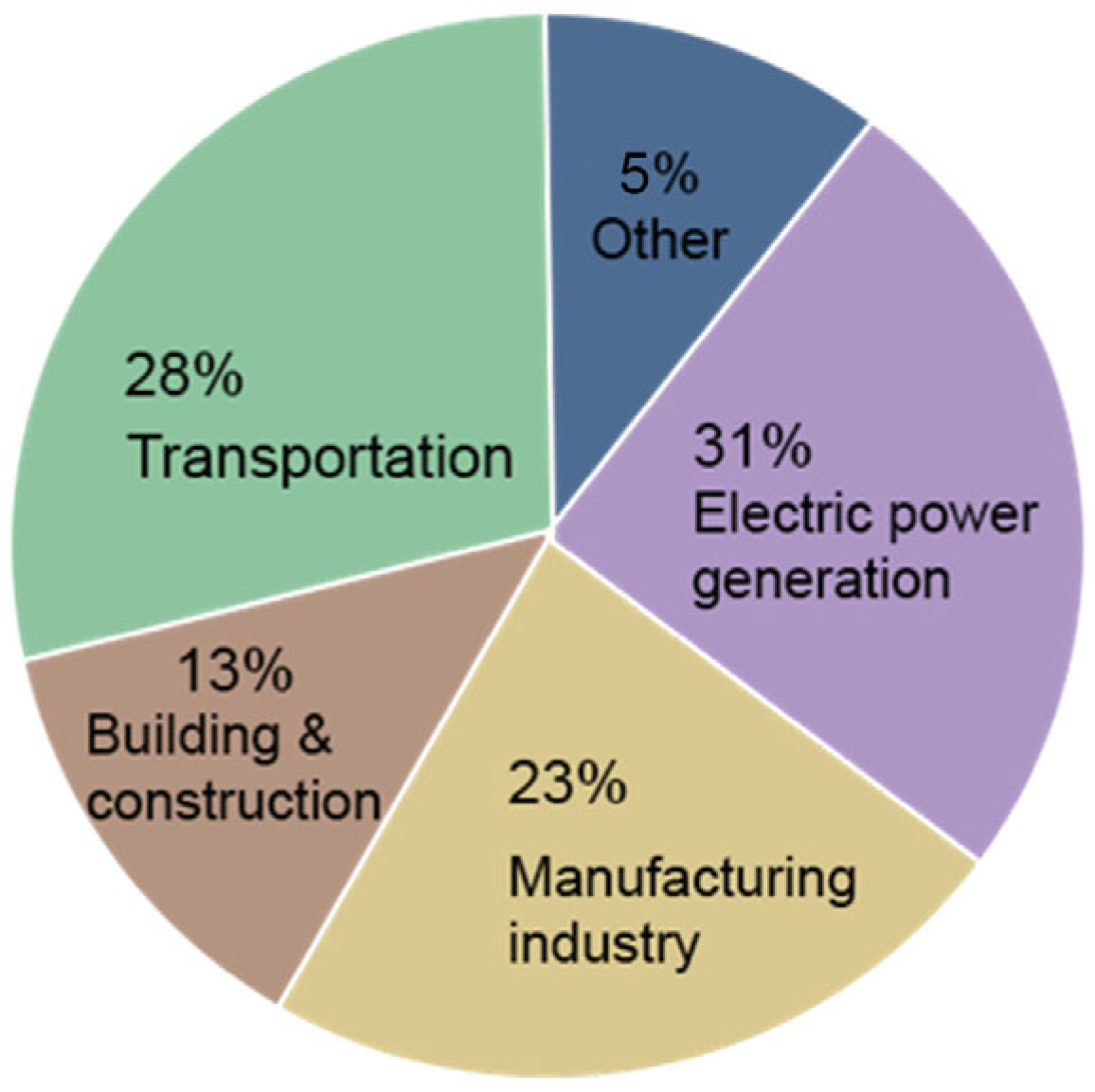

The residential building industry significantly adds to the global environmental problems through CO

2 emissions and material consumption. According to the USA Environmental Protection Agency, the electric power generating sector is the largest contributor, responsible for 31 percent of global emissions. The buildings and construction sector account for an alarming 13 percent of world emissions [

1] (

Figure 1). The transportation contributes 28 percent [

1]. The manufacturing industry sector contributes 23 percent [

1], as the production and utilization of materials like cement, steel, and aluminum have a substantial carbon footprint. The remaining 5 percent of emissions includes sectors such as agriculture, land use change, and waste [

1]. This distribution highlights the significant impact of the buildings and construction sector underscoring the need for targeted emission reduction strategies in these areas.

Historically, the construction sector’s advancements have primarily focused on diminishing the “operational” carbon emissions of buildings, which arise from heating, cooling, and lighting. Forecasts indicate that these operating emissions will diminish from 75 percent to 50 percent of the sector’s overall emissions in the forthcoming decades [

1,

2]. As a result, more designers are paying attention to embodied impacts, especially the substantial amount of energy and materials a building uses throughout its lifetime. The construction industry plays a significant role in the unsustainable depletion of natural resources. It relies largely on non-renewable elements like minerals, metals, and fossil fuels, which are diminishing quickly. As the need for new buildings globally keeps going up, it is more important than ever to use strategies that save resources and energy. These actions not only benefit the environment but are also good for business since they help make sure that materials will last a long time. The way the construction industry is currently functioning, with accelerated material use and inefficient building practices, is a challenge that the industry and society will have to deal with urgently.

Reevaluating house design and construction is needed as globally, urban populations rise and demand for housing grows. Often at the price of long-term sustainability, using traditional building techniques, designers and builders give priority to affordability or aesthetics. Often, these approaches produce high degrees of material waste, limited adaptability, and constructions that are difficult to change or reuse across time. Using prefabricated systems and modular dimensions in residential design offers one possible response to these difficulties. As will be demonstrated below, modular housing can lower embodied and operating energy by maximizing material efficiency and streamlining building techniques, thereby lowering costs as well.

Other technological innovations have the potential to significantly influence the future of prefabricated houses. Three-dimensional printing and robotic manufacturing are revolutionizing the construction process, rendering mass customization more viable and cost-effective. Three-dimensional printing is characterized in the literature as an automated, additive manufacturing technique that fabricates three-dimensional solid objects from a computer model. In a 3-D printing process, the 3-D CAD model is divided into a series of 2-D layers, which the printer then deposits to construct the model.

Three-dimensional printing possesses the capacity to transform the construction industry. It enables extensive manufacturing while preserving customization. Mass customization has been a goal for the construction industry for several decades. Various efforts have been undertaken to achieve mass customization, including the use of prefabricated components [

3]. To save costs associated with complexity, prefabricated components are generally standardized, leading to a limited range of prefabricated products. Conversely, 3-D printing technology enables the creation of customized goods without incurring extra expenses, even for complex architectural designs [

4].

As 3-D printing increasingly advances in construction, the integration of Design for Manufacture and Assembly (DfMA) concepts is crucial to fully exploit its potential in optimizing production, minimizing material waste, and improving buildability [

5]. DfMA is a design technique aimed at improving the efficiency, cost effectiveness, and constructability of items, particularly in construction, by integrating manufacturing and assembly considerations at the early stages of the design process [

6]. DfMA consists of two components: Design for Manufacture (DfM) and Design for Assembly (DfA). DfM prioritizes the simplification of component manufacturing, while DfA underscores the ease and efficiency of assembly, whether on-site or in a factory setting.

In the author’s view, there is currently a fundamental gap in the approach to waste reduction. Attention was mostly paid to end products rather than to the design process. This paper argues and demonstrates that reducing waste can be achieved by designing buildings that minimize it either through modularity, prefabrication, or design for dismantling (DfD).

In order to demonstrate this viewpoint and practice, the objectives of this paper are to (i) investigate the concept of modularity in residential construction and its effect on material consumption, (ii) explore the concept of Design for Disassembly, and (iii) examine challenges related to implementing modular prefabrication and DfD in the construction industry.

As delineated above, dwellings are currently designed with little attention to modularity as a cost reduction mechanism. A gap currently exists whereby literature dwells primarily on functionality and aesthetics. Little was investigated in modularity. Therefore, the research question that this paper addresses is how can application of strategies such as modularity and DfD can lower energy and material consumption, making a dwelling more affordable and sustainable?

2. Methodology

To investigate the use of modular design and DfD in residential construction and their effect on material consumption and energy performance, this paper uses a literature review, prototype construction and research, material waste analysis as a result of size selection and industry, as well as policy evaluation. To define modularity and sustainability in the building industry, the author examined architectural literature and technical reports and evaluated their effect on housing. It should be noted that the author undertook the design and construction of a prototype, the Grow Home, to test his assumption and demonstrate the use of standardized and modular/prefabricated construction methods, including footprint analysis, modular proportions, efficient framing practices, and DfD. Based on the dwelling’s dimensions and volume, the author used energy-calculating methods and material consumption to determine the outcome. The data sources were based on calculations made by the author of the design. In a discussion segment, the author’s research identifies problems with modularity and material recycling in home construction by looking at the scientific contributions by experts.

As will be explained in detail below, the research demonstrates that by selecting an appropriate floor plan and designing it using modular dimensions with reductions in wall area, a substantial amount of lumber can be saved. Selecting an appropriate form will also result in making the unit energy efficient, and, as an indirect outcome, reducing CO2 emissions.

3. Definition and the Merit of Modularity

In product design, modularity refers to the division of a complicated structure into smaller, self-sufficient pieces called modules or subassemblies, each responsible for a certain function [

3]. A product is considered modular if each module aligns precisely with its designated function and modules interact little, meaning that altering one module does not affect the functionality of others [

7]. This design approach facilitates flexibility, ease of customization, and efficient production, as modules can be replaced or improved without necessitating a whole system’s overhaul. Modularity has facilitated the shift from mass production to mass customization, addressing unique client needs while preserving manufacturing efficiency [

8].

In the construction industry, modularity provides the conceptual and operational foundation for prefabrication, a method in which building components are manufactured off-site and assembled on-site. Panelized construction is the most widely adopted technique. A panelized home is a structure made up of prefabricated panels that are assembled on site [

9]. These panels come in a range of sizes and materials, some of which are windows, insulation, or framing [

9]. The panels include the following: (1)

closed (fully sheathed) panels, which come complete with framing, insulation, and finishes; (2)

open-sheathed panels, with one face finished, allowing interior work during assembly; and (3)

unsheathed panels, providing only structural framing for maximum on-site flexibility [

9].

Prefabrication enhances design flexibility and construction efficiency while significantly contributing to material conservation in various aspects. Prefabrication possesses precision manufacturing capabilities and reduces waste [

9]. Computer Numerical Control (CNC) and automated technologies make it possible to cut, assemble, and optimize materials very accurately when they are made in a manufacturing setting [

9]. This reduces off-cuts, mistakes in size, and the use of too many resources compared to building by hand on site [

9]. Moreover, modular prefabrication relies on the repetition of standardized units (e.g., wall panels and pods), which simplifies procurement, reduces variety in material sizes, and minimizes surplus [

9]. This also supports easier material reuse across different projects. Furthermore, the modular prefabricated systems, featuring distinct boundaries and specified interfaces, correspond with Design for Disassembly (DfD) principles. Integrating BIM and digital fabrication diminishes construction errors, conflicts, and dimensional discrepancies, hence reducing the necessity for remedial measures and excessive material consumption. This facilitates future reutilization, recycling, and the circular use of construction materials.

As a result, the incorporation of modularity and prefabrication enhances manufacturing efficiency and configuration flexibility, while directly facilitating sustainable resource utilization and waste minimization. The advantages are particularly apparent in industrialized construction systems, where precision, repetition, and protection can be meticulously regulated.

4. Design for Disassembly (DfD)

Design for Disassembly (DfD) is an approach in sustainable architecture and engineering that focuses on making buildings and products that can be easily taken apart when they are no longer useful [

10]. This makes it possible to reuse, recycle, or repurpose parts [

10]. As more and more people around the world learn about climate change, resource depletion, and construction waste, DfD has become a more important part of the talks about the circular economy and building practices that are good for the environment.

Guy and Ciarimboli (2005) did some early work to lay the groundwork for DfD [

11]. They outlined important principles of DfD, such as modularity, easy connections, labeling materials, and layered systems [

11]. They argued that building designs with reversible connections and paths for taking things apart without damaging them could cut down on demolition waste and make it easier to retrieve materials [

11]. Crowther [

12] also talked about how important it is to break building systems (e.g., structure, services, and finishes) into separate layers that age and need maintenance at different rates. This makes the building more adaptable and easier to take apart.

Life cycle assessments (LCAs) have shown that DfD is good for the environment. According to LCA research, buildings designed to be taken apart can cut embodied energy and CO

2 emissions by up to 30–40 percent compared to regular construction [

13,

14]. This is mostly because structural elements can be reused, and less waste is sent to landfills. Also, DfD helps save resources by making building parts last longer and using fewer new materials [

15].

5. Case Study: The Grow Home

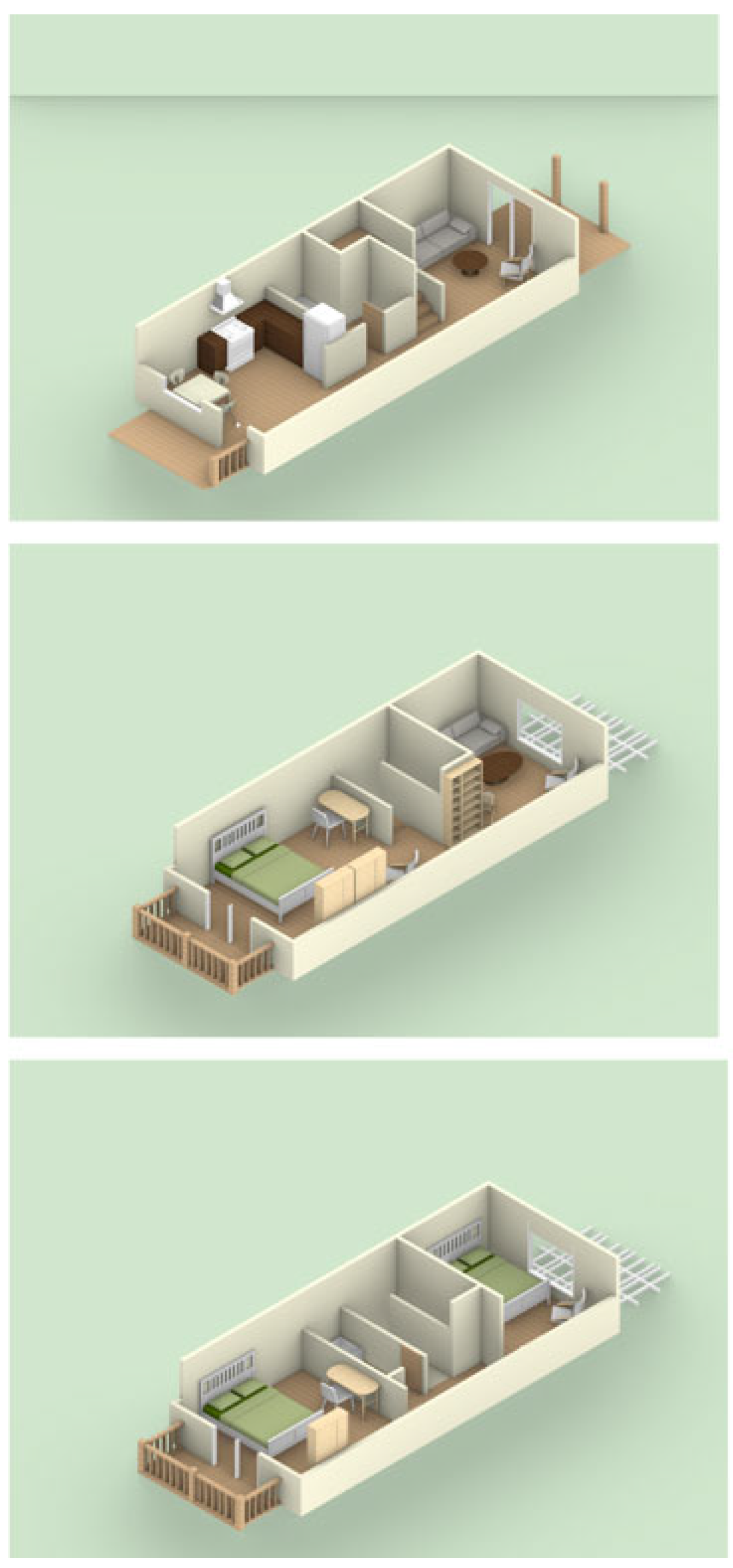

The Grow Home was constructed in Montreal, Canada, exemplified strategies that address housing affordability and sustainability [

16,

17] (

Figure 2). The unit was a two-story structure of 4.9 m (16 feet) in width, intended for first-time home buyers [

17]. The primary level of the unit comprises a back living area, a kitchen, a bathroom, and a central staircase. The upper level remained unpartitioned, creating a loft-style space, whilst the first floor was completed. The open-plan design on the upper level provided inhabitants with the flexibility to configure the space according to their preferences (

Figure 3,

Figure 4 and

Figure 5).

6. Reducing Energy Consumption Through Footprint Analysis

In addition to modularity, the Grow Home incorporates a number of design strategies that contribute to resource conservation by lowering the quantity of building materials used and increasing the building envelope’s thermal efficiency. Since the selling price and running costs will be reduced, the changes will also make the product more marketable and cheaper. There are a few fundamental tactics that were used, and none of them will disrupt a builder’s conventional work routine.

6.1. Benchmark Validation

Building size has a significant impact on energy consumption; downsizing to a smaller home will lower the carbon footprint due to the reduced energy investment during construction and operation. Also, a result of downsizing will be saving costs on equipment since the smaller volume will require fewer heating, cooling, and air conditioning (HVAC) systems. Dwelling size and type are the strongest predictors of residential energy consumption, making them focal points worth exploring to reduce their environmental impacts [

19]. Given that the initial embodied energy of one square meter of floor area lies within 10–19 gigajoules (GJ), each unit requires an additional 370–703 gigajoules (GJ) for an increase in floor area, as explained by [

20]. Furthermore, electricity use is strongly correlated with floor area and increases on average by 49 kWh (176.4 MJ) for every additional square meter of floor area. Therefore, the additional heating and cooling demands required for extra space offset a significant share of the energy and greenhouse gas emissions reductions that could have been achieved otherwise [

20].

6.2. Prefabrication and Modularity

Modular and prefabricated framing practices, including increasing spacing between components, eliminating redundant lumber for interior finishes, and aligning floor joists with wall studs to remove the need for double top plates, can reduce the amount of lumber used. In the case of a small unit, applying these three techniques can lead to measurable benefits. Our comparative studies demonstrate that modular design, where spacing wall studs at 610 mm instead of 405 mm, reduced lumber use by over 12% [

16]. Aligning floor joists with studs eliminated 61 m of additional wall framing, and using two studs at corners instead of three saved another 19.5 m. Combined, these framing optimizations resulted in 713 kg of lumber saved per unit, with associated cost reductions of CAD 539 and total embodied energy savings of approximately 5262 MJ. This means that for every four houses built using these principles, the savings would be equivalent to constructing and heating an additional home for one year.

6.3. Building Configuration/Plan Simplification

Simplifying the configuration of the unit is one of the easiest approaches to reduce waste as well as cut heat loss and material use. More corners and a larger perimeter result in a more complicated building form that calls for more envelope. Higher heat loss and, as a result, more building expenses follow from this. The floor-area-to-perimeter ratio should, generally, be increased.

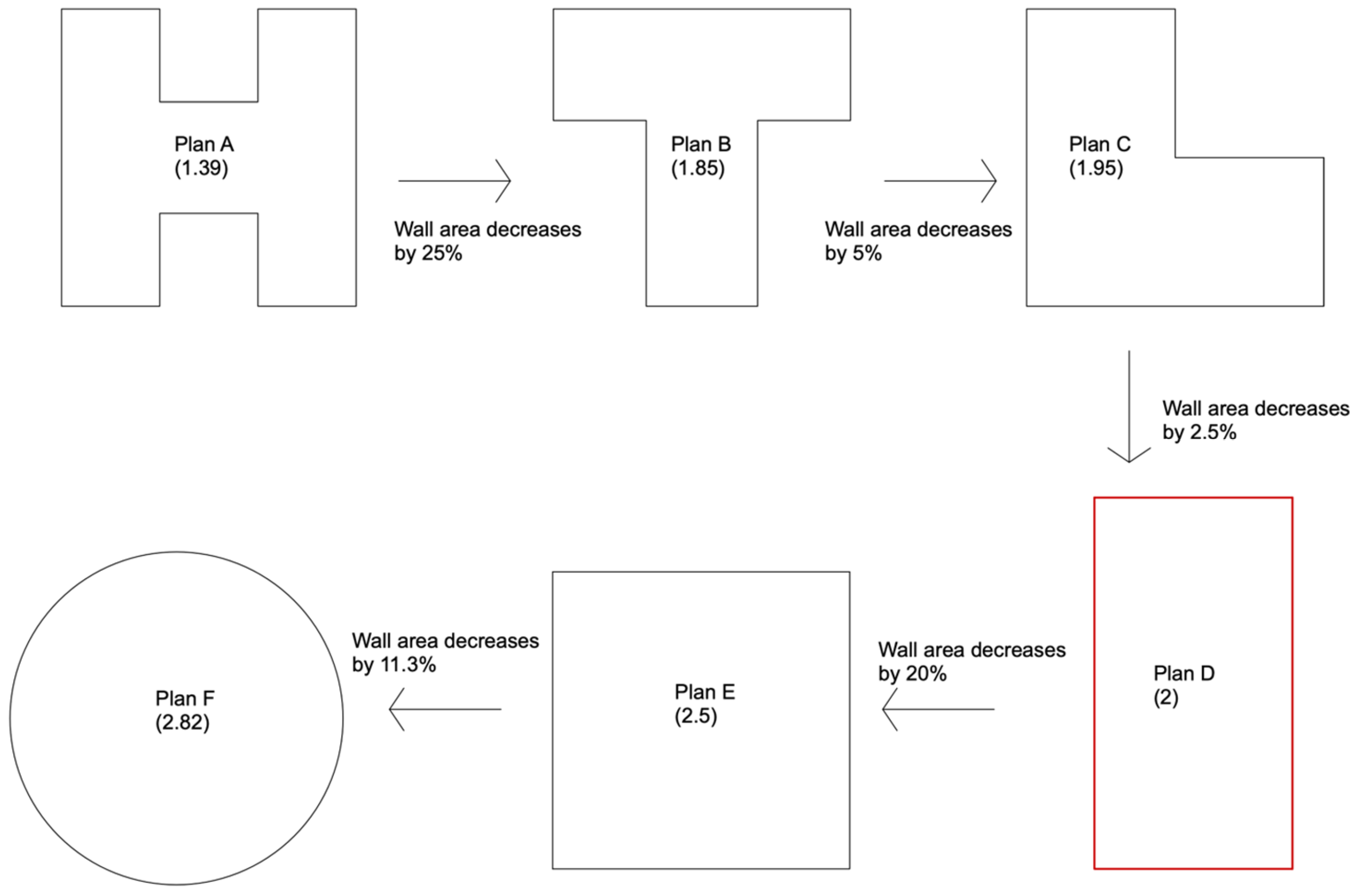

Figure 6 illustrates seven building plans with the same floor area but varying shapes, each labeled with its corresponding floor-area-to-perimeter ratio. Plan A, an H-shaped layout, has the lowest efficiency (ratio 1.39) and the highest wall area. As the shape becomes more compact, transitioning through T-shaped (Plan B, 1.85), L-shaped (Plan C, 1.95), and rectangular (Plan D, 2.0) forms, the wall area decreases incrementally. Further transitions to square (Plan E, 2.5) and finally to a circular plan (Plan F, 2.82) demonstrate the highest efficiencies, with significant reductions in wall area. For example, the shift from Plan A to Plan D results in a 40 percent reduction in wall area, while the square and circle reduce wall area even further.

Since there are most likely fewer windows and fewer corners, a basic plan is less expensive to create. From the basement to the roof, envelope costs are lowered; simple layouts usually call for less cutting and fitting of building materials. As so, the management choreography is simpler, and the amount of waste is lowered.

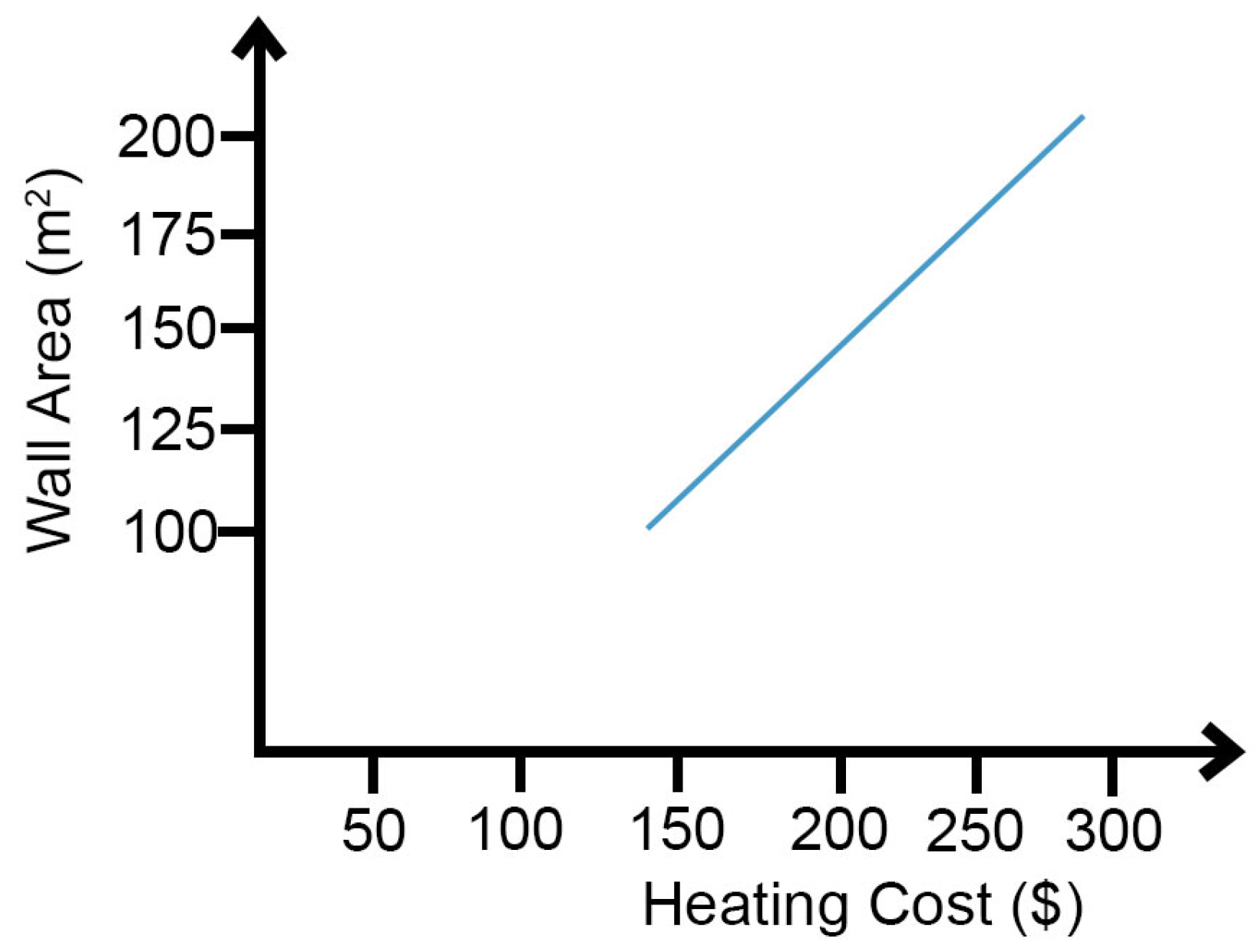

Heat loss corresponds proportionately with changes in the exposed wall area. The average the Province of Quebec, Canada (where the unit was built) power rate as of 2023 is roughly CAD 0.0759 per kwh [

21]. Conductive heat losses from the walls alone can save around CAD 90 in heating costs yearly for a small (100 m

2) house in Montreal when a plan is simplified from an “H” form to a rectangle (

Table 1). If one considers the extra heat losses from the basement and infiltration, these savings might be readily quadrupled.

Although their area-to-perimeter ratios are even higher, the square (Plan E, 2.5) and circle (Plan F, 2.82) are less useful for real-world homes because of spatial organization and furniture placement problems. Plan D finds the finest mix between functional interior design and material economy. For internal planning and spatial organization, the rectangular arrangement is sometimes more sensible. Because of this, the Grow Home was built on small lots and designed with a rectangular footprint, which suited rowhouses especially. This small, linear design has many financial and environmental benefits as well. Grow Homes greatly cut building material use and energy consumption by sharing party walls. Furthermore, reducing heat loss and gain by shared walls helps to lower heating and cooling expenditures. Higher densities also help to lower infrastructure and utility service costs. Grow Homes only have half the roof area and one-third of the external wall area compared to a traditional detached house, which helps to further material savings and energy economy (

Figure 7).

7. Reducing Material Waste Through Modular Dimensioning and Efficient Framing Practices

Efficient building dimensioning, permitting the modular arrangement of the building materials, is another basic and efficient approach to cutting material waste. Fundamentally, designing within conventional measurements for structural frame members like studs, joists, and plywood could save a lot of money. Placing and dimensioning windows appropriately and locating partitions to line up with the structural studs can completely save a ton of lumber in an average detached house by eliminating the need for an extra stud at the end of the wall. General dimensions for stud spacing, such as a 405 mm (16 inches) module, have been estimated for use in this regard.

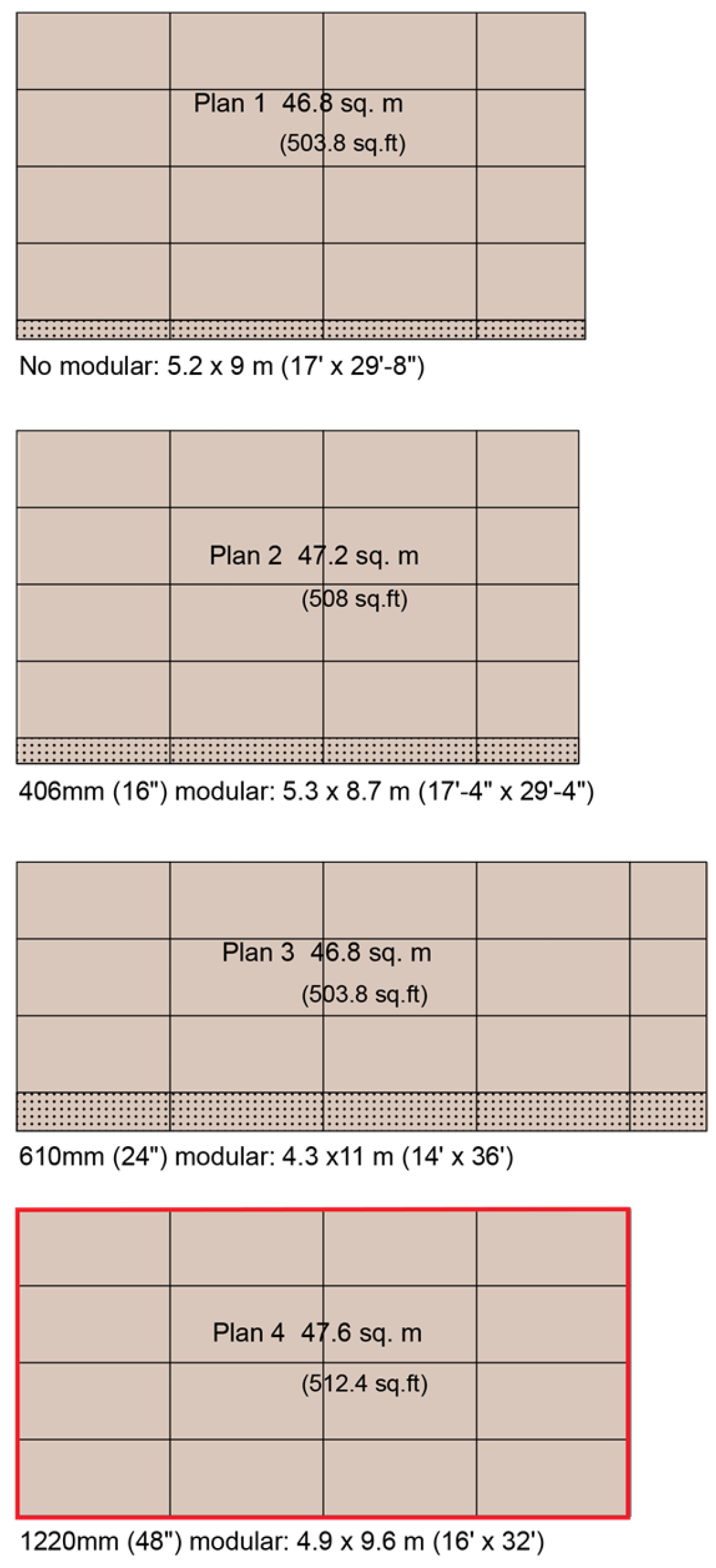

Figure 8 shows four basic designs with different module dimensions yet roughly the same floor area and layout. Given that neither floor area nor perimeter differs significantly between the alternatives, theoretically, the amount of structural wood needed to create these designs should be almost the same.

Table 2 presents the measured quantities of key structural materials, such as joists, studs, and sheathing material, needed for a two-story house with four different housing plans. With a maximum difference of just about 10 m

2, the sheathing needs across the four plans remain rather constant. Given that the floor and wall surface areas do not vary greatly, this implies module size has little effect on sheathing consumption. Plan 1 (no module) and Plan 2 (406 mm module) require 340.4 m and 346.0 m, respectively, while Plans 3 and 4 (610 mm and 1220 mm module) drop sharply to roughly 270 m. Joist use shows a clear reduction with larger modules. Larger spacing modules can thus significantly lower joist requirements, so saving both material and cost. Although the number of studs in Plans 1 and 3 is similar, Plan 4 lowers this figure to 480.6 m, which implies that larger module spacing tends to lower the total number of wall studs needed.

While the overall measured material needs are not much different for designs using different modules, the waste produced in every design can vary greatly. Those designs based on smaller modules or random dimensions often produce more waste overall. Cut-offs too small waste between 6 percent and 7 percent of the material purchased for Plan 1 (random dimensions) not being able to be used again. Since the plans call for bigger modules, this waste is lowered gradually.

Built using a 1220 mm (48 inches) module, the structural frame requires very little cutting and generates either minimal or none at all of waste. As a result, 5 percent less sheathing material has to be bought. This high efficiency is one reason why the Grow Home adopts the Plan 4 module, offering significantly better material utilization than traditional designs.

Assuming all reasonably sized material cut from a whole sheet or length of lumber is reused, the amount of wasted material for each plan in

Table 3 represents ideal conditions. In actual building, some, if not most of the “scrap”, probably would not be found or used. For example, lumber falling on wet ground is not likely to be recovered, nor is that which is cut in a place far from the area where it can be reused.

8. Reducing Material Waste and Saving Energy Through Design for Disassembly (DfD)

From the outset, the Grow Home was conceived with disassembly in mind. Every major piece can be removed, reused, or recycled with almost no damage. The first step is to keep the main frame on a strict 600 mm (two-foot) grid and use bolts, self-tapping screws, and other connectors that can be removed and replaced instead of nails or glue (

Figure 9). One can then take off the walls, joists, and sill plates one bay at a time. This is helpful for both small additions and for salvaging at the end of life (

Table 4).

The second layer of intervention relates to the envelope. The façades are finished with clip-on metal or wood cassettes that are hung on dry rails instead of vinyl or glued sheathing. The same goes for standing seam metal roofing, which is also fastened mechanically. More than 90 percent of the skin can be reused or sold again after decades of use because cladding and roof panels are made of one material and cannot be damaged by prying tools. The same logic applies to floor and roof assemblies: factory-made cassettes in cross-laminated timber or open-web joists are screwed into place so that whole panels can be craned out for structural upgrades or to get to hidden services safely.

This means that a living room wall can be taken down and put back up in one day without drywall waste. In that area, there are manifold plumbing, flex-ducts, and plug-in cable harnesses. This means that a future owner can easily change the kitchen pod or upgrade the pipes by simply removing quick-release fittings instead of opening up structural cavities.

All these upgrades add only a small amount to the upfront budget, mostly for stronger connectors and extra paperwork, yet they slash renovation and demolition waste by over two-thirds. Also, it would speed up future remodels and create extra value from reclaimed CLT panels, aluminum studs, and façades. The Grow Home’s low-cost, do-it-yourself philosophy is still the same. However, the house can now be modified or taken apart with the same set of tools.

The DfD-enabled Grow Home is much better for the environment and the economy in the long term than traditional mechanical demolition. Traditional building methods only reuse or recycle about 30 percent of the materials used to build a structure, sending the rest to a landfill. With DfD strategies, 70–90 percent of the materials can be taken apart and used again [

24]. A normal 185.8-square-meter (2000-square-foot) wood-frame house produces about 115 pounds of debris per square foot when it is torn down, and 80 pounds of that is still sent to a landfill [

23]. However, DfD cuts that number to less than 30 pounds per square foot with a 75 percent diversion rate. Also, when buildings are carefully taken apart instead of crushed, comparative studies demonstrate that their CO

2 emissions at the end of their lives can be cut by up to 40 percent. Material reuse is a great way to save energy. Traditional methods need 100 percent of the energy to remelt aluminum because almost nothing is saved, but DfD only needs 5 percent of the energy to remelt aluminum, which keeps 95 percent of the energy that was already in it [

22]. DfD may raise upfront costs by 10–12 percent because of reversible connectors and material documentation. However, these costs are balanced out by lower deconstruction costs and material recovery at the end of the product’s life.

9. Discussion

Although modular homes have many benefits, they also present a few significant barriers that limit their widespread adoption. During the design and early planning phases, manufacturing modular homes places great weight on accuracy, which can lead to several problems [

25]. A mistake can arise during the design or manufacturing process; it can have expensive repercussions since mistakes are often repeated across several units before they are found [

25]. This risk emphasizes the need for quality control, especially. Furthermore, the necessity of thorough planning and coordination at the beginning can cause the design process to last longer [

25]. Unlike conventional builds, where some decisions can be made gradually on-site, projects may take more time to be finalized and approved before manufacturing starts, possibly postponing the whole building schedule.

Transportation is a major prefabricated construction issue. Since home components or panels are shipped to the site, it costs more money, time, and requires more planning. Different prefabricated homes have varied shipping distances and difficulties. Modular homes arrive with drywall, electrical fixtures, plumbing, flooring, and cabinetry. This makes exporting the home more difficult and requires all pieces to be intact. Shipping distance limits are also many. Prefabricated homes often ship 400–645 km (250–400 miles) [

26,

27]. Road quality and width in different countries limit dimensions, weight, and border crossing delays, making anything above this distance impractical. Shipping between states and provinces can be complicated by these regulations. Shipping dimensions are usually 4–4.2 m (13–14 feet) tall, 4.5–4.8 m (15–16 feet) broad, and 15.2–21.3 m (50–70 feet) long [

26,

27]. These constraints suit other consumer products, but homes are huge and have parts outside these numbers. Thus, modular home producers usually build standardized dwellings within the limits. These limits affect panelized dwellings less because sections can be stacked or supplied individually if they exceed them. Traditional on-site building materials must still be delivered. Due to shipping limits, typically constructed home parts are smaller and standardized [

26,

27]. Shipping is more complicated than on-site construction; hence, transportation costs more. Large shipments may need police escorts for road safety. In general, distance permits and vehicle count drive transportation expenses, so shipping and transportation issues prevent prefabricated homes from being widely built, despite their many benefits.

Despite its benefits, several challenges hinder the widespread adoption of DfD. Cost remains a key barrier; while DfD can lower end-of-life costs, initial design and construction expenses are often higher due to the need for specialized connectors and detailed documentation [

28]. Unlike conventional construction, DfD requires the use of specialized, often more expensive, reversible connectors, which allow components to be easily dismantled without damage. Additionally, it demands comprehensive planning and meticulous documentation, such as materials passports and disassembly guides, to ensure future recovery and reuse.

Although certain materials may be suitable for new construction, numerous panels may not meet structural standards for reuse, raising inquiries regarding optimal recycling or reinterpretation methods. The requirement for ample space and organization, which are occasionally deficient in towns with constrained industrial capacity [

29]. These materials may ultimately end up in landfills in the absence of effective solutions, contradicting the principles of sustainable deconstruction.

An essential yet often overlooked aspect of resource recovery is the segregation of construction and demolition waste. According to Bressanelli et al. [

28] this lack of short-term economic incentives, combined with fragmented supply chains and limited contractor experience with DfD practices, continues to slow its integration into mainstream construction [

28]. In the absence of designated facilities, reusable things are ultimately disposed of in landfills. Consequently, establishing an operational supply chain for salvaged materials is imperative. Governments and corporations must collaborate on programs to connect suppliers with consumers, ensuring that recovered materials are reintegrated into new construction projects rather than discarded.

Manufacturing modular homes in a controlled environment, which is characteristic of prefabricated homes, has many benefits. This method is a more efficient process for creating homes for various reasons. First, many unforeseen interruptions are avoided during prefabricated homes’ construction due to the indoor and controlled environment where construction takes place. In traditional home construction, poor weather in the form of rain, intense heat, intense cold, and snow can interfere with construction since a lot of the work is performed outdoors [

30]. Furthermore, in traditional construction, internal components of the home can be subject to intense weather during the construction process, which can degrade the materials. The Forintek Institute estimated that the average triplex takes 11 to 13 weeks to complete with on-site construction [

30]. This means that the internal components of this unit will be subject to 11 to 13 weeks of weather, which it is not designed to withstand [

30]. While this decay is not obvious initially, it can manifest in the form of decay or mold later. Meanwhile, elements of prefabricated homes remain in controlled, indoor spaces until they are needed. This means that there is less contact with the weather and less risk of decay. In fact, elements of prefabricated homes are generally of better quality than on-site construction, partially for the decreased exposure to weather, but also for the increased quality control within the factories.

A method to control the use of material in the housing sector is by creating a material passport (MP): a standardized digital description of material flows, building compositions, and general building characteristics. The material passport aggregates material and building data to create a standardized resource. The objective is to bridge the gap between the building sector and its many relevant stakeholders, presenting housing data in an easily digestible format, guiding occupants in all phases of a building’s life cycle. This form of documentation promotes circularity, as extensive knowledge on how a building is constructed can help actors properly deconstruct or disassemble a building, facilitating recovery and recycling [

17].

10. Conclusions

The study demonstrated that modular construction offers clear benefits in terms of cost efficiency, reduced construction time, and material savings, effectively leading to sustainability. Its ability to support flexible, future-proof design and solve housing shortages is well documented. However, despite these benefits, modular building still has many obstacles that prevent its more general acceptance. Among these are ongoing social stigma, little design freedom, logistical restrictions, and legal obstacles. Overcoming these challenges will call for changes in public opinion, policy support, industry practices, and technological innovation, as well as technical mastery. The full potential of modular building can only be fulfilled in determining the direction of housing by means of such coordinated initiatives.

The linear economic model commonly used today is unsustainable. The extraction of new raw materials and the disposal of used materials emit large amounts of fossil fuels and create excessive waste. The circular economy model is an alternative that promotes long product life spans and therefore minimizes waste and demand for raw materials. Circularity is based on six key principles: reduce, reuse, recycle, redesign, remanufacture, and recovery.

Several aspects of circularity were explored throughout this paper. Homes must keep up to date with new technologies and information. By studying the home in layers, updates can be made with minimal disruption to other parts of the home. Utilizing circularity minimizes the waste created by these updates. Further, this improves adaptability since the home will be adaptable across time and technologies.

The main pillars of sustainability are environmental, economic, and social aspects. The depletion of non-renewable natural resources, elevated levels of greenhouse gas emissions, and climate change are a few of the environmental challenges that this paper addresses. The paper demonstrated that DfD cuts that number to less than 30 pounds per square foot with a 75 percent diversion rate. Also, when buildings are carefully taken apart instead of crushed, comparative studies demonstrate that their CO2 emissions at the end of their lives can be cut by up to 40 percent.

Most low-density, low-rise homes are constructed of solid sawn lumber. Considered to be an inexpensive renewable resource and due to its low embodied energy, wood has become the material of choice over light gauge steel, for example, in house building. According to the Nebraska Energy Office, the amount of lumber necessary to build a 1700-square-foot (160-square-meter) wood-frame home, including its structure and finishes, consumes one acre (0.4 hectares) of forest [

31]. The figure becomes even more staggering when one considers that some two million dwelling units are constructed each year in the U.S. alone. The building process is also responsible for a large amount of waste generated. Some 8000 pounds (3.6 tonnes) are produced when a 2000-square-foot (190-square-meter) home is constructed, all of which is shipped to landfills [

31].

Along with expansion in house size, the energy consumed grew. According to the U.S. Energy Information Administration [

32] energy consumption in the residential sector rose from 14,930 trillion BTU to 21,879 trillion. Since some 60 percent of the total energy used in the residential sector is for space heating, the increase can be attributed to a rise in the home’s area, number of windows installed, and poor construction practices. The increase can also be due to a number of features that have become standard items of a modern home.

Air conditioners, large energy consumers and emitters of CFC refrigerants, are quickly becoming the norm in North American households. According to a report on household energy use by Natural Resources Canada in 2003, 45 percent of Canadian households made use of some sort of air conditioning unit compared with 25 percent in 1993 [

33]. Some attribute the increase to the recent rise in hotter-than-average summers, while others argue that this is just another manifestation of North American household consumption. According to Natural Resources Canada [

33], an average room air conditioner uses roughly the same amount of energy in one cooling season that a refrigerator uses in a year.

On the economic front, increasing costs of material, labor, land, and infrastructure have posed economic challenges, with affordability being paramount among them. Social challenges are also drawing the attention of designers, builders, and homeowners. As the “baby-boom” generation is retiring, housing an elderly population will take priority in many nations. Designing smaller units that respond to the needs of seniors will be a priority.

The paper addresses these three pillars by providing quantitative evidence that designing modular, small, and energy-efficient units would reduce construction and upkeep costs, making them affordable and, as a result, sustainable.

The case study prototype (Plan D, 2.0) resulted in material savings and demonstrated that further transitions to square (Plan E, 2.5) and finally to circular plan (Plan F, 2.82) had the highest efficiencies, with significant reductions in wall area. The author, however, argues that circular types of living will not be accepted in the marketplace. The research also demonstrated that by using modular building practice of a 1220 mm (48 inches) module, the structural frame requires very little cutting and generates either minimal waste or none at all. In addition, it was demonstrated that DfD cuts account for less than 30 pounds per square foot with a 75 percent diversion rate. Also, when buildings are carefully taken apart instead of crushed, comparative studies demonstrate that their CO2 emissions at the end of their lives can be cut by up to 40 percent.