Thin-Film Solar Cells for Building-Integrated Photovoltaic (BIPV) Systems

Abstract

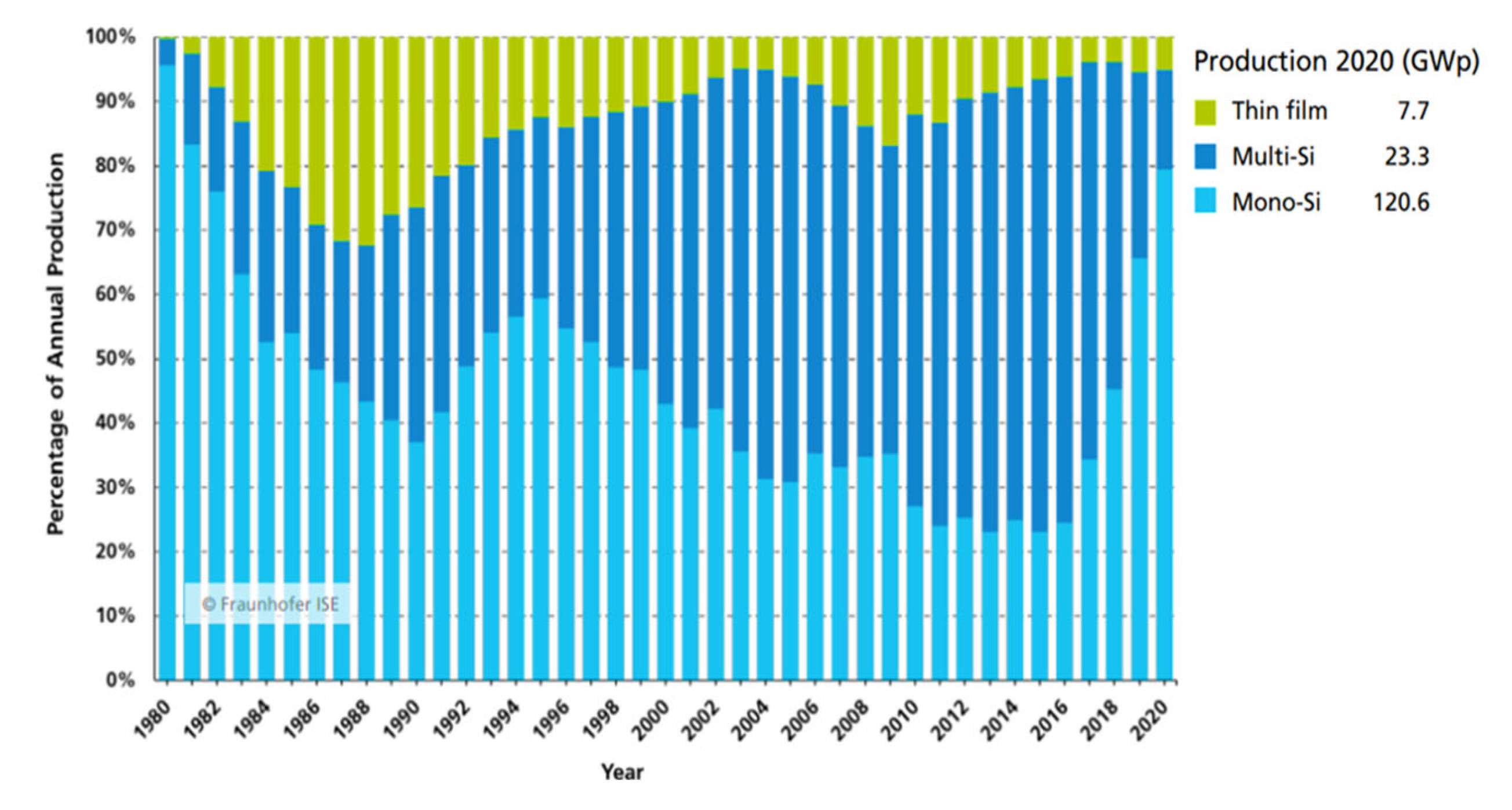

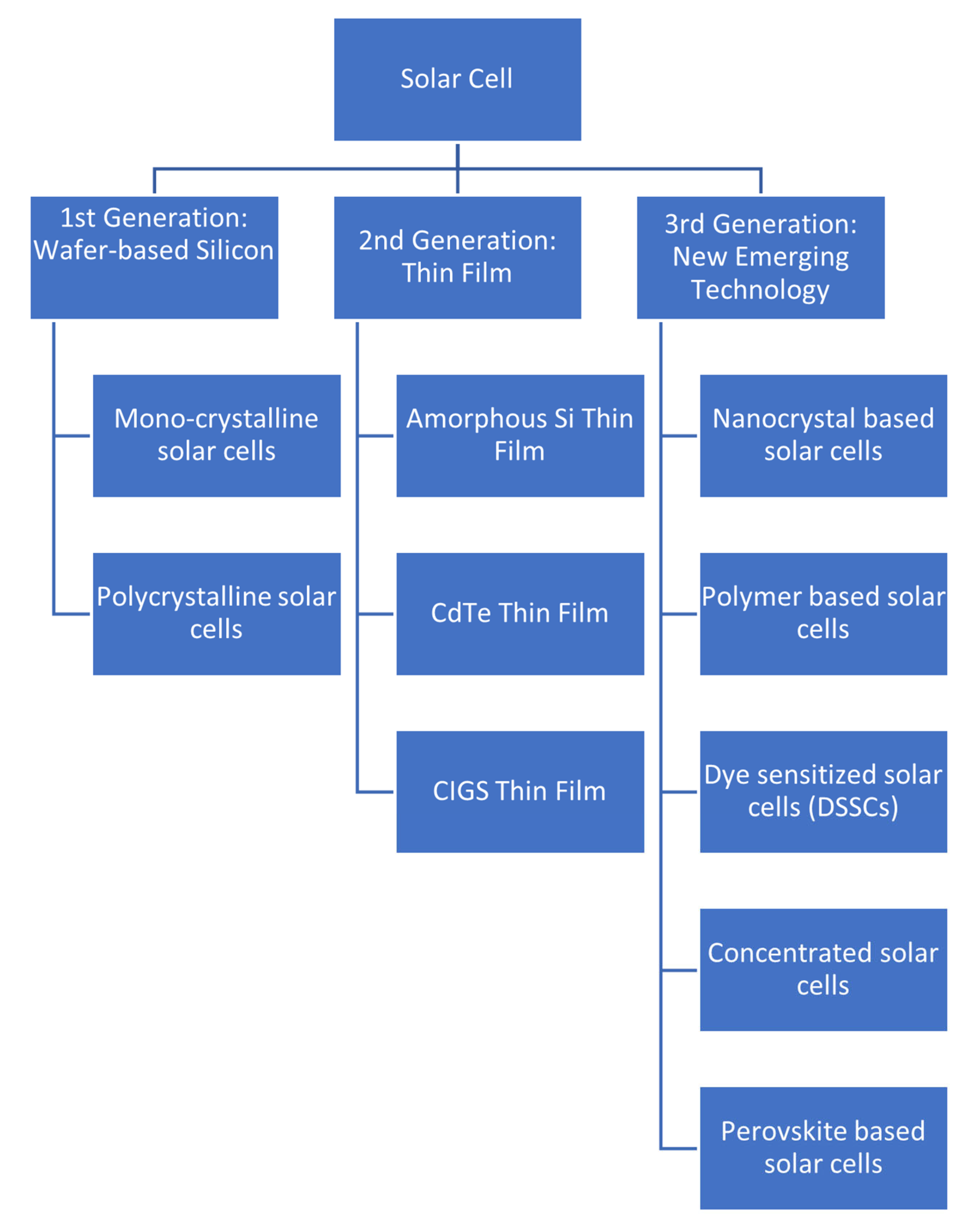

1. Introduction

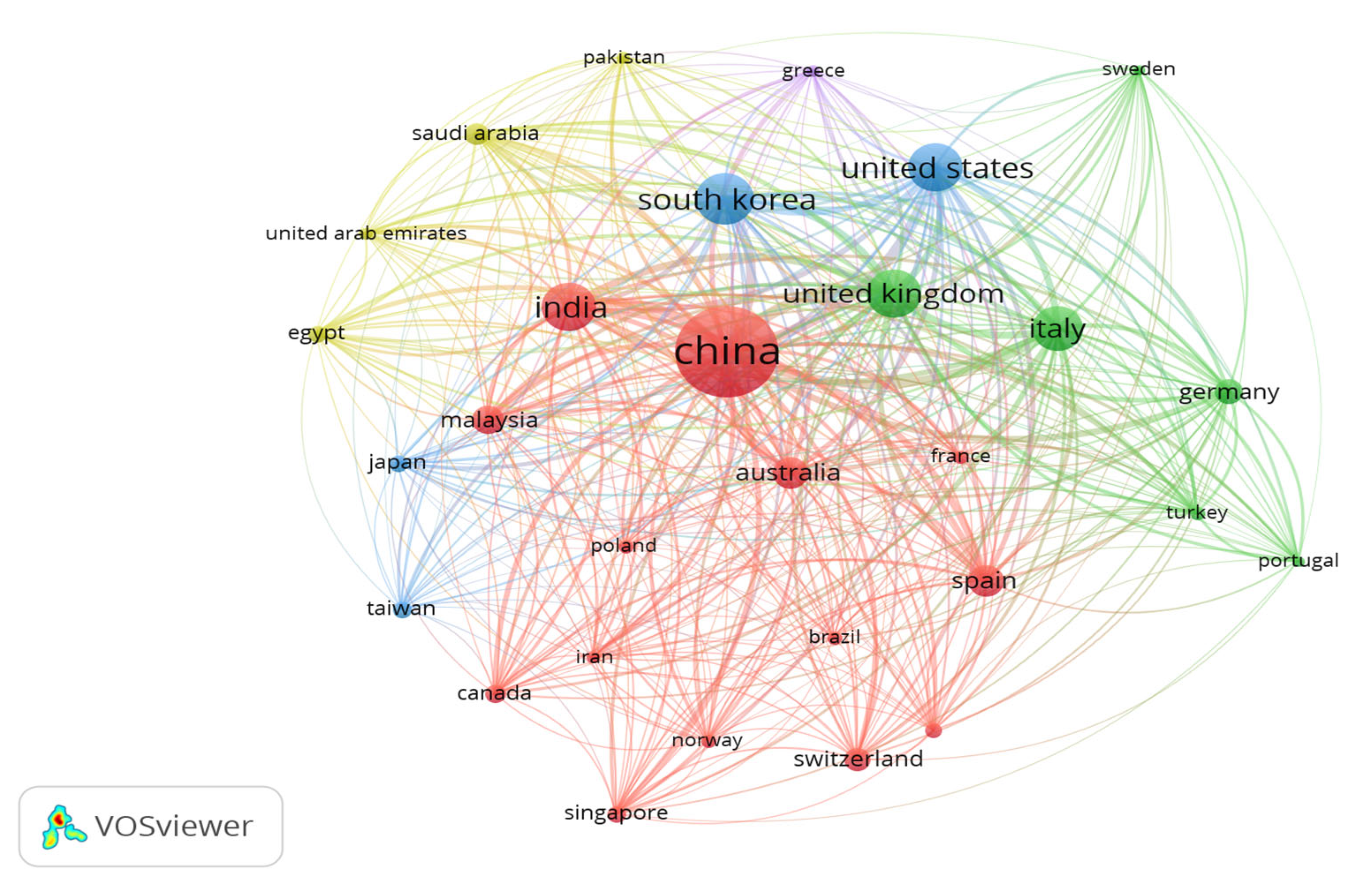

2. Methodology

3. Results

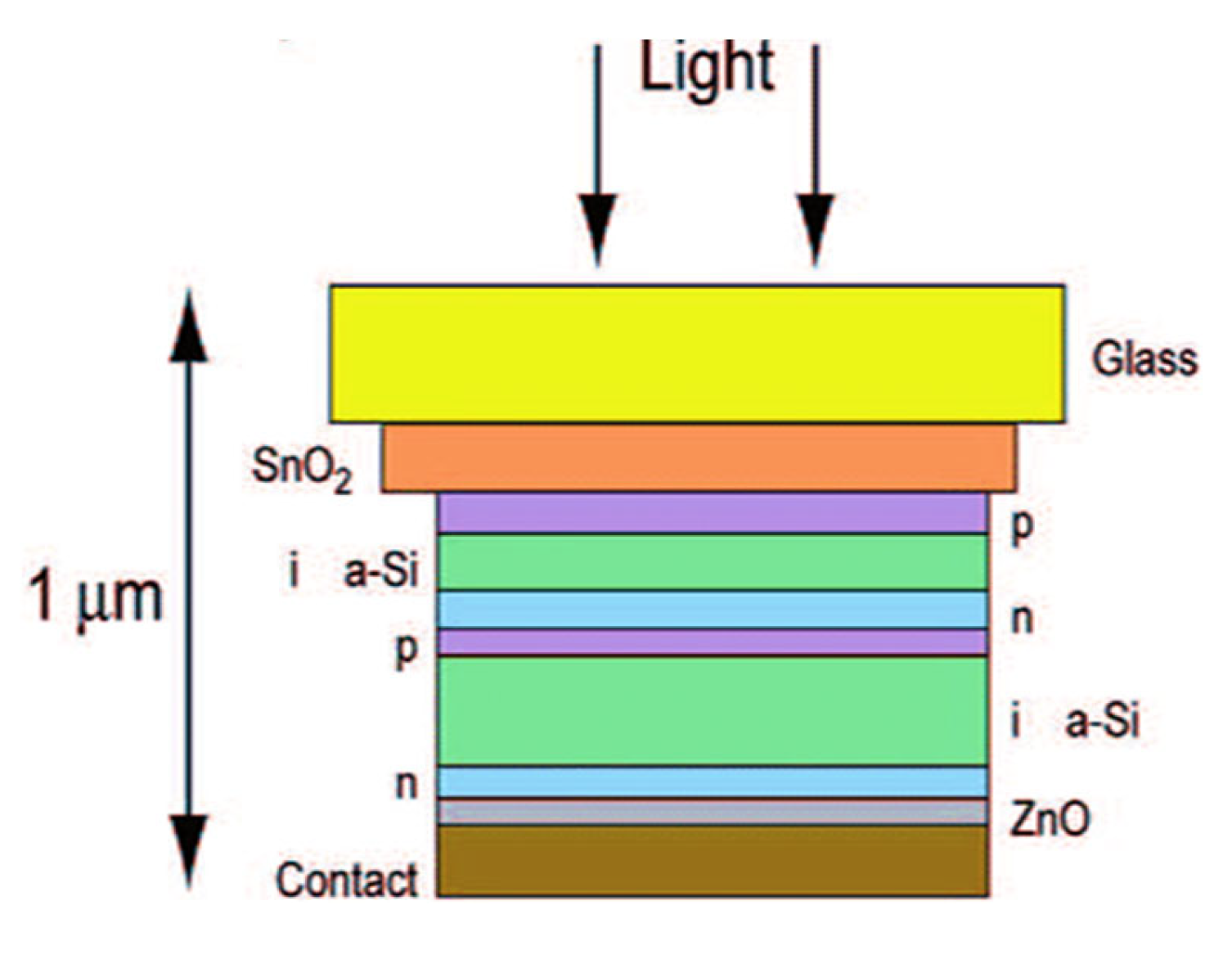

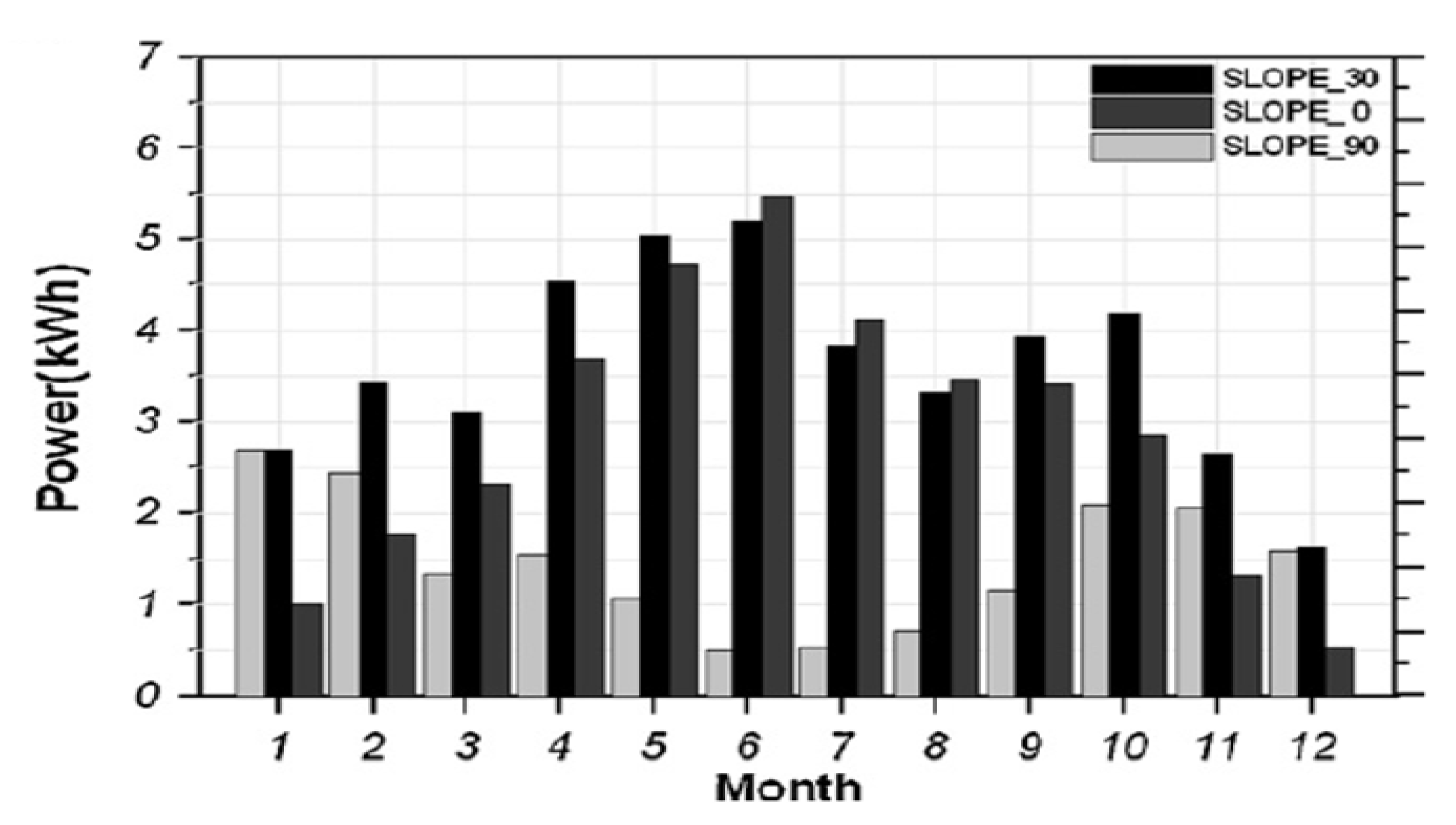

3.1. Amorphous Silicon (a-Si) Thin-Film Solar Cells in BIPV

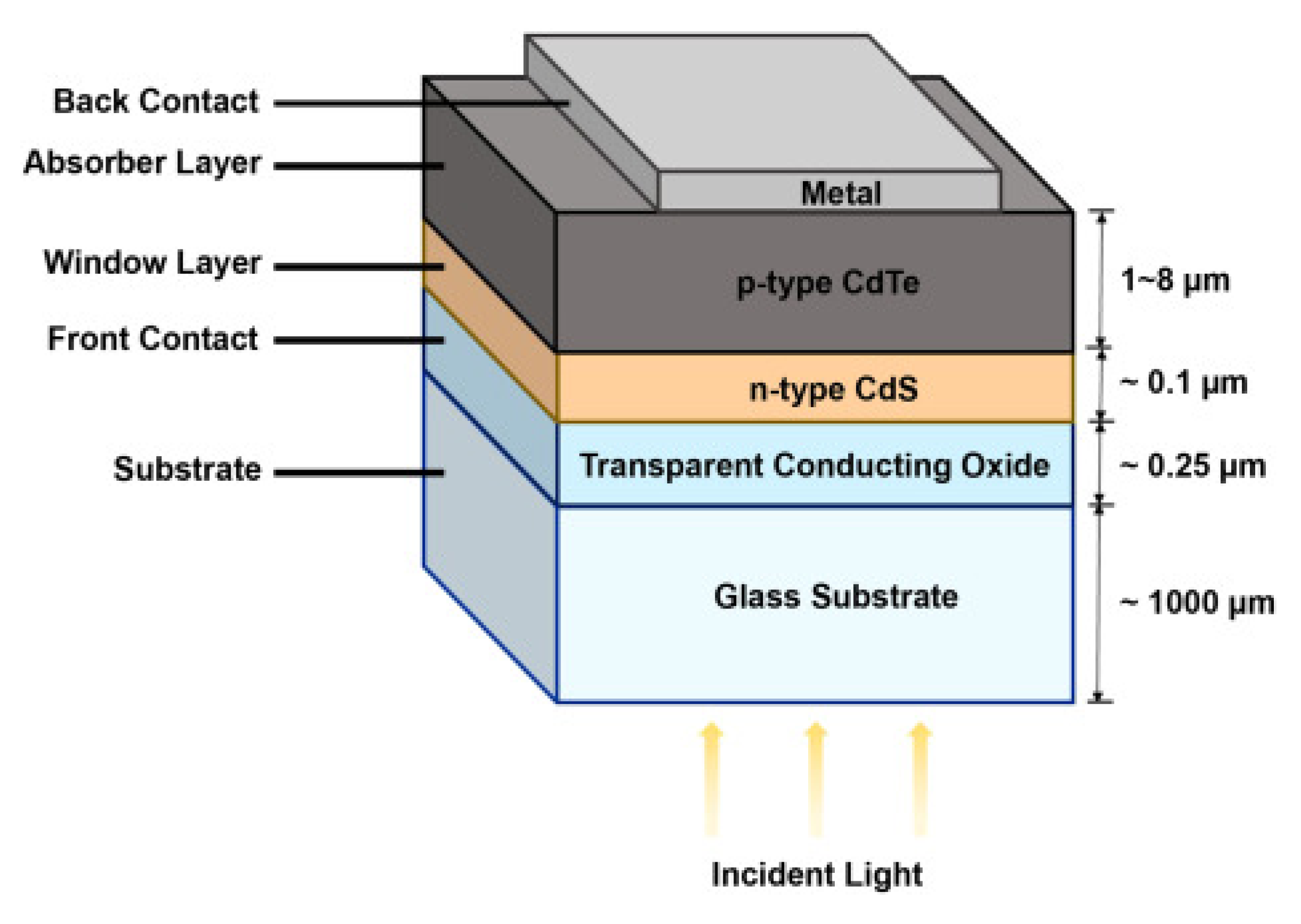

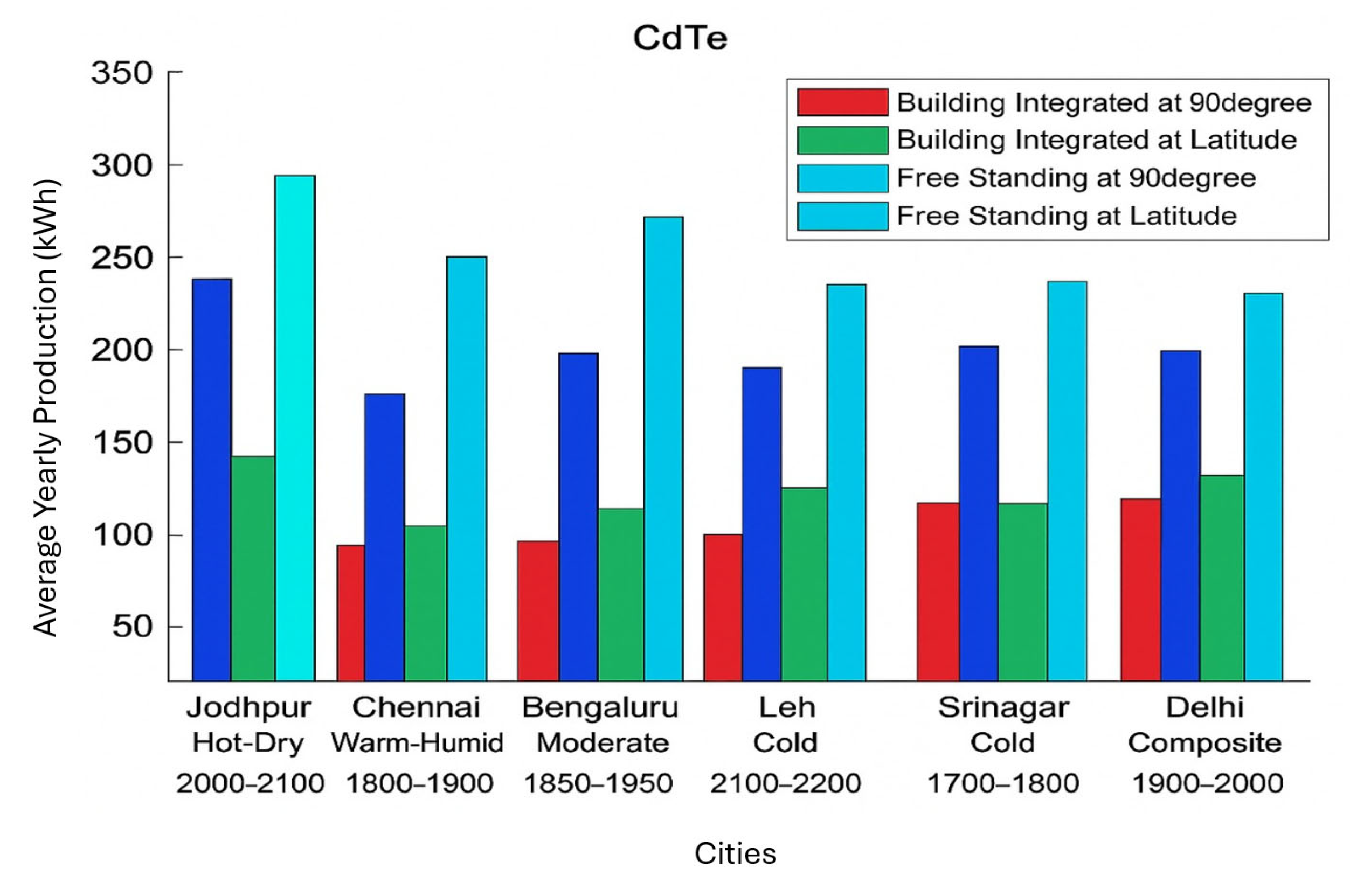

3.2. Cadmium Telluride (CdTe) Thin-Film Solar Cells in BIPV

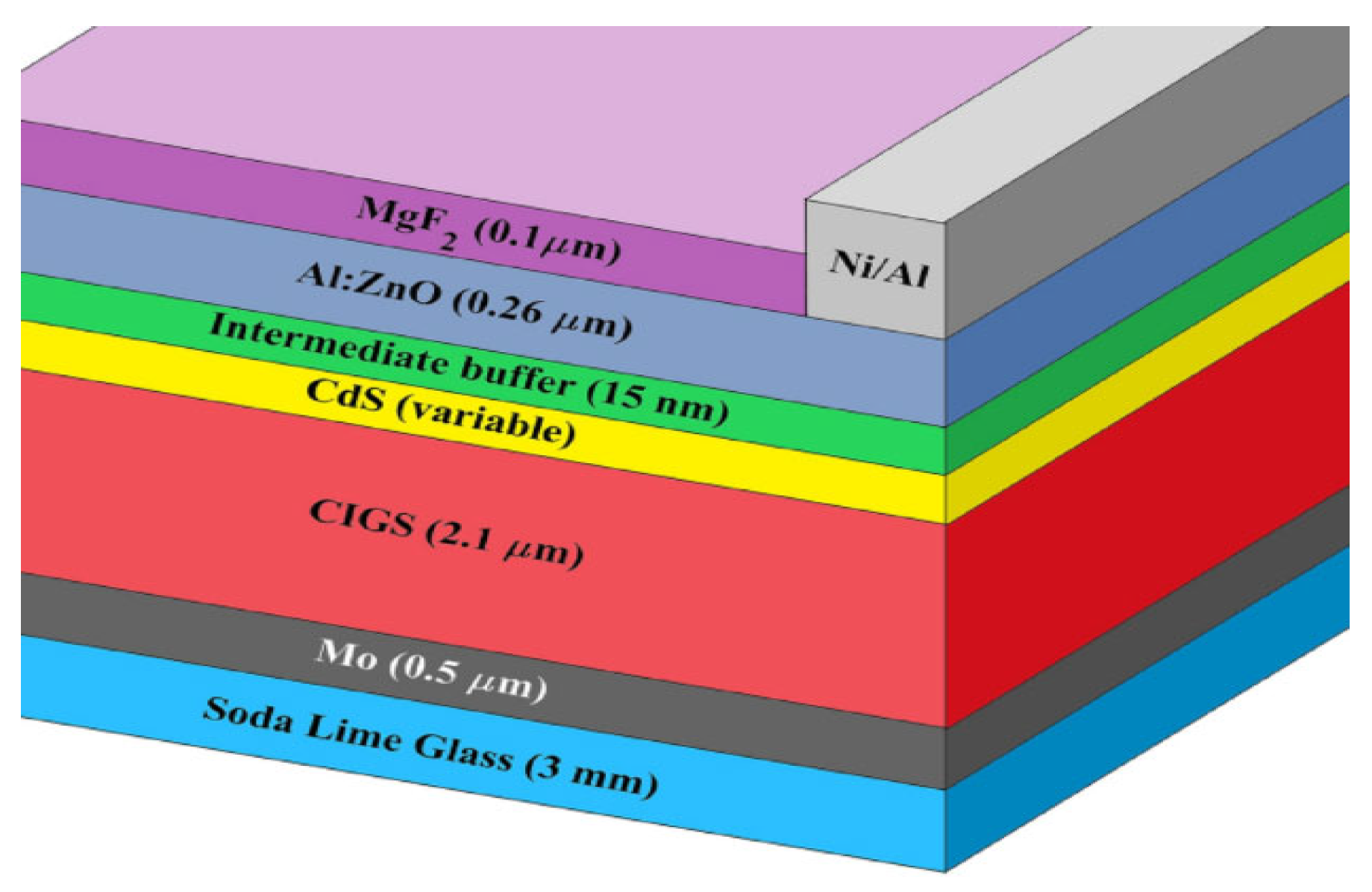

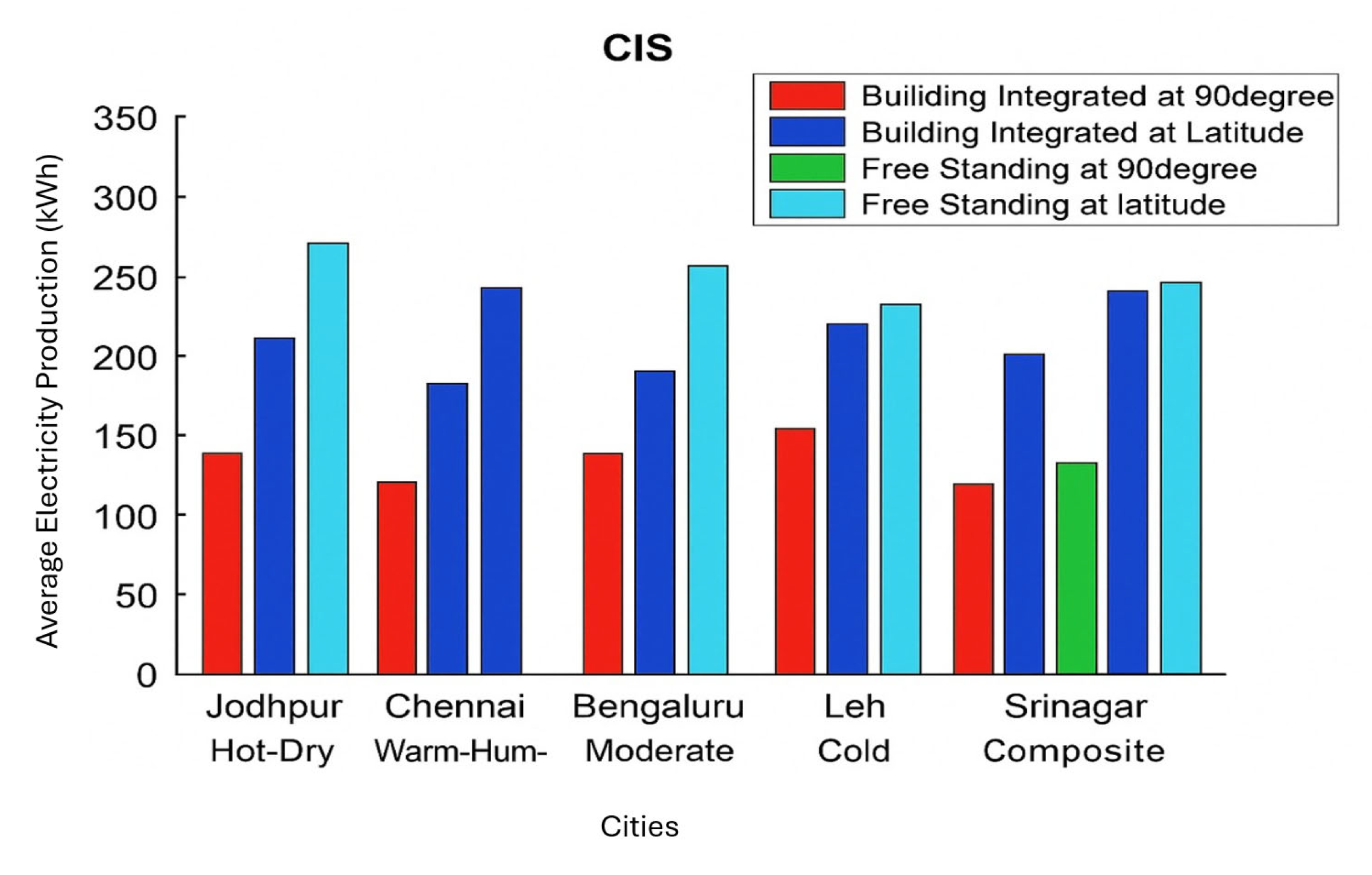

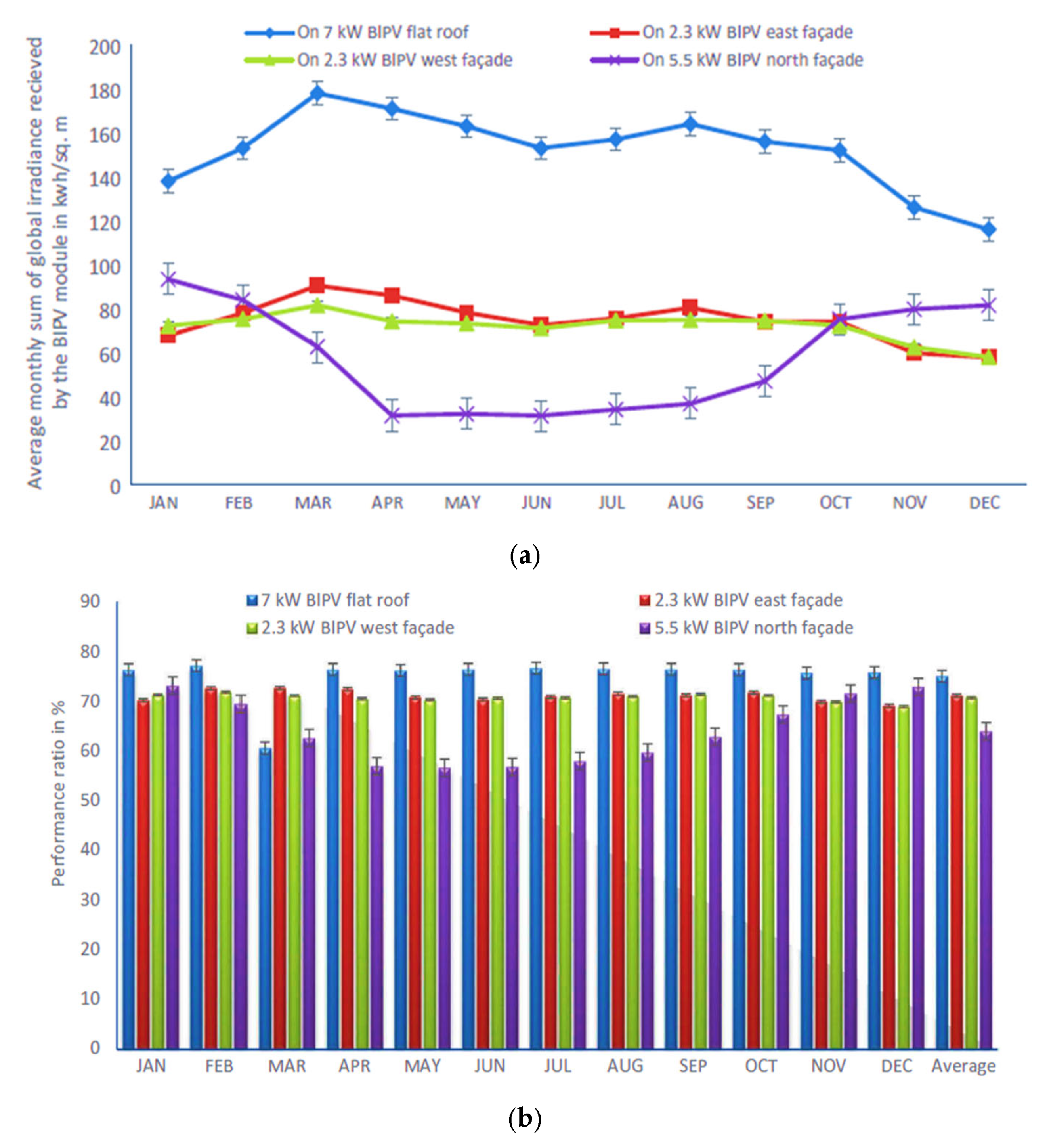

3.3. Copper Indium (Gallium) Diselenide (CI(G)S) Thin-Film Solar Cells in BIPV

3.4. Gallium Arsenide (GaAs) Thin Film Solar Cells in BIPV

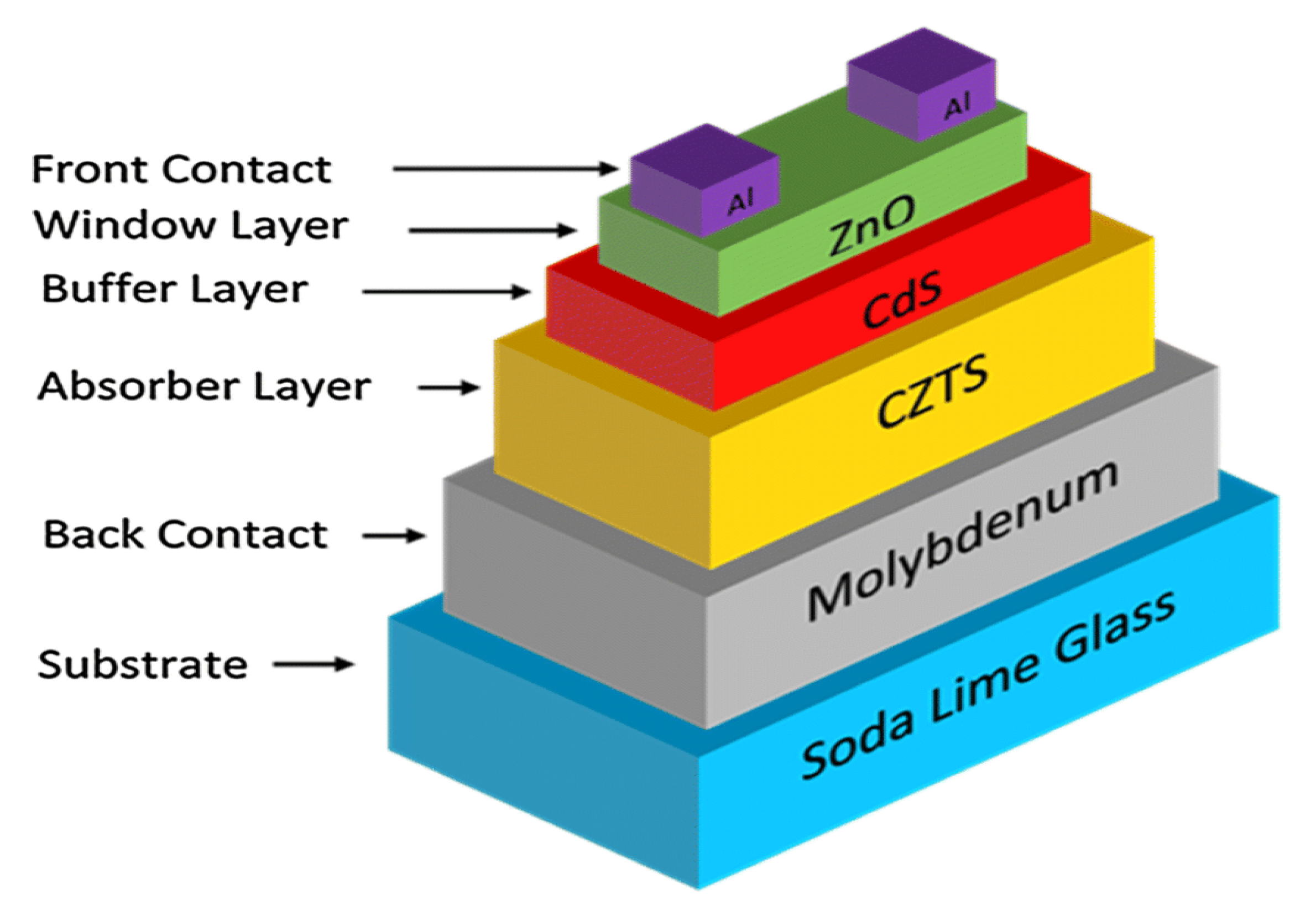

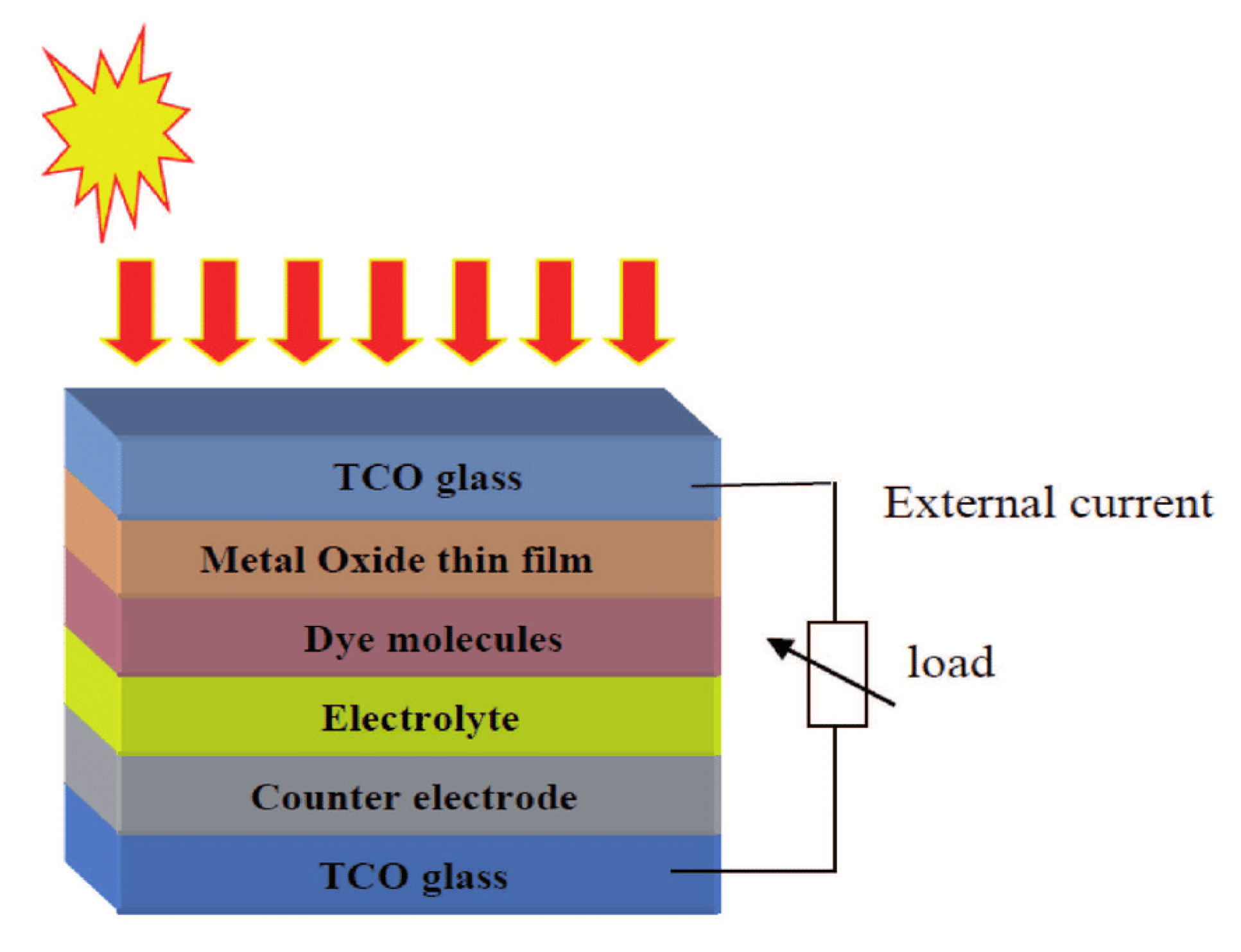

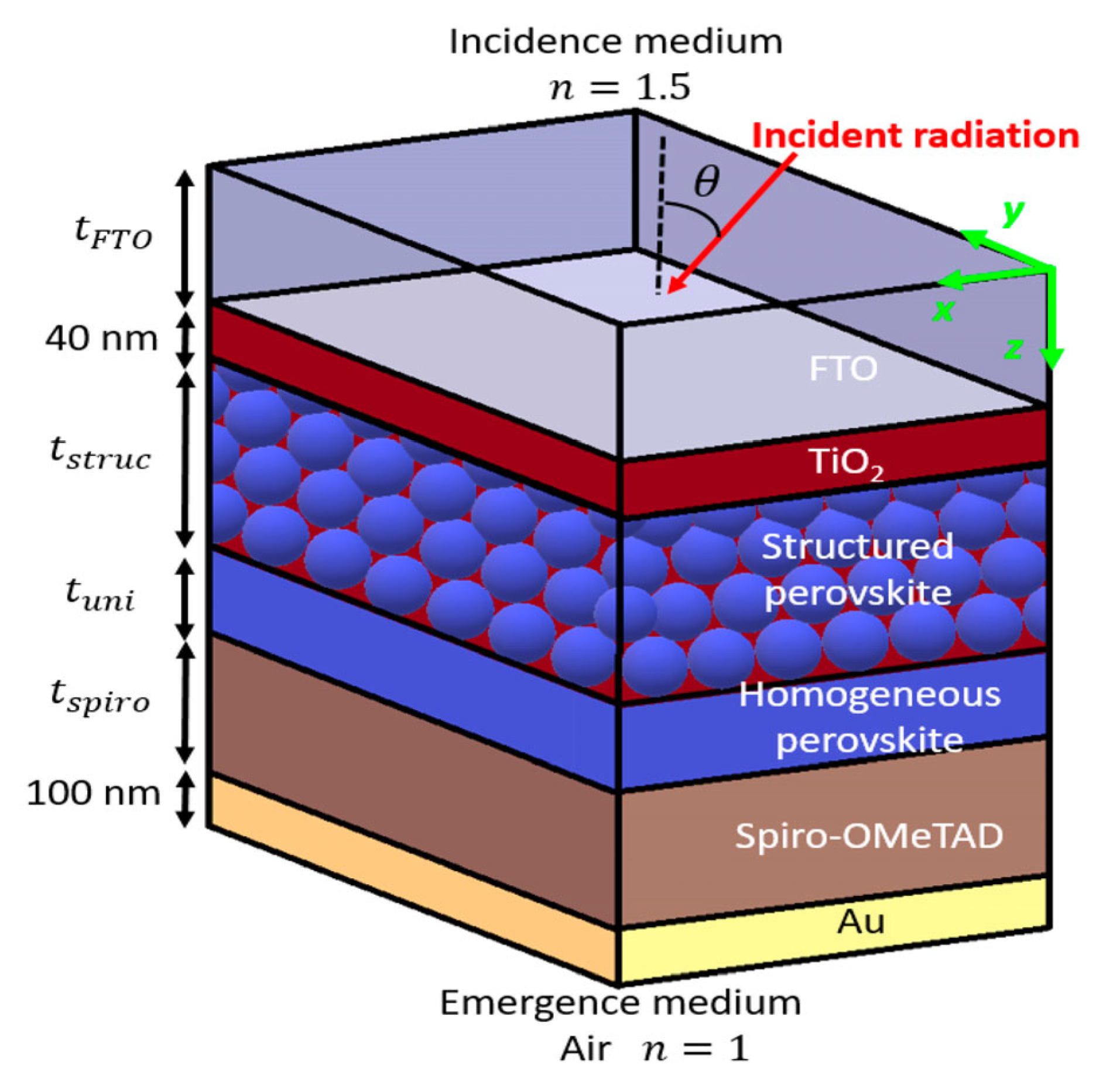

3.5. Third-Generation Thin-Film Solar Cells in BIPV

4. Results and Perspective

4.1. Health and Environmental Hazards of Thin-Film BIPV Systems

4.2. Future Directions and Opportunities

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fam, A.; Fam, S. Review of the US 2050 long term strategy to reach net zero carbon emissions. Energy Rep. 2024, 12, 845–860. [Google Scholar] [CrossRef]

- Paone, A.; Bacher, J.-P. The impact of building occupant behavior on energy efficiency and methods to influence it: A review of the state of the art. Energies 2018, 11, 953. [Google Scholar] [CrossRef]

- Mirasgedis, S.; Cabeza, L.F.; Vérez, D. Contribution of buildings climate change mitigation options to sustainable development. Sustain. Cities Soc. 2024, 106, 105355. [Google Scholar] [CrossRef]

- Lu, M.; Lai, J. Review on carbon emissions of commercial buildings. Renew. Sustain. Energy Rev. 2020, 119, 109545. [Google Scholar] [CrossRef]

- Mohammad, A.K.; Garrod, A.; Ghosh, A. Do Building Integrated Photovoltaic (BIPV) windows propose a promising solution for the transition toward zero energy buildings? A review. J. Build. Eng. 2023, 79, 107950. [Google Scholar] [CrossRef]

- Ghosh, A. Fenestration integrated BIPV (FIPV): A review. Solar Energy 2022, 237, 213–230. [Google Scholar] [CrossRef]

- Block, A.B.; Palou, J.E.; Courtant, M.; Virtuani, A.; Cattaneo, G.; Roten, M.; Li, H.-Y.; Despeisse, M.; Hessler-Wyser, A.; Desai, U.; et al. Colouring solutions for building integrated photovoltaic modules: A review. Energy Build. 2024, 314, 114253. [Google Scholar] [CrossRef]

- Hegedus, S. Thin film solar modules: The low cost, high throughput and versatile alternative to Si wafers. Prog. Photovolt. Res. Appl. 2006, 14, 393–411. [Google Scholar] [CrossRef]

- Phocas, M.C.; Christoforou, E.G.; Matheou, M.; Dimitriou, P. Concept analysis of an adaptive building envelope with thin-film photovoltaic modules. Energy Build. 2024, 311, 114150. [Google Scholar] [CrossRef]

- Reddy, P.; Gupta, M.V.N.S.; Nundy, S.; Karthick, A.; Ghosh, A. Status of BIPV and BAPV system for less energy-hungry building in India—A review. Appl. Sci. 2020, 10, 2337. [Google Scholar] [CrossRef]

- Batista, F.; Guimarães, A.S.; Palmero-Marrero, A.I. Building Integrated Photovoltaics: A multi-level design review for optimized implementation. Renew. Sustain. Energy Rev. 2025, 220, 115837. [Google Scholar] [CrossRef]

- Costa, S.C.S.; Kazmerski, L.L.; Diniz, A.S.A. Impact of soiling on Si and CdTe PV modules: Case study in different Brazil climate zones. Energy Convers. Manag. X 2021, 10, 100084. [Google Scholar] [CrossRef]

- Smith, A.R.; Ghamari, M.; Velusamy, S.; Sundaram, S. Thin-Film Technologies for Sustainable Building-Integrated Photovoltaics. Energies 2024, 17, 6363. [Google Scholar] [CrossRef]

- Wijewardane, S.; Kazmerski, L.L. Inventions, innovations, and new technologies: Flexible and lightweight thin-film solar PV based on CIGS, CdTe, and a-Si:H. Sol. Compass 2023, 7, 100053. [Google Scholar] [CrossRef]

- Chen, L.; Baghoolizadeh, M.; Basem, A.; Ali, S.H.; Ruhani, B.; Sultan, A.J.; Salahshour, S.; Alizadeh, A. A comprehensive review of a building-integrated photovoltaic system (BIPV). Int. Commun. Heat Mass Transf. 2024, 159, 108056. [Google Scholar] [CrossRef]

- Rossi, F.; Kipyator, M.J.; Aernouts, T.; Pettersson, H.; Basosi, R.; Parisi, M.L.; Sinicropi, A. Unveiling the potential of perovskite solar systems in building integrated installations: A consequential and prospective life cycle assessment and economic analysis. Energy Build. 2024, 312, 114214. [Google Scholar] [CrossRef]

- Eder, G.; Peharz, G.; Bonomo, P.; Saretta, E.; Frontini, F.; López, C.S.P.; Wilson, H.R.; Eisenlohr, J.; Chivelet, N.M.; Karlsson, S.; et al. Coloured BIPV; IEA: Paris, France, 2019. [Google Scholar]

- Farrell, C.; Osman, A.; Doherty, R.; Saad, M.; Zhang, X.; Murphy, A.; Harrison, J.; Vennard, A.; Kumaravel, V.; Al-Muhtaseb, A.; et al. Technical challenges and opportunities in realising a circular economy for waste photovoltaic modules. Renew. Sustain. Energy Rev. 2020, 128, 109911. [Google Scholar] [CrossRef]

- Muteri, V.; Cellura, M.; Curto, D.; Franzitta, V.; Longo, S.; Mistretta, M.; Parisi, M.L. Review on life cycle assessment of solar photovoltaic panels. Energies 2020, 13, 252. [Google Scholar] [CrossRef]

- Roy, A.; Ghosh, A.; Bhandari, S.; Sundaram, S.; Mallick, T.K. Perovskite solar cells for bipv application: A review. Buildings 2020, 10, 129. [Google Scholar] [CrossRef]

- Santos, P.; Bomberg, M. Buildings’ Thermal Behaviour and Energy Efficiency for a Sustainable Construction. Available online: https://www.mdpi.com/books/reprint/9046-buildings-thermal-behaviour-and-energy-efficiency-for-a-sustainable-construction (accessed on 31 December 2021).

- Chopra, K.L.; Paulson, P.D.; Dutta, V. Thin-Film Solar Cells: An Overview. Prog. Photovolt. Res. Appl. 2004, 12, 69–92. [Google Scholar] [CrossRef]

- Scarpulla, M.A.; McCandless, B.; Phillips, A.B.; Yan, Y.; Heben, M.J.; Wolden, C.; Xiong, G.; Metzger, W.K.; Mao, D.; Krasikov, D.; et al. CdTe-based thin film photovoltaics: Recent advances, current challenges and future prospects. Sol. Energy Mater. Sol. Cells 2023, 255, 112289. [Google Scholar] [CrossRef]

- Kartikay, P.; Mokurala, K.; Sharma, B.; Kali, R.; Mukurala, N.; Mishra, D.; Kumar, A.; Mallick, S.; Song, J.; Jin, S.H. Recent advances and challenges in solar photovoltaic and energy storage materials: Future directions in Indian perspective. J. Phys. Energy 2021, 3, 034018. [Google Scholar] [CrossRef]

- Muhammad, J.Y.; Waziri, A.B.; Shitu, A.M.; Ahmad, U.M.; Muhammad, M.H.; Alhaji, Y.; Olaniyi, A.T.; Bala, A.A. Recent Progressive Status of Materials for Solar Photovoltaic Cell: A Comprehensive Review. Sci. J. Energy Eng. 2019, 7, 77. [Google Scholar] [CrossRef]

- Göksu, A.U.; Gedik, G.Z. The effect of CIS BIPV as a shading device on building life cycle energy performance. Int. J. Sustain. Energy 2023, 42, 575–593. [Google Scholar] [CrossRef]

- Priya, P.; Stonier, A.A. Emerging innovations in solar photovoltaic (PV) technologies: The perovskite solar cells and more. Energy Rep. 2025, 14, 216–242. [Google Scholar] [CrossRef]

- Meheretu, G.M.; Worku, A.K.; Yihunie, M.T.; Koech, R.K.; Wubetu, G.A. The recent advancement of outdoor performance of perovskite photovoltaic cells technology. Heliyon 2024, 10, e36710. [Google Scholar] [CrossRef]

- Khir, H.; Pandey, A.; Saidur, R.; Ahmad, M.S.; Samykano, M. Advancements, challenges and future prospects of flexible Pb-free perovskite solar cells. J. Power Sources 2025, 656, 238025. [Google Scholar] [CrossRef]

- ElKhamisy, K.; Abdelhamid, H.; El-Rabaie, E.-S.M.; Abdel-Salam, N. A Comprehensive Survey of Silicon Thin-film Solar Cell: Challenges and Novel Trends. Plasmonics 2024, 19, 1–20. [Google Scholar] [CrossRef]

- Tanaka, K.; Shimakawa, K. Structure. In Amorphous Chalcogenide Semiconductors and Related Materials; Springer: New York, NY, USA, 2011; pp. 29–62. [Google Scholar] [CrossRef]

- Zeman, M.; Schropp, R.E.I. 1.17—Thin-Film Silicon PV Technology. In Comprehensive Renewable Energy; Sayigh, A., Ed.; Elsevier: Oxford, UK, 2012; pp. 389–398. [Google Scholar] [CrossRef]

- Nkuissi, H.J.T.; Konan, F.K.; Hartiti, B.; Ndjaka, J. Toxic Materials Used in Thin Film Photovoltaics and Their Impacts on Environment; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Yao, Z.; Si, W.; Zhao, Y.; Moya, P.P.; Özkol, E.; Yang, G.; Gonugunta, P.; Anusuyadevi, P.R.; Taheri, P.; Isabella, O. Influence of deposition power of PECVD intrinsic a-Si:H buffer layer on n+ poly-Si/SiOx/c-Si passivating contacts. Sol. Energy Mater. Sol. Cells 2025, 290, 113709. [Google Scholar] [CrossRef]

- Van Sark, W.G.J.H.M. Methods of Deposition of Hydrogenated Amorphous Silicon for Device Applications. In Advances in Plasma-Grown Hydrogenated Films; Francombe, M.H., Ed.; Thin Films and Nanostructures; Academic Press: Oxford, UK, 2002; Volume 30, pp. 1–215. [Google Scholar] [CrossRef]

- Tong, J.; Jiang, Q.; Zhang, F.; Kang, S.B.; Kim, D.H.; Zhu, K. Wide-Bandgap Metal Halide Perovskites for Tandem Solar Cells. ACS Energy Lett. 2021, 6, 232–248. [Google Scholar] [CrossRef] [PubMed]

- Radue, C.; van Dyk, E.E. A comparison of degradation in three amorphous silicon PV module technologies. Sol. Energy Mater. Sol. Cells 2010, 94, 617–622. [Google Scholar] [CrossRef]

- Lai, F.-I.; Yang, J.-F.; Hsu, Y.-C.; Kuo, S.-Y. Enhanced conversion efficiency of a-si:H thin-film solar cell using zno nanorods. Crystals 2020, 10, 1082. [Google Scholar] [CrossRef]

- Biyik, E.; Araz, M.; Hepbasli, A.; Shahrestani, M.; Yao, R.; Shao, L.; Essah, E.; Oliveira, A.C.; del Caño, T.; Rico, E.; et al. A key review of building integrated photovoltaic (BIPV) systems. Eng. Sci. Technol. Int. J. 2017, 20, 833–858. [Google Scholar] [CrossRef]

- Thermal Performance Evaluation and Energy Saving Potential of Semi-Transparent CdTe in Façade BIPV. Available online: http://shura.shu.ac.uk/information.html (accessed on 31 December 2021).

- Husain, A.A.; Hasan, W.Z.W.; Shafie, S.; Hamidon, M.N.; Pandey, S.S. A review of transparent solar photovoltaic technologies. Renew. Sustain. Energy Rev. 2018, 94, 779–791. [Google Scholar] [CrossRef]

- Khalifeeh, R.; Alrashidi, H.; Sellami, N.; Mallick, T.; Issa, W. State-of-the-art review on the energy performance of semi-transparent building integrated photovoltaic across a range of different climatic and environmental conditions. Energies 2021, 14, 3412. [Google Scholar] [CrossRef]

- Yadav, S.; Hachem-Vermette, C. Performance evaluation of semitransparent PV window systems employing periodic thermal model. Appl. Energy 2024, 353, 122076. [Google Scholar] [CrossRef]

- Ghosh, A. Potential of building integrated and attached/applied photovoltaic (BIPV/BAPV) for adaptive less energy-hungry building’s skin: A comprehensive review. J. Clean. Prod. 2020, 276, 123343. [Google Scholar] [CrossRef]

- Ludin, N.A.; Affandi, N.A.A.; Purvis-Roberts, K.; Ahmad, A.; Ibrahim, M.A.; Sopian, K.; Jusoh, S. Environmental Impact and Levelised Cost of Energy Analysis of Solar Photovoltaic Systems in Selected Asia Pacific Region: A Cradle-to-Grave Approach. Sustainability 2021, 13, 396. [Google Scholar] [CrossRef]

- Amoruso, F.M.; Schuetze, T. Carbon Life Cycle Assessment and Costing of Building Integrated Photovoltaic Systems for Deep Low-Carbon Renovation. Sustainability 2023, 15, 9460. [Google Scholar] [CrossRef]

- Dai, Y.; Bai, Y. Performance improvement for building integrated photovoltaics in practice: A review. Energies 2021, 14, 178. [Google Scholar] [CrossRef]

- Slaoui, A.; Collins, R. Photovoltaics: Advanced Inorganic Materials. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Oxford, UK, 2008; pp. 1–11. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Maghami, M.R. Harnessing photovoltaic innovation: Advancements, challenges, and strategic pathways for sustainable global development. Energy Convers. Manag. X 2025, 27, 101058. [Google Scholar] [CrossRef]

- Barbón, A.; Bayón-Cueli, C.; Bayón, L.; Rodríguez-Suanzes, C. Analysis of the tilt and azimuth angles of photovoltaic systems in non-ideal positions for urban applications. Appl. Energy 2022, 305, 117802. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, M.; Yang, H. A review of the energy performance and life-cycle assessment of building-integrated photovoltaic (BIPV) systems. Energies 2018, 11, 3157. [Google Scholar] [CrossRef]

- Wu, X.; Wang, Y.; Deng, S.; Su, P. Climate-Responsive Design of Photovoltaic Façades in Hot Climates: Materials, Technologies, and Implementation Strategies. Buildings 2025, 15, 1648. [Google Scholar] [CrossRef]

- Mehta, K.; Lamba, R.; Sinha, S.; Kumar, N. BIPV in India: Opportunities, challenges, and pathways for urban planning and smart cities. Sol. Compass 2025, 15, 100133. [Google Scholar] [CrossRef]

- Alsema, E.A.; de Wild-Scholten, M. The real environmental impacts of crystalline silicon PV modules: An analysis based on up-to-date manufacturers data. In Proceeding of the 20th European Photovoltaic Solar Energy Conference, Barcelona, Spain, 6–10 June 2005. [Google Scholar]

- Manimaran, U.; Dangate, M.S. A Review on Conducting Materials in CdTe Photovoltaic Cells. ACS Omega 2025, 10, 23858–23872. [Google Scholar] [CrossRef]

- Rahman, K.S. Subchapter 3.1—Cadmium telluride (CdTe) thin film solar cells. In Comprehensive Guide on Organic and Inorganic Solar Cells; Akhtaruzzaman, M., Selvanathan, V., Eds.; Solar Cell Engineering; Academic Press: Oxford, UK, 2022; pp. 65–83. [Google Scholar] [CrossRef]

- Ma, X.; Ghosh, A.; Cuce, E.; Saboor, S. Building integrated photovoltaic-thermal systems (BIPVT) and spectral splitting technology: A critical review. Next Sustain. 2024, 4, 100056. [Google Scholar] [CrossRef]

- Alrashidi, H.; Ghosh, A.; Issa, W.; Sellami, N.; Mallick, T.K.; Sundaram, S. Evaluation of solar factor using spectral analysis for CdTe photovoltaic glazing. Mater. Lett. 2019, 237, 332–335. [Google Scholar] [CrossRef]

- Romeo, A.; Artegiani, E. CdTe-based thin film solar cells: Past, present and future. Energies 2021, 14, 1684. [Google Scholar] [CrossRef]

- Morales-Acevedo, A. Can we improve the record efficiency of CdS/CdTe solar cells? Sol. Energy Mater. Sol. Cells 2006, 90, 2213–2220. [Google Scholar] [CrossRef]

- Tong, J.; Dong, C.; Yao, M.; Wang, Q.; Shen, C.; Yue, Y.; Yan, L.; Gao, Y.; Yue, G.; Zhang, W.; et al. 22.1% Carbon-Electrode Perovskite Solar Cells by Spontaneous Passivation and Self-Assembly of Hole-Transport Bilayer. ACS Nano 2025, 19, 12960–12970. [Google Scholar] [CrossRef]

- Paudel, N.R.; Poplawsky, J.D.; Moore, K.L.; Yan, Y. Current Enhancement of CdTe-Based Solar Cells. IEEE J. Photovolt. 2015, 5, 1492–1496. [Google Scholar] [CrossRef]

- Corti, P.; Bonomo, P. SUPSI-Swiss BIPV Competence Centre. Available online: www.solarchitecture.ch (accessed on 14 October 2020).

- Morrison, A.; Davie, G.; Ryder, D.; Kakoullis, G.; Richardson, N. Tel: +44 (0) 207 871 0122 Fax: +44 (0) 207 871 0101 E-mail: info@pv-tech.org. Available online: www.pv-tech.org (accessed on 11 May 2012).

- Rahman, T.; Al Mansur, A.; Lipu, M.S.H.; Rahman, S.; Ashique, R.H.; Houran, M.A.; Elavarasan, R.M.; Hossain, E. Degradation analysis of photovoltaic modules with solar cells manufactured with SiO2 + TiO2 thin films. Renew. Energy 2025, 244, 122749. [Google Scholar] [CrossRef]

- Rahman, T.; Al Mansur, A.; Lipu, M.S.H.; Rahman, S.; Ashique, R.H.; Houran, M.A.; Elavarasan, R.M.; Hossain, E. Investigation of Degradation of Solar Photovoltaics: A Review of Aging Factors, Impacts, and Future Directions toward Sustainable Energy Management. Energies 2023, 16, 3706. [Google Scholar] [CrossRef]

- Luo, W.; Clement, C.E.; Khoo, Y.S.; Wang, Y.; Khaing, A.M.; Reindl, T.; Kumar, A.; Pravettoni, M. Photovoltaic module failures after 10 years of operation in the tropics. Renew. Energy 2021, 177, 327–335. [Google Scholar] [CrossRef]

- Mendoza-Pérez, R.; Sastre-Hernández, J.; Contreras-Puente, G.; Vigil-Galán, O. CdTe solar cell degradation studies with the use of CdS as the window material. Sol. Energy Mater. Sol. Cells 2009, 93, 79–84. [Google Scholar] [CrossRef]

- Rawat, R.; Kaushik, S.C.; Sastry, O.S.; Bora, B.; Singh, Y.K. Long-term Performance Analysis of CdTe PV module in real operating conditions. Mater Today Proc. 2018, 5 Pt 2, 23210–23217. [Google Scholar] [CrossRef]

- Chen, K.; Zuo, J.; Chang, R. Compendium of degradation rates of global photovoltaic (PV) technology: Insights from technology, climate and geography. Sol. Energy Mater. Sol. Cells 2025, 293, 113839. [Google Scholar] [CrossRef]

- Bosio, A.; Pasini, S.; Romeo, N. The history of photovoltaics with emphasis on CdTe solar cells and modules. Coatings 2020, 10, 344. [Google Scholar] [CrossRef]

- Gyamfi, S.; Aboagye, B.; Peprah, F.; Obeng, M. Degradation analysis of polycrystalline silicon modules from different manufacturers under the same climatic conditions. Energy Convers. Manag. X 2023, 20, 100403. [Google Scholar] [CrossRef]

- Powalla, M.; Paetel, S.; Ahlswede, E.; Wuerz, R.; Wessendorf, C.D.; Friedlmeier, T.M. Thin-film solar cells exceeding 22% solar cell efficiency: An overview on CdTe-, Cu(In,Ga)Se2-, and perovskite-based materials. Appl. Phys. Rev. 2018, 5. [Google Scholar] [CrossRef]

- Nallapaneni, M.K.; Mahendran, S. Performance comparison of BAPV and BIPV systems with c-Si, CIS and CdTe photovoltaic technologies under tropical weather conditions. Case Stud. Therm. Eng. 2019, 13, 100374. [Google Scholar] [CrossRef]

- Sorgato, M.J.; Schneider, K.; Rüther, R. Technical and economic evaluation of thin-film CdTe building-integrated photovoltaics (BIPV) replacing façade and rooftop materials in office buildings in a warm and sunny climate. Renew Energy 2018, 118, 84–98. [Google Scholar] [CrossRef]

- Singh, D.; Gautam, A.K.; Chaudhary, R. Potential and performance estimation of free-standing and building integrated photovoltaic technologies for different climatic zones of India. Energy Built Environ. 2022, 3, 40–55. [Google Scholar] [CrossRef]

- Feng, X.; Ma, T.; Yamaguchi, Y.; Peng, J.; Dai, Y.; Ji, D. Potential of residential building integrated photovoltaic systems in different regions of China. Energy Sustain. Dev. 2023, 72, 19–32. [Google Scholar] [CrossRef]

- Meybodi, M.A.; Beath, A.C. Impact of cost uncertainties and solar data variations on the economics of central receiver solar power plants: An Australian case study. Renew. Energy 2016, 93, 510–524. [Google Scholar] [CrossRef]

- Curtin, A.M.; Vail, C.A.; Buckley, H.L. CdTe in thin film photovoltaic cells: Interventions to protect drinking water in production and end-of-life. Water-Energy Nexus 2020, 3, 15–28. [Google Scholar] [CrossRef]

- Degradation and Failure Modes in New Photovol-taic Cell and Module Technologies 2025 PVPS Task 13 Reliability and Performance of Photovoltaic Systems. Available online: www.iea-pvps.org (accessed on 31 December 2021).

- Rohom, A.B.; Londhe, P.U.; Han, J.I.; Chaure, N.B. Studies on the graded band-gap copper indium di-selenide thin film solar cells prepared by electrochemical route. Appl. Surf. Sci. 2019, 466, 358–366. [Google Scholar] [CrossRef]

- Ramanujam, J.; Singh, U.P. Copper indium gallium selenide based solar cells—A review. Energy Environ. Sci. 2017, 10, 1306–1319. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Siefer, G.; Hao, X. Solar cell efficiency tables (version 62). Prog. Photovolt. Res. Appl. 2023, 31, 651–663. [Google Scholar] [CrossRef]

- Ramanathan, K.; Keane, J.; Noufi, R. Properties of High-Efficiency CIGS Thin-Film Solar Cells. 2005. Available online: http://www.osti.gov/bridge (accessed on 31 December 2021).

- Ghamsari-Yazdel, F.; Gharibshahian, I.; Sharbati, S. Thin oxide buffer layers for avoiding leaks in CIGS solar cells; a theoretical analysis. J. Mater. Sci. Mater. Electron. 2021, 32, 7598–7608. [Google Scholar] [CrossRef]

- Ramanujam, J.; Bishop, D.M.; Todorov, T.K.; Gunawan, O.; Rath, J.; Nekovei, R.; Artegiani, E.; Romeo, A. Flexible CIGS, CdTe and a-Si:H based thin film solar cells: A review. Prog. Mater. Sci. 2020, 110, 100619. [Google Scholar] [CrossRef]

- Maoz, M.; Abbas, Z.; Shah, S.A.B.; Lughi, V. Recent Advances in Flexible Solar Cells; Materials, Fabrication, and Commercialization. Sustainability 2025, 17, 1820. [Google Scholar] [CrossRef]

- Sudarsan, V. Chapter 4—Materials for Hostile Chemical Environments. In Materials Under Extreme Conditions; Tyagi, A.K., Banerjee, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 129–158. [Google Scholar] [CrossRef]

- Mesloub, A.; Albaqawy, G.A.; Kandar, M.Z. The optimum performance of Building Integrated Photovoltaic (BIPV) Windows under a semi-arid climate in Algerian Office Buildings. Sustainability 2020, 12. [Google Scholar] [CrossRef]

- Ramanan, P.; Kalidasa, M.K.; Karthick, A. Performance analysis and energy metrics of grid-connected photovoltaic systems. Energy Sustain. Dev. 2019, 52, 104–115. [Google Scholar] [CrossRef]

- Alhammadi, N.; Rodriguez-Ubinas, E.; Alzarouni, S.; Alantali, M. Building-integrated photovoltaics in hot climates: Experimental study of CIGS and c-Si modules in BIPV ventilated facades. Energy Convers. Manag. 2022, 274, 116408. [Google Scholar] [CrossRef]

- Miles, R.W.; Zoppi, G.; Forbes, I. Inorganic photovoltaic cells. Mater. Today 2007, 10, 20–27. [Google Scholar] [CrossRef]

- Lu, F.; Kwon, M.; Jang, J. Application of Copper Indium Gallium Selenide Thin-Film Solar Technology in Green Retrofitting of Aging Residential Buildings. Buildings 2025, 15, 1633. [Google Scholar] [CrossRef]

- Piliougine, M.; Sánchez-Friera, P.; Petrone, G.; Sánchez-Pacheco, F.J.; Spagnuolo, G.; Sidrach-de-Cardona, M. New model to study the outdoor degradation of thin–film photovoltaic modules. Renew Energy 2022, 193, 857–869. [Google Scholar] [CrossRef]

- Roslan, F.N.; Bermakai, M.Y.; Yusoff, M.Z.M.; Yusof, N. Electrical performance of GaAs/p-Si solar cells with double-layer anti-reflective coatings using 1D simulation. Next Res. 2025, 2, 100750. [Google Scholar] [CrossRef]

- Woo, S.; Ryu, G.; Kim, T.; Hong, N.; Han, J.-H.; Chu, R.J.; Bae, J.; Kim, J.; Lee, I.-H.; Jung, D.; et al. Growth and Fabrication of GaAs Thin-Film Solar Cells on a Si Substrate via Hetero Epitaxial Lift-Off. Appl. Sci. 2022, 12, 820. [Google Scholar] [CrossRef]

- Kim, C.-W.; Park, G.-Y.; Shin, J.-C.; Kim, H.-J. Efficiency Enhancement of GaAs Single-Junction Solar Cell by Nanotextured Window Layer. Appl. Sci. 2022, 12, 601. [Google Scholar] [CrossRef]

- Oni, A.M.; Mohsin, A.S.M.; Rahman, M.M.; Bhuian, M.B.H. A comprehensive evaluation of solar cell technologies, associated loss mechanisms, and efficiency enhancement strategies for photovoltaic cells. Energy Rep. 2024, 11, 3345–3366. [Google Scholar] [CrossRef]

- Tanaka, A. Toxicity of indium arsenide, gallium arsenide, and aluminium gallium arsenide. Toxicol. Appl. Pharmacol. 2004, 198, 405–411. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Gu, X.; Chen, Z.; Han, X.; Yu, N.; Wei, Y.; Gao, J.; Chen, H.; Zhang, M.; Wang, A.; et al. Achieving Record-Efficiency Organic Solar Cells upon Tuning the Conformation of Solid Additives. J. Am. Chem. Soc. 2022, 144, 14731–14739. [Google Scholar] [CrossRef] [PubMed]

- Maalouf, A.; Okoroafor, T.; Jehl, Z.; Babu, V.; Resalati, S. A comprehensive review on life cycle assessment of commercial and emerging thin-film solar cell systems. Renew. Sustain. Energy Rev. 2023, 186, 113652. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, J.; Ma, X.; Gao, J.; Xu, C.; Yang, K.; Wang, Z.; Zhang, J.; Zhang, F. A critical review on semitransparent organic solar cells. Nano Energy 2020, 78, 105376. [Google Scholar] [CrossRef]

- Zhang, H.; Ng, Z.-N.; Kang, C.C.; Tan, J.D.; Ariannejad, M.; Bhuiyan, M.A.S.; Chan, K.-Y. Efficiency enhancement of CZTS solar cell with WO3 buffer layer using CZTSe BSF layer. Energy Rep. 2024, 12, 2707–2719. [Google Scholar] [CrossRef]

- Maklavani, S.E.; Mohammadnejad, S. Enhancing the open-circuit voltage and efficiency of CZTS thin-film solar cells via band-offset engineering. Opt. Quantum Electron. 2020, 52, 72. [Google Scholar] [CrossRef]

- Huang, T.J.; Yin, X.; Qi, G.; Gong, H. CZTS-based materials and interfaces and their effects on the performance of thin film solar cells. Phys. Status Solidi (RRL) Rapid Res. Lett. 2014, 9999, 735–762. [Google Scholar] [CrossRef]

- Sasikumar, R.; Thirumalaisamy, S.; Kim, B.; Hwang, B. Dye-sensitized solar cells: Insights and research divergence towards alternatives. Renew. Sustain. Energy Rev. 2024, 199, 114549. [Google Scholar] [CrossRef]

- Agarwal, R.; Vyas, Y.; Chundawat, P.; Dharmendra; Ameta, C. Outdoor Performance and Stability Assessment of Dye-Sensitized Solar Cells (DSSCs); IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Dai, S.; Weng, J.; Sui, Y.; Chen, S.; Xiao, S.; Huang, Y.; Kong, F.; Pan, X.; Hu, L.; Zhang, C.; et al. The design and outdoor application of dye-sensitized solar cells. Inorganica Chim. Acta 2008, 361, 786–791. [Google Scholar] [CrossRef]

- Anitha, A.E.; Dotter, M. A Review on Liquid Electrolyte Stability Issues for Commercialization of Dye-Sensitized Solar Cells (DSSC). Energies 2023, 16, 5129. [Google Scholar] [CrossRef]

- Wang, X.; Yang, J.; Zhong, J.; Yu, J.; Pan, X. Innovative Materials for High-Performance Tin-Based Perovskite Solar Cells: A Review. Polymers 2024, 16, 3053. [Google Scholar] [CrossRef] [PubMed]

- Lobet, M.; Mayer, A.; Maho, A.; Piron, P.; Dewalque, J.; Henrist, C.; Loicq, J. Opal-Like Photonic Structuring of Perovskite Solar Cells Using a Genetic Algorithm Approach. Appl. Sci. 2020, 10, 1783. [Google Scholar] [CrossRef]

- Khalid, M.; Mallick, T.K. Stability and Performance Enhancement of Perovskite Solar Cells: A Review. Energies 2023, 16, 4031. [Google Scholar] [CrossRef]

- Ghosh, A.; Mesloub, A.; Touahmia, M.; Ajmi, M. Visual Comfort Analysis of Semi-Transparent Perovskite Based Building Integrated Photovoltaic Window for Hot Desert Climate (Riyadh, Saudi Arabia). Energies 2021, 14, 1043. [Google Scholar] [CrossRef]

- Ghosh, A.; Bhandari, S.; Sundaram, S.; Mallick, T.K. Carbon counter electrode mesoscopic ambient processed & characterised perovskite for adaptive BIPV fenestration. Renew. Energy 2020, 145, 2151–2158. [Google Scholar] [CrossRef]

- Ali, A.O.; Elgohr, A.T.; El-Mahdy, M.H.; Zohir, H.M.; Emam, A.Z.; Mostafa, M.G.; Al-Razgan, M.; Kasem, H.M.; Elhadidy, M.S. Advancements in photovoltaic technology: A comprehensive review of recent advances and future prospects. Energy Convers. Manag. X 2025, 26, 100952. [Google Scholar] [CrossRef]

- Bhandari, K.P.; Collier, J.M.; Ellingson, R.J.; Apul, D.S. Energy payback time (EPBT) and energy return on energy invested (EROI) of solar photovoltaic systems: A systematic review and meta-analysis. Renew. Sustain. Energy Rev. 2015, 47, 133–141. [Google Scholar] [CrossRef]

- Kato, K.; Hibino, T.; Komoto, K.; Ihara, S.; Yamamoto, S.; Fujihara, H. A life-cycle analysis on thin—“lm CdS/CdTe PV modules”. Sol. Energy Mater. Sol. Cells 2001, 67, 279–287. [Google Scholar] [CrossRef]

- Witto, N. Life Cycle Assessment of CIGS Thin-Film Including End-of-Life Options. Master’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2023. [Google Scholar]

- International Renewable Energy Agency. Renewable Energy Technologies: Cost Analysis Series. 2012. Available online: www.irena.org/Publications (accessed on 11 May 2012).

- Sung, W.; Lee, H.; Choi, W.; Han, S.G.; Kim, J.; Cho, K.; Kim, S.H.; Lee, D.; Kim, H.D.; Ohkita, H. Nanomorphology dependence of the environmental stability of organic solar cells. NPG Asia Mater. 2022, 14, 56. [Google Scholar] [CrossRef]

- Amrillah, T. Enhancing the value of environment-friendly CZTS compound for next generation photovoltaic device: A review. Sol. Energy 2023, 263, 111982. [Google Scholar] [CrossRef]

- Lindahl, J.; Westerberg, A. National Survey Report of PV Power Applications in Sweden 2021; Swedish Energy Agency: Eskilstuna, Sweden, 2022. [Google Scholar]

- Sahare, S.; Pham, H.D.; Angmo, D.; Ghoderao, P.; MacLeod, J.; Khan, S.B.; Lee, S.; Singh, S.P.; Sonar, P. Emerging Perovskite Solar Cell Technology: Remedial Actions for the Foremost Challenges. Adv. Energy Mater. 2021, 11, 2101085. [Google Scholar] [CrossRef]

- Hossen, M.S.; Alam, K.; Mostakim, A.; Mahmud, U.; Imran, A.; Al Fathah, A. Integrating Solar Cells into Building Materials (Building-Integrated Photovoltaics—BIPV) to Turn Buildings into Self-Sustaining Energy Sources. Int. J. Sci. Res. Manag. 2022, 10, 946–962. [Google Scholar] [CrossRef]

- Mishra, R.; Panda, A.; Sharma, P. Comprehensive study on photovoltaic cell’s generation and factors affecting its performance: A Review. Mater. Renew. Sustain. Energy 2025, 14, 1–28. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Siefer, G.; Hinken, D.; Rauer, M.; Hohl-Ebinger, J.; Hao, X. Solar cell efficiency tables (Version 64). Prog. Photovoltaics: Res. Appl. 2024, 32, 425–441. [Google Scholar] [CrossRef]

- Elangovan, N.K.; Kannadasan, R.; Beenarani, B.; Alsharif, M.H.; Kim, M.-K.; Inamul, Z.H. Recent developments in perovskite materials, fabrication techniques, band gap engineering, and the stability of perovskite solar cells. Energy Rep. 2024, 11, 1171–1190. [Google Scholar] [CrossRef]

- Jäger-Waldau, A. Status of thin film solar cells in research, production and the market. Sol. Energy 2004, 77, 667–678. [Google Scholar] [CrossRef]

- Arce-Plaza, A.; Sánchez-Rodriguez, F.; Courel-Piedrahita, M.; Galán, O.V.; Hernandez-Calderon, V.; Ramirez-Velasco, S.; López, M.O. CdTe Thin Films: Deposition Techniques and Applications. In Coatings and Thin-Film Technologies; Perez-Taborda, J.A., Bernal, A.G.A., Eds.; IntechOpen: London, UK, 2018; Chapter 7. [Google Scholar] [CrossRef]

- Ahmed, S.; Ali, A.; Ansari, J.A.; Qadir, S.A.; Kumar, L. A Comprehensive Review of Solar Photovoltaic Systems: Scope, Technologies, Applications, Progress, Challenges, and Recommendations. IEEE Access 2025, 13, 69723–69750. [Google Scholar] [CrossRef]

- Buonomenna, M.G. Inorganic Thin-Film Solar Cells: Challenges at the Terawatt-Scale. Symmetry 2023, 15, 1718. [Google Scholar] [CrossRef]

- Birkmire, R.W.; McCandless, B.E. CdTe thin film technology: Leading thin film PV into the future. Curr. Opin. Solid State Mater. Sci. 2010, 14, 139–142. [Google Scholar] [CrossRef]

- Kong, H.; Yu, Z.; Zhang, J.; Han, Y.; Wu, L.; Wang, H.; Wang, J. Perspective of CIGS-BIPV’s Product Competitiveness in China. Int. J. Photoenergy 2020, 2020, 1–10. [Google Scholar] [CrossRef]

- Fthenakis, V.M. Chapter IV-1-A—Overview of Potential Hazards. In McEvoy’s Handbook of Photovoltaics (Third Edition); Kalogirou, S.A., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 1195–1212. [Google Scholar] [CrossRef]

- Ramos-Ruiz, A.; Wilkening, J.V.; Field, J.A.; Sierra-Alvarez, R. Leaching of cadmium and tellurium from cadmium telluride (CdTe) thin-film solar panels under simulated landfill conditions. J. Hazard Mater. 2017, 336, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Fthenakis, V.M.; Moskowitz, P.D. Characterization and control of phosphine hazards in photovoltaic cell manufacture. Solar Cells 1987, 22, 303–317. [Google Scholar] [CrossRef]

- Srivishnu, K.S.; Markapudi, P.R.; Sundaram, S.; Giribabu, L. Semitransparent Perovskite Solar Cells for Building Integrated Photovoltaics: Recent Advances. Energies 2023, 16, 889. [Google Scholar] [CrossRef]

- Akomea-Ampeh, M.; Atekwana, E.A.; Steele, E.P.; Cagle, A.E.; Armstrong, A.; Thackeray, S.J.; Sadro, S.; Ololade, O.O.; Fasipe, O.A.; Hernandez, R.R. Metal contaminant risk at active floating photovoltaic sites and future research roadmap. J. Environ. Manag. 2025, 383, 125216. [Google Scholar] [CrossRef] [PubMed]

- Preet, S.; Smith, S.T. A comprehensive review on the recycling technology of silicon based photovoltaic solar panels: Challenges and future outlook. J. Clean Prod. 2024, 448, 141661. [Google Scholar] [CrossRef]

- Akram, W.; Li, X.; Ahmed, S.; Ouyang, Z.; Li, G. A review of life cycle assessment and sustainability analysis of perovskite/Si tandem solar cells. R. Soc. Chemistry 2024. [Google Scholar] [CrossRef]

- Roy, P.; Ghosh, A.; Barclay, F.; Khare, A.; Cuce, E. Perovskite Solar Cells: A Review of the Recent Advances. Coatings 2022, 12, 1089. [Google Scholar] [CrossRef]

- Li, J.; Liu, Z.; Han, G.; Demian, P.; Osmani, M. The Relationship Between Artificial Intelligence (AI) and Building Information Modeling (BIM) Technologies for Sustainable Building in the Context of Smart Cities. Sustainability 2024, 16, 10848. [Google Scholar] [CrossRef]

- Sinha, A.; Qian, J.; Moffitt, S.L.; Hurst, K.; Terwilliger, K.; Miller, D.C.; Schelhas, L.T.; Hacke, P. UV-induced degradation of high-efficiency silicon PV modules with different cell architectures. Prog. Photovolt. Res. Appl. 2023, 31, 36–51. [Google Scholar] [CrossRef]

- Jha, S.K.; Ghosh, A. Towards sustainable water resources: A critical review of evaluating traditional and solar-based desalination technologies and innovations. Desalination Water Treat. 2025, 322, 101246. [Google Scholar] [CrossRef]

- Jha, S.K.; Sankar, A.; Zhou, Y.; Ghosh, A. Incorporation of Phase Change Materials in Buildings. Constr. Mater. 2024, 4, 676–703. [Google Scholar] [CrossRef]

- Karthick, A.; Murugavel, K.K.; Ghosh, A.; Sudhakar, K.; Ramanan, P. Investigation of a binary eutectic mixture of phase change material for building integrated photovoltaic (BIPV) system. Sol. Energy Mater. Sol. Cells 2020, 207, 110360. [Google Scholar] [CrossRef]

- Poudhar, A.; Ghosh, A. Phase change materials for energy efficiency in photovoltaic systems and buildings: A review. J. Build. Eng. 2025, 104, 112360. [Google Scholar] [CrossRef]

| Azimuth Angle (°) | Direction | Relative Power Performance (%) | Approx. Module Efficiency (%) | Representative Location (Latitude, Longitude) | Observation |

|---|---|---|---|---|---|

| 0 | South | 100 | 2.5 | New Delhi, India (28.6° N, 77.2° E) | Baseline orientation; optimal solar incidence on module surface |

| 30 | Southwest 30° | 99 | 2.48 | Tokyo, Japan (35.7° N, 139.7° E) | Slight decrease due to 30° deviation from south |

| 60 | Southwest 60° | 93 | 2.33 | Rome, Italy (41.9° N, 12.5° E) | Moderate efficiency loss as the module faces further from the optimal direction |

| 90 | West | 83 | 2.08 | Berlin, Germany (52.5° N, 13.4° E) | Significant reduction in performance for west-facing modules |

| 270 | East | 78 | 1.95 | Beijing, China (39.9° N, 116.4° E) | Lower efficiency due to reduced morning irradiance capture |

| 300 | Southeast 60° | 88 | 2.20 | Sydney, Australia (33.9° S, 151.2° E) | Moderate performance reduction for southeast 60° orientation |

| 330 | Southeast 30° | 96 | 2.40 | Los Angeles, USA (34.0° N, 118.2° W) | Slight reduction compared to south-facing orientation |

| Location/Study | Average Temperature (°C) | Relative Humidity (%) | Annual Irradiance (kWh/m2) | Module Construction/ Encapsulation | Operational Duration (Years) | Observed Degradation Rate (%/Year) |

|---|---|---|---|---|---|---|

| India (Chandigarh) [63] | 28 | 65 | 1850 | Glass/Glass (EVA encapsulant) | 5 | 0.6–0.8 |

| Thailand [64] | 30 | 75 | 1900 | Glass/Backsheet | 4 | 1.1–1.4 |

| Brazil (Recife) [65] | 29 | 80 | 2000 | Glass/Backsheet (polymeric) | 6 | 1.5–2.0 |

| Malaysia (Kuala Lumpur) [66] | 31 | 85 | 1950 | Glass/Glass with edge sealant | 5 | 0.5–0.7 |

| Singapore [67] | 30 | 80 | 2000 | Glass/Backsheet (EVA) | 8 | 0.9–1.2 |

| Technology | EPBT (Years) | LCOE (USD/kWh) | Geographic Context |

|---|---|---|---|

| a-Si (Amorphous Si) [116] | 1.5–2.5 | 0.08–0.12 | Europe (Germany, Spain) |

| CdTe (Cadmium Telluride) [117] | 1.0–1.8 | 0.06–0.10 | Tropical (India, Brazil, Malaysia) |

| CIGS/CIS [118] | 1.5–2.0 | 0.05–0.09 | Europe (Germany, Netherlands) |

| GaAs [119] | 2.0–3.5 | 0.15–0.25 | USA (Arizona, California) |

| OSCs (Organic) [120] | 0.5–1.5 | 0.10–0.14 | East Asia (Japan, South Korea) |

| CZTS (Cu2ZnSnS4) [121] | 1.8–2.5 | 0.08–0.11 | Europe (France) |

| DSSC (Dye-Sensitized) [122] | 1.0–1.8 | 0.09–0.13 | Europe (Italy, Sweden) |

| Perovskite [123] | 0.3–0.8 | 0.05–0.09 | Asia (China, Singapore) |

| Technology | Cell Efficiency (%) | Module Efficiency (%) | Source/Developer | Temperature Coefficient (%/°C) |

|---|---|---|---|---|

| Crystalline Silicon (c-Si) | 26.8 ± 0.4 | 22.8 ± 0.3 | NREL | −0.35 |

| Amorphous Silicon (a-Si) | 10.2 ± 0.3 | 9.1 | AIST | −0.18 |

| Cadmium Telluride (CdTe) | 21.1 ± 0.4 | 18.6 ± 0.5 | First Solar | −0.25 |

| Copper Indium Gallium Selenide (CIGS) | 21.7 ± 0.5 | 19.2 ± 0.5 | Solar Frontier | −0.30 |

| Gallium Arsenide (GaAs) | 28.8 ± 0.9 | 25.1 ± 0.8 | Alta Devices | −0.25 |

| Copper Zinc Tin Sulfide (CZTS) | 10.0 ± 0.2 | — | UNSW | −0.35 |

| Dye-Sensitized Solar Cell (DSSC) | 13.5 ± 0.3 | 10.5 | EPFL | −0.45 |

| Perovskite | 27.3 ± 0.5 | 22.8 ± 0.4 | NREL/KAUST | −0.20 |

| Technology | Market Share (2024) | Price Range ($/W) | Category |

|---|---|---|---|

| Crystalline Silicon (c-Si) | ~91% | 0.18–0.30 | Module |

| Amorphous Silicon (a-Si) | 2.0% | 0.69 | Module |

| Cadmium Telluride (CdTe) | 5.1% | 0.40 | Module |

| CIGS | 2.0% | 0.60 | Module |

| GaAs | <1% | 50.0 | Cell |

| Perovskite | <1% | 0.25–0.35 (estimated) | Cell/Module |

| Material | Source | DOT Hazard Classification | Critical Health Effects |

|---|---|---|---|

| Arsenic | GaAs | Poison | Cancer, lung toxicity |

| Cadmium | CdTe, CdS | Poison | Kidney and bone damage |

| Indium | CIGS | Not regulated | Pulmonary fibrosis |

| Tellurium | CdTe | Not regulated | Cyanosis, liver effects |

| Hydrogen Fluoride | a-Si | Corrosive | Burns, respiratory hazard |

| Arsine | GaAs (CVD) | Highly toxic gas | Blood, kidney toxicity |

| Silane | a-Si deposition | Pyrophoric gas | Explosion hazard |

| Hydrogen Selenide | CIS | Highly toxic gas | Irritant, lung damage |

| Phosphine | a-Si dopant | Pyrophoric gas | Fire and irritation hazard |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jha, S.K.; Farooq, A.S.; Ghosh, A. Thin-Film Solar Cells for Building-Integrated Photovoltaic (BIPV) Systems. Architecture 2025, 5, 116. https://doi.org/10.3390/architecture5040116

Jha SK, Farooq AS, Ghosh A. Thin-Film Solar Cells for Building-Integrated Photovoltaic (BIPV) Systems. Architecture. 2025; 5(4):116. https://doi.org/10.3390/architecture5040116

Chicago/Turabian StyleJha, Subodh Kumar, Abubakar Siddique Farooq, and Aritra Ghosh. 2025. "Thin-Film Solar Cells for Building-Integrated Photovoltaic (BIPV) Systems" Architecture 5, no. 4: 116. https://doi.org/10.3390/architecture5040116

APA StyleJha, S. K., Farooq, A. S., & Ghosh, A. (2025). Thin-Film Solar Cells for Building-Integrated Photovoltaic (BIPV) Systems. Architecture, 5(4), 116. https://doi.org/10.3390/architecture5040116