Immersive Technology Integration for Improved Quality Assurance and Assessment Jobs in Construction

Abstract

1. Introduction and Background

2. Literature Review

2.1. Quality Failures in Construction Projects

2.2. Analysis of IMT Tools Implementation for Quality Assurance in Existing Construction Studies

2.3. Development Platforms and Tools

2.4. Integration with Other Technologies

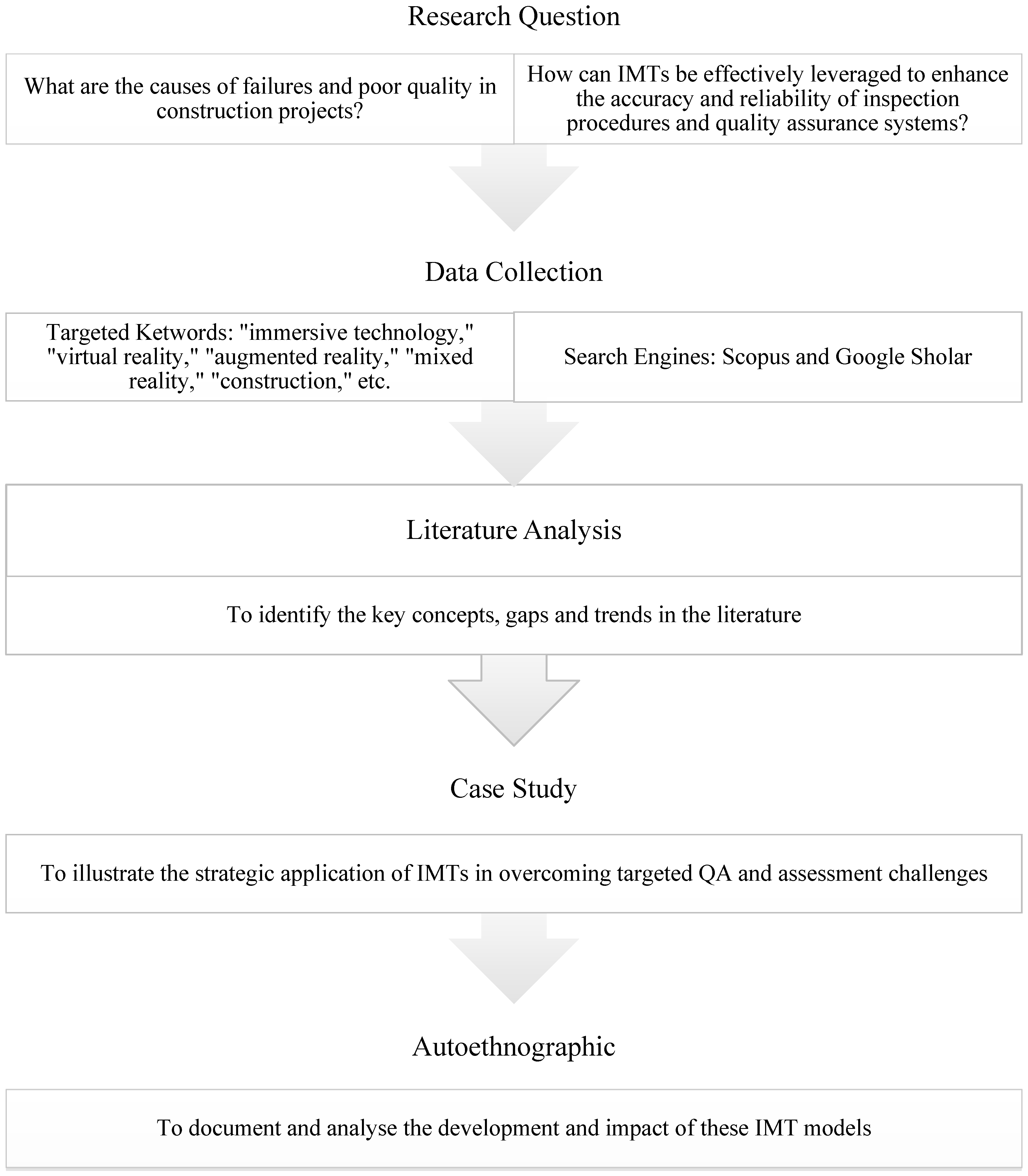

3. Research Method

- Identify knowledge gaps.

- Scope a body of literature.

- Clarify concepts, and

- Explore how research is conducted.

- “immersive technology”, “virtual reality”, “augmented reality”, “mixed reality”,

- “construction”, “quality assurance”, “quality inspection”, “quality check”,

- “building information modelling”, “safety inspection”, “environmental compliance”,

- “site management”, “defect detection”, “progress monitoring”, “inspection”, “assessment task”.

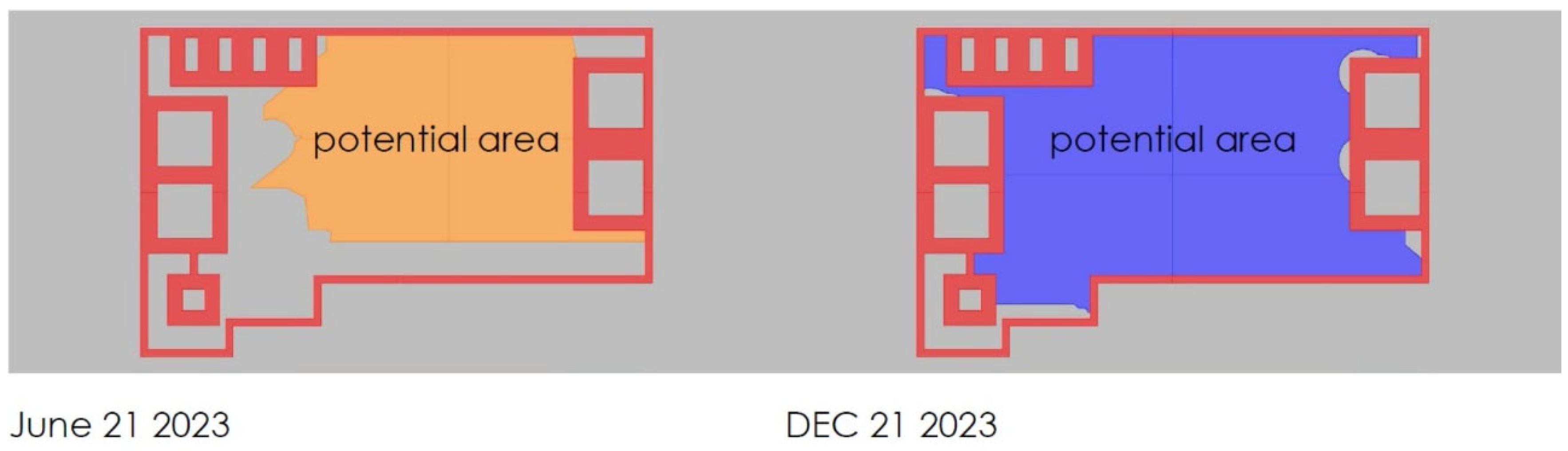

- Remote layout assessments of photovoltaic (PV) systems, and

- Evaluation of site conditions for pre-construction setup.

4. Case Study Analysis: Enhancing Inspection and QA on Site

4.1. Case Study 1: Remote Evaluation of Solar Panel Placement Using Immersive and BIM Technologies

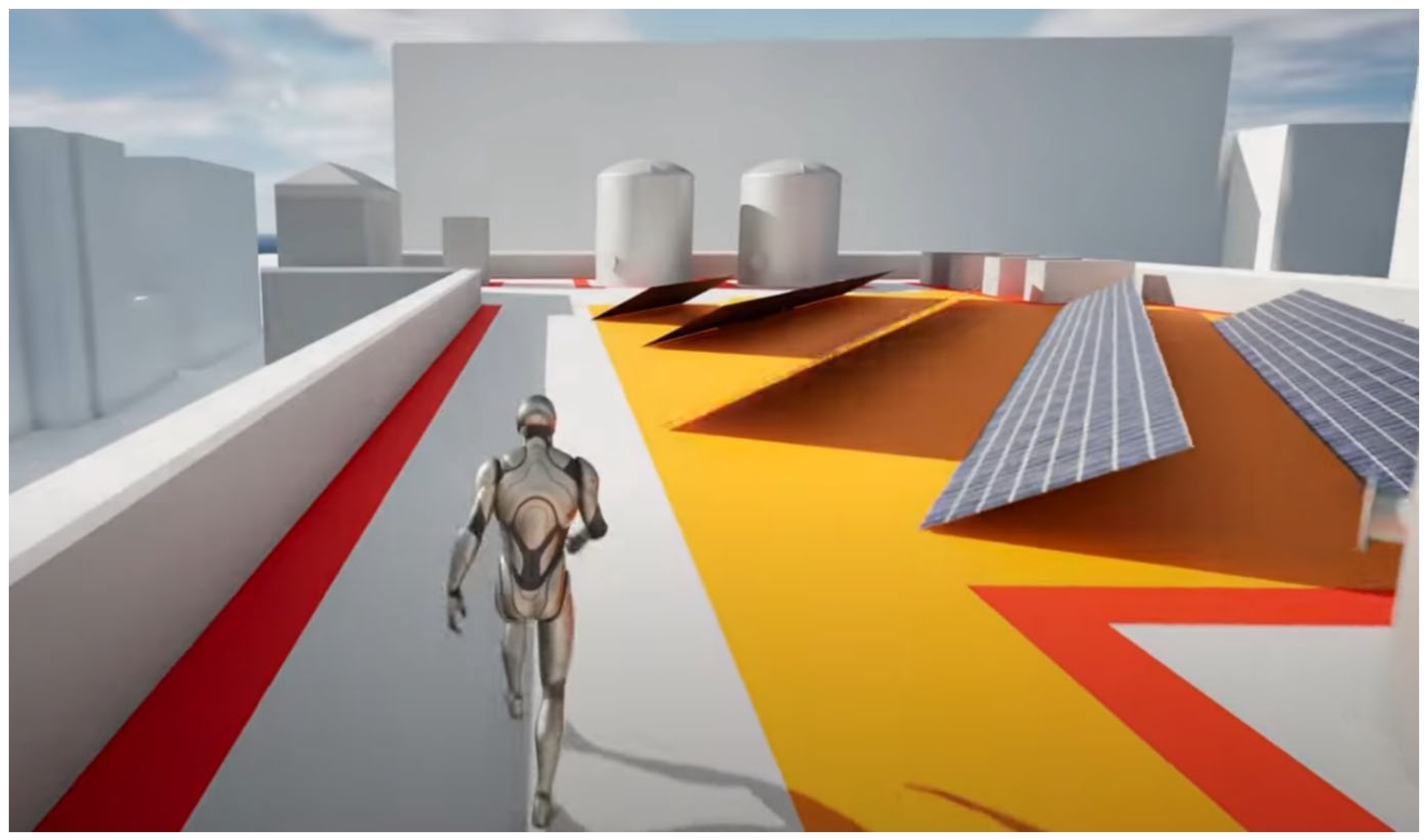

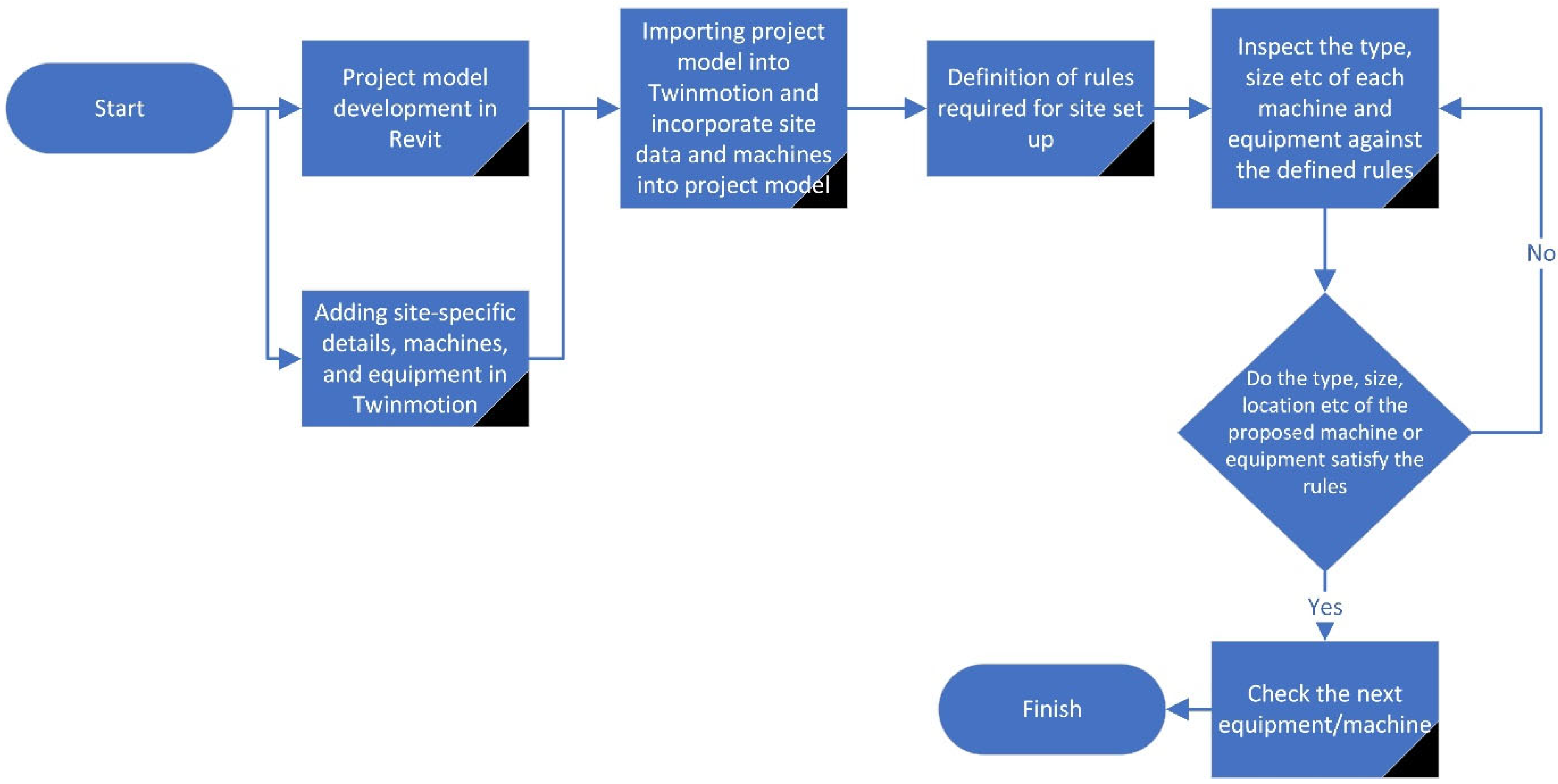

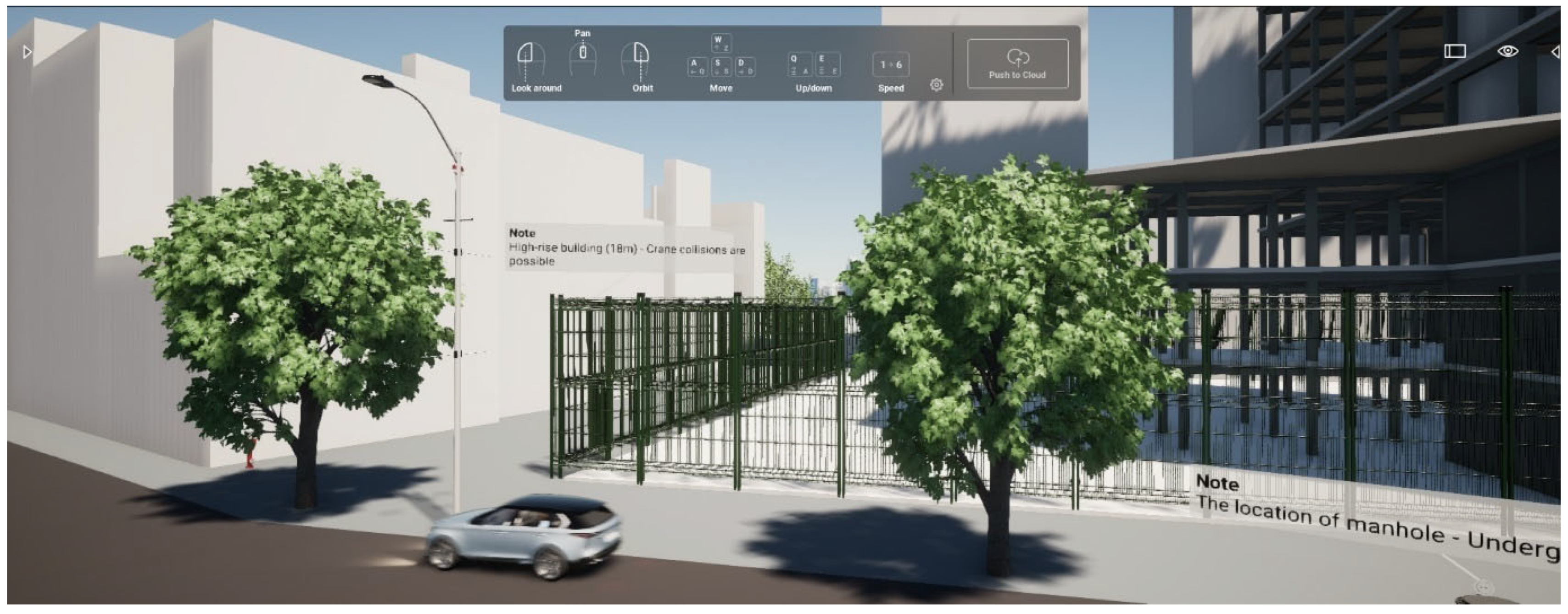

4.2. Case Study 2: Construction Site Mobilization Through the Integration of BIM and IMT

5. Results

5.1. Literature Review Findings

5.2. Case Study Results

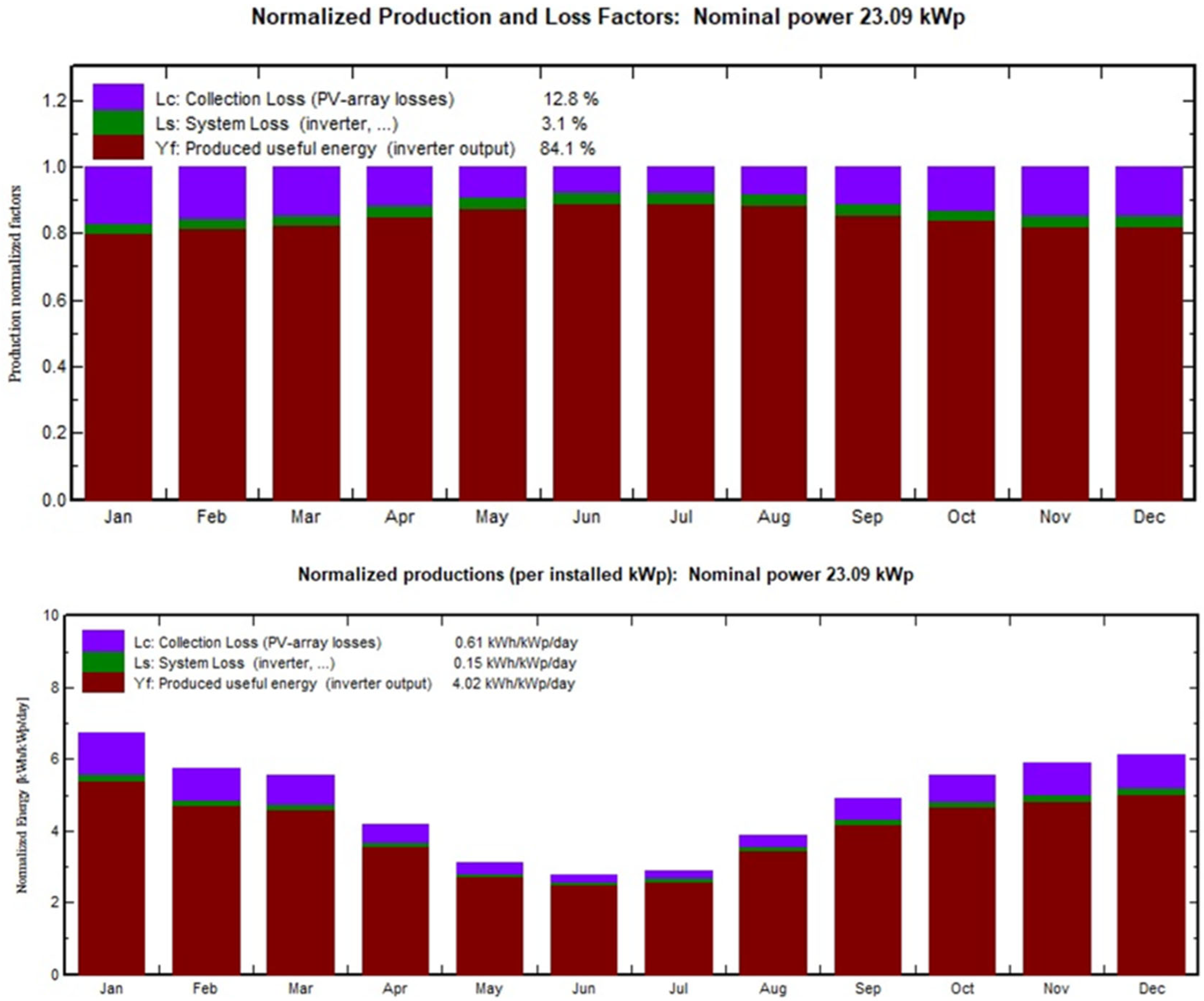

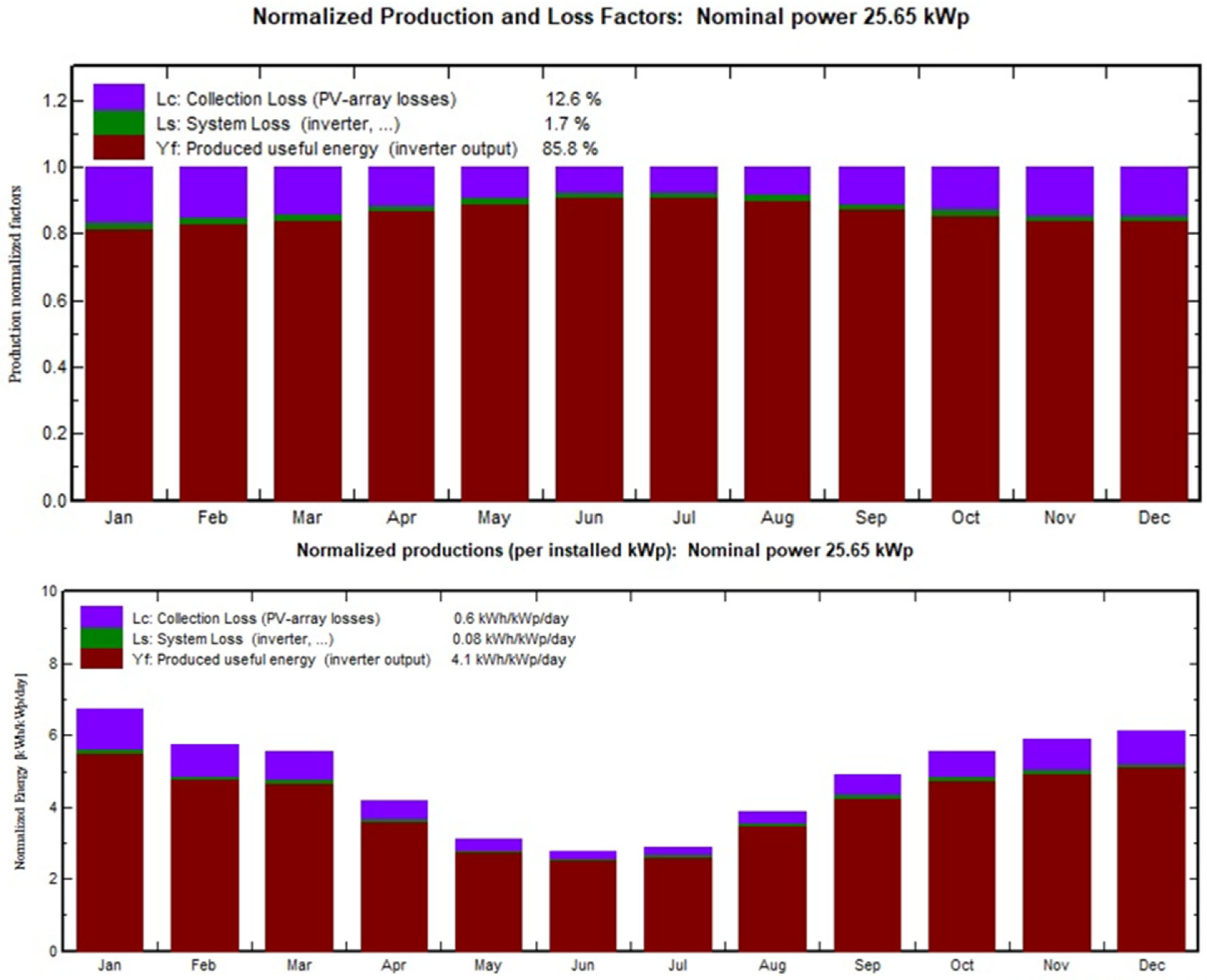

5.2.1. Case Study 1 Results: Solar Panel Placement Optimization

- Travel distance can vary, and consequently, the estimated travel cost may fluctuate significantly.

- In the IMT-enabled approach, an immersive technology technician with the appropriate skill set is hired to carry out remote assessments.

- The cost of software licenses is variable and depends on the type and scope of licensing agreements.

- The number of days needed for physical site visits and IMT model generation depends on the project’s size and complexity. Here, we assume two full days for physical assessment and IMT model creation for each project. This allocation is based on the assumption that the BIM model can be produced within a short timeframe, as it only requires the 3D geometry of the rooftop and the precise location of MEP equipment at roof level.

5.2.2. Case Study 2 Results: Construction Site Mobilization

6. Discussion

6.1. Theoretical Implications

6.2. Comparative Analysis: IMT Versus Traditional Assessment Methods

6.3. Implementation Challenges and Practical Considerations

6.3.1. Technical Barriers

6.3.2. Human and Skills-Related Barriers

6.3.3. Organizational and Cultural Barriers

6.3.4. Economic and Contractual Barriers

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Love, P.E.D.; Li, H. Quantifying the causes and costs of rework in construction. Constr. Manag. Econ. 2000, 18, 479–490. [Google Scholar] [CrossRef]

- Jingmond, M.; Ågren, R. Unravelling causes of defects in construction. Constr. Innov. 2015, 15, 198–218. [Google Scholar] [CrossRef]

- Arditi, D.; Gunaydin, H.M. Perceptions of Process Quality in Building Projects. J. Manag. Eng. 1999, 15, 43–53. [Google Scholar] [CrossRef]

- Kazar, G.; Doğan, N.B.; Ayhan, B.U.; Tokdemir, O.B. Quality Failures–Based Critical Cost Impact Factors: Logistic Regression Analysis. J. Constr. Eng. Manag. 2022, 148, 04022138. [Google Scholar] [CrossRef]

- Kamat, V.R.; Martinez, J.C.; Fischer, M.; Golparvar-Fard, M.; Peña-Mora, F.; Savarese, S. Research in Visualization Techniques for Field Construction. J. Constr. Eng. Manag. 2011, 137, 853–862. [Google Scholar] [CrossRef]

- Sacks, R.; Pikas, E. Building Information Modeling Education for Construction Engineering and Management. I: Industry Requirements, State of the Art, and Gap Analysis. J. Constr. Eng. Manag. 2013, 139, 04013016. [Google Scholar] [CrossRef]

- Wang, P.; Wu, P.; Wang, J.; Chi, H.-L.; Wang, X. A Critical Review of the Use of Virtual Reality in Construction Engineering Education and Training. Int. J. Environ. Res. Public Health 2018, 15, 1204. [Google Scholar] [CrossRef]

- Park, C.-S.; Lee, D.-Y.; Kwon, O.-S.; Wang, X. A framework for proactive construction defect management using BIM, augmented reality and ontology-based data collection template. Autom. Constr. 2013, 33, 61–71. [Google Scholar] [CrossRef]

- Cho, J.; Kim, S.; Kim, N.; Kang, S. Development of a Remote Collaboration System for Interactive Communication with Building Information Model in Mixed Reality. Appl. Sci. 2022, 12, 8738. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Kang, S.-C.; Al-Hussein, M. Virtual reality applications for the built environment: Research trends and opportunities. Autom. Constr. 2020, 118, 103311. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, M.; Fan, X.; Sun, Z.; Li, M.; Li, W.; Huang, L. Extended Reality for Safe and Effective Construction Management: State-of-the-Art, Challenges, and Future Directions. Buildings 2023, 13, 155. [Google Scholar] [CrossRef]

- Love, P.E.D.; Edwards, D.J.; Irani, Z.; Walker, D.H.T. Project Pathogens: The Anatomy of Omission Errors in Construction and Resource Engineering Project. IEEE Trans. Eng. Manag. 2009, 56, 425–435. [Google Scholar] [CrossRef]

- Balouchi, M.; Gholhaki, M.; Niousha, A. Reworks causes and related costs in construction: Case of Parand mass housing project in Iran. Int. J. Qual. Reliab. Manag. 2019, 36, 1392–1408. [Google Scholar] [CrossRef]

- Ford, G.; Gosling, J.; Naim, M. On quality and complexity: Non-conformance failures, management perspectives and learning outcomes on a highways megaproject. Int. J. Qual. Reliab. Manag. 2023, 40, 2539–2558. [Google Scholar] [CrossRef]

- Ghafoor, S.; Gurmu, A.; Sadick, A.-M.; Kite, J. Compliance risks in the construction of residential buildings: A systematic literature review. Smart Sustain. Built Environ. 2025, 1–29. [Google Scholar] [CrossRef]

- Hudson, F.S.; Sutrisna, M.; Chawynski, G. A certification framework for managing the risks of non-compliance and non-conformance building products: A Western Australian perspective. Int. J. Build. Pathol. Adapt. 2020, 39, 312–343. [Google Scholar] [CrossRef]

- Lambers, R.; Lamari, F.; Skitmore, M.; Rajendra, D. Key residential construction defects: A framework for their identification and correlated causes. Constr. Innov. 2023, 24, 1425–1459. [Google Scholar] [CrossRef]

- Salleh, N.M.; Alang, N.; Saberi, M.H.; Mamter, S.; Sohod, Z.B.M. Factors affecting quality of workmanship in building construction. Int. J. Acad. Res. Bus. Soc. Sci. 2022, 7, 1620–1628. [Google Scholar] [CrossRef]

- Suleiman, A. Causes and effects of poor communication in the construction industry in the MENA region. J. Civ. Eng. Manag. 2022, 28, 365–376. [Google Scholar] [CrossRef]

- Burati, J.L.; Farrington, J.J.; Ledbetter, W.B. Causes of Quality Deviations in Design and Construction. J. Constr. Eng. Manag. 1992, 118, 34–49. [Google Scholar] [CrossRef]

- Keane, P.; Sertyesilisik, B.; Ross, A.D. Variations and Change Orders on Construction Projects. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2010, 2, 89–96. [Google Scholar] [CrossRef]

- Wu, C.-H.; Hsieh, T.-Y.; Cheng, W.-L. Statistical analysis of causes for design change in highway construction on Taiwan. Int. J. Proj. Manag. 2005, 23, 554–563. [Google Scholar] [CrossRef]

- Atkinson, A.R. The role of human error in construction defects. Struct. Surv. 1999, 17, 231–236. [Google Scholar] [CrossRef]

- London, K.; Pablo, Z.; Gu, N. Explanatory defect causation model linking digital innovation, human error and quality improvement in residential construction. Autom. Constr. 2021, 123, 103505. [Google Scholar] [CrossRef]

- Lopez, R.; Love, P.E.D.; Edwards, D.J.; Davis, P.R. Design Error Classification, Causation, and Prevention in Construction Engineering. J. Perform. Constr. Facil. 2010, 24, 399–408. [Google Scholar] [CrossRef]

- Hartung, J.F. Errors and Omissions Policies in thr Construction Process. Real Prop. Probate Trust J. 1982, 17, 666–673. [Google Scholar]

- Wilson, J.U.; Odesola, I.A. Design-Related Causes of Rework and the Performance of Oil and Gas Projects in Nigeria. Int. J. Sustain. Constr. Eng. Technol. 2017, 8, 60–76. [Google Scholar]

- Li, X.; Yi, W.; Chi, H.-L.; Wang, X.; Chan, A.P.C. A critical review of virtual and augmented reality (VR/AR) applications in construction safety. Autom. Constr. 2018, 86, 150–162. [Google Scholar] [CrossRef]

- Chalhoub, J.; Ayer, S.K. Using Mixed Reality for electrical construction design communication. Autom. Constr. 2018, 86, 1–10. [Google Scholar] [CrossRef]

- Zaher, M.; Greenwood, D.; Marzouk, M. Mobile augmented reality applications for construction projects. Constr. Innov. 2018, 18, 152–166. [Google Scholar] [CrossRef]

- Lin, J.J.; Golparvar-Fard, M. Visual and virtual progress monitoring in Construction 4.0. In Construction 4.0; Routledge: Abingdon, UK, 2020; pp. 240–263. [Google Scholar]

- Chen, Y.-J.; Lai, Y.-S.; Lin, Y.-H. BIM-based augmented reality inspection and maintenance of fire safety equipment. Autom. Constr. 2020, 110, 103041. [Google Scholar] [CrossRef]

- Eswaran, M.; Inkulu, A.k.; Tamilarasan, K.; Bahubalendruni, M.V.A.R.; Jaideep, R.; Faris, M.S.; Jacob, N. Optimal layout planning for human robot collaborative assembly systems and visualization through immersive technologies. Expert Syst. Appl. 2024, 241, 122465. [Google Scholar] [CrossRef]

- Sacks, R.; Brilakis, I.; Pikas, E.; Xie, H.S.; Girolami, M. Construction with digital twin information systems. Data-Centric Eng. 2020, 1, e14. [Google Scholar] [CrossRef]

- Li, R.Y.M.; Chau, K.W.; Ho, D.C.w. AI Object Detection, Holographic Hybrid Reality and Haemodynamic Response to Construction Site Safety Risks. In Current State of Art in Artificial Intelligence and Ubiquitous Cities; Li, R.Y.M., Chau, K.W., Ho, D.C.W., Eds.; Springer Nature: Singapore, 2022; pp. 117–134. [Google Scholar]

- Davila Delgado, J.M.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Golparvar-Fard, M.; Peña-Mora, F.; Savarese, S. Automated Progress Monitoring Using Unordered Daily Construction Photographs and IFC-Based Building Information Models. J. Comput. Civ. Eng. 2015, 29, 04014025. [Google Scholar] [CrossRef]

- Behzadan, A.H.; Dong, S.; Kamat, V.R. Augmented reality visualization: A review of civil infrastructure system applications. Adv. Eng. Inform. 2015, 29, 252–267. [Google Scholar] [CrossRef]

- Alkan, I.B.; Basaga, H.B. Augmented reality technologies in construction project assembly phases. Autom. Constr. 2023, 156, 105107. [Google Scholar] [CrossRef]

- Bosché, F.; Abdel-Wahab, M.; Carozza, L. Towards a Mixed Reality System for Construction Trade Training. J. Comput. Civ. Eng. 2016, 30, 04015016. [Google Scholar] [CrossRef]

- Li, W.; Huang, H.; Solomon, T.; Esmaeili, B.; Yu, L.F. Synthesizing Personalized Construction Safety Training Scenarios for VR Training. IEEE Trans. Vis. Comput. Graph. 2022, 28, 1993–2002. [Google Scholar] [CrossRef]

- Dunston, P.S.; Wang, X. Mixed Reality-Based Visualization Interfaces for Architecture, Engineering, and Construction Industry. J. Constr. Eng. Manag. 2005, 131, 1301–1309. [Google Scholar] [CrossRef]

- Tan, Y.; Xu, W.; Chen, P.; Zhang, S. Building defect inspection and data management using computer vision, augmented reality, and BIM technology. Autom. Constr. 2024, 160, 105318. [Google Scholar] [CrossRef]

- Grant, M.J.; Booth, A. A typology of reviews: An analysis of 14 review types and associated methodologies. Health Inf. Libr. J. 2009, 26, 91–108. [Google Scholar] [CrossRef] [PubMed]

- Guerin, B.; Janta, B.; van Gorp, A. Desk-based research and literature review. In Evaluating Interventions that Prevent or Counter Violent Extremism; RAND Corporation: Santa Monica, CA, USA, 2018; Volume 63. [Google Scholar]

- Munn, Z.; Peters, M.D.J.; Stern, C.; Tufanaru, C.; McArthur, A.; Aromataris, E. Systematic review or scoping review? Guidance for authors when choosing between a systematic or scoping review approach. BMC Med. Res. Methodol. 2018, 18, 143. [Google Scholar] [CrossRef] [PubMed]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- K Robert, Y. Case Study Research and Applications: Design and Methods; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Miles, M.B. Qualitative Data Analysis: An Expanded Sourcebook; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 1994. [Google Scholar]

- Stake, R. Case Study Research; Springer: Cham, Switzerland, 1995. [Google Scholar]

- Ellis, C.; Adams, T.; Bochner, A. Autoethnography: An overview. Forum Qual. Res. 2011, 12, 273–290. [Google Scholar]

- Muncey, T. Doing Autoethnography. Int. J. Qual. Methods 2005, 4, 69–86. [Google Scholar] [CrossRef]

- Cunningham, S.J.; Jones, M. Autoethnography: A tool for practice and education. In Proceedings of the 6th ACM SIGCHI New Zealand Chapter’s International Conference on Computer-Human Interaction: Making CHI Natural, Auckland, New Zealand, 7–8 July 2005; pp. 1–8. [Google Scholar]

- Kennett, C.L. Autoethnography as Method by H. Chang. Int. J. Multicult. Educ. 2010, 12, 1–2. [Google Scholar] [CrossRef]

- Butz, D.; Besio, K. The Value of Autoethnography for Field Research in Transcultural Settings. Prof. Geogr. 2004, 56, 350–360. [Google Scholar] [CrossRef]

- de Sá, B.A.; Dezuo, T.; Ohf, D. Shadow modelling algorithm for photovoltaic systems analysis and simulation. In Proceedings of the Congresso Brasileiro de Automática-CBA, Online, 23–26 November 2020. [Google Scholar]

- Twinmotion. Twinmotion: A Cutting-Edge Real-Time Visualization Tool. 2024. Available online: https://www.twinmotion.com/en-US (accessed on 20 March 2024).

- Love, P.E.D.; Matthews, J.; Ika, L.A.; Teo, P.; Fang, W.; Morrison, J. From Quality-I to Quality-II: Cultivating an error culture to support lean thinking and rework mitigation in infrastructure projects. Prod. Plan. Control 2023, 34, 812–829. [Google Scholar] [CrossRef]

- Babalola, I.H.; Aigbavboa, C.O.; Aliu, J.; Oke, A.E. Influence of emotional intelligence attributes on human resource management practices implementation in the Nigerian construction industry. J. Eng. Des. Technol. 2025, 23, 935–952. [Google Scholar] [CrossRef]

| Quality Failure Terms | Main Causes | References |

|---|---|---|

| Rework | - Design errors and omissions. - Poor communication and coordination. - Inadequate planning and scheduling. - Ineffective quality control and assurance. - Scope creep and uncontrolled changes. - Incomplete or inaccurate as-built documentation | [1,13,27] |

| Non-conformance | - Inadequate quality planning and control. - Lack of understanding of requirements and specifications. - Poor workmanship and human error. - Use of non-compliant or defective materials. - Inadequate inspection and testing. - Lack of training and competency of personnel. - Ineffective communication and coordination. | [14,15,16] |

| Defects | - Poor workmanship and lack of skill. - Use of substandard or defective materials. - Inadequate supervision and quality control. - Inadequate design specifications and detailing. - Poor site conditions and environmental factors. - Lack of adherence to construction procedures and standards. - Damage during handling or installation. | [2,17,18] |

| Deviations | - Design changes and modifications. - Unforeseen site conditions. - Unavailability of specified materials or equipment. - Changes in client requirements or preferences. - Inadequate planning and scheduling. - Poor communication and coordination. - Lack of adherence to approved plans and specifications. | [19,20,21,22] |

| Errors | - Lack of experience or competency of personnel. - Inadequate design reviews and verifications. - Poor communication and coordination. - Inadequate or unclear project information. - Time pressures and workload. - Lack of attention to detail. - Inadequate use of technology and automation. - Human factors such as fatigue. | [23,24,25] |

| Omissions | - Inadequate design reviews and coordination. - Lack of detailed and comprehensive project documentation. - Poor communication and information sharing. - Time and cost pressures. - Lack of experience or knowledge of project requirements. - Ineffective use of checklists and quality control tools.—Human errors and oversights. | [12,20,25,26] |

| Quality Failure Type | Specific Failure Types | Root Causes | Traditional Detection Point | IMT Prevention Mechanism | Specific IMT Applications | Supporting Evidence |

|---|---|---|---|---|---|---|

| Rework | Design coordination rework MEP system relocations Structural modifications Architectural refinishing | Spatial clash conflicts Interface misalignments Specification contradictions As-built deviations | During coordination meetings or after construction on site | Proactive design validation: Virtual clash detection and spatial coordination | VR multi-discipline design reviews AR spatial conflict visualization Real-time design coordination | [8,34] |

| Non-conformance | Incorrect material installation Non-compliant construction methods Specification deviations Code violation installations | Specification misinterpretation Inadequate work instructions Communication gaps Insufficient verification | Site inspections and QA/QC checks | Real-time compliance monitoring: Specification verification at point of installation | AR specification overlay during installation Digital compliance checklists Real-time code verification | [29,32] |

| Defects | Surface finish defects Dimensional inaccuracies Joint and connection failures Material degradation issues Workmanship defects | Inadequate workmanship Environmental exposure Material handling damage Insufficient quality control Low skills | Quality inspections and punch-list reviews | Predictive quality control: Process Standardization and environmental monitoring | VR workmanship training AR dimensional verification Environmental condition monitoring MR for construction trade training | [11,40,41] |

| Deviations | Unauthorised design changes Material substitutions Construction sequence modifications Dimensional adjustments | Field condition adaptations Material availability issues Construction constraints Communication breakdowns | Change order submissions and design review meetings | Controlled change management: Impact simulation and stakeholder coordination | VR change impact simulation AR site condition documentation Collaborative decision platforms | [36,37] |

| Errors | Measurement and layout errors Installation sequence mistakes Connection and assembly errors Calculation and planning errors Workmanship errors Design coordination errors | Human oversight Information complexity Time pressures Experience limitations Lack of understanding of project processes | On-site verification or after error discovery during construction | Cognitive support systems: Information delivery, training and decision assistance | AR measurement guidance VR sequence training Step-by-step installation guidance MR for construction trade training MR for design comprehension and collaboration | [38,40,42] |

| Omissions | Missing building components Incomplete installations Absent safety features Documentation gaps | Checklist oversights Communication failures Documentation inadequacies Inspection limitations | Final walkthroughs, handover inspections, or client snagging | Systematic verification: Mandatory completion checklists with visual verification | AR completion status overlay VR comprehensive walkthroughs Digital progress tracking | [31,39] |

| Simulation Parameters | 90 Modules | 82 Modules |

|---|---|---|

| Site | Melbourne | Melbourne |

| System type | Grid-Connected | Grid-Connected |

| Simulation period | 1 January–31 December | 1 January–31 December |

| PV module type | 72 cells | 72 cells |

| Inventor unit power | 7.5 kW | 4.2 kW |

| System production | 38.3 MWh/year | 33.8 MWh/year |

| Normalized production | 4.10 kWh/kWp/day | 4.02 kWh/kWp/day |

| PV-array losses | 12.6% | 12.8% |

| Array losses | 0.60 kWh/KWp/day | 0.61 kWh/KWp/day |

| Produced Useful Energy | 85.8% | 84.1% |

| Case Study | IMT Technology Used | Quality Failure Category | Specific Failure Type | Specific Prevention Mechanism | Outcome Achievement |

|---|---|---|---|---|---|

| Case study 1: PV Panels Layout design: BIM–UE5 integration enabled 3D shadow analysis across all seasons, optimizing placement from 82 to 90 modules. | Unreal Engine 5 + Revit + Rhino 3D + Grasshopper | Rework | Panel repositioning due to shading miscalculations | Preventing panel repositioning |

|

| Non-conformance | Compliance with mounted PV installation | Ensured clearance compliance pre-installation | Visualized real-time compliance checking | ||

| Errors |

| Eliminated shading-related performance losses |

| ||

| Case study 2: Site mobilization: Revit–Twinmotion workflow enabled spatially accurate equipment placement | Revit + Twinmotion | Rework | Equipment repositioning due to spatial conflicts. For example, the locations of manholes and the loading bay. | Prevented repositioning cycles |

|

| Non-conformance | Safety clearance violations | Twinmotion verified crane access, site access, spacing, and utility clearances | Optimized site use | ||

| Errors | Site congestion and spatial clashes | Prevented sequence-related errors |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahankoob, A.; Abbasnejad, B.; Soltani, S.; Na, R. Immersive Technology Integration for Improved Quality Assurance and Assessment Jobs in Construction. Architecture 2025, 5, 107. https://doi.org/10.3390/architecture5040107

Ahankoob A, Abbasnejad B, Soltani S, Na R. Immersive Technology Integration for Improved Quality Assurance and Assessment Jobs in Construction. Architecture. 2025; 5(4):107. https://doi.org/10.3390/architecture5040107

Chicago/Turabian StyleAhankoob, Alireza, Behzad Abbasnejad, Sahar Soltani, and Ri Na. 2025. "Immersive Technology Integration for Improved Quality Assurance and Assessment Jobs in Construction" Architecture 5, no. 4: 107. https://doi.org/10.3390/architecture5040107

APA StyleAhankoob, A., Abbasnejad, B., Soltani, S., & Na, R. (2025). Immersive Technology Integration for Improved Quality Assurance and Assessment Jobs in Construction. Architecture, 5(4), 107. https://doi.org/10.3390/architecture5040107