Impact of Bioinspired Infill Pattern on the Thermal and Energy Efficiency of 3D Concrete Printed Building Envelope

Abstract

1. Introduction

Literature Review

| Title | Authors | Materials and Methods | Results and Findings |

|---|---|---|---|

| Computational assessment of thermal performance of 3D-printed concrete wall structures with cavities | Marais et al., 2021 [18] | The research used the finite element method (FEM) to analyze the thermal performance of 3D-printed concrete wall structures with different cavity arrangements and materials. | The study found that the thermal performance of 3DCP walls with cavities is material dependent. The inclusion of cavities in lightweight foam concrete walls with lower thermal conductivity worsens their thermal performance, while the inclusion of cavities in high-performance concrete walls with higher thermal conductivity improves their thermal performance in summer. |

| Developing an integrated 3D-printed façade with complex geometries for active temperature | Sarakinioti et al., 2018 [16] | The research followed a methodology that involved the design and production of facade panels using 3DP technology. The research involved simulations to understand the thermal effects of the system on indoor spaces in different climates. The methodology was interdisciplinary, involving researchers from various fields. | The study found that integrating multiple functions for optimizing thermal performances and creating mono-material structures is possible with 3DP technology. It proved that low thermal conductivity is achievable by controlling the size and geometry of the cells, and the material is a major parameter for achieving low thermal conductivity. |

| Energy efficient 3D-printed buildings: Material and techniques selection worldwide study | Alkhalidi and Hatuqay, 2020 [5] | The research followed a methodology that involved designing wall configurations using Ansys Workbench to achieve a thermal transmittance that complies with national regulations for each climatic zone. The results were then plotted in Autodesk Revit and Green Building Studio energy simulation to determine the energy demand of the designed structure. | The study found that a balance between cavities and 3D-printed material should be maintained to achieve the desired U-values and structural performance. The researchers also estimated the annual energy demand for each climatic zone, indicating that the building’s annual energy demand depends mainly on the difference between the ambient air and the indoor temperatures. |

| Energy Performance of 3D-Printed Concrete Walls: A Numerical Study | Suntharalingam et al., 2021 [7] | The research followed a methodology that involved conducting numerical simulations and analysis to determine the U-values of different 3D-printed concrete (3DPC) wall configurations. The study included a series of 32 simulations with different 3DPC wall configurations, and the results were interpreted to draw conclusions about the energy performance of the walls. | The study found that the 3D-printed concrete cavity walls had low energy performance, as the U-values did not meet standard regulations. However, their performance improved with cavity insulation, resulting in a minimum thermal transmittance value of 0.34 W/mK. Additionally, the study proposed a suitable equation to find the U-values of 100 mm-thick cavity wall panels with different configurations. |

2. Materials and Methods

2.1. Bioinspired Patterns Identification and Shortlisting

2.2. Thermal Performance Testing

2.3. Energy Performance Testing

2.4. Model Validation

2.5. Design Criteria

3. Results and Findings

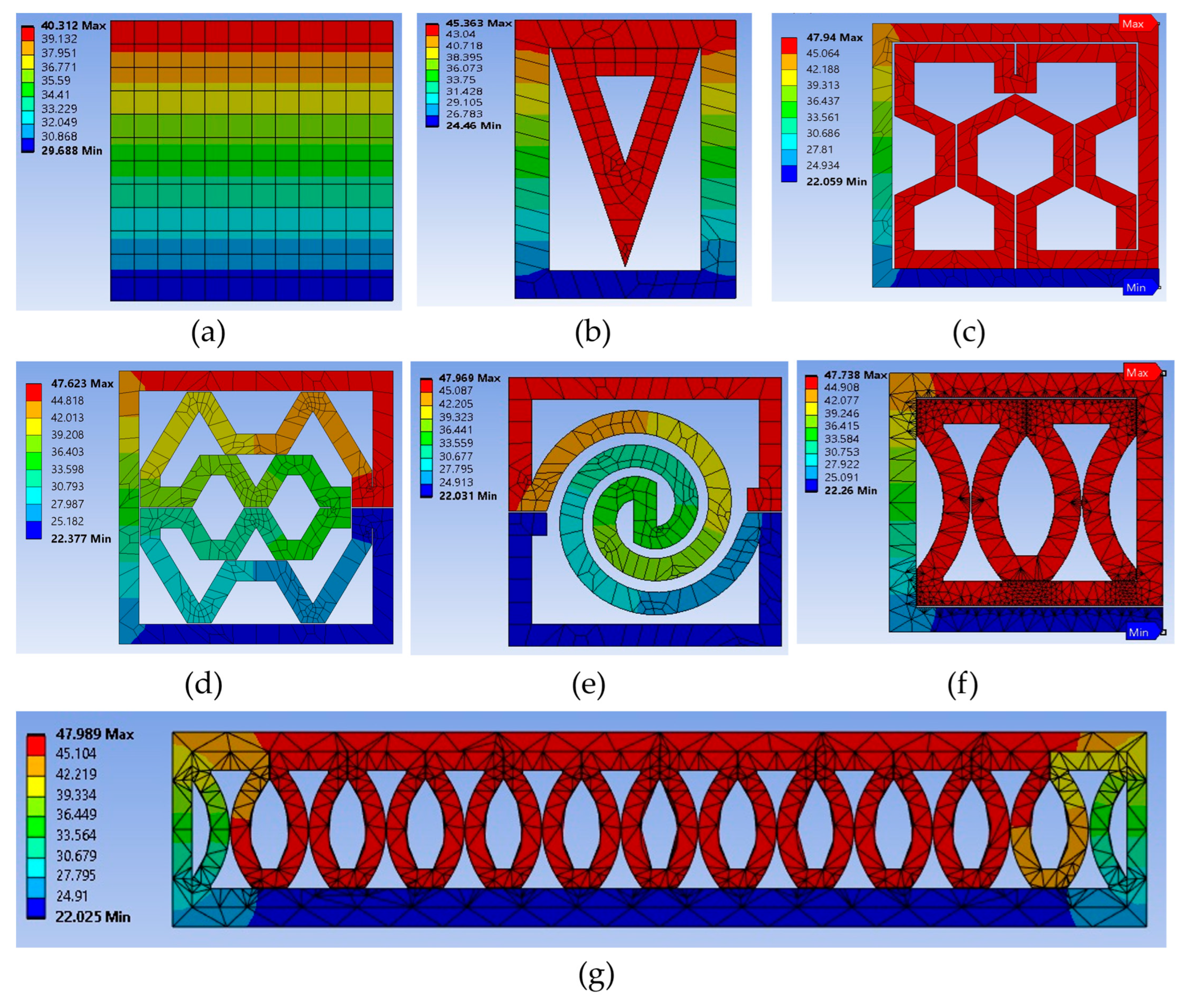

3.1. Thermal Performance Analysis

3.1.1. Simulation Experiment

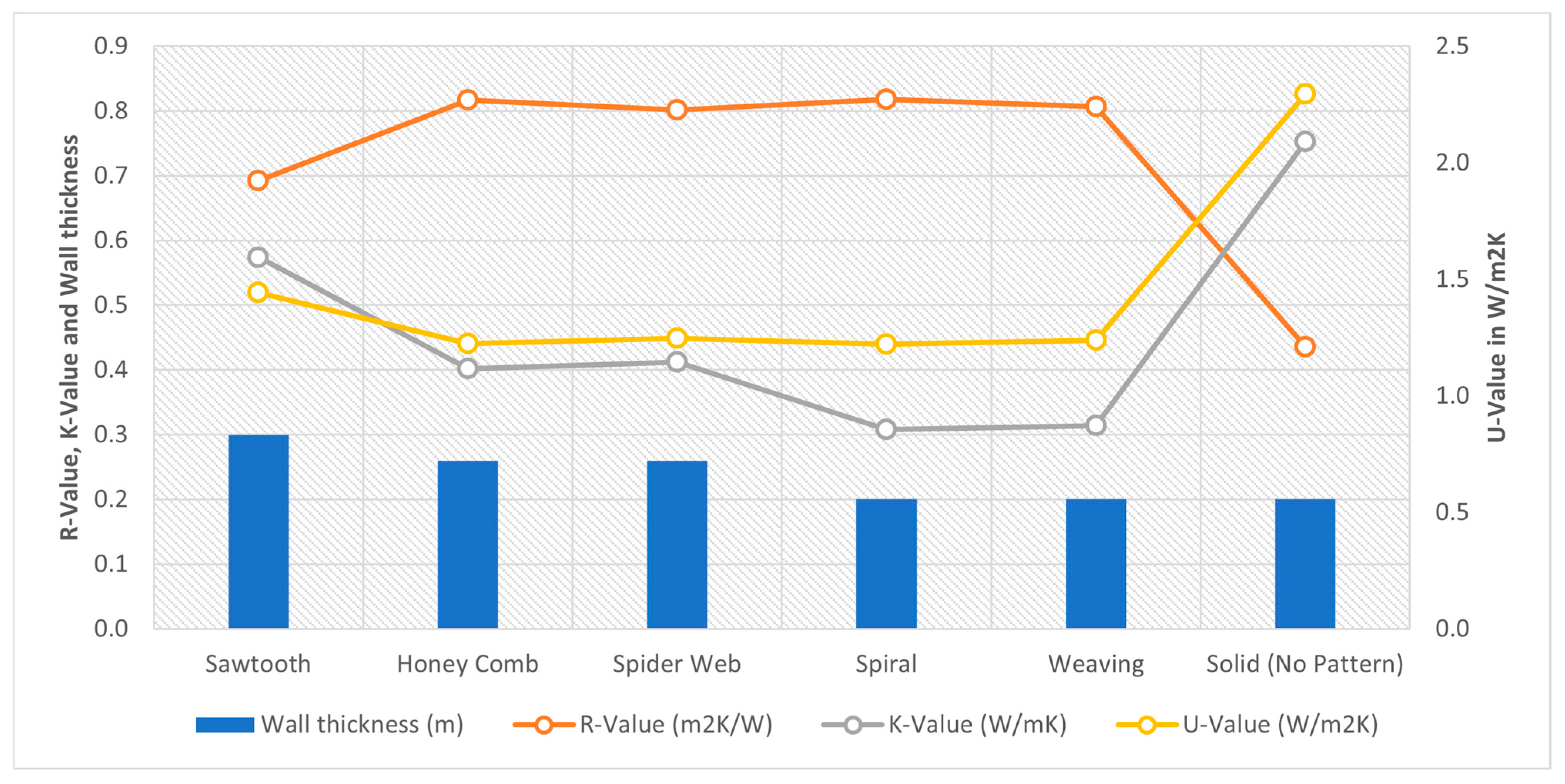

3.1.2. Findings of Thermal Analysis

3.2. Energy Performance Analysis

4. Discussion

4.1. Thermal Analysis

4.2. Energy Analysis

5. Conclusions

- The spiral pattern showed strong thermal performance with a U-value of 1.22 W/m2K, over 45% more efficient than the cast concrete U-value of 2.3 W/m2K. The other three bioinspired patterns: honeycomb, weaving, and spiderweb’s thermal performance are also comparable with the spiral pattern.

- A significant reduction in the U-value of the cavity walls was observed compared to the solid concrete wall. However, the pattern of the cavity played a significant role in reducing the thermal transmittance value further.

- From the energy efficiency perspective, the spiral pattern performed well and saved energy by almost 43% compared to the conventional solid cast concrete building. Following the spiral are the other three patterns: honeycomb, weaving, and spiderweb.

- In comparison to the common sawtooth pattern, the performance of almost all the bioinspired patterns is higher in terms of thermal and energy efficiency. In thermal and energy efficiency, almost all the bioinspired patterns are nearly 15% more efficient than the common sawtooth pattern used in 3DCP buildings.

- In material saving, all the 3D-printed patterns saved 25% to 40% of material in comparison to the solid concrete, which makes it a sustainable alternative to the conventional construction system.

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3DCP, 3DPC | 3-Dimensional Concrete Printing |

| 3DP | 3-Dimensional Printing |

| FEM | Finite Element Method |

| U | Thermal Transmittance |

| R | Thermal Resistance |

| K | Thermal Conductivity |

| ABC | Acrylonitrile Butadiene Styrene |

| PLA | Poly Lactic Acid |

| IES | Integrated Environmental Solutions |

| GBS | Green Building Studio |

| L + H | Ladybug + Honeybee |

References

- United Nations Environment Program. 2020 Global Status Report for Buildings and Construction—Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector, Nairobi. 2020. Available online: https://globalabc.org/sites/default/files/inline-files/2020%20Buildings%20GSR_FULL%20REPORT.pdf (accessed on 10 March 2025).

- Kaszyńska, M.; Skibicki, S.; Hoffmann, M. 3D Concrete Printing for Sustainable Construction. Energies 2020, 13, 6351. [Google Scholar] [CrossRef]

- Kellert, S.R.; Heerwagen, J.H.; Mador, M.L. Biophilic Design; John Wiley & Sons, Inc.: New York, NY, USA, 2008. [Google Scholar]

- Gruber, P. Biomimetics—Materials, Structures and Processes; Springer: Berlin/Heidelberg, Germany, 2011; pp. 127–148. [Google Scholar] [CrossRef]

- Alkhalidi, A.; Hatuqay, D. Energy efficient 3D printed buildings: Material and techniques selection worldwide study. J. Build. Eng. 2020, 30, 101286. [Google Scholar] [CrossRef]

- Rattanongphisat, W.; Rordprapat, W. Strategy for energy efficient buildings in tropical climate. Energy Procedia 2014, 52, 10–17. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Upasiri, I.; Gatheeshgar, P.; Poologanathan, K.; Nagaratnam, B.; Santos, P.; Rajanayagam, H. Energy Performance of 3D-Printed Concrete Walls: A Numerical Study. Buildings 2021, 11, 432. [Google Scholar] [CrossRef]

- Abdel-Rahman, W.S.M. Thermal performance optimization of parametric building envelope based on bio-mimetic inspiration. Ain Shams Eng. J. 2021, 12, 1133–1142. [Google Scholar] [CrossRef]

- Webb, M. Biomimetic building facades demonstrate potential to reduce energy consumption for different building typologies in different climate zones. Clean Technol. Environ. Policy 2021, 24, 493. [Google Scholar] [CrossRef] [PubMed]

- Chirat, R.; Goriely, A.; Moulton, D.E. The physical basis of mollusk shell chiral coiling. Proc. Natl. Acad. Sci. USA 2021, 118, e2109210118. [Google Scholar] [CrossRef] [PubMed]

- Bhat, C.; Kumar, A.; Lin, S.-C.; Jeng, J.-Y. A novel bioinspired architectured materials with interlocking designs based on tessellation. Addit. Manuf. 2022, 58, 103052. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, X.; Li, P.; Huang, G.; Feng, S.; Shen, C.; Han, B.; Zhang, X.; Jin, F.; Xu, F.; et al. Bioinspired engineering of honeycomb structure—Using nature to inspire human innovation. Prog. Mater. Sci. 2015, 74, 332–400. [Google Scholar] [CrossRef]

- Regassa, Y.; Lemu, H.G.; Sirabizuh, B.; Rahimeto, S. Studies on the geometrical design of spider webs for reinforced composite structures. J. Compos. Sci. 2021, 5, 57. [Google Scholar] [CrossRef]

- Das, S.; Shanmugam, N.; Kumar, A.; Jose, S. Review: Potential of biomimicry in the field of textile technology. Bioinspired Biomim. Nanobiomaterials 2017, 6, 224–235. [Google Scholar] [CrossRef]

- Tamimi, A.A.; Hassan, H.; Rodriguez-Ubinas, E.; Alhaidary, H.; Mansouri, A. Thermal performance of 3D concrete printed walls: Calculated and in-situ measured U-values. J. Asian Archit. Build. Eng. 2023, 23, 1903–1915. [Google Scholar] [CrossRef]

- Sarakinioti, M.V.; Turrin, M.; Konstantinou, T.; Tenpierik, M.; Knaack, U. Developing an integrated 3D-printed façade with complex geometries for active temperature control. Mater. Today Commun. 2018, 15, 275–279. [Google Scholar] [CrossRef]

- Ha, N.S.; Lu, G. A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. Part B Eng. 2020, 181, 107496. [Google Scholar] [CrossRef]

- Marais, H.; Christen, H.; Cho, S.; De Villiers, W.; Van Zijl, G. Computational assessment of thermal performance of 3D printed concrete wall structures with cavities. J. Build. Eng. 2021, 41, 102431. [Google Scholar] [CrossRef]

- Abu Bakar, N.N.; Hassan, M.Y.; Abdullah, H.; Rahman, H.A.; Abdullah, M.P.; Hussin, F.; Bandi, M. Energy efficiency index as an indicator for measuring building energy performance: A review. Renew. Sustain. Energy Rev. 2015, 44, 1–11. [Google Scholar] [CrossRef]

- Jahan, A.; Mustapha, F.; Sapuan, S.M.; Ismail, M.Y.; Bahraminasab, M. A framework for weighting of criteria in ranking stage of material selection process. Int. J. Adv. Manuf. Technol. 2012, 58, 411–420. [Google Scholar] [CrossRef]

- Henrique Dos Santos, G.; Fogiatto, M.A.; Mendes, N. Numerical analysis of thermal transmittance of hollow concrete blocks. J. Build. Phys. 2017, 41, 7–24. [Google Scholar] [CrossRef]

- Roudsari, M.S.; Pak, M.; Viola, A. Ladybug: A parametric environmental plugin for grasshopper to help designers create an environmentally-conscious design. In Proceedings of the BS2013: 13th Conference of International Building Performance Simulation Association, Chambery, France, 26–28 August 2013; Volume 13, pp. 3128–3135. [Google Scholar]

- Mateus, N.M.; Pinto, A.; Da Graça, G.C. Validation of EnergyPlus thermal simulation of a double skin naturally and mechanically ventilated test cell. Energy Build. 2014, 75, 511–522. [Google Scholar] [CrossRef]

- Andelkovic, A.S.; Mujan, I.; Dakić, S. Experimental validation of a EnergyPlus model: Application of a multi-storey naturally ventilated double skin façade. Energy Build. 2016, 118, 27–36. [Google Scholar] [CrossRef]

- Reeves, T.; Olbina, S.; Issa, R. Validation of BEM Tools- Ecotect, Green Building Studio and IES. In Proceedings of the Winter Simulation Conference (WSC), Berlin, Germany, 9–12 December 2012; pp. 1–12. [Google Scholar] [CrossRef]

- Hu, J.; Wang, Z.; Chen, W. A Study on Automatic Form Optimization Procedures of Building Performance Design Based on “ladybug+Honeybee”. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 531. [Google Scholar] [CrossRef]

- Mahadevan, M.; Francis, A.; Thomas, A. A simulation-based investigation of sustainability aspects of 3D printed structures. J. Build. Eng. 2020, 32, 101735. [Google Scholar] [CrossRef]

- Blanco, J.M.; Frómeta, Y.G.; Madrid, M.; Cuadrado, J. Thermal performance assessment of walls made of three types of sustainable concrete blocks by means of fem and validated through an extensive measurement campaign. Sustainability 2021, 13, 386. [Google Scholar] [CrossRef]

- AlZahrani, A.A.; Alghamdi, A.A.; Basalah, A.A. Computational Optimization of 3D-Printed Concrete Walls for Improved Building Thermal Performance. Buildings 2022, 12, 2267. [Google Scholar] [CrossRef]

- Piccioni, V.; Turrin, M.; Tenpierik, M. A Performance-Driven Approach for the Design of Cellular Geometries with Low Thermal Conductivity for Application in 3D-Printed Façade Components. In Proceedings of the Symposium on Simulation for Architecture and Urban Design (SimAUD 2020), Virtual Event, 25–27 May 2020; Volume 37, pp. 327–344. Available online: https://repository.tudelft.nl/islandora/object/uuid%3A07b77206-404d-41dc-b55e-ef447686b856 (accessed on 10 March 2025).

- Al-Tamimi, A.S.; Al-Osta, M.A.; Al-Amoudi, O.S.B.; Ben-Mansour, R. Effect of Geometry of Holes on Heat Transfer of Concrete Masonry Bricks Using Numerical Analysis. Arab. J. Sci. Eng. 2017, 42, 3733–3749. [Google Scholar] [CrossRef]

- Kočí, V.; Bažantová, Z.; Černý, R. Computational analysis of thermal performance of a passive family house built of hollow clay bricks. Energy Build. 2014, 76, 211–218. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arumugam, G.; Kusumo, C.M.L.; Mari, T.S. Impact of Bioinspired Infill Pattern on the Thermal and Energy Efficiency of 3D Concrete Printed Building Envelope. Architecture 2025, 5, 77. https://doi.org/10.3390/architecture5030077

Arumugam G, Kusumo CML, Mari TS. Impact of Bioinspired Infill Pattern on the Thermal and Energy Efficiency of 3D Concrete Printed Building Envelope. Architecture. 2025; 5(3):77. https://doi.org/10.3390/architecture5030077

Chicago/Turabian StyleArumugam, Girirajan, Camelia May Li Kusumo, and Tamil Salvi Mari. 2025. "Impact of Bioinspired Infill Pattern on the Thermal and Energy Efficiency of 3D Concrete Printed Building Envelope" Architecture 5, no. 3: 77. https://doi.org/10.3390/architecture5030077

APA StyleArumugam, G., Kusumo, C. M. L., & Mari, T. S. (2025). Impact of Bioinspired Infill Pattern on the Thermal and Energy Efficiency of 3D Concrete Printed Building Envelope. Architecture, 5(3), 77. https://doi.org/10.3390/architecture5030077