Evaluation of the Physical and Mechanical Properties of Handmade Paints with Inorganic Pigments from Cusco According to American Society for Testing and Materials’ Standards for Architectural Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Extraction and Processing of Pigments

2.1.1. Selection of Pigment Sources

2.1.2. Pigment Processing Methods

- Sedimentation method (MS): the extracted materials were suspended in water and left at rest to allow particle separation by density. The settled material was then filtered and dried;

- Ball milling method (MG): a high-energy ball mill was used, operating at 300 rpm for 2 h, with the aim of achieving a finer and more homogeneous particle size distribution.

2.2. Formulation of Paints

2.2.1. Components of the Paint

2.2.2. Mixing and Preparation Process

2.2.3. Application on Test Panels

2.3. Environmental Exposure Testing and Pathology Assessment

2.3.1. Atmospheric Factor Exposure Testing (Natural Durability)

2.3.2. Pathology Assessment: Cracking, Delamination, and Blistering

2.3.3. Measurement of Chromatic Discoloration

2.3.4. Design of the Exposure Test and Sample Coding (See Table 1)

| Sample Code | Pigment Processing Method | Pigment Type | Binder Content (%) | Notes |

|---|---|---|---|---|

| MS-01 | Sedimentation (MS) | Natural ochre | 40 | Standard formulation |

| MS-02 | Sedimentation (MS) | Cusco red | 60 | High hematite content |

| MS-06 | Sedimentation (MS) | Yellow earth | 20 | Fine pigment |

| MS-14 | Sedimentation (MS) | Clayey brown | 40 | Variable granulometry |

| MG-02 | Ball Milling (MG) | Cusco red | 60 | High homogeneity |

| MG-06 | Ball Milling (MG) | Yellow earth | 20 | Medium dispersion |

| MG-14 | Ball Milling (MG) | Clayey brown | 40 | Well-ground pigment |

2.4. Quality Assessment According to ASTM Standards

2.4.1. Adhesion Test (ASTM D3359—Cross-Cut Method) [30]

2.4.2. Drying Time Assessment (ASTM D1640—Surface and Total Drying) [31]

- Surface drying: it is recommended to lightly press a dry cotton pad on the surface every 10 min until no residue remains;

- Total drying: this was evaluated by applying a standard weight of 100 g on the paint every 30 min until no marks were left.

2.4.3. Hardness Test (ASTM D3363—Pencil Hardness Method) [32]

2.5. Ethical Considerations and Data Availability

3. Results

3.1. Resistance to Atmospheric Factors in the City of Cusco

3.1.1. Pathology of Cracking MS and MG (See Figure 2)

- Figure 2 shows the results of the presence of surface cracking pathology in paint samples produced with inorganic pigments obtained through the sedimentation process (MS) and ball milling (MG), respectively, exposed to real atmospheric conditions in the city of Cusco for 15 weeks (S1 to S15), which included rainy seasons (high humidity) and dry seasons (sharp temperature changes ranging from 23 °C in the morning to −3 °C at night), representing the most extreme atmospheric characteristics of this city;

- On the vertical axis, the cumulative cracking index is quantified, expressed as the total number of visible cracks per evaluated surface area. It is observed that the MS-05 and MG-05 samples exhibit the highest cracking values, with 39 and 106 cracks, respectively, at the end of the test, indicating a lower structural stability of the paint film;

- In contrast, samples such as MS-01, MS-03, MG-01, and MG-03 show a more stable response, with significantly lower cracking levels, below 20 cracks in MS and 50 cracks in MG, suggesting a greater compatibility between pigment, binder, and substrate;

- These results indicate that the choice of pigment processing method (MS-MG) has a direct relationship with the mechanical behavior of the paint samples exposed to atmospheric factors in the city of Cusco.

3.1.2. Pathology of MS and MG Detachment (See Figure 3)

- Figure 3 illustrates the behavior of the paint samples in response to the delamination of paint film layers after progressive exposure to simulated environmental conditions over 15 weeks (S1 to S15), assessing the cumulative amount of delaminated areas per unit surface area. The vertical axis indicates the delamination index, measured in normalized units of affected area;

- In the samples with pigments processed by sedimentation (MS), delamination gradually increases starting from week 2, reaching a maximum of 21 units in MS-05, while the other samples remain between 11 and 19 units by the end of the test;

- On the other hand, the samples with pigments obtained through the ball milling process (MG) exhibit different behavior, as the detachment index reaches a value of 15 units from week 2 and remains almost constant until week 15 without significant increases, which demonstrates greater surface stability of the samples but with no evidence of progressive improvement;

- The milling process generates finer particles that favor effective initial adhesion, but without positive evolution against long-term environmental degradation. The method of obtaining the pigment through sedimentation shows greater variability and progression of deterioration related to the heterogeneous distribution of particle sizes, which compromises cohesion as the test progresses.

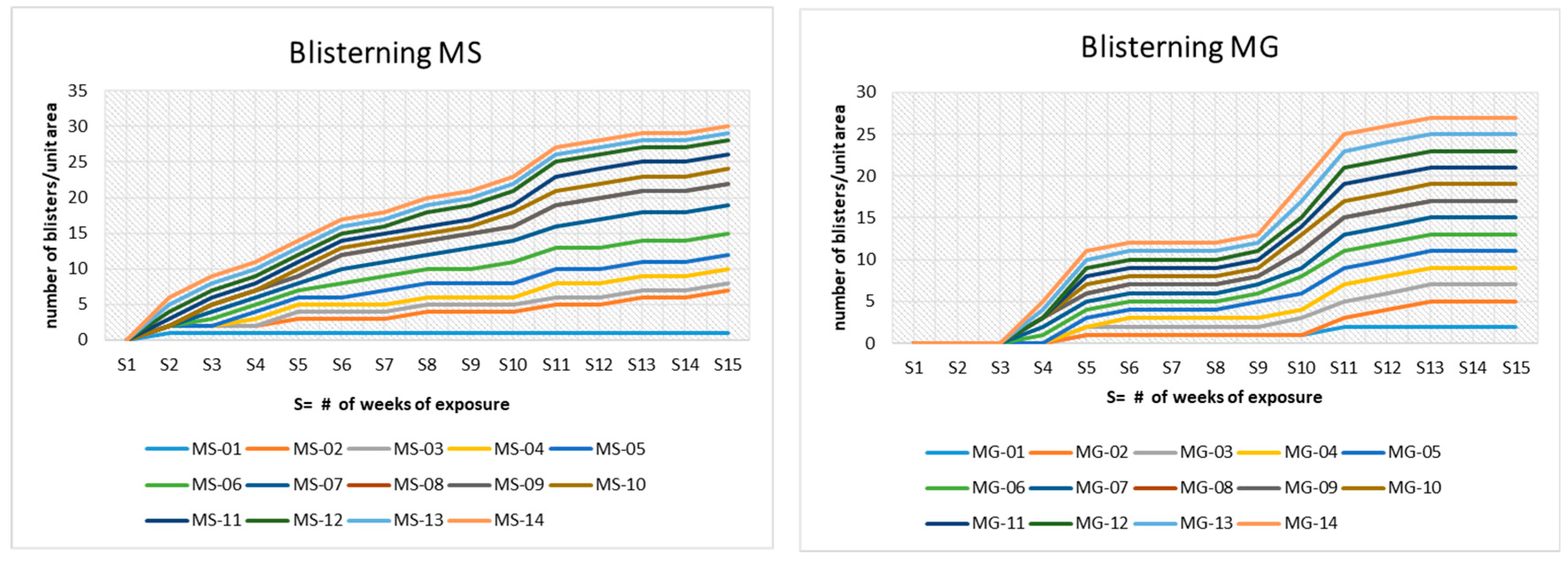

3.1.3. Blistering Pathology MS and MG (See Figure 4)

- Figure 4 illustrates the evolution of blistering pathology in the paint films exposed to the environmental conditions of Cusco, differentiating between two methods of pigment extraction (sedimentation—MS—and ball milling—MG); the vertical axis presents a quantitative index of the number of blisters per unit area, while the horizontal axis (S1–S15) indicates the amount of exposure time (weeks);

- In the MS samples, a progressive increase in blistering is observed starting from week 2, reaching maximum values of 32 units in MS-01 and 30 in MS-05, while the less affected samples, such as MS-06 and MS-07, do not exceed 18 units;

- Additionally, the MG samples show similar evidence regarding the progression of the pathology, but with a more evident acceleration between week 5 and week 10; starting from this week, the values stabilize, reaching a maximum of 28 units in MG-01;

- On average, the MG samples exhibit blistering values between 15 and 27 units, with a standard deviation of ±3.5, suggesting greater homogeneity in response to exposure to atmospheric factors in Cusco compared to the MS samples, which record a standard deviation of ±5.2;

- The difference can be attributed to the greater granulation regularity of the pigments obtained by milling with balls, which improves the internal distribution of the coating but does not necessarily enhance its resistance to moisture accumulation; in contrast, the sedimentation technique generates more irregular surfaces with greater susceptibility to moisture accumulation, which intensifies the blistering pathology in certain samples.

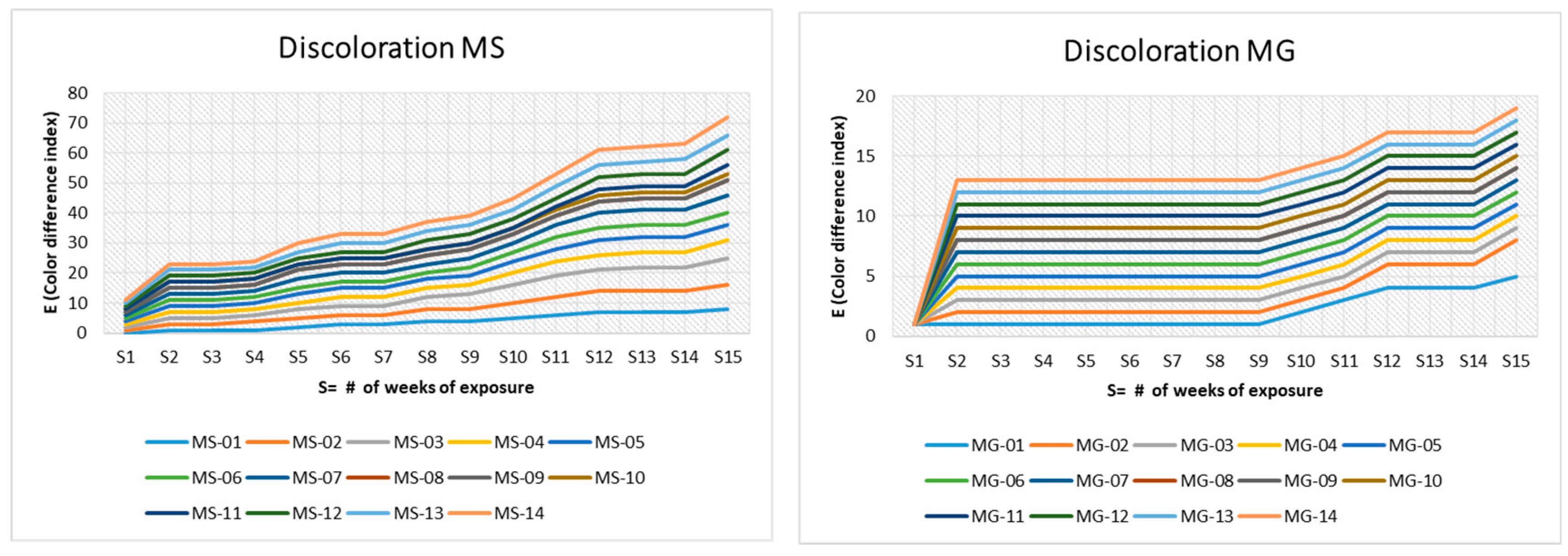

3.1.4. MS and MG Color Degradation Pathology (See Figure 5)

- The graph shows the evolution of the decoration index ΔE* in architectural paint samples exposed to atmospheric conditions for 15 weeks, comparing inorganic pigments obtained by sedimentation (MS) and ball mill grinding (Mg);

- The MS samples have increased their initial ΔE* values from 10 to maximum values between 60 and 75 by week 15, indicating a dramatic and visually distinct color change. In contrast, the Mg samples maintained their low and stable results throughout the test, with a ΔE* varying from 10 to 14 units until week 10, slightly rising to 18 units by week 15, which is still considered moderate in terms of durability and color retention;

- Based on this result, the pigments obtained by ball mill grinding (Mg) exhibit greater resistance to photodegradation and better color stability, possibly due to improved particle size homogeneity and effectiveness in pigment dispersion within the binder; additionally, the low statistical dispersion of Mg samples compared to MS demonstrated greater reproducibility and reliability under real environmental conditions.

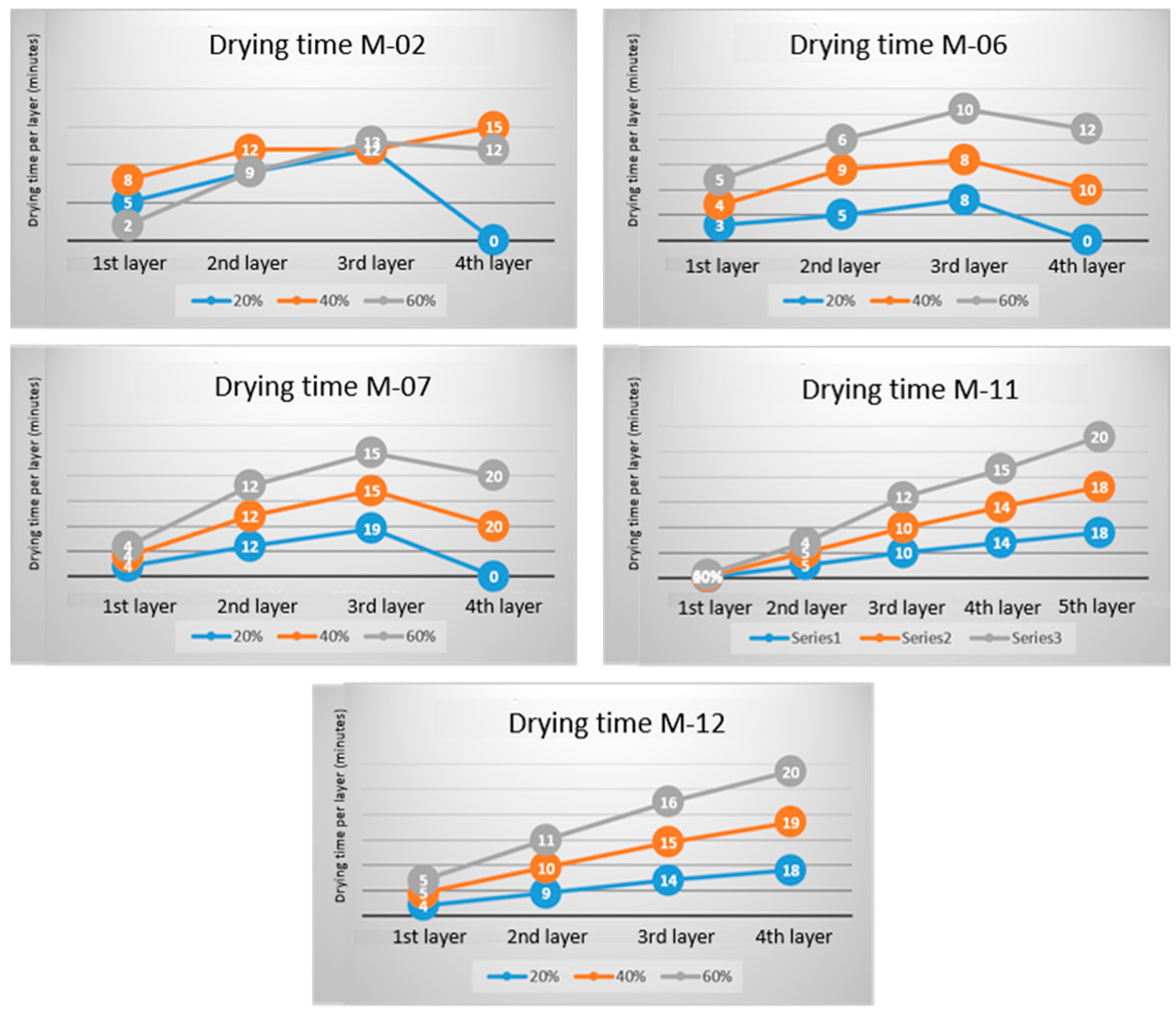

3.1.5. ASTM D-1640 Drying Time 31 (See Figure 6 and Table 2)

- ASTM D1640 is a commonly used instrument that determines the drying and curing time of organic coatings at various stages, such as touch dry, hardening, and complete drying; the ASTM 1640 test investigated samples with different additions of PVA binder (20%, 40%, and 60%) applied in successive layers;

- The findings for samples M-02, M-06, M-07, M-11, and M-12 allow us to detect trends in the variation in drying time compared to the percentage of PVA and the number of layers applied; in general, the increase in the amount of PVA results in a gradual increase in drying time, as evidenced in all analyzed samples. M-07 had the highest drying times in the 60% range, with the fourth layer reaching 20 min. According to this behavior, the film produced on the surface takes longer to lose moisture due to its greater water retention and lower porosity;

- On the other hand, in samples M-02 and M-06, the drying time behavior is more variable. In M-02, the drying of the last layer for 20% PVA shows a sharp drop to 0 min, suggesting a possible complete absorption of the solvent or a difference in evaporation depending on the arrangement of the material. In contrast, sample M-06 shows a more uniform increase in drying times, highlighting the increasing trend of drying time with successive layers;

- Regarding sample M-11, a linear increasing behavior is observed in each of the layers, with drying time values depending on the accumulated thickness. This aligns with the behavior required for sample M-12, where a greater number of layers results in an average increase in drying time, with maximum values of 20 min at 60% in the fourth layer;

- Therefore, based on the results obtained, the formulation with the highest percentage of PVA and a greater number of layers dries in longer times, which should be considered when thinking about multiple layers during a coating process. On the other hand, variability was observed concerning the drying process in some of the samples; thus, it is possible to consider that factors such as substrate absorption, ambient humidity, and application uniformity can affect the solvent evaporation processes of the paint.

| Drying Time in Minutes | |||||

|---|---|---|---|---|---|

| 1st Layer (min) | 2nd Layer (min) | 3rd Layer (min) | 4th Layer (min) | ||

| M-02 | 20% | 5 | 9 | 12 | 0 |

| 40% | 8 | 12 | 12 | 15 | |

| 60% | 2 | 9 | 13 | 12 | |

| M-06 | 20% | 3 | 5 | 8 | 0 |

| 40% | 4 | 9 | 8 | 10 | |

| 60% | 5 | 6 | 10 | 12 | |

| M-07 | 20% | 4 | 12 | 19 | 0 |

| 40% | 4 | 12 | 15 | 20 | |

| 60% | 4 | 12 | 15 | 20 | |

| M-11 | 20% | 5 | 10 | 14 | 18 |

| 40% | 5 | 10 | 14 | 18 | |

| 60% | 4 | 12 | 15 | 20 | |

| M-12 | 20% | 4 | 9 | 14 | 18 |

| 40% | 5 | 10 | 15 | 19 | |

| 60% | 5 | 11 | 16 | 20 | |

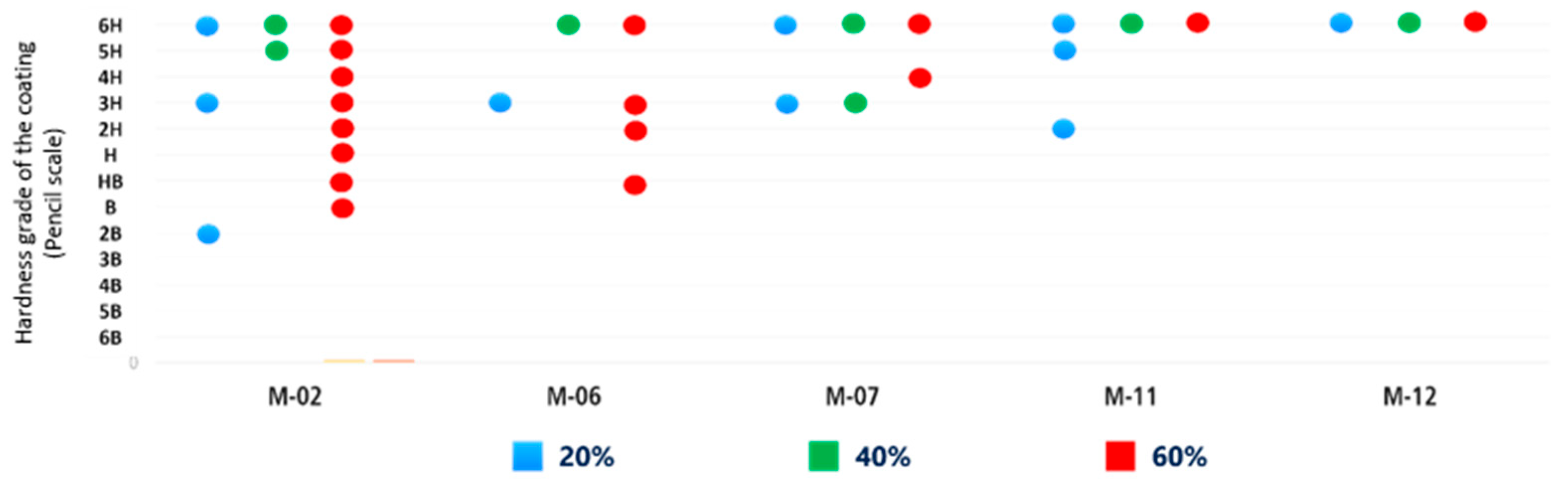

3.1.6. ASTM D-3363, Hardness [32] (See Figure 7)

- In this analysis, five samples have been considered: M-02, M-06, M-07, M-11, and M-12, with three binder dosages of 20%, 40%, and 60%, to study the applicability of such coatings as paint; generally speaking, the samples with a higher concentration of binder improve the hardness of the coating and reach optimal levels in some of them, although there are variations among the samples, reflecting different mechanical behaviors and surface resistance;

- Sample M-02: this sample shows variable hardness depending on the concentration of the binder. At 20%, the values range between 2B, 3H, and 6H, indicating low resistance at certain points. At 40%, there is an improvement reaching 5H and 6H, demonstrating an increase in resistance. At 60%, the hardness varies widely from B to 6H, suggesting inconsistencies in the formulation of the coating. Due to this variability, sample M-02 is considered optimal for manufacturing as paint by modifying the formulation to ensure uniformity in hardness;

- Sample M-06: a more stable behavior is observed compared to M-02. At 20%, the hardness is 3H, indicating acceptable resistance for basic applications. At 40%, it reaches 6H, showing significant improvement. With 60%, it presents values between HB and 6H, suggesting greater mechanical resistance. Overall, M-06 meets the hardness requirements to be considered suitable as paint, although it is recommended to evaluate the homogeneous distribution of hardness at higher concentrations of binder;

- Sample M-07: the hardness of this sample varies moderately. At 20%, it shows values ranging from 3H to 6H, indicating some resistance, although with slight variability. At 40%, it remains within a range of 3H to 6H, which indicates stability in surface hardness. With 60%, it improves slightly, reaching values between 4H and 6H. Although the sample shows a tendency to withstand a higher concentration of binder, the variability on the scale suggests the need for optimization in the formulation to ensure uniform hardness across the surface;

- Sample M-11: this sample demonstrates good stability in its hardness values. At 20%, it shows values between 2H, 5H, and 6H, which already indicates acceptable resistance. At 40% and 60%, it maintains a hardness of 6H, confirming excellent mechanical resistance and surface stability. Since the sample meets the required standards, it is considered suitable for manufacturing as paint without the need for adjustments in its formulation;

- Sample M-12: it is the sample with the best performance in terms of hardness. At 20%, it already reaches a level of 6H, demonstrating superior resistance from the lowest concentration of binder. At 40% and 60%, it maintains the same value of 6H, suggesting excellent stability and uniformity in surface hardness. Due to its high performance, M-12 is fully suitable for manufacturing as a high-resistance paint without requiring modifications to its formulation;

- Samples M-12 and M-11 meet the requirements of the ASTM D-3363 standard and can be used for the production of paints with high scratch resistance. Sample M-06 is also suitable, although it could benefit from slight optimization. In contrast, samples M-02 and M-07 show variations in hardness that could improve their performance, so they require adjustments in their formulation to enhance their uniformity and mechanical resistance.

3.1.7. ASTM D-3359, Adhesion [30] (See Table 3)

- The ASTM D-3359 adhesion test allows for the classification of coating resistance concerning substrate separation based on a grid cut or “X” incision method (ranging from 0B to 5B, where 5B indicates maximum adhesion and 0B indicates complete failure). In this test, five samples (M-02, M-06, M-07, M-11, and M-12) with different concentrations of PVA (20%, 40%, and 60%) were used in three repetitions to determine their suitability for paint manufacturing;

- Sample M-02 shows an adhesion of 5B at all PVA concentrations (20%, 40%, and 60%), indicating that the cohesion of the coating with the substrate is very good, with no visible detachments observed in any of the repetitions; this behavior allows us to infer that the formulation of this sample is suitable for use in paint manufacturing without the need for adjustments;

- Sample M-06 also exhibits a presence of 5B at all concentrations, reaffirming the strong bond of the surface and the correct performance of the coating with stable behavior, making this sample suitable for use in paint manufacturing, meeting the requirements of the ASTM D-3359 standard;

- In the case of sample M-07, a slight variability is observed in the 20% concentration, with one repetition showing 4B, although it generally maintains values of 5B in most tests. At the 40% and 60% concentrations, the adhesion is uniform with 5B across all repetitions, indicating overall good adhesion. However, the slight variability at the lower concentration suggests the need for more precise control in the formulation;

- Sample M-11 exhibits behavior similar to M-07, with values of 5B in most concentrations; although, at the 20% concentration, a repetition shows 4B, suggesting a slight decrease in adhesion under this condition. Nevertheless, the overall values remain high, making it suitable for paint manufacturing with reliable adhesion;

- On the other hand, sample M-12 shows the most variable results in the test. At 20% PVA, adhesion fluctuates between 2B and 3B, indicating a notable loss of cohesion between the coating and the substrate. At 40%, lower adhesion is detected with values ranging from 1B to 3B, demonstrating considerable detachment and compromising its performance. However, at 60% PVA, there is a consistent improvement in adhesion, reaching 4B, indicating a relative enhancement.

| Sample | 1 | 2 | 3 |

|---|---|---|---|

| M-02-20% | 5B | 5B | 5B |

| M-02-40% | 5B | 5B | 5B |

| M-02-60% | 5B | 5B | 5B |

| M-06-20% | 5B | 5B | 5B |

| M-06-40% | 5B | 5B | 5B |

| M-06-60% | 5B | 5B | 5B |

| M-07-20% | 5B | 5B | 4B |

| M-07-40% | 5B | 5B | 5B |

| M-07-60% | 5B | 5B | 5B |

| M-11-20% | 5B | 5B | 4B |

| M-11-40% | 5B | 5B | 5B |

| M-11-60% | 5B | 5B | 5B |

| M-12-20% | 3B | 2B | 3B |

| M-12-40% | 1B | 3B | 3B |

| M-12-60% | 4B | 4B | 4B |

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation | Meaning |

| ASTM | American Society for Testing and Materials |

| PVA | Polyvinyl acetate |

| VOCs | Volatile organic compounds |

| MS | Sedimentation method |

| MG | Ball milling method |

| S# | Stage number in the durability test (e.g., S1, S2, etc.) |

| UV | Ultraviolet |

| NCS | Natural Color System |

| HB | Hardness classification in pencil test (between H and B scales) |

| H | Hard (pencil hardness scale) |

| B | Black (pencil softness scale) |

| µm | Micrometer (micron) |

| RPM | Revolutions Per Minute |

| g | Gram |

| %RH | Percentage of Relative Humidity |

| C | Celsius (°C) |

| mm | Millimeter |

| µg/m³ | Micrograms per cubic meter |

| LD | Linear Dichroism |

References

- Arias, J. Occupational diseases and their impact on public health. Occup. Health J. 2012, 28, 45–56. [Google Scholar]

- Li, X.; Ning, N.; Hao, Y.; Sun, H.; Gao, L.; Jiao, M.; Wu, Q.; Quan, H. Neurotoxic syndromes caused by industrial chemicals in the workplace. Int. J. Environ. Res. Public Health 2013, 10, 1125–1140. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Zhang, X.; Yang, Y.; Li, X.; Xu, H.; Zhao, J.; Pattelli, L.; Pan, L.; Zhao, J.; Li, Y. An inorganic water-based paint for high-durability passive radiative cooling. J. Mater. Chem. C 2025, 13, 4137–4144. [Google Scholar] [CrossRef]

- Del Amo, D.B.; Romagnoli, R.; Deya, M.C.; González, J.A. High performance water-based paints with non-toxic anticorrosive pigments. Prog. Org. Coat. 2002, 45, 389–397. [Google Scholar] [CrossRef]

- Pilon, L.; Day, D.; Maslen, H.; Stevens, O.P.J.; Carslaw, N.; Shaw, D.R.; Sneddon, H.F. Development of a solvent sustainability guide for the paints and coatings industry. Green Chem. 2024, 26, 9697–9711. [Google Scholar] [CrossRef]

- CETESB—Companhia Ambiental do Estado de Sao Paulo. Low VOC Paints: Environmental Impact Assessment; CETESB—Companhia Ambiental do Estado de Sao Paulo: Sao Paulo, Brazil, 2008. [Google Scholar]

- Cocchetti, V.; Pieralli, I.; Angelin, E. A formulation for a new environmentally friendly varnish for paintings. Coatings 2023, 13, 1566. [Google Scholar] [CrossRef]

- Cardoso, A.; Lima, F.; Rocha, M. Earth-based paints: Formulation and evaluation. J. Build. Mater. Sustain. 2014, 8, 223–231. [Google Scholar]

- Houben, H.; Guillaud, H. Earth Construction: A Comprehensive Guide; Intermediate Technology Publications: London, UK, 2006. [Google Scholar]

- Triat, B. Mineral pigments and their use in natural paint production. Mater. Sci. J. 2010, 7, 78–92. [Google Scholar]

- Resende, M.; Santos, P.; Oliveira, J. Clay-based coatings and their structural stability. Appl. Clay Sci. 2014, 98, 45–56. [Google Scholar] [CrossRef]

- Riveros Alcedo, R.G. Volatile Organic Compounds (VOCs) in the Paint and Solvent Industry in Peru—Case Study Analysis and Strategies for Environmental and Occupational Health Management. Master’s Thesis, Pontifical Catholic University of Peru, Lima, Peru, 2017. Available online: http://hdl.handle.net/20.500.12404/8838 (accessed on 1 May 2025).

- Andina. Peru Is the Only Latin American Country Still Using Lead-Based Decorative Paints. Andina News Agency. 2020. Available online: https://andina.pe/agencia/noticia-afirman-peru-es-unico-pais-latinoamericano-usa-plomo-pinturas-819095.aspx (accessed on 1 May 2025).

- Quiteño, A.A. Development of Earth-Based Paint for the Protection of Adobe Walls Using Soils from the Western Region of El Salvador. Res. Yearb. 2018, 7, 193–198. Available online: https://es.scribd.com/document/763981720/LEIDO-Elaboracion-de-pintura-a-base-de-tierra-para-la-proteccion-de-las-paredes-de-adobe-con-tierras-de-la-zona-occidental-de-El-Salvador (accessed on 1 May 2025).

- Feilden, B.M. Guidelines for the Management of World Cultural Heritage Sites. ICCROM. 2003. Available online: https://www.iccrom.org/sites/default/files/2018-02/2003_feilden_manual_manejo_spa_85882_light.pdf (accessed on 1 May 2025).

- Tressmann, D.M.G.A.; Pedroti, L.G.; de Carvalho, A.F.; Ribeiro, J.C.L.; de Paula Cardoso, F.; Lopes, M.M.S.; de Oliveira, A.F.; Ferreira, S.O. Research into the use of marble waste as mineral filler in soil pigment-based paints and as an active pigment in waterborne paints. Constr. Build. Mater. 2020, 241, 117976. [Google Scholar] [CrossRef]

- Lopes, M.M.S.; Sant’Ana, R.D.C.S.; Pedroti, L.G.; Ribeiro, J.C.L.; de Carvalho, A.F.; de Paula Cardoso, F.; Mendes, B.C. Influence of the incorporation of granite waste on the hiding power and abrasion resistance of soil pigment-based paints. Constr. Build. Mater. 2019, 205, 463–474. [Google Scholar] [CrossRef]

- Lopes, M.M.S.; Pedroti, L.G.; de Lima, G.E.S.; Ribeiro, J.C.L.; Nalon, G.H.; Mendes, B.C.; de Oliveira, A.L. Influence of the incorporation of granite waste on the weathering resistance of soil pigment-based paints. In Characterization of Minerals, Metals, and Materials; Springer International Publishing: Berlin/Heidelberg, Germany, 2021; pp. 471–481. [Google Scholar] [CrossRef]

- Lopes, M.M.; Pedroti, L.; Lima, G.E.S.; Ribeiro, J.C.L.; Nalon, G.; Mendes, B.; de Oliveira, A.L. Comparative analysis of granite residue and soil-based pigments in architectural paint formulations. J. Build. Eng. 2023, 77, 107585. [Google Scholar] [CrossRef]

- Maulana, S.; Wibowo, E.S.; Mardawati, E.; Iswanto, A.H.; Papadopoulos, A.; Lubis, M.A.R. Eco-Friendly and High-Performance Bio-Polyurethane Adhesives from Vegetable Oils: A Review. Polymers 2024, 16, 1613. [Google Scholar] [CrossRef] [PubMed]

- de FARIA, F.C.; Schmid, A.L.; de MIRANDA, I.P.H. Abrasion resistance of paints made with curcumin pigment and PVA resin. Archit. Civ. Eng. Environ. 2024, 17, 43–50. [Google Scholar] [CrossRef]

- Xu, K.; Xiao, X.; Wang, L.; Lou, M.; Wang, F.; Li, C.; Ren, H.; Wang, X.; Chang, K. Data-Driven Materials Research and Development for Functional Coatings. Adv. Sci. 2024, 11, 2405262. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Chen, Q.; Wang, H.; Shen, P.; Li, Z.; He, W. Deep learning-based acoustic emission data clustering for crack evaluation of welded joints in field bridges. Autom. Constr. 2024, 165, 105540. [Google Scholar] [CrossRef]

- Xia, Z.; Shu, J.; Ding, W.; Gao, Y.; Duan, Y.; Debono, C.J.; Prakash, V.; Seychell, D.; Borg, R.P. Complete-coverage path planning for surface inspection of cable-stayed bridge tower based on building information models and climbing robots. Comput.-Aided Civ. Infrastruct. Eng. 2025, 1–23. [Google Scholar] [CrossRef]

- ASTM D5722-22; Standard Practice for Performing Accelerated Outdoor Weathering of Factory-Coated Embossed Hardboard Using Concentrated Natural Sunlight and a Soak-Freeze-Thaw Procedure. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D714-02; Standard Test Method for Evaluating Degree of Blistering of Paints. ASTM International: West Conshohocken, PA, USA, 2002. [CrossRef]

- ASTM D661-93(2019); Standard Test Method for Evaluating Degree of Cracking of Exterior Paints. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM D662-93(2019); Standard Test Method for Evaluating Degree of Erosion of Exterior Paints. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM D2244-16; Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM D3359-22; Standard Test Methods for Rating Adhesion by Tape Test. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM D1640/D1640M-14(2022); Standard Test Methods for Drying, Curing, or Film Formation of Organic Coatings. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM D3363-22; Standard Test Method for Film Hardness by Pencil Test. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vargas Febres, C.G.; Torres Barchino, A.; Serra Lluch, J.; Gudiel Rodríguez, E.R. Evaluation of the Physical and Mechanical Properties of Handmade Paints with Inorganic Pigments from Cusco According to American Society for Testing and Materials’ Standards for Architectural Applications. Architecture 2025, 5, 35. https://doi.org/10.3390/architecture5020035

Vargas Febres CG, Torres Barchino A, Serra Lluch J, Gudiel Rodríguez ER. Evaluation of the Physical and Mechanical Properties of Handmade Paints with Inorganic Pigments from Cusco According to American Society for Testing and Materials’ Standards for Architectural Applications. Architecture. 2025; 5(2):35. https://doi.org/10.3390/architecture5020035

Chicago/Turabian StyleVargas Febres, Carlos Guillermo, Ana Torres Barchino, Juan Serra Lluch, and Edwin Roberto Gudiel Rodríguez. 2025. "Evaluation of the Physical and Mechanical Properties of Handmade Paints with Inorganic Pigments from Cusco According to American Society for Testing and Materials’ Standards for Architectural Applications" Architecture 5, no. 2: 35. https://doi.org/10.3390/architecture5020035

APA StyleVargas Febres, C. G., Torres Barchino, A., Serra Lluch, J., & Gudiel Rodríguez, E. R. (2025). Evaluation of the Physical and Mechanical Properties of Handmade Paints with Inorganic Pigments from Cusco According to American Society for Testing and Materials’ Standards for Architectural Applications. Architecture, 5(2), 35. https://doi.org/10.3390/architecture5020035