Abstract

Assai (Euterpe oleracea Martius) is a superfruit widely consumed in several countries, mainly produced in the Amazon region. The significant growth of the market for this fruit has raised environmental concerns regarding the disposal of production waste, especially the seeds that are not utilized and represent approximately 80% of the fruit. In the present study, strategies were developed for transforming these seed wastes into new products, using green solvents for extraction under conditions conducive to technology transfer and with feasible quality control through simple bench techniques, which represents an ideal approach for establishing a truly sustainable process. A significant interaction between solvent and extraction method was observed, impacting both yields and total phenols. Phenolic compounds are substances known for their health benefits, functioning as antioxidants and consequently aiding in disease prevention. The phenolic content observed in the extractions increased from 22.68% to 44.74% under optimal conditions during extraction via hot maceration (50 °C) in 100% ethanol for 2 h, which also enhanced yield and increased antioxidant capacity. The extracts displayed remarkable free radical scavenging activities (IC50 = 6.54 μg/mL in ABTS and IC50 = 14.71 μg/mL in DPPH), approaching the Trolox and quercetin standards, respectively. The optimized method paved the way for the industrial-scale utilization of the residues of this valuable Amazonian fruit.

1. Introduction

The consumption of assai fruit (or açaí, as it is called locally) has been on the rise worldwide, a trend often attributed to its perceived health benefits and high nutritional value [1]. Brazil, as the leading producer of assai globally, holds a prominent position in the market, boasting a substantial production of 1.6 million tons in 2019 alone [2]. This significant output contributes to a thriving market valued at USD 610 million in Brazil. Of this production, 95% is destined for the Brazilian, while the remaining 5% is exported. Key destinations for assai exports include the United States, European Union, Japan, and Australia [2]. Several products derived from assai pulp are available in the market, ranging from energy drinks and ice creams to yoghurts, nutraceuticals, cosmetics, and perfumes. Indeed, all of these products utilize only the pulp of the fruit, which represents a small portion of the overall fruit. Meanwhile, the seeds, constituting approximately 80–95% of the fruit, are often overlooked and considered as production residues [3].

The waste from assai production is considered a significant problem for the Amazon region, as the processing of these fruits is carried out mainly in fruit-producing regions. Very hard and bulky, assai seeds have become an important environmental liability for the weakest link among stakeholders in the assai production chain. It is estimated that at least 1.4 million tons of seeds are generated annually from assai processing [4]. These residues are characterized chemically as sources of lipids (2.75 ± 0.01 g/100 g), proteins (4.89 ± 0.03 g/100 g), fatty acids (oleic, linoleic, and myristic), and phenolics (procyanidin B1 and B2, catechin, and epicatechin) [5]. Moreover, their distinction lies in their elevated phenolic content in comparison to the pulp. Phenolic compounds are associated with health benefits due to their antioxidant properties and their role in protecting against chronic diseases caused by free radicals. These properties are associated with the ability of phenolics to interrupt oxidative processes by donating hydrogen atoms or electrons to free radicals. These phenolic compounds obtained from natural sources are of interest to industries due to their low toxicity compared to synthetic antioxidants [6]. Recently published papers describe antioxidant (2,2-diphenyl-1-picrylhydrazyl (DPPH), 2,2-azino-bis(3-ethyl-benzothiazoline-6-sulfonate) (ABTS), and Oxygen Radical Absorbance Capacity (ORAC)), antibacterial (Staphylococcus aureus and Enterococcus faecalis), and antifungal activities (Candida albicans) observed in extracts from assai seeds [5,7,8]. Thus, phenolics obtained from assai residues can be seen as promising sources for applications in various industries that use antioxidants in their products, such as supplements, food, pharmaceutical, and cosmetic industries [9].

Considering the potential application of this by-product in the generation of new value-added products, the development of extraction and concentration methodologies for bioactive substances has been the subject of study. One of the widely used tools in method optimization is response surface methodology. This experimental design is used for analyses where several explanatory variables (factors) influence a dependent variable (response), allowing the identification of mathematical and statistical relationships among predetermined levels, resulting in a more suitable response for the involved process. This is a mathematical and statistical technique that has been widely used in processes aimed at obtaining antioxidant extracts and that have variables such as differences in extraction methodologies, solvent, temperature, pH, and particle size. Several authors have used this tool in recent years to obtain the best extraction conditions for antioxidant substances from assai pulp and seeds [5,10,11,12]. Although there are studies on optimizing the extraction of bioactive phenolics from assai seeds, there is a lack of research evaluating the use of different extraction methods and their influence on other parameters. Other studies with Amazon fruit residues have also used this technique for the evaluation of extraction parameters, such as the research by Yamaguchi et al. [13]. Green solvents, such as ethanol and water mixtures, were used since they are not aggressive to the environment, present very low toxicity, are easy to find, recover, and manipulate, and are also able to extract a wide range of medium polar substances, depending on the amount of water [13].

With the increase in the production, consumption, and export of Amazon assai, generating millions of tons of unused seeds that exhibit high biological activity as described in the literature, there is a need to harness this source of biomolecules. Also, it is necessary to establish techniques aimed at utilizing the seeds that can be used on an industrial scale, but also that can be feasible to be performed in the small Amazonian cities. This study aims to investigate methods for optimizing the extraction of phenolic substances and antioxidant capacity from assai seeds, comparing yields and seeking possibilities for the use of residues from the assai extractive industry in the Amazon.

2. Materials and Methods

2.1. Experimental Procedure

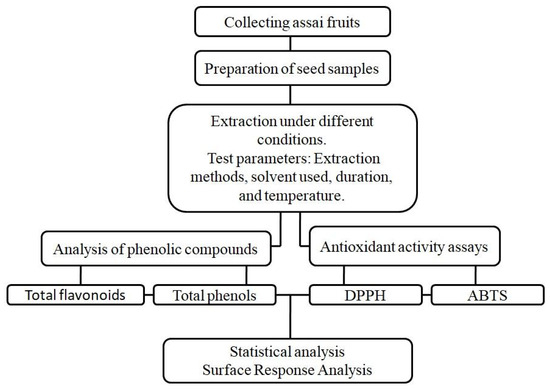

The design of the experiments was conducted as presented in Figure 1. After collecting and preparing the seeds, several preliminary experiments were performed to establish the design space. With the parameters set, the extractions were performed and several analyses of phenolics and antioxidants were used as response variables.

Figure 1.

Workflow diagram of the study.

2.2. Chemicals, Reagents, and Materials

Trolox (6-hydroxy-2,5,7,8-tetramethylchroman-2-caboxylic acid), DPPH (α,α-diphenyl-picrylhadrazyl), ABTS [2,2′-azino-bis(3-ethylbenzothiazoline-sulfonic)], quercetin, and BHA were obtained from Sigma-Aldrich (St. Louis, MO, USA). Extraction solvents used were ethanol (HPLC grade) obtained from Merck (Darmstadt, Germany). Water was obtained from the laboratory distillation system.

2.3. Plant Material

The assai seeds were collected in February 2013 in the city of Coari (Amazon, Brazil) when the study was conducted. A voucher sample was deposited at the UFAM herbarium and the biological sampling was registered on the National System of Genetic Resource Management and Associated Traditional Knowledge (SISGEN), following Brazilian legislation regarding biodiversity scientific exploitation, Code A33E5CC. The seeds were dried in an air-circulating oven at 40 °C for 48 h, ground in a four-knife mill (SP-32, SPLABOR, Presidente Prudente, Brazil), and subjected to different extraction systems, at proportions of 100, 80, 50, and 20% (ethanol: water). The extracts were prepared in amber bottles, using a ratio of plant material to solvent of 1:10 (w/v). After the extractions, the solutions were filtered, and the solvent was evaporated using a rotary evaporator (Model 802, FISATOM, São Paulo, Brazil) and a desiccator. The extraction methods were:

- (A)

- Maceration (CM)–room temperature: The plant material was added to an amber bottle for 48 h at room temperature (25 °C).

- (B)

- Maceration (HM)–hot temperature: The plant material and solvent were added to an amber bottle and hot extraction was carried out, at a temperature of 50 °C, for 2 h under stirring with a glass rod.

- (C)

- Sonication (NS)–neutral solvent: It was extracted using an ultrasound (Model USC–1800, ULTRONIC, Indaiatuba, Brazil) for 30 min.

- (D)

- Sonication (AS)–acid solvent: The plant material was added to an amber bottle and then the acidified solvent (10 μL of 10% HCl in 100 mL of solvent) was added and extracted under ultrasound for 30 min.

2.4. Quantification of the Phenolic Compounds

2.4.1. Total Phenolic

To determine the total phenolics in assai seed extracts, the Folin–Ciocalteu method described by Singleton and Rossi [14] adapted for microplate use was employed. In this method, 10 µL of the extract solution (1 mg/mL in DMSO) was combined with 50 µL of Folin–Ciocalteu reagent (Sigma-Aldrich Chemie, Steinheim, Germany) and was allowed to react for 8 min. Subsequently, 240 µL of sodium carbonate (Na2CO3) was added. After incubation at room temperature for 3 min, the absorbance of the reaction mixture was measured at 715 nm using a microplate reader (DTX 800 multimode detector UV/Visible spectrophotometer, Beckman Coulter, Indianapolis, IN, USA) against a methanol blank. Gallic acid was used as the standard. The experiments were conducted in triplicate, and the mean results were determined. The total phenolic content data were expressed as a percentage using the following equation:

where abssample is the absorbance of the gallic acid standard and Absstandard is the absorbance of the sample and was expressed as mg of gallic acid equivalents (GAE) per 100 g of fresh fruits. All tests were conducted in triplicate.

% total phenolics = (abssample × 100)/Absstandard

2.4.2. Total Flavonoids

In the determination of total flavonoids, the aluminum chloride colorimetric method described by Chang et al. [15] was utilized and adapted for microplate use. Each fruit extract (30 µg of 1:10 g/mL) in DMSO was individually mixed with 90 µL of ethanol, 6 µL of 10% aluminum chloride, 6 µL of 1 M potassium acetate, and 168 µL of distilled water. The mixture was left at room temperature for 30 min, and the absorbance of the reaction mixture was measured at 405 nm using a microplate reader (DTX 800 multimode detector UV/Visible spectrophotometer, Beckman Coulter, Indianapolis, IN, USA). Data for the total flavonoid content in the dry matter were expressed as a percentage of quercetin.

2.5. Antioxidant Capacity

2.5.1. DPPH Radical

The scavenging capacity against the DPPH radical was determined using the method described by Molyneux [16]. For this scavenging assay, a 96-well plate (Corning®, New York, NY, USA) was utilized. In total, 30 μL of extracts at varying concentrations (1–100 µg/mL) were diluted in DMSO and combined with 270 µL of DPPH in ethanol. The plate was kept in the dark for 30 min, after which the absorbance of the solution was measured at 517 nm using a microplate reader (DTX 800 multimode detector UV/Visible spectrophotometer, Beckman Coulter, Indianapolis, IN, USA). Blanks (DMSO) and standards (quercetin solutions in DMSO) were run simultaneously. Extracts were initially tested at a single concentration of 100 µg/mL, and those showing promising evidence of antioxidant activity were further tested over a range of concentrations to establish the IC50 (the concentration reducing DPPH absorbance by 50%). It was calculated using the following formula:

where: Ablank is the absorbance of the control reaction (containing all reagents except the test compound), and Asample is the absorbance of the test compound. The antioxidant activity was calculated using the equation: % inhibition = 100 × (1 − sample abs/control abs).

IC50 (%) = [(Ablank − Asample)/Ablank] × 100

2.5.2. ABTS Radical

The second method was used ABTS•+ method, based on the procedure described by Re et al. [17]. ABTS radical cation (ABTS•+) was produced by reacting ABTS stock solution with 2.45 mM potassium persulfate (final concentration) and allowing the mixture to stand in the dark at room temperature for 12–16 h before use. The ABTS•+ was diluted to the absorbance of 0.70 ± 0.02 and stored for offline and online assays. A total of 30 µL of diluted extracts in different concentrations (1–100 µg/mL) were added with 270 µL of ABTS•+ solution and were stood in the dark at room temperature for 15 min. The absorbance was measured at 734 nm with a microplate reader (DTX 800 multimode detector UV/Visible spectrophotometer, Beckman Coulter, Indianapolis, IN, USA). All determinations were carried out in triplicate, for each concentration for both standard and samples. The percentage inhibition of absorbance at 734 nm was calculated and plotted as a function of concentration of antioxidants and Trolox, for the standard reference data. Extracts were first tested at a single concentration of 100 µg/mL, and those showing good evidence of antioxidant activity were tested over a range of concentrations to establish the IC50. The same equation as the previous methodology was used to calculate the concentration.

2.6. Experimental Design

To assess the effect of extraction method and solvent type, a Multivariate Analysis of Variance (MANOVA) was employed based on a factorial experimental design with multivariate response, using a 24-factorial design. The extraction technique factor consisted of four levels: hot maceration (HM), room temperature maceration (CM), sonication with neutral solvent (NS), and sonication with active solvent (AS), while the solvent factor included ethanol and water at the following levels: 100% (1:0), 80% (4:1), 50% (1:1), and 20% (1:4) (EtOH:H2O). The multivariate response was represented by the quintuple: % yield, % phenolics, % flavonoids, ABTS•+ antioxidant capacity, and DPPH• antioxidant capacity. The MANOVA is unbalanced due to obtaining three measurements of the percentage yield and nine measurements of percentage readings for the remaining evaluated items.

The structural model used for the factorial design was represented by

where μ = (μR, μFe, μFl) is the vector of global averages, Ϯj = (ϮjR, ϮjFe, ϮjFl) measures the effect of the j-th extraction method, βk = (βkR, βkFe, βkFl) represents the effect of the k-th type of solvent, γjk = (γjkR, γjkFe, γjkFl) measures the interaction effect of method–solvent, and Єijk represents the random error. Mean comparisons among factor levels (method, solvent, and method–solvent) were conducted using the Tukey test. The analyses were performed using the open-source software R. 2.14.0®.

Yijk = μ + Ϯj + βk + γjk + Єijk

3. Results

Preliminary studies have indicated the high antioxidant potential of acai seeds related to the presence of phenolic substances [7]. In this study, a meticulous selection of diverse extraction techniques was undertaken to procure bioactive extracts, accompanied by a comprehensive evaluation of optimal parameters encompassing time, temperature, extraction solvent, and methodology. The selection criteria prioritized pivotal factors including the yield of crude extracts, percentage of bioactive compounds, total phenolic content, and antioxidant activity, which were assessed via DPPH and ABTS radical scavenging capacity. These parameters served as key response variables in the optimization analysis, as detailed in Table 1.

Table 1.

Results from assai optimization assays.

All these factors presented in Table 1 were analyzed, and upon evaluating the results of MANOVA in terms of p-values, it was observed that both the type of solvent and the extraction method, as well as the interaction effect between solvent and extraction method, significantly affected (p < 0.05) the percentage yield, phenolic content, and antioxidant activity. Table 2 presents the correlation between the observed variables. The existence of correlations is considered to the closer to one in absolute value.

Table 2.

Correlation matrix of errors related to the response variables from assai seed extractions.

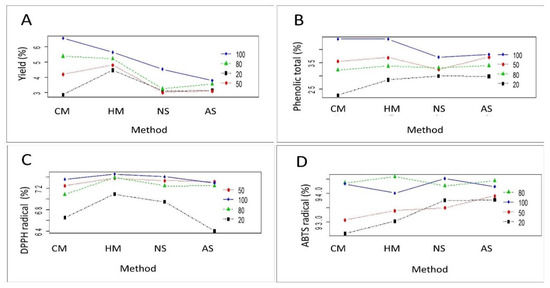

Therefore, the partial correlation matrix of errors (Table 2) obtained for the set of response variables (yield, phenolics, and antioxidant activity, presented in Table 1) indicated weak correlations, suggesting that individual analyses for the percentage of yields, phenolics, and flavonoids should be conducted using a factorial experimental design. The results were obtained through individual factorial analysis (ANOVA) as described in Table 3 and also illustrated in Figure 2 and Figure 3. In Figure 2, the influence of the solvent (100% ethanol or water with 80%, 50% and 20% ethanol) was evaluated, being compared to each methodology. The comparison was performed to four different results: (A) Yield; (B) Phenolic compounds, (C) Scavenging DPPH radical and (D) Scavenging ABTS radical.

Table 3.

ANOVA data.

Figure 2.

Influence of the solvent on the methodologies for the results of (A) Yield, (B) Phenolic compounds, (C) Scavenging DPPH radical and (D) Scavenging ABTS radical.

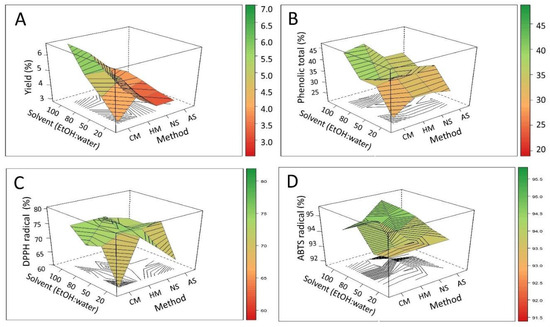

Figure 3.

Surface Response analysis to (A) Yield, (B) Phenolic compounds, (C) Scavenging DPPH radical and (D) Scavenging ABTS radical.

In Figure 3, the visualization of the results on the Surface Response graphics significantly enhances our understanding of how the methods of extraction and solvents influence the outcomes. The relevance of temperature in this context could be emphasized. One notable result, crucial for a wide range of biomass reuse studies, is the significance of such research, as they can potentially multiply the yield several times, transitioning from the minimal extraction of bioactive to results comparable to purified standards.

To assess the impact of extraction time, the optimal conditions determined beforehand were tested across various experiments utilizing pure ethanol as a solvent. The period ranged from 10 to 60 min for sonication, 1 h to 3 days for cold maceration (at room temperature), and hot maceration, as outlined in Table 4. The most promising results in terms of yield were further scrutinized for their antioxidant properties, including DPPH, ABTS, and total phenolic content, as presented in Table 5.

Table 4.

Influence of the extraction time on yield of various extraction methods. Interactions sharing the same letter do not exhibit significant differences.

Table 5.

Antioxidant capacity with the best extraction parameters. Interactions sharing the same letter do not exhibit significant differences.

4. Discussion

The increasing consumption of Amazonian assai, which has emerged as a significant opportunity in the local bioeconomy, has also become a major environmental risk due to the intensive generation of waste from fruit seeds. Highly lightweight, hard, bulky, and extensively generated in different cooperatives, assai waste has become a problem in small Amazonian towns, being one of the main materials in municipal landfills. Fair trade initiatives cannot truly succeed if the waste burden remains with the most vulnerable stakeholders. Therefore, it is crucial to develop strategies for transforming this waste into new products, fostering a circular economy that is also equitable. To achieve this, the new by-products must offer substantial added value. If the alternatives are animal feed or composting, they represent an environmental liability for the producer.

The utilization of green solvents like ethanol and water for extraction, under conditions conducive to technology transfer and with quality control feasible through simple bench techniques, represents an ideal approach for establishing a truly sustainable bioeconomy. Dealing with the disposal of waste seeds from assai pulp extraction has emerged as a pressing issue, particularly for the sustainability endeavors of international cosmetics companies. Numerous studies, such as the one conducted by Melo et al. [5], have sought viable and eco-friendly solutions for this waste management challenge. It is crucial to acknowledge that while the internal fatty material of the seed can be efficiently extracted and utilized like other plant-based fats, it is the outer husk that poses the main challenge. This bulky outer layer, rich in phenolic compounds, constitutes the primary residue. Extracting these compounds may require specialized conditions such as acidity, ultrasound, or elevated temperatures to optimize the process.

In natural product chemistry, the extraction process traditionally focused on describing the composition and properties of extracts using only one condition, often overlooking important characteristics of target molecules like polarity, acidity, and their interaction with the plant matrix. They often relied on methods with extended extraction times, the employment of toxic solvents, and temperature control focused solely on maximizing extraction yield. Unfortunately, this approach sometimes led to the extraction of metabolites with little relevance and inadvertently degraded desired compounds, resulting in highly inefficient processes.

There is an increasing demand to reduce production costs through selective extraction that allows higher yields of the target compounds with biological activities. Statistical tools that assist in directing optimal extraction conditions from a set of predefined response variables have significantly updated the possibilities of utilizing plant biomass.

In Table 1, the responses regarding the total yield, percentage of total phenols, and the percentages of inhibition of stable DPPH and ABTS free radicals were observed in different extraction solvents (mixtures of water and ethanol, containing 20, 40, 50, 80, and 100%, i.e., pure ethanol), as well as the two methodologies and temperatures: ambient temperature maceration (CM), hot maceration (HM, 50 °C), neutral sonication (NS), and acidic sonication (AS).

In the present study, the use of solvents such as ethanol and water were due to these solvents being indicated for the extraction of the predominant class of phenolics in the seeds. Some of the best results, such as a yield greater than 6% and total phenolics above 44% were observed using 100% ethanol as solvent and maceration, rather than sonication. The correlation of these results was evaluated using MANOVA (Table 2), an oriented new statistical analysis using ANOVA (Table 3). In Melo’s studies [5], various mixtures of water and ethanol were tested for the extraction of phenolic constituents and antioxidants (ABTS) from assai peels. In this study, temperature did not influence the antioxidant activity of the extracts, and the best antioxidant activity was observed in the highest ethanol concentrations tested: 50–80% ethanol (%v/v).

The optimal conditions were revisited, this time varying the extraction time based on the previously identified best results, as outlined in Table 4. Acid sonication was conducted for 20 min and yielded results comparable to neutral sonication also conducted for 20 min. However, the yields achieved through sonication were lower compared to those observed with maceration. Cold maceration (CM) at room temperature was conducted for durations of one hour, one day, two days, and three days, while hot maceration (HM) at 50 °C was performed for one, two, and three hours. Interestingly, the yield obtained after one day of cold maceration was similar to that achieved after 2 or 3 h hot maceration. The most favorable results were obtained through cold maceration after 2 days, and extending the cold extraction period by an additional day did not return further improvements on yield. These findings hold significant promise from a sustainability perspective, as they suggest that optimizing the solvent system can potentially reduce the need for other extraction technologies such as ultrasound-assisted extraction, and minimize the required heat and extraction time.

Following the yield optimization, the antioxidant capacity of the obtained extracts was assessed using three widely applicable methods for quality control: DPPH, ABTS, and total phenolics. As depicted in Table 5, the results demonstrate the remarkable success of the optimization process across all extraction techniques. Notably, the HM extract exhibited significant free radical scavenging activities, with IC50 values of 6.53 μg/mL in ABTS and 14.71 μg/mL in DPPH, closely approaching the Trolox and quercetin standards (IC50 values of 10.61 μg/mL and 7.24 μg/mL, respectively), with very significant activity at the ABTS assay compared to Trolox. It is noteworthy that these exceptional outcomes were achieved through a low-technology extraction method, namely maceration. Furthermore, the modest temperature elevation, reaching only 50 °C, underscores the relevance of such studies for genuine sustainability in waste management and reuse, particularly in the Amazon region where ambient temperatures prevail.

Other studies conducted with assai pulp, such as the research by Borges et al. [11], have shown a positive influence of using acidification for the extraction of bioactive phenolics from the pulp using ethanol acidified with HCl. These results differed from our study, as the enhanced extraction observed in Borges’ study was associated with the presence of anthocyanins, which are present in the pulp and may not have yielded similar results in the seeds due to differences in composition between pulp and seeds. In Borges’ optimization of phenolics, the optimal method involved using a solvent comprising 40% ethanol acidified with 0.01 M HCl in a 1:80 ratio and utilizing sonication for 30 min, which resulted in an antioxidant activity against ABTS radical of 45 µM ET/g FW. Similarly, in the optimization study of bioactive phenolic extraction from assai fruit conducted by Pompeu et al. [10], results similar to Borges’ were found regarding the extracting solvent. In this study, the best extraction results for phenolics were achieved using 45% ethanol in a 0.006 mol/L HCl acid medium at a temperature of 56 °C, albeit through maceration.

5. Conclusions

The implementation of the Surface Response methodology and statistical optimization techniques in the extraction processes has yielded a commercially viable method (hot maceration at 50 °C in 100% ethanol for 2 h) for producing highly antioxidant extracts, as demonstrated using ABTS (6.53 ± 0.10 µg/mL) and DPPH (14.71 ± 0.04 µg/mL) assays. These extracts exhibit activity comparable to purified antioxidant standards while employing a simple, scalable, green, and environmentally friendly methodology. While numerous studies have underscored the potential of green techniques applied to assai seeds, many have failed to establish reliable conditions suitable for application in small localities within the Amazon region. In contrast, our study has demonstrated consistency with the sustainable development objectives sought by local communities and overseas companies utilizing assai pulp in various products, thereby addressing concerns surrounding fair-trade practices. Furthermore, the process of obtaining concentrated extracts of antioxidant compounds from the seeds generates a significant mass residue that can still be reused for bioenergy generation, given its richness in cellulose and hemicellulose materials.

Author Contributions

Conceptualization, K.K.d.L.Y., V.F.d.V.-J. and E.S.L.; methodology, K.K.d.L.Y., V.F.d.V.-J. and E.S.L.; formal analysis, Y.C.-S., D.D., C.V.L.P. and K.K.d.L.Y.; investigation, D.D., L.F.R.P., C.V.L.P., E.S.L., V.F.d.V.-J. and K.K.d.L.Y.; resources, K.K.d.L.Y., V.F.d.V.-J. and E.S.L.; data curation, K.K.d.L.Y., V.F.d.V.-J. and E.S.L.; writing—original draft preparation, Y.C.-S., K.K.d.L.Y., V.F.d.V.-J. and E.S.L.; writing—review and editing, Y.C.-S., K.K.d.L.Y., V.F.d.V.-J. and E.S.L.; supervision, V.F.d.V.-J. and E.S.L.; project administration, V.F.d.V.-J. and E.S.L.; funding acquisition, V.F.d.V.-J. and E.S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by CNPq (Grant number 310782/2022-8), and FAPERJ (Grant Numbers E-26/200.512/2023 and E-26/211.315/2021); and FAPEAM (PROSPAM/008/2021 and Produtividade/CT&I/013/2022).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Linan, L.Z.; Cidreira, A.C.M.; Rocha, C.Q.; Menezes, F.F.; Rocha, G.J.M.; Paiva, A.E.M. Utilization of Acai Berry Residual Biomass for Extraction of Lignocellulosic Byproducts. J. Bioresour. Bioprod. 2021, 6, 323–337. [Google Scholar] [CrossRef]

- CONAB (Companhia Nacional de Abastecimento). Açaí (Fruto). Análise Mensal. 2019. Available online: https://www.conab.gov.br/info-agro/analises-do-mercado-agropecuario-e-extrativista/analises-do-mercado/historico-mensal-de-sociobiodiversidade/item/15517-acai-analise-mensal-dezembro-2020 (accessed on 27 February 2024).

- Laurindo, L.F.; Barbalho, S.M.; Araújo, A.C.; Guiguer, E.L.; Mondal, A.; Bachtel, G.; Bishayee, A. Açaí (Euterpeoleracea Mart.) in Health and Disease: A Critical Review. Nutrients 2023, 15, 989. [Google Scholar] [CrossRef] [PubMed]

- Jorge, F.T.A.; Silva, A.S.; Brigagão, G.V. Açaí waste valorization via mannose and polyphenols production: Techno-economic and environmental assessment. Biomass Conver. Bioref. 2024, 14, 3739–3752. [Google Scholar] [CrossRef]

- Melo, P.S.; Selani, M.M.; Gonçalves, R.H.; Paulino, J.O.; Massarioli, A.P.; Alencar, S.M. AçaiSeeds: An Unexplored Agro-Industrial Residue as a Potential Source of Lipids, Fibers, and Antioxidant Phenolic Compounds. Ind. Crop. Prod. 2021, 161, 113204. [Google Scholar] [CrossRef]

- Zeb, A. Concept, mechanism, and applications of phenolic antioxidants in foods. J. Food Biochem. 2020, 44, e13394. [Google Scholar] [CrossRef] [PubMed]

- Martins, G.R.; Amaral, F.R.L.; Brum, F.L.; Mohana-Borges, R.; Moura, S.S.T.; Ferreira, F.A.; Sangenito, L.S.; Santos, A.L.S.; Figueiredo, N.G.; Silva, A.S. Chemical Characterization, Antioxidant and Antimicrobial Activities of Açaí Seed (Euterpe oleracea Mart.) Extracts Containing A- and B-Type Procyanidins. LWT 2020, 132, 109830. [Google Scholar] [CrossRef]

- Martins, G.R.; Mattos, M.M.G.; Nascimento, F.M.; Brum, F.L.; Mohana-Borges, R.; Figueiredo, N.G.; Neto, D.F.M.; Domont, G.B.; Nogueira, F.C.S.; Paiva Campos, F.A.; et al. Phenolic Profile and Antioxidant Properties in Extracts of Developing Açaí (Euterpe oleracea Mart.) Seeds. J. Agric. Food Chem. 2022, 70, 16218–16228. [Google Scholar] [CrossRef]

- Albuquerque, B.R.; Heleno, S.A.; Oliveira, M.B.P.P.; Barros, L.; Ferreira, I.C.F.R. Phenolic compounds: Current industrial applications, limitations and future challenges. Food Funct. 2021, 12, 14–29. [Google Scholar] [CrossRef] [PubMed]

- Pompeu, D.R.; Silva, E.M.; Rogez, H. Optimisation of the solvent extraction of phenolic antioxidants from fruits of Euterpe oleracea using Response Surface Methodology. Bioresour. Technol. 2009, 100, 6076–6082. [Google Scholar] [CrossRef] [PubMed]

- Borges, P.R.; Tavares, E.G.; Guimarães, I.C.; de Paulo Rocha, R.; Araujo, A.B.; Nunes, E.E.; Vilas Boas, E.V. Obtaining a protocol for extraction of phenolics from açaí fruit pulp through Plackett-Burman design and response surface methodology. Food Chem. 2016, 210, 189–199. [Google Scholar] [CrossRef] [PubMed]

- Moura, C.; Reis, A.S.; Silva, L.D.; Lima, V.A.; Oldoni, T.L.C.; Pereira, C.; Carpes, S.T. Optimization of phenolic compounds extraction with antioxidant activity from açaí, blueberry and goji berry using response surface methodology. Emir. J. Food Agric. 2018, 30, 180–189. [Google Scholar]

- Yamaguchi, K.K.L.; Dias, D.S.; Lamarão, C.V.; Castelo, K.F.A.; Lima, M.S.; Antonio, A.S.; Converti, A.; Lima, E.S.; Veiga-Junior, V.F. Amazonian Bacuri (Platoniainsignis Mart.) Fruit Waste Valorisation Using Response Surface Methodology. Biomolecules 2021, 11, 1767. [Google Scholar] [CrossRef] [PubMed]

- Singleton, V.L.; Rossi, J.A.J. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- Chang, C.C.; Yang, M.H.; Wen, H.M.; Chern, J.C. Estimation of total flavonoid content in propolis by two complementary colorimetric methods. J. Food Drug Anal. 2002, 10, 178–182. [Google Scholar]

- Molyneux, P. The use of the stable free radical diphenylpicrylhydrazyl (DPPH) for estimating antioxidant activity. J. Sci. Technol. 2004, 26, 211–219. [Google Scholar]

- Re, R.; Pellegrini, N.; Proteggent, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS+ radical cation decolorization assay. Free Radic. Biol. Med. 1998, 26, 1231–1237. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).