Comparative Characteristics of Various Cereals in Terms of Fodder Value, Antinutrients and Use for Poultry Feeding

Abstract

1. Introduction

2. Fodder Value of Different Varieties of Cereals

3. Levels of Amino Acids in Compound Feed from Cereals

4. Vitamins and Microelements

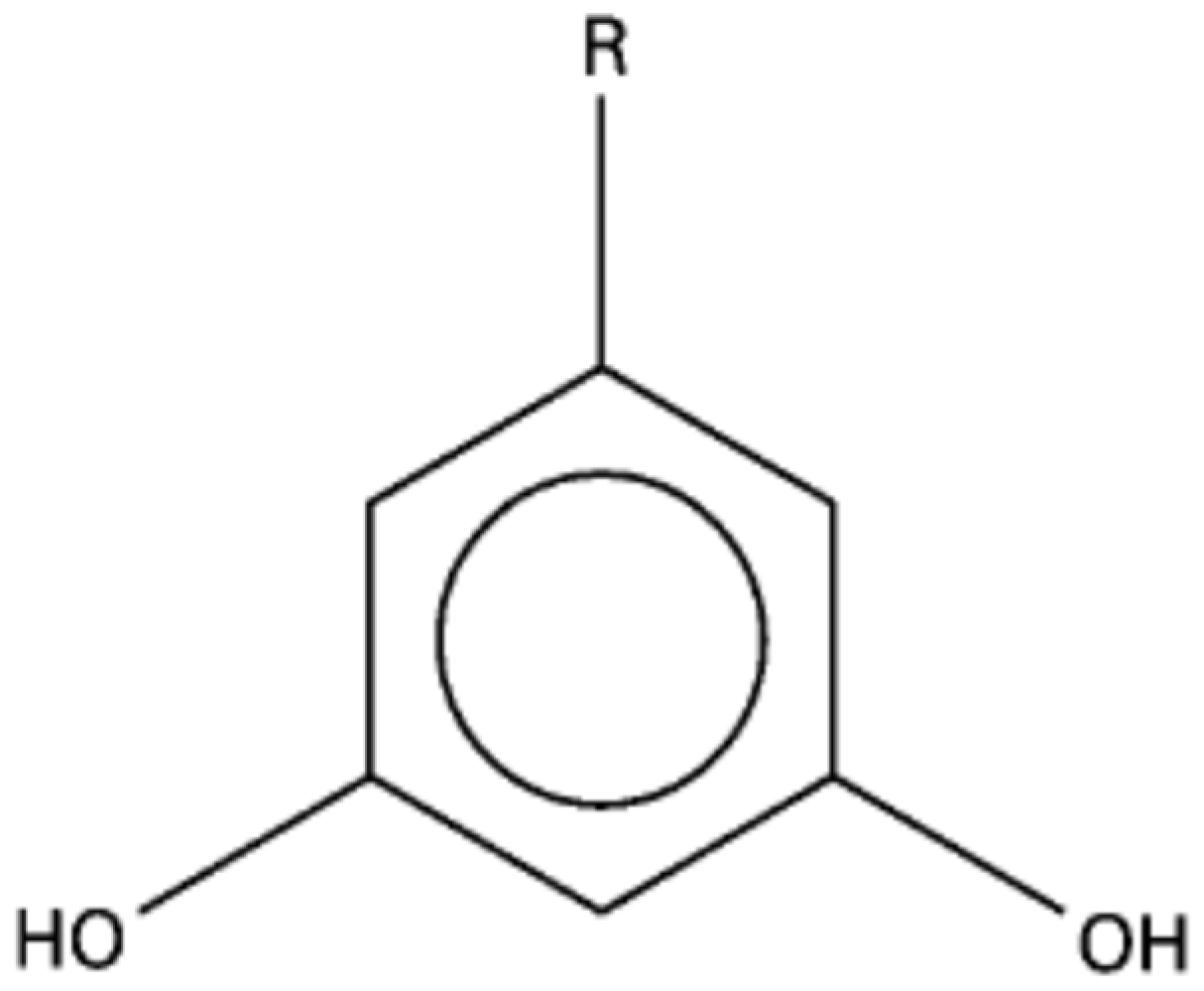

5. Nutritional Value as Affected by Antinutritional Factors in Cereals

6. Cereal Feeding Effect in Various Poultry Breeds

7. Ways to Increase the Efficiency of Using Cereals in Compound Feed for Poultry

7.1. Enzyme Preparations

7.2. Grain Processing

7.3. CRISPR-Edited Cereal Varieties

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jeyasri, R.; Muthuramalingam, P.; Satish, L.; Pandian, S.K.; Chen, J.-T.; Ahmar, S.; Wang, X.; Mora-Poblete, F.; Ramesh, M. An overview of abiotic stress in cereal crops: Negative impacts, regulation, biotechnology and integrated omics. Plants 2021, 10, 1472. [Google Scholar] [CrossRef]

- Nayik, G.A.; Tufail, T.; Anjum, F.M.; Javed Ansari, M. (Eds.) Cereal Grains: Composition, Nutritional Attributes, and Potential Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar] [CrossRef]

- Harlan, J.R.; de Wet, J.M.; Price, E.G. Comparative evolution of cereals. Evolution 1973, 27, 311–325. [Google Scholar] [CrossRef]

- Jin, Z.; Tilman, D. Crop diversity benefits increase with nation size. Nat. Food 2024, 5, 463–464. [Google Scholar] [CrossRef]

- Giordano, M.; Petropoulos, S.; Rouphael, Y. Response and defence mechanisms of vegetable crops against drought, heat and salinity stress. Agriculture 2021, 11, 463. [Google Scholar] [CrossRef]

- Kumari, V.V.; Roy, A.; Vijayan, R.; Banerjee, P.; Verma, V.C.; Nalia, A.; Pramanik, M.; Mukherjee, B.; Ghosh, A.; Reja, H.; et al. Drought and heat stress in cool-season food legumes in sub-tropical regions: Consequences, adaptation, and mitigation strategies. Plants 2021, 10, 1038. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, H.; Wang, L.; Qian, H. Physical, functional, and sensory characteristics of cereal extrudates. Int. J. Food Prop. 2014, 17, 1921–1933. [Google Scholar] [CrossRef]

- O’Neil, C.E.; Nicklas, T.A.; Zanovec, M.; Cho, S. Whole-grain consumption is associated with diet quality and nutrient intake in adults: The National Health and Nutrition Examination Survey, 1999–2004. J. Am. Diet. Assoc. 2010, 110, 1461–1468. [Google Scholar] [CrossRef]

- Papanikolaou, Y.; Fulgoni, V.L. Certain grain foods can be meaningful contributors to nutrient density in the diets of US children and adolescents: Data from the National Health and Nutrition Examination Survey, 2009–2012. Nutrients 2017, 9, 160. [Google Scholar] [CrossRef]

- Rajkumar, G.; Selvakulasingam, B. Comparative study of nutrient composition of selected cereal grains available in Jaffna, Sri Lanka. Ann. Biol. Res. 2019, 10, 21–24. Available online: https://www.researchgate.net/publication/335712795 (accessed on 18 April 2025).

- Torbica, A.; Belović, M.; Popović, L.; Čakarević, J.; Jovičić, M.; Pavličević, J. Comparative study of nutritional and technological quality aspects of minor cereals. J. Food Sci. Technol. 2021, 58, 311–322. [Google Scholar] [CrossRef]

- Alexandratos, N.; Bruinsma, J. World Agriculture Towards 2030/2050: The 2012 Revision. ESA Working Paper No. 12-03; FAO: Rome, Italy, 2012; Available online: https://www.fao.org/4/ap106e/ap106e.pdf (accessed on 18 April 2025).

- Olugbire, O.O.; Olorunfemi, S.; Oke, D.O. Global utilisation of cereals: Sustainability and environmental issues. Agro-Science 2021, 20, 9–14. [Google Scholar] [CrossRef]

- Kchaou, R.; Benyoussef, S.; Jebari, S.; Harbaoui, K.; Berndtsson, R. Forage potential of cereal–legume mixtures as an adaptive climate change strategy under low input systems. Sustainability 2023, 15, 338. [Google Scholar] [CrossRef]

- Bessarabova, R.F.; Toporova, L.B.; Egorov, I.A. Feed and Feeding of Poultry; Kolos: Moscow, Russia, 1992; Available online: https://elibrary.ru/item.asp?id=21391195 (accessed on 18 April 2025). (In Russian)

- Lemesheva, M.M. Poultry Feeding; Slobozhanshchyna: Sumy, Ukraine, 2003. (In Ukrainian) [Google Scholar]

- Egorov, I.A.; Imangulov, S.A. Results and prospects of research on feeding highly productive cross-breed poultry. Sb. Nauch. tr. VNITIP [Collect. Sci. Pap. All-Russ. Res. Tech. Poult. Inst.] 2005, 80, 98–103. Available online: https://www.elibrary.ru/item.asp?id=21185755 (accessed on 18 April 2025). (In Russian).

- Svezhentsov, A.I.; Urdzik, R.M.; Egorov, I.A. Feed and Feeding of Poultry; Art Press: Dnepropetrovsk, Ukraine, 2006; Available online: https://elibrary.ru/item.asp?id=21391203 (accessed on 18 April 2025). (In Russian)

- Gaviley, O.V. Efficiency of the Use of Triticale in Fodder for Breeding Chickens. Ph.D. Thesis, State Poultry Research Station of NAAS, Kharkov State Zooveterinary Academy, Kharkiv, Ukraine, 2018. [Google Scholar]

- Kyrychenko, V.V.; Maklyak, K.M.; Varenyk, B.F.; Kutishcheva, N.M.; Trotsenko, V.I. The practical characteristics expressing of three-linear sunflower hybrids in different agro-climatic zones of Ukraine. Vìsn. Sumsʹkogo Nac. Agrar. Unìv. Ser. Agron. Bìol. [Bull. Sumy Natl. Agrar. Univ. Ser. Agron. Biol.] 2016, 9, 129–133. Available online: https://web.archive.org/web/20220325181928/http://repo.snau.edu.ua/bitstream/123456789/5660/1/32.pdf (accessed on 18 April 2025). (In Ukrainian).

- Smith, R.L.; Jensen, L.S.; Hoveland, C.S.; Hanna, W.W. Use of pearl millet, sorghum, and triticale grain in broiler diets. J. Prod. Agric. 1989, 2, 78–82. [Google Scholar] [CrossRef]

- Bratishko, N.; Gaviley, E.; Pritulenko, O.; Tereshchenko, A. Triticale in compound feed for chicken breeders. Pticevod. [Poult. Farm.] 2008, 9, 30–32. Available online: https://www.elibrary.ru/item.asp?id=11566990 (accessed on 18 April 2025). (In Russian).

- Bratishko, N.I.; Gaviley, E.V.; Pritulenko, O.V.; Tereshchenko, A.V. Triticale in feeding meat-egg chickens. Pticevod. [Poult. Farm.] 2012, 4, 41–43. Available online: https://www.elibrary.ru/item.asp?id=17668326 (accessed on 18 April 2025). (In Russian).

- Bratyshko, N.I.; Gaviley, O.V.; Tereshchenko, O.V.; Prytulenko, O.V. Effect of triticale on the vitamin content of eggs of different chicken breeds. Ptahìvnictvo [Poult. Farm.] 2010, 65, 93–100. Available online: http://avianua.com/archiv/ptahivnictvo/65/10.pdf (accessed on 18 April 2025). (In Ukrainian).

- Zhukorskyi, O.; Prytulenko, O.; Tereshchenko, O.; Bratyshko, N. The presence of soybean, triticale and sorghum in compound feed for poultry is fully justified. Zerno i khlib [Grain Bread] 2012, 2, 14–16. Available online: https://www.researchgate.net/publication/342832208 (accessed on 18 April 2025). (In Ukrainian).

- Różewicz, M. Production, use and efficiency of utilising grains of various cereal species as feed resources for poultry production. Pol. J. Agron. 2019, 38, 66–74. [Google Scholar] [CrossRef]

- Farahat, M.; Badawi, M.; Hussein, A.; Attia, G. Effect of replacing dietary corn by sorghum on the growth performance, shank skin pigmentation, carcass traits, caecal microflora and nutrient digestibility of broiler chickens. Int. J. Poult. Sci. 2020, 19, 424–431. [Google Scholar] [CrossRef]

- Gaviley, O.V.; Katerynych, O.O.; Ionov, I.A.; Dekhtiarova, O.O.; Griffin, D.K.; Romanov, M.N. Triticale: A general overview of its use in poultry production. Encyclopedia 2024, 4, 395–414. [Google Scholar] [CrossRef]

- IndiaMART. Poultry Feed Black Rice, Sree Karpagavinayagar Stores. 2017. Available online: https://www.indiamart.com/proddetail/poultry-feed-black-rice-22989634233.html (accessed on 18 April 2025).

- Asyifah, M.N.; Abd-Aziz, S.; Phang, L.Y.; Azlian, M.N. Brown rice as a potential feedstuff for poultry. J. Appl. Poult. Res. 2012, 21, 103–110. [Google Scholar] [CrossRef]

- Nanto-Hara, F.; Ohtsu, H.; Yamazaki, M.; Hirakawa, T.; Sato, K.; Murakami, H. Effects of dietary brown rice on the growth performance, systemic oxidative status, and splenic inflammatory responses of broiler chickens under chronic heat stress. J. Poult. Sci. 2021, 58, 154–162. [Google Scholar] [CrossRef]

- Gradziuk, P.; Jończyk, K.; Gradziuk, B.; Wojciechowska, A.; Trocewicz, A.; Wysokiński, M. An economic assessment of the impact on agriculture of the proposed changes in EU biofuel policy mechanisms. Energies 2021, 14, 6982. [Google Scholar] [CrossRef]

- Liu, X.; Unaegbunam, E.; Stuart, D.T. Co-production of isobutanol and ethanol from prairie grain starch using engineered Saccharomyces cerevisiae. Fermentation 2021, 7, 150. [Google Scholar] [CrossRef]

- Wilczyński, D.; Talaśka, K.; Wałęsa, K.; Wojtkowiak, D.; Bembenek, M. Experimental study on the cutting process of single triticale straws. Materials 2023, 16, 3943. [Google Scholar] [CrossRef]

- Obidziński, S.; Cwalina, P.; Kowczyk-Sadowy, M.; Krasowska, M.; Sienkiewicz, A.; Faszczewski, D.; Szyszlak-Bargłowicz, J. The use of bread bakery waste as a binder additive in the production of fuel pellets from straw. Energies 2023, 16, 7313. [Google Scholar] [CrossRef]

- Aaman, P.; Hesselman, K. Analysis of starch and other main constituents of cereal grains. Swed. J. Agric. Res. 1984, 14, 135–139. Available online: https://agris.fao.org/search/en/records/6471ba8c77fd37171a6d7ad1 (accessed on 18 April 2025).

- Erickson, J.P. Triticale—A review of its nutritional value. Millg. Feed Fertil. 1984, 167, 13–15. Available online: https://www.cabidigitallibrary.org/doi/full/10.5555/19841460877 (accessed on 18 April 2025).

- Al-Athari, A.K.; Guenter, W. Nutritional value of triticale (Carman) for broiler diets. Anim. Feed Sci. Technol. 1988, 22, 119–130. [Google Scholar] [CrossRef]

- Al-Athari, A.K.; Guenter, W. The effect of fat level and type on the utilization of triticale (cultivar Carman) by broiler chicks. Anim. Feed Sci. Technol. 1989, 22, 273–284. [Google Scholar] [CrossRef]

- Flores, M.P.; Castaño, J.I.R.; McNab, J.M. Effect of enzyme supplementation of wheat and triticale based diets for broilers. Anim. Feed Sci. Technol. 1994, 49, 237–243. [Google Scholar] [CrossRef]

- Samtiya, M.; Aluko, R.E.; Dhewa, T. Plant food anti-nutritional factors and their reduction strategies: An overview. Food Prod. Process. Nutr. 2020, 2, 6. [Google Scholar] [CrossRef]

- Xu, X.; Tao, J.; Wang, Q.; Ge, J.; Li, J.; Gao, F.; Gao, S.; Yang, Q.; Feng, B.; Gao, J. A comparative study: Functional, thermal and digestive properties of cereal and leguminous proteins in ten crop varieties. LWT 2023, 187, 115288. [Google Scholar] [CrossRef]

- Tarasewicz, Z.; Gardzielewska, J.; Szczerbińska, D.; Ligocki, M.; Jakubowska, M.; Majewska, D. The effect of feeding with low-protein feed mixes on the growth and slaughter value of young male Pharaoh quails. Arch. Anim. Breed. 2007, 50, 520–530. [Google Scholar] [CrossRef]

- Grela, E.R.; Kowalczuk-Vasilev, E.; Świątkiewicz, M.; Skiba, G. Barley, triticale, or rye? The type of grain can affect the growth performance and meat quality of sustainable raised pigs. Animals 2023, 13, 1331. [Google Scholar] [CrossRef]

- Jensen, L.S.; Chang, C.H.; Wyatt, R.D. Influence of carbohydrate source on liver fat accumulation in hens. Poult. Sci. 1976, 55, 700–709. [Google Scholar] [CrossRef]

- Campbell, G.L.; Classen, H.L.; Goldsmith, K.A. Effect of fat retention on the rachitogenic effect of rye fed to broiler chicks. Poult. Sci. 1983, 62, 2218–2223. [Google Scholar] [CrossRef]

- D’Alfonso, T.N.; Corbett, J.L. Factors affecting ileal digestible energy of corn in poultry diets. Rec. Adv. Anim. Nutr. Aust. 2003, 14, 151–156. [Google Scholar]

- Panin, I. The corn as an ingredient of compound feeds. Kombikorma [Compound Feeds] 2006, 6, 67–68. Available online: https://elibrary.ru/item.asp?id=9282026 (accessed on 18 April 2025). (In Russian with English description).

- Hossan, M.S.; Kruk, Z.A.; Lee, B.D. Nutritive value of corn distillers died grains with solubles as an ingredient of poultry diets: A review. Worlds Poult. Sci. J. 2010, 66, 411–432. [Google Scholar] [CrossRef]

- Lázaro, R.; Garcia, M.; Medel, P.; Mateos, G.G. Influence of enzymes on performance and digestive parameters of broilers fed rye-based diets. Poult. Sci. 2003, 82, 132–140. [Google Scholar] [CrossRef]

- Péron, A.; Gomez, J.; Mignon-Grasteau, S.; Sellier, N.; Besnard, J.; Derouet, M.; Juin, H.; Carré, B. Effects of wheat quality on digestion differ between the D+ and D- chicken lines selected for divergent digestion capacity. Poult. Sci. 2006, 85, 462–469. [Google Scholar] [CrossRef]

- Fernandez, R.; Lucas, E.; McGinnis, J. Comparative nutritional value of different cereal grains as protein sources in a modified chick bioassay. Poult. Sci. 1974, 53, 39–46. [Google Scholar] [CrossRef]

- McCracken, K.J.; Quintin, G. Metabolisable energy content of diets and broiler performance as affected by wheat specific weight and enzyme supplementation. Br. Poult. Sci. 2000, 41, 332–342. [Google Scholar] [CrossRef]

- Volyanskaya, A.R.; Akberdin, I.R.; Kulyashov, M.A.; Yevshin, I.S.; Romanov, M.N.; Shagimardanova, E.I.; Gusev, O.A.; Kolpakov, F.A. A bird’s-eye overview of molecular mechanisms regulating feed intake in chickens—With mammalian comparisons. Anim. Nutr. 2024, 17, 61–74. [Google Scholar] [CrossRef]

- Pirgozliev, V.R.; Rose, S.P.; Kettlewell, P.S. Effect of ambient storage of wheat samples on their nutritive value for chickens. Br. Poult. Sci. 2006, 47, 342–349. [Google Scholar] [CrossRef]

- Scott, T.A.; Silversides, F.G.; Classen, H.L.; Swift, M.L.; Bedford, M.R.; Hall, J.W. A broiler chick bioassay for measuring the feeding value of wheat and barley in complete diets. Poult. Sci. 1998, 77, 449–455. [Google Scholar] [CrossRef]

- McCracken, K.J.; Preston, C.M.; Butler, C. Effects of wheat variety and specific weight on dietary apparent metabolisable energy concentration and performance of broiler chicks. Br. Poult. Sci. 2002, 43, 253–260. [Google Scholar] [CrossRef]

- Pettersson, D.; Åman, P. Effects of enzyme supplementation of diets based on wheat, rye or triticale on their productive value for broiler chickens. Anim. Feed Sci. Technol. 1988, 20, 313–324. [Google Scholar] [CrossRef]

- Barneveld, R.J.; Cooper, K.V. Nutritional Quality of Triticale for Pigs and Poultry. In Proceedings of the 5th International Triticale Symposium, Radzików, Poland, 30 June–5 July 2002; Plant Breeding and Acclimatization Institute: Radzików, Poland, 2002; Volume I, pp. 277–282. Available online: https://www.cabidigitallibrary.org/doi/full/10.5555/20123096537 (accessed on 18 April 2025).

- MacAuliffe, T.; McGinnis, J. Effect of ultraviolet light and oral vitamin D3 on rachitic chicks fed diets containing either corn or rye. Poult. Sci. 1976, 55, 2305–2309. [Google Scholar] [CrossRef]

- Odetallah, N.H.; Parks, C.W.; Ferket, P.R. Effect of wheat enzyme preparation on the performance characteristics of tom turkeys fed wheat-based rations. Poult. Sci. 2002, 81, 987–994. [Google Scholar] [CrossRef]

- Kuznetsova, T. The effect of the enzyme and acidifier on the egg quality. Kombikorma [Compound Feeds] 2007, 2, 78–80. Available online: https://elibrary.ru/item.asp?id=9474339 (accessed on 18 April 2025). (In Russian with English description).

- Jiang, Z.; Zhou, Y.; Lu, F.; Han, Z.; Wang, T. Effects of different levels of supplementary alpha-amylase on digestive enzyme activities and pancreatic amylase mRNA expression of young broilers. Asian-Australas. J. Anim. Sci. 2008, 21, 97–102. [Google Scholar] [CrossRef]

- Lázaro, R.; Latorre, M.A.; Medel, P.; Gracia, M.; Mateos, G.G. Feeding regimen and enzyme supplementation to rye-based diets for broilers. Poult. Sci. 2004, 83, 152–160. [Google Scholar] [CrossRef]

- Shafey, T.M.; Dingle, J.G.; McDonald, M.W. Comparison between wheat, triticale, rye, soyabean oil and strain of laying bird on the production, and cholesterol and fatty acid contents of eggs. Br. Poult. Sci. 1992, 33, 339–346. [Google Scholar] [CrossRef] [PubMed]

- Pan, C.F.; Igbasan, F.A.; Guenter, W.; Marquardt, R.R. The effects of enzyme and inorganic phosphorus supplements in wheat- and rye-based diets on laying hen performance, energy, and phosphorus availability. Poult. Sci. 1998, 77, 83–109. [Google Scholar] [CrossRef]

- Kim, S.M.; Patel, M.B.; Reddy, S.J. Effects of different cereal grains in diets for laying hens on production parameters and liver fat content. Poult. Sci. 1976, 55, 520–530. [Google Scholar] [CrossRef]

- Richter, G.; Lemser, A. The use of native triticale in poultry. 3. Use in laying hens. Arch. Tierernahr. 1993, 43, 237–244. [Google Scholar] [CrossRef]

- Çiftci, I.; Yenise, E.; Eleroglu, H. Use of triticale alone and in combination with wheat or maize: Effects of diet type and enzyme supplementation on hen performance, egg quality, organ weights, intestinal viscosity and digestive system characteristics. Anim. Feed Sci. Technol. 2003, 105, 149–161. [Google Scholar] [CrossRef]

- Wu, G. Amino Acids: Biochemistry and Nutrition, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar] [CrossRef]

- D’Mello, J.P.F. (Ed.) Amino Acids in Animal Nutrition, 2nd ed.; CABI Publishing: Wallingford, UK, 2003. [Google Scholar] [CrossRef]

- Lukht, G.V. The influence of heat treatment on the nutritional value of compound feeds. Kombikorma [Compd. Feeds] 1999, 8, 43–45. (In Russian) [Google Scholar]

- De Lange, L.; Rombouts, C.; Elferink, G.O. Practical application and advantages of using total digestible amino acids and undigestible crude protein to formulate broiler diets. Worlds Poult. Sci. J. 2003, 59, 447–457. [Google Scholar] [CrossRef]

- Serova, O.; Red, E.; Sadovnikova, N. Optimization and reduction in cost of rations for industrial poultry. Pticevod. [Poult. Farm.] 2005, 10, 23–26. Available online: https://elibrary.ru/item.asp?id=16711218 (accessed on 18 April 2025). (In Russian).

- Lenkova, T.N. Multienzyme compositions in compound feeds containing non-traditional components. Ptica i pticeprodukty [Poult. Chicken Products] 2007, 2, 46–49. Available online: https://elibrary.ru/item.asp?id=15489799 (accessed on 18 April 2025). (In Russian).

- Okolelova, T.M.; Savchenko, V.S. Determination of the effectiveness of dietary supplements Livamin and Fitoliv in feed for broilers. In Materials of the VI International Poultry Veterinary Congress, Moscow, Russia, 26–29 April 2010; Smolensky, V.I., Ed.; ZAO Znak Corporation: Moscow, Russia, 2010; pp. 244–246. Available online: https://elibrary.ru/item.asp?id=27133771 (accessed on 18 April 2025). (In Russian)

- Petrukhin, I.V.; Poloz, D.D. Feed and Feed Additives; Rosagropromizdat: Moscow, Russia, 1989; Available online: https://www.studmed.ru/petruhin-i-v-korma-i-kormovye-dobavki_1506641238b.html (accessed on 18 April 2025). (In Russian)

- Sharshunov, V.A.; Popkov, N.A.; Ponomarenko, Y.A.; Chervyakov, A.V.; Bortnik, S.A.; Kandaurov, S.N.; Koshkin, S.D.; Ponomarenko, V.S. Compound Feeds and Feed Additives; Ekoperspektiva: Minsk, Belarus, 2002; Available online: https://elibrary.ru/item.asp?id=47111223 (accessed on 18 April 2025). (In Russian)

- Ponomarenko, Y.A.; Fisinin, V.I.; Egorov, I.A. Feed, Feed Additives, Biologically Active Substances for Poultry; VNITIP: Sergiev Posad, Russia, 2009; Available online: https://elibrary.ru/item.asp?id=19514172 (accessed on 18 April 2025). (In Russian)

- National Research Council. Nutrient Requirements of Swine, 11th ed.; National Research Council of the National Academies, The National Academies Press: Washington, DC, USA, 2012; Available online: https://nap.nationalacademies.org/catalog/13298/nutrient-requirements-of-swine-eleventh-revised-edition (accessed on 18 April 2025)ISBN 0309224233.

- Ibatullin, I.I.; Kryvenok, M.Y.; Ilchuk, I.I.; Yastrebov, K.Y.; Yanchevskyi, O.S. Digestibility of feed nutrients and methionine balance in the body of chickens of the parent flock at different levels of methionine in the diets. Sučasne Ptahìvnictvo [Mod. Poult. Farm.] 2013, 5, 2–5. Available online: https://lib.dsau.dp.ua/book/105660?lang=en (accessed on 18 April 2025). (In Ukrainian).

- Otchenashko, V.V. Productivity of meat quails fed compound feeds with different levels of crude protein. Sb. Nauč. Tr. SWorld [Collect. Sci. Pap. SWorld] 2013, 4, 79–87. Available online: https://elibrary.ru/item.asp?id=21110040 (accessed on 18 April 2025). (In Ukrainian).

- Emtseva, M.V. The use of Vrn genes for creation of triticale forms with different length of vegetation period. Sel’Skokhozyaistvennaya Biol. [Agric. Biol.] 2019, 55, 3–14. [Google Scholar] [CrossRef]

- Fagundes, N.S.; Milfort, M.C.; Williams, S.M.; Da Costa, M.J.; Fuller, A.L.; Menten, J.F.; Rekaya, R.; Aggrey, S.E. Dietary methionine level alters growth, digestibility, and gene expression of amino acid transporters in meat-type chickens. Poult. Sci. 2020, 99, 67–75. [Google Scholar] [CrossRef]

- Rani, M.; Singh, G.; Siddiqi, R.A.; Gill, B.S.; Sogi, D.S.; Bhat, M.A. Comparative quality evaluation of physicochemical, technological, and protein profiling of wheat, rye, and barley cereals. Front. Nutr. 2021, 8, 694679. [Google Scholar] [CrossRef]

- Narushin, V.G.; Volkova, N.A.; Vetokh, A.N.; Dzhagaev, A.Y.; Volkova, L.A.; Griffin, D.K.; Romanov, M.N.; Zinovieva, N.A. Metabolic rate and egg production in Japanese quails can be predicted by assessing growth parameters of laying hens. Animals 2024, 14, 258. [Google Scholar] [CrossRef]

- Chen, C.H.; Bushuk, W. Nature of proteins in Triticale and its parental species: I. Solubility characteristics and amino acid composition of endosperm proteins. Can. J. Plant Sci. 1970, 50, 9–14. [Google Scholar] [CrossRef]

- Nte, I.J.; Gunn, H.H. Cysteine in broiler poultry nutrition. In Bioactive Compounds—Biosynthesis, Characterization and Applications; Queiroz Zepka, L., Nascimento, T.C.d., Jacob-Lopes, E., Eds.; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Egorov, B.V.; Makarinskaya, A.V.; Sitko, A.N. Problem of providing feed products with lysine. Efektyvni kormy ta hodivlya [Eff. Feeds Feeding] 2006, 3, 46–50. Available online: https://lib.dsau.dp.ua/book/27778 (accessed on 18 April 2025). (In Russian).

- Egorov, B.V.; Makarinskaya, A.V.; Sitko, A.N. The problem of providing lysine to feed products. Hran. i pererab. zerna [Grain Storage Process.] 2006, 6, 40–43. Available online: https://lib.dsau.dp.ua/book/28240 (accessed on 18 April 2025). (In Russian).

- WHO/FAO/UNU. Protein and Amino Acid Requirements in Human Nutrition; Report of a Joint WHO/FAO/UNU Expert Consultation, Geneva, Switzerland, 9–16 April 2002; WHO Technical Report Series No. 935.; WHO: Geneva, Switzerland, 2007. [Google Scholar]

- Pesti, G.M. Impact of dietary amino acid and crude protein levels in broiler feeds on biological performance. J. Appl. Poult. Res. 2009, 18, 477–486. [Google Scholar] [CrossRef]

- Wu, Y.B.; Ravindran, V.; Thomas, D.G.; Birtles, M.J.; Hendriks, W.H. Influence of method of whole wheat inclusion and xylanase supplementation on the performance, apparent metabolisable energy, digestive tract measurements and gut morphology of broilers. Br. Poult. Sci. 2004, 45, 385–394. [Google Scholar] [CrossRef]

- He, W.; Li, P.; Wu, G. Amino acid nutrition and metabolism in chickens. Adv. Exp. Med. Biol. 2021, 1285, 109–131. [Google Scholar] [CrossRef]

- Arkhipov, A.V. Ways to improve the efficiency of feed use. Pticevod. [Poult. Farm.] 1989, 3, 14–17. (In Russian) [Google Scholar]

- Myer, R.O.; Brendemuhl, J.H.; Barnett, R.D. Crystalline lysine and threonine supplementation of soft red winter wheat or triticale, low-protein diets for growing-finishing swine. J. Anim. Sci. 1996, 74, 577–583. [Google Scholar] [CrossRef] [PubMed]

- Lagodyuk, P.; Slabitskyi, Y.; Ratych, I.; Kyryliv, Y. Synthetic Amino Acids and Sulfur—Stimulators of Animal and Poultry Productivity: Methodical Recommendations; n.p.: Lviv, Ukraine, 1987. (In Ukrainian) [Google Scholar]

- Popkov, N.A.; Fisinin, V.I.; Egorov, I.A.; Ponomarenko, Y.A.; Sharshunov, V.A.; Ponomarenko, V.S. Feed and Biologically Active Substances; Беларуская навука: Minsk, Belarus, 2005; Available online: https://elibrary.ru/item.asp?id=23202572 (accessed on 18 April 2025). (In Russian)

- Alagawany, M.; El-Hindawy, M.M.; Ali, A.A.; Soliman, M.M. Protein and total sulfur amino acids relationship effect on performance and some blood parameters of laying hens. Egypt. J. Nutr. Feed. 2011, 14, 477–487. Available online: https://www.researchgate.net/publication/258763293 (accessed on 18 April 2025).

- Yegorov, I.A.; Imangulov, S.A. Improving normalyzed nutrition system of poultry of high-productive crosses under modern conditions. Dokl. Ross. Akad. S.-kh. Nauk [Dokl. Russ. Acad. Agric. Sci.] 2005, 5, 36–38. Available online: https://www.elibrary.ru/item.asp?id=18215028 (accessed on 18 April 2025). (In Russian).

- Podobed, L.I. Comparative effectiveness of lysine feed preparations in mixed feed for farm animals and poultry. Efektyvne tvarynnytstvo [Eff. Anim. Husb.] 2006, 7, 22–27. Available online: https://lib.dsau.dp.ua/book/37046?lang=en (accessed on 18 April 2025). (In Russian).

- Manni, K.; Lötjönen, T.; Huuskonen, A. Comparing spring triticale varieties to barley and wheat varieties when harvested as whole crop. Agric. Food Sci. 2021, 30, 24–35. [Google Scholar] [CrossRef]

- Surai, P.F.; Fisinin, V.I. Antioxidant Systems of the Body: From Vitamin E to Polyphenols and Beyond. In Proceedings of the 35th Western Nutrition Conference, Edmonton, AB, Canada, 24–25 September 2014; pp. 265–277. Available online: https://www.cabidigitallibrary.org/doi/pdf/10.5555/20163076348 (accessed on 18 April 2025).

- Waldman, A.R.; Surai, P.F.; Ionov, I.A.; Sakhatsky, N.I. Vitamins in Animal Nutrition (Metabolism and Requirements); RIP Original: Kharkov, Ukraine, 1993. (In Russian) [Google Scholar]

- Surai, P.F.; Kochish, I.I.; Romanov, M.N.; Griffin, D.K. Nutritional modulation of the antioxidant capacities in poultry: The case of vitamin E. Poult. Sci. 2019, 98, 4030–4041. [Google Scholar] [CrossRef]

- Surai, P.F.; Fisinin, V.I.; Grozina, A.A.; Kochish, I.I.; Nikonov, I.N.; Romanov, M.N. From Regulation of Vitagens to Optimization of Microbiota: New Approaches to Maintaining Intestinal Health in Poultry. In World and Russian Trends in Development of Poultry Industry: Realities and Challenges of Future. In Proceedings of the 19th International Conference, Sergiyev Posad, Russia, 15–17 May 2018; Fisinin, V.I., Ed.; World’s Poultry Science Association, Russian Branch. All-Russian Research and Technological Poultry Institute: Sergiyev Posad, Russia, 2018; pp. 80–81. Available online: https://elibrary.ru/item.asp?id=32796640 (accessed on 18 April 2025). (In Russian).

- Surai, P.F.; Kochish, I.I.; Fisinin, V.I.; Nikonov, I.N.; Romanov, M.N. Polyphenolic Compounds in Poultry Nutrition: Microbiota, Redox Balance and Vitagenes in the Gut. In Materials of the 2nd International Scientific and Practical Conference on Molecular Genetic Technologies for Analysis of Gene Expression Related to Animal Productivity and Disease Resistance; Sel’skokhozyaistvennye tekhnologii: Moscow, Russia, 2020; pp. 100–114. (In Russian with English summary). [Google Scholar] [CrossRef]

- Ionov, I.A.; Katerinich, O.O.; Kuchmistov, V.O.; Anisimova, O.V.; Griffin, D.K.; Romanov, M.N.; Zhukova, I.O. Vitamin E and A availability in goose embryos and goslings and improvement of reproduction traits depending on the starting temperature regime of egg incubation. Poultry 2023, 2, 305–319. [Google Scholar] [CrossRef]

- Surai, P.F.; Ionov, I.A.; Bondarenko, Y.V. The content of carotenoids and vitamin A in the yolk of poultry eggs. Naučno-teh. Bûll. Inst. Pticevod. [Poult. Res. Inst. Ukr. Acad. Agrar. Sci. Kharkiv Ukr.] 1992, 33, 28–33. (In Russian) [Google Scholar]

- Khvostik, V.P.; Bondarenko, Y.V. Yakisni pokaznyky yayets’ m’yaso-yayechnykh kurey riznoho henezysu [Qualitative indicators of eggs of meat and egg chickens of different genesis]. Vìsn. Sumsʹkogo Nac. Agrar. Unìv. Ser. Tvarynnytstvo [Bull. Sumy Natl. Agrar. Univ. Ser. Livest.] 2020, 4, 82–87. Available online: https://snaubulletin.com.ua/index.php/ls/article/download/262/227 (accessed on 18 April 2025). (In Ukrainian).

- Singh, P.K. Significance of phytic acid and supplemental phytase in chicken nutrition: A review. Worlds Poult. Sci. J. 2008, 64, 553–580. [Google Scholar] [CrossRef]

- Prajapati, M.; Shah, H. Impacts and industrial applications of phytic acid and phytase. J. Pure Appl. Microbiol. 2022, 16, 2292–2302. [Google Scholar] [CrossRef]

- Bresler, V.M. Biological basis for the formation of nutrition type. In Production and Use of Feed Microbial Protein; n.p.: Moscow, Russia, 1989; pp. 63–72. (In Russian) [Google Scholar]

- Choct, M.; Annison, G. The inhibition of nutrient digestion by wheat pentosans. Br. J. Nutr. 1992, 67, 123–132. [Google Scholar] [CrossRef]

- Annison, G. Determination of the AME of wheat using gnotobiotic chickens. In Recent Advances in Animal Nutrition in Australia; University of New England: Armidale, Australia, 1989; p. 2A. Available online: https://www.cabidigitallibrary.org/doi/full/10.5555/19891422072 (accessed on 18 April 2025).

- Mathlouthi, N.; Lalles, J.P.; Lepercq, P.; Juste, C.; Larbier, M. Xylanase and β-glucanase supplementation improve conjugated bile acid fraction in intestinal contents and increase villus size of small intestine wall in broiler chickens fed a rye-based diet. J. Anim. Sc. 2002, 80, 2773–2779. [Google Scholar] [CrossRef]

- Kozmina, N.P. Biochemistry of Grain and Products of Its Processing; Kolos: Moscow, Russia, 1976; Available online: https://www.studmed.ru/kozmina-n-p-biohimiya-zerna-i-produktov-ego-pererabotki_3e96aa3e455.html (accessed on 18 April 2025). (In Russian)

- Fincher, G.B.; Stone, B.A. Cell walls and their components in cereal grain technology. Adv. Cereal Sci. Technol. 1986, 8, 207–295. Available online: https://pascal-francis.inist.fr/vibad/index.php?action=getRecordDetail&idt=7415418 (accessed on 18 April 2025).

- Annison, G. Polysaccharide composition of Australian wheats and the digestibility of their starches in broiler chicken diets. Aust. J. Exp. Agric. 1990, 30, 183–186. [Google Scholar] [CrossRef]

- Knudsen, K.E. Fiber and nonstarch polysaccharide content and variation in common crops used in broiler diets. Poult. Sci. 2014, 93, 2380–2393. [Google Scholar] [CrossRef]

- Antoniou, T.; Marquardt, R.R. Influence of rye pentosans on the growth of chicks. Poult. Sci. 1981, 60, 1898–1904. [Google Scholar] [CrossRef]

- Okolelova, T.M.; Kulakov, A.V.; Moloskin, S.A.; Grachev, D.M. Current Problems in the Use of Biologically Active Substances and the Production of Premixes; n.p.: Sergiev Posad, Russia, 2002; Available online: https://elibrary.ru/item.asp?id=22397504 (accessed on 18 April 2025). (In Russian)

- Aftab, U.; Bedford, M.R. The use of NSP enzymes in poultry nutrition: Myths and realities. Worlds Poult. Sci. J. 2018, 74, 277–286. [Google Scholar] [CrossRef]

- Iji, P.A. The impact of cereal non starch polysaccharides on intestinal development and function in broiler chickens. Worlds Poult. Sci. J. 1999, 55, 375–387. [Google Scholar] [CrossRef]

- Suchecka, D.; Gromadzka-Ostrowska, J.; Żyła, E.; Harasym, J.; Oczkowski, M. Selected physiological activities and health promoting properties of cereal beta-glucans. A review. J. Anim. Feed Sci. 2017, 26, 183–191. [Google Scholar] [CrossRef]

- Novak, M.; Vetvicka, V. β-glucans, history, and the present: Immunomodulatory aspects and mechanisms of action. J. Immunotoxicol. 2008, 5, 47–57. [Google Scholar] [CrossRef]

- Choct, M. Enzymes for the feed industry: Past, present and future. Worlds Poult. Sci. J. 2006, 62, 5–16. [Google Scholar] [CrossRef]

- Masenya, T.I.; Mlambo, V.; Mnisi, C.M. Complete replacement of maize grain with sorghum and pearl millet grains in Jumbo quail diets: Feed intake, physiological parameters, and meat quality traits. PLoS ONE 2021, 16, e0249371. [Google Scholar] [CrossRef]

- Okolelova, T.M.; Kulakov, A.V.; Moloskin, S.A.; Grachev, D.M. Antinutrient feed factors and enzymes. Efektyvni Kormy ta Hodivlya [Eff. Feeds Feeding] 2005, 3, 33–41. (In Russian) [Google Scholar]

- Zannini, E.; Bravo Núñez, Á.; Sahin, A.W.; Arendt, E.K. Arabinoxylans as functional food ingredients: A review. Foods 2022, 11, 1026. [Google Scholar] [CrossRef]

- Ragaee, S.M.; Campbell, G.L.; Scoles, G.J.; McLeod, J.G.; Tyler, R.T. Studies on rye (Secale cereale L.) lines exhibiting a range of extract viscosities. 1. Composition, molecular weight distribution of water extracts, and biochemical characteristics of purified water-extractable arabinoxylan. J. Agric. Food Chem. 2001, 49, 2437–2445. [Google Scholar] [CrossRef]

- Ross, A.B.; Shepherd, M.J.; Knudsen, K.E.B.; Glitsø, L.V.; Bowey, E.; Phillips, J.; Rowland, I.; Guo, Z.X.; Massy, D.J.R.; Åman, P.; et al. Absorption of dietary alkylresorcinols in ileal-cannulated pigs and rats. Br. J. Nutr. 2003, 90, 787–794. [Google Scholar] [CrossRef]

- Annison, G. Relationship between the levels of non-starch polysaccharides and the apparent metabolisable energy of wheat assayed in broiler chickens. J. Agric. Food Chem. 1991, 39, 1252–1256. [Google Scholar] [CrossRef]

- Zabolotneva, A.A.; Shatova, O.P.; Sadova, A.A.; Shestopalov, A.V.; Roumiantsev, S.A. An overview of alkylresorcinols biological properties and effects. J. Nutr. Metab. 2022, 2022, 4667607. [Google Scholar] [CrossRef]

- Tian, S.; Sun, Y.; Chen, Z.; Zhao, R. Bioavailability and bioactivity of alkylresorcinols from different cereal products. J. Food Qual. 2020, 2020, 5781356. [Google Scholar] [CrossRef]

- Wilson, B.J.; McNab, J.M. The nutritive value of triticale and rye in broiler diets containing field beans (Vicia faba L.). Br. Poult. Sci. 1975, 16, 17–22. [Google Scholar] [CrossRef]

- Landfried, K.E. Die Eignung von Triticale als Futter für Geflügel [The suitability of Triticale as feed for poultry]. Osterr. Geflugelwirtsch. [Austrian Poult. Farm.] 1989, 28, 310–314. (In German) [Google Scholar]

- Tletzeruk, I.; Chikov, A. The use of triticale in diets of chickens. Pticevod. [Poult. Farm.] 2009, 4, 14–17. Available online: https://elibrary.ru/item.asp?id=16897376 (accessed on 18 April 2025). (In Russian with English summary).

- Nuriev, G.G.; Borovik, E.S. Results of studies on replacing wheat with triticale grain in the diet of broiler chickens. Vestn. Brânskoj GSHA [Vestn. Bryansk State Agric. Acad.] 2012, 6, 20–24. Available online: https://www.bgsha.com/download/education/library/vestnik/vestnik-6-2012.pdf (accessed on 18 April 2025). (In Russian).

- Jaroni, D.; Scheideler, S.E.; Beck, M.; Wyatt, C. The effect of dietary wheat middlings and enzyme supplementation. 1. Late egg production efficiency, egg yields, and egg composition in two strains of Leghorn hens. Poult. Sci. 1999, 78, 841–847. [Google Scholar] [CrossRef]

- Jadhao, S.B.; Chandramoni; Tiwari, C.M.; Khan, M.Y. Efficiency of utilization of energy from maize- and broken rice-based diets in old White Leghorn and Rhode Island Red laying hens. Br. Poult. Sci. 1999, 40, 275–283. [Google Scholar] [CrossRef]

- Moiseeva, I.G. Cholesterol in hen’s eggs. Pticevod. [Poult. Farm.] 1964, 7, 29. Available online: https://www.cabidigitallibrary.org/doi/full/10.5555/19651400243 (accessed on 18 April 2025). (In Russian).

- Moiseeva, I.G. Soderzhanie lipidov i kholesterina v iatsakh kur russkoĭ beloĭ porody v sviazi s produktivnost’iu [The lipid and cholesterin contents of hen’s eggs of the Russian white breed in relation to productiveness]. Tr. Akad. Nauk SSSR Inst. Genet. 1965, 33, 119–128. Available online: https://www.cabidigitallibrary.org/doi/full/10.5555/19660103382 (accessed on 18 April 2025). (In Russian).

- Moiseeva, I.G. Content of lipids and cholesterol in eggs of Russian White chickens. Collect. Work. Young Sci. All-Union Res. Tech. Poult. Inst. 1966, 8, 225–235. (In Russian) [Google Scholar]

- Nadeem, M.; Anjum, F.M.; Amir, R.M.; Khan, M.R.; Hussain, S.; Javed, M.S. An overview of anti-nutritional factors in cereal grains with special reference to wheat—A review. Pak. J. Food Sci. 2010, 20, 54–61. Available online: https://www.researchgate.net/publication/233816063 (accessed on 18 April 2025).

- Egorov, I.; Egorova, A. The role of enzyme preparations in increasing the efficiency of compound feeds containing difficult-to-hydrolyze components. Ptitsefabrika [Poult. Farm] 2008, 12, 16–36. Available online: https://www.elibrary.ru/item.asp?id=26305913 (accessed on 18 April 2025). (In Russian).

- Coppedge, J.R.; Oden, L.A.; Ratliff, B.; Brown, B.; Ruch, F.; Lee, J.T. Evaluation of nonstarch polysaccharide-degrading enzymes in broiler diets varying in nutrient and energy levels as measured by broiler performance and processing parameters. J. Appl. Poult. Res. 2012, 21, 226–234. [Google Scholar] [CrossRef]

- Ma, J.; Dai, H.; Liu, H.; Du, W. Effects of cutting stages and additives on the fermentation quality of triticale, rye and oat silage in Qinghai-Tibet Plateau. Agronomy 2022, 12, 3113. [Google Scholar] [CrossRef]

- Bedford, M.R.; Morgan, A.J. The use of enzymes in poultry diets. Worlds Poult. Sci. J. 1996, 52, 61–68. [Google Scholar] [CrossRef]

- Okolelova, T.M.; Fisinin, V.I.; Dogadaev, D.A. Enzymes in Poultry Feeding: Guidelines; VNITIP: Sergiev Posad, Russia, 2005. (In Russian) [Google Scholar]

- Brenes, A.; Centeno, C.; Viveros, A.; Arija, I. Effect of enzyme addition on the nutritive value of high oleic acid sunflower seeds in chicken diets. Poult. Sci. 2008, 87, 2300–2310. [Google Scholar] [CrossRef]

- Svezhentsov, A.I.; Gorlach, S.A.; Martynyak, S.V. Compound Feeds, Premixes, BMVD for Animals and Poultry; Art Press: Dnepropetrovsk, Ukraine, 2008. (In Russian) [Google Scholar]

- Bouyeh, M.; Gevorgian, O.X. Influence of different levels of lysine, methionine and protein on the performance of laying hens after peak. J. Anim. Vet. Adv. 2011, 10, 532–537. [Google Scholar] [CrossRef]

- Datsyuk, I.; Bondarenko, V. Slaughter indicators of young pigs when feeding BVMD “Activities” and premix “Intremix”. Sci. Eur. 2021, 3, 10–23. [Google Scholar] [CrossRef]

- Kislukhina, O.V. Enzymes in Food and Feed Production; DeLi Print: Moscow, Russia, 2002; Available online: https://www.livelib.ru/book/1000022283-fermenty-v-proizvodstve-pischi-i-kormov-o-v-kisluhina (accessed on 18 April 2025). (In Russian)

- Zarghi, H.; Golian, A. Effect of triticale replacement and enzyme supplementation on performance and blood chemistry of broiler chickens. J. Anim. Vet. Adv. 2009, 8, 1316–1321. Available online: https://www.researchgate.net/publication/202542972 (accessed on 18 April 2025).

- Okolelova, T.M.; Kulakov, A.V.; Moloskin, S.A. Vitamin and Mineral Nutrition of Poultry; n.p.: Moscow, Russia, 2000; Available online: https://elibrary.ru/item.asp?id=22397498 (accessed on 18 April 2025). (In Russian)

- Scholtyssek, S.; Knorr, R. The effect of a cellulolytic enzyme mixture in the broiler feed with triticale and rye. Arch. Geflugelk. 1987, 51, 10–15. Available online: https://agris.fao.org/search/en/providers/122438/records/64775177a3fd11e430392767 (accessed on 18 April 2025).

- Kononenko, S.I. Efficiency of using enzymatic preparations in concentrates for swine. Probl. Biol. Produkt. Zivotn. [Probl. Prod. Anim. Biol.] 2009, 1, 86–91, (In Russian with English summary). [Google Scholar]

- Agrawal, P.K. Changes in amylase, starch and reducing sugars during grain development in triticale and their relation to grain shrivelling. Cereal Res. Commun. 1977, 5, 225–233. Available online: https://www.jstor.org/stable/23778562 (accessed on 18 April 2025).

- Fontes, C.M.G.A.; Ponte, P.I.P.; Reis, T.C.; Soares, M.C.; Gama, L.T.; Dias, F.M.V.; Ferreira, L.M.A. A family 6 carbohydrate-binding module potentiates the efficiency of a recombinant xylanase used to supplement cereal-based diets for poultry. Br. Poult. Sci. 2004, 45, 648–656. [Google Scholar] [CrossRef]

- Gao, F.; Jiang, Y.; Zhou, G.H.; Han, Z.K. The effects of xylanase supplementation on growth, digestion, circulating hormone and metabolite levels, immunity and gut microflora in cockerels fed on wheat-based diets. Br. Poult. Sci. 2007, 48, 480–488. [Google Scholar] [CrossRef] [PubMed]

- Kalmendal, R.; Tauson, R. Effects of a xylanase and protease, individually or in combination, and an ionophore coccidiostat on performance, nutrient utilization, and intestinal morphology in broiler chickens fed a wheat-soybean meal-based diet. Poult. Sci. 2012, 91, 1387–1393. [Google Scholar] [CrossRef] [PubMed]

- Gracheva, I.M.; Krivova, A.Y. Technology of Enzyme Preparations, 3rd ed.; Elevar: Moscow, Russia, 2000; Available online: https://www.elibrary.ru/item.asp?id=28410320 (accessed on 18 April 2025). (In Russian)

- Tumene, M. Who needs enzymes and why. Zivotnovod. Rossii [Anim. Husb. Russ.] 2004, 8, 36–37. (In Russian) [Google Scholar]

- Kononenko, S.I.; Paksyutov, N.S. Enzyme preparation Ronozyme WX in compound feed with triticale for young pigs. Tr. Kubanskogo Gos. Agrar. Un-ta [Works Kuban State Agrar. Univ.] 2009, 1, 169–171. Available online: https://www.elibrary.ru/item.asp?id=12861304 (accessed on 18 April 2025). (In Russian with English summary).

- Perttilä, S.; Valaja, J.; Partanen, K.; Jalava, T.; Kiiskinen, T.; Palander, S. Effects of preservation method and β-glucanase supplementation on ileal amino acid digestibility and feeding value of barley for poultry. Br. Poult. Sci. 2001, 42, 218–229. [Google Scholar] [CrossRef]

- Wang, Z.R.; Qiao, S.Y.; Lu, W.Q.; Li, D.F. Effects of enzyme supplementation on performance, nutrient digestibility, gastrointestinal morphology, and volatile fatty acid profiles in the hindgut of broilers fed wheat-based diets. Poult. Sci. 2005, 84, 875–881. [Google Scholar] [CrossRef]

- Korolev, A.; Sobolev, M. Preparations of the Fermentol group. Pticevod. [Poult. Farm.] 2007, 12, 36. Available online: https://www.elibrary.ru/item.asp?id=9916037 (accessed on 18 April 2025). (In Russian).

- Kuznetsova, T. Enzymes and acidifiers in rye-based feeds. Pticevod. [Poult. Farm.] 2007, 7, 15. (In Russian) [Google Scholar]

- Lazareva, N. Enzyme Wheat ZV 200 in broiler diets. Pticevod. [Poult. Farm.] 2007, 5, 41–42. (In Russian) [Google Scholar]

- Olukosi, O.A.; Cowieson, A.J.; Adeola, O. Influence of enzyme supplementation of maize–soyabean meal diets on carcase composition, whole-body nutrient accretion and total tract nutrient retention of broilers. Br. Poult. Sci. 2008, 49, 436–445. [Google Scholar] [CrossRef]

- García, M.; Lázaro, R.; Latorre, M.A.; Gracia, M.I.; Mateos, G.G. Influence of enzyme supplementation and heat processing of barley on digestive traits and productive performance of broilers. Poult. Sci. 2008, 87, 940–948. [Google Scholar] [CrossRef]

- Lakomyy, A.A. The influence of biologically active additives on the productivity of broiler chickens. Obrazovanie, nauka i proizvodstvo [Educ. Sci. Prod.] 2016, 1, 20–22. Available online: https://elibrary.ru/item.asp?id=25917747 (accessed on 18 April 2025). (In Russian).

- Kryukov, V.; Bevzyuk, V. Sunflower meal and feed enzymes. Pticevod. [Poult. Farm.] 1997, 4, 19–20. (In Russian) [Google Scholar]

- Partridge, G. Feed enzyme technology aims to reduce feed costs. Food Int. 2008, 4, 36–38. Available online: https://www.cabidigitallibrary.org/doi/full/10.5555/20083114283 (accessed on 18 April 2025).

- Kurkiev, U.K.; Kurkiev, K.U. Triticale Resistance to Yellow Rust. In Scientific Support for the Production of Triticale Grain and Its Processing Products; Abstracts of Reports of the Scientific Practical Conference, Kharkiv, Ukraine, 6–8 July 2005; V.Ya. Yuriev Institute of Plant Production: Kharkiv, Ukraine, 2005; pp. 3–15. (In Ukrainian) [Google Scholar]

- Guerreiro, C.I.P.D.; Ribeiro, T.; Ponte, P.I.P.; Lordelo, M.M.S.; Falcao, L.; Freire, J.P.B.; Ferreira, L.M.A.; Prates, J.A.M.; Fontes, C.M.G.A. Role of a family 11 carbohydrate-binding module in the function of a recombinant cellulase used to supplement a barley-based diet for broiler chickens. Br. Poult. Sci. 2008, 49, 446–454. [Google Scholar] [CrossRef]

- Romero, L. Effect of feed enzymes on poultry intestinal health. Tsenovik [Pricer] 2015, 4, 78–83. Available online: https://web.archive.org/web/20230224050139/https://issuu.com/annapimenova/docs/cenovik_04_2015_web_d47d6cec1fe80f (accessed on 18 April 2025). (In Russian).

- Rotter, B.A.; Marquardt, R.R.; Guenter, W.; Biliaderis, C.; Newman, C.W. In vitro viscosity measurements of barley extracts as predictors of growth responses in chicks fed barley-based diets supplemented with a fungal enzyme preparation. Can. J. Anim. Sci. 1989, 69, 431–439. [Google Scholar] [CrossRef]

- Parsaie, S.; Shariatmadari, F.; Zamiri, M.J.; Khajeh, K. Influence of wheat-based diets supplemented with xylanase, bile acid and antibiotics on performance, digestive tract measurements and gut morphology of broilers compared with a maize-based diet. Br. Poult. Sci. 2007, 48, 594–600. [Google Scholar] [CrossRef]

- Rutherfurd, S.M.; Chung, T.K.; Moughan, P.J. The effect of a commercial enzyme preparation on apparent metabolizable energy, the true ileal amino acid digestibility, and endogenous ileal lysine losses in broiler chickens. Poult. Sci. 2007, 86, 665–672. [Google Scholar] [CrossRef]

- Pan, L.; Huang, K.H.; Middlebrook, T.; Zhang, D.; Bryden, W.L.; Li, X. Rumen degradability of barley, oats, sorghum, triticale, and wheat in situ and the effect of pelleting. Agriculture 2021, 11, 647. [Google Scholar] [CrossRef]

- Preston, C.M.; McCracken, K.J.; McAllister, A. Effect of diet form and enzyme supplementation on growth, efficiency and energy utilisation of wheat-based diets for broilers. Br. Poult. Sci. 2000, 41, 324–331. [Google Scholar] [CrossRef]

- Venäläinen, E.; Valkonen, E.; Jalava, T.; Valaja, J. Effect of Crimped Barley on the Performance of Broiler Chickens. In Proceedings of the 16th European Symposium on Poultry Nutrition, Strasbourg, France, 26–30 August 2007; European Federation of WPSA Branches, Working Group No. 2 Nutrition: Strasbourg, France, 2007; pp. 79–82. Available online: https://wpsa.fr/images/publications/espn_2007_proceedings.pdf (accessed on 18 April 2025).

- Karabulya, B.V. Extrusion Technology Is a Promising Way to Create New Food Products; MoldNIINTI: Chisinau, Moldova, 1989. (In Russian) [Google Scholar]

- Hrytsenko, R.B.; Prytulenko, O.V.; Tereshchenko, O.V.; Gaviley, O.V. Economic efficiency of using triticale extrudates in feeding poultry breeders. Ptahìvnictvo [Poult. Farm.] 2009, 63, 54–61. Available online: https://www.researchgate.net/publication/342883188 (accessed on 18 April 2025). (In Ukrainian).

- Dryga, N.M.; Zverev, F.I.; Chumakov, N.Y. Extrusion is an effective way to process plant feed. Nauk.-Teh. Bûl.—Livest. Farm. Inst. For.-Steppe Poles. Ukr. SSR 1979, 26, 41–45. (In Russian) [Google Scholar]

- Trunova, L.; Boyko, L.; Zotkin, V. Production of full-fat soybeans using modern extruders. Kombikorma [Compound Feeds] 2003, 8, 31–32. (In Russian) [Google Scholar]

- Sharan, A.V.; Shapovelenko, O.I. Research on the technology of extruding sprouted wheat grains. Hran. i Pererab. Zerna [Grain Storage Process.] 2004, 9, 40–41. Available online: https://dspace.nuft.edu.ua/items/5d1f0b4d-c0d4-4b10-95a4-33eb5de6cd29 (accessed on 18 April 2025). (In Ukrainian).

- Toporova, L.V.; Troshkin, A.N.; Todorova, I.V. Rational ways to increase the nutritional value of full-fat soybeans and prospects for use in animal feeding. Efektyvni Kormy ta Hodivlya [Eff. Feeds Feeding] 2006, 6, 22–25. Available online: https://lib.dsau.dp.ua/book/37019 (accessed on 18 April 2025). (In Russian).

- Zhushman, A.I.; Koptelova, E.K.; Karpov, V.G. Modern Advances in Technology of Extruded Starch Products; AgroNIITEIPP: Moscow, Russia, 1989. (In Russian) [Google Scholar]

- Kovbasa, V.M.; Myronova, N.G.; Shapoval, S.V. Changes in the carbohydrate complex of cereals during extrusion. Vìsn. agrar. nauki [Bull. Agric. Sci.] 1997, 3, 55–57. (In Ukrainian) [Google Scholar]

- Makowska, A.; Baranowska, H.M.; Michniewicz, J.; Chudy, S.; Kowalczewski, P.Ł. Triticale extrudates—Changes of macrostructure, mechanical properties and molecular water dynamics during hydration. J. Cereal Sci. 2017, 74, 250–255. [Google Scholar] [CrossRef]

- Gulati, P.; Brahma, S.; Rose, D.J. Chapter 13–Impacts of extrusion processing on nutritional components in cereals and legumes: Carbohydrates, proteins, lipids, vitamins, and minerals. In Extrusion Cooking, 2nd ed.; Ganjyal, G.M., Ed.; Elsevier Inc.: Amsterdam, The Netherlands; Woodhead Publ., Cereals & Grains Association: Duxford, UK, 2020; pp. 415–443. [Google Scholar] [CrossRef]

- Kokin, V.K.; Orlov, A.I.; Vorobyova, A.S. The influence of extrusion of components on the quality of compound feeds. In Production, Storage and Use of Compound Feeds, Proceedings of the All-Union Research Institute of Feed Industry; All-Union Research Institute of Feed Industry: Moscow, Russia, 1979; pp. 74–76. [Google Scholar]

- Ushkalova, V.N. Food Lipid Stability; Kolos: Moscow, Russia, 1973; Available online: https://books.google.com/books?id=HEKLAAAACAAJ (accessed on 18 April 2025). (In Russian)

- Bogdanov, G.A.; Zverev, A.I.; Prokopenko, L.S.; Privalo, O.E. Handbook of Feed and Feed Additives; Bogdanov, G.A., Ed.; Urozhay: Kiev, Ukraine, 1984. (In Russian) [Google Scholar]

- Escalante-Aburto, A.; Figueroa-Cárdenas, J.d.D.; Dominguez-Lopez, A.; García-Lara, S.; Ponce-García, N. Multivariate analysis on the properties of intact cereal kernels and their association with viscoelasticity at different moisture contents. Foods 2023, 12, 808. [Google Scholar] [CrossRef]

- Dziki, D.; Hassoon, W.H.; Kramek, A.; Krajewska, A. Grinding characteristics of new varieties of winter triticale grain. Processes 2023, 11, 1477. [Google Scholar] [CrossRef]

- Diependaete, J. Aliment flocon: Digestion facile, lactation tranguelle [Cereal food: Easy digestion, easy lactation]. Agrusert 1985, 1051, 27. (In French) [Google Scholar]

- Shahzad, R.; Jamil, S.; Ahmad, S.; Nisar, A.; Khan, S.; Amina, Z.; Kanwal, S.; Aslam, H.M.U.; Gill, R.A.; Zhou, W. Biofortification of cereals and pulses using new breeding techniques: Current and future perspectives. Front. Nutr. 2021, 8, 721728. [Google Scholar] [CrossRef] [PubMed]

- Monisha, M.; Swetha, L.; Shai Prasanna, G.S. Enhancing nutritional quality through genomic tools. In Advances in Genomics for Crop Improvement; Thange, V.B., Vishwakarma, S.K., Shamkuwar, S.G., Vishwakarma, S.K., Shekhawat, P.K., Eds.; Golden Leaf Publishers: Lucknow, Uttar Pradesh, India, 2025; pp. 313–344. [Google Scholar]

- Dellino, M.; de Giovanni, C.; Miazzi, M.M.; Montemurro, C.; Nigro, D. Genome editing technologies to improve health-related phytocompounds in crops. Food Front. 2025. [Google Scholar] [CrossRef]

- Ijaz, S.; Iqbal, J.; Abbasi, B.A.; Ullah, Z.; Yaseen, T.; Murtaza, G.; Iqbal, R.; Hyder, S.; Harsonowati, W.; Kanwal, S.; et al. Biofortification of cereals and pulses using new breeding techniques. In Crop Biofortification: Biotechnological Approaches for Achieving Nutritional Security Under Changing Climate; Shah, A.N., Faiz, S., Aslam, M., Iqbal, J., Qayyum, A., Eds.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2025; pp. 33–50. [Google Scholar] [CrossRef]

- Ahmar, S.; Hensel, G.; Gruszka, D. CRISPR/Cas9-mediated genome editing techniques and new breeding strategies in cereals—Current status, improvements, and perspectives. Biotechnol. Adv. 2023, 69, 108248. [Google Scholar] [CrossRef]

- Basu, U.; Riaz Ahmed, S.; Bhat, B.A.; Anwar, Z.; Ali, A.; Ijaz, A.; Gulzar, A.; Bibi, A.; Tyagi, A.; Nebapure, S.M.; et al. A CRISPR way for accelerating cereal crop improvement: Progress and challenges. Front. Genet. 2023, 13, 866976. [Google Scholar] [CrossRef]

- Bratyshko, N.I.; Gaviley, O.V.; Prytulenko, O.V.; Tereshchenko, O.V.; Polyakova, L.L.; Hrytsenko, R.B. A method of increasing the efficiency of using triticale in feeding laying hens. Ptahìvnictvo [Poult. Farm.] 2009, 63, 101–109. Available online: https://www.researchgate.net/publication/342782229 (accessed on 18 April 2025).

- Bratyshko, N.I.; Prytulenko, O.V.; Tereshchenko, O.V.; Gaviley, O.V.; Hrytsenko, R.B. The Economic Efficiency of Using Triticale Extrudates in Breeding Poultry. In Proceedings of the V International Conference “Poultry Industry-2009”, Sudak, Ukraine, 21–24 September 2009; pp. 36–40. Available online: https://www.researchgate.net/publication/342781962 (accessed on 18 April 2025). (In Ukrainian).

| Cereals | Moisture (%) | Crude Protein (%) | Crude Fat (%) | Starch (%) | Amylose (%) |

|---|---|---|---|---|---|

| Corn | 13.94 | 6.86 | 0.51 | 63.12 | 26.80 |

| Rice | 14.97 | 7.06 | 0.66 | 81.36 | 21.26 |

| Millet | 10.93 | 11.20 | 2.47 | 69.83 | 18.84 |

| Black rice | 13.67 | 8.52 | 2.16 | 69.36 | 15.03 |

| Wheat | 12.14 | 12.09 | 1.55 | 73.40 | 25.42 |

| Barley | 12.75 | 11.04 | 1.75 | 74.94 | 37.19 |

| Oat | 13.02 | 12.80 | 6.14 | 66.11 | 48.27 |

| Buckwheat | 12.84 | 12.77 | 1.32 | 63.26 | 32.54 |

| Sorghum | 13.64 | 10.19 | 0.95 | 70.85 | 12.92 |

| Cereal | Factor | Protein Quality (%) | |||||

|---|---|---|---|---|---|---|---|

| Available Carbohydrates (%) | Energy (kJ/100 g) | Digestible Energy (%) | True Digestibility | Biological Value | Net Protein Utilization | Utilization Protein | |

| Wheat | 69.7 | 1570 | 86.4 | 96.0 | 55.0 | 53.0 | 5.6 |

| Corn | 63.6 | 1660 | 87.2 | 95.0 | 61.0 | 58.0 | 5.7 |

| Rice | 64.3 | 1610 | 96.3 | 99.7 | 74.0 | 73.8 | 5.4 |

| Barley | 55.8 | 1630 | 81.0 | 88.0 | 70.0 | 62.0 | 6.8 |

| Sorghum | 62.9 | 1610 | 79.9 | 84.8 | 59.2 | 50.0 | 4.2 |

| Oat | 62.9 | 1640 | 70.6 | 84.1 | 70.4 | 59.1 | 5.5 |

| Millet | 63.4 | 1650 | 87.2 | 93.0 | 60.0 | 56.0 | 6.4 |

| Rye | 71.8 | 1570 | 85.0 | 77.0 | 77.7 | 59.0 | 5.1 |

| Cereal | Essential Amino Acids (g/16 g N) | |||

|---|---|---|---|---|

| Lysine | Threonine | Methionine + Cysteine | Tryptophan | |

| Wheat | 2.3 | 2.8 | 3.6 | 1.0 |

| Corn | 2.5 | 3.2 | 3.9 | 0.6 |

| Rice | 3.8 | 3.6 | 3.9 | 1.1 |

| Barley | 3.2 | 2.9 | 3.9 | 1.7 |

| Sorghum | 2.7 | 3.3 | 2.8 | 1.0 |

| Oat | 4.0 | 3.6 | 4.8 | 0.9 |

| Millet | 2.7 | 3.2 | 3.6 | 1.3 |

| Rye | 3.7 | 3.3 | 3.7 | 1.0 |

| Amino Acids | Barley | Rye | Triticale | Oat | Sorghum | Millet |

|---|---|---|---|---|---|---|

| Histidine | 33.6 | 15.5 | 26.8 | 37.2 | 18.8 | 23.2 |

| Isoleucine | 111.2 | 26.4 | 33.3 | 70.8 | 33.1 | 48.5 |

| Leucine | 12.1 | 71.3 | 87.0 | 132.1 | 138.2 | 193.0 |

| Lysine | 55.2 | 89.9 | 43.9 | 36.0 | 12.0 | 17.9 |

| Methionine + Cysteine | 58.6 | 17.1 | 40.7 | 51.6 | 17.3 | 33.8 |

| Phenylalanine + Tyrosine | 228.4 | 19.4 | 45.5 | 79.2 | 54.8 | 46.4 |

| Threonine | 49.1 | 36.4 | 39.8 | 60.0 | 29.3 | 36.9 |

| Valine | 56.0 | 66.7 | 47.2 | 103.2 | 42.8 | 54.9 |

| Cereal | Vitamins (mg/100 g) | ||

|---|---|---|---|

| B1 (Thiamine) | B₂ (Riboflavin) | B₃ (Niacin) | |

| Wheat | 0.45 | 0.10 | 3.7 |

| Corn | 0.32 | 0.10 | 1.9 |

| Rice | 0.29 | 0.04 | 4.0 |

| Barley | 0.10 | 0.04 | 2.7 |

| Sorghum | 0.33 | 0.13 | 3.4 |

| Oat | 0.60 | 0.14 | 1.3 |

| Millet | 0.63 | 0.33 | 2.0 |

| Rye | 0.66 | 0.25 | 1.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaviley, O.V.; Katerynych, O.O.; Ionov, I.A.; Griffin, D.K.; Dekhtiarova, O.O.; Romanov, M.N. Comparative Characteristics of Various Cereals in Terms of Fodder Value, Antinutrients and Use for Poultry Feeding. Encyclopedia 2025, 5, 63. https://doi.org/10.3390/encyclopedia5020063

Gaviley OV, Katerynych OO, Ionov IA, Griffin DK, Dekhtiarova OO, Romanov MN. Comparative Characteristics of Various Cereals in Terms of Fodder Value, Antinutrients and Use for Poultry Feeding. Encyclopedia. 2025; 5(2):63. https://doi.org/10.3390/encyclopedia5020063

Chicago/Turabian StyleGaviley, Olena V., Oleg O. Katerynych, Igor A. Ionov, Darren K. Griffin, Olena O. Dekhtiarova, and Michael N. Romanov. 2025. "Comparative Characteristics of Various Cereals in Terms of Fodder Value, Antinutrients and Use for Poultry Feeding" Encyclopedia 5, no. 2: 63. https://doi.org/10.3390/encyclopedia5020063

APA StyleGaviley, O. V., Katerynych, O. O., Ionov, I. A., Griffin, D. K., Dekhtiarova, O. O., & Romanov, M. N. (2025). Comparative Characteristics of Various Cereals in Terms of Fodder Value, Antinutrients and Use for Poultry Feeding. Encyclopedia, 5(2), 63. https://doi.org/10.3390/encyclopedia5020063