Provenance in the Context of Metrological Traceability

Abstract

1. Introduction

2. Background and Relevance with Metrological Traceability

“The property of the result of a measurement or the value of a standard whereby it can be related to stated references, usually national or international standards, through an unbroken chain of comparisons all having stated uncertainties. It is noted that traceability only exists when scientifically rigorous evidence is collected on a continuing basis showing that the measurement is producing documented results for which the total measurement uncertainty is quantified.”

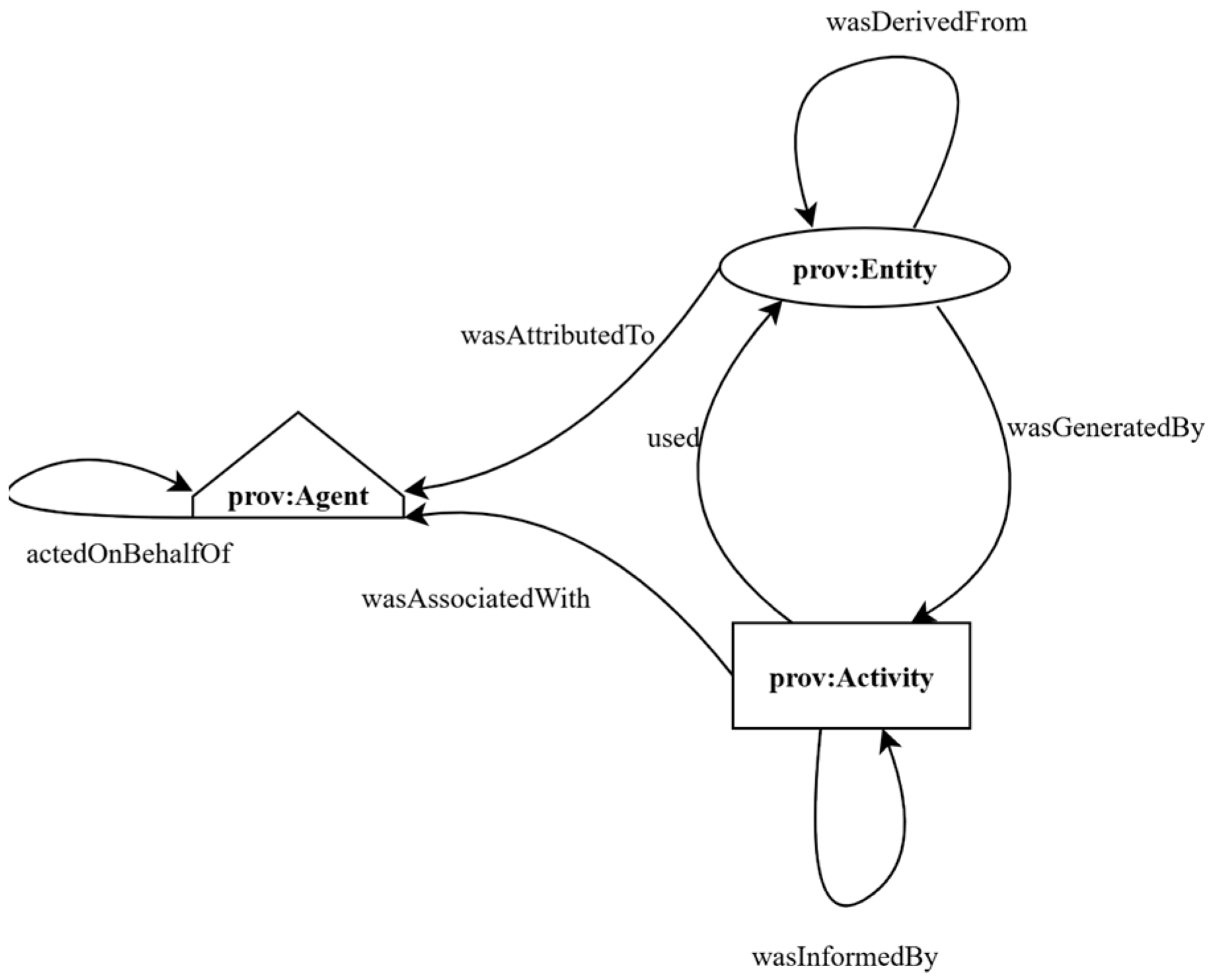

3. Provenance and the W3C Family of Specifications

3.1. Core Concepts of the PROV Data Model

- Identifier: Identifies an instance of a class. An identifier is required for entities, activities, and agents. Two entities (respectively, activities and agents) are equal if they have the same identifier.

- Label: Provides a human-readable representation of an instance of a PROV data model type or relation.

- Location: Defines an identifiable geographic or non-geographic place.

- Type: Defines the type or subclass of an agent or entity. Multiple types can be defined.

- Role: Defines the function of an agent or entity in an activity.

- Value: Provides a direct representation of an entity.

3.2. Relationships in PROV-DM

- wasGeneratedBy: relates an entity with the activity from which produces it (metrological example: a measurement result can be generated by a calibration).

- used: connects an activity with an entity that plays a role in its occurrence (metrological example: calibration activity can use a collection of working measurement standards).

- wasAssociatedWith: connects an agent with an activity for which it is responsible (metrological example: a NMI can be associated with report issuance).

- wasAttributedTo: connects an agent with an entity to which it is attributed (metrological example: a calibration report can be attributed to a laboratory, or a measurement artifact can be attributed to a client).

3.3. Extended PROV Structures

- SoftwareAgent: A software agent is a subclass of an agent responsible for software execution (e.g., a specific server that executes data processing steps on data received from a data acquisition system).

- Person: A person is a subclass of an agent specifying an individual responsible for activities.

- Organization: An organization is a subclass of an agent responsible for activities or entities.

- Plan: A subclass of an entity representing a set of actions intended by agents. (e.g., detailed documentation of a measurement procedure or method adhered to by a measurement technician).

- Collection: An entity providing a structure to some constituent that must be an entity as well. The provenance of a collection can be expressed as well as its member entities (e.g., an ensemble of check standards used to validate the stability of a working standard).

3.4. Provenance in Calibration Certificates

3.5. Provenance of Document Creation and Editing

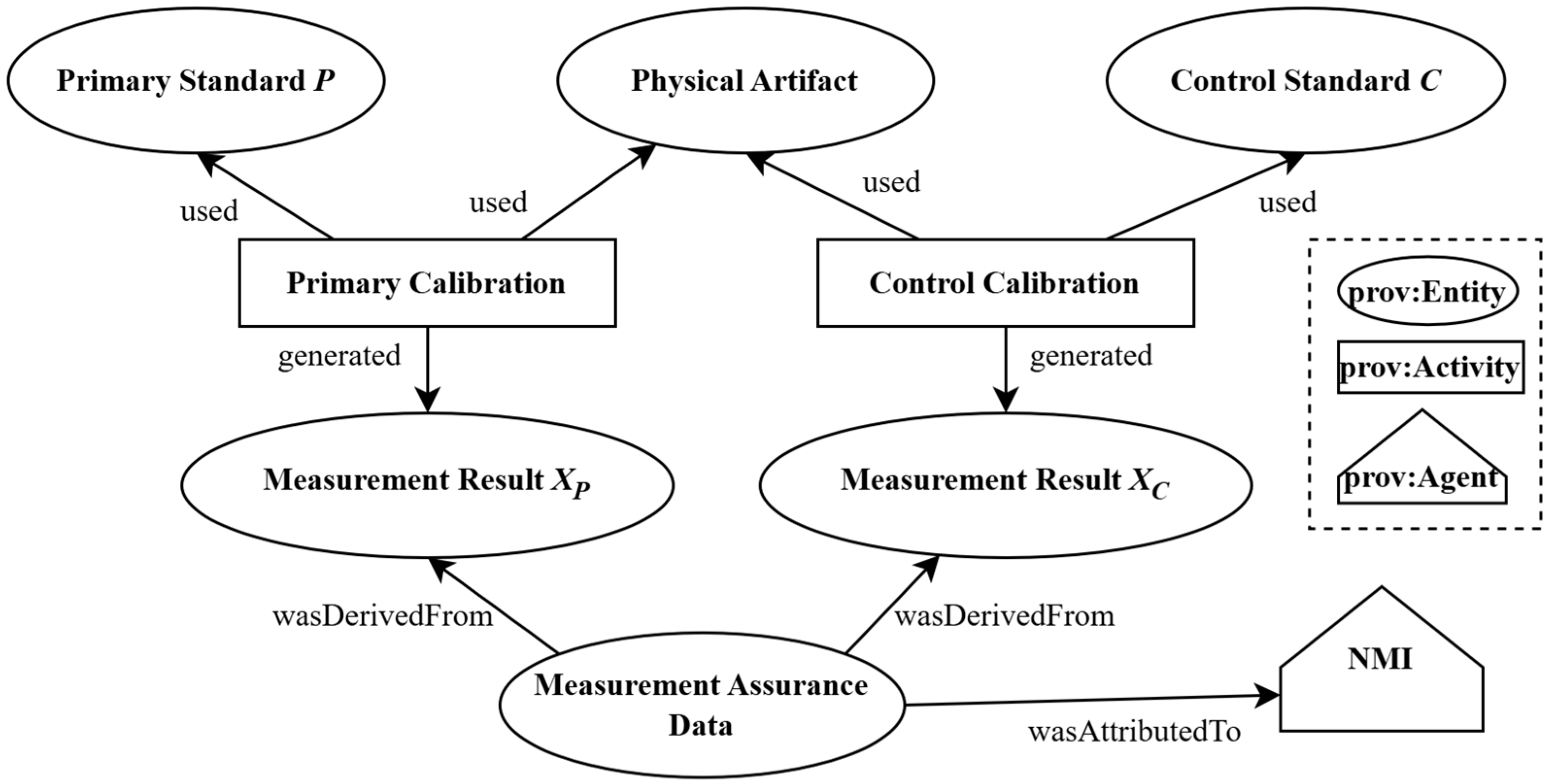

4. Provenance Use Cases in Metrology

4.1. Documenting a Metrological Timeline with PROV-O

4.2. Representing the Digital Calibration Certificate Schema with PROV Classes and Attributes

4.2.1. Digital Calibration Certificate Model

4.2.2. Administrative Data Elements and PROV Mappings

- agent(ror.org/04mte1k06, [dcc:contact= “Bob”, ex:name= “National Research Council Canada”, prov:type = ‘prov:Organization’])

- agent(ex:responsibleAgent1, [dcc:respPerson:person:name= “Alice”, prov:role= “technician”, prov:type= ‘prov:Person’])

- agent(ex:responsibleAgent2, [dcc:respPerson:person:name= “Bob”, prov:role= “authoriser”, prov:type= ‘prov:Person’])

- activity(ex:calibration, [prov:label= “Calibration activity”, prov:location=”National Research Council Canada Dimensional Laboratory”, prov:startedAtTime= “2012-04-02T13:35:23Z”, prov:endedAtTime = “2012-04-04T13:35:23Z”)

- activity(ex:authorisation, prov:label =“Authorisation of certificate”)

- wasAssociatedWith(ex:calibration, ex:responsbleAgent1, -, [ prov:role=“technician”])

- wasAssociatedWith(ex:authorisation, ex:responsibleAgent2, -, [ prov:role=“authoriser”])

- Agent(ex:customer1234, [ex:name= “Primary Calibration Laboratory”, prov:label= “Customer for calibration])

- Entity(ex:itemCollection, [prov:label= “Primary Calibration Laboratory items for calibration”, prov:type= ‘prov:Collection’])

- wasAttributedTo(ex:itemCollection, ex:customer1234)

- entity(LS–2024–0001, [prov:label= “Calibration certificate”, prov:type = ‘document’, prov:generatedAtTime = “2012-04-03T13:35:23Z”])

- wasAttributeTo(LS–2024–0001, https://ror.org/04mte1k06 (accessed on 1 May 2025))

4.2.3. Measurement Result Elements and PROV Mappings

4.2.4. PROV Representation of the Digital Calibration Certificate

4.3. Calibration: Enhancing Traceability Information Through Detailed Provenance Modelling

- Characterization: This activity establishes the relationship between quantity values with measurement uncertainties provided by measurement standards, and the indications and associated uncertainties attributed to the artifact carrying the quantity. It results in the creation of a measurement model that defines the artifact’s behaviour and quantifies uncertainties, ensuring traceability to the standards.

- Measurement Attribution: This activity applies the measurement model to produce a measurement result, consisting of a quantity value and an associated uncertainty. The measurement result is then attributed to a measurand, contextualizing the result within the calibration process.

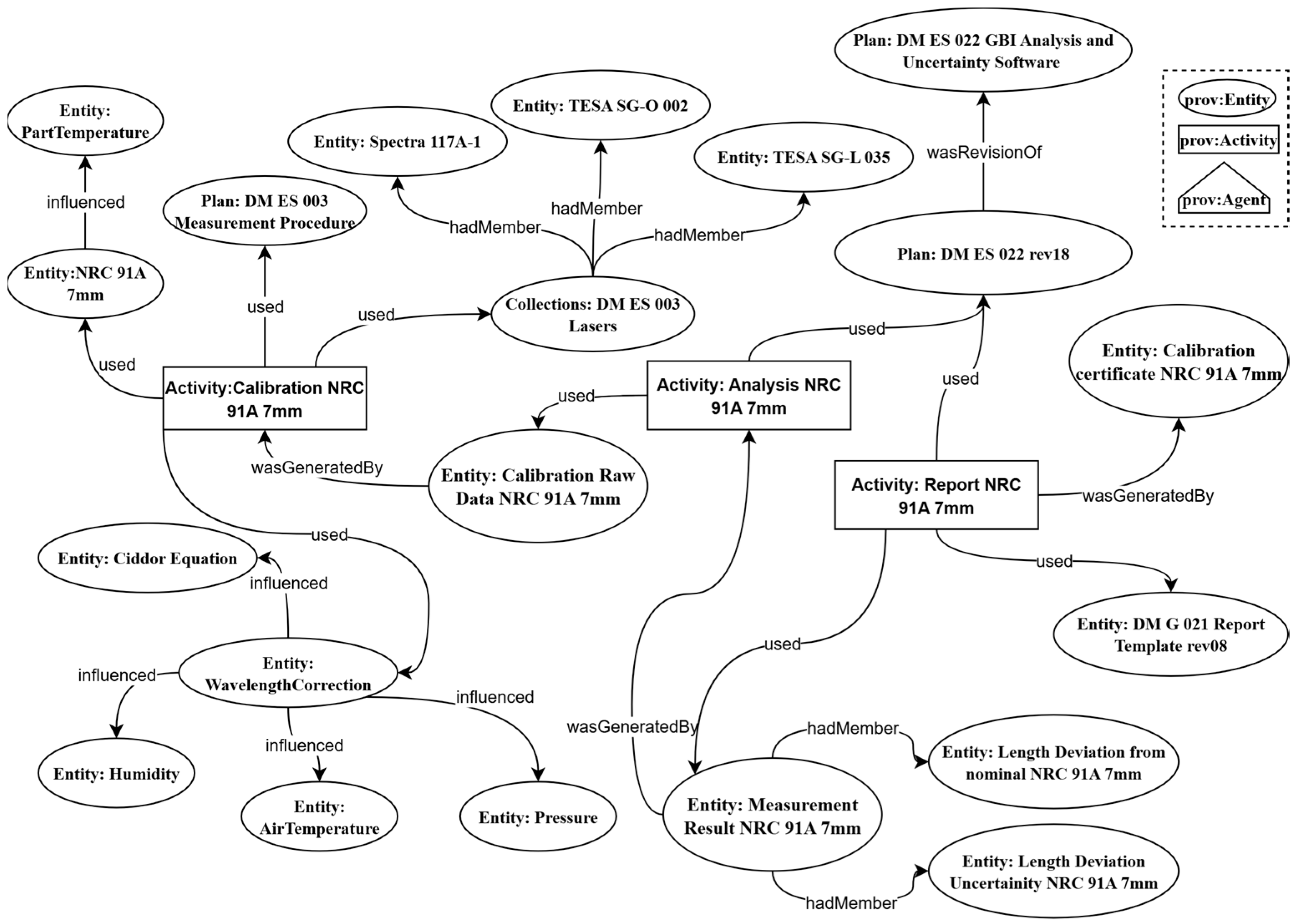

4.4. Gauge Block Calibration and Traceability

5. Discussion

6. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Provenance Information for a Calibration Certificate in PROV-N Notation

document entity(ex:calibrationCertificate, [prov:type:“document”]) activity(ex:calibrationActivity, -, -, [ prov:location = “NMI X Measurement Laboratory Y” ]) activity(ex:certificateGeneration) activity(ex:certificateAuthorization) entity(dcc:dccSoftware, [ prov:type = “prov:Plan”]) entity(dcc:measurementResult) entity(ex:signedCertificate) entity(dcc:influenceConditions, [ prov:type = “prov:Collection”]) entity(dcc:measuringEquipment, [ prov:type = “prov:Collection ”]) entity(dcc:usedMethod, [ prov:type = “prov:Plan”]) agent(dcc:respAgent, [ prov:type=“Person”]) agent(ex:NMI, [ prov:type=“Organization”]) agent(ex:authorizingAgent, [ prov:type=“Person”]) wasGeneratedBy(dcc:measurementResult, ex:calibrationActivity, -) wasGeneratedBy(ex:certificateGeneration, ex:calibrationCertificate, -) wasGeneratedBy(ex:signedCertificate, ex:certificateAuthorization, -) used(ex:certificateGeneration, dcc:measurementResult, -) used(ex:certificateGeneration, dcc:dccSoftware, -) used(ex:calibrationActivity, dcc:usedMethod, -) used(ex:calibrationActivity, dcc:measuringEquipment, -) used(ex:calibrationCertificate, ex:certificateAuthorization, -) wasAssociatedWith(ex:calibrationActivity, ex:responsibleAgent, -, [ prov:role=“technician”]) wasAssociatedWith(ex:certificateGeneration,-, dcc:dccSoftware) wasAssociatedWith(ex:certificateAuthorization, ex:authorizingAgent, -, [prov:role=“authority”]) wasDerivedFrom(ex:signedCertificate, ex:calibrationCertificate, ex:certificateAuthorization, [ prov:type = “signed”]) wasAttributedTo(ex:signedCertificate, ex:NMI, [ prov:type=“issuer”]) wasInfluencedBy(dcc:measurementResult, dcc:influenceConditions) endDocument

Appendix B. Provenance Information for the Measurement Result of Gauge Block Calibration Performed at NRC in PROV-N Notation

document

entity(ex:NRC91A_7mm,

[ prov:label=“Select Short Gauge Block Tungsten Carbide

7mm thermal expansion coefficient”,

prov:type=“Calibrated Artifact”,

prov:value=“4.23 × 10−6K−1”])

entity(ex:DM-ES-003, [ prov:label=“Method of exact fractions”,

prov:type=“prov:Plan”])

entity(ex:TESA_SG-L_035_OFS-2024-0006_20240502,

[ prov:label=“TESA SG-L Laser calibrated vacuum wavelength report OFS-2024-006 2024-05-02”, prov:type=“measurement standard”, prov:value=“+5.435153892E+2 nm”])

entity(ex:TESA_SG-O_002_OFS-2024-0005_20240430,

[ prov:label=“TESA SG-O Laser calibrated vacuum wavelength report OFS-2024-0005 2024-04-30”, prov:type=“measurement standard”, prov:value=“+6.119703724E+2 nm”])

entity(ex:Spectra_117A-1_X082787_OFS-2024-0002_20240508,

[ prov:label=“Spectra_117A-1 Laser calibrated vacuum wavelength report OFS-2024-0002 20240508”, prov:type=“measurement standard”, prov:value=“+6.329909778E+2 nm”])

entity(ex:DM-ES-003_Lasers,

[ prov:label=“Laser collection”,

prov:type=“prov:Collection”,

prov:type=“measurement standard”])

hadMember(ex:DM-ES-003_Lasers,

ex:TESA_SG-L_035_OFS-2024-0006_20240502)

hadMember(ex:DM-ES-003_Lasers,

ex:TESA_SG-O_002_OFS-2024-0005_20240430)

hadMember(ex:DM-ES-003_Lasers,

ex:Spectra_117A-1_X082787_OFS-2024-0002_20240508)

entity(ex:WavelengthCorrection,

[ prov:label=“Vaccum Wavelength correction refractive index in air”, prov:type=“correction”])

entity(ex:AirTemperature,

[ prov:label=“Influence quantity for wavelength correction”, prov:type=“influence quantity”])

entity(ex:PartTemperature,

[ prov:label=“Influence quantity for thermal expansion of material”, prov:type=“influence quantity”])

entity(ex:Humidity,

[ prov:label=“Influence quantity for wavelength correction”, prov:type=“influence quantity”])

entity(ex:Pressure,

[ prov:label=“Influence quantity for wavelength correction”, prov:type=“influence quantity”])

entity(ex:Ciddor,

[ prov:label=“Ciddor equation for refractive index in air”, prov:type=“document”])

wasInfluencedBy(ex:WavelengthCorrection, ex:AirTemperature)

wasInfluencedBy(ex:WavelengthCorrection, ex:Humidity)

wasInfluencedBy(ex:WavelengthCorrection, ex:Pressure)

wasInfluencedBy(ex:WavelengthCorrection, ex:Ciddor)

wasInfluencedBy(ex:NRC91A_7mm, ex:PartTemperature)

entity(ex:MeasurementResult_NRC91A_7mm_nominal,

[ prov:label=“Deviation from nominal length”, prov:type=“prov:Collection”])

entity(ex:Length_Deviation_NRC91A_7mm_nominal,

[ prov:label=“Quantity value for deviation from nominal length”, prov:type=“quantity value”, prov:value=“+2 nm”])

entity(ex:Length_Deviation_Uncertainty_NRC91A_7mm_nominal,

[ prov:label=“Expanded Uncertainty for deviation from nominal length”, prov:type=“expanded uncertainty”, prov:value=“31 nm”])

hadMember(ex:MeasurementResult_NRC91A_7mm_nominal,

ex:Length_Deviation_NRC91A_7mm_nominal)

hadMember(ex:MeasurementResult_NRC91A_7mm_nominal,

ex:Length_Deviation_Uncertainty_NRC91A_7mm_nominal)

activity(ex:calibration_NRC91A_7mm, [ prov:type=“calibration”])

wasGeneratedBy(ex:MeasurementResult_NRC91A_7mm_nominal,

ex:calibration_NRC91A_7mm, -)

used(ex:calibration_NRC91A_7mm, ex:WavelengthCorrection, -)

used(ex:calibration_NRC91A_7mm, ex:NRC91A_7mm, -)

used(ex:calibration_NRC91A_7mm, ex:DM-ES-003_Lasers, -)

endDocument

References

- Massimiliano, M.; Abdallah, M.; Andrea, M.; Sassone, V.; Jason, R. Using PROV and Blockchain to Achieve Health Data Provenance. 2020. Available online: https://www.researchgate.net/publication/342183389_Using_PROV_and_Blockchain_to_Achieve_Health_Data_Provenance?channel=doi&linkId=5ee7ca2b299bf1faac56a418&showFulltext=true (accessed on 1 May 2025).

- Kanwal, S.; Khan, F.Z.; Lonie, A.; Sinnott, R.O. Investigating reproducibility and tracking provenance—A genomic workflow case study. BMC Bioinform. 2017, 18, 337. [Google Scholar] [CrossRef]

- Servillat, M.; Riebe, K.; Boisson, C.; Bonnarel, F.; Galkin, A.; Louys, M.; Nullmeier, M.; Renault-Tinacci, N.; Sanguillon, M.; Streicher, O. IVOA Provenance Data model Version 1.0, IVOA Recommendation 11 April 2020. Available online: https://www.ivoa.net/documents/ProvenanceDM/ (accessed on 1 May 2025).

- Cheney, J.; Chiticariu, L.; Tan, W.-C. Provenance in Databases: Why, How, and Where. Found. Trends Databases 2009, 1, 379–474. [Google Scholar] [CrossRef]

- Cuevas-Vincenttin, V.; Ludäscher, B.; Missier, P.; Belhajjame, K.; Chirigati, F.; Wei, Y.; Dey, S.; Kianmajd, P.; Koop, D.; Bowers, S.; et al. ProvONE: A PROV Extension Data Model for Scientific Workflow Provenance. 2016. Available online: https://jenkins-1.dataone.org/jenkins/view/Documentation%20Projects/job/ProvONE-Documentation-trunk/ws/provenance/ProvONE/v1/provone.html (accessed on 17 July 2025).

- Curbera, F.; Doganata, Y.; Martens, A.; Mukhi, N.K.; Slominski, A. Business Provenance—A Technology to Increase Traceability of End-to-End Operations. In On the Move to Meaningful Internet Systems: OTM 2008; Lecture Notes in Computer Science; Meersman, R., Tari, Z., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; Volume 5331. [Google Scholar] [CrossRef]

- Moreau, L.; Missier, P. PROV-DM: The PROV Data Model. W3C Recommendation. 30 April 2013. Available online: https://www.w3.org/TR/2013/REC-prov-dm-20130430/ (accessed on 2 May 2025).

- CIPM. Mutual Recognition of National Measurement Standards and of Calibration and Measurement Certificates Issued by National Metrology Institutes. 1999. Available online: https://www.bipm.org/documents/20126/43742162/CIPM-MRA-2003.pdf (accessed on 17 April 2023).

- Wilkinson, M.D.; Dumontier, M.; Jan Aalbersberg, I.J.; Appleton, G.; Axton, M.; Baak, A.; Blomberg, N.; Boiten, J.-W.; da Silva Santos, L.B.; Bourne, P.E.; et al. The FAIR Guiding Principles for Scientific Data Management and Stewardship. Sci. Data 2016, 3, 160018. [Google Scholar] [CrossRef]

- Haertig, F.; Hornig, J.; Wiedenhofer, T.; Hackel, S.G. The digital calibration certificate. PTB-Mitteilungen 2017, 127, 7. [Google Scholar] [CrossRef]

- ISO/IEC 17025:2017; General Requirements for the Competence of Testing and Calibration Laboratories, 3rd ed. International Standards Organisation: Geneva, Switzerland, 2017.

- Hebner, R.E. Calibration Traceability: A Summary of NIST’s View. In Proceedings of the 5th US–Italy Bilateral Seminar, Gaithersburg, MD, USA, 26–29 February 1996. [Google Scholar]

- Ehrlich, C.D.; Rasberry, S.D. Metrological Timelines in Traceability. Metrologia 1997, 34, 503–514. [Google Scholar] [CrossRef][Green Version]

- Joint Committee for Guides in Metrology (JCGM). The International Vocabulary of Metrology—Basic and General Concepts and Associated Terms (VIM), 3rd ed.; JCGM: Sèvres, France, 2012. [Google Scholar]

- Missier, P.; Belhajjame, K.; Cheney, J. The W3C PROV Family of Specifications for Modelling Provenance Metadata. In Proceedings of the 16th International Conference on Extending Database Technology, Genoa, Italy, 18 March 2013; ACM: New York, NY, USA; pp. 773–776. [Google Scholar] [CrossRef]

- Carata, L.; Akoush, S.; Balakrishnan, N.; Bytheway, T.; Sohan, R.; Seltzer, M.; Hopper, A. A Primer on Provenance. Commun. ACM 2014, 57, 52–60. [Google Scholar] [CrossRef]

- Cheney, J.; Chapman, A.; Davidson, J.; Forbes, A.B. Data provenance, curation and quality in metrology. In Advanced Mathematical and Computational Tools in Metrology and Testing XII; World Scientific Publishing Co. Pte Ltd.: Singapore, 2022; Voluem 90, pp. 167–187. [Google Scholar] [CrossRef]

- Gil, Y.; Miles, S. (Eds.) PROV Model Primer. W3C Note. 30 April 2013. Available online: http://www.w3.org/TR/2013/NOTE-prov-primer-20130430/ (accessed on 1 May 2025).

- Physikalisch-Technische Bundesanstalt. DCC—Digital Calibration Certificate Version 3.3. 2024. Available online: https://gitlab.com/ptb/dcc/xsd-dcc/ (accessed on 28 July 2025).

- Moreau, L.; Missier, P. PROV-N: The Provenance Notation. W3C Recommendation. 30 April 2013. Available online: https://www.w3.org/TR/2013/REC-prov-o-20130430/ (accessed on 2 May 2025).

- Research Organization Registry. Available online: https://ror.org/ (accessed on 17 July 2025).

- Quinn, T.J. Mise en Pratique of the definition of the metre (1992). Metrologia 1992, 30, 523–541. [Google Scholar] [CrossRef]

- Moreau, L.; Clifford, B.; Freire, J.; Futrelle, J.; Gil, Y.; Groth, P.; Kwasnikowska, N.; Miles, S.; Missier, P.; Myers, J.; et al. The open provenance model core specification (v1.1). Future Gener. Comput. Syst. 2010, 27, 743–756. [Google Scholar] [CrossRef]

- Physikalisch-Technische Bundesanstalt. D-SI—Digital System of Units Version 2.2.1. 2024. Available online: https://gitlab1.ptb.de/d-ptb/d-si/xsd-d-si/ (accessed on 28 July 2025).

- Bureau International des Poids et Mesures. SI Digital Framework—Digital References for FAIR Measurement Data. Available online: https://si-digital-framework.org/ (accessed on 28 July 2025).

- Hall, B.; Kuster, M. Metrological support for quantities and units in digital systems. Meas. Sens. 2021, 18, 100102. [Google Scholar] [CrossRef]

- Kuster, M. A guide to standardizing digital calibration and measurement capabilities. Metrologist 2022, 15, 36–47. [Google Scholar]

- Bharti, P.; Yang, Q.; Forbes, A.; Romanchikova, M.; Hippolyte, J.-L. Ontology Development for Measurement Process and Uncertainty of Results. Meas. Sens. 2021, 18, 100325. [Google Scholar] [CrossRef]

| VIM/DCC Concept | PROV-DM Class |

|---|---|

| Client | Agent |

| Calibration Laboratory | Agent |

| Responsible Person | Agent |

| Software/Hardware system | Agent |

| Characterization | Activity |

| Calibration | Activity |

| Authorisation | Activity |

| Software | Entity |

| Calibration Certificate | Entity |

| Calibrated Artifact | Entity |

| Measurement Result | Entity |

| Quantity Value | Entity |

| Measurement Uncertainty | Entity |

| Measurement Standard | Entity |

| Influence Quantity | Entity |

| Measurand | Entity |

| Correction | Entity |

| Measurement Capability | Entity |

| Measurement Method | Entity |

| Measurement Procedure | Entity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

White, R.M. Provenance in the Context of Metrological Traceability. Metrology 2025, 5, 52. https://doi.org/10.3390/metrology5030052

White RM. Provenance in the Context of Metrological Traceability. Metrology. 2025; 5(3):52. https://doi.org/10.3390/metrology5030052

Chicago/Turabian StyleWhite, Ryan M. 2025. "Provenance in the Context of Metrological Traceability" Metrology 5, no. 3: 52. https://doi.org/10.3390/metrology5030052

APA StyleWhite, R. M. (2025). Provenance in the Context of Metrological Traceability. Metrology, 5(3), 52. https://doi.org/10.3390/metrology5030052