Chromogenic Approach for Oxygen Sensing Using Tapered Coreless Optical Fibre Coated with Methylene Blue

Abstract

1. Introduction

2. Experiment

2.1. Methylene Blue (MB) Sol–Gel Preparation

- A 0.006 gm amount of Methylene Blue is dissolved in 3 mL ethanol and sonicated for 20 min.

- A 1 mL volume of deionised water is acidified by 30 µL of HCL (0.04 mol/V).

- A 4.5 mL volume of TEOS is mixed with 5.5 mL of ethanol by stirring them for 20 min.

- The acidified water prepared in Step 2 is added to the above solution in Step 3 and stirred continuously for 20 min.

- A 1 mL volume of the Methylene Blue solution prepared in Step 1 is added to the above solution (Step 4) and stirred for another 20 min.

- The above solution is ready to be used for coating the TNC optical fibre structure.

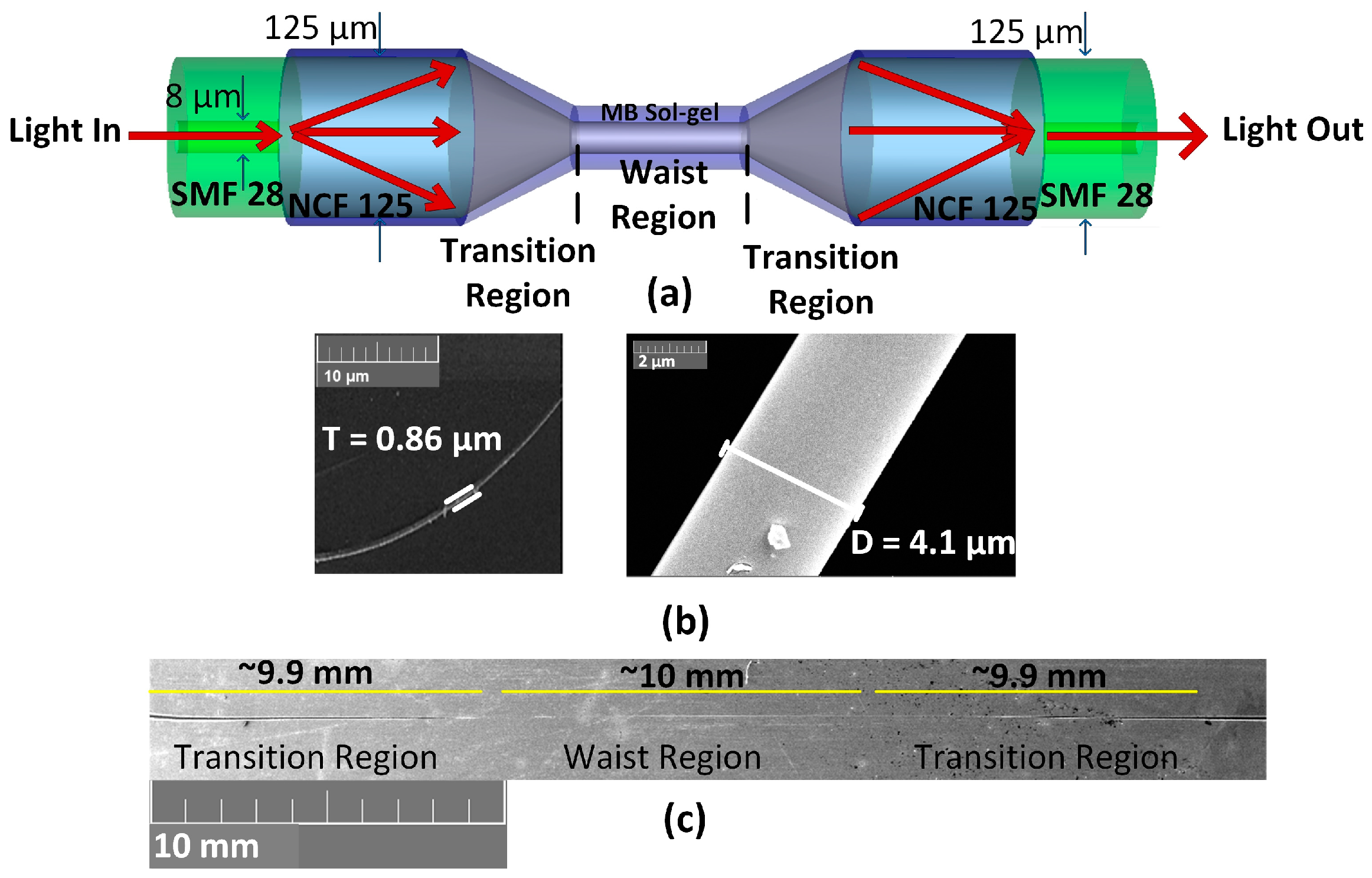

2.2. Functionalise Tapered Coreless Optical Fibre Sensor

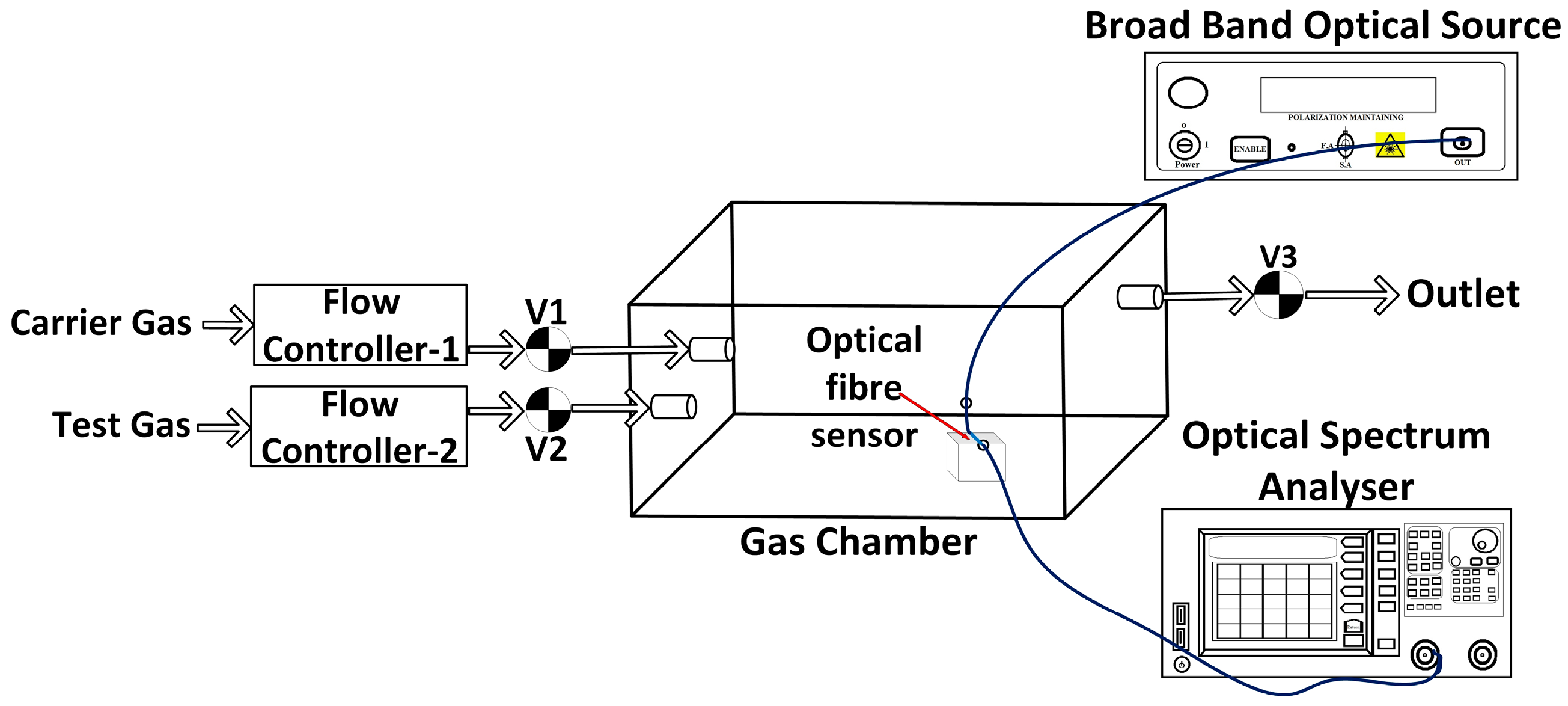

2.3. Experimental Setup

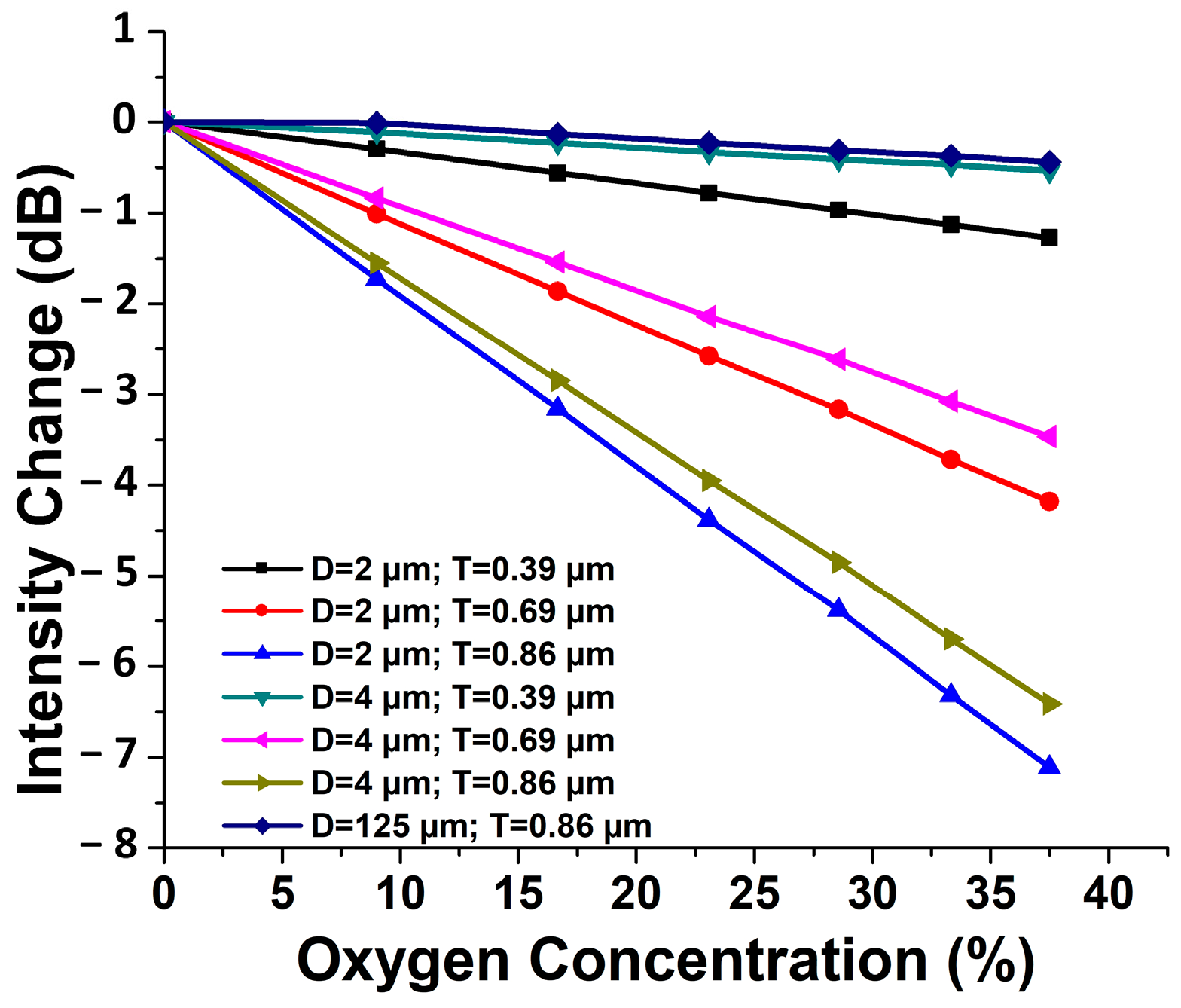

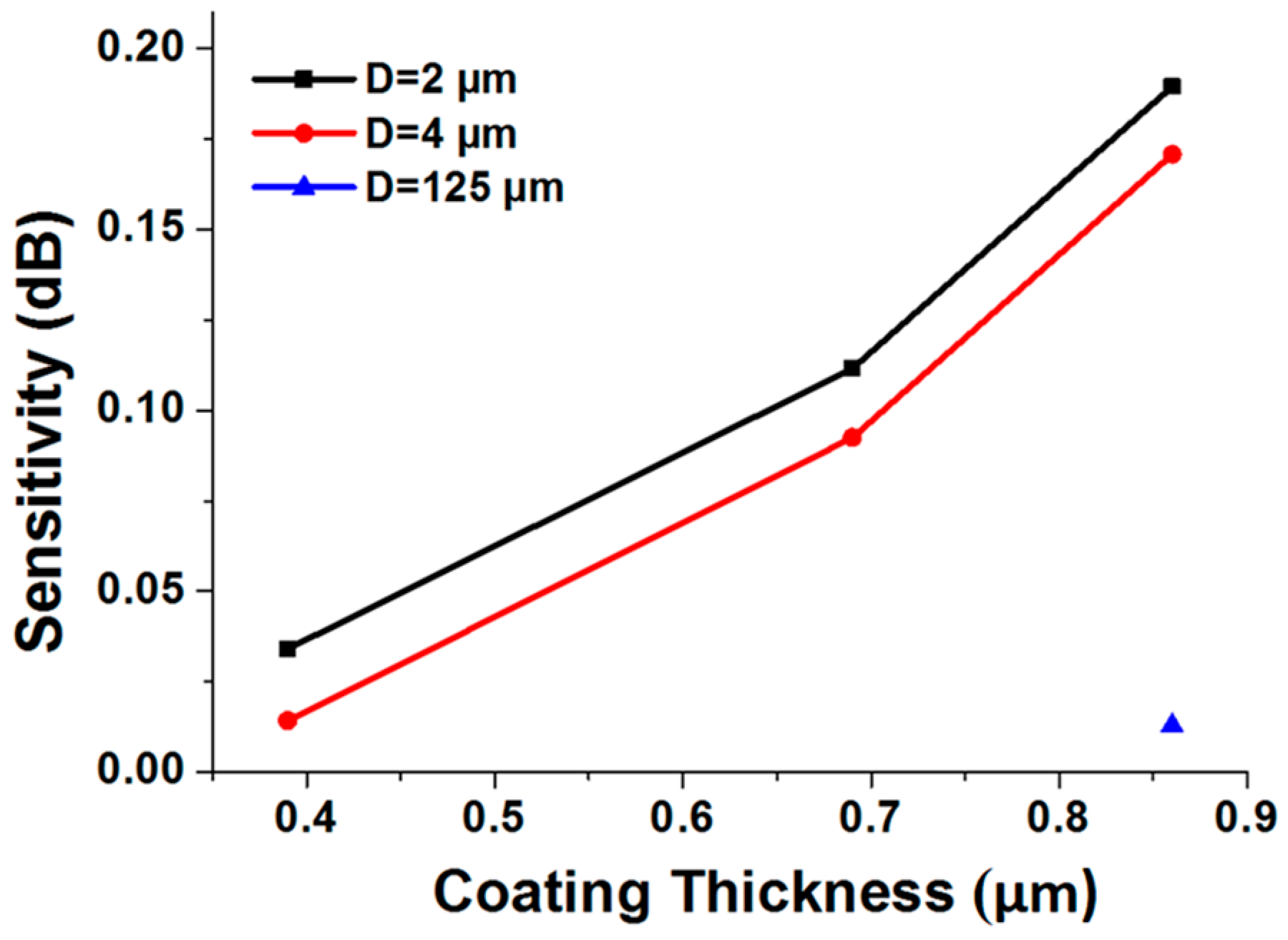

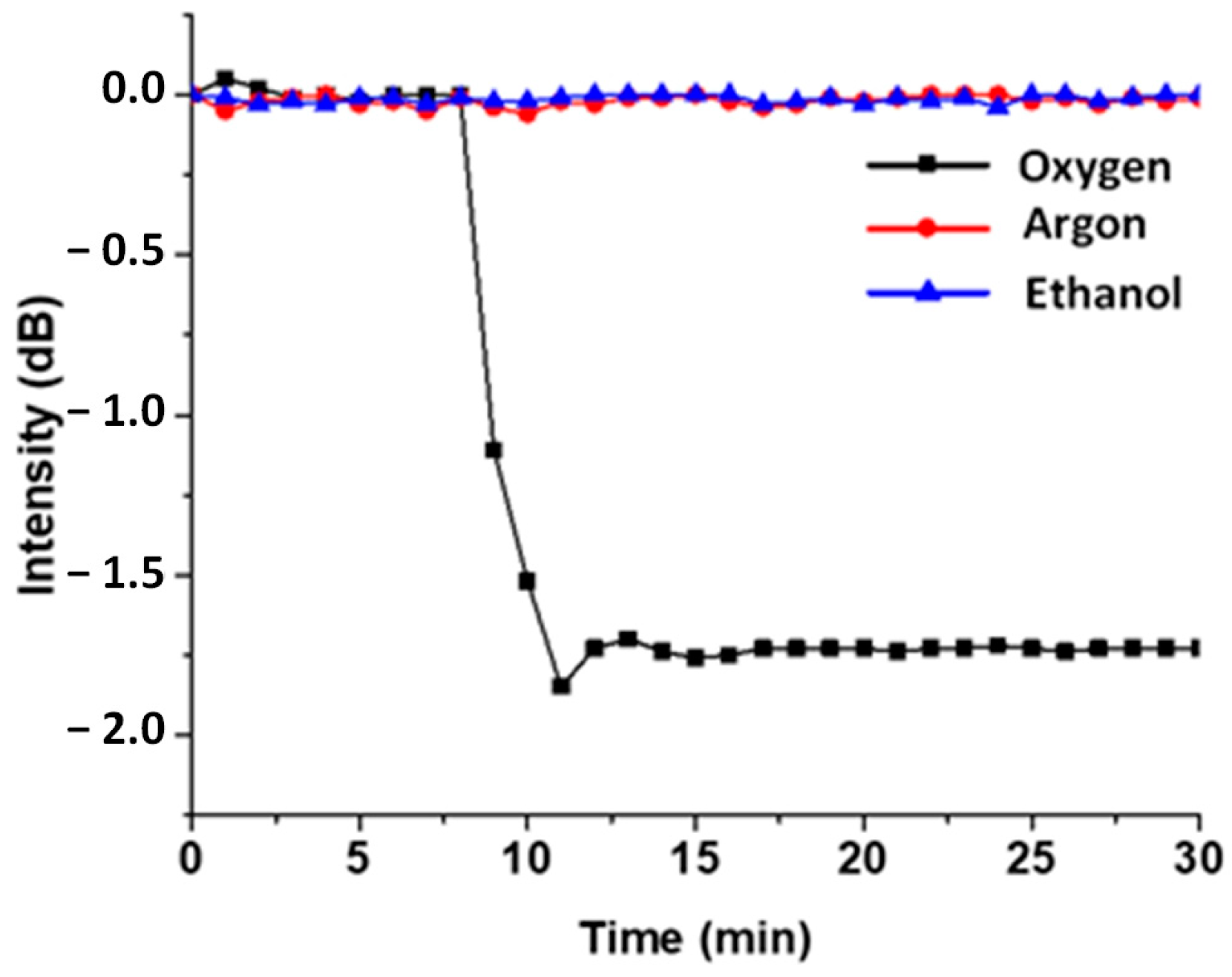

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Neil McManus, C.I.H.; Roh, C. Oxygen: Health Effects and Regulatory Limits Part II: Consensus and Regulatory Standards and Realities of Oxygen Measurement; Northwest Occupation Health and Safety: Winnipeg, MB, Canada, 2009. [Google Scholar]

- Wang, X.D.; Wolfbeis, O.S. Optical methods for sensing and imaging oxygen: Materials, spectroscopies and applications. Chem. Soc. Rev. 2014, 43, 3666–3761. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Cheng, J.; Zhou, L.; Zhou, X.; Xiang, H. Ratiometric optical oxygen sensing: A review in respect of material design. Analyst 2012, 137, 4885–4901. [Google Scholar] [CrossRef] [PubMed]

- Wolfbeis, O.S.; Leiner, M.J. Recent progress in optical oxygen sensing. Opt. Fibers Med. III 1988, 906, 42–48. [Google Scholar]

- Joe, H.E.; Yun, H.; Jo, S.H.; Jun, M.B.; Min, B.K. A review on optical fiber sensors for environmental monitoring. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 173–191. [Google Scholar] [CrossRef]

- McEvoy, A.K.; McDonagh, C.; MacCraith, B.D. Optimisation of sol-gel-derived silica films for optical oxygen sensing. J. Sol-Gel Sci. Technol. 1997, 8, 1121–1125. [Google Scholar] [CrossRef]

- Duong, H.D.; Sohn, O.J.; Rhee, J.I. Development of a ratiometric fluorescent glucose sensor using an oxygen-sensing membrane immobilized with glucose oxidase for the detection of glucose in tears. Biosensors 2020, 10, 86. [Google Scholar] [CrossRef] [PubMed]

- Baleizao, C.; Nagl, S.; Schaferling, M.; Berberan-Santos, M.N.; Wolfbeis, O.S. Dual fluorescence sensor for trace oxygen and temperature with unmatched range and sensitivity. Anal. Chem. 2008, 80, 6449–6457. [Google Scholar] [CrossRef] [PubMed]

- Duong, H.D.; Rhee, J.I. Ratiometric fluorescent biosensors for glucose and lactate using an oxygen-sensing membrane. Biosensors 2021, 11, 208. [Google Scholar] [CrossRef] [PubMed]

- Apreleva, S.V.; Wilson, D.F.; Vinogradov, S.A. Tomographic imaging of oxygen by phosphorescence lifetime. Appl. Opt. 2006, 45, 8547–8559. [Google Scholar] [CrossRef]

- Zang, L.; Zhao, H. Correlation between the triplet-state energy of metalloporphyrins and oxygen response of their phosphorescence. J. Phys. Chem. C 2020, 124, 25004–25009. [Google Scholar] [CrossRef]

- Ziemer, L.S.; Lee, W.M.; Vinogradov, S.A.; Sehgal, C.; Wilson, D.F. Oxygen distribution in murine tumors: Characterization using oxygen-dependent quenching of phosphorescence. J. Appl. Physiol. 2005, 98, 1503–1510. [Google Scholar] [CrossRef] [PubMed]

- Villa, M.; Del Secco, B.; Ravotto, L.; Roy, M.; Rampazzo, E.; Zaccheroni, N.; Prodi, L.; Gingras, M.; Vinogradov, S.A.; Ceroni, P. Bright phosphorescence of all-organic chromophores confined within water-soluble silica nanoparticles. J. Phys. Chem. C 2019, 123, 29884–29890. [Google Scholar] [CrossRef]

- Howard, S.S.; Straub, A.; Horton, N.G.; Kobat, D.; Xu, C. Frequency-multiplexed in vivo multiphoton phosphorescence lifetime microscopy. Nat. Photonics 2013, 7, 33–37. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.; Li, Y.; Luo, Q.; Yang, C.; Gui, W. Axial section multi-reflection cavity-like enhanced oxygen detection in pharmaceutical vial. In Proceedings of the Eighteenth National Conference on Laser Technology and Optoelectronics, Shanghai, China, 10–13 June 2023; Volume 12792, pp. 454–463. [Google Scholar]

- Nishida, K.; Nakauchi, R.; Maeda, Y.; Umekawa, T.; Kawasaki, M. Measurement Technique of Oxygen Concentration in Narrow Channels of PEFCs Based on Transmission Laser Absorption Spectroscopy. ECS Trans. 2021, 104, 233. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Zhou, X.; Zhang, Z. Sensitive dual sensing system for oxygen and pressure based on deep ultraviolet absorption spectroscopy. Sens. Actuators B Chem. 2019, 281, 514–519. [Google Scholar] [CrossRef]

- Ai, X.; Zhang, Y.; Zhang, Z. Highly sensitive trace oxygen sensing based on far-ultraviolet absorption spectroscopy. Analyst 2022, 147, 4365–4370. [Google Scholar] [CrossRef] [PubMed]

- Larsson, J.; Leander, D.; Lewander Xu, M.; Fellman, V.; Bood, J.; Krite Svanberg, E. Comparison of dermal vs internal light administration in human lungs using the TDLAS-GASMAS technique—Phantom Studies. J. Biophotonics 2019, 12, e201800350. [Google Scholar] [CrossRef] [PubMed]

- Martin-Vela, J.A.; Gallegos-Arellano, E.; Sierra-Hernández, J.M.; Estudillo-Ayala, J.M.; Jauregui-Vázquez, D.; Avila-Garcia, M.S.; Ramírez-Gasca, H.; Rojas-Laguna, R. All single-mode-fiber supercontinuum source setup for monitoring of multiple gases applications. Sensors 2020, 20, 3239. [Google Scholar] [CrossRef] [PubMed]

- Choi, M.H.; Lee, J.; Seo, Y.J. Dual-site ligation-assisted loop-mediated isothermal amplification (dLig-LAMP) for colorimetric and point-of-care determination of real SARS-CoV-2. Microchim. Acta 2022, 189, 176. [Google Scholar] [CrossRef]

- Yu, J.; Wang, D.; Tipparaju, V.V.; Tsow, F.; Xian, X. Mitigation of humidity interference in colorimetric sensing of gases. ACS Sens. 2020, 6, 303–320. [Google Scholar] [CrossRef]

- Quaranta, M.; Borisov, S.M.; Klimant, I. Indicators for optical oxygen sensors. Bioanal. Rev. 2012, 4, 115–157. [Google Scholar] [CrossRef] [PubMed]

- Zhujun, Z.; Seitz, W.R. Optical sensor for oxygen based on immobilized hemoglobin. Anal. Chem. 1986, 58, 220–222. [Google Scholar] [CrossRef]

- Xia, P.; Zhou, H.; Sun, H.; Sun, Q.; Griffiths, R. Research on a Fiber Optic Oxygen Sensor Based on All-Phase Fast Fourier Transform (apFFT) Phase Detection. Sensors 2022, 22, 6753. [Google Scholar] [CrossRef] [PubMed]

- Rivero, P.J.; Goicoechea, J.; Arregui, F.J. Optical fiber sensors based on polymeric sensitive coatings. Polymers 2018, 10, 280. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Farmery, A.D.; Obeid, A.; Hahn, C.E. A cylindrical-core fiber-optic oxygen sensor based on fluorescence quenching of a platinum complex immobilized in a polymer matrix. IEEE Sens. J. 2011, 12, 71–75. [Google Scholar] [CrossRef]

- Inglev, R.; Møller, E.; Højgaard, J.; Bang, O.; Janting, J. Optimization of All-Polymer Optical Fiber Oxygen Sensors with Antenna Dyes and Improved Solvent Selection Using Hansen Solubility Parameters. Sensors 2020, 21, 5. [Google Scholar] [CrossRef] [PubMed]

- Inglev, R.; Møller, E.; Atzen, N.; Højgaard, J.; Janting, J.; Bang, O. All Polymer Optical Fiber Sensor for Dissolved Oxygen in Fish Farms. In Optical Fiber Sensors; Optica Publishing Group: Washington, DC, USA, 2020; p. Th4-29. [Google Scholar]

- Wei, Y.B.; Chang, J.; Lian, J.; Liu, T.Y. Multi-point optical fibre oxygen sensor based on laser absorption spectroscopy. Optik 2015, 126, 2394–2397. [Google Scholar] [CrossRef]

- Hung, S.S.; Chang, H.C.; Chang, I.N. A portable array-type optical fiber sensing instrument for real-time gas detection. Sensors 2016, 16, 2087. [Google Scholar] [CrossRef]

- Loannou, A.; Zavrou, S.; Christofi, A.; Kalli, K. Femtosecond laser modified Fabry-Pérot interferometer optical fibre tip sensor for monitoring dissolved oxygen. In Micro-Structured and Specialty Optical Fibres VII; SPIE: Bellingham, WA, USA, 2022; Volume 12140, pp. 87–93. [Google Scholar]

- Madhav, K. Eaton Intelligent Power Ltd. 2020 Oxygen Sensor Having a Tip Coated Large Diameter Optical Fiber Utilizing a Trichroic Prism or Tricolor Sensor. U.S. Patent 10,620,128, 14 April 2020. [Google Scholar]

- Rasyied, A.Z.; Mazlee, N.N.; Salim, M.R.; Nurulain, S.; Manap, H. The potential development of oxygen optical fibre gas sensor for automotive industry. J. Telecommun. Electron. Comput. Eng. 2018, 10, 1–4. [Google Scholar]

- Yu, H.; Yu, B.; Song, Y.; Hai, P. Recent advances of cyclometalated Ir (III) complexes for optical oxygen sensing. Inorg. Chim. Acta 2023, 550, 121435. [Google Scholar] [CrossRef]

- Zhao, Z.; Duan, Y. A low-cost fibre-optic humidity sensor based on silica sol–gel film. Sens. Actuators B Chem. 2011, 160, 1340–1345. [Google Scholar] [CrossRef]

- Korposh, S.; James, S.W.; Lee, S.W.; Tatam, R.P. Tapered optical fibre sensors: Current trends and future perspectives. Sensors 2019, 19, 2294. [Google Scholar] [CrossRef] [PubMed]

- Figueira, R.B.; de Almeida, J.M.; Ferreira, B.; Coelho, L.; Silva, C.J. Optical fiber sensors based on sol–gel materials: Design, fabrication and application in concrete structures. Mater. Adv. 2021, 2, 7237–7276. [Google Scholar] [CrossRef]

- Zhu, Y.; Shao, C.; Wang, F.; Wang, M.; Zhang, L.; Dai, Y.; Yu, C.; Hu, L. Improved Radiation Resistance of Er-Yb Co-Doped Silica Fiber by Pretreating Fibers. Photonics 2023, 10, 414. [Google Scholar] [CrossRef]

| Sensor No. | Layer Thickness (µm) | Dia. of TNC Optical Fibre Sensor (µm) | Sensitivity (dB/O2%) |

|---|---|---|---|

| 1 | 0.86 | 2 | 0.189 |

| 2 | 0.69 | 0.112 | |

| 3 | 0.39 | 0.034 | |

| 4 | 0.86 | 4 | 0.171 |

| 5 | 0.69 | 0.092 | |

| 6 | 0.39 | 0.014 | |

| 7 | 0.86 | 125 | 0.013 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, R.; Wight, N. Chromogenic Approach for Oxygen Sensing Using Tapered Coreless Optical Fibre Coated with Methylene Blue. Metrology 2024, 4, 295-303. https://doi.org/10.3390/metrology4020018

Kumar R, Wight N. Chromogenic Approach for Oxygen Sensing Using Tapered Coreless Optical Fibre Coated with Methylene Blue. Metrology. 2024; 4(2):295-303. https://doi.org/10.3390/metrology4020018

Chicago/Turabian StyleKumar, Rahul, and Neil Wight. 2024. "Chromogenic Approach for Oxygen Sensing Using Tapered Coreless Optical Fibre Coated with Methylene Blue" Metrology 4, no. 2: 295-303. https://doi.org/10.3390/metrology4020018

APA StyleKumar, R., & Wight, N. (2024). Chromogenic Approach for Oxygen Sensing Using Tapered Coreless Optical Fibre Coated with Methylene Blue. Metrology, 4(2), 295-303. https://doi.org/10.3390/metrology4020018