Abstract

This study evaluates the effect of zirconium (Zr) incorporation on the structural, microstructural, and functional properties of lead-free ceramics based on the 0.95(Bi0.5Na0.5)TiO3–0.05BaTiO3 (BNT–5BT) system. Two distinct doping strategies were investigated: (i) the substitutional incorporation of Zr4+ at the Ti4+ site (BNT–5BT–xZrsub), and (ii) the addition of ZrO2 in excess (BNT–5BT–xZrexc). The samples were synthesized via conventional solid-state reaction and characterized using X-ray diffraction (XRD), field emission scanning electron microscopy (FE-SEM/EDS), and electrical measurements, including dielectric, ferroelectric, and piezoelectric responses. Both doping routes were found to influence phase stability and electromechanical performance. Substitutional doping notably reduced the coercive field while preserving high remanent polarization, resulting in an enhanced piezoelectric coefficient (d33). These results highlight the potential of Zr-modified BNT–5BT ceramics for lead-free energy harvesting applications.

1. Introduction

Environmental regulations and increasing awareness regarding the toxicity of lead-based materials have prompted the development of lead-free alternatives to conventional piezoelectrics such as Pb(Zr,Ti)O3 (PZT). Although PZT exhibits excellent electromechanical properties, its lead content poses significant environmental and health concerns, motivating the search for functional materials with comparable performance [1,2].

Among various lead-free candidates, Bi0.5Na0.5TiO3 (BNT)-based ceramics have received considerable attention due to their high Curie temperature (~320 °C), strong ferroelectric response, and compositional flexibility [3,4]. Nevertheless, pure BNT ceramics are limited by a high coercive field (Ec ≈ 73 kV/cm), high dielectric losses, and difficulty in achieving full polarization under moderate electric fields [5,6].

Solid solutions with BaTiO3 (BT), particularly the composition 0.95(Bi0.5Na0.5TiO3)–0.05BaTiO3 (BNT–5BT), have been proposed to address these issues. This composition is located near a morphotropic phase boundary (MPB), where rhombohedral and tetragonal phases coexist, resulting in enhanced ferroelectric and piezoelectric properties [7,8]. However, additional modifications are often necessary to further reduce hysteresis, improve thermal and electrical stability, and adapt the material for energy conversion applications. In addition to actuation and sensing, BNT-based materials have also been investigated for energy storage applications, owing to their high polarization, large recoverable energy density, and fast discharge rates. Recent studies have explored strategies such as phase boundary engineering and grain orientation control to improve their energy storage performance [9,10,11]. These developments underscore the importance of understanding the interplay between local structure, defects, and functional response to enable broader multifunctional applications. In recent years, energy harvesting (EH) technologies have received increasing attention as a sustainable strategy for converting ambient mechanical energy into electrical power. Piezoelectric materials are particularly well suited for this purpose due to their intrinsic ability to directly couple mechanical stress and electric polarization [12]. In this framework, lead-free BNT–BT-based ceramics have emerged as attractive candidates for EH applications, combining strong ferroelectric and piezoelectric responses with environmental compatibility. The compositional versatility of these systems allows for targeted modifications aimed at optimizing their energy conversion efficiency, making them promising materials for the development of self-powered microdevices and environmentally friendly energy solutions [13,14].

Zirconium (Zr) has been extensively studied as a dopant to modify the structural and functional behavior of BNT-based ceramics. Zr can be incorporated into the perovskite structure via two primary mechanisms:

- -

- Substitutional doping: Replacing Ti4+ in the B-site of the ABO3 lattice [15,16,17].

- -

- Excess doping: Adding ZrO2 in excess to the BaTiO3 or Bi0.5Na0.5TiO3 compositions, potentially leading to the formation of secondary phases when solubility limits are exceeded [18,19].

Substitutional incorporation of Zr4+ can induce local lattice distortions that disrupt long-range ferroelectric order, favoring the formation of polar nanoregions and relaxor behavior [15]. These effects typically result in a reduction in the coercive field, narrower hysteresis loops, and enhanced domain wall mobility—characteristics that are beneficial for low-field operation in energy harvesting systems [12]. Furthermore, substitutional doping has been associated with improved electromechanical response due to increased domain reversibility under applied electric fields [20].

In contrast, excess Zr addition may result in the segregation of Zr-rich phases at grain boundaries. These secondary phases can influence sintering behavior, densification, and alter grain growth dynamics [20,21]. In some cases, they have been associated with reduced dielectric losses and improved resistivity, possibly due to a decrease in oxygen vacancy concentration or the passivation of defects associated with volatile species like Bi [22]. However, excessive secondary phase formation may compromise phase purity and reduce the active piezoelectric contribution.

Given these distinct effects, a comparative understanding of the two possible Zr incorporation mechanisms—substitutional doping and excess addition—is essential for optimizing the structural and functional performance of BNT–BT-based ceramics. While substitutional Zr4+ can modify the tolerance factor and local bonding environment within the perovskite lattice, potentially favoring relaxor behavior and enhancing piezoelectric response, excess ZrO2 tends to segregate at grain boundaries and influence microstructural evolution and dielectric stability [23,24]. Moreover, subtle changes in the local order induced by Zr additions may control the formation of polar nanoregions and modulate energy storage capabilities [25]. Despite the extensive use of Zr in BNT-based systems, a direct comparison between these two doping strategies under identical processing conditions is still lacking.

In this work, we systematically investigate and compare the structural, microstructural, dielectric, ferroelectric, and piezoelectric responses of BNT–5BT ceramics modified by either substitutional Zr4+ doping at the B-site or excess ZrO2 addition. By correlating phase evolution, domain structure, and electromechanical behavior across both doping routes, we aim to clarify the underlying mechanisms governing functional enhancement and assess the suitability of each approach for developing lead-free ceramics for energy harvesting applications.

2. Materials and Methods

Ceramic samples of 0.95(Bi0.5Na0.5)TiO3–0.05BaTiO3 (BNT–5BT) were prepared via the conventional solid-state reaction route. Analytical grade Bi2O3 (Aldrich, 99.9%, St. Louis, MO, USA), Na2CO3 (Biopack, 99.5%, Vienna, Austria), BaCO3 (Biopack, 99.5%), TiO2 (Aldrich, 99%), and ZrO2 (Aldrich, 99.9%) were used as starting materials. Two doping strategies were employed for zirconium incorporation. For substitutional addition, (Bi0.5Na0.5)0.95Ba0.05Ti1-xZrxO3 samples with x = 0.5, 1, 2, and 4 mol% were synthesized, while, for excess ZrO2 addition, 0.95(Bi0.5Na0.5)TiO3–0.05BaTiO3 + xZrO2 compositions with x = 0.5, 1, and 2 mol% were formulated. The samples were prepared by weighing the stoichiometric amounts of each component according to the selected compositions, followed by ball milling in ethanol with zirconia media in a planetary mill (Fritsch Pulverisette 7, Pittsboro, NC, USA) at 1450 rpm for 3 h. The slurry was dried and calcined in air at 750 °C for 2 h. The calcined powders were milled again to ensure homogeneity, uniaxially pressed into disks (10 mm diameter, ~1 mm thickness) at 200 MPa, and sintered in air at 1150 °C for 2 h. All samples were processed identically to enable reliable comparative analysis. It should be noted that the 4 mol% substitutional sample was included solely to assess the effect of over-doping on functional properties, and the structural and microstructural characterization is not included.

Phase identification was performed by X-ray diffraction (XRD) using a PANalytical X’Pert PRO (Almelo, The Netherlands) diffractometer with Cu Kα radiation (λ = 0.154056 nm), operated at 40 kV and 40 mA. Diffraction patterns were collected in the 2θ range of 20–80°, with a step size of 0.03334° and a counting time of 100 s per step. Peak profiles were analyzed assuming a Gaussian shape to assess phase evolution and potential secondary phase formation.

The microstructure of fractured surfaces was examined using a field emission scanning electron microscope (FE-SEM, Hitachi S-4700, Tokyo, Japan) equipped with energy dispersive spectroscopy (EDS) for elemental analysis. Apparent density was determined using the Archimedes method in distilled water.

For electrical measurements, silver paste electrodes were applied to both faces of the sintered disks and fired at 550 °C for 30 min. The dielectric properties (permittivity and loss tangent) were measured using an LCR meter (HP 4284A, Palo Alto, CA, USA) over a frequency range of 100 Hz to 1 MHz, from room temperature to 500 °C. The polarization–electric-field (P–E) hysteresis loops were recorded in silicone oil using a modified Sawyer–Tower circuit under an applied field of up to 4 kV/mm at 50 Hz. Piezoelectric coefficients (d33) were measured using a quasi-static piezometer (YE2730A, Sinocera, Shanghai, China) after poling the samples at 2.5 kV/mm in a silicone oil bath at 150 °C for 30 min. Resonance and anti-resonance frequencies (fr and fa) were determined using an impedance analyzer (HIOKI 3535 LCR HiTESTER, Nagano, Japan).

3. Results

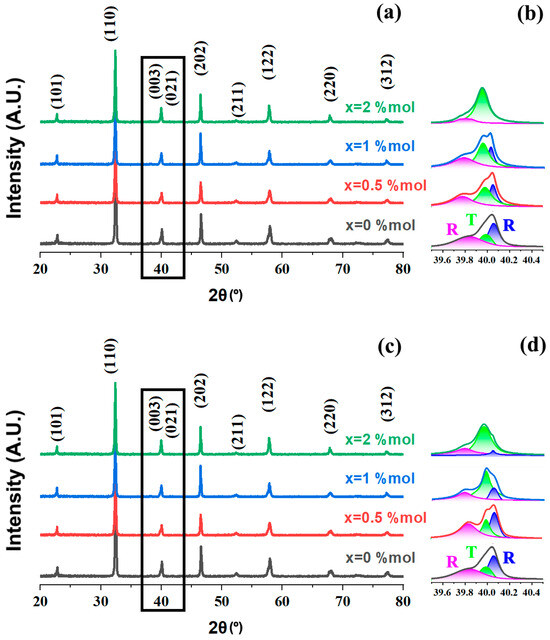

The effect of the zirconium incorporation route on the crystalline structure of BNT–5BTceramics was evaluated using X-ray diffraction (XRD), as shown in Figure 1. In both Zr series added in excess (Figure 1a,b) and substitutionally (Figure 1c,d), the diffraction patterns correspond to a perovskite structure without detectable secondary phases within the resolution limits of the technique. However, the analysis of the selected reflections indicates subtle differences in the structural evolution of the system, which appear to be influenced by the specific zirconium incorporation route.

Figure 1.

X-ray diffraction patterns of BNT–5BT ceramics doped with Zr using two different strategies: excess ZrO2 addition (top, (a,b)) and substitutional incorporation of Zr4+ at the B-site (bottom, (c,d)). All samples were sintered at 1150 °C for 2 h. Insets show magnified views of the 39.6°–40.4° 2θ region (b,d), where peak deconvolution using Gaussian functions reveals the evolution of rhombohedral (R) and tetragonal (T) phase contributions.

Although no secondary phases were detected by XRD, it should be noted that the maximum Zr modification level in the structurally characterized samples was 2 mol%. At such low concentrations, possible impurity phases (e.g., ZrO2-rich regions) may fall below the detection threshold of laboratory XRD, which is typically around 2–3 wt%. Therefore, the absence of observable secondary phases in XRD does not rule out the presence of minor segregated regions.

Furthermore, the XRD patterns reveal characteristic features associated with the coexistence of rhombohedral and tetragonal phases, such as the broadening and asymmetry of the (110)/(111) pseudo-cubic reflections. While these observations qualitatively support the presence of a morphotropic phase boundary, no quantitative phase analysis via Rietveld refinement was conducted in this study. Consequently, phase coexistence is discussed based on the diffraction profile features commonly reported in BNT–BT-based systems.

Detailed analysis of the (003)/(021) peaks, as shown in the deconvoluted profiles, revealed the coexistence of rhombohedral (R) and tetragonal (T) phases in the undoped composition, characteristic of a morphotropic phase boundary (MPB) region. As the Zr concentration increased, a progressive reduction in the R phase contribution was observed in both doping strategies, although the rate of this structural evolution differed significantly. In the samples with excess Zr addition, the rhombohedral fraction decreased more rapidly, and the relative intensity of the tetragonal peak increased with clearer definition, indicating a faster transformation toward a predominantly tetragonal configuration. In contrast, in the substitutionally doped system, although a reduction in the R phase also occurred, it was less pronounced, and phase coexistence was preserved up to 2 mol% Zr. This behavior suggests that substitutional incorporation favors the retention of the MPB and local distortions that enable structural coexistence, while excess addition promotes a more rapid transformation toward a tetragonal structure, possibly associated with local strains or partial segregation of Zr within the microstructure.

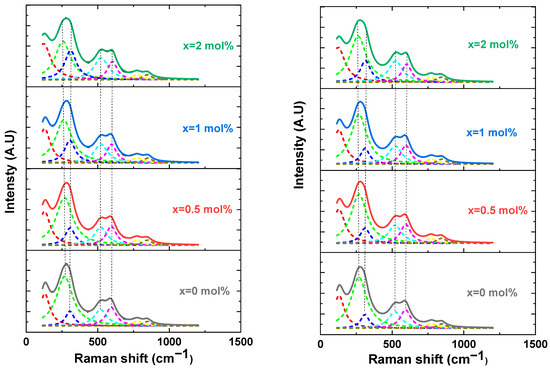

The effect of the Zr doping strategy on the local structure of BNT–5BT ceramics was further investigated using Raman spectroscopy (Figure 2). All spectra exhibit broad bands characteristic of a pseudo-cubic perovskite structure with short-range polar order, typical of BNT-based systems. In the excess-doped series, the band around 305 cm−1 became progressively more intense and asymmetric with increasing Zr content, suggesting enhanced B-site distortion and the development of tetragonal character. Despite expectations based on structural considerations, a clear shift in the band around 540 cm−1 was not observed in our spectra. According to previous studies, such a shift, when present, is indicative of increased Ti–O bond stiffness and local anisotropy [26,27]. In this case, however, band broadening or overlap with adjacent modes may hinder the resolution of such effects. These changes are consistent with the XRD results and support the occurrence of a progressive rhombohedral-to-tetragonal evolution in this series.

Figure 2.

Raman spectra of selected BNT–5BT–xZr ceramics for both substitutional (left) and excess (right) Zr incorporation routes. The experimental spectra (solid lines) were deconvoluted using Voigt functions (dotted lines) to highlight changes in the vibrational modes.

The incorporation mechanism of Zr4+ in the BNT–5BT perovskite structure is dependent on the doping route. Under substitutional doping conditions, Zr4+ ions likely occupy the B-site of the ABO3 structure, replacing Ti4+ due to their comparable ionic radii and charge balance, as previously reported for similar systems [24]. This substitution can locally distort the BO6 octahedra and influence ferroelectric and relaxor behavior. In contrast, excess ZrO2 addition may lead to the partial segregation of Zr-rich regions at the grain boundaries, with minimal incorporation into the lattice. Such effects, though subtle and often below XRD detection limits, are supported by microstructural observations and literature data.

The samples with substitutional Zr incorporation also showed modifications in the Raman spectra, particularly increased broadening and reduced definition of bands in the 200–400 cm−1 region, indicative of local structural disorder. However, taking into account the band located at 305 cm−1, clear evidence of tetragonal character development was not observed. Instead, the changes suggest that excess Zr primarily induces local distortions and strain, without promoting a well-defined phase transition toward tetragonality [20,28]. These observations further highlight the differences in structural evolution between the two doping strategies.

To gain further insight into the structural response induced by Zr incorporation, Raman spectra were deconvoluted using Voigt functions, and the position and full width at half maximum (FWHM) of the main vibrational bands were extracted. The mode near 305 cm−1, typically associated with TiO6 octahedral vibrations, exhibited a gradual increase in intensity with increasing excess Zr, as reflected in the FWHM increase in the ~305 cm−1 band from 79 cm−1 to 98 cm−1 between samples with 0.5 and 2 mol% excess Zr. This behavior is consistent with the partial development of tetragonal-like local distortions, as reported in prior studies on BNT–BT-based systems doped with transition metals. However, no abrupt peak splitting or emergence of new Raman-active modes was detected across the doping range, suggesting that the overall symmetry remains predominantly tetragonal or weakly distorted rhombohedral. The observed band broadening and asymmetric line shapes—quantified through the FWHM values—indicate enhanced local disorder, likely arising from lattice strain and chemical heterogeneity introduced by excess Zr. Therefore, the changes in Raman response support a trend toward increased structural complexity, but do not confirm a complete rhombohedral-to-tetragonal phase transition.

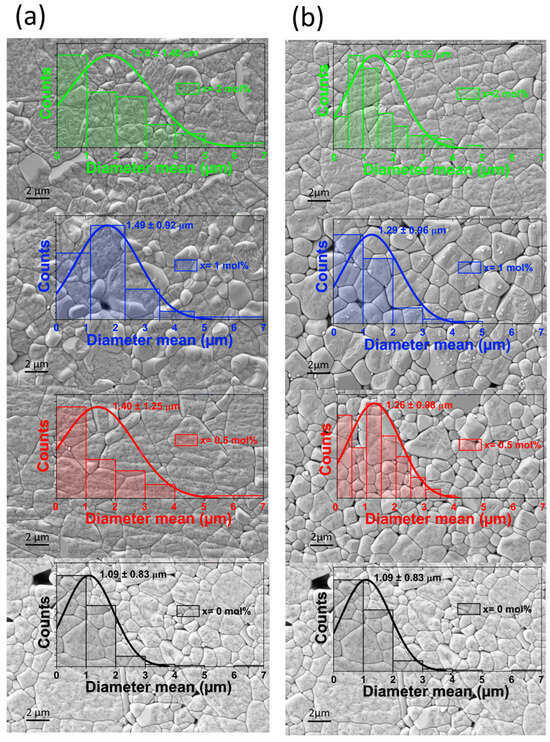

FE-SEM micrographs and grain size distributions of BNT–5BT ceramics doped with Zr via excess addition and substitutional incorporation are shown in Figure 3. All samples exhibited dense microstructures with low porosity concentrated at grain junctions. Grain growth was observed in both doping strategies with increasing Zr content, though the mechanisms differ. In the case of excess Zr addition, the average grain size increased from 1.09 ± 0.89 µm (undoped) to 1.78 ± 1.40 µm for x = 2 mol%. This enhancement is attributed to the formation of a transient liquid phase during sintering, likely due to the reaction between ZrO2 and Na2CO3, possibly forming Na2ZrO3 (melting point ≈ 851 °C), which promotes grain coarsening [29,30]. In this way, EDS analysis revealed the presence of Ti–Ba-rich elongated grains (possibly Ba6Ti17O40) and Zr–Na-rich agglomerates, particularly at higher dopant levels.

Figure 3.

FE-SEM micrographs of BNT–5BT ceramics doped with Zr via two strategies: excess addition (a) and substitutional incorporation (b). The images reveal significant microstructural differences between the two doping approaches.

For substitutional doping, the mean grain size reached 1.37 ± 0.92 µm for x = 2 mol%. While part of the Zr4+ is incorporated into the perovskite lattice, excess dopant tends to segregate, forming rod-like secondary phases and localized Zr-rich regions. Similar effects have been reported in other Zr-doped BT systems, where increasing dopant content leads to rounded or rectangular grains and more heterogeneous grain growth [15,17].

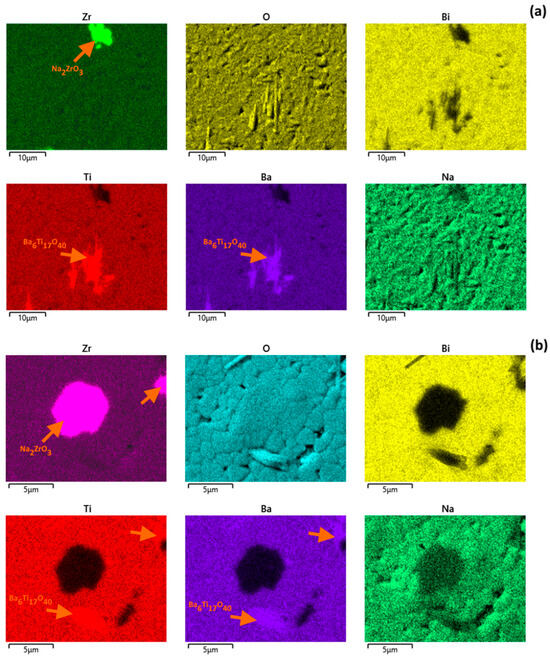

To complement the XRD results and assess the elemental distribution in the doped samples, EDS mapping was performed on polished cross-sections of BNT–5BT ceramics with Zr added either in excess or substitutionally (see Figure 4). Furthermore, Figure 4a shows the EDS maps for the BNT–5BT–2Zrexc composition. The main elements (Ti, Ba, Bi, Na, and O) are homogeneously distributed across the matrix. However, a distinct Zr-rich region is observed, suggesting the formation of a secondary Zr-enriched phase, possibly Na2ZrO3. In addition, the Ti–Ba-rich region can be associated with the Ba6Ti17O40, which was previously reported for BaTiO3 ceramics [31]. The absence of peaks, corresponding to secondary phases, in the XRD diffractograms indicates that the segregated phases are either present in very low amounts or lack long-range crystalline order, as detectable by XRD.

Figure 4.

Two-dimensional elemental distribution maps obtained by EDS for BNT–5BT ceramics doped with 2 mol% Zr using two different strategies: (a) Zr added in excess (BNT–5BT–2Zrexc) and (b) substitutional incorporation of Zr4+ at the B-site (BNT–5BT–2Zrsub).

In contrast, the EDS maps for the BNT–5BT–2Zrsub composition (Figure 4b) reveal a generally homogeneous elemental distribution with localized Zr enrichment. This suggests that not all Zr4+ is fully incorporated into the perovskite lattice, although it likely substitutes Ti4+ at the B-site. Additionally, the presence of Ti–Ba-rich regions, possibly corresponding to Ba6Ti17O40, can be observed, similar to those found in the excess-doped samples. These secondary phases, though not detected by XRD, are consistent with previous reports in BaTiO3-based systems and may arise from local compositional imbalances or sintering conditions. The observed features support the substitutional doping mechanism and also highlight the formation of minor secondary phases, reinforcing the complexity of Zr incorporation in this system.

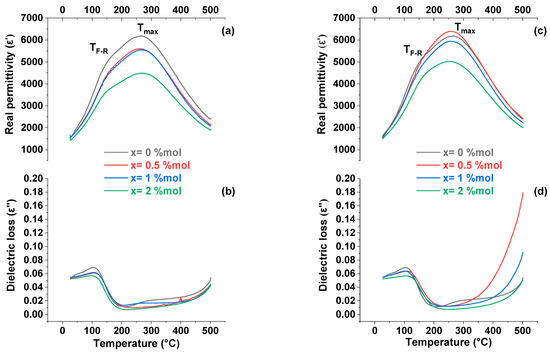

The temperature dependence of the relative permittivity (εr) and dielectric loss (tan δ) for BNT–5BT ceramics doped with Zr via excess addition and substitutional incorporation is shown in Figure 5. All samples exhibit a broad dielectric maximum (Tmax), typical of relaxor behavior. For the excess Zr series, Tmax remains relatively constant with increasing dopant content, while the ferroelectric-to-relaxor transition temperature (TF–R) decreases. This anomaly is commonly reported in BNT–BT-based systems and is associated with the disruption of long-range polar order due to compositional or structural disorder [32]. Additionally, εr values at Tmax decrease with Zr content, suggesting increased structural disorder and disruption of long-range polar order. The reduction in dielectric peak intensity may be associated with the formation of local defects or inhomogeneities due to Zr-rich agglomerates and secondary phases [33].

Figure 5.

Temperature dependence of the relative permittivity (εr) and dielectric loss (tan δ) for BNT–5BT ceramics doped with Zr via (a,b) excess addition and (c,d) substitutional incorporation, measured at 1 kHz.

In contrast, the decrease in Tmax observed for the substitutional series correlates with structural trends identified by XRD. As shown in Figure 1, the progressive merging of the (110)/(111) reflections indicate a reduction in rhombohedral distortion and a transition toward higher structural symmetry. This structural evolution weakens long-range ferroelectric coherence, which explains the lower Tmax and broadened dielectric response. The dielectric behavior is, therefore, consistent with suppressed domain correlations and the emergence of relaxor-like characteristics driven by local structural disorder.

In contrast, the substitutionally doped samples exhibit a shift of Tmax to lower temperatures with increasing Zr content, while TF–R remains nearly unchanged. This behavior is consistent with a transition toward a relaxor-like state, promoted by the incorporation of larger Zr4+ ions into the B-site, which introduces local strain and breaks long-range ferroelectric correlations [34]. The dielectric loss increases slightly with Zr content in both series but remains within acceptable levels for actuator and energy harvesting applications. These results confirm that both doping strategies affect the dielectric response differently, as follows: substitutional Zr incorporation modifies the local structure and phase transition behavior, while excess Zr primarily introduces disorder and reduces permittivity.

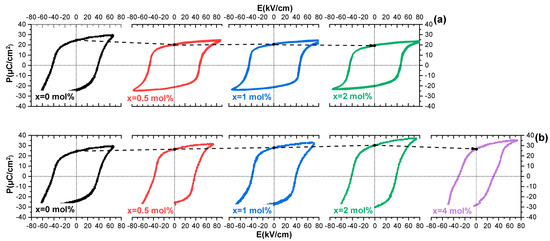

The piezoelectric coefficient (d33), remanent polarization (Pr), coercive field (Ec), and density (ρ) for BNT–5BT ceramics doped with Zr via both excess addition and substitutional incorporation are summarized in Table 1. For the excess Zr series, d33 increases from 110 pC/N (undoped) to a maximum of 135 pC/N at 2 mol% Zr, along with a steady reduction in Pr and Ec. This trend suggests that excess Zr induces structural disorder that facilitates domain wall motion, possibly due to local inhomogeneities or internal bias fields, despite a decrease in overall polarization [32]. Within the excess Zr series, Ec decreases progressively from 0.5 to 2 mol% Zr, indicating reduced energy barriers for switching. However, compared to the undoped composition, Ec remains slightly higher, which may reflect increased local fields or defect-related pinning at low doping levels. In this way, Figure 6 shows the polarization–electric-field (P–E) loops measured at room temperature for selected BNT–5BT samples. Substitutional doping with Zr enhances remanent polarization and reduces coercive field, consistent with improved domain switching. In contrast, excess Zr addition slightly suppresses ferroelectric response, possibly due to local compositional disorder.

Table 1.

Characteristic values for BNT–5BT–xZrexc and BNT–5BT–xZrsust ceramics sintered at 1150 °C. ρ: density; d33: piezoelectric coefficient; Pr: remanent polarization; Ec: coercive field.

Figure 6.

Hysteresis loops at room temperature for BNT–5BT ceramic undoped and BNT–5BT ceramics doped with Zr via (a) excess addition and (b) substitutional incorporation.

In contrast, substitutional doping leads to a more pronounced improvement in functional properties. At 2 mol% Zr, the d33 reaches 140 pC/N, and Pr increases continuously with Zr content, while Ec remains moderate. This behavior points to a more effective integration of Zr into the perovskite lattice, enabling enhanced polarization rotation and domain switching. To assess the doping limit, a sample with 4 mol% substitutional Zr was also synthesized. In this case, d33 drops sharply to 90 pC/N and Pr is slightly reduced, likely due to the formation of secondary phases and increased defect concentration, which hinder domain activity [22]. Given the marked deterioration in properties, this sample was not further analyzed in the structural and dielectric sections, as it lies beyond the optimal doping range. Similar performance degradation at high Zr levels has been reported in the literature for BNT–BT systems [29].

The contrasting trends observed between the two doping strategies highlight their distinct effects on the ferroelectric–piezoelectric response. Substitutional incorporation of Zr4+ (0.72 Å) at the B-site—replacing smaller Ti4+ cations (0.605 Å)—induces local lattice distortions that soften the polarization energy landscape, thereby promoting domain wall mobility. This explains the increase in Pr and moderate Ec values observed in the substitutionally doped samples (Figure 6 and Table 1). Conversely, excess Zr introduces chemical inhomogeneity and grain size refinement, which collectively restrict domain switching and reduce Pr, despite slightly lowering Ec. These distinct mechanisms of structural and defect-driven modulation govern functional behavior and must be carefully considered when optimizing doping strategies for energy harvesting applications.

Substitutional Zr doping up to 2 mol% appears to preserve the MPB-like character of BNT–5BT, as evidenced by the enhancement in d33 and Pr. However, at higher concentrations (e.g., 4 mol%), this trend reverses, as follows: both piezoelectric and ferroelectric performance deteriorate, likely due to subtle structural disorder or defect accumulation not detected by XRD or Raman spectroscopy.

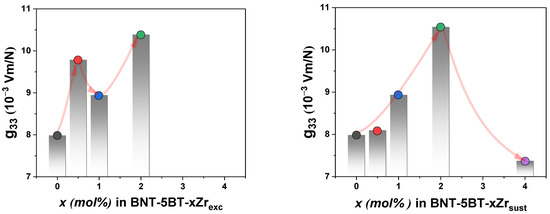

To evaluate the piezoelectric energy harvesting potential of the materials, Figure 7 presents the evolution of the piezoelectric voltage coefficient (g33 = d33/ε0εr) as a function of Zr concentration for both doping strategies, including excess addition (BNT–5BT–xZrexc, x = 0, 0.5, 1, and 2 mol%) and substitutional incorporation (BNT–5BT–xZrsub, x = 0, 0.5, 1, 2, and 4 mol%). For this calculation, the measurement of dielectric permittivity was recorded at 1 kHz and room temperature. In the excess-doped series, g33 does not exhibit a clear compositional trend, although the highest value (10.38 × 10−3 V·m/N) is observed at 2 mol% Zr. In contrast, the substitutionally doped series shows a more defined response, as follows: g33 increases with Zr content, reaching a maximum of 10.54 × 10−3 V·m/N at 2 mol%, followed by a notable decrease at 4 mol%, where the value drops below that of the undoped reference.

Figure 7.

Evolution of the piezoelectric voltage coefficient (g33) with Zr content for BNT–5BT ceramics doped via excess addition (left) and substitutional incorporation (right).

In both systems, the compositions exhibiting the highest g33 values also show increased relative density, enhanced d33 coefficients, and a more pronounced tetragonal phase, without full suppression of the rhombohedral contribution. This coexistence of phases, combined with enhanced polarization anisotropy, appears to favor the optimization of voltage generation.

Among all tested compositions, BNT–5BT–2Zrsub demonstrated the highest g33 value and thus represents the most promising candidate for piezoelectric energy harvesting applications within the scope of this study.

4. Conclusions

A 0.95(Bi0.5Na0.5)TiO3–0.05BaTiO3 (BNT–5BT)-based system was used to investigate the effect of the Zr doping strategy—excess addition versus substitutional incorporation—on the structural, dielectric, and piezoelectric properties of lead-free ceramics. By combining X-ray diffraction (XRD), Raman spectroscopy, microstructural analysis, and electrical characterization, the impact of each incorporation route was analyzed in terms of phase coexistence, local disorder, and electromechanical performance.

From a structural point of view, XRD analyses revealed that substitutional Zr doping maintains the morphotropic phase boundary (MPB), promoting a progressive rhombohedral-to-tetragonal transformation without complete phase separation. In contrast, excess Zr addition leads to a faster evolution toward a tetragonal structure, accompanied by peak broadening and increased structural disorder. These differences are also reflected in the Raman spectra, where substitutional Zr doping results in more defined vibrational modes, particularly those related to TiO6 octahedral distortions. This may suggest enhanced local polarization anisotropy, although further analysis would be needed to confirm this interpretation.

FE-SEM observations showed grain growth in both doping strategies with increasing Zr content, but with more uniform growth in the excess-doped series, likely due to liquid-phase-assisted sintering through Na2ZrO3 formation. In both cases, regions consistent with the presence of minor secondary phases such as Ba6Ti17O40 were detected, although these were not evident in XRD patterns.

Dielectric and piezoelectric measurements confirmed that substitutional doping leads to a decrease in Tmax and enhancement in both d33 and g33, with the best performance observed at 2 mol% Zr. The highest g33 value (10.54 × 10−3 V·m/N) was found for BNT–5BT–2Zrsub, which also showed increased remanent polarization and moderate coercive field, suggesting favorable domain wall mobility and phase coexistence. The sample with 4 mol% Zr prepared for the substitutional series confirmed the detrimental effect of over-doping and helped to establish the optimal doping range.

In summary, the Zr incorporation route plays a critical role in tuning the structure–property relationships in BNT–5BT ceramics. Substitutional doping near the MPB region enables local symmetry distortions and phase coexistence that enhance energy harvesting performance, offering a promising strategy for the development of advanced lead-free piezoelectric materials.

Author Contributions

Conceptualization, L.R. and M.D.; methodology, M.C.; software, M.D.; validation, L.R. and M.C.; formal analysis, M.D.; investigation, M.D.; resources, L.R.; data curation, M.D.; writing—original draft preparation, M.D.; writing—review and editing, L.R. and M.C.; visualization, L.R.; supervision, M.C.; project administration, M.C. and L.R.; funding acquisition, M.C. and L.R. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to thank National University of Mar del Plata (Argentina) Project (15/G577) and CONICET (PIP 2487) for providing financial support.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting the reported results are all included in the article. For more information, it is suggested to contact the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of this study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Panda, P.K. Review: Environmental Friendly Lead-Free Piezoelectric Materials. J. Mater. Sci. 2009, 44, 5049–5062. [Google Scholar] [CrossRef]

- EU-Directive 2002/95/EC. “Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (RoHS)”. Off. J. Eur. Union 2013, 46, 19–23. [Google Scholar]

- Shrout, T.R.; Zhang, S.J. Lead-Free Piezoelectric Ceramics: Alternatives for PZT? J. Electroceram. 2007, 19, 113–126. [Google Scholar] [CrossRef]

- Jones, G.O.; Thomas, P.A. Investigation of the Structure and Phase Transitions in the Novel A-Site Substituted Distorted Perovskite Compound Na0.5Bi0.5TiO3. Acta Crystallogr. B 2002, 58, 168–178. [Google Scholar] [CrossRef]

- Zhang, S.; Shrout, T.; Nagata, H.; Hiruma, Y.; Takenaka, T. Piezoelectric Properties in (K0.5Bi0.5)TiO3-(Na0.5Bi0.5)TiO3-BaTiO3 Lead-Free Ceramics. T-UFFC 2007, 54, 910–917. [Google Scholar] [CrossRef]

- Dittmer, R.; Webber, K.G.; Aulbach, E.; Jo, W.; Tan, X.; Rödel, J. Electric-Field-Induced Polarization and Strain in 0.94(Bi1/2Na1/2)TiO3–0.06BaTiO3 under Uniaxial Stress. Acta Mater. 2013, 61, 1350–1358. [Google Scholar] [CrossRef]

- Ma, C.; Guo, H.; Tan, X. A New Phase Boundary in (Bi1/2Na1/2)TiO3−BaTiO3 Revealed via a Novel Method of Electron Diffraction Analysis. Adv. Funct. Mater. 2013, 23, 5261–5266. [Google Scholar] [CrossRef]

- Reichmann, K.; Feteira, A.; Li, M. Bismuth Sodium Titanate Based Materials for Piezoelectric Actuators. Materials 2015, 8, 8467–8495. [Google Scholar] [CrossRef]

- Ma, Z.; Zhu, J.; Wu, J.; Hu, Y.; Lou, X.; Sun, N.; Zhao, Y.; Li, Y.; Hao, X. Optimization of Energy Storage Properties in (1 − x)Na0.5Bi0.5TiO3-xSr0.7La0.2TiO3-Relaxed Ferroelectric Ceramics. J. Adv. Dielectr. 2022, 13, 2242003. [Google Scholar] [CrossRef]

- Wang, C.; Lou, X. High Energy Storage Properties of 0.94Bi0.5Na0.5TiO3-0.06BaTiO3 Ceramics by Incorporating Sr0.8Bi0.1γ0.1Ti0.8Zr0.2O2.95. Microstructures 2023, 3, 2023023. [Google Scholar] [CrossRef]

- Ji, H.; Wang, D.; Bao, W.; Lu, Z.; Wang, G.; Yang, H.; Mostaed, A.; Li, L.; Feteira, A.; Sun, S.; et al. Ultrahigh Energy Density in Short-Range Tilted NBT-Based Lead-Free Multilayer Ceramic Capacitors by Nanodomain Percolation. Energy Storage Mater. 2021, 38, 113–120. [Google Scholar] [CrossRef]

- Sezer, N.; Koç, M. A Comprehensive Review on the State-of-the-Art of Piezoelectric Energy Harvesting. Nano Energy 2021, 80, 105567. [Google Scholar] [CrossRef]

- Ozgul, M.; Kucuk, A. B2O3 Doping in 0.94(Bi0.5Na0.5)TiO3−0.06BaTiO3 Lead-Free Piezoelectric Ceramics. Ceram. Int. 2016, 42, 19119–19123. [Google Scholar] [CrossRef]

- Jaita, P.; Manotham, S.; Rujijanagul, G. Influence of Al2O3 Nanoparticle Doping on Depolarization Temperature, and Electrical and Energy Harvesting Properties of Lead-Free 0.94(Bi0.5Na0.5)TiO3–0.06BaTiO3 Ceramics. RSC Adv. 2020, 10, 32078–32087. [Google Scholar] [CrossRef] [PubMed]

- Barick, B.K.; Choudhary, R.N.P.; Pradhan, D.K. Dielectric and Impedance Spectroscopy of Zirconium Modified (Na0.5 Bi0.5)TiO3 Ceramics. Ceram. Int. 2013, 39, 5695–5704. [Google Scholar] [CrossRef]

- Oksuz, K.; Sen, S.; Sen, U.; Öksüz, K. Influence of ZrO2 Addition on the Structure and Dielectric Properties of BaTiO3 Ceramics. Acta Phys. Pol. A 2017, 131, 197–199. [Google Scholar] [CrossRef]

- Watcharapasorn, A.; Jiansirisomboon, S.; Tunkasiri, T. Microstructure and Mechanical Properties of Zirconium-Doped Bismuth Sodium Titanate Ceramics. Chiang Mai J. Sci. 2006, 33, 169–173. [Google Scholar]

- Armstrong, T.R.; Morgens, L.E.; Maurice, A.K.; Buchanan, R.C. Effects of Zirconia on Microstructure and Dielectric Properties of Barium Titanate Ceramics. J. Am. Ceram. Soc. 1989, 72, 605–611. [Google Scholar] [CrossRef]

- Liu, T.; Liu, Z.; Lin, J.; Chen, K. Improving Energy Storage Performance and High-Temperature Stability in Bi0.5Na0.5TiO3-Based Lead-Free Dielectric Ceramics by ZrO2 Doping. Ceram. Int. 2023, 49, 37349–37355. [Google Scholar] [CrossRef]

- Ullah, A.; Ullah, M.; Ullah, A.; Ullah, A.; Saddiq, G.; Ullah, B.; Zeb, A.; Ullah Jan, S.; Kim, I.W. Dielectric and Electromechanical Properties of Zr-Doped BNT-ST Lead-Free Piezoelectric Ceramics. J. Korean Phys. Soc. 2019, 74, 589–594. [Google Scholar] [CrossRef]

- Yao, Y.-Q.; Tseng, T.-Y.; Chou, C.-C.; Chen, H.H.D. Phase Transition and Piezoelectric Property of (Bi0.5Na0.5)0.94Ba0.06ZryTi1−yO3(Y=−0.04) Ceramics. J. Appl. Phys. 2007, 102, 094102. [Google Scholar] [CrossRef]

- Liu, W.; Ren, X. Large Piezoelectric Effect in Pb-Free Ceramics. Phys. Rev. Lett. 2009, 103, 257602. [Google Scholar] [CrossRef]

- Yadav, A.K.; Yoo, I.-R.; Choi, S.-H.; Song, H.-C.; Cho, K.-H. Electric Field-Induced Strain Enhancement in Pb-Free Na0.46Bi0.47La0.01Ba0.05TiO3 Ceramics Modified by (Al0.50Nb0.50)4+ Complex Ions. J. Alloys Compd. 2025, 1033, 181266. [Google Scholar] [CrossRef]

- Lee, W.-C.; Huang, C.-Y.; Tsao, L.-K.; Wu, Y.-C. Chemical Composition and Tolerance Factor at the Morphotropic Phase Boundary in (Bi0.5Na0.5)TiO3-Based Piezoelectric Ceramics. J. Eur. Ceram. Soc. 2009, 29, 1443–1448. [Google Scholar] [CrossRef]

- Yadav, A.K.; Yoo, I.-R.; Choi, S.-H.; Park, J.-Y.; Kim, M.-S.; Cho, J.; Song, H.-C.; Cho, K.-H. Enhanced Temperature Stability of Dielectric Permittivity and Energy Storage Properties of BNT-Based Lead-Free Relaxor Ceramics. Ceram. Int. 2025, 51, 12049–12059. [Google Scholar] [CrossRef]

- Prado, A.; Rubio-Marcos, F.; Ramajo, L.; Castro, M.S. Dielectric and Ferroelectric Properties Evolution of (1−x)(Bi0.5Na0.5TiO3)–xK0.5Na0.5NbO3 Piezoceramics. Bull. Mater. Sci. 2020, 43, 282. [Google Scholar] [CrossRef]

- Bokov, A.A.; Ye, Z.-G. Recent Progress in Relaxor Ferroelectrics with Perovskite Structure. In Progress in Advanced Dielectrics; World Scientific: Singapore, 2019; pp. 105–164. ISBN 978-981-12-1042-6. [Google Scholar]

- Song, T.K.; Park, J.; Lee, S.; Lee, M.; Kim, D.; Sung, Y.; Kim, M.; Cho, J.; Choi, B.; Kim, S. Effects of Zr Doping on the Depolarization Temperature and the Piezoelectric Properties in (Bi0.5Na0.5)TiO3BaTiO3 Lead-Free Ceramics. JKPS 2010, 57, 1905–1908. [Google Scholar] [CrossRef]

- Peng, C.; Li, J.-F.; Gong, W. Preparation and Properties of (Bi1/2Na1/2)TiO3–Ba(Ti,Zr)O3 Lead-Free Piezoelectric Ceramics. Mater. Lett. 2005, 59, 1576–1580. [Google Scholar] [CrossRef]

- Iyer, V.S.; Venugopal, V.; Mohapatra, S.; Singh, Z.; Roy, K.N.; Prasad, R.; Sood, D.D. Standard Molar Gibbs Free Energy of Formation of Na2ZrO3(s). J. Chem. Thermodyn. 1988, 20, 781–784. [Google Scholar] [CrossRef]

- Brzozowski, E.; Castro, M.S. Grain Growth Control in Nb-Doped BaTiO3. J. Mater. Process. Technol. 2005, 168, 464–470. [Google Scholar] [CrossRef]

- Takenaka, T.; Kei-ichi Maruyama, K.M.; Koichiro Sakata, K.S. (Bi1/2Na1/2)TiO3-BaTiO3 System for Lead-Free Piezoelectric Ceramics. Jpn. J. Appl. Phys. 1991, 30, 2236. [Google Scholar] [CrossRef]

- Mishra, P.; Sonia; Kumar, P. Enhanced Dielectric and Piezoelectric Properties of BZT–BCT System near MPB. Ceram. Int. 2014, 40, 14149–14157. [Google Scholar] [CrossRef]

- Guo, Y.; Kakimoto, K.; Ohsato, H. Structure and Electrical Properties of Lead-Free (Na0.5K0.5)NbO3-BaTiO3 Ceramics. Jpn. J. Appl. Phys. 2004, 43, 6662–6666. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).