1. Introduction

Over the last few decades, there has been a growing interest in the therapeutic potential of natural products, such as essential oils (EOs), which present a wide range of biological properties, including antimicrobial [

1], antioxidant [

2], antivirus [

3], anticancer [

4] and neuroprotective [

5] activities. Thereafter, EOs have found a considerable range of applications as naturally occurring bioactive agents in the field of medicine, food and cosmetic preservation [

6]. The biological activities of EOs are assigned to several small molecules, including terpenoids, phenolic and aliphatic constituents. It is important to note that the place of origin of the EO, the climatic conditions, as well as the part of the plant and the method used for its extraction, significantly affect its composition and therefore its biological activities [

7].

Essential oils are well known for their ability to scavenge free radicals [

8], as well as to inhibit acetylcholinesterase activity [

9] and suppress Aβ peptide deposits [

10]. Acetylcholinesterase (AChE) is a type-B carboxylesterase that catalyzes the hydrolysis of the neurotransmitter acetylcholine in choline and acetic acid [

11]. AChE inhibitors are a constantly developing research field since they comprise the main therapeutic strategy for Alzheimer’s Disease (AD) presently. Specifically, the decrease in acetylcholine levels is of major importance for the decline of the cognitive function of AD patients [

12], while some of the most well-known AChE inhibitors are natural products, such as galantamine and phytostigmine. Therefore, several plant species (e.g., essential oils) producing a wide arrow of bioactive compounds, such as alkaloids, coumarins, terpenes, flavonoids and polyphenols, have been examined for their AChE inhibitory activity in the research of potential anti-AD drugs with fewer side effects [

13,

14].

Eos of plant species belonging to Cupressaceae family, primarily from the genera

Juniperus and

Cupressus, are reported to display potent biological activities.

Juniperus phoenicea, also known as cedar, is a coniferous tree and is considered an important medicinal plant largely used in traditional medicine. Its range covers the whole Mediterranean region, from the Canary Islands, the Atlas Mountains in Africa and the Atlantic coast of Portugal in the West to Jordan and Saudi Arabia in the East [

15]. Its properties are mainly based on its chemical composition, containing monoterpenes, such as α-pinene, myrcene and δ-3-carene as major constituents [

16,

17]. The cedar

(J. phoenicea) essential oil (CEO) is known to possess inherent properties, including antimicrobial [

17], antioxidant [

18], anti-inflammatory [

19] and neuroprotective, also expressed by its ability to inhibit AChE activity. For instance,

Juniperus phoenicea EO derived using different solvents from the berries of the plant collected from Turkey presented 75% inhibition at 200 μg/mL [

20].

Despite the multiple biological responses of the CEO, there is a challenging problem concerning its use in a final product due to its volatility, hydrophobic nature and sensitivity in the presence of light, oxygen and heat [

21]. A common approach to overcome these limitations is nano- and microencapsulation, which is widely considered as a viable, promising and efficient technique for the development of new functional pharmaceutical, cosmetic, etc., products [

22]. So far, several nanoencapsulation strategies have been developed for the delivery of natural compounds using various biodegradable carriers [

23]. In fact, the encapsulation of EOs in different carriers has already been proven effective in enhancing their biological activity [

24,

25]. Among various methods for maintaining the quality of the EO and improving its physicochemical (e.g., aqueous solubility) and biological properties, complexation with natural and chemically modified cyclodextrins was found to be a successful strategy [

26].

Cyclodextrins (CDs) are cyclic oligosaccharides consisting of six (α-cyclodextrin), seven (β-cyclodextrin) and eight (γ-cyclodextrin) d-(+)-glucopyranose units linked by α-D-(1→4) linkages. The structure of cyclodextrin molecules resembles truncated cones with the secondary hydroxyl groups located at the wider edge of the ring and the primary groups on the narrower edge. Hydrogen atoms are directed to the inner part of the ring, resulting in a hydrophobic cavity along with a hydrophilic character outside of the ring. Hence, cyclodextrins are soluble in water and simultaneously may accommodate a broad range of hydrophobic bioactive species inside their cavity through the formation of host–guest inclusion complexes (ICs) [

27,

28]. Several EOs have been reported to form supermolecular inclusion complexes with β-CD, such as oregano [

29] and eucalyptus [

30] essential oils. The complexation of EOs with β-CD increases their aqueous solubility and thermal stability (heat-promoted decomposition in higher temperatures), offers their controlled release [

30] and maintains or enhances their bioactivity [

31].

However, to our knowledge, there are no reports that have examined the formation of inclusion complexes of Cedar essential oil derived from a Greek region with β-cyclodextrin, along with their ability to inhibit acetylcholinesterase in vitro. The present study focuses on the encapsulation of the CEO in β-CD and the characterization of the novel inclusion complexes concerning their thermal and physicochemical properties. The in vitro release profile and the kinetic modeling were studied, as well as the effect of the β-cyclodextrin concentration in the aqueous solubility of cedar essential oil. The overall goal of this research is to propose a new method for the efficient encapsulation of the CEO and to demonstrate its feasibility in inhibiting acetylcholinesterase activity effectively.

2. Materials and Methods

2.1. Materials

Cedar (Juniperus phoenicea) essential oil of food-grade quality, obtained by steam distillation from the berries of J. phoenicea, which were collected from Viotia, Greece, during the summer of 2017, was kindly provided by the Laboratory of Nutritional Physiology and Feeding, Animal Sciences and Aquaculture Faculty, Agricultural University of Athens (A.U.A., Athens, Greece). β-Cyclodextrin (β-CD) of >99% purity was purchased from Fluka (Gillingham, England), while ethanol of analytical reagent grade, ethyl acetate, hexane, K2HPO4 and KH2PO4 of ACS grade and anhydrous sodium sulfate were purchased from Merck Millipore (Billerica, MA, USA). Acetylcholinesterase from Electrophorus electricus, type VI-S (Saint Louis, MO, USA), and trizma-base 99% were purchased from Merck Millipore (Billerica, MA, USA). Acetylthiocholine iodide 98%, 5,5′-dithiobis-(2-nitrobenzoic acid) 99%, Galantamine hydrobromide 98% and Dimethyl sulfoxide (DMSO) 99.8% were purchased from Alfa Aesar (Haverhill, MA, USA). The materials were used without further purification. For the preparation of solutions, ultra-pure water was used.

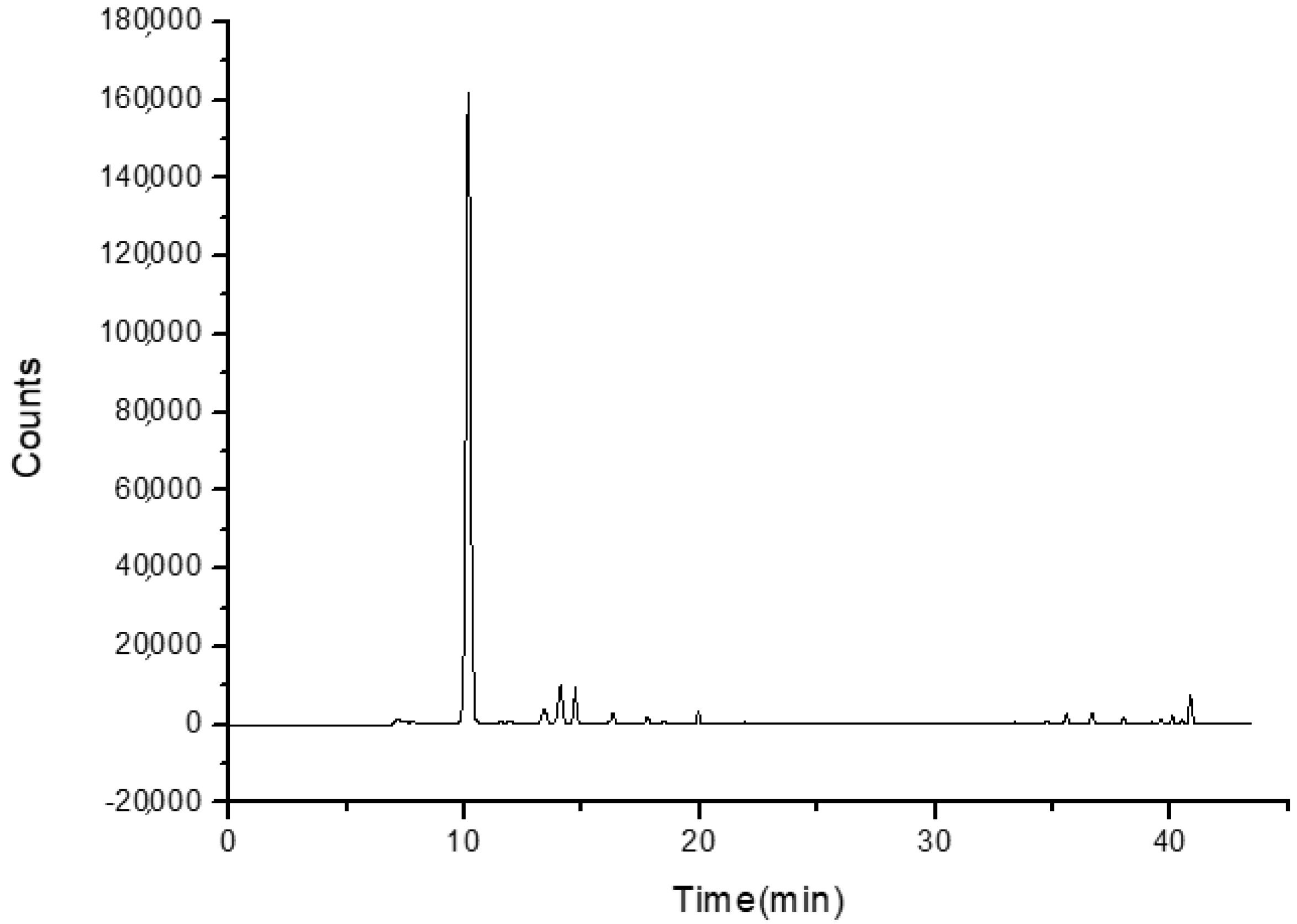

2.2. Chemical Analysis of CEO

The CEO was analyzed using a GC-MS VARIAN 450 GC hyphenated with a VARIAN 220 MS IT Mass Spectrometer. The method of ionization was Electron Impact, and mass analysis was performed using Ion Trap. The FactorFour capillary column (VF-5 ms; 30 m × 0.25 mm I.D.; DF = 0.25) was used, and helium was the carrier gas at a flow rate of 1.0 mL/min. The column temperature was initially kept at 36 °C and then gradually increased to 190 °C at a 3 °C min−1. The mass range was recorded from m/z 40 to 650. The injection port temperature was at 250 °C. The samples of CEO were appropriately diluted in hexane and injected manually in the split mode (split ratio: 1:50).

2.3. Preparation of β-CD–CEO Inclusion Complexes

The β-CD–CEO ICs were prepared by the co-precipitation method [

29]. Different batches of inclusion complexes (ICs) were prepared by varying the CEO-to-β-CD mass ratio. Briefly, β-CD was dissolved in defined volumes of an ethanol and double-deionized water mixture (1:2

v/

v) to achieve a concentration of 100 mg/mL. The solution was magnetically stirred at 55 ± 0.5 °C until the complete dissolution of β-CD. Subsequently, the defined mass of CEO was added dropwise in the β-CD solution to obtain the determined β-CD:CEO mass ratio each time (90:10, 85:15, 80:20, 70:30 (

w/

w)). The formed emulsion was continuously stirred at room temperature for 24 h until the β-CD–CEO ICs were formed. The final dispersion was kept in the refrigerator for 24 h, after which the β-CD–CEO ICs were recovered by vacuum filtration. The recovered ICs were dried in a high-pressure Edward’s pump for 4 h and were stored in the refrigerator for further analysis and characterization.

The process yield was determined using Equation (1):

2.4. Characterization of the β-CD–CEO ICs

2.4.1. Inclusion Efficiency of the β-CD–CEO ICs

The inclusion efficiency (%IE) of cedar essential oil in the β-CD–CEO ICs was measured directly by quantification of the encapsulated EO in the final dried ICs via Ultraviolet-Visible Spectroscopy using a JASCO double-beam V-770 UV-Vis/NIR spectrophotometer. For the analyses, 50 mg of dried ICs were dispersed in 4 mL of double-deionized water and 2 mL of hexane. The dispersion was sonicated at 80 °C for 20 min. The organic phase was separated from the aqueous phase and then was dried using anhydrous sodium sulfate. Subsequently, the hexane was evaporated from the organic phase using a rotary evaporator at room temperature for 30 min. Ethyl acetate was then added, and the absorption of the EO was measured at 252 nm. The IE (%) was calculated using the following Equation (2):

2.4.2. Determination of Size, Size Distribution and Zeta-Potential

Dynamic Light Scattering (DLS) using a Zetasizer Nano ZS device (Malvern Instruments, Malvern, UK) was utilized to measure the size, size distribution and zeta-potential of the ICs. For the DLS measurements, aqueous solutions (pH 7.0) of the final dried β-CD–CEO ICs were adequately diluted. The samples were placed in a folded capillary cell (DTS1070, Malvern, UK). The size, polydispersity index (PDI) and zeta-potential measurements were carried out in triplicate at 25 ± 1 °C. The results were reported as mean ± standard deviation (SD).

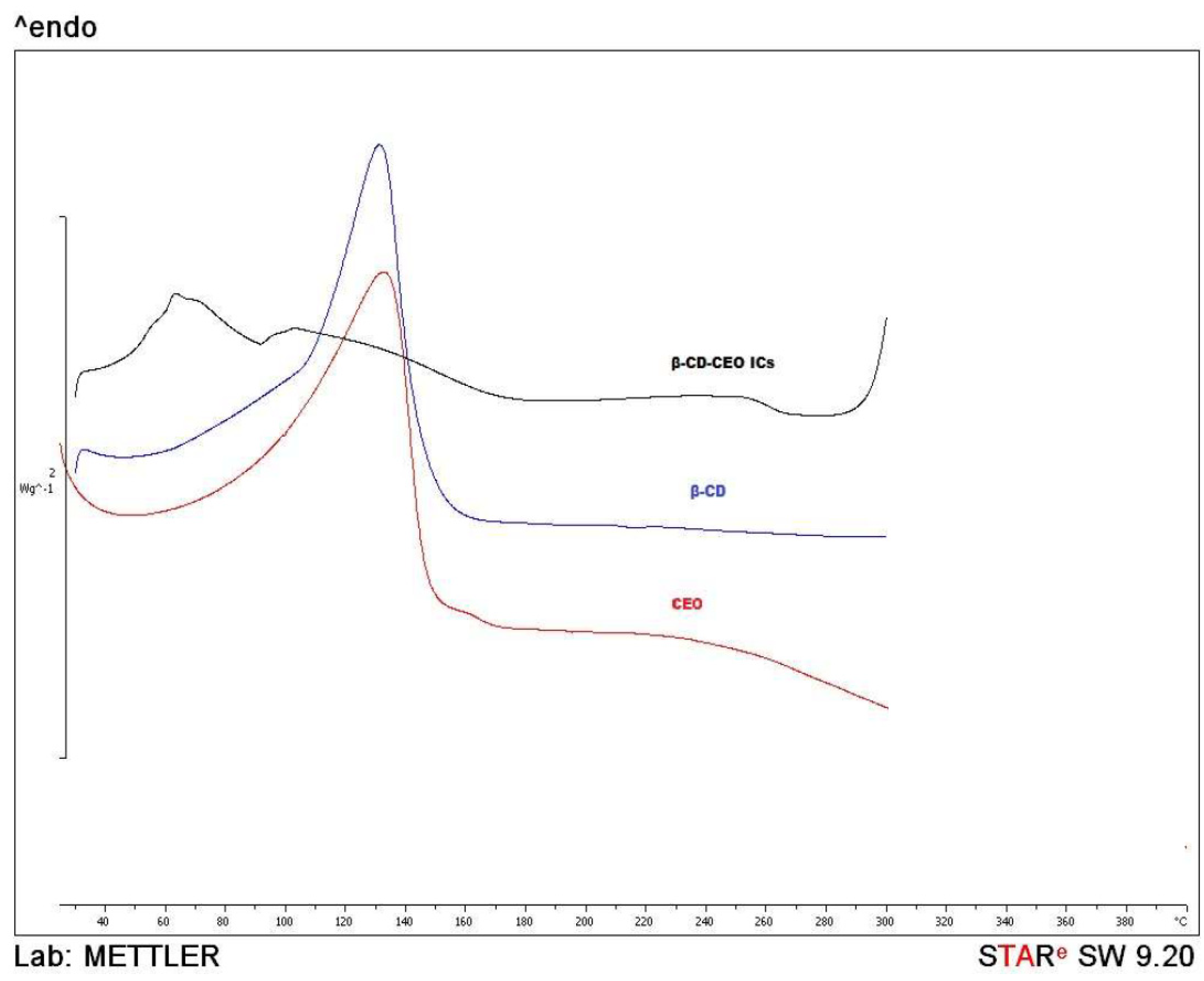

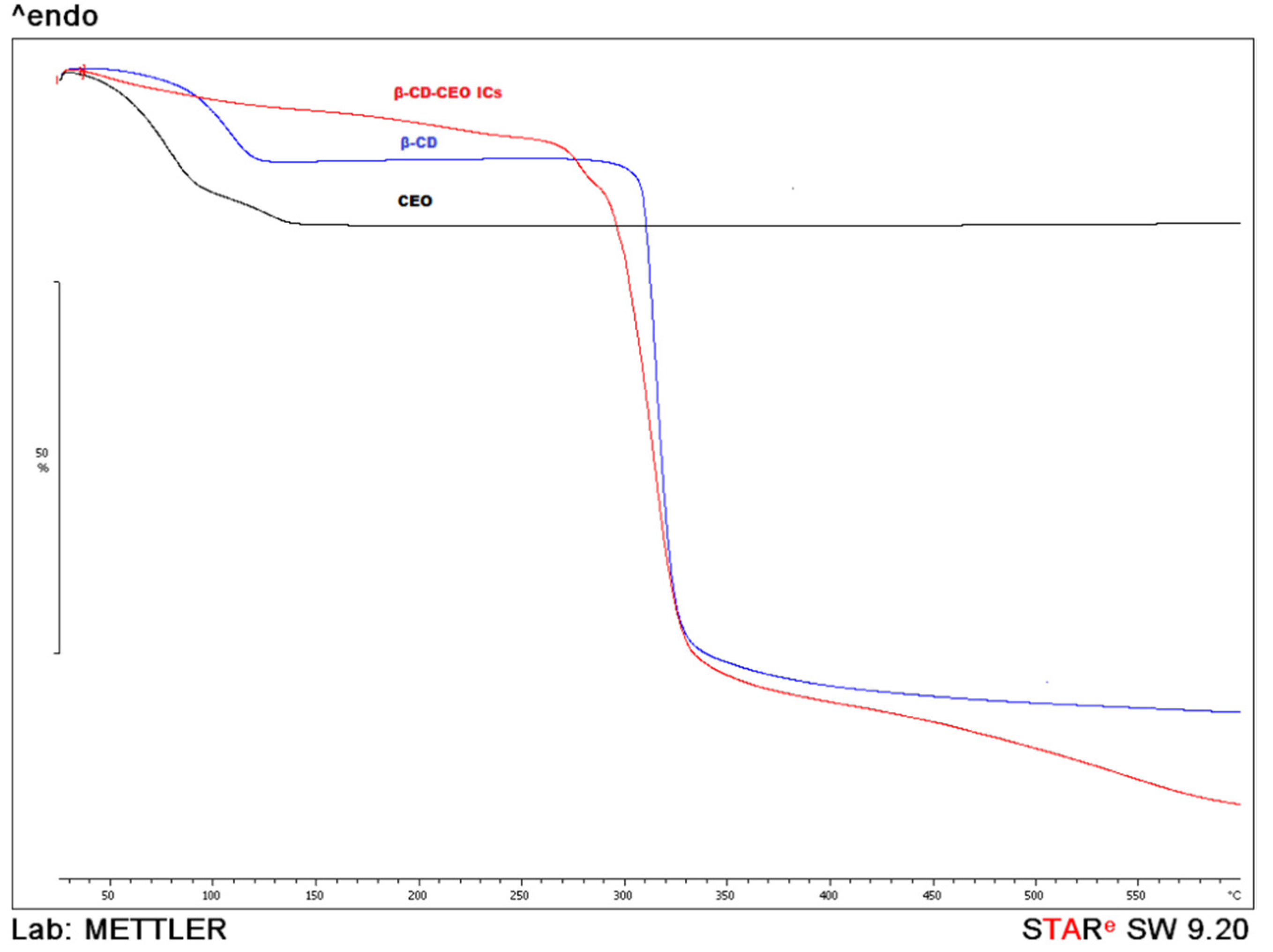

2.4.3. Thermal Properties

The thermal properties of the ICs (β-CD:CEO = 80:20 (w/w)) were studied using the Differential Scanning Calorimetry (DSC) method (DSC 1 STARe System device, Mettler Toledo, Columbus, OH, USA), and the Thermogravimetric (TG) analysis (TGA/DSC 1 STARe System Thermobalance, Mettler Toledo, Columbus, OH, USA). Both analyses were conducted for the pure β-CD, CEO and for the final dried β-CD–CEO ICs. For the DSC analyses, the samples were heated from 30 °C to 300 °C, with a heating rate of 10 °C/min under nitrogen gas flow (20 mL/min), while for the Thermogravimetric (TG) analyses, they were heated from 25 °C to 600 °C, at a heating rate of 10 °C/min under nitrogen gas flow (10 mL/min).

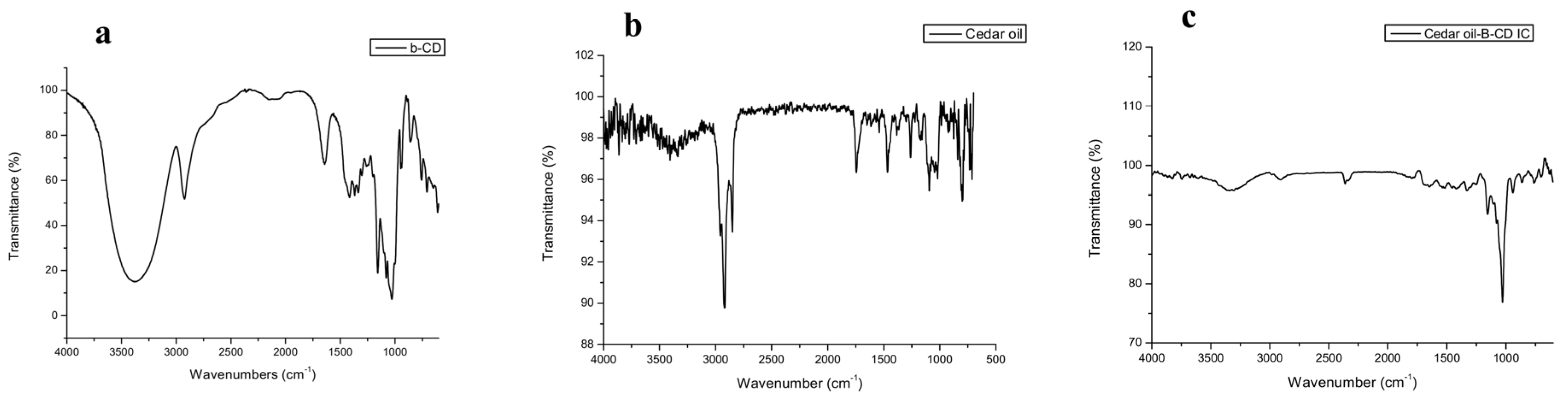

2.4.4. Fourier Transform Infrared Spectroscopy (FT-IR Spectroscopy)

The FT-IR-ATR spectra of the CEO, free β-CD and the β-CD–CEO ICs (β-CD:CEO = 80:20 (w/w)) were obtained using a JASCO FT/IR-4200 spectrometer (Japan Spectroscopic Company, Tokyo, Japan). IR analyses were carried out in the scanning range of 500–4000 cm−1.

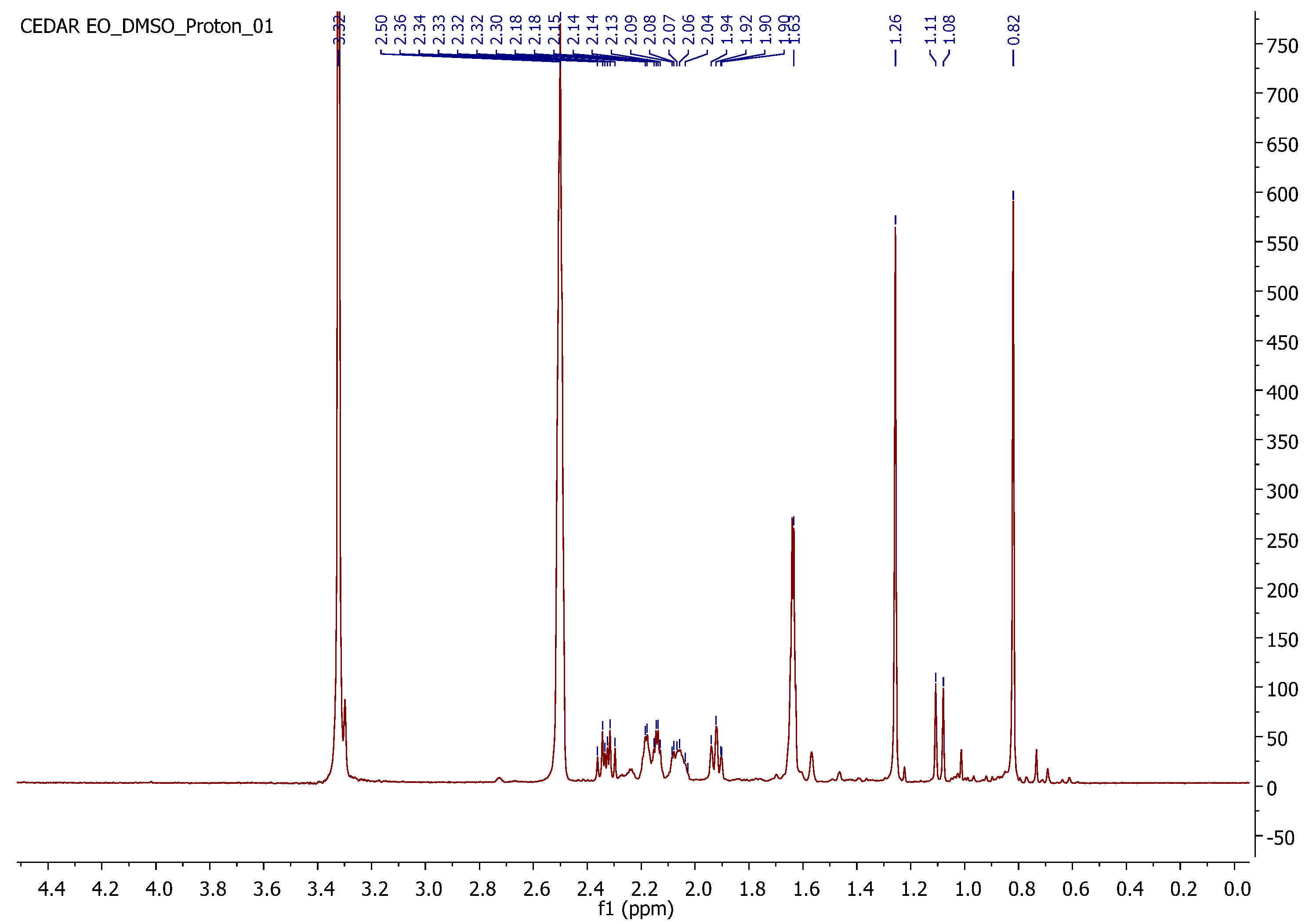

2.4.5. Nuclear Magnetic Resonance Spectroscopy (NMR Spectroscopy)

NMR spectrometry was used to confirm the formation of inclusion complexes. The 1H-NMR spectra of the final dried β-CD–CEO ICs (β-CD:CEO = 80:20 (w/w)) and β-CD were recorded on theVarian 300 MHz spectrometer (Varian, Palo Alto, CA, USA) of the Institute of Chemical Biology of National Hellenic Research Foundation. The spectra were obtained using deuterium oxide (D2O) as a solvent. The coupling constants (J) are expressed in hertz (Hz), and the chemical shifts (δ) are reported in parts per million (ppm) relative to the solvent.

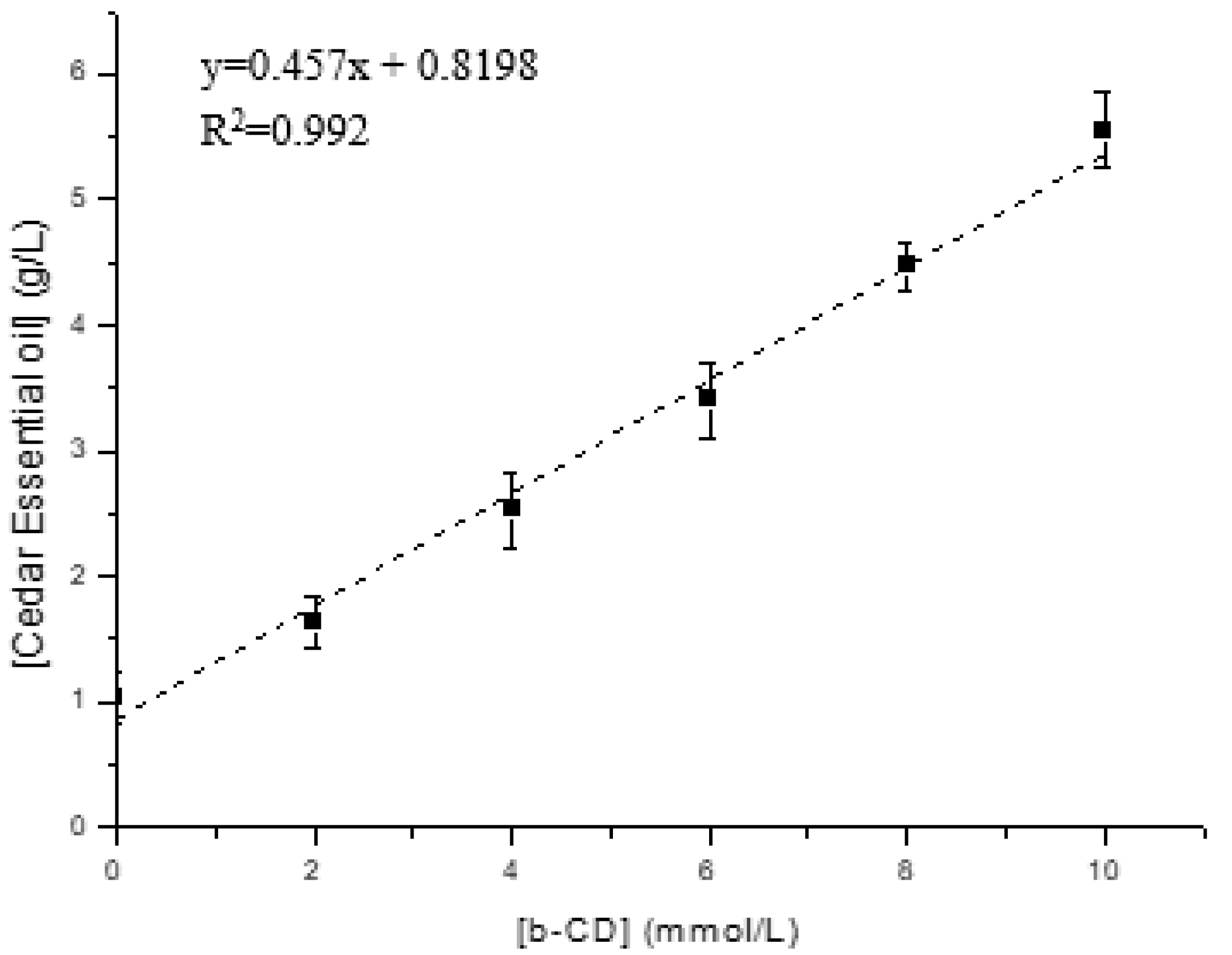

2.5. Phase Solubility Studies

The phase solubility studies were conducted to investigate the effect of β-CD on the solubility of the cedar essential oil (CEO). An excess amount of the cedar essential oil (15 g/L) was added in an aqueous buffer (pH 7.4) containing increasing amounts of β-CD (ranging from 0 to 10 mmol/L) at 37 °C. The amount of cedar essential oil in suspension after equilibration for 72 h and filtration through a 0.45 μm membrane filter was determined by ultraviolet-to-visible (UV-Vis) spectroscopy [

32,

33,

34].

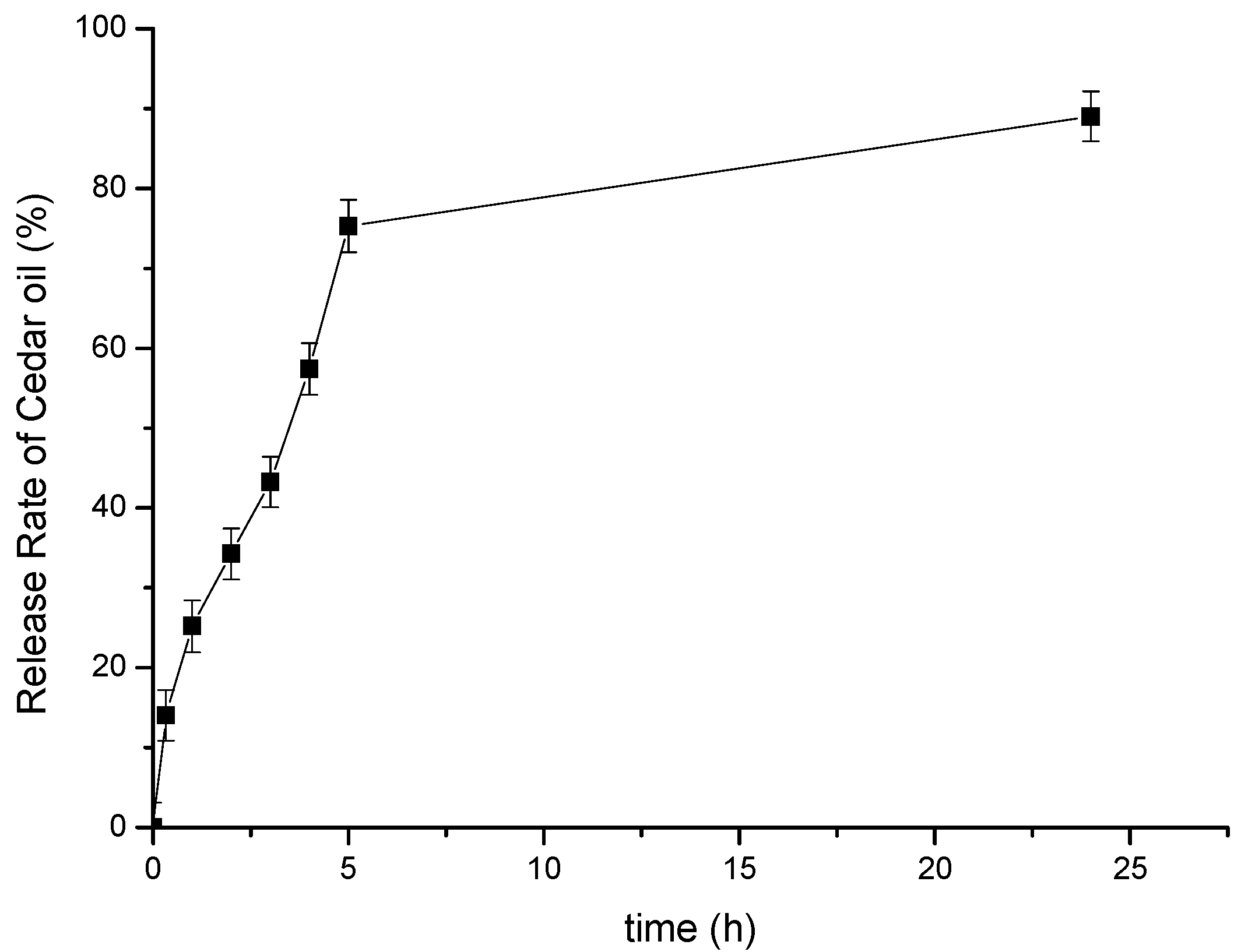

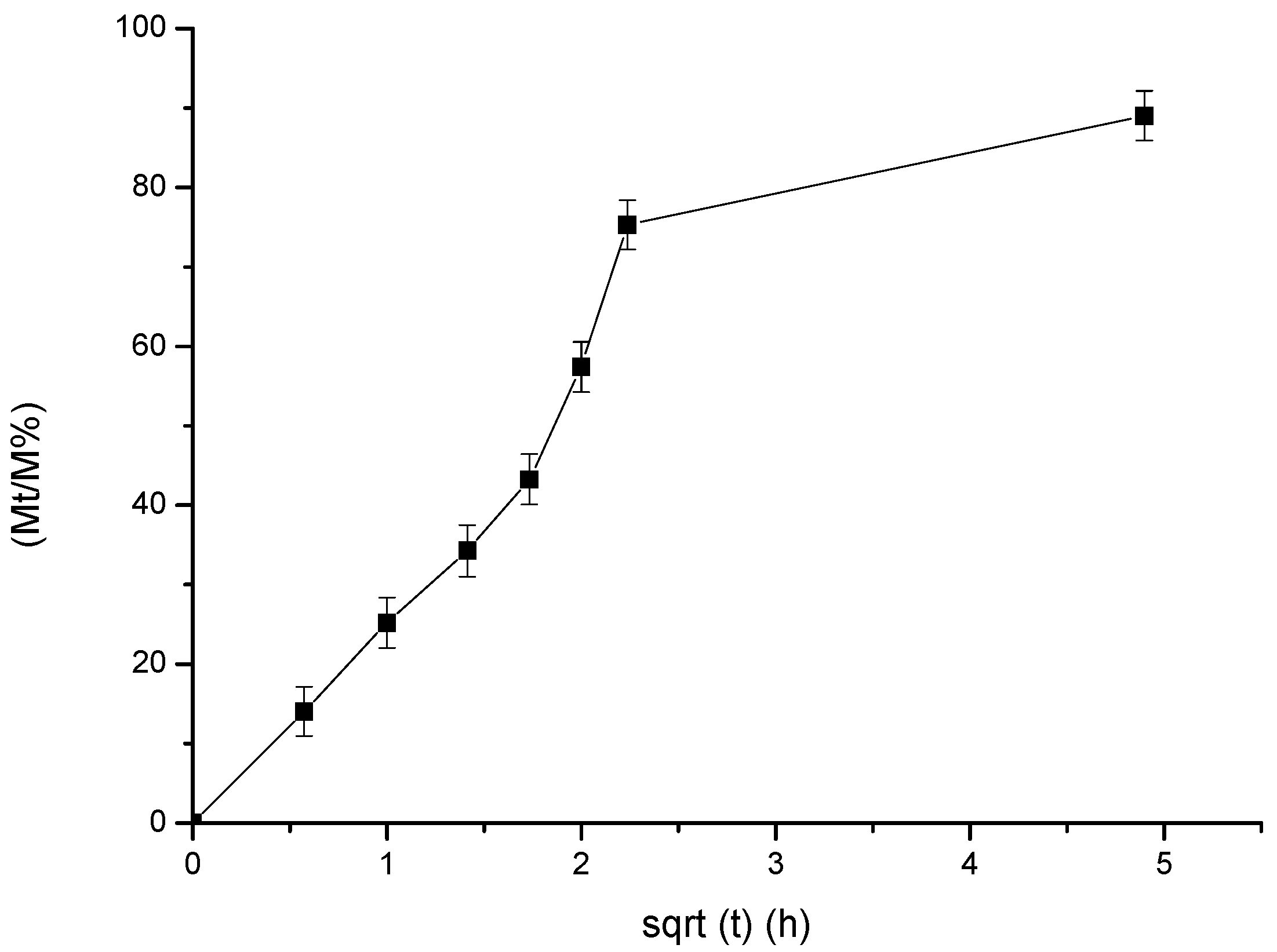

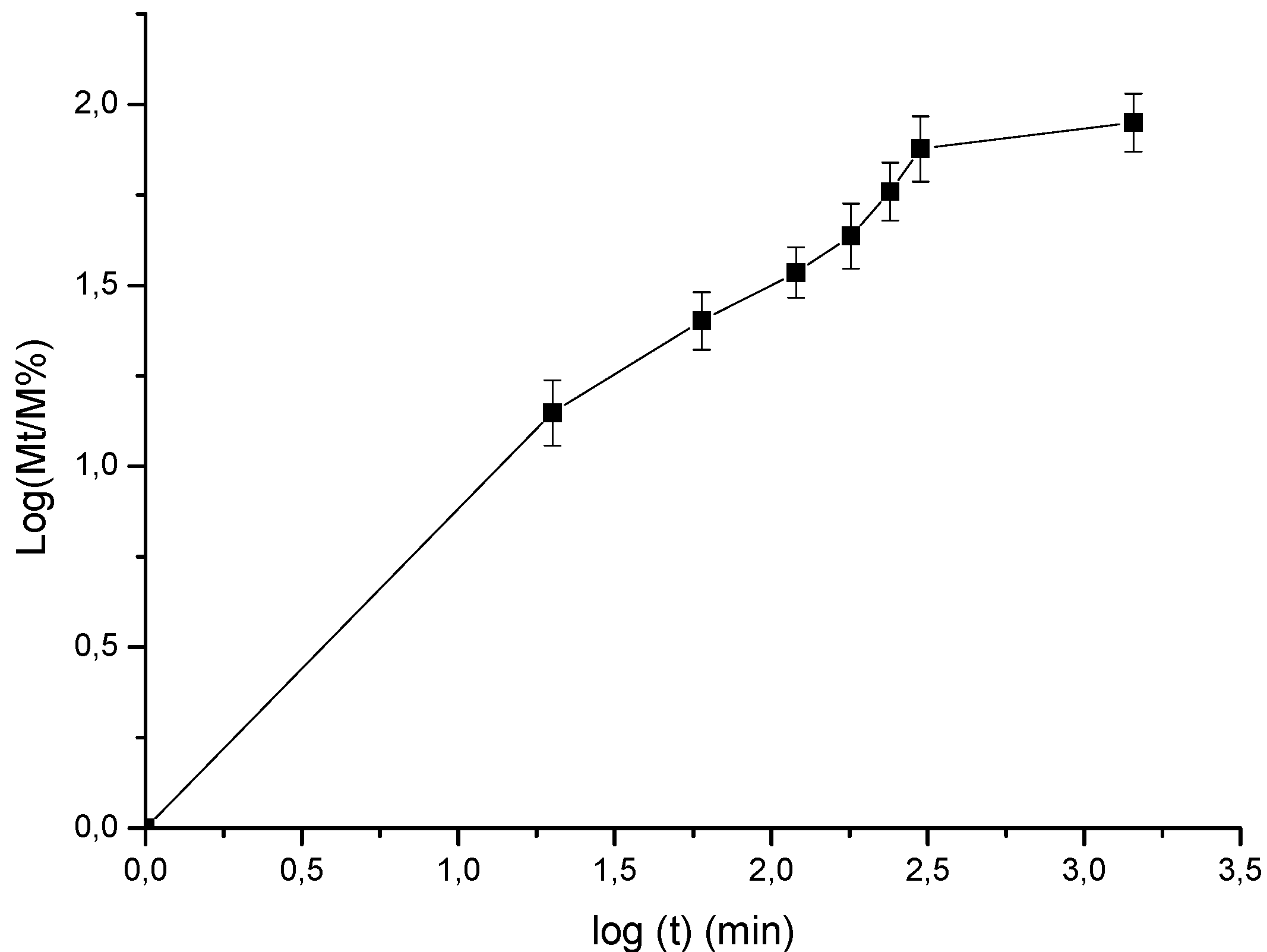

2.6. In Vitro Release Study of the β-CD–Cedar Essential Oil (CEO) ICs

The release profile of the β-CD–Cedar Essential Oil (CEO) IC (β-CD:CEO = 80:20 (

w/

w)) was studied in phosphate-buffered solution (pH 7.4) at 37 °C. In particular, the release rate of CEO from β-CD–CEO ICs was carried out by adding 200 mg of β-CD–CEO ICs into 30 mL of phosphate-buffered solution (pH 7.4) and was kept under magnetic stirring (400 rpm) for 24 h. At specific time intervals, 2 mL samples were manually withdrawn from the dissolution medium and replaced with a fresh medium to maintain a constant volume. The accumulated release amount of CEO from β-CD–CEO ICs was measured using UV-vis spectroscopy. The obtained release data were further analyzed by kinetic studies according to zero order, first order, second order, Higuchi and Korsmeyer-Peppas models. The selection of the most appropriate model was based on the obtained R

2 values [

35].

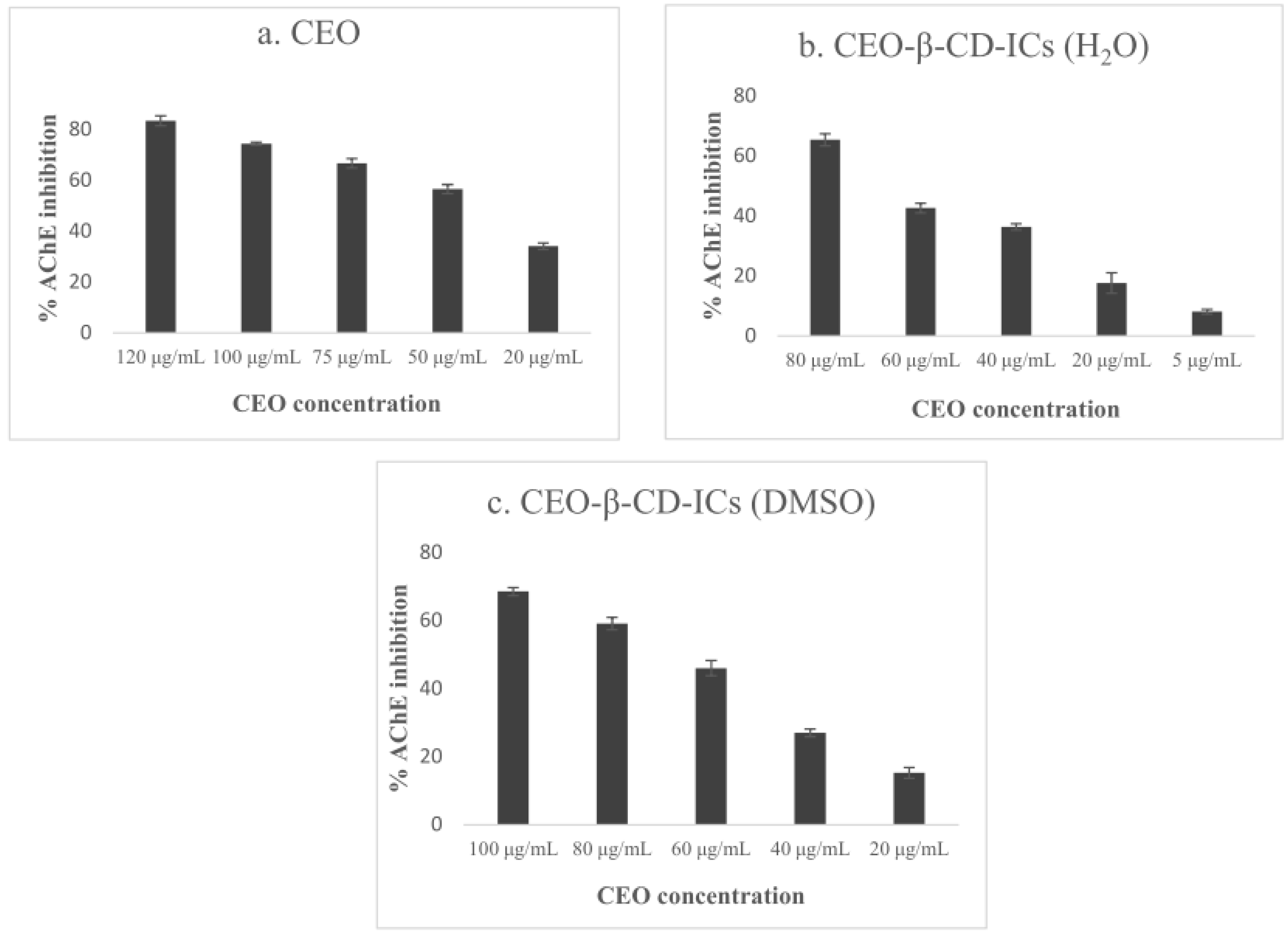

2.7. In Vitro Acetylcholinesterase Inhibition Assay

Inhibition of AChE activity was assessed using a modified 96-well microplate assay [

36], based on Ellman’s method [

37]. Specifically, thiocholine, which is the product of acetylthiocholine (ATCI) hydrolysis by AChE, reacts with Ellman’s reagent (DTNB) to produce 2-nitrobenzoate-5-mercaptothiocholine and 5-thio-2-nitrobenzoate, which can be detected at 412 nm.

For free CEO, β-CD or galantamine hydrobromide, Tris-HCl 50 mM pH 8.0, each sample dissolved in DMSO and 0.1 units/mL of

electrophorus electricus AChE was added in each well and incubated for 15 min. Then DTNB (3 mM) was added, as well as ATCI (14 mM), which initiated the reaction. Absorbance was measured at t = 0 and t = 10 min after substrate’s addition at 412 nm. The percentage of inhibition was calculated by comparing the difference of absorbance’s values for the sample and the control (DMSO), using the following Equation (3):

For the β-CD–CEO ICs (β-CD:CEO = 80:20 (w/w)), Tris-HCl 50 mM pH 8.0 and β-CD–CEO ICs dispersed in ultra-pure water or DMSO were added in each well, while electrophorus electricus AChE (0.1 units/mL) was added either instantly or after 2 h, 5 h and 24 h and incubated for 15 min. All the other proceedings were the same as described for free CEO inhibitory activity, while the control mixture contained water or DMSO, respectively. The IC50 values were calculated using the GraphPad Prism software (v. 8.0.2.) by non-linear regression.