Carbon Emission and Cost Analysis of Using Hybrid Fibre White Topping Overlays—A Road Rehabilitation Feasibility Study

Abstract

:1. Introduction

2. Background and Research Significance

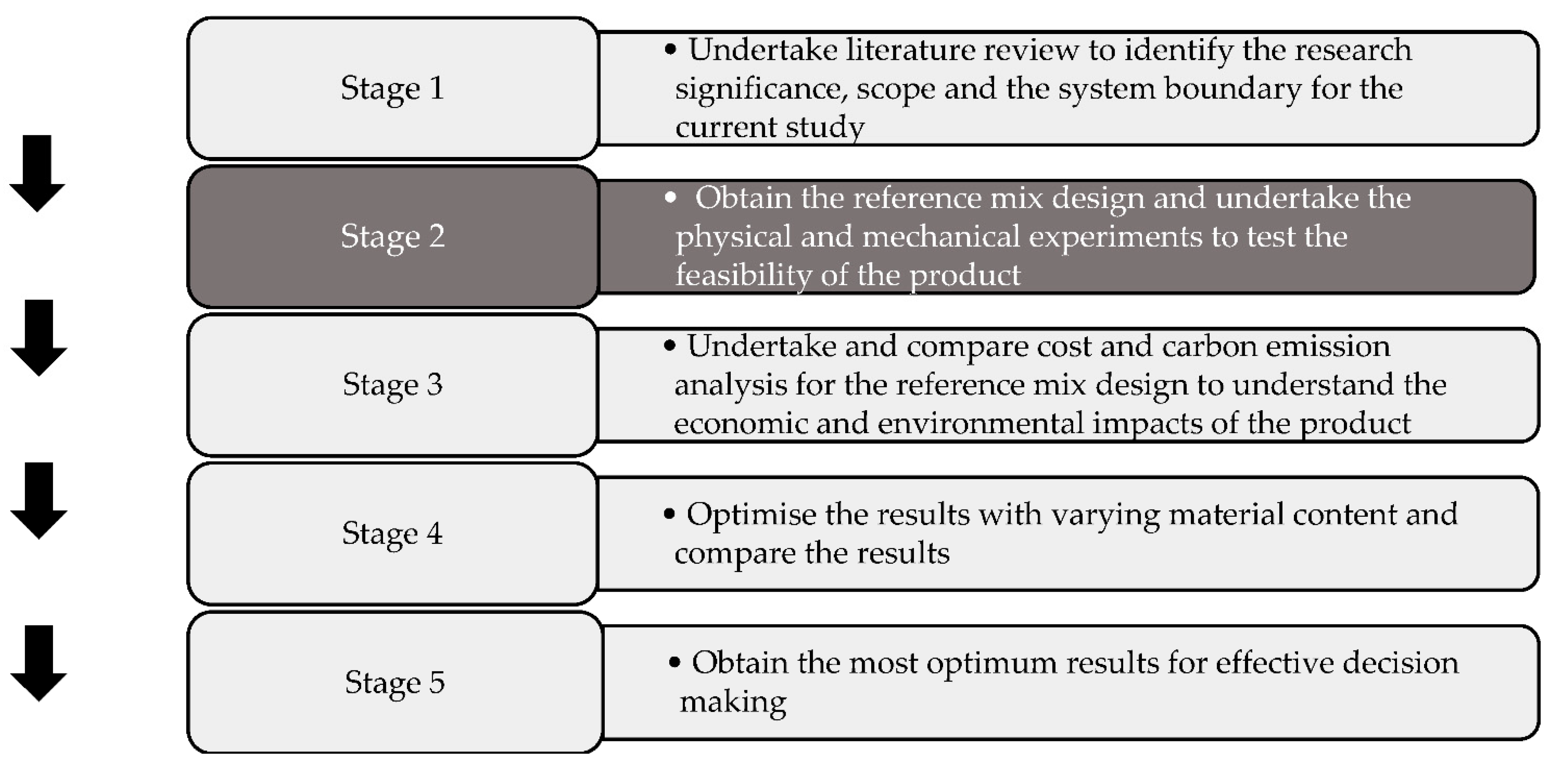

3. Research Methodology

4. Mix Design and Experimental Procedure

4.1. General Experimental Details

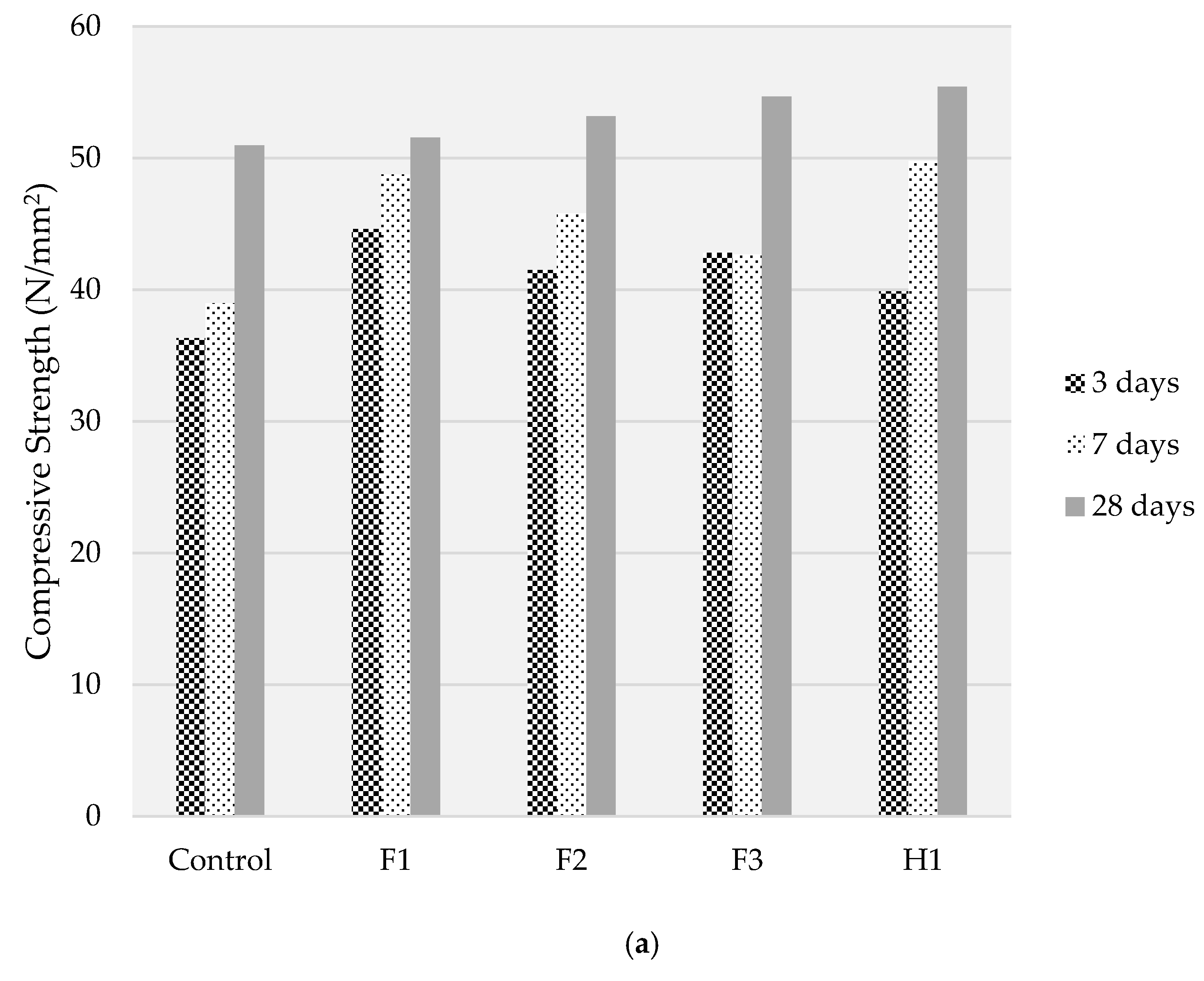

4.2. Compressive Strength Testing Procedure

4.3. Split Tensile Strength Testing Procedure

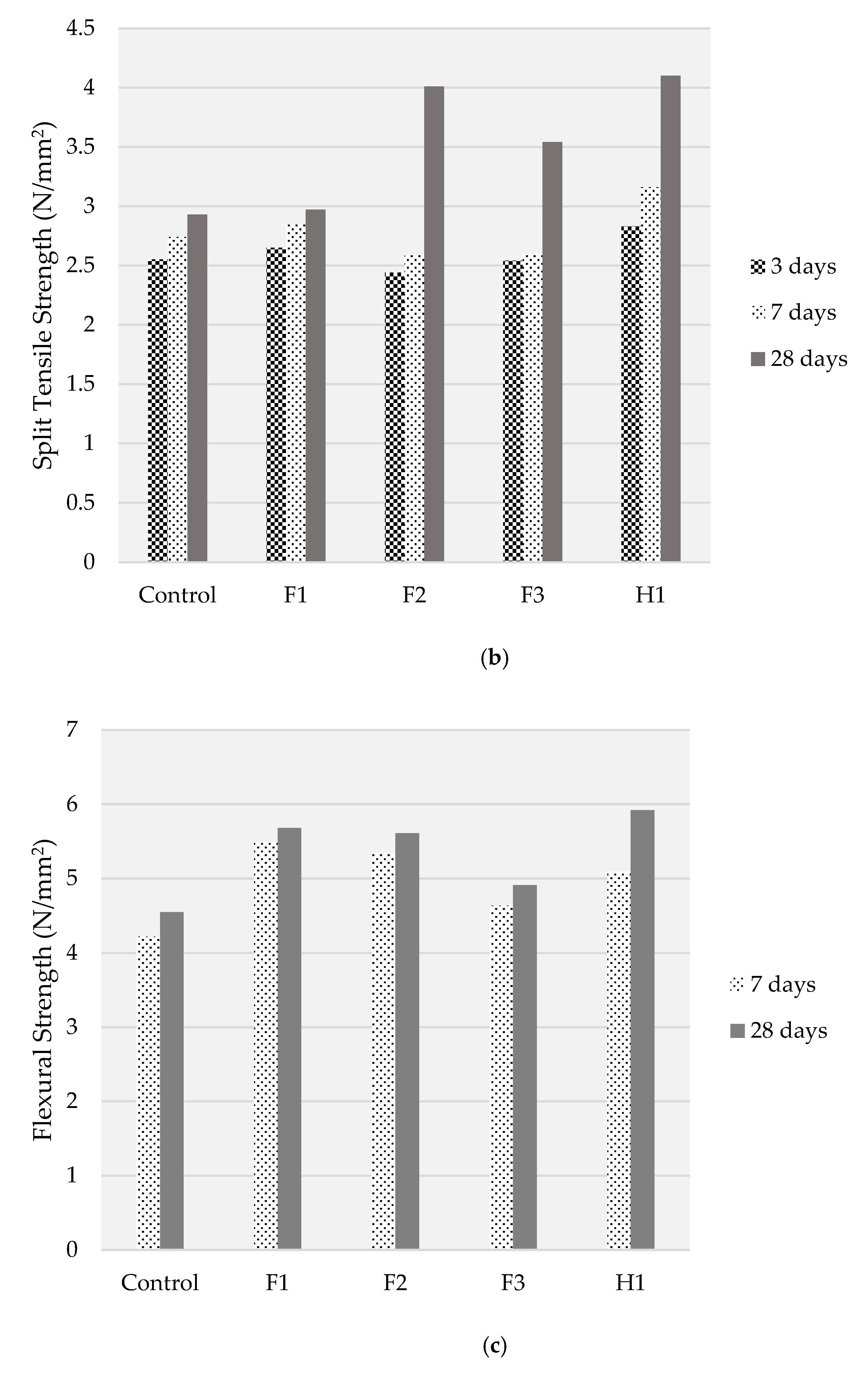

4.4. Flexural Strength Testing Procedure

5. Assessment Models and Methodology

5.1. Goal, Scope, System Boundary and Functional Unit

5.2. Mathematical Models and Inventory Analysis

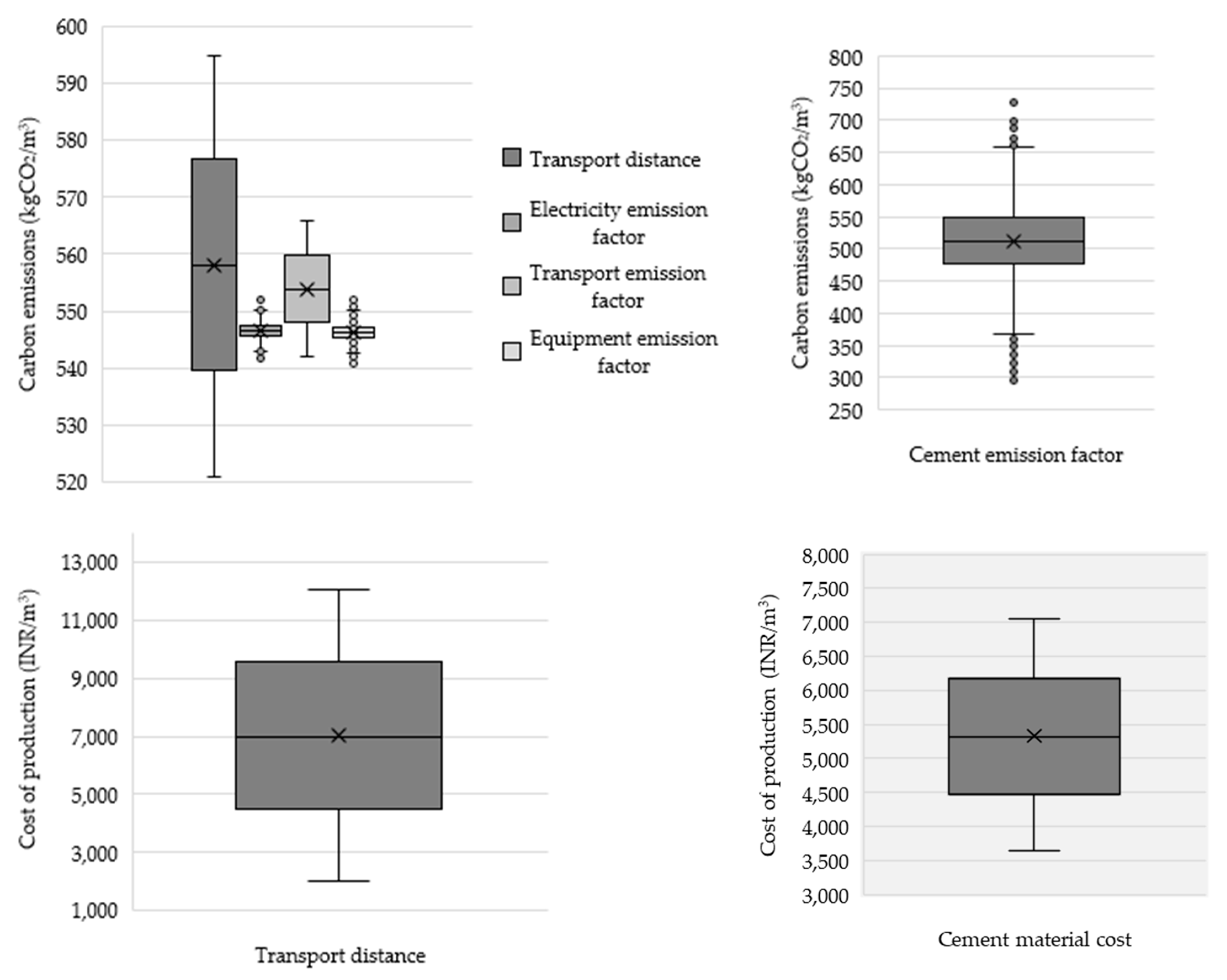

5.3. Sensitivity Analysis Using Monte-Carlo Simulation

5.4. Multi-Objective Function

5.5. Limitations and Assumptions

- The study results were based on laboratory-scale production of materials, and mass-scale industry production could exhibit different results.

- The study assumed that fibres used in the mix are extracted from plastic materials and the sorting, conversion process in the optimisation calculation.

- The study considered a maximum fibre content based on the reference sample results and assumed varying fibre content do not affect physical and mechanical characteristics significantly.

- In instances emission inventories were not available, emission factors were obtained from previously published literature.

- Some other phenomena in concrete such as carbonisation and carbon sequestration were not considered in the current study.

- Waste treatment and transportation of concrete raw material are not considered in the current study scope.

- Retail prices were used for raw material procurement costs, and these may differ from bulk costs.

- The study presented only compressive, split tensile and flexural strengths of the samples to demonstrate strength characteristics of the samples.

6. Results and Discussions

6.1. Experimental Results

6.2. Carbon Emissions and Manufacturing Cost Results

6.3. Sensitivity Results

6.4. Multi-Objective Optimisation Results

- The minimum and maximum fibre content limits were assumed as the fibre content in F1 sample and H1 hybrid mix respectively (0.9 < F1 + F2 + F3 < 3.0) and F1, F2, F3 > 0;

- Transportation distance was considered as a discrete value;

- Transportation cost was considered as a function of the travel distance and the weight of the materials transported;

7. Conclusions and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ruikar, M. National statistics of road traffic accidents in India. J. Orthop. Traumatol. Rehabil. 2013, 6, 1. [Google Scholar] [CrossRef]

- Sharma, A.; Vohra, E. Critical evaluation of road infrastructure in India: A cross-country view. Eng. Constr. Arch. Manag. 2009, 16, 73–91. [Google Scholar] [CrossRef]

- Dadhich, G.; Patel, H.; Patel, M.A. Treatment of Distressed Urban Roads using Ultrathin White-Topping: A Case Study Of Daman City (Ut), India. Available online: https://ukiericoncretecongress.com/ucc2013/files/Proceedings/pdf/UCC-2019-415.pdf (accessed on 28 November 2021).

- Rasmussen, R.O.; Rozycki, D.K. NCHRP Synthesis 338: Thin and Ultra-thin Whitetopping; National Research Council: Washington, DC, USA, 2004; pp. 3–9.

- Tayabji, S.; Gisi, A.; Blomberg, J.; DeGraaf, D. New applications for thin concrete overlays: Three case studies. In National Conference on Preservation, Repair, and Rehabilitation of Concrete Pavements; 2009. Available online: rosap.ntl.bts.gov (accessed on 28 November 2021).

- Goel, P.; Kumar, R.; Bhattacharjee, B. Performance of synthetic fibre reinforced concrete in the construction of concrete pavements. Indian Concr. J. 2015, 89, 52–61. [Google Scholar]

- Qian, C.; Stroeven, P. Development of hybrid polypropylene-steel fibre-reinforced concrete. Cem. Concr. Res. 2000, 30, 63–69. [Google Scholar] [CrossRef]

- Jundhare, D.; Khare, K.; Jain, R. Three dimensional nonlinear finite element modeling of conventional whitetopping of asphalt pavements. Indian Highw. 2014, 42, 6. Available online: trid.trb.org (accessed on 28 November 2021).

- Barman, M. Bonded Whitetopping Overlay Design Considerations with Regard to the Prevention of Reflection Cracking, Joint Sealing and the Use of Dowel Bars. Available online: engineering.pitt.edu (accessed on 28 November 2021).

- Li, L.; Chen, K. Quantitative assessment of carbon dioxide emissions in construction projects: A case study in Shenzhen. J. Clean. Prod. 2017, 141, 394–408. [Google Scholar] [CrossRef]

- Dimoula, V.; Kehagia, F.; Tsakalidis, A. A holistic approach for estimating carbon emissions of road and rail transport systems. Aerosol Air Qual. Res. 2016, 16, 61–68. [Google Scholar] [CrossRef] [Green Version]

- Luo, W.; Sandanayake, M.; Zhang, G.; Tan, Y. Construction Cost and Carbon Emission Assessment of a Highway Construction—A Case towards Sustainable Transportation. Sustainability 2021, 13, 7854. [Google Scholar] [CrossRef]

- Jang, W.; You, H.-W.; Han, S.H. Quantitative Decision Making Model for Carbon Reduction in Road Construction Projects Using Green Technologies. Sustainability 2015, 7, 11240–11259. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Zhao, F.; Liu, Z.; Ou, X.; Hao, H. Greenhouse gas emissions from road construction in China: A province-level analysis. J. Clean. Prod. 2017, 168, 1039–1047. [Google Scholar] [CrossRef]

- Huang, Y.; Hakim, B.; Zammataro, S. Measuring the carbon footprint of road construction using CHANGER. Int. J. Pavement Eng. 2013, 14, 590–600. [Google Scholar] [CrossRef]

- Lin, B.; Liu, C.; Wang, H.; Lin, R. Modeling the railway network design problem: A novel approach to considering carbon emissions reduction. Transp. Res. Part D Transp. Environ. 2017, 56, 95–109. [Google Scholar] [CrossRef]

- Chan, R.; Santana, M.A.; Oda, A.M.; Paniguel, R.C.; Vieira, L.B.; Figueiredo, A.D.; Galobardes, I. Analysis of potential use of fibre reinforced recycled aggregate concrete for sustainable pavements. J. Clean. Prod. 2019, 218, 183–191. [Google Scholar] [CrossRef]

- Adesina, A.J. Performance of fibre reinforced alkali-activated composites—A review. Materialia 2020, 12, 100782. [Google Scholar] [CrossRef]

- Branston, J.; Booya, E.; Gorospe, K.; Adesina, A.; Das, S.; Lawn, D. Microstructure and mechanical properties of basalt fibre reinforced concrete. In Proceedings of the 17th Euroseminar on microscopy applied to building materials, Toronto, ON, Canada, 20–23 May 2019; pp. 121–127. [Google Scholar]

- Ali, B.; Qureshi, L.A.; Khan, S.U. Flexural behavior of glass fiber-reinforced recycled aggregate concrete and its impact on the cost and carbon footprint of concrete pavement. Constr. Build. Mater. 2020, 262, 120820. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Kurda, R. Environmental and economic benefits of steel, glass, and polypropylene fiber reinforced cement composite application in jointed plain concrete pavement. Compos. Commun. 2020, 22, 100437. [Google Scholar] [CrossRef]

- Sinha, V.; Kumar, S.; Jain, R. Whitetopping-A cost effective Rehabilitation Alternative for Preserving Bituminous Pavements on Long Term Basis. J. Indian Roads Congr. 2007, 68, 3. [Google Scholar]

- Bezabih, A.G.; Chandra, S. Comparative study of flexible and rigid pavements for different soil and traffic conditions. J. Indian Roads Congr. 2009, 70, 153–162. [Google Scholar]

- Gautam, A.; Batra, R.; Singh, N. A study on use of rice husk ash in concrete. Int. J. Educ. Appl. Res. 2019, 4, 75–81. [Google Scholar] [CrossRef]

- IRC. Standard Specifications and Code of Practice for Road Bridges; IRC:78; Indian Road Congress: New Delhi, India, 2014. [Google Scholar]

- Reddy, A.V.C.; Nivitha, M.; Palanikumar, M. Influence of axle load on the fatigue life of thin whitetopping with fibre-reinforced concrete. Sādhanā 2021, 46, 163. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S. Greenhouse gas emissions of different fly ash based geopolymer concretes in building construction. J. Clean. Prod. 2018, 204, 399–408. [Google Scholar] [CrossRef]

- Reddy, K.; Sharon, H. 143: Indigenous solar desalination technologies for sustainable potable water supply. In Conference Proceedings Volume 2; University of Nottingham: Nottingham, UK, 2018; p. 144. Available online: https://nottingham-repository.worktribe.com/index.php/preview/1608182/SET2018%20Proceedings%20Volume%202.pdf#page=152 (accessed on 28 November 2021).

- Hammond, G.P.; Jones, C.I. ICE Database. 2011. Available online: http://www.ecocem.ie/downloads/Inventory_of_Carbon_and_Energy.pdf (accessed on 24 June 2015).

- Hammond, G.; Jones, C. Inventory of Carbon & Energy: ICE; Sustainable Energy Research Team, Department of Mechanical Engineering, University of Bath: Bath, UK, 2008; Available online: https://www.appropedia.org/w/images/5/56/ICE_Version_1.6a.pdf (accessed on 28 November 2021).

- IS 516 (1959); Methods of Tests for Strength of Concrete. Bureau of Indian Standards: New Delhi, India, 2004. Available online: https://www.bis.gov.in (accessed on 28 November 2021).

- Yan, H.; Shen, Q.; Fan, L.C.; Wang, Y.; Zhang, L. Greenhouse gas emissions in building construction: A case study of One Peking in Hong Kong. Build. Environ. 2010, 45, 949–955. [Google Scholar] [CrossRef] [Green Version]

- Hong, J.; Shen, G.Q.; Feng, Y.; Lau, W.S.T.; Mao, C. Greenhouse gas emissions during the construction phase of a building: A case study in China. J. Clean. Prod. 2015, 103, 249–259. [Google Scholar] [CrossRef] [Green Version]

- Sandanayake, M.; Zhang, G.; Setunge, S. Environmental emissions at foundation construction stage of buildings—Two case studies. Build. Environ. 2016, 95, 189–198. [Google Scholar] [CrossRef]

- Tiewsoh, L.S.; Jirásek, J.; Sivek, M. Electricity generation in India: Present state, future outlook and policy implications. Energies 2019, 12, 1361. [Google Scholar] [CrossRef] [Green Version]

- Mittal, M.L.; Sharma, C.; Singh, R. Estimates of emissions from coal fired thermal power plants in India. In Proceedings of the 2012 International Emission Inventory Conference, 2012; pp. 13–16. Available online: https://www3.epa.gov/ttn/chief/conference/ei20/session5/mmittal.pdf (accessed on 28 November 2021).

- Sandanayake, M.; Law, D.; Sargent, P. A new framework for assessing the environmental impacts of circular economy friendly soil waste-based geopolymer cements. Build. Environ. 2022, 210, 108702. [Google Scholar] [CrossRef]

- Shen, L.; Zhao, J.; Wang, L.; Liu, L.; Wang, Y.; Yao, Y.; Geng, Y.; Gao, T.; Cao, Z. Calculation and evaluation on carbon emission factor of cement production in China. Chin. Sci. Bull. 2016, 61, 2926–2938. [Google Scholar] [CrossRef] [Green Version]

- Graham, L.A.; Rideout, G.; Rosenblatt, D.; Hendren, J. Greenhouse gas emissions from heavy-duty vehicles. Atmos. Environ. 2008, 42, 4665–4681. [Google Scholar] [CrossRef]

- IPCC. IPCC Fourth Assessment Report; IPCC: Geneva, Switzerland, 2007. [Google Scholar]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef] [Green Version]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S.; Wanijuru, D. Sustainable criterion selection framework for green building materials—An optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 2020, 25, e00178. [Google Scholar] [CrossRef]

- Wang, W.; Zmeureanu, R.; Rivard, H. Applying multi-objective genetic algorithms in green building design optimization. Build. Environ. 2005, 40, 1512–1525. [Google Scholar] [CrossRef]

- Kumar, R.; Rockett, P. Improved sampling of the Pareto-front in multiobjective genetic optimizations by steady-state evolution: A Pareto converging genetic algorithm. Evol. Comput. 2002, 10, 283–314. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| No. | Physical Properties | F1 | F2 | F3 |

|---|---|---|---|---|

| 1. | Material | Polyolefin | Polyolefin-twisted | Polypropylene |

| 2. | Form | Structured fibres in bundles | Fibrillated | Fibrillated |

| 3. | Length, mm | 50 | 19 | 12 |

| 4. | Colour | Yellow | Beige | White |

| 5. | Tensile Strength, N/mm2 | 618 | 400 | 250 |

| 6. | Indicative Photograph |  |  |  |

| 7. | Carbon emission factor (kgCO2/kg) | 1.57 | 1.69 | 2.97 |

| Water | Cement | Fine Aggregates | Coarse Aggregates | Superplasticizer | |

|---|---|---|---|---|---|

| Amount (kgs) | 158.0 | 416.0 | 670.0 | 1196.0 | 2.45 |

| Emission factor | 0.0025 | 0.93 | 0.0048 | 0.083 | 5.2 × 10−6 |

| Reference | [27,28] | [27,29] | [27,30] | [27,29] | [27] |

| No | Type of Mix | Fibre Dosage, kg/m3 | Price per kg |

|---|---|---|---|

| 1 | Plain | 0.00 | - |

| 2 | F1 | 3.00 | 1500 |

| 3 | F2 | 1.00 | 1500 |

| 4 | F3 | 0.90 | 376 |

| 5 | H1 (F1 + F2 + F3) | 1.50 + 0.50 + 0.45 | - |

| Energy Source | Coal | Hydro | Nuclear | Renewable | Natural Gas | Diesel | Reference |

|---|---|---|---|---|---|---|---|

| % Contribution | 70.64 | 12.04 | 3.31 | 10.3 | 3.7 | 0.5 | [35] |

| Average carbon emission factor (kgCO2/kWh) | 1.19 | 0.002 | 0.015 | 0.0012 | 0.41 | 0.84 | [33,36] |

| Input Variable | Unit | Range | Distribution | References |

|---|---|---|---|---|

| Transport distance | km | 10–200 | Uniform | - |

| Electricity emission factor | kgCO2/kWh | 0.03–1.13 | Lognormal | [33,38] |

| Transport emission factor | kgCO2/t-km | 0.12–0.25 | Uniform | [29,38,39] |

| Cement emission factor | kgCO2/kg | 0.62–1.14 | Normal | [40,41,42] |

| Diesel emission factor | kgCO2/kg | 2.61–3.20 | Lognormal | [33,38] |

| Raw material cost | INR/kg | 5% to 95% of the initial value | Uniform | - |

| Region | F1 | F2 | F3 | % Carbon Emission Escalation | % Cost Escalation |

|---|---|---|---|---|---|

| High-cost saving | 0.70 | 0.70 | 0.50 | 0.33 | 47.07 |

| High-cost saving | 0.80 | 0.70 | 0.40 | 0.30 | 49.33 |

| High-cost saving | 0.90 | 0.60 | 0.50 | 0.35 | 50.08 |

| Feasible | 0.70 | 0.65 | 0.55 | 0.34 | 45.93 |

| Feasible | 0.90 | 0.70 | 0.30 | 0.28 | 51.59 |

| High carbon savings | 0.90 | 0.70 | 0.40 | 0.33 | 52.35 |

| High carbon savings | 0.90 | 0.70 | 0.50 | 0.39 | 53.10 |

| High carbon savings | 0.70 | 0.90 | 0.40 | 0.34 | 52.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuruvachalil, L.; Sandanayake, M.; Kumanayake, R.; Radhakrishna. Carbon Emission and Cost Analysis of Using Hybrid Fibre White Topping Overlays—A Road Rehabilitation Feasibility Study. Future Transp. 2022, 2, 263-280. https://doi.org/10.3390/futuretransp2010014

Kuruvachalil L, Sandanayake M, Kumanayake R, Radhakrishna. Carbon Emission and Cost Analysis of Using Hybrid Fibre White Topping Overlays—A Road Rehabilitation Feasibility Study. Future Transportation. 2022; 2(1):263-280. https://doi.org/10.3390/futuretransp2010014

Chicago/Turabian StyleKuruvachalil, Lujain, Malindu Sandanayake, Ramya Kumanayake, and Radhakrishna. 2022. "Carbon Emission and Cost Analysis of Using Hybrid Fibre White Topping Overlays—A Road Rehabilitation Feasibility Study" Future Transportation 2, no. 1: 263-280. https://doi.org/10.3390/futuretransp2010014

APA StyleKuruvachalil, L., Sandanayake, M., Kumanayake, R., & Radhakrishna. (2022). Carbon Emission and Cost Analysis of Using Hybrid Fibre White Topping Overlays—A Road Rehabilitation Feasibility Study. Future Transportation, 2(1), 263-280. https://doi.org/10.3390/futuretransp2010014