Molecular, Crystalline, and Microstructures of Lipids from Astrocaryum Species in Guyana and Their Thermal and Flow Behavior

Abstract

1. Introduction

2. Materials and Methods

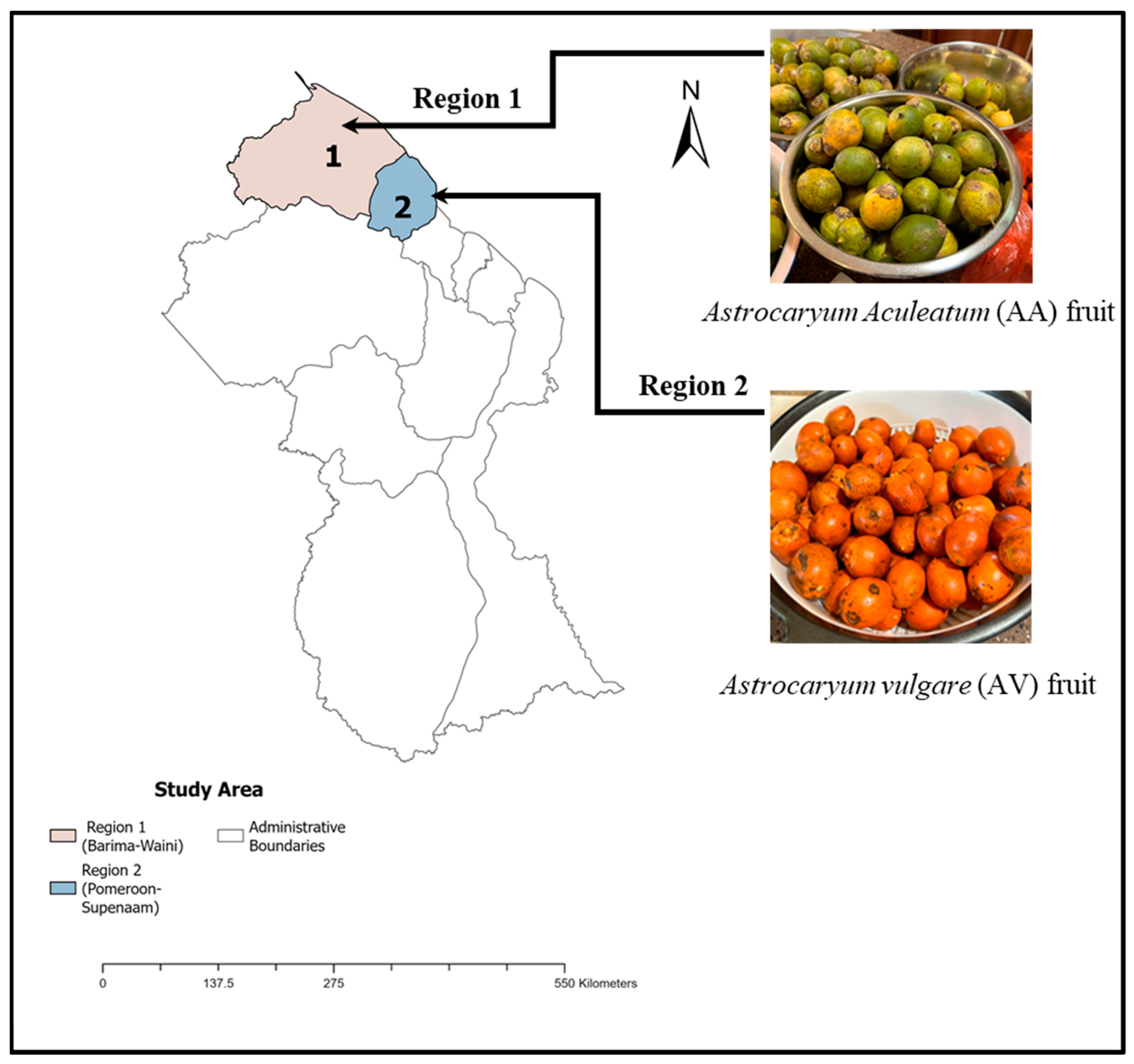

2.1. Sample Collection, Processing and Handling

2.2. Oil Extraction

2.3. Fourier-Transform Infrared Spectroscopy (FTIR)

2.4. Electrospray Ionization Mass Spectrometry (ESI-MS)

2.5. Thermogravimetric Analysis (TGA)

2.6. Differential Scanning Calorimetry (DSC)

2.7. X-ray Diffraction (XRD)

2.8. Polarized-Light Microscopy (PLM)

2.9. Viscosity and Flow Behavior

3. Results and Discussion

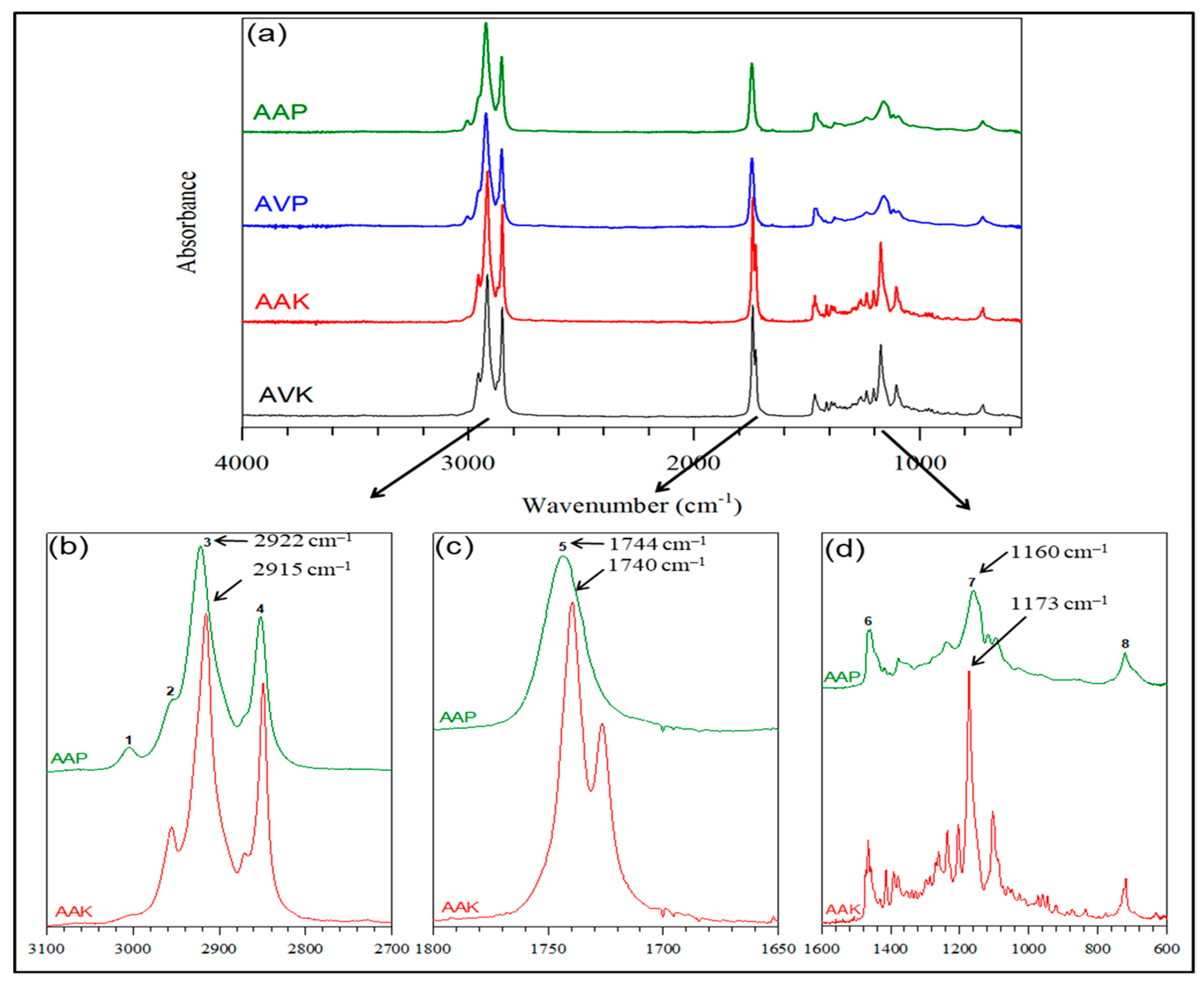

3.1. Functional Group Identification and Interaction

3.2. Lipid Composition

3.3. Thermal Degradation

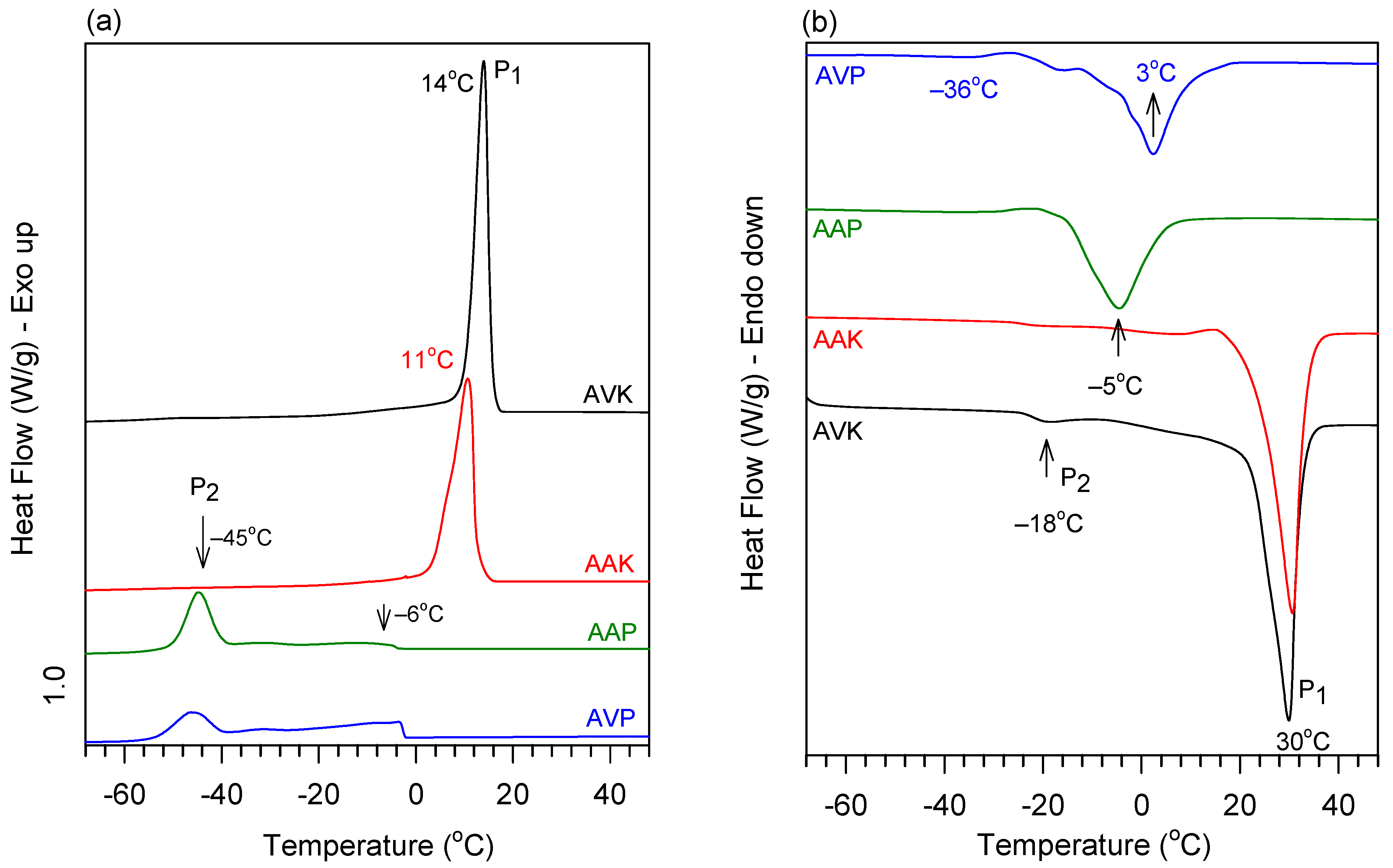

3.4. Thermal Phase Behavior

3.4.1. Crystallization

3.4.2. Melting

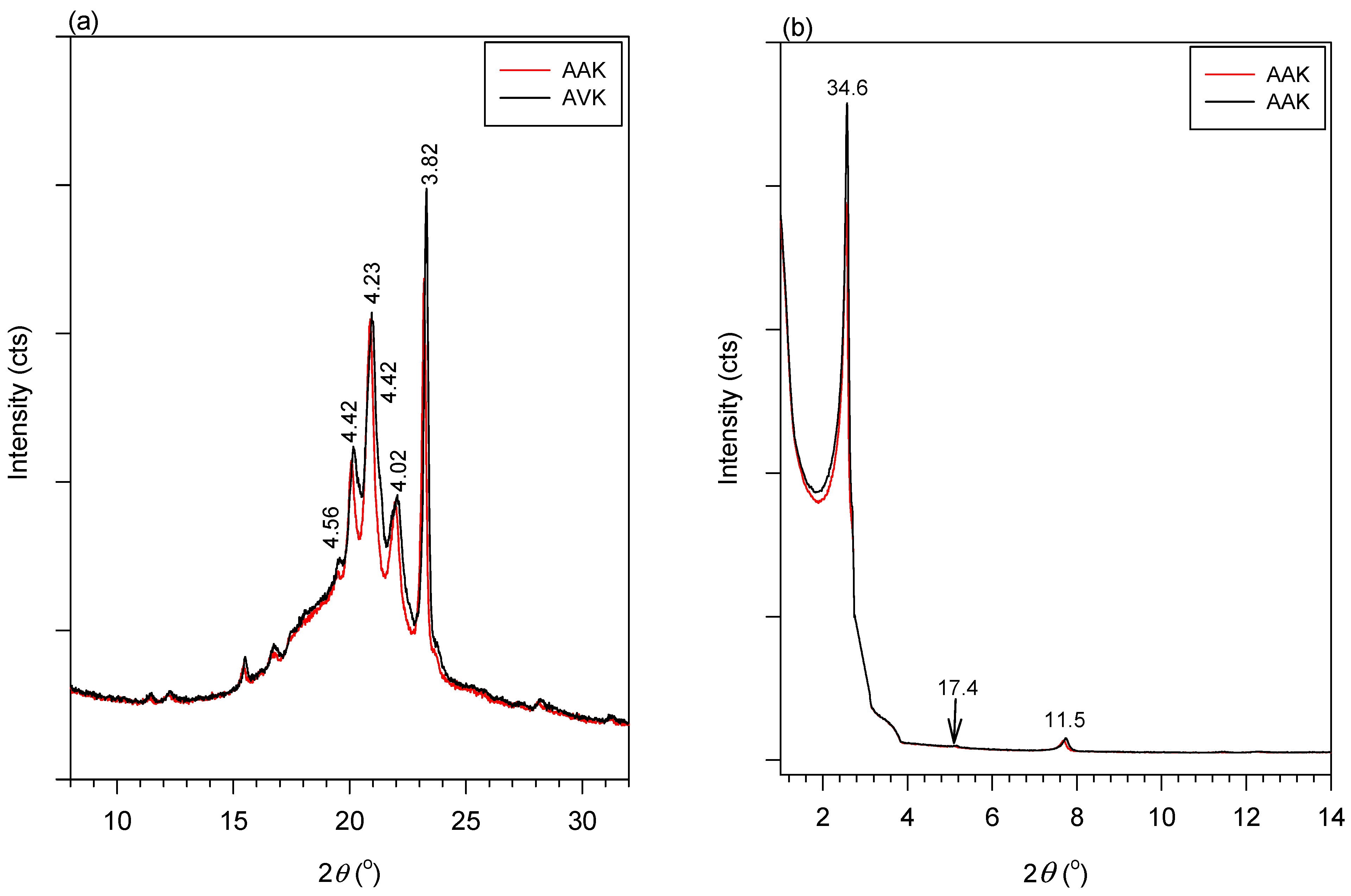

3.5. Crystal Type and Polymorphism

3.6. Microstructure

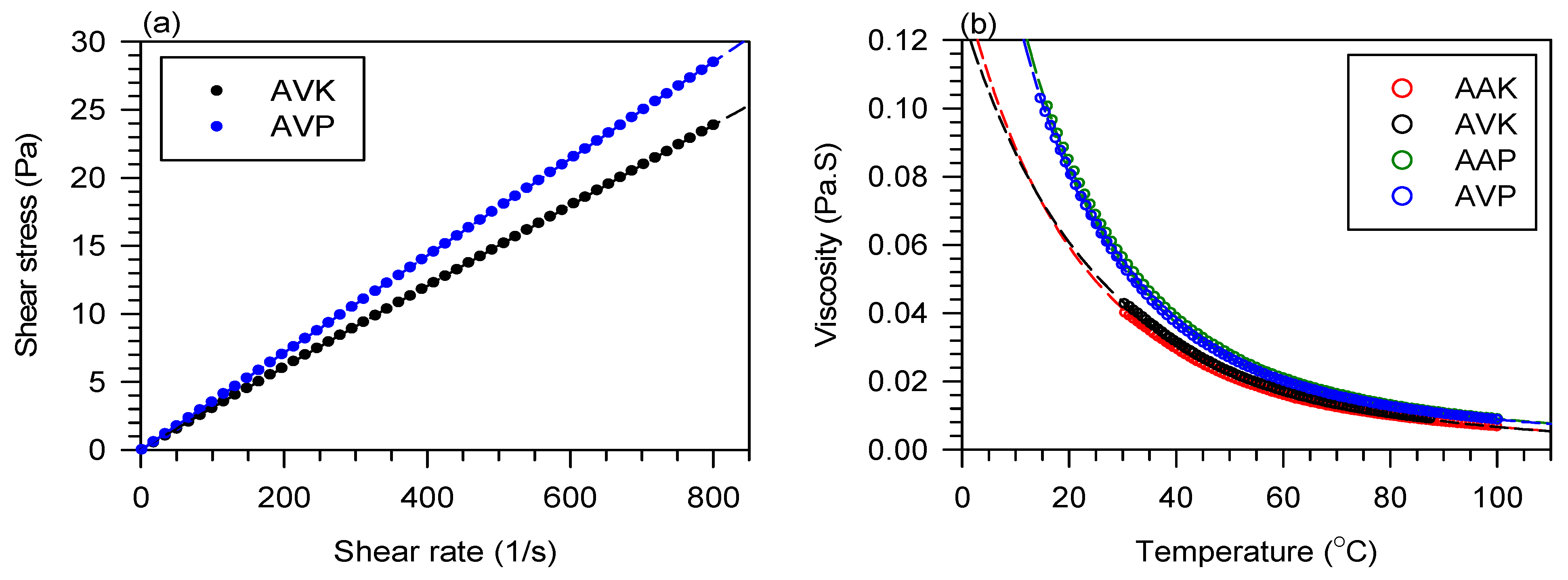

3.7. Viscosity and Flow Behavior

3.8. Comparison of the Chemical and Physical Properties with Other Selected Oils and Fats

3.8.1. TAG Profile Comparison

3.8.2. Melting Point Comparison

3.8.3. Viscosity and Flow Behavior Comparison

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dini, I.; Laneri, S. The New Challenge of Green Cosmetics: Natural Food Ingredients for Cosmetic Formulations. Molecules 2021, 26, 3921. [Google Scholar] [CrossRef]

- Rocca, R.; Acerbi, F.; Fumagalli, L.; Taisch, M. Sustainability paradigm in the cosmetics industry: State of the art. Clean. Waste Syst. 2022, 3, 100057. [Google Scholar] [CrossRef]

- Traversier, M.; Gaslondes, T.; Milesi, S.; Michel, S.; Delannay, E. Polar lipids in cosmetics: Recent trends in extraction, separation, analysis and main applications. Phytochem. Rev. 2018, 17, 1179–1210. [Google Scholar] [CrossRef]

- Bonnet, C. Lipids, a natural raw material at the heart of cosmetics innovation. OCL 2018, 25, D501. [Google Scholar] [CrossRef]

- Rabasco Álvarez, A.M.; González Rodríguez, M.L. Lipids in pharmaceutical and cosmetic preparations. Grasas Aceites 2000, 51, 74–96. [Google Scholar] [CrossRef]

- Kristmundsdóttir, T.; Skúlason, S. Lipids as Active Ingredients in Pharmaceuticals, Cosmetics and Health Foods. In Lipids and Essential Oils as Antimicrobial Agents; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2011; pp. 151–177. [Google Scholar]

- Teixeira, G.L.; Ibañez, E.; Block, J.M. Emerging Lipids from Arecaceae Palm Fruits in Brazil. Molecules 2022, 27, 4188. [Google Scholar] [CrossRef] [PubMed]

- Machado, A.P.d.F.; Nascimento, R.d.P.d.; Alves, M.d.R.; Reguengo, L.M.; Marostica Junior, M.R. Brazilian tucumã-do-Amazonas (Astrocaryum aculeatum) and tucumã-do-Pará (Astrocaryum vulgare) fruits: Bioactive composition, health benefits, and technological potential. Food Res. Int. 2022, 151, 110902. [Google Scholar] [CrossRef] [PubMed]

- Kahn, F.; Moussa, F. Economic Importance of Astrocaryum aculeatum (Palmae) in Central Brazilian Amazonia. Acta Bot. Venez. 1999, 22, 237–245. [Google Scholar]

- Falcao, A.d.O.; Speranza, P.; Ueta, T.; Martins, M. Antioxidant potential and modulatory effects of restructured lipids from the Amazonian palms on liver cells. Food Technol. Biotechnol. 2017, 55, 553–561. [Google Scholar] [PubMed]

- Bezerra, C.V.; Rodrigues, A.; de Oliveira, P.D.; da Silva, D.A.; da Silva, L.H.M. Technological properties of amazonian oils and fats and their applications in the food industry. Food Chem. 2017, 221, 1466–1473. [Google Scholar] [CrossRef] [PubMed]

- Cardona Jaramillo, J.E.; Carrillo Bautista, M.P.; Alvarez Solano, O.A.; Achenie, L.E.K.; González Barrios, A.F. Impact of the Mode of Extraction on the Lipidomic Profile of Oils Obtained from Selected Amazonian Fruits. Biomolecules 2019, 9, 329. [Google Scholar] [CrossRef] [PubMed]

- Burlando, B.; Cornara, L. Revisiting Amazonian Plants for Skin Care and Disease. Cosmetics 2017, 4, 25. [Google Scholar] [CrossRef]

- Mosquera Narvaez, L.E.; Ferreira, L.M.; Sanches, S.; Alesa Gyles, D.; Silva-Júnior, J.O.; Ribeiro Costa, R.M. A Review of Potential Use of Amazonian Oils in the Synthesis of Organogels for Cosmetic Application. Molecules 2022, 27, 2733. [Google Scholar] [CrossRef]

- Ibiapina, A.; Gualberto, L.d.S.; Dias, B.B.; Freitas, B.C.B.; Martins, G.A.d.S.; Melo Filho, A.A. Essential and fixed oils from Amazonian fruits: Proprieties and applications. Crit. Rev. Food Sci. Nutr. 2022, 62, 8842–8854. [Google Scholar] [CrossRef] [PubMed]

- Kahn, F. The genus Astrocaryum (Arecaceae). Rev. Peru. Biol. 2008, 15, 31–48. [Google Scholar] [CrossRef]

- Deonarine, S.; Soodoo, N.; Bouzidi, L.; Narine, S.S. Oil Extraction and Natural Drying Kinetics of the Pulp and Seeds of Commercially Important Oleaginous Fruit from the Rainforests of Guyana. Processes 2023, 11, 3292. [Google Scholar] [CrossRef]

- Menezes, E.G.O.; Barbosa, J.R.; Pires, F.C.S.; Ferreira, M.C.R.; de Souza e Silva, A.P.; Siqueira, L.M.M.; de Carvalho Junior, R.N. Development of a new scale-up equation to obtain Tucumã-of-Pará (Astrocaryum vulgare Mart.) oil rich in carotenoids using supercritical CO2 as solvent. J. Supercrit. Fluids 2022, 181, 105481. [Google Scholar] [CrossRef]

- Souza, A.G.; Santos, J.C.O.; Conceição, M.M.d.; Silva, M.C.D.; Prasad, S. A thermoanalytic and kinetic study of sunflower oil. Braz. J. Chem. Eng. 2004, 21, 265–273. [Google Scholar] [CrossRef]

- Silva, M.B.; Perez, V.H.; Pereira, N.R.; Silveira, T.d.C.; da Silva, N.R.F.; de Andrade, C.M.; Sampaio, R.M. Drying kinetic of tucum fruits (Astrocaryum aculeatum Meyer): Physicochemical and functional properties characterization. J. Food Sci. Technol. 2018, 55, 1656–1666. [Google Scholar] [CrossRef]

- Craveiro Holanda Malveira Maia, G.; da Silva Campos, M.; Barros-Monteiro, J.; Eduardo Lucas Castillo, J.; Soares Faleiros, M.; Souza de Aquino Sales, R.; Moraes Lopes Galeno, D.; Lira, E.; das Chagas do Amaral Souza, F.; Ortiz, C.; et al. Effects of Astrocaryum aculeatum Meyer (Tucumã) on Diet-Induced Dyslipidemic Rats. J. Nutr. Metab. 2014, 2014, 202367. [Google Scholar] [CrossRef]

- Pardauil, J.J.; de Molfetta, F.A.; Braga, M.; de Souza, L.K.; Filho, G.N.; Zamian, J.R.; Da Costa, C. Characterization, thermal properties and phase transitions of amazonian vegetable oils. J. Therm. Anal. Calorim. 2017, 127, 1221–1229. [Google Scholar] [CrossRef]

- Oboh, F.O.J.; Oderinde, R.A. Analysis of the pulp and pulp oil of the tucum (Astrocaryum vulgare Mart) fruit. Food Chem. 1988, 30, 277–287. [Google Scholar] [CrossRef]

- de Santana Lopes, A.; Gomes Pacheco, T.; Nascimento da Silva, O.; Magalhães Cruz, L.; Balsanelli, E.; Maltempi de Souza, E.; de Oliveira Pedrosa, F.; Rogalski, M. The plastomes of Astrocaryum aculeatum G. Mey. and A. murumuru Mart. show a flip-flop recombination between two short inverted repeats. Planta 2019, 250, 1229–1246. [Google Scholar] [CrossRef] [PubMed]

- Santosa, M.; Marmesatb, S.; Britoc, E.; Alvesd, R.; Dobarganesb, M. Major components in oils obtained from Amazonian palm fruits. Grasas Aceites 2013, 64, 3. [Google Scholar]

- dos Santos, O.V.; Pinaffi-Langley, A.C.d.C.; Ferreira, M.C.R.; de Souza, A.L.G.; Carvalho-Junior, R.N.; Teixeira-Costa, B.E. Effect of extraction type on the fatty acids profile and physicochemical properties of biolipids from Astrocaryum vulgare pulp: Supercritical CO2 versus n-hexane extractions. Int. J. Food Sci. Technol. 2023, 58, 3982–3995. [Google Scholar] [CrossRef]

- Mendonça Morais, R.; Roberta Pinheiro Pantoja, K.; Gama Ortiz Menezes, E.; Cristina Seabra Pires, F.; Quaresma da Silva de Aguiar, I.; Cristine Melo Aires, G.; de Freitas Maués de Azevedo, F.; Nunes de Carvalho Junior, R. Tucumã of Pará oil: Chemical profile, biological activities, and methods of extraction. Peer Rev. 2023, 5, 369–392. [Google Scholar] [CrossRef]

- Baldissera, M.D.; Souza, C.F.; Doleski, P.H.; Grando, T.H.; Sagrillo, M.R.; da Silva, A.S.; Leal, D.B.R.; Monteiro, S.G. Treatment with tucumã oil (Astrocaryum vulgare) for diabetic mice prevents changes in seric enzymes of the purinergic system: Improvement of immune system. Biomed. Pharmacoter. 2017, 94, 374–379. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, A.M.; Darnet, S.; Silva, L.H. Fatty acid profiles and tocopherol contents of buriti (Mauritia flexuosa), patawa (Oenocarpus bataua), tucuma (Astrocaryum vulgare), mari (Poraqueiba paraensis) and inaja (Maximiliana maripa) fruits. J. Braz. Chem. Soc. 2010, 21, 2000–2004. [Google Scholar] [CrossRef]

- Linhares, B.M.; Costa, A.; Abreu, H.D.; Melo, A.; Ribeiro, P.R.; Montero, I.F.; Melo Filho, A.; Santos, R.C. Fatty Acids Profile, Physicalchemical Properties and Minerals with Quantify Indicador of Astrocaryum aculeatum Pulp Oil. J. Agric. Sci 2017, 9, 352. [Google Scholar] [CrossRef]

- Bora, P.S.; Narain, N.; Rocha, R.V.M.; De Oliveira Monteiro, A.C.; De Azevedo Moreira, R. Characterisation of the Oil and Protein Fractions of Tucuma (Astrocaryum Vulgare Mart.) Fruit Pulp and Seed Kernel Caracterización de las fracciones Protéicas y Lipídicas de Pulpa y Semillas de Tucuma (Astrocaryum Vulgare Mart.) Caracterización das Fraccións Protéicas e Lipídicas da Pulpa e Semillas de Tucuma (Astrocaryum Vulgare Mart.). Cienc. Tecnol. Aliment. 2001, 3, 111–116. [Google Scholar]

- Didonet, A.A.; Antoniassi, R.; Back, G.R.; de Faria-Machado, A.F.; Wilhelm, A.E.; Ferraz, I.D.K. Characterization of amount and quality of tucuman kernel oil as a potential biomass. J. Am. Oil Chem. Soc. 2020, 97, 955–962. [Google Scholar] [CrossRef]

- Gomes, A.T.A.; Pereira, R.R.; Duarte Junior, A.P.; da Cruz Rodrigues, A.M.; Remédios, C.M.R.; Brasil, D.d.S.B.; Morais, L.R.B.; Silva-Júnior, J.O.C.; Ribeiro-Costa, R.M. Tucumã (Astrocaryum vulgare) fat: An Amazonian material as a pharmaceutical input for lipid nanoparticle production. J. Therm. Anal. Calorim. 2020, 147, 355–365. [Google Scholar] [CrossRef]

- Bereau, D.; Benjelloum-Mlayah, B.; Banoub, J.; Bravo, R. FA and unsaponifiable composition of five Amazonian palm kernel oils. J. Am. Oil Chem. Soc. 2003, 80, 49–53. [Google Scholar] [CrossRef]

- Bony, E.; Boudard, F.; Brat, P.; Dussossoy, E.; Portet, K.; Poucheret, P.; Giaimis, J.; Michel, A. Awara (Astrocaryum vulgare M.) pulp oil: Chemical characterization, and anti-inflammatory properties in a mice model of endotoxic shock and a rat model of pulmonary inflammation. Fitoterapia 2012, 83, 33–43. [Google Scholar] [CrossRef] [PubMed]

- da Silva Sousa, H.M.; Leal, G.F.; da Silva Gualberto, L.; de Freitas, B.C.B.; Guarda, P.M.; Borges, S.V.; Morais, R.A.; de Souza Martins, G.A. Exploration of the chemical characteristics and bioactive and antioxidant potential of tucumã (Astrocaryum vulgare), peach palm (Bactris gasipaes), and bacupari (Garcinia gardneriana) native Brazilian fruits. Biomass Convers. Biorefinery 2023. [Google Scholar] [CrossRef]

- Rossato, A.; da Silva Silveira, L.; Lopes, L.Q.S.; De Sousa Filho, W.P.; Schaffer, L.F.; Santos, R.C.V.; Sagrillo, M.R. Evaluation in vitro of antimicrobial activity of tucumã oil (Astrocaryum vulgare). Arch. Biosci. Health 2019, 1, 99–112. [Google Scholar] [CrossRef]

- Nascimento, K.; Copetti, P.M.; Fernandes, A.; Klein, B.; Fogaça, A.; Zepka, L.Q.; Wagner, R.; Ourique, A.F.; Sagrillo, M.R.; da Silva, J.E.P. Phytochemical analysis and evaluation of the antioxidant and antiproliferative effects of Tucumã oil nanocapsules in breast adenocarcinoma cells (MCF-7). Nat. Prod. Res. 2021, 35, 2060–2065. [Google Scholar] [CrossRef]

- Copetti, P.; Oliveira, P.; Vaucher, R.; Duarte, M.; Krause, L. Tucumã extracts decreases PML/RARA gene expression in NB4/APL cell line. Arch. Biosci. Health 2019, 1, 77–98. [Google Scholar] [CrossRef]

- Guex, C.G.; Cassanego, G.B.; Dornelles, R.C.; Casoti, R.; Engelmann, A.M.; Somacal, S.; Maciel, R.M.; Duarte, T.; Borges, W.d.S.; Andrade, C.M.d.; et al. Tucumã (Astrocaryum aculeatum) extract: Phytochemical characterization, acute and subacute oral toxicity studies in Wistar rats. Drug Chem. Toxicol. 2022, 45, 810–821. [Google Scholar] [CrossRef]

- Bonadiman, B.; Chaves, C.; Assmann, C.E.; Weis, G.C.C.; Alves, A.O.; Gindri, A.L.; Chaves, C.; da Cruz, I.B.M.; Zamoner, A.; Bagatini, M.D. Tucumã (Astrocaryum aculeatum) Prevents Oxidative and DNA Damage to Retinal Pigment Epithelium Cells. J. Med. Food 2021, 24, 1050–1057. [Google Scholar] [CrossRef] [PubMed]

- Uncu, O.; Ozen, B.; Tokatli, F. Use of FTIR and UV–visible spectroscopy in determination of chemical characteristics of olive oils. Talanta 2019, 201, 65–73. [Google Scholar] [CrossRef]

- Nimbkar, S.; Leena, M.M.; Moses, J.A.; Anandharamakrishnan, C. Medium chain triglycerides (MCT): State-of-the-art on chemistry, synthesis, health benefits and applications in food industry. Compr. Rev. Food Sci. Food Saf. 2022, 21, 843–867. [Google Scholar] [CrossRef] [PubMed]

- Heym, F.; Etzold, B.J.M.; Kern, C.; Jess, A. An improved method to measure the rate of vaporisation and thermal decomposition of high boiling organic and ionic liquids by thermogravimetrical analysis. Phys. Chem. Chem. Phys. 2010, 12, 12089–12100. [Google Scholar] [CrossRef] [PubMed]

- Bouzidi, L.; Boodhoo, M.V.; Kutek, T.; Filip, V.; Narine, S.S. The binary phase behavior of 1,3-dilauroyl-2-stearoyl-sn-glycerol and 1,2-dilauroyl-3-stearoyl-sn-glycerol. Chem. Phys. Lipids 2010, 163, 607–629. [Google Scholar] [CrossRef] [PubMed]

- Macridachis, J.; Bayés-García, L.; Calvet, T. Mixing phase behavior of trilaurin and monounsaturated triacylglycerols based on palmitic and oleic fatty acids. J. Therm. Anal. Calorim. 2023, 148, 12987–13001. [Google Scholar] [CrossRef]

- Nagamizu, H.; Miyagawa, Y.; Ogawa, T.; Adachi, S. Phase Behavior of Binary Mixtures of Tripalmitin, Triolein, and Trilinolein. Food Sci. Technol. Res. 2020, 26, 589–595. [Google Scholar] [CrossRef]

- Bouzidi, L.; Narine, S.S. Evidence of critical cooling rates in the nonisothermal crystallization of triacylglycerols: A case for the existence and selection of growth modes of a lipid crystal network. Langmuir 2010, 26, 4311–4319. [Google Scholar] [CrossRef] [PubMed]

- Himawan, C.; Starov, V.; Stapley, A. Thermodynamic & kinetic aspects of fat crystallisation. Adv. Colloid Interface Sci. 2006, 122, 3–33. [Google Scholar]

- Che Man, Y.B.; Haryati, T.; Ghazali, H.M.; Asbi, B.A. Composition and thermal profile of crude palm oil and its products. J. Am. Oil Chem. Soc. 1999, 76, 237–242. [Google Scholar] [CrossRef]

- Marangoni, A.G.; Wesdorp, L.H. Structure and Properties of Fat Crystal Networks, 2nd ed.; Taylor & Francis: New York, NY, USA, 2012. [Google Scholar]

- Narine, S.S.; Marangoni, A.G. Fractal nature of fat crystal networks. Phys. Rev. E 1999, 59, 1908–1920. [Google Scholar] [CrossRef]

- Marangoni, A.G.; Ollivon, M. Fractal character of triglyceride spherulites is a consequence of nucleation kinetics. Chem. Phys. Lett. 2007, 442, 360–364. [Google Scholar] [CrossRef]

- Hondoh, H.; Ueno, S. Polymorphism of edible fat crystals. Prog. Cryst. Growth Charact. Mater. 2016, 62, 398–399. [Google Scholar] [CrossRef]

- Tchobo, F.P.; Seid, A.M.; Nonviho, G.; Zinsou, R.; Mazou, M.; Djossou, A.J. Physicochemical Variability of Shea Butter (Vitellaria paradoxa) from the Regions of Chad. Am. J. Food Sci. Technol. 2018, 6, 253–257. [Google Scholar]

- Segall, S.D.; Artz, W.E.; Raslan, D.S.; Ferraz, V.P.; Takahashi, J.A. Analysis of triacylglycerol isomers in Malaysian cocoa butter using HPLC–mass spectrometry. Food Res. Int. 2005, 38, 167–174. [Google Scholar] [CrossRef]

- Yanty, N.; Marikkar, J.; Abdulkarim, S. Determination of types of fat ingredient in some commercial biscuit formulations. Int. Food Res. J. 2014, 21, 277. [Google Scholar]

- Cabral, E.C.; da Cruz, G.F.; Simas, R.C.; Sanvido, G.B.; Gonçalves, L.d.V.; Leal, R.V.; da Silva, R.C.; da Silva, J.C.; Barata, L.E.; da Cunha, V.S. Typification and quality control of the Andiroba (Carapa guianensis) oil via mass spectrometry fingerprinting. Anal. Methods 2013, 5, 1385–1391. [Google Scholar] [CrossRef]

- James, S.O.; Bouzidi, L.; Emery, R.J.N.; Narine, S.S. Lipid Fractionation and Physicochemical Characterization of Carapa guianensis Seed Oil from Guyana. Processes 2023, 11, 2565. [Google Scholar] [CrossRef]

- Reyes-Hernández, J.; Dibildox-Alvarado, E.; Charó-Alonso, M.A.; Toro-Vazquez, J.F. Physicochemical and Rheological Properties of Crystallized Blends Containing trans-free and Partially Hydrogenated Soybean Oil. J. Am. Oil Chem. Soc. 2007, 84, 1081–1093. [Google Scholar] [CrossRef]

- Kumar, P.P.; Krishna, A.G. Physicochemical characteristics of commercial coconut oils produced in India. Grasas Aceites 2015, 66, e062. [Google Scholar]

- Abdul-Hammed, M.; Jaji, A.O.; Adegboyega, S.A. Comparative studies of thermophysical and physicochemical properties of shea butter prepared from cold press and solvent extraction methods. J. King Saud Univ. Sci. 2020, 32, 2343–2348. [Google Scholar] [CrossRef]

- Colella, M.F.; Marino, N.; Oliviero Rossi, C.; Seta, L.; Caputo, P.; De Luca, G. Triacylglycerol Composition and Chemical-Physical Properties of Cocoa Butter and Its Derivatives: NMR, DSC, X-ray, Rheological Investigation. Int. J. Mol. Sci. 2023, 24, 2090. [Google Scholar] [CrossRef] [PubMed]

- Landfeld, A.; Novotna, P.; Strohalm, J.; Houska, M.; Kyhos, K. Viscosity of cocoa butter. Int. J. Food Prop. 2000, 3, 165–169. [Google Scholar] [CrossRef]

- Tangsathitkulchai, C.; Sittichaitaweekul, Y.; Tangsathitkulchai, M. Temperature effect on the viscosities of palm oil and coconut oil blended with diesel oil. J. Am. Oil Chem. Soc. 2004, 81, 401–405. [Google Scholar] [CrossRef]

| Peak Number | Band Position (cm−1) | Wavelength (nm) | Assignment |

|---|---|---|---|

| 1 | 3005 | 3328 | Cis double-bond (H–C=C–H) sym stretch |

| 2 | 2953 | 3386 | Methyl group (C–H) asym stretch |

| 3 | 2925 | 3419 | Methylene group (C–H) asym stretch |

| 4 | 2854 | 3504 | Methyl and methylene group (C–H) sym stretch |

| 5 | 1740 | 5747 | Ester carbonyl group (C=O) stretch |

| 6 | 1460 | 6849 | Methylene (C–H2) scissoring |

| 7 | 1161 | 8613 | Alkoxy group (C–O) stretch |

| 8 | 722 | 13,850 | Methylene group (C–H2) rocking |

| Compound | Abbr. | Chemical Formula | [M] (amu) | [M+Na]+ (m/z) | Relative Intensity (%) |

|---|---|---|---|---|---|

| Triacylglycerols (TAGs) | |||||

| 2-(palmitoyloxy)propane-1,3-diyl dioleate | POO | C55H102O6 | 858.76 | 881.76 | 43.046 |

| propane-1,2,3-triyl trioleate (OOO) | OOO | C57H104O7 | 884.77 | 907.77 | 27.868 |

| 2-(oleoyloxy)propane-1,3-diyl dipalmitate | POP | C53H100O6 | 832.75 | 855.74 | 17.333 |

| 2-(stearoyloxy)propane-1,3-diyl dioleate | SOO | C57H106O6 | 886.80 | 909.78 | 9.131 |

| 3-(oleoyloxy)propane-1,2-diyl distearate | SSO | C57H108O6 | 888.81 | 911.79 | 1.275 |

| propane-1,2,3-triyl tristearate | SSS | C57H110O6 | 890.83 | 913.75 | 0.822 |

| propane-1,2,3-triyl tripalmitate | PPP | C51H98O6 | 806.74 | 829.73 | 0.525 |

| Diacylglycerols (DAGs) | |||||

| 2-hydroxypropane-1,3-diyl dioleate | OO | C39H72O5 | 620.54 | 643.53 | 51.993 |

| 3-hydroxy-2-(palmitoyloxy)propyl oleate | PO | C39H70O5 | 594.52 | 617.51 | 42.326 |

| 2-hydroxypropane-1,3-diyl dipalmitate | PP | C35H68O5 | 568.51 | 591.50 | 5.681 |

| Monoacylglycerols (MAGs) | |||||

| 2,3-dihydroxypropyl oleate | O | C21H40O4 | 356.29 | 379.28 | 78.716 |

| 1,3-dihydroxypropan-2-yl palmitate | P | C19H38O4 | 330.28 | 353.28 | 21.284 |

| Compound | Abbr. | Chemical Formula | [M] (amu) | [M+Na]+ (m/z) | Relative Intensity (%) |

|---|---|---|---|---|---|

| Triacylglycerols (TAGs) | |||||

| propane-1,2,3-triyl tridodecanoate | LLL | C39H74O6 | 638.55 | 661.54 | 30.07 |

| 3-(tetradecanoyloxy)propane-1,2-diyl didodecanoate | LLM | C41H78O6 | 666.58 | 689.57 | 26.10 |

| 3-(dodecanoyloxy)propane-1,2-diyl ditetradecanoate | MML | C43H82O6 | 694.61 | 717.60 | 9.99 |

| 3-(decanoyloxy)propane-1,2-diyl didodecanoate | LLC10 | C37H70O6 | 610.52 | 633.51 | 11.97 |

| 3-(octanoyloxy)propane-1,2-diyl didodecanoate | LLC8 | C35H66O6 | 582.49 | 605.48 | 10.49 |

| 3-(tetradecanoyloxy)propane-1,2-diyl didodecanoate | MMM | C45H86O6 | 722.64 | 745.64 | 3.06 |

| 3-(oleoyloxy)propane-1,2-diyl didodecanoate | LLO | C45H84O6 | 720.63 | 743.62 | 1.31 |

| 3-(hexanoyloxy)propane-1,2-diyl didodecanoate | LLC6 | C33H62O6 | 554.45 | 577.44 | 2.21 |

| 1-(dodecanoyloxy)-3-(tetradecanoyloxy)propan-2-yl oleate | LOM | C47H88O6 | 748.66 | 771.65 | 0.94 |

| 2-(dodecanoyloxy)propane-1,3-diyl dioleate | LOO | C51H94O6 | 802.71 | 825.69 | 0.79 |

| 3-(palmitoyloxy)propane-1,2-diyl ditetradecanoate | MMP | C47H90O6 | 750.67 | 773.66 | 0.93 |

| 3-(oleoyloxy)propane-1,2-diyl ditetradecanoate | MMO | C49H92O6 | 776.69 | 799.69 | 0.00 |

| 2-(tetradecanoyloxy)propane-1,3-diyl dioleate | MOO | C53H96O6 | 830.74 | 853.72 | 0.32 |

| 3-(dodecanoyloxy)-2-(tetradecanoyloxy)propyl (9Z,12Z)-octadeca-9,12-dienoate | LLiM | C47H88O6 | 745.64 | 769.62 | 0.47 |

| propane-1,2,3-triyl trioleate | OOO | C57H104O7 | 884.77 | 907.77 | 0.35 |

| 2-(palmitoyloxy)propane-1,3-diyl dioleate | POO | C55H102O6 | 858.76 | 881.76 | 0.27 |

| 3-(((9Z,12Z)-octadeca-9,12-dienoyl)oxy)propane-1,2-diyl didodecanoate | LLLi | C45H82O6 | 718.61 | 741.59 | 0.39 |

| 2-(dodecanoyloxy)propane-1,3-diyl dioctanoate | LC8C8 | C31H58O6 | 526.42 | 549.42 | 0.34 |

| Diacylglycerols (DAGs): | |||||

| 2-hydroxy-3 (tetradecanoyloxy)propyl palmitate | PM | C33H64O5 | 540.48 | 563.38 | 22.48 |

| 3-hydroxypropane-1,2-diyl didodecanoate | LL | C27H52O5 | 456.38 | 479.37 | 54.37 |

| 3-(dodecanoyloxy)-2-hydroxypropyl tetradecanoate | LM | C29H56O5 | 484.41 | 507.37 | 19.95 |

| 3-hydroxypropane-1,2-diyl ditetradecanoate | MM | C31H60O5 | 512.44 | 535.44 | 3.21 |

| Monoacylglycerols (MAGs) | |||||

| 1,3-dihydroxypropan-2-yl palmitate | P | C19H38O4 | 330.28 | 353.26 | 100 |

| Compound | Abbr. | Chemical Formula | [M] (amu) | [M+Na]+ (m/z) | Relative Intensity (%) |

|---|---|---|---|---|---|

| Triacylglycerols (TAGs) | |||||

| propane-1,2,3-triyl trioleate | OOO | C57H104O6 | 884.77 | 907.77 | 38.04 |

| 2-(stearoyloxy)propane-1,3-diyl dioleate | SOO | C57H106O6 | 886.80 | 909.78 | 18.72 |

| 3-(((9Z,12Z)-octadeca-9,12-dienoyl)oxy)propane-1,2-diyl dioleate | OOLi | C57H102O6 | 882.77 | 905.75 | 16.99 |

| 2-(palmitoyloxy)propane-1,3-diyl dioleate | POO | C55H102O6 | 858.76 | 881.76 | 13.49 |

| 2-(oleoyloxy)propane-1,3-diyl (9Z,9’Z,12Z,12’Z)-bis(octadeca-9,12-dienoate) | OLiLi | C57H100O6 | 880.75 | 903.74 | 8.65 |

| propane-1,2,3-triyl tri[(9Z,12Z)-octadeca-9,12-dienoate] | LiLiLi | C57H98O6 | 878.74 | 901.74 | 2.34 |

| 2-(oleoyloxy)propane-1,3-diyl dipalmitate | PPO | C53H100O6 | 832.75 | 855.74 | 1.76 |

| Diacylglycerols (DAGs) | |||||

| 2-hydroxypropane-1,3-diyl dioleate | OO | C39H72O5 | 620.54 | 643.53 | 78.55 |

| 3-hydroxy-2-(palmitoyloxy)propyl oleate | PO | C39H70O5 | 594.52 | 617.51 | 19.90 |

| 2-hydroxypropane-1,3-diyl dipalmitate | PP | C35H68O5 | 568.51 | 591.50 | 1.55 |

| Monoacylglycerols (MAGs) | |||||

| 2,3-dihydroxypropyl oleate | O | C21H40O4 | 356.29 | 379.29 | 77.82 |

| 1,3-dihydroxypropan-2-yl palmitate | P | C19H38O4 | 330.28 | 353.28 | 22.18 |

| Compound | Abbr. | Chemical Formula | [M] (amu) | [M+Na]+ (m/z) | Relative Intensity (%) |

|---|---|---|---|---|---|

| Triacylglycerols (TAGs) | |||||

| propane-1,2,3-triyl tridodecanoate | LLL | C39H74O6 | 638.55 | 661.54 | 30.90 |

| 3-(tetradecanoyloxy)propane-1,2-diyl didodecanoate | LLM | C41H78O6 | 666.58 | 689.57 | 26.08 |

| 3-(dodecanoyloxy)propane-1,2-diyl ditetradecanoate | MML | C43H82O6 | 694.61 | 717.60 | 10.46 |

| 3-(decanoyloxy)propane-1,2-diyl didodecanoate | LLC10 | C37H70O6 | 610.52 | 633.51 | 8.98 |

| 3-(octanoyloxy)propane-1,2-diyl didodecanoate | LLC8 | C35H66O6 | 582.49 | 605.48 | 7.43 |

| propane-1,2,3-triyl tritetradecanoate | MMM | C45H86O6 | 722.64 | 745.64 | 3.69 |

| 3-(oleoyloxy)propane-1,2-diyl didodecanoate | LLO | C45H84O6 | 720.63 | 743.62 | 2.37 |

| 3-(hexanoyloxy)propane-1,2-diyl didodecanoate | LLC6 | C33H62O6 | 554.45 | 577.44 | 1.87 |

| 1-(dodecanoyloxy)-3-(tetradecanoyloxy)propan-2-yl oleate | LOM | C47H88O6 | 748.66 | 771.65 | 1.73 |

| 3-(dodecanoyloxy)propane-1,2-diyl dioleate | LOO | C51H94O6 | 802.71 | 825.69 | 1.49 |

| 3-(palmitoyloxy)propane-1,2-diyl ditetradecanoate | MMP | C47H90O6 | 750.67 | 773.66 | 1.23 |

| 3-(oleoyloxy)propane-1,2-diyl ditetradecanoate | MMO | C49H92O6 | 776.69 | 799.69 | 1.12 |

| 3-(dodecanoyloxy)-2-(tetradecanoyloxy)propyl (9Z,12Z)-octadeca-9,12-dienoate | LLiM | C47H88O6 | 745.64 | 769.62 | 0.53 |

| propane-1,2,3-triyl trioleate | OOO | C57H104O7 | 884.77 | 907.77 | 0.52 |

| 3-(((9Z,12Z)-octadeca-9,12-dienoyl)oxy)propane-1,2-diyl didodecanoate | LLLi | C45H82O6 | 718.61 | 741.59 | 0.34 |

| 2-(tetradecanoyloxy)propane-1,3-diyl dioleate | MOO | C53H96O6 | 830.74 | 853.72 | 0.59 |

| 2-(palmitoyloxy)propane-1,3-diyl dioleate | POO | C55H102O6 | 858.76 | 881.76 | 0.38 |

| 2-(dodecanoyloxy)propane-1,3-diyl dioctanoate | LC8C8 | C31H58O6 | 526.42 | 549.42 | 0.29 |

| Diacylglycerols (DAGs) | |||||

| 3-hydroxypropane-1,2-diyl didodecanoate | LL | C27H52O5 | 456.38 | 479.37 | 58.10 |

| 3-(dodecanoyloxy)-2-hydroxypropyl tetradecanoate | LM | C29H56O5 | 484.41 | 507.37 | 37.58 |

| 3-hydroxypropane-1,2-diyl ditetradecanoate | MM | C31H60O5 | 512.44 | 535.44 | 4.32 |

| Monoacylglycerols (MAGs) | |||||

| 1,3-dihydroxypropan-2-yl palmitate | P | C19H38O4 | 330.28 | 353.26 | 100 |

| Samples | TGA | DTG | |

|---|---|---|---|

| (°C) | (°C) | (°C) | |

| AAK | 287 | 370 | - |

| AVK | 298 | 373 | - |

| AAP | 329 | 405 | 233 |

| AVP | 320 | 402 | 231 |

| Sample | (°C) | (°C) | (°C) | (°C) | (°C) | (J/g) |

| Crystallization | ||||||

| AAK | 12 | 11 | -- | -- | 3 | 123 |

| AVK | 16 | 14 | -- | -- | 10 | 130 |

| AVP | −2 | −5 | −32 | −46 | −54 | 68 |

| AAP | 1 | −2 | −31 | −45 | −51 | 62 |

| Melting | ||||||

| Sample | (°C) | (°C) | (°C) | (°C) | (°C) | (J/g) |

| AAK | −27 | −18 | 31 | -- | 34 | 125 |

| AVK | −29 | −19 | 30 | -- | 33 | 133 |

| AVP | −53 | −35 | −16 | 3 | 11 | 76 |

| AAP | −59 | −43 | −5 | -- | 4 | 67 |

| Samples | A | Std. Error | m | Std. Error |

|---|---|---|---|---|

| AVP | 3.37 | 0.02 | 3.17 | 0.02 |

| AAP | 3.58 | 0.02 | 2.99 | 0.02 |

| AVK | 13.84 | 4.45 | 0.70 | 0.23 |

| AAK | 11.59 | 2.90 | 0.83 | 0.22 |

| AVP (This Work) | AAP (This Work) | AVK (This Work) | AAK (This Work) | Palm Oil [57] | Shea Butter [55] | Cocoa Butter [56] | Crabwood Oil [58,59] | Coconut Oil [60,61] |

|---|---|---|---|---|---|---|---|---|

| POO 43.0% | OOO 38.0% | LLL 30.1% | LLL 30.9% | PPO 31.6% | SOS 55% | POS 40.8% | POO 25.0% | LLL 21.9% |

| OOO 27.9% | SOO 18.7% | LLM 26.1% | LLM 26.1% | POO 24.8% | SOO 32.3% | SOS 29.9% | PPO 14.0% | C10LL 18.6% |

| POP 17.3% | OOLi 17.00% | LLC10 12.0% | MML 10.5% | PPL 10.2% | POO 3.8% | POP 14.5% | OOO 11.0% | LLM 17.2% |

| SOO 9.1% | POO 13.5 | LLC8 10.5% | LLC10 9.0% | POL 9.9% | SLO 2.8% | PLS 5.5% | PLO 8.8% | C10C10L 14.3% |

| SSO 1.3% | LiLiLi 2.3% | LLM 10.0% | LLC8 7.4% | SPO 5.7% | OOS 2.6% | SOO 3.1% | POS 11.2% | LMM 9.6% |

| SSS 0.8% | PPO 1.76% | MMM 3.1% | MMM 3.7% | PPP 4.8% | POS 1.5% | PLP 2.7% | OOS 8.0% | LMP 4.7% |

| PPP 0.5% | LLC6 2.6%- | LLO 2.4% | OOO 4.0% | SSO 1.0% | SLS 1.2% | PPL 4.6% | C6C10L 3.7% | |

| -- | LLO 1.3% | LLC6 1.9% | SOO 2.7% | POP 0.4% | OOO 0.7% | OOL 4.2% | LLO 2.0% | |

| LLO 2.4% | LOM 0.9% | LOM 1.7% | PLL 2.1% | SLL 0.3% | -- | SSO 3.5% | LPP 1.7% | |

| -- | -- | LOO 0.8% | MMP 1.2% | OOL 1.6% | OOO 0.3% | -- | PPS 2.2% | C6C6L 1.0% |

| Physical Properties | AVK | AAK | Shea Butter | Cocoa Butter |

|---|---|---|---|---|

| Melting (Tp) (°C) | 30 ± 1 | 31 ± 1 | 37 [62] | 29 [63] |

| Fats | Oils | |||||||

|---|---|---|---|---|---|---|---|---|

| Physical Properties | AVK | AAK | Shea Butter [62] | Cocoa Butter [64] | AVP | AAP | Palm Oil [65] | Coconut Oil [65] |

| Dynamic Viscosity @ 40 °C (mPa·S) | 28.29 | 29.36 | 46.98 | 42.30 | 36.35 | 35.03 | 54.80 | 22.35 |

| Flow Behavior | Newtonian | Newtonian | Newtonian | Newtonian | Newtonian | Newtonian | Newtonian | Newtonian |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deonarine, S.; Soodoo, N.; Bouzidi, L.; Emery, R.J.N.; Martic, S.; Narine, S.S. Molecular, Crystalline, and Microstructures of Lipids from Astrocaryum Species in Guyana and Their Thermal and Flow Behavior. Thermo 2024, 4, 140-163. https://doi.org/10.3390/thermo4010009

Deonarine S, Soodoo N, Bouzidi L, Emery RJN, Martic S, Narine SS. Molecular, Crystalline, and Microstructures of Lipids from Astrocaryum Species in Guyana and Their Thermal and Flow Behavior. Thermo. 2024; 4(1):140-163. https://doi.org/10.3390/thermo4010009

Chicago/Turabian StyleDeonarine, Shaveshwar, Navindra Soodoo, Laziz Bouzidi, R. J. Neil Emery, Sanela Martic, and Suresh S. Narine. 2024. "Molecular, Crystalline, and Microstructures of Lipids from Astrocaryum Species in Guyana and Their Thermal and Flow Behavior" Thermo 4, no. 1: 140-163. https://doi.org/10.3390/thermo4010009

APA StyleDeonarine, S., Soodoo, N., Bouzidi, L., Emery, R. J. N., Martic, S., & Narine, S. S. (2024). Molecular, Crystalline, and Microstructures of Lipids from Astrocaryum Species in Guyana and Their Thermal and Flow Behavior. Thermo, 4(1), 140-163. https://doi.org/10.3390/thermo4010009