Synergistic Multi-Enzyme Modification of Ramie Fabric: Optimized Process for Alleviating Prickle Sensation and Enhancing Comfort

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pretreatment

2.3. Single-Factor Experiments

2.4. Response Surface Optimization

2.5. Compound Enzyme Modification Experiments

2.6. Prickle Sensation Evaluation

2.7. Surface Morphology and Chemical Analysis

3. Results and Discussion

3.1. Single-Factor Experiment Results

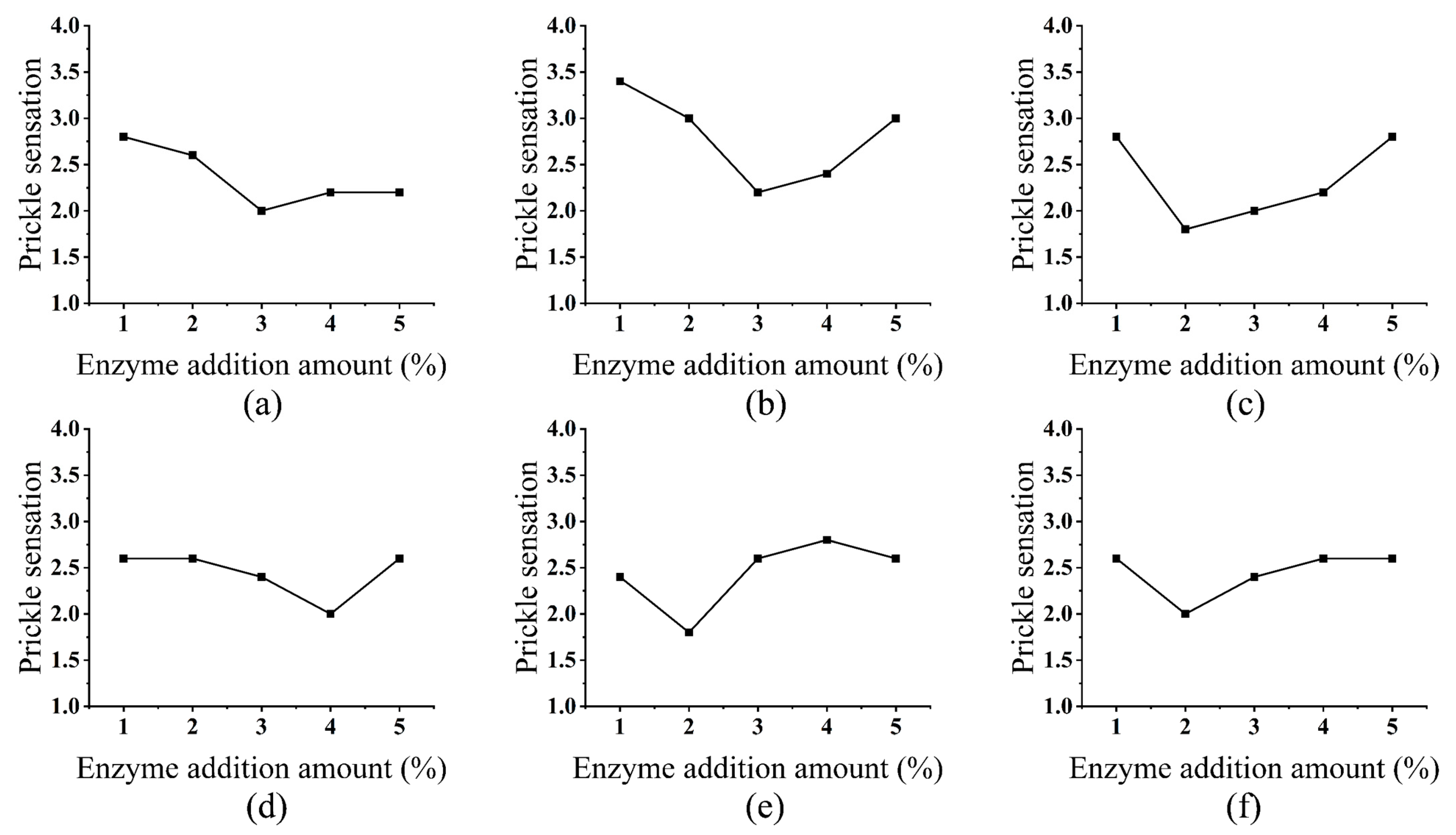

3.1.1. Effect of Enzyme Dosage

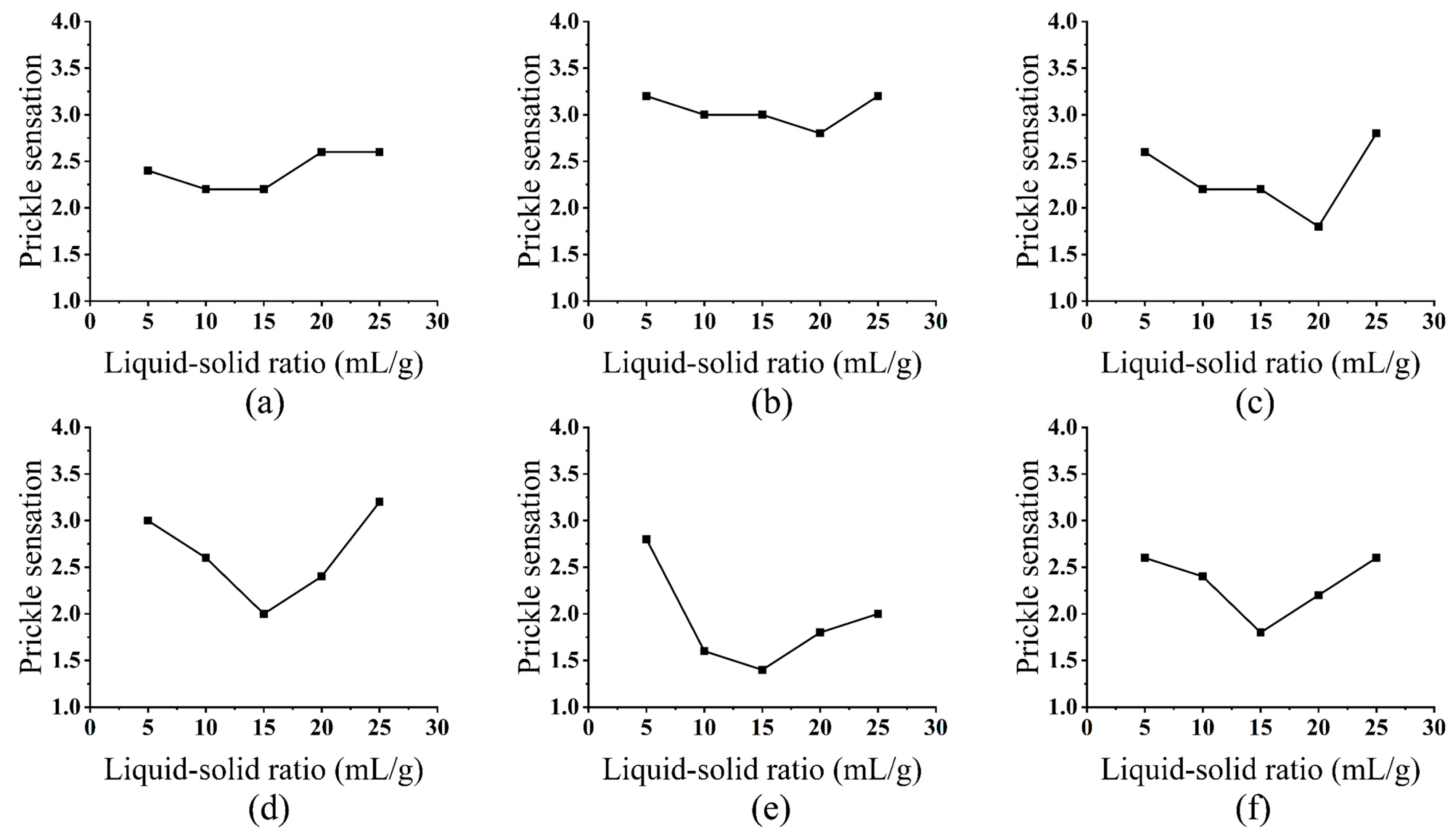

3.1.2. Effect of Liquid-to-Solid Ratio

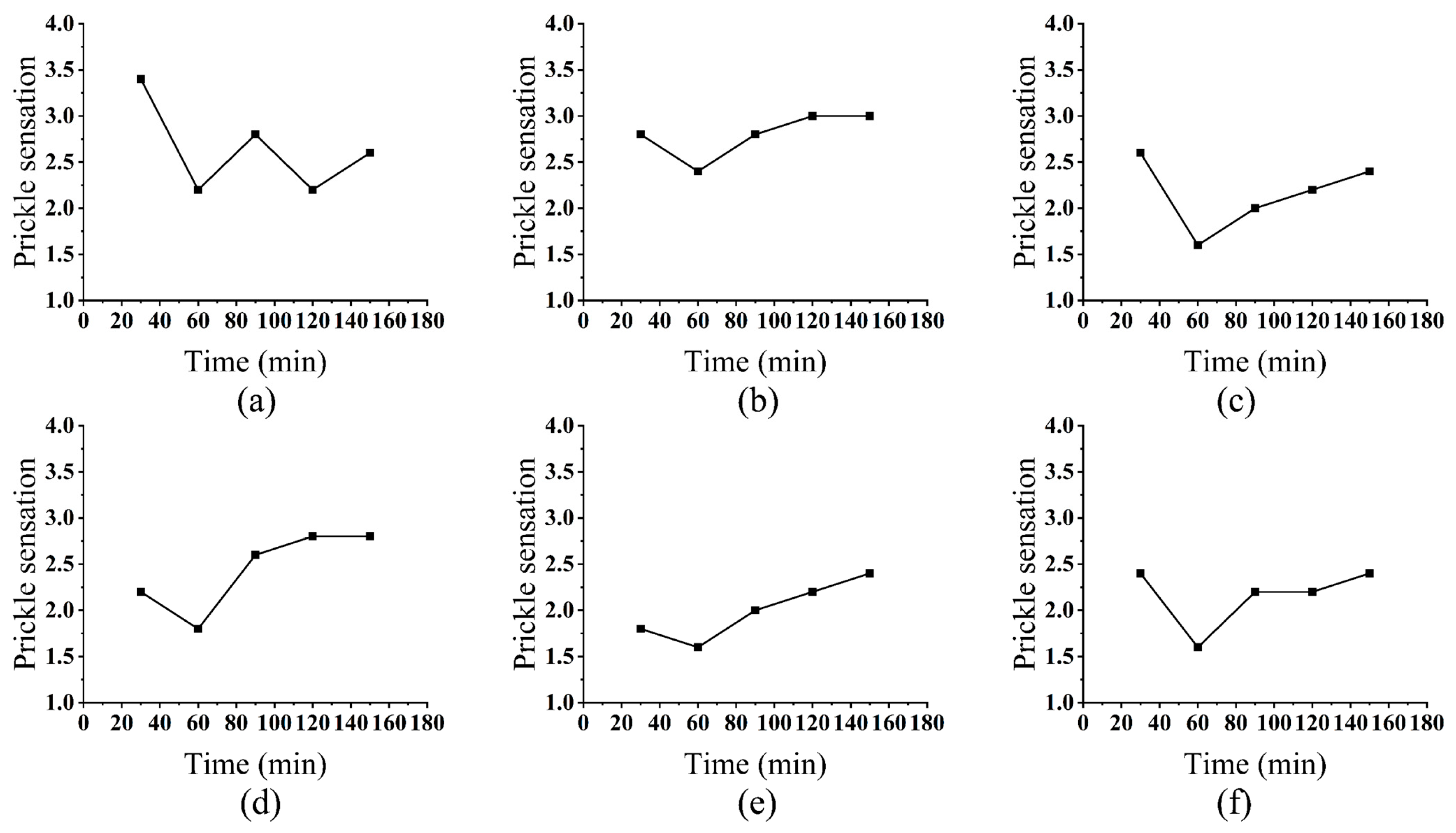

3.1.3. Effect of Treatment Time

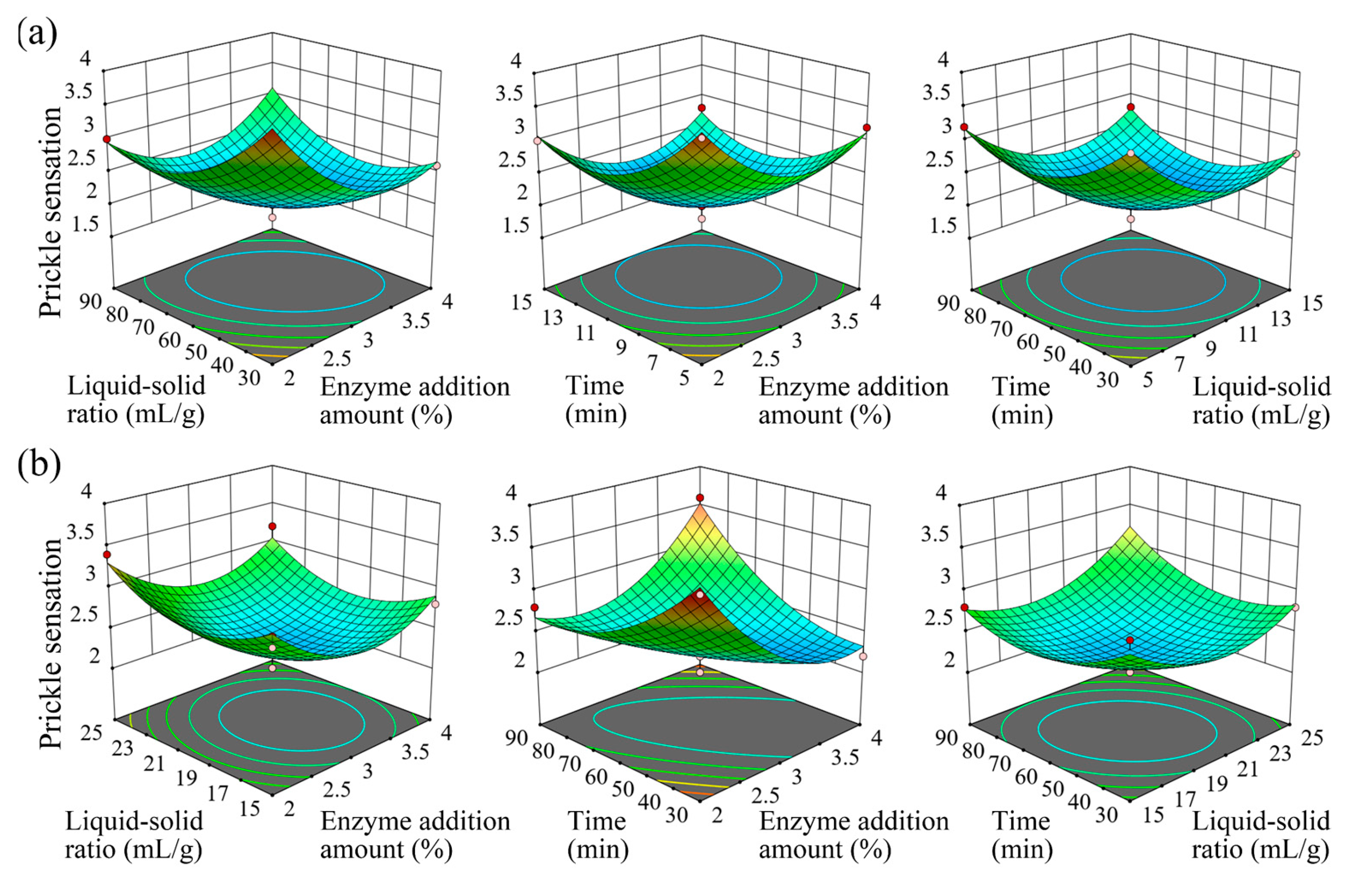

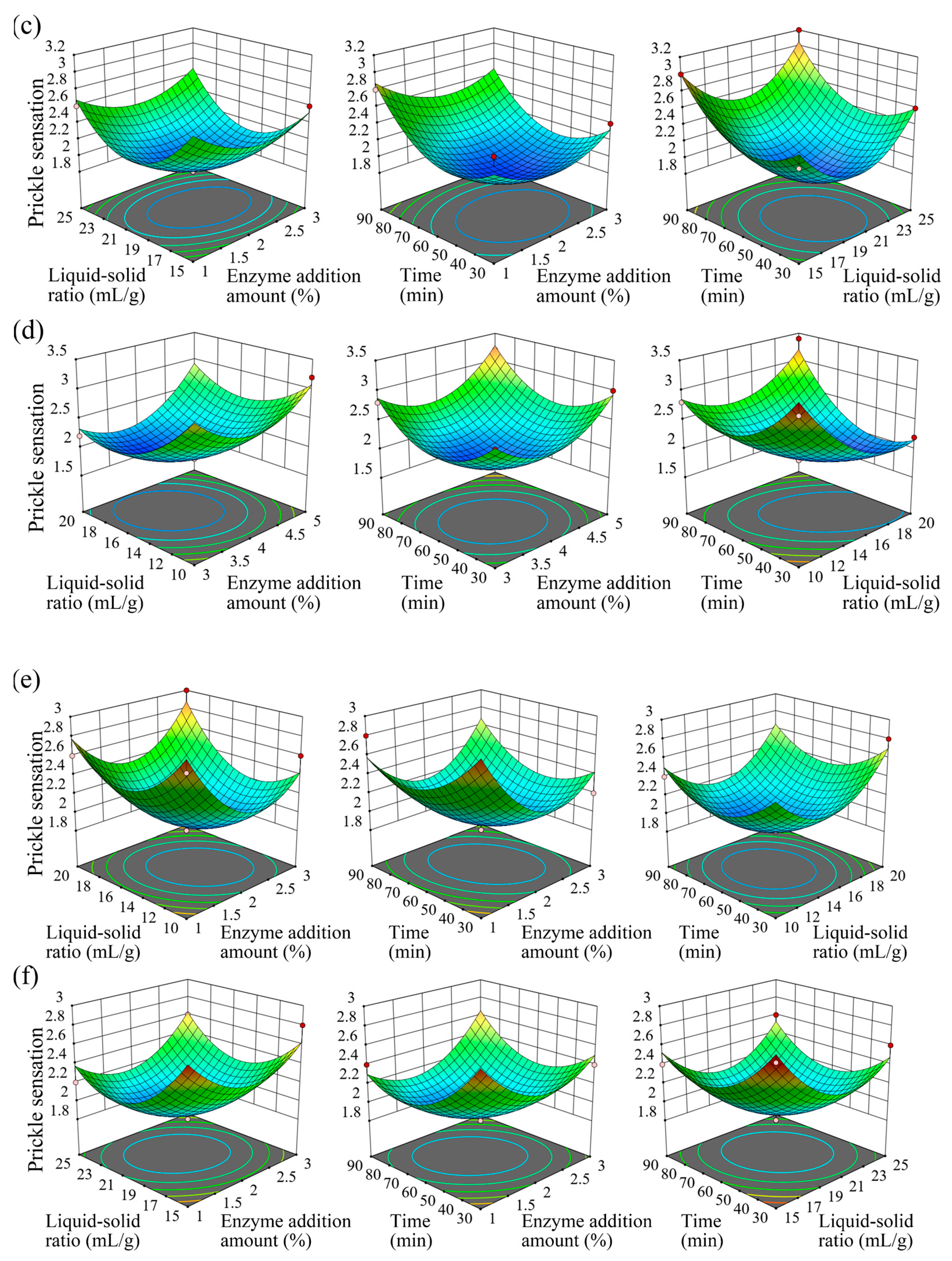

3.2. Response Surface Optimization Experimental Results

3.2.1. Cellulase and Laccase

3.2.2. Hemicellulase, Xylanase, and Pectinase

3.2.3. Alkaline Protease

3.2.4. Parameter Interaction Analysis and Optimal Condition Validation

3.3. Compound Enzyme Experiment Results

3.3.1. Evaluation of Prickle Sensation

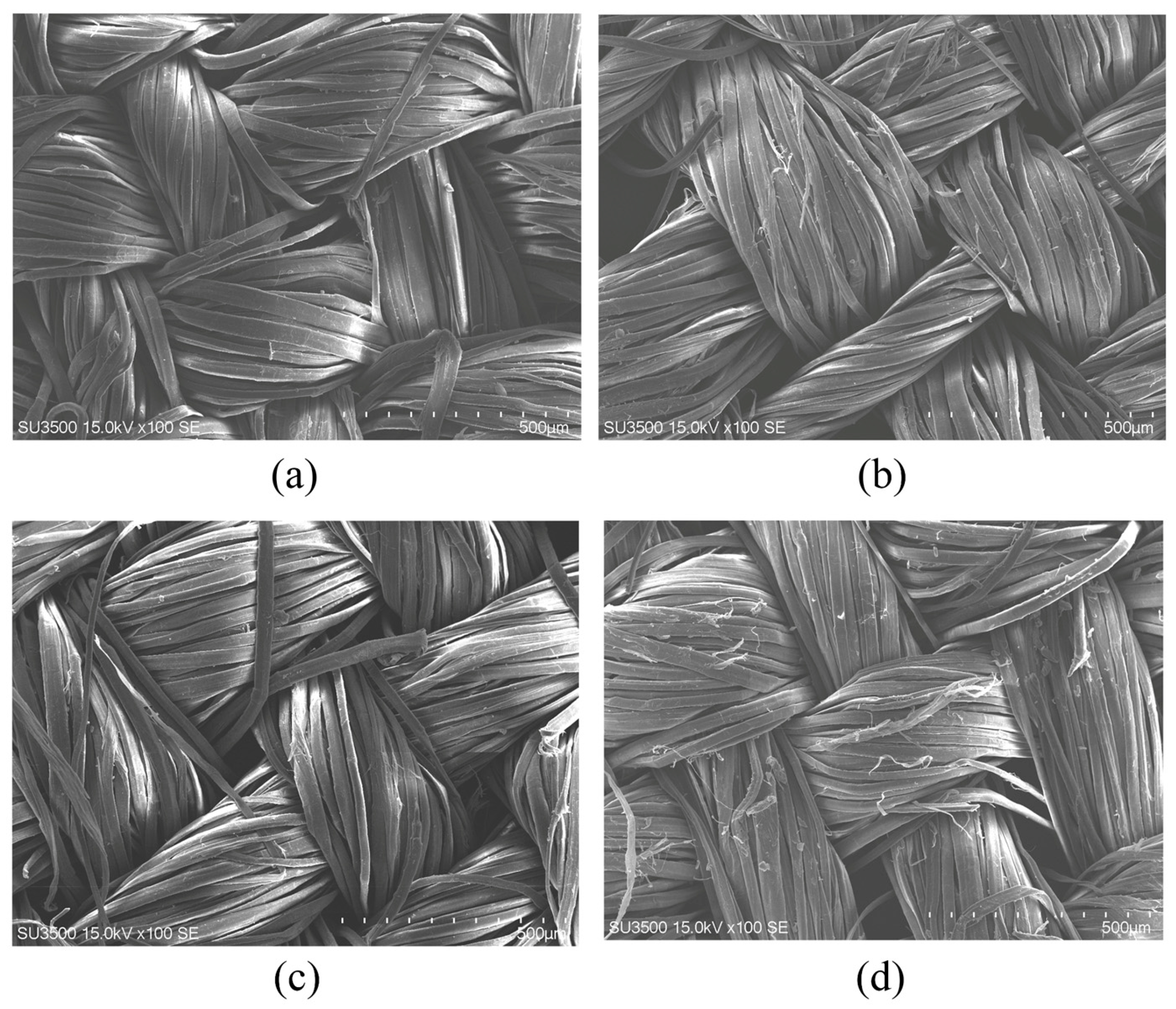

3.3.2. Evaluation of Surface Appearance

3.3.3. Mechanisms and Industrial Advantages

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thapliyal, D.; Verma, S.; Sen, P.; Kumar, R.; Thakur, A.; Tiwari, A.K.; Singh, D.; Verros, G.D.; Arya, R.K. Natural fibers composites: Origin, importance, consucmption pattern, and challenges. J. Compos. Sci. 2023, 7, 506. [Google Scholar] [CrossRef]

- Yu, H.; Christopher, H.; Liu, X.; Stuart, G.; Wang, X. A modified resistance to compression (RtC) test for evaluation of natural fiber softness. Text. Res. J. 2022, 92, 1771–1781. [Google Scholar] [CrossRef]

- Zhao, W.; Sui, Z.; Zhang, Q.; Sun, L.; Zu, B. Hydrophobic and mechanical strength enhancement of hemp fabric and paper enabled by waterborne polyurethane-derived functional coating. Cellulose 2024, 31, 1687–1703. [Google Scholar] [CrossRef]

- Wei, S.; Xiong, S.; Zhang, S.; Cui, Y.; Wang, S.; Lu, X.; Chen, J.; Zhang, M.; Yang, B. A study on the antibacterial property and biocompatibility of ramie fiber. Biomed. Mater. 2023, 18, 045010. [Google Scholar] [CrossRef]

- Vasile, S.; Vermeire, S.; Vandepitte, K.; Troch, V.; Raeve, A.D. Effect of Weave and Weft Type on Mechanical and Comfort Properties of Hemp-Linen Fabrics. Materials 2024, 17, 1650. [Google Scholar] [CrossRef]

- Ornaghi, H.L.; Neves, R.M.; Agnol, L.D.; Kerche, E.; Lazzari, L.K. Structure versus Property Relationship of Hybrid Silk/Flax Composites. Textiles 2024, 4, 344–355. [Google Scholar] [CrossRef]

- Tanasa, F.; Teaca, C.A.; Nechifor, M.; Ignat, M.; Duceac, I.A.; Ignat, L. Highly specialized textiles with antimicrobial functionality—Advances and challenges. Textiles 2023, 3, 219–245. [Google Scholar] [CrossRef]

- Mariz, J.; Guise, C.; Silva, T.L.; Rodrigues, L.; Silva, C.J. Hemp: From field to fiber—A review. Textiles 2024, 4, 165–182. [Google Scholar] [CrossRef]

- Milanovic, J.Z.; Milosevic, M.; Korica, M.; Jankovic-Castvan, I.; Kostic, M.M. Oxidized hemp fibers with simultaneously increased capillarity and reduced moisture sorption as suitable textile material for advanced application in sportswear. Fibers Polym. 2021, 22, 2052–2062. [Google Scholar] [CrossRef]

- Arunprasath, K.; Arumugaprabu, V.; Amuthakkannan, P.; Manikandan, V. Synergistic Utilization of Flax Fiber Polymer Composites: A Review. Adv. Mater. Lett. 2021, 12, 1–9. [Google Scholar] [CrossRef]

- Liu, X.; Yang, C.; Sun, M.; Quan, G.; Gong, B.; Kang, Q.; Xiao, L.; Zhu, W.; Wang, H. Preparation of new natural hemp fiber-based antibacterial hydrogel dressing and its performance in promoting wound healing of bacterial infection. Colloid Surf. A-Physicochem. Eng. Asp. 2025, 719, 137008. [Google Scholar] [CrossRef]

- Korodowou, I.; Farissi, L.E.; Ammari, M.; Allal, L.B. Evaluating sisal fibers as an eco-friendly and cost-efficient alternative to cotton for the Moroccan absorbent hygiene and textile industries. Ind. Crop. Prod. 2024, 222, 119779. [Google Scholar] [CrossRef]

- Wojtasik, W.; Kostyn, K.; Preisner, M.; Czuj, T.; Zimniewska, M.; Szopa, J.; Wróbel-Kwiatkowska, M. Cottonization of Decorticated and Degummed Flax Fiber-A Novel Approach to Improving the Quality of Flax Fiber and its Biomedical Applications. J. Nat. Fibers 2024, 21, 2368143. [Google Scholar] [CrossRef]

- Das, A.; Alagirusamy, R. Improving tactile comfort in fabrics and clothing. In Improving Comfort in Clothing; Song, G., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2011; pp. 216–244. [Google Scholar]

- Asad, R.A.; Yu, W.; Zheng, Y.H.; He, Y. Characterization of prickle tactile discomfort properties of different textile single fibers using an axial fiber-compression-bending analyzer (FICBA). Text. Res. J. 2015, 85, 512–523. [Google Scholar] [CrossRef]

- Gomez, N.A.; Grech, B.E.; Muscat, M.; Muscat-Fenech, C.D.; Camilleri, D.; Sinagra, E.; Lanfranco, S. Chemical and physical modifications of the surface of sisal agave fibre used as a reinforcement in epoxy resin-A Review. J. Nat. Fibers 2024, 21, 2390077. [Google Scholar] [CrossRef]

- Koksharov, S.A.; Bikbulatova, A.A.; Kornilova, N.L.; Aleeva, S.V.; Lepilova, O.V.; Nikiforova, E.N. Justification of an Approach to Cellulase Application in Enzymatic Softening of Linen Fabrics and Clothing. Text. Res. J. 2022, 92, 4208–4229. [Google Scholar] [CrossRef]

- Hu, R.; Zhao, Z.; Zhou, J.; Pu, Q.; Dong, Q.; Liu, Y.; Huang, H.; Lu, M. Surface micro-dissolution of ramie fabrics with NaOH/urea to eliminate hairiness. Cellulose 2017, 24, 5251–5259. [Google Scholar] [CrossRef]

- Machado, V.; Marinho, A.; Vieira de Castro, P.; Silva, T. From fabric to finish: The cytotoxic impact of textile chemicals on humans health. Textiles 2025, 5, 16. [Google Scholar] [CrossRef]

- Ni, X.; Dong, A.; Wang, Q.; Fan, X.; Yuan, J.; Yu, Y.; Wang, P. Characterization and performance of ramie fabrics treated with modified cellulase. J. Text. Inst. 2015, 106, 780–786. [Google Scholar] [CrossRef]

- Zhou, C.; Cao, Y.; Xue, Y.; Liu, W.; Ju, J.; Ma, Y. Structure of an alkaline pectate lyase and rational engineering with improved thermo-alkaline stability for efficient ramie degumming. Int. J. Mol. Sci. 2022, 24, 538. [Google Scholar] [CrossRef]

- Tang, Q.; Chen, Y.; Du, M.; Yu, J.; Li, Z.; Ding, B. Research progress in Ramie fiber extraction: Degumming method, working mechanism, and fiber performance. Ind. Crop. Prod. 2024, 222, 119876. [Google Scholar] [CrossRef]

- Jordanov, I.; Stevens, D.L.; Tarbuk, A.; Magovac, E.; Bischof, S.; Grunlan, J.C. Enzymatic modification of polyamide for improving the conductivity of water-based multilayer nanocoatings. ACS Omega 2019, 4, 12028–12035. [Google Scholar] [CrossRef] [PubMed]

- FZ/T 30005-2009; Subjective Evaluation Method of Ramie Fabric Evoked Prickle. Standards Press of China: Beijing, China, 2009.

- Saha, P.; Roy, D.; Manna, S.; Chowdhury, S.; Banik, S.; Sen, R.; Jo, J.; Kim, J.K.; Adhiikari, B. Biodegradation of chemically modified lignocellulosic sisal fibers: Study of the mechanism for enzymatic degradation of cellulose. e-Polymers 2015, 15, 185–194. [Google Scholar] [CrossRef]

- Fan, F.; Zhu, M.; Fang, K.; Xie, J.; Deng, Z.; Wang, X.; Zhang, Z.; Cao, X. Comparative study on enhanced pectinase and alkali-oxygen degummings of sisal fibers. Cellulose 2021, 28, 8375–8386. [Google Scholar] [CrossRef]

- Luo, L.; Guo, Z.; Wang, P.; Wang, Q.; Xu, B.; Yu, Y. Degradation of pectic polysaccharides by ascorbic acid/H2O2-pectinase system and its application in cotton scouring. Cellulose 2024, 31, 10007–10023. [Google Scholar] [CrossRef]

- Singhal, A.; Jin, J.; Banu, M.; Taub, A. Effect of enzyme retting conditions on bast bundle differentiation and mechanical properties of flax technical fibers. Ind. Crop. Prod. 2023, 205, 117478. [Google Scholar] [CrossRef]

- Sahi, A.K.; Singh, M.K.; Das, A. Study on the characteristics of cottonized Indian industrial hemp fibers. J. Nat. Fibers 2022, 19, 8842–8853. [Google Scholar] [CrossRef]

- Xu, K.; Huo, Y.; Tang, S.; Han, S.; Lin, Y.; Zheng, S. A novel laccase for alkaline medium temperature environments in the textile industry. Biotechnol. J. 2024, 19, 2400383. [Google Scholar] [CrossRef]

- Wu, Y.; Shu, T.; Li, P.; Wang, Z.; Wang, H.; Pan, F.; Li, Y.; Yu, T.; Yu, L. A novel endo-β-1, 4-xylanase xyl-1 from aspergillus terreus HG-52 for high-efficiency ramie degumming. J. Nat. Fibers 2022, 19, 13890–13900. [Google Scholar] [CrossRef]

- Pan, Y.; He, W.; Gao, J.; Luo, Y. Microencapsulated alkaline protease with enhanced stability and temperature resistance for silk degumming. Colloid Surf. A-Physicochem. Eng. Asp. 2025, 707, 135894. [Google Scholar] [CrossRef]

- Sahin, B.; Ozbey-Unal, B.; Dizge, N.; Keskinler, B.; Balcik, C. Optimization of immobilized urease enzyme on porous polymer for enhancing the stability, reusability and enzymatic kinetics using response surface methodology. Colloid Surf. B-Biointerfaces 2024, 240, 113986. [Google Scholar] [CrossRef]

- Gül, E.; Dursun, A.Y.; Tepe, O.; Akaslan, G.; Pampal, F.G. Optimizing pectin lyase production using the one-factor-at-a-time method and response surface methodology. Biotechnol. Appl. Biochem. 2024, 72, 638–651. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, J.; Wang, Y.; Duan, C.; Liu, Y.; Lu, M. Study on the ramie fabric treated with copper ammonia to slenderize fiber for eliminating prickle. J. Nat. Fibers 2023, 20, 2120150. [Google Scholar] [CrossRef]

- Sayeed, M.A.; Paharia, A. Optimisation of the surface treatment of jute fibres for natural fibre reinforced polymer composites using Weibull analysis. J. Text. Inst. 2019, 110, 1588–1595. [Google Scholar] [CrossRef]

| Sample No. | Enzyme Combination | Prickle Sensation Score |

|---|---|---|

| 1# | Xylanase (4%) + hemicellulase (2%) + cellulase (3%) + laccase (3%) | 2 |

| 2# | Xylanase (4%) + cellulase (3%) + laccase (3%) | 2 |

| 3# | Hemicellulase (2%) + cellulase (3%) + laccase (3%) | 1.8 |

| 4# | Untreated | 3.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Zhou, X.; Deng, L.; Shen, X.; Cheng, L.; Xi, G.; Chen, C.; Peng, Z.; Hu, Y.; Tan, S.; et al. Synergistic Multi-Enzyme Modification of Ramie Fabric: Optimized Process for Alleviating Prickle Sensation and Enhancing Comfort. Textiles 2025, 5, 60. https://doi.org/10.3390/textiles5040060

Yang Q, Zhou X, Deng L, Shen X, Cheng L, Xi G, Chen C, Peng Z, Hu Y, Tan S, et al. Synergistic Multi-Enzyme Modification of Ramie Fabric: Optimized Process for Alleviating Prickle Sensation and Enhancing Comfort. Textiles. 2025; 5(4):60. https://doi.org/10.3390/textiles5040060

Chicago/Turabian StyleYang, Qi, Xiang Zhou, Ling Deng, Xiangying Shen, Lifeng Cheng, Guoguo Xi, Chen Chen, Zhenghong Peng, Yuqin Hu, Si Tan, and et al. 2025. "Synergistic Multi-Enzyme Modification of Ramie Fabric: Optimized Process for Alleviating Prickle Sensation and Enhancing Comfort" Textiles 5, no. 4: 60. https://doi.org/10.3390/textiles5040060

APA StyleYang, Q., Zhou, X., Deng, L., Shen, X., Cheng, L., Xi, G., Chen, C., Peng, Z., Hu, Y., Tan, S., & Duan, S. (2025). Synergistic Multi-Enzyme Modification of Ramie Fabric: Optimized Process for Alleviating Prickle Sensation and Enhancing Comfort. Textiles, 5(4), 60. https://doi.org/10.3390/textiles5040060