Abstract

Multifunctional composites and smart textiles are an important advancement in material science, offering a variety of capabilities that extend well beyond traditional structural functions. These advanced materials are poised to revolutionize applications across a wide range of industries, including aerospace, healthcare, military, and consumer electronics, by embedding functionalities such as structural health monitoring, signal transmission, power transfer, self-healing, and environmental sensing. This review, which draws on insights from various disciplines, including material science, engineering, and technology, explores the manufacturing techniques employed in creating multifunctional composites, focusing on modifying textiles to incorporate conductive fibers, sensors, and functional coatings. The various multifunctional capabilities that result from these modifications and manufacturing techniques are examined in detail, including structural health monitoring, power conduction, power transfer, wireless communication, power storage, energy harvesting, and data transfer. The outlook and potential for future developments are also surveyed, emphasizing the need for improved durability, scalability, and energy efficiency. Key challenges are identified, such as ensuring material compatibility, optimizing fabrication techniques, achieving reliable performance under diverse conditions, and modeling multifunctional systems. By addressing these challenges through ongoing research and further innovation, we can significantly enhance the performance and utility of systems, driving advancements in technology and improving quality of life.

1. Introduction

Fiber-reinforced composite structures are widely recognized for their exceptional mechanical properties, lightweight nature, and versatility, making them indispensable in aerospace, marine, automotive, and offshore industries [1,2]. However, implementation of these advanced materials is hindered by significant challenges, particularly in extreme environments where understanding damage mechanics is crucial [3]. The main drawbacks of composite materials are their initial and maintenance costs and complex damage mechanisms, which necessitate monitoring to ensure structural integrity [4]. These challenges are compounded when facing unpredictable and harsh conditions, requiring materials to perform reliably under stress and degradation over time. However, costs can be reduced by consolidating functions that require separate materials and complex installations via a single multifunctional composite component that integrates multiple systems. This integration decreases the need for additional hardware, reduces the weight and complexity of the structure, and minimizes initial and maintenance expenses [5]. Such an approach not only streamlines design and manufacturing processes but also offers a more sustainable solution by reducing the material footprint. Furthermore, real-time monitoring and early damage detection performed by embedded sensors can prevent catastrophic failures and extend the service life of the composite, thereby lowering long-term operational and maintenance costs [6].

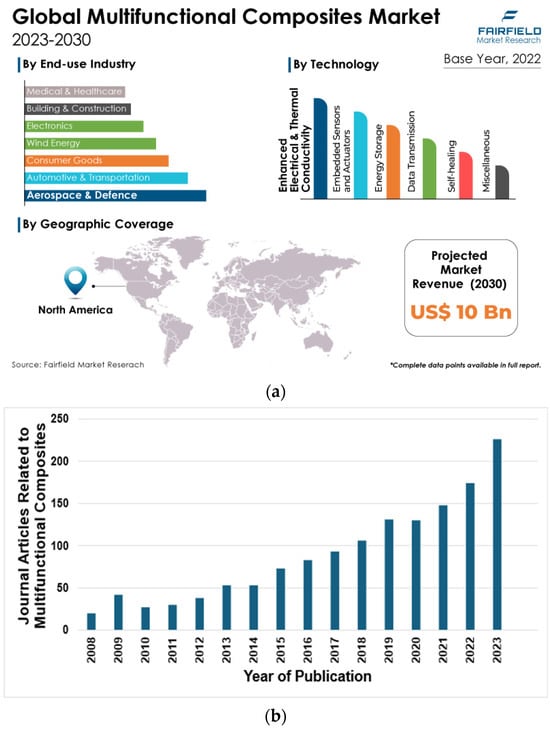

Due to these advantages, multifunctional composites have emerged as a vital technology to enhance the safety and performance of composite structures. Global trends, illustrated in Figure 1a, show that multifunctional composites impact a broad range of industries that utilize a wide variety of technologies. This widespread adoption underscores the growing recognition of multifunctional composites as a key innovation driver across sectors. One such technology is structural health monitoring (SHM) of composites, which has made it possible to reduce maintenance and repair costs while improving the reliability of these materials [7]. Recent advancements in this field have focused on distributed sensing, sensor networks, damage-tolerant optimized structures, and gradual damage detection [8,9]. Despite these advancements, challenges remain, particularly in implementing these systems on a large scale and monitoring dynamic conditions [10,11]. The integration of these monitoring systems requires overcoming technical hurdles related to scalability and signal processing and ensuring the reliability of sensors under varying operational conditions.

Figure 1.

(a) Global industry trends for multifunctional composites [12] and (b) recent journal articles for multifunctional composites (data collected from Scopus).

Additional capabilities of multifunctional composites include power transmission, signal transmission, and data transfer, which are gaining traction as viable solutions to be incorporated within composite systems. These composites integrate conductive elements within their structure to perform multiple functions simultaneously, enhancing their overall utility [13,14]. For instance, embedding conductive yarns within a composite can enable real-time failure detection and structural health monitoring, providing a significant advantage over traditional external sensors [6]. Such innovations represent a shift toward more integrated and seamless systems that blend functionality with the structural integrity of the composite, thereby reducing the need for external systems. One approach involves using braided conductive yarns, such as those made from Kevlar fibers combined with Nitinol fibers, which are integrated into carbon/epoxy prepregs to form multifunctional structures [6]. These embedded sensors can monitor the strain and detect damage within the composite, making them particularly suitable for high-performance aerospace applications where real-time structural health assessment is critical. Another approach is to utilize the conductive nature of the fiber material itself, such as carbon fiber, for damage detection via the piezo-resistance response. This method utilizes the modified four-probe resistivity measurement method to ascertain the piezo-resistance response associated with full-field damage evolution during blast-loading scenarios [15]. These methods not only enhance the durability and resilience of composites but also contribute to the advancement of intelligent materials capable of self-assessment and adaptation in response to environmental changes. Other solutions include modifying the matrix of the composite with conductive elements [16,17].

Despite these advancements, several challenges must be addressed to realize the full potential of multifunctional composites. These include design optimization of the embedded sensors, understanding the composite’s electromechanical performance under various loading conditions, and developing scalable manufacturing processes. The body of work addressing such challenges is steadily growing, as illustrated in Figure 1b. This review aims to provide an overview of fiber-reinforced composite structures with multifunctional capabilities in the context of smart textiles, discussing the current state of the art, outlining key challenges, and addressing future directions in this rapidly evolving field. The review will emphasize fiber-reinforced composite structures that achieved multifunctionality through fiber or fabric alterations rather than systems that achieved multifunctionally by adding external sensors.

2. Multifunctional Composites

2.1. Principles and Interests

Multifunctional composites leverage a variety of materials and integration techniques to achieve enhanced performance capabilities beyond structural integrity. The primary goal in manufacturing these composites is to enhance the base textile materials with additional functionalities such as electrical conductivity, sensing, and self-healing properties, which are then incorporated into a reinforced composite system. Ideally, these functionalities are seamlessly integrated into the overall operation of the composite system. There has been an increased interest in multifunctional systems due to the need to develop new composites and structures that can perform multiple functions [18], as illustrated in Figure 1b.

2.2. Material Modifications and Combinations

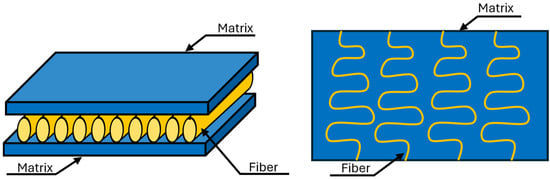

Creating multifunctional composites by modifying textile fabrics to become smart textile fabrics involves integrating diverse combinations of advanced materials and components. This is achieved through several methods, some of which are discussed in subsequent sections. The key components of reinforced composites are the matrix and the reinforcing fibers, as illustrated in Figure 2. The combination of either a fiber or matrix component that adds functionality along with the other corresponding components yields structures with unique electrical and mechanical properties. For most multifunctional systems, one of those components must be conductive for electric-related functions. Conductive fibers, such as carbon fibers, metal-coated polymer yarns, and conductive textiles, play a crucial role in this system. These fibers provide electrical conductivity, enabling functions like damage monitoring and signal transmission. They can be woven or embroidered into textiles to form flexible circuits and sensors, facilitating real-time monitoring and data transmission. Matrix modifications, such as carbon nanotube (CNT) additives, can also be embedded into the polymer matrix to enhance the mechanical strength and electrical conductivity of the embedded fabric or conductor. This integration allows for advanced sensing capabilities, such as detecting the onset and evolution of damage within the composite [19,20]. Other possibilities include a hybrid system, which combines different fiber materials or matrix combinations to enhance or tailor the functionality by leveraging the unique properties of each component. Embedding these materials involves advanced weaving techniques, coating applications, and layered structures, ensuring that the textile maintains its structural integrity while providing multifunctional capabilities [14,16,21].

Figure 2.

Schematic illustration of reinforced composite systems.

2.3. Manufacturing Multifunctional Composites

Multifunctional composites can be manufactured using several composite manufacturing techniques. The first step is to modify the existing textile material with some multifunctional capability. The modification process includes embedding conductive fibers, sensors, and functional coatings into the textile base. These modified textiles can then be transformed into reinforced composite systems through traditional manufacturing techniques or new additive techniques. These methods provide several options to manufacture multifunctional composites that are structurally sound and have advanced functionalities suitable for a wide range of applications. Since different applications require various capabilities, there is no one specific method to manufacture these complex systems. However, the following review outlines different processes currently implemented or could be used to create these multifunctional composites, focusing on modifying textiles (rather than the matrix) and their integration into reinforced composite systems.

2.3.1. Modifying Textiles

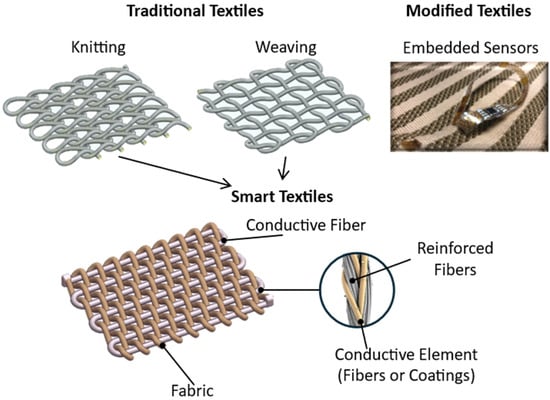

To create multifunctional textiles, the base materials must be modified to incorporate additional functionalities [22]. This modification typically involves integrating conductive fibers, sensors, or other functional elements into the textile structure, as seen in Figure 3. They include, but are not limited to, the techniques mentioned below.

Figure 3.

Smart textiles utilizing different configurations and techniques to achieve multifunctionality.

Integration of Conductive Fibers: Conductive fibers can be woven or embroidered onto the textile base to impart electrical properties, as illustrated in Figure 3. For example, incorporating silver-coated fibers or carbon nanotubes into the weave can provide conductivity, which is essential for applications in signal transmission and power distribution [23]. Conductive threads can also be embroidered into specific patterns to create antennas or sensors for wireless communication or other applications [24].

Embedding Sensors and Actuators: Smart textiles can be embedded with various sensors and actuators to enable environmental sensing, health monitoring, and adaptive responses. These elements can be integrated during the weaving or knitting process, or they can be attached post-production using adhesives or encapsulation techniques [25,26]. For instance, thermocouples can be integrated to monitor temperature, while piezoelectric fibers can be used for vibration sensing.

Applying Functional Coatings: Functional coatings can be applied to textiles to impart properties such as conductivity, self-healing, antimicrobial activity, or UV protection. Coating techniques include dip coating, spray coating, and layer-by-layer deposition. These coatings can be formulated with nanoparticles or other active agents to provide the desired functionalities [27,28].

2.3.2. Traditional Manufacturing

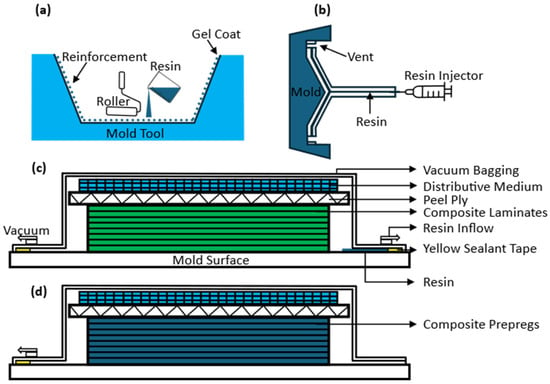

Once the textiles have been modified to include multifunctional capabilities, they can be integrated into composite systems using traditional composite manufacturing techniques. These techniques ensure that the functional textiles contribute to both the structural integrity and the additional functionalities of the composite material. The traditional manufacturing, shown in Figure 4, includes, but is not limited to, the techniques mentioned below.

Figure 4.

Traditional composites manufacturing processes showing (a) hand lay-up, (b) resign transfer molding, (c) vacuum-assisted resin transfer molding, and (d) prepreg lay-up.

Hand Lay-Up: The hand lay-up process involves manually placing layers of modified textiles and impregnating them with a resin matrix, as seen in Figure 4. This technique is versatile and allows for precise placement of functional elements within the composite [29,30]. After placing the textiles, the resin is applied and cured, forming a solid composite structure. This method is suitable for producing large, complex shapes but can be labor-intensive and may result in variable quality.

Resin Transfer Molding (RTM): RTM involves placing the modified textile preforms into a mold and then injecting resin under pressure. This process ensures thorough impregnation of the fibers and can produce high-quality, consistent composites. RTM is well suited for integrating functional textiles as it allows for precise control over the fiber–resin ratio and ensures good bonding between the functional elements and the matrix [31,32].

Vacuum-Assisted Resin Transfer Molding (VARTM): VARTM is a variation of RTM where a vacuum is used to draw the resin into the mold, impregnating the textile preforms. This technique offers advantages in terms of reducing voids and improving the overall quality of the composite [33]. VARTM is particularly effective for producing large, complex structures and is compatible with a wide range of resins and fibers, including those modified for multifunctional capabilities [34].

Prepreg Lay-Up: Prepreg lay-up involves using pre-impregnated textile fibers that already contain a partially cured resin. These prepregs are laid into a mold and then fully cured under heat and pressure. This method provides excellent control over fiber alignment and resin distribution, resulting in high-quality composites with consistent properties. Prepregs can be tailored to include various functional elements, making them ideal for producing multifunctional composites [35], showcasing great potential for cost reduction [36].

2.3.3. Additive Manufacturing and Emerging Capabilities

After the textiles have been modified, additive manufacturing (AM) can also be used to deposit the multifunctional yarns into a structural system. This technique could potentially allow for the manufacturing of a structural system that could not be achieved utilizing traditional manufacturing techniques. Direct and indirect AM methods can produce novel multifunctional structures with unique performance capabilities. While several AM methods and techniques exist, this review will focus on the techniques that integrate continuous fibers, which could be adapted for smart textiles.

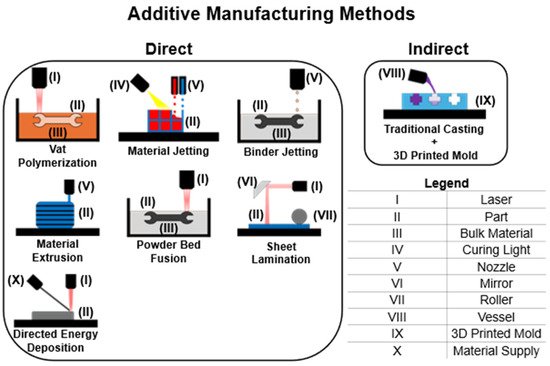

Direct AM methods fall under seven main categories as outlined by the American Society for Testing and Materials [37]. These categories are vat polymerization, material jetting, binder jetting, material extrusion, powder bed fusion, sheet lamination, and directed energy deposition, which are explained briefly in the context of fiber-reinforced composite multifunctional structures and are illustrated in Figure 5.

Figure 5.

Additive manufacturing methods.

Vat Polymerization: Vat polymerization involves using a light source to cure a cavity filled with a liquid photopolymer according to a desired pattern. This technique has been advanced to embed continuous fibers into the polymer matrix during printing. For example, Lu et al. developed the process of continuous fiber-reinforced vat photopolymerization (CONFIB-VAT), which produced tensile specimens with mechanical properties unaffected by printing direction [38]. This method can be enhanced by post-curing, which improves the mechanical properties of the printed specimens. For the transparent resin investigated, a 10% fiber volume content enhanced the ultimate tensile strength of the printed specimens by approximately 431%. The developed method can achieve and exceed the fiber volume content of commercially available materials [39,40]. Moreover, incorporating reinforcing fibers with electrical or data transfer capabilities could significantly expand the functionality of the resulting structures. Vat polymerization allows for fibers to be placed on the resin surface or mixed in with the resin before curing [41]. While mixing allows for smaller-sized fibers, placing fibers on the surface can accommodate larger-sized fibers, which is advantageous for creating unbroken conductive paths.

Material Jetting: The material jetting process involves discharging bulk material as droplets according to a desired pattern. This bulk material, often a photopolymer, is cured via UV lighting. Print direction can influence the structure’s performance [42]. Most studies on material jetted fiber-reinforced composites focus on structural performance enhancements [43]. Reinforcing fibers can be printed or placed, and material jetting is particularly suitable for a multi-material printing approach, enabling the integration of different-sized fibers within a UV-cured polymer matrix.

Binder Jetting: Similar to material jetting, binder jetting discharges a binding material to selectively bind powder build material. Research on binder jetting primarily focuses on the mechanical properties of the reinforcing fibers [44,45]. While nanoparticles and nanofibers have been utilized, incorporating larger-scale reinforcing fibers remains challenging due to fiber placement, mixing, and binder deposition issues.

Material Extrusion: Material extrusion is the most commonly used AM method for fiber-reinforced composites [46]. This technique involves precisely distributing material through a nozzle. Continuous fiber-reinforced material extrusion offers significant potential for integrating smart textile functionalities, such as electrical conductivity and sensing capabilities. The primary mode of material extrusion is fused-deposition modeling (FDM), also known as fused-filament fabrication (FFF). This method allows for the addition of multifunctional properties by utilizing unique fiber filler materials or materials with novel characteristics [47,48,49,50].

For optimal manufacturing using the FFF method, parameters such as the thickness of the deposited layers, extrusion speed, bead width, orientation of fibers, print direction, material volume composition, and printing pattern all have significant effects [51,52]. To achieve a desired manufacturing outcome, printing bulk material, fiber material, and printing parameters must be carefully considered. Additionally, hardware modifications to existing manufacturing systems may be required.

Powder Bed Fusion: Powder bed fusion is a method where thermal energy is used to combine areas of a powder bed according to the desired printing pattern. Of the various powder bed fusion techniques, selective laser sintering is more commonly used [53]. For additive manufacturing, various experimental and numerical works have investigated the effect of the reinforcing fibers on the mechanical properties of fiber-reinforced composites in relation to parameters such as fiber orientation, density, and others [42,54,55]. Multifunctionality, as outlined previously in this work, was not an aspect of the previous works that have been reviewed. However, multifunctional fiber-reinforced composite structures created through powder bed fusion will require fibers that will be relatively undisturbed by the intensity and motion of the energy source during the fusing process. To this end, reinforcing fibers would be required to have high melting points and enhanced resiliency. Additionally, if larger-scale fibers were to be used, the fusion process would need to be adjusted to ensure that the bulk material is properly fused between the fibers.

Sheet Lamination: Sheet lamination involves bonding successive sheets of various materials to create a desired structure. The successive layers of the structure can be bonded using adhesive, thermal, clamping, or ultrasonic means [18]. Due to the high concentration of work in other additive manufacturing spheres, this method could be further investigated. Introductory works would likely focus on the fabrication, the coupling, and the multifunctional performance of the fiber-reinforced layers. Bhatt et al. have presented an extension of the sheet lamination object manufacturing process by using a robotic cell to perform sheet manipulation and handling and making multiple advances [56].

Directed Energy Deposition: Directed energy deposition (DED) involves using a focused energy source to melt the deposited material together. While some work involving DED additive manufacturing has focused on the enhanced mechanical properties of fiber-reinforced materials [57,58], to date, there is no work concerning DED in the context of fiber-reinforced multifunctional structures. This could be due to the high levels of thermal energy typically utilized with the DED technique, which could severely damage or alter the multifunctional fiber material that would be incorporated into a potential system. For successful implementation of this method for fiber-reinforced multifunctional structures, careful attention would have to be paid to minimizing damage during manufacture, ensuring quality bonding between layers made of different materials, and ensuring optimal multifunctional performance.

In addition to these direct methods, indirect AM techniques involve creating a mold or template subsequently used to produce the final composite structure. In essence, they are a combination of traditional manufacturing methods and direct AM methods. These methods can also be adapted to integrate continuous fibers and other smart textile functionalities. Note that Figure 5 only shows a representative process of indirect molding.

2.3.4. Spinning Techniques

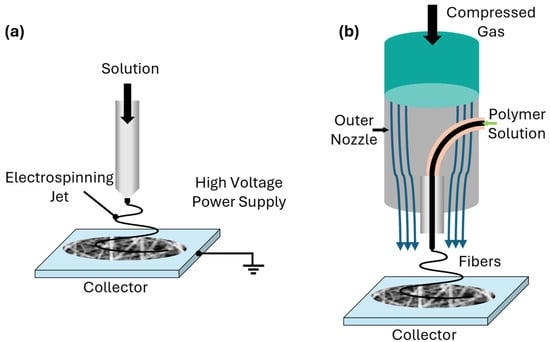

Spinning techniques are a common way of preparing polymeric nanofibers with diameters ranging from a few micrometers to nanometers. With the increased interest and advances in nanoscience and nanotechnology, advances in micro- and nanocarbon structures have received significant attention. At the current stage, researchers have focused on the fabrication of polymer nanocomposites by incorporating carbon nanotubes, which has shown a considerable increase in physical properties such as Young’s modulus, tensile strength, and conductively [59,60]. These nanocomposites can be fabricated using several techniques, electrospinning and solution blow spinning being the most commonly used techniques. The electrospinning technique provides versatility during the manufacturing process and consists of five components: a high-voltage power supply, a polymer solution, a mouth feed to feed the solution, an electrically conductive blunted needle, and a grounded collector, as illustrated in Figure 6a [60,61].

Figure 6.

Spinning techniques. (a) Electrospinning and (b) solution blow technique.

Similarly, the solution blow technique consists of a concentric nozzle with two channels for the gas steam and polymer solution, a compressed gas source, and a collector. The pressure drops around the nozzle tip due to the increased air velocity in the outer nozzle, shaping the solution into a structure that is deposited at the collector, as illustrated in Figure 6b [62,63].

3. Capabilities and Applications

3.1. Structural Health Monitoring (SHM)

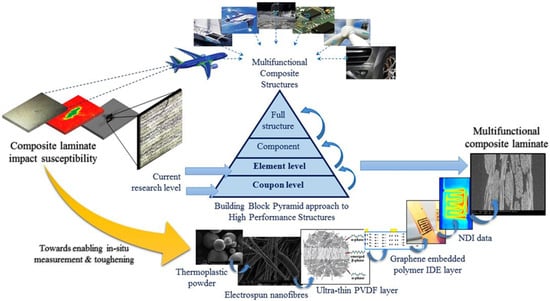

Multifunctional composites have significant potential for enhancing structural health monitoring (SHM). Incorporating sensors, conductive elements, and other smart features into the fabric or matrix of the composite, real-time monitoring and response to external stimuli can be obtained, as suggested in Figure 7 [64]. The primary advantage of multifunctional composites in SHM is their ability to detect damage, such as cracks or delamination, and monitor the overall health of the structure without the need for external sensors [7].

Figure 7.

Multilevel use case of multifunctional structures and their capabilities for health monitoring, reproduced with permission from [64].

Recent studies have focused on embedding conductive yarns within the composite matrix to create a multifunctional system capable of structural reinforcement and real-time monitoring. For example, by braiding Kevlar fibers with Nitinol fibers and integrating them into a carbon/epoxy prepreg, researchers have developed composites that can monitor strain and detect damage through changes in electrical resistance [6]. These integrated sensors are capable of capturing displacements, velocities, and strains, which adds to the reliability of SHM systems [1,2].

Additionally, fiber-optic sensors have been embedded in composites for SHM applications. Refs. [65,66] demonstrated surface-mounted optical fiber strain sensors for monitoring aerospace-grade composite structures. These sensors, evaluated against in-flight conditions, provided valuable data on structural health [8]. The integration of piezoresistive materials into composites allows for monitoring dynamic loading conditions, such as those experienced during shock or blast events. These materials change their electrical resistance in response to mechanical strain, directly measuring the deformation and damage within the composite [15]. By integrating these functionalities, multifunctional composites can offer real-time data on the material’s structural integrity, enabling proactive maintenance and enhancing the safety and performance of the structure. Much work is being performed with SHM alone, and all the intricacies and innovations in this topic merit their review. This manuscript focuses on its general use, emphasizing modifications to the composite fabric.

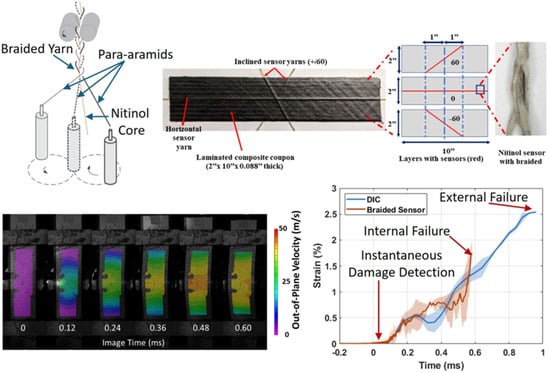

Failure detection is critical to structural health monitoring, particularly in high-performance applications where early damage detection can prevent catastrophic failures. Multifunctional composites with embedded sensors offer a robust solution for real-time failure detection, providing valuable data on the onset and progression of damage within the material. One effective approach to failure detection involves using embedded conductive yarns that serve as strain-sensitive elements. In a study by Chaudhary et al., Kevlar-Nitinol braided yarns were embedded within carbon/epoxy composites and subjected to Mach 2 air blast loads using a shock tube apparatus. The embedded sensors recorded electrical performance changes, while the Digital Image Correlation (DIC) technique captured full-field displacements, velocities, and strains [6]. The results revealed that the laminated composite experienced through-thickness failure at approximately 2.5% strain, which was visually observable, as seen in Figure 8. However, the embedded sensors detected out-of-range electrical measurements at around 1.5% strain, indicating the presence of interlaminar damage before visible structural damage occurred [6]. This demonstrates the embedded sensors’ ability to detect delamination-type failures, highlighting their advantages over conventional external sensors [7,67].

Figure 8.

Multifunctional composite system with embedded conductive yarns for shock load monitoring and damage detection.

Furthermore, piezoresistive materials in hybrid composite lay-ups have shown promise in failure detection under dynamic loading conditions. Lincon et al. investigated the damage mechanisms and piezo-resistance response of intralaminar glass/carbon hybrid composites under blast-loading conditions [15]. The study found that the piezoresistive response of the composite provided valuable information on the extent and location of damage, enabling accurate detection of failure modes such as delamination and fiber breakage [15]. These embedded sensors and piezoresistive elements offer significant improvements in SHM by providing early warnings of structural failure, thus preventing more severe damage [6,11,68].

These studies illustrate the effectiveness of multifunctional composites in failure detection. They leverage the capabilities of embedded sensors and smart materials to provide real-time, accurate data on structural integrity. By integrating these advanced monitoring systems, multifunctional composites can enhance high-performance structures’ safety, reliability, and longevity, making them a valuable tool in modern engineering applications [8,9].

3.2. Power Conduction

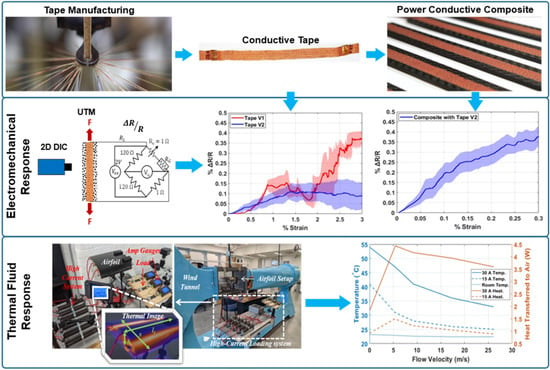

Multifunctional composites have demonstrated significant potential in power conduction applications. These materials can perform structural reinforcement and electrical conduction by embedding conductive elements within the composite matrix. One approach to integrating power conduction capabilities in composites involves embedding conductive elements within the composite matrix. Chaudhary et al. developed conductive tapes by braiding copper strands with Para-aramid fibers and incorporating them into carbon/epoxy prepregs. This configuration allows the composite to maintain structural integrity while providing a conductive path for electrical power transmission. The conductive tapes were integrated into the composite matrix and subjected to tensile loading conditions to evaluate their electromechanical performance [13].

During experimentation, the conductive tapes were incorporated within an electrical bridge to record their resistance change as a function of mechanical strain. The DIC technique was used to obtain in-plane displacements and strains as a function of time. Additionally, low-speed flight condition experiments were conducted with an airfoil-shaped composite system in a wind tunnel to study the temperature performance of these structures under high currents, as seen in Figure 9. Computational models were also created to expand the experimental efforts and evaluate the system’s multiscale performance [13].

Figure 9.

Power conduction and high-current transmission capabilities of multifunctional carbon/epoxy composites. Note: The arrow represents the transition either to manufacturing procedures or corresponding performance.

The study found that the mechanical load on the conductive tape is mainly carried by the Para-aramid yarns, leading to a relatively consistent electrical performance. The experimental results showed that the conductive tapes maintained their electrical response until structural failure, indicating that the electrical performance is stable under mechanical strain [13]. This is particularly important for applications where maintaining electrical connectivity under mechanical loads is critical, such as in the aerospace and automotive industries [18].

Furthermore, integrating power transmission capabilities into composite structures can significantly reduce the system’s operational space and weight. Combining structural and electrical functions within a single material minimizes the need for additional wiring and components, leading to a more efficient and compact design. This approach also enhances the overall system reliability and reduces the complexity of the installation and maintenance processes [69].

In addition to structural and electrical performance, thermal management is a crucial aspect of multifunctional composites used for power transmission. High-current applications can generate significant heat, which needs to be efficiently dissipated to maintain the integrity and performance of the composite. The study by Chaudhary et al. conducted wind tunnel experiments to evaluate the cooling effects on the conductive tapes embedded in an airfoil composite shell. The experiments demonstrated that surface temperature decreases with an increase in airflow, indicating effective cooling of high-current conductors placed on the external skin of the composites [13].

The heat transfer analysis revealed that the system cools more efficiently at higher airflow velocities, which is beneficial for applications such as aerospace, where airflow can be utilized to manage thermal loads. This thermal management capability allows for optimizing the wiring and structural systems, leading to lighter and smaller designs that do not compromise performance [70].

Integrating power transmission capabilities into multifunctional composites offers a promising solution for advanced engineering applications, combining structural reinforcement, electrical connectivity, and efficient thermal management within a single material. This approach not only enhances the performance and reliability of the system but also contributes to cost and weight reduction, making it an attractive option for industries such as aerospace, automotive, and portable electronics.

3.3. Power Transfer and Wireless Communications

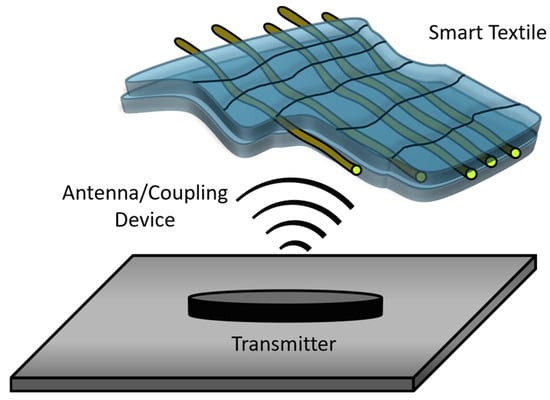

Multifunctional composites and smart textiles hold significant potential for signal transmission and wireless communications applications, such as charging (power transfer) and antennas. This concept is depicted in Figure 10. Significant progress has been made in recent years in integrating these functionalities into smart textiles, though it is still a relatively new and expanding research field. There is still very little work on integrating these capabilities into a reinforced composite system and studying the effects of this system with a matrix component.

Figure 10.

A schematic representation of power transfer and wireless communication utilizing multifunctional composites and smart textiles.

3.3.1. Power Transfer and Wireless Charging

Power transfer via inductive coupling is a promising approach for integrating wireless charging capabilities into smart textiles. By embedding inductive coils into textile materials, it is possible to transfer power wirelessly to embedded sensors and devices. [71] demonstrated the feasibility of using textile-based NFC antennas for wireless power transfer. This method allows for the creation of smart garments that can be powered by nearby smartphones, eliminating the need for bulky batteries and enhancing the wearability of textiles [71].

In addition to inductive coupling, smart textiles can incorporate continuous conductive paths to facilitate power distribution across the material. This approach involves embedding conductive threads or fibers within the textile, creating a network that can distribute power to various integrated devices. Such designs significantly enhance the functionality of wearable electronics by providing a reliable power source throughout the garment. These conductive paths ensure power can be delivered consistently and efficiently to all embedded components, further improving the overall performance and usability of smart textiles.

3.3.2. Wireless Data Transmission

Antennas are a key application of smart textiles in wireless communications. Integrating conductive fibers into textiles makes it possible to create flexible, lightweight antennas suitable for on-body and off-body communication. For instance, Gorgutsa et al. discussed the emissive properties of wearable textiles made from multi-material fibers for network applications at 2.4 GHz. These textiles incorporated polymer–glass–metal fiber composites into traditional weaving processes, producing garments that could communicate wirelessly while maintaining their mechanical and aesthetic properties. The study demonstrated that these textiles provided good radio-frequency (RF) emissive properties, making them suitable for short-range wireless communications [72].

Other applications, such as near-field communication (NFC) technology, are another area in which smart textiles can excel. Garnier et al. discussed textile NFC antennas for power and data transmission across clothes [71]. These antennas, made by embroidering conductive threads into geometric shapes, successfully transmitted power and data without traditional electronic components. In addition, other applications include integrating multi-material fibers into textiles to address challenges associated with traditional planar electronics. For example, Gorgutsa et al. discussed fiber-based RF antennas embedded in textiles [72]. These antennas, designed for 2.4 GHz wireless communication, were made from hollow-core silica fibers coated with silver. The resulting textiles exhibited robust RF properties, were suitable for both on-body and off-body applications, and could be integrated into garments using standard weaving processes.

3.4. Power Storage

Multifunctional composites have garnered significant interest in energy storage applications. These materials combine traditional composites’ mechanical strength and stiffness with energy storage capabilities, making them ideal for various high-performance applications, including electric vehicles, aerospace, and portable electronics [73]. Several works in this area have been published, and many different approaches have been taken to incorporate power storage into composites. Some of the key approaches found in the literature are briefly described below.

3.4.1. Embedded Systems

Embedded energy storage systems incorporate energy-storing materials directly into the composite structure, as illustrated in Figure 11. For instance, batteries and supercapacitors can be embedded into fiber-reinforced polymers to create structural energy storage composites. This method leverages the mechanical properties of the composite material while integrating energy storage capabilities without significantly affecting structural integrity [31]. Recent advancements have focused on optimizing the dispersion and alignment of energy storage materials within the composite matrix to enhance mechanical and electrical performance.

Figure 11.

A schematic representation of a multifunctional structure capable of energy harvesting using thermoelectric, piezoelectric, photovoltaic, and energy storage elements.

3.4.2. Structural Supercapacitors

Structural supercapacitors are designed to perform dual functions: mechanical support and energy storage [73,74]. They typically consist of carbon fibers that act as electrodes and a solid polymer electrolyte that serves as the dielectric. These supercapacitors are advantageous due to their high-power density, long cycle life, and the ability to charge and discharge rapidly. They also eliminate the need for additional components like current collectors, reducing overall weight and complexity [75]. Advances in material science have led to the development of flexible and stretchable supercapacitors, expanding their application range to include wearable electronics and portable devices.

3.4.3. Laminated Structural Batteries

Though not the focus of this review, multifunctional composites with power storage capabilities can also be made using laminated structural batteries by incorporating thin-film batteries within the composite laminate layers [76]. This design ensures that the energy storage components contribute to the structural integrity of the composite. Such batteries can maintain functionality under mechanical stress, making them suitable for applications with critical energy storage and structural performance [31]. Innovations in this area have focused on improving the interfacial bonding between the battery components and the composite layers to enhance mechanical robustness and electrical conductivity.

3.4.4. Multifunctional Energy Storage Devices

These devices combine energy storage with other functionalities, such as sensing and actuation. For instance, carbon nanotubes and graphene can be integrated into the composite matrix to enhance mechanical and electrical properties, enabling the composite to store energy and simultaneously provide structural support [77]. Current research is exploring the use of hybrid nanomaterials and advanced manufacturing techniques further to improve the multifunctionality and performance of these composites.

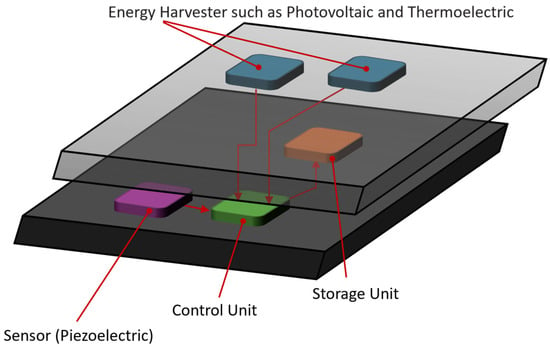

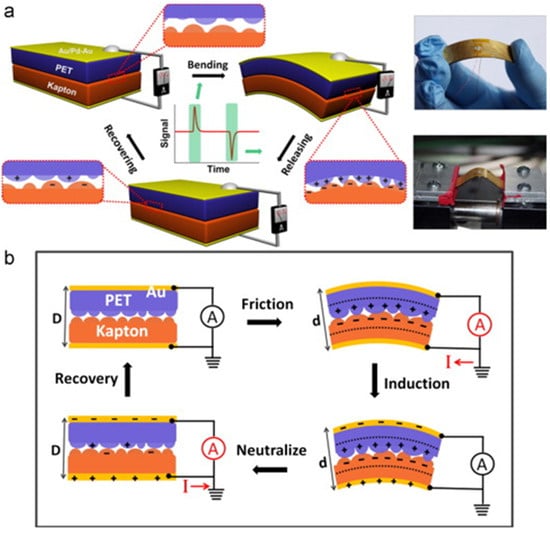

3.5. Energy Harvesting

Multifunctional composites are gaining significant attention for their potential to integrate energy-harvesting capabilities. These advanced materials incorporate energy-harvesting elements within the composite matrix, as illustrated in Figure 12. The incorporation of these elements enables the conversion of ambient energy sources into usable electrical energy while maintaining their primary mechanical properties [65].

Figure 12.

Schematic illustration of the structure and working principle of the triboelectric generator (a) with the structure of an integrated generator in bending and releasing process and (b) proposed mechanism of the triboelectric generator, reproduced with permission from [78].

One approach to integrating energy harvesting involves embedding piezoelectric materials within the composite structure [78]. Piezoelectric materials generate electrical charge in response to mechanical strain, making them ideal for harvesting energy from vibrations, stresses, and deformations. In a study by Jagath Narayana et al., piezoelectric fibers were embedded within carbon/epoxy composites to develop a system capable of energy harvesting under dynamic loading conditions. This setup allows the composite to harvest energy from mechanical deformations, which can be used to power sensors or other electronic components integrated within the structure [79].

Another approach involves triboelectric nanogenerators (TENGs), which can convert mechanical energy from vibrations and movements into electrical energy. Zhu et al. demonstrated using TENG technology embedded in composite materials to harvest energy from environmental vibrations. This method involves layering materials with different triboelectric properties, which generate an electric charge when brought into contact and then separated. The harvested energy can be stored in integrated capacitors or used directly to power low-energy devices [80].

Furthermore, incorporating thermoelectric materials into composite structures can enable thermal energy harvesting. These materials convert temperature gradients into electrical energy, making them suitable for applications where temperature differences are prevalent. Studies have shown that embedding thermoelectric materials within composites can effectively utilize waste heat from industrial processes or ambient temperature variations to generate power [81]. Other work has also shown that textiles with embedded photovoltaic elements can harvest energy from sunlight, providing a sustainable power source for wearable electronics [82].

Integrating microchannels within the composite structure also presents a novel method for energy harvesting. Saeed et al. designed microchannels within laminated composite structures to transport fluids that can be used for cooling and energy generation. The fluid flow through these channels can drive micro-turbines or other energy conversion devices, providing a versatile approach to harvesting energy from fluid dynamics [83]. There is a significant opportunity for further exploration and development in this area, especially in optimizing the integration of energy-harvesting elements and improving the efficiency and scalability of these systems.

3.6. Data Transfer

Multifunctional composites’ potential for data transmission applications is relatively unexplored compared to other applications like SHM. Incorporating conductive yarns into textile fabrics for data transmission offers several advantages. These materials can replace traditional wires and circuit boards, leading to more flexible, durable, and lightweight systems. This integration allows for the development of smart textiles that can seamlessly blend into everyday items, enhancing their functionality and connectivity [84,85]. This functionality is often overlooked due to its relative simplicity compared to other functionalities, but the coupled electromechanical response can alter the electrical response of a smart textile, especially if embedded into a matrix composite [14]. Currently, the work performed in this area for reinforced composites is limited.

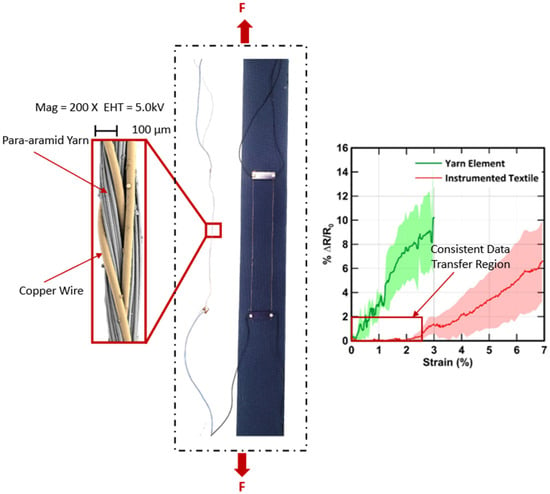

For smart textiles, a precursor of multifunctional reinforced composites, one approach to integrating data transmission involves embedding conductive yarns within the textile matrix. Chaudhary et al. investigated the electromechanical performance of textile fabrics with conductive yarn elements specifically for data transfer capabilities. The study focused on evaluating the electromechanical response of copper yarn elements stitched axially to the textile fabric while assessing the mechanical response of the system during tensile tests under axial loading, as seen in Figure 13. The results highlight that the electrical performance will be influenced by mechanical loads. Also, the influence of mechanical loads can be optimized by optimizing braiding or stitching patterns for the specific system under consideration [14].

Figure 13.

Recent work on smart textiles showcasing the electromechanical performance of textile fabrics with conductive yarn elements for data transfer capabilities [14].

3.7. Additional Multifunctionalities

Multifunctional composites and smart textiles offer a range of advanced capabilities that extend beyond the applications already discussed. These additional functionalities significantly enhance the performance and utility of composite systems across various domains. While the following capabilities are briefly described, it is important to note that the functionalities achievable with smart textiles are not confined to those mentioned here. This is a rapidly evolving research field, and the focus of this manuscript aligns with the authors’ specific areas of expertise. Consequently, the capabilities outlined below are succinctly covered and warrant further investigation by the reader to appreciate their potential and applications.

Adaptive Functions: Composites that can change their properties in response to external stimuli, enhancing their functionality in various applications. These materials can respond to environmental changes, mechanical stress, or other external factors.

Shape Memory Alloys (SMAs): SMAs can recover their original shape after deformation when exposed to a specific temperature. This property makes them useful in adaptive structures that require shape reconfiguration or actuation capabilities [86].

Electroactive Polymers (EAPs): EAPs can change shape or size when subjected to an electric field, making them suitable for applications such as actuators, sensors, and artificial muscles [87].

Environmental Sensing: Smart textiles and composites can integrate sensors to monitor environmental conditions, providing valuable data for various applications, including healthcare, environmental monitoring, and structural health.

Textile-Based Sensors: Fabrics can incorporate sensors to detect physiological signals such as heart rate, temperature, and movement. For example, fabrics with embedded thermocouples can measure temperature, while carbon electrodes can detect specific environmental features like oxygen and moisture [82].

Biosensors: Smart textiles can integrate biosensors to monitor health parameters such as glucose levels, pH, and pathogens. These sensors provide real-time data, enabling timely medical interventions [25].

Cloaking and Thermal Regulation: Cloaking materials can manipulate electromagnetic waves to render objects invisible or reduce their visibility. Thermal regulation involves managing heat transfer to maintain a comfortable temperature.

Metamaterials for Cloaking: Metamaterials can be engineered to control electromagnetic waves, effectively hiding objects from detection by bending light around them [88].

Thermal Regulation Textiles: Textiles with integrated thermoelectric materials can provide active heating or cooling, enhancing comfort and reducing energy consumption. These materials can adjust their thermal properties in response to environmental changes, maintaining an optimal temperature for the wearer [77].

EMI Shielding: Incorporating conductive materials such as graphene or metal fibers into textiles can provide EMI shielding, protecting electronic devices from electromagnetic interference [89].

Antimicrobial Properties: Smart textiles can integrate antimicrobial agents to prevent bacterial growth, making them suitable for healthcare and hygiene applications. For example, textiles coated with silver nanoparticles or other antimicrobial substances can inhibit bacterial growth and reduce the risk of infections [25].

Self-Healing: Self-healing composites are designed to recover autonomously from damage, significantly enhancing their durability and reliability. These materials can repair micro-cracks and other forms of damage through intrinsic or extrinsic mechanisms. There are different approaches to self-healing, such as capsule-based self-healing [90], vascular self-healing [91], and intrinsic self-healing [27]. Some of these approaches focus on additives or modifying a composite’s matrix to achieve self-healing, but intrinsic healing looks at the material’s capabilities for healing.

4. Design Challenges

Designing and modeling multifunctional composite systems present challenges that span material selection, fabrication techniques, and performance optimization. The complexity arises from integrating diverse functionalities and structural integrity into a single material system. Below is an overview of the key challenges identified in the reviewed manuscripts.

4.1. Material Compatibility and Integration

Selecting materials that can seamlessly integrate various functionalities without compromising the primary structural properties is a significant challenge. For example, integrating conductive fibers into textiles requires careful consideration of their mechanical properties and compatibility with the base material. The challenge lies in maintaining the integrity and functionality of the composite system under operational stresses and environmental conditions [71,72]. After material selection, embedding sensors, actuators, and other functional elements into textiles can be problematic due to the physical inhomogeneity of textile materials. The integration process must ensure that these elements do not adversely affect the flexibility, durability, and aesthetic properties of the textiles. Techniques such as embroidery and coating must be optimized to balance functionality and textile properties [72].

4.2. Challenges with Fabrication Techniques

Traditional textile fabrication methods, such as weaving and knitting, must be adapted to incorporate functional materials without compromising the structural and functional integrity of the final product. One of the main challenges is developing processes that can efficiently integrate conductive fibers and sensors into the textile matrix. The proximity of these functional elements within the textile structure can lead to issues such as short circuits and signal interference, which must be addressed through innovative fabrication techniques [92]. If multifunctionality is achieved through applications such as coatings or embroidering conductive threads onto textiles, additional steps in the manufacturing process can be introduced that can affect scalability and cost-effectiveness. Ensuring uniformity and reliability of the coatings or embroidered elements is crucial for maintaining the desired functionalities. The challenge is developing methods that consistently produce high-quality multifunctional textiles at scale [93].

4.3. Performance Optimization and Testing

Achieving the desired electrical performance, such as conductivity and signal transmission, while maintaining mechanical strength and flexibility is a critical challenge. The embedded functional elements must not degrade the textile’s structural properties. For instance, past work shows that the electrical performance of wearable antennas can be affected by bending and stretching [71,94]. In addition, these systems must perform reliably under various environmental conditions, including exposure to moisture, temperature fluctuations, mechanical stresses, and fatigue. Ensuring that the functional elements, such as conductive fibers and sensors, remain operational under these conditions requires extensive testing and optimization. This involves developing protective coatings and encapsulation techniques to safeguard the functional elements without compromising performance [72].

4.4. Modeling and Simulation

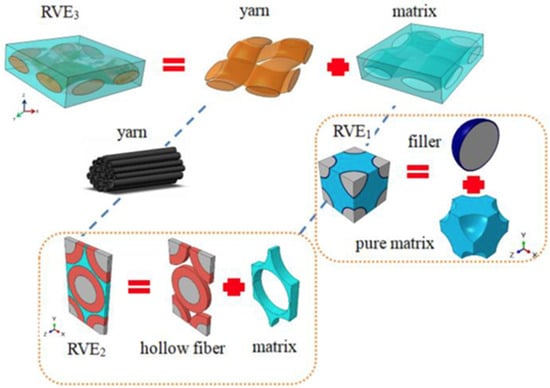

Modeling the behavior of multifunctional composites under different conditions is complex due to the interaction between various integrated functionalities. Simulation tools must account for the composite material’s electrical, thermal, and mechanical interactions. This requires advanced modeling techniques to accurately predict performance and guide the design process [72]. Smart hierarchical textile composites with wavy yarn structures exhibit heterogeneous microstructures requiring computational homogenization across various scales to predict properties from stiffness to conductivity. Analytical methods, while efficient, often oversimplify heterogeneity, leading to unreliable predictions under complex conditions. In contrast, computational techniques provide precise representations but are resource-intensive [95,96,97]. Multiscale computational homogenization, linking heterogeneous unit cells to each Gauss point within the virtual macro-homogeneous structure, captures physical and geometric transformations at each scale, culminating in a homogenized constitutive relationship at the macroscopic level [98]. Overall, numerical methods provide unique, high-fidelity models that capture the geometry, the underlying structure at multiple scales, and the multiphysics behavior of multifunctional fiber-reinforced composite textiles.

4.4.1. Developing Geometries for Simulation

Fiber stacking sequence and configuration are crucial in textile composites, significantly influencing their mechanical properties and overall performance. Typically, fibers in these composites are woven or knitted into complex interlacing patterns, optimizing tensile and flexural strength. The stacking sequence, particularly how layers are arranged and bonded, affects the composite’s response to multi-directional loads, enhancing interlaminar shear strength and improving impact resistance [99].

Finite element analysis (FEA) simulations predict composite performance under various conditions, ensuring reliability and effectiveness. Tailoring fiber orientation and sequence to specific applications provides unique properties like anisotropy or isotropy in material behavior. Including voids and interfacial debonding at the sub-microscale level in simulations enhances the reliability of multifunctional composites’ global electromechanical and thermal properties. This planning and simulation enable superior durability and efficiency [99,100].

4.4.2. Textile Multiscale Modeling Techniques

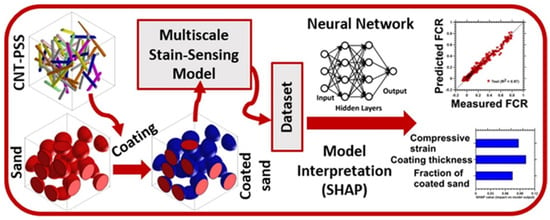

Integrating multiscale modeling in textile-reinforced multifunctional composites is a key step in the design process. At the nanoscale, FEA modeling focuses on the fundamental properties of the fibers and the matrix, including their interaction. This scale examines the structural integrity of individual fibers, the bonding strength between fibers and the matrix, and the influence of nanoscale additives like nanoparticles or nanotubes. As the scale shifts from nano to micro, the focus includes the architecture of the textiles—how fibers are interwoven, the density of the weave, and fiber orientation—all significantly affecting the material’s mechanical properties and behavior under stress [101]; both of these scales are illustrated in Figure 14. At the macro scale, modeling incorporates large-scale structural considerations, such as the overall design of a composite component and its behavior under various conditions. Multiscale studies using FEA to evaluate the multiphysics properties of multifunctional textile-integrated composites are limited due to modeling complexities and computational demands.

Figure 14.

Nano- and microscales in a progressive modeling framework of woven composites, reproduced with permission from [101].

A recent study by Nayak and Das developed a hierarchical twill-weave composite with carbon nanotubes (CNTs) in a polystyrene (PSS) matrix, enhancing strain-sensing capabilities through multiscale numerical simulations. This study effectively linked strain-induced variations in the electrical properties of the composite to its structural changes, highlighting the role of CNT dispersion and orientation. The study demonstrated excellent agreement with experimental observations, underscoring the advanced capabilities of multiscale FEA in smart textile development and setting a benchmark for future research in integrating nanotechnology with textile composites [102].

4.4.3. Integrating Multiphysics Responses

It is also critical to consider the multiphysics response of the smart textile, such as its electromechanical or electromagnetic properties for multifunctional composites that have such responses. L. Alonso-González et al. established a three-step modeling technique for electromagnetic analysis tailored to woven structures. This method enhances the design of smart textiles functioning as antennas and wearable microwave circuits by examining their conductive and dielectric properties. The method involves analyzing threads, transforming multifilament threads into monofilaments, and using homogeneous materials for the simplest yet effective representation of electromagnetic pathways [103].

Commonly used software such as 3Dweave and TextGen facilitates the simulation of multifilament smart textile prototypes but does not simulate electromechanical and electromagnetic properties. Specialized software like Ansys HFSS and CST Studio Suite adeptly analyzes these properties. Comprehensive simulations of fiber-reinforced composites can be conducted using advanced software, such as COMSOL, ABAQUS, and Altair HyperWorks Suite, amongst others, supporting a broader range of simulation capabilities.

4.4.4. Application of Deep Neural Networks for Design Optimization

When multiscale FEA becomes computationally intensive, deep neural networks (DNN) can also be adapted into a cost-effective alternative for predictive modeling and simulation, optimizing composites’ multifunctional capabilities, as illustrated by Figure 15 [104]. DNNs excel with large datasets and intricate models, where traditional FEA may be prohibitive. These networks, trained using datasets from FEA studies, capture nuanced data relationships that are not apparent through conventional methods. DNNs’ predictive power relies on high-quality training data and precise ground truth measurements, ensuring accurate and generalizable learned patterns. They integrate various data types, predicting complex material responses under varied conditions. For example, DNNs can predict the mechanical properties of new composite materials or failure modes under stress scenarios. Continuous improvement in prediction accuracy is enabled by DNNs’ adaptability to new data.

Figure 15.

A multiscale optimization scheme using neural networks, reproduced with permission from [104].

A study by Xin Liu et al. demonstrated the use of multiscale modeling coupled with DNNs to optimize the design of woven composites [105]. This study employed the mechanics of structure genome (MSG) to predict effective material properties, training DNN models for efficient surrogate models with high accuracy. This integration of MSG and DNNs represents a significant advance in predictive modeling and design optimization of textile composites, overcoming traditional computational bottlenecks [105]. As fiber-reinforced textile composites evolve, integrating advanced multiscale modeling and simulation techniques is essential. Future developments should enhance simulation accuracy with detailed microstructural features and leverage deep neural networks for efficient predictive modeling, improving composites’ performance and reliability under operational stresses. This approach will expand their application in innovative industries such as aerospace, automotive, and smart textiles, driving advancements in composite materials technology to meet future engineering challenges.

5. Future Directions

The multifunctional composites and smart textiles field is rapidly evolving, with numerous opportunities for further research and development. Outlined below are some areas of high potential where future research can make a deep and lasting impact:

Enhanced Durability and Reliability: Future research should aim to improve the durability and reliability of multifunctional composites under various environmental conditions. This includes developing materials that withstand extreme temperatures, humidity, and mechanical stresses. Advances in protective coatings and encapsulation techniques will be crucial to ensuring the long-term performance of these materials [72].

Scalability and Manufacturing Techniques: Scaling up the production of multifunctional composites and smart textiles while maintaining high quality and consistency is a significant challenge. Research should focus on developing efficient manufacturing techniques that can be easily adapted for large-scale production. This includes exploring novel fabrication methods, such as advanced weaving and knitting techniques, as well as automated processes that can integrate functional elements seamlessly into textiles [41,106].

Advanced Sensing and Actuation: Expanding the range of sensing and actuation capabilities integrated into smart textiles will open up new applications. Research should explore using novel materials like graphene and other nanomaterials to develop highly sensitive and responsive sensors. Integrating more sophisticated actuators can also enable advanced functionalities, such as adaptive responses to environmental changes [25].

Energy Efficiency and Storage: Improving the energy efficiency of smart textiles and developing advanced energy storage solutions are critical for enhancing their practicality. Research should focus on lightweight, high-capacity batteries and energy-harvesting technologies supporting autonomous smart textile systems. This includes integrating photovoltaic elements and piezoelectric materials into textiles to harness energy from sunlight and mechanical movements [82].

Interoperability and Integration: Ensuring that multifunctional composites and smart textiles can seamlessly integrate with existing technologies and systems is essential for widespread adoption. Future research should explore the development of standardized interfaces and protocols that enable interoperability between smart textiles and other electronic devices. This will facilitate the integration of these materials into various applications, from healthcare to consumer electronics [71].

Sustainability and Environmental Impact: As the demand for multifunctional composites and smart textiles grows, it is important to consider their environmental impact. Future research should focus on developing sustainable materials and manufacturing processes that minimize waste and reduce the carbon footprint of production. This includes exploring biodegradable materials and recycling techniques to recover valuable components from end-of-life products [25].

Data Security and Privacy: As smart textiles become more integrated into daily life, ensuring the security and privacy of the data they collect will be paramount. Future research should explore encryption techniques, secure data transmission protocols, and privacy-preserving methods to protect user information [107].

Advanced Human–Machine Interfaces (HMIs): Future research could explore the development of smart textiles that facilitate more intuitive and efficient HMIs. This includes the integration of touch-sensitive or gesture-responsive fibers, enabling seamless interaction with electronic devices and systems. Such advancements could revolutionize wearable technology, providing new ways for users to control and interact with their gadgets [108,109].

6. Concluding Remarks

Multifunctional composites and smart textiles represent a significant advancement in material science. Despite the promising developments, several challenges remain. The durability and reliability of these materials under diverse environmental conditions are critical for their widespread adoption. Future research must focus on enhancing the robustness of multifunctional composites to ensure they can withstand extreme temperatures, humidity, and mechanical stresses.

Furthermore, the scalability of manufacturing processes to produce high-quality, consistent, multifunctional composites at large volumes remains a significant hurdle. Developing efficient, automated manufacturing techniques seamlessly integrating functional elements into textiles will be essential for commercial success [72,106]. Furthermore, ensuring interoperability and integration with existing technologies is vital for the practical application of multifunctional composites. Standardized interfaces and protocols will facilitate the seamless integration of smart textiles with other electronic devices, expanding their usability [71].

Overall, the future of multifunctional composites and smart textiles is promising, with the potential to significantly enhance the performance and utility of systems across multiple industries. Ongoing research and development efforts are expected to address current challenges, paving the way for these advanced materials’ widespread adoption and commercialization. As this field continues to evolve, integrating multifunctional capabilities into composites will likely lead to unprecedented advancements in material science and engineering, driving innovation and improving quality of life globally.

Author Contributions

Conceptualization, B.C. and H.M.; Methodology, B.C., T.W. and H.M.; Software, B.C.; Validation, B.C., T.W., B.O., S.D. and H.M.; Formal analysis, B.C. and H.M.; Investigation, B.C., T.W. and H.M.; Writing – original draft preparation, B.C., T.W., B.O. and H.M.; writing—review and editing, B.C., T.W., B.O., S.D. and H.M.; Visualization, B.C., T.W. and H.M.; project administration, B.C.; Funding acquisition, H.M. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully acknowledge the financial support provided by 401 Tech Bridge from Rhode Island, USA. Their generous funding for several past and current projects has significantly contributed to the accumulation of knowledge and expertise that has enabled the creation of this review article.

Data Availability Statement

No new data were generated or analyzed during this review. Instead, this manuscript compiles information from existing data from previously published studies to present a new discussion. All original data and detailed methodologies can be found in the works cited within this review. Readers interested in the primary data sources are encouraged to consult the referenced articles for further information.

Acknowledgments

The authors would like to acknowledge industry partners who have worked with us in the past during our efforts to study this topic; we thank Jim Owens from Nautilus Defense specifically for being a supportive partner on several previous and current projects. Without the unwavering support from our partners and sponsors, the insights presented here would not have been possible.

Conflicts of Interest

The authors declare no conflicts of interest relevant to this manuscript. This includes any financial, personal, or professional affiliations or relationships that could be perceived to influence the research, analysis, or conclusions presented in this review. The authors have conducted this study objectively, and the interpretations and conclusions are solely based on the evidence and information from the cited works.

References

- Barbero, E.J. Introduction to Composite Materials Design, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- Adumitroaie, A.; Barbero, E.J. Stiffness and Strength Prediction for Plain Weave Textile Reinforced Composites. Mech. Adv. Mater. Struct. 2012, 19, 169–183. [Google Scholar] [CrossRef]

- Matos, H.; Ngwa, A.N.; Chaudhary, B.; Shukla, A. Review of Implosion Design Considerations for Underwater Composite Pressure Vessels. J. Mar. Sci. Eng. 2024, 12, 1468. [Google Scholar] [CrossRef]

- Berthelot, J.-M.; Ling, F.F. Composite Materials: Mechanical Behavior and Structural Analysis; Springer: Berlin/Heidelberg, Germany, 1999; Volume 435. [Google Scholar]

- Barnett, D.M.; Rawal, S.; Rummel, K. Multifunctional Structures for Advanced Spacecraft. J. Spacecr. Rocket. 2001, 38, 226–230. [Google Scholar] [CrossRef]

- Chaudhary, B.; Matos, H.; Das, S.; Owens, J. Multifunctional composite structures with embedded conductive yarns for shock load monitoring and failure detection. Smart Mater. Struct. 2024, 33, 037001. [Google Scholar] [CrossRef]

- Güemes, A.; Fernandez-Lopez, A.; Pozo, A.R.; Sierra-Pérez, J. Structural Health Monitoring for Advanced Composite Structures: A Review. J. Compos. Sci. 2020, 4, 13. [Google Scholar] [CrossRef]

- Güemes, A.; Fernández-López, A.; Díaz-Maroto, P.F.; Lozano, A.; Sierra-Perez, J. Structural Health Monitoring in Composite Structures by Fiber-Optic Sensors. Sensors 2018, 18, 1094. [Google Scholar] [CrossRef]

- Alokita, S.; Rahul, V.; Jayakrishna, K.; Kar, V.R.; Rajesh, M.; Thirumalini, S.; Manikandan, M. 4—Recent advances and trends in structural health monitoring. In Structural Health Monitoring of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead Publishing: Sawston, UK, 2019; pp. 53–73. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, R.; Yu, F.; Okabe, Y. Application of an Optical Fiber Sensor for Nonlinear Ultrasonic Evaluation of Fatigue Crack. IEEE Sens. J. 2019, 19, 4992–4999. [Google Scholar] [CrossRef]

- Andreades, C.; Meo, M.; Ciampa, F. Tensile and fatigue testing of impacted smart CFRP composites with embedded PZT transducers for nonlinear ultrasonic monitoring of damage evolution. Smart Mater. Struct. 2020, 29, 055034. [Google Scholar] [CrossRef]

- Multifunctional Composites Market Size, Trends, Growth 2030. Available online: https://www.fairfieldmarketresearch.com (accessed on 10 July 2024).

- Chaudhary, B.; Matos, H.; Das, S.; Owens, J. Multifunctional Carbon/Epoxy Composites with Power Transmission Capabilities. Mater. Today Commun. 2023, 35, 105665. [Google Scholar] [CrossRef]

- Chaudhary, B.; Lyngdoh, G.A.; Owens, J.; Das, S.; Matos, H. An investigation into the electromechanical performance of textile fabrics with conductive yarn elements for data transfer capabilities. Text. Res. J. 2024, 94, 2079–2091. [Google Scholar] [CrossRef]

- Lincon, M.; Chaudhary, B.; Matos, H.; Chalivendra, V.B.; Shukla, A. Failure Analysis and Piezo-resistance Response of Intralaminar Glass/Carbon Hybrid Composites Under Blast Loading Conditions. J. Eng. Mater. Technol. 2024, 147, 1–41. [Google Scholar] [CrossRef]

- Chalivendra, V. Damage sensing in natural fiber/epoxy composites. In Handbook of Epoxy/Fiber Composites; Mavinkere Rangappa, S., Parameswaranpillai, J., Siengchin, S., Thomas, S., Eds.; Springer: Singapore, 2020; pp. 1–17. [Google Scholar] [CrossRef]

- Sousa, R.; Chalivendra, V. Electro-mechanical behavior of multi-functional glass fiber composites under dynamic Mode-I fracture loading. J. Compos. Mater. 2023, 57, 4009–4023. [Google Scholar] [CrossRef]

- Gibson, R.F. A review of recent research on mechanics of multifunctional composite materials and structures. Compos. Struct. 2010, 92, 2793–2810. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.-W. Carbon Nanotube Networks: Sensing of Distributed Strain and Damage for Life Prediction and Self Healing. Adv. Mater. 2006, 18, 2837–2841. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.-W. Carbon nanotube-based health monitoring of mechanically fastened composite joints. Compos. Sci. Technol. 2008, 68, 2557–2561. [Google Scholar] [CrossRef]

- Pinto, M.; Chalivendra, V.B.; Kim, Y.K.; Lewis, A.F. Improving the strength and service life of jute/epoxy laminar composites for structural applications. Compos. Struct. 2016, 156, 333–337. [Google Scholar] [CrossRef]

- de Araujo, M.; Fangueiro, R.; Geraldes, M.J. Developing fibrous multifunctional structures for technical applications. AUTEX Res. J. 2005, 5, 49–54. [Google Scholar] [CrossRef]

- Gorgutsa, S.; Bachus, K.; LaRochelle, S.; Oleschuk, R.D.; Messaddeq, Y. Washable hydrophobic smart textiles and multi-material fibers for wireless communication. Smart Mater. Struct. 2016, 25, 115027. [Google Scholar] [CrossRef]

- Garnier, B.; Mariage, P.; Rault, F.; Cochrane, C.; Koncar, V. Electronic-components less fully textile multiple resonant combiners for body-centric near field communication. Sci. Rep. 2021, 11, 2159. [Google Scholar] [CrossRef]

- Chen, G.; Xiao, X.; Zhao, X.; Tat, T.; Bick, M.; Chen, J. Electronic Textiles for Wearable Point-of-Care Systems. Chem. Rev. 2022, 122, 3259–3291. [Google Scholar] [CrossRef]

- Phan, P.T.; Thai, M.T.; Hoang, T.T.; Davies, J.; Nguyen, C.C.; Phan, H.-P.; Lovell, N.H.; Do, T.N. Smart textiles using fluid-driven artificial muscle fibers. Sci. Rep. 2022, 12, 11067. [Google Scholar] [CrossRef] [PubMed]

- Caruso, M.M.; Blaiszik, B.J.; White, S.R.; Sottos, N.R.; Moore, J.S. Full Recovery of Fracture Toughness Using a Nontoxic Solvent-Based Self-Healing System. Adv. Funct. Mater. 2008, 18, 1898–1904. [Google Scholar] [CrossRef]

- Subbiah, D.K.; Balasubramanian, S.; Kulandaisamy, A.J.; Jayanth Babu, K.; Das, A.; Rayappan, J.B.B. Surface modification of textiles with nanomaterials for flexible electronics applications. In Advances in Functional Finishing of Textiles; Shahid, M., Adivarekar, R., Eds.; Springer: Singapore, 2020; pp. 1–42. [Google Scholar] [CrossRef]

- Hand Lay-Up—An Overview|ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/engineering/hand-lay-up (accessed on 1 July 2024).

- Avila, A.F.; Morais, D.T.S. A multiscale investigation based on variance analysis for hand lay-up composite manufacturing. Compos. Sci. Technol. 2005, 65, 827–838. [Google Scholar] [CrossRef]

- Pereira, T.; Guo, Z.; Nieh, S.; Arias, J.; Hahn, H.T. Energy Storage Structural Composites: A Review. J. Compos. Mater. 2009, 43, 549–560. [Google Scholar] [CrossRef]

- Lim, S.T.; Lee, W.I. An analysis of the three-dimensional resin-transfer mold filling process. Compos. Sci. Technol. 2000, 60, 961–975. [Google Scholar] [CrossRef]

- Tamakuwala, V.R. Manufacturing of fiber reinforced polymer by using VARTM process: A review. Mater. Today Proc. 2021, 44, 987–993. [Google Scholar] [CrossRef]

- Wanchoo, P.; Chaudhary, B.; Li, H.-W.-X.; Matos, H.; Shukla, A. Blast failure and energy analysis of rubber-modified carbon-fiber vinyl-ester composite laminates. Mech. Mater. 2023, 183, 104685. [Google Scholar] [CrossRef]

- Silveira, D.C.; Gomes, N.; Rezende, M.C.; Botelho, E.C. Electromagnetic Properties of Multifunctional Composites Based on Glass Fiber Prepreg and Ni/Carbon Fiber Veil. J. Aerosp. Technol. Manag. 2017, 9, 231–240. [Google Scholar] [CrossRef]

- Meredith, J.; Bilson, E.; Powe, R.; Collings, E.; Kirwan, K. A performance versus cost analysis of prepreg carbon fibre epoxy energy absorption structures. Compos. Struct. 2015, 124, 206–213. [Google Scholar] [CrossRef]

- Additive Manufacturing—General Principles—Fundamentals and Vocabulary. Available online: https://www.astm.org/f3177-21.html (accessed on 7 July 2024).

- Lu, Y.; Han, X.; Gleadall, A.; Chen, F.; Zhu, W.; Zhao, L. Continuous fibre reinforced Vat photopolymerisation (CONFIB-VAT). Addit. Manuf. 2022, 60, 103233. [Google Scholar] [CrossRef]

- Asif, S.; Chansoria, P.; Shirwaiker, R. Ultrasound-assisted vat photopolymerization 3D printing of preferentially organized carbon fiber reinforced polymer composites. J. Manuf. Process. 2020, 56, 1340–1343. [Google Scholar] [CrossRef]

- Khatua, V.; Gurumoorthy, B.; Ananthasuresh, G.K. A vat photopolymerization process for structures reinforced with spatially steered flexible fibers. Addit. Manuf. 2024, 86, 104183. [Google Scholar] [CrossRef]

- Zindani, D.; Kumar, K. An insight into additive manufacturing of fiber reinforced polymer composite. Int. J. Lightweight Mater. Manuf. 2019, 2, 267–278. [Google Scholar] [CrossRef]

- Tee, Y.L.; Tran, P.; Leary, M.; Pille, P.; Brandt, M. 3D Printing of polymer composites with material jetting: Mechanical and fractographic analysis. Addit. Manuf. 2020, 36, 101558. [Google Scholar] [CrossRef]

- Gülcan, O.; Günaydın, K.; Tamer, A. The State of the Art of Material Jetting—A Critical Review. Polymers 2021, 13, 2829. [Google Scholar] [CrossRef]

- Enrique, P.D.; Marzbanrad, E.; Mahmoodkhani, Y.; Keshavarzkermani, A.; Al Momani, H.; Toyserkani, E.; Zhou, N.Y. Design of binder jet additive manufactured co-continuous ceramic-reinforced metal matrix composites. J. Mater. Sci. Technol. 2020, 49, 81–90. [Google Scholar] [CrossRef]

- Shakor, P.; Chu, S.H.; Puzatova, A.; Dini, E. Review of binder jetting 3D printing in the construction industry. Prog. Addit. Manuf. 2022, 7, 643–669. [Google Scholar] [CrossRef]