Abstract

Textiles are composed of different types of fibers; thus, different processes for end-of-life recovery are currently applied. After collection, a prior sorting process is essential to classify the textiles and assess their quality in order to ensure that the best available technology is selected, with mechanical recycling being the most widespread and mature. Nevertheless, it still has important limitations as it is not suitable for the treatment of all fibers, especially those of non-organic origin and blends. On the other hand, chemical recycling appears to be a necessary technology to valorize the fibers that cannot be reused or mechanically recycled and to avoid landfilling. This article aims to provide an overview of the available technologies in the field of textile waste recycling, including collection, pretreatment, and mechanical and chemical recycling processes. Each technology is described identifying pros and cons, and a techno-economical assessment is presented including technology readiness levels (TRLs), investments, and costs. European and Spanish regulations and policies on textile waste are analyzed to identify the trends and directions the sector is moving towards.

1. Introduction

According to the European Parliament and Council [1], textile products are defined as “any raw, semi-worked, worked, semi-manufactured, manufactured, semi-made-up or made-up product, which is exclusively composed of textile fibers, regardless of the mixing or assembly process employed”. Furthermore, products containing at least 80% by weight of textile fibers are also classed as textile products.

Therefore, textile products comprise those found in items such as clothing, furniture, medical, protective equipment, buildings, and vehicles. Regarding their end-of-life management, in the EU, textiles are to be urgently considered as they represent the fourth-largest environmental and climate-change-impacting waste, followed by food, housing, and mobility. It is also the third-highest area of water consumption and land use, and the fifth-highest in terms of primary raw material use and greenhouse gas emissions [2].

Lately, the fashion industry has been encouraging and generating a pattern of consumption based on an almost constant discarding of clothing items, promoted by the launch of an increasing number of new campaigns every year.

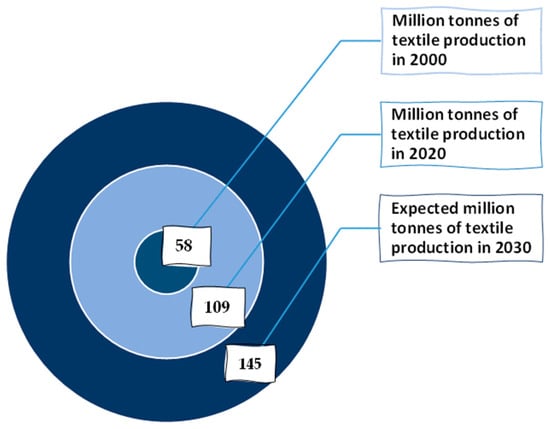

The two largest European clothing brands release, on average, between 16 and 24 collections per year, resulting in exponentially increasing volumes of textiles being produced, with an expected production of 145 Mton being expected for 2030 (Figure 1). Worldwide, it is estimated that 87% of the fibers used in these textiles is landfilled or incinerated after its first use, corresponding to an estimated annual loss of value more than USD 100 billion [3,4].

Figure 1.

Global textile fiber production. Data taken from reference [5].

Each year in the EU, up to 2.1 million tons of post-consumer clothing and home textiles are collected separately for recycling or resale in global reuse markets, accounting for roughly 38% of textiles introduced to the EU market, while the remaining 62% are believed to be discarded in mixed waste streams [5].

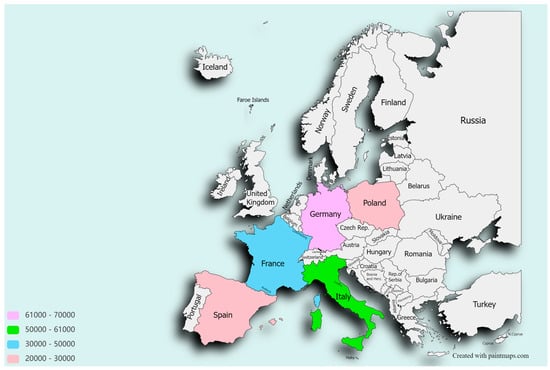

On the one hand, when talking about significant volumes of clothing and footwear generated per country, Germany is the one with the highest score (68.780 M€), followed by Italy (60.352 M€), France (42.746 M€), Poland (28.010 M€), and Spain (25.341 M€) [6], as can be seen in Figure 2.

Figure 2.

Clothing and footwear volumes per country in 2022 (chain-linked volumes; in EUR millions). Data taken from reference [7].

In the case of volumes of household textiles (such as bed linen, towels, curtains, carpets…) generated per EU country, Germany is, again, the one with the highest score (68.375), followed by France (3.153), Italy (3.066), Spain (2.321), and the Netherlands (2.285), as can be seen in Figure 3.

Figure 3.

Household textiles per country in 2022 (Chain − linked volumes; in EUR millions). Data taken from reference [7].

On the other hand, it is very difficult to know exact and recent data on the consumption of new textiles, the separation and collection of used textiles, the fate of separately collected textiles, and the consumption of secondhand textiles. As can be seen in Table 1, there are many countries that provide this data, except in 2013, 2016, and 2012, when they were not obliged to report these data, although they may have reported it voluntarily. However, all the data provided is outdated, and that’s the problem.

Table 1.

Data provided by each country [2].

Recent data indicate that in 2018, the European Union exported approximately 1.5 million tons of used clothing to countries in Asia and Africa [6]. But in 2020, to prevent the spread of COVID-19, huge restrictive measures were taken, causing a decrease of 14% in clothing importation in 2020, but this follows a disproportionate increase over the previous decade (up by 64% compared with 2010).

Most of the imported clothes came from China (30%), followed by Bangladesh (18%), Turkey (12%), the UK (6%), and India and Vietnam (4%). Germany imported approximately € 17 billion worth of clothes in 2020 (25% of EU-imported clothes), followed by Spain and France. Meanwhile Italy exported clothes worth € 10 billion (33% of EU-exported clothes), followed by Germany, Spain, and France [8].

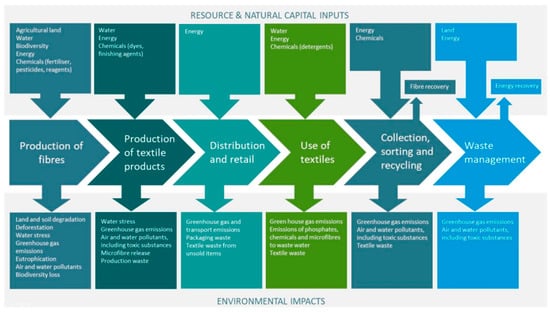

From an environmental perspective, the textile industry has a considerable impact, including aspects such as global warming, water consumption, land use (i.e., the conversion of ecosystems to agricultural lands), the use of chemicals, and the emission of microplastics [3]. Figure 4 shows the resources and natural capital used as well as the environmental impacts related to the lifecycle of textile products. Environmental impacts occur throughout the entire lifecycle of textile products, from the production of raw materials to manufacturing, transportation, use, and disposal. It is estimated that between 4% to 6% of the EU’s environmental footprint in various impact categories (i.e., raw material use, water, and land use) is attributed to textile product consumption. Regarding human, freshwater, and marine toxicity, the use stage (e.g., garment washing) dominates the environmental impacts. Concerning land use and eutrophication and, to a lesser extent, greenhouse gas emissions, the production phase predominates.

Figure 4.

Resource and natural capital inputs. Figure taken from reference [9].

Furthermore, the textile industry faces significant environmental and resource challenges, as 63% of textile fibers are derived from petrochemical products [10]. The main problem is the emission of large amounts of carbon dioxide (CO2) during their production and disposal [11]. The remaining 37% are predominantly cotton-based products, a water-intensive crop associated with water depletion and pollution due to intensive pesticide use [12,13]. Hence, it has been estimated that for the industry, the impact of the use of clothing in some countries (e.g., Sweden) needs to be reduced by 30–100% by 2050 to be considered sustainable [14,15]. This significant transition requires a combination of different impactful actions.

According to the Ellen MacArthur Foundation, an estimated 114 million tons of textile waste is generated globally each year. On the one side, around 14 million tons of clothing are collected for recycling globally each year, of which, only the 12% is downcycled into lower-value applications such as insulation, and less than 1% is used to make new clothing in a closed-loop economy (converting textiles back into textile products). The prevalence of polyester in fast fashion contributes to an increasing amount of discarded textiles being incinerated in waste-to-energy plants due to its high calorific value [16].

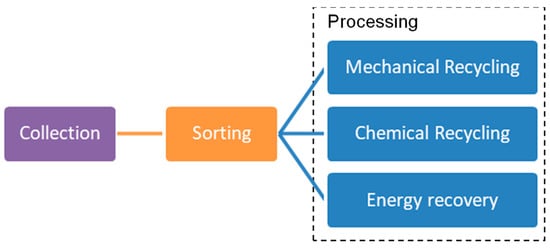

Therefore, recycling is deemed as a highly relevant impact-reduction measure, which is currently based on two technologies: mechanical, where textiles are shredded to obtain recycled fibers, [17] and chemical [18], where fibers are decomposed to obtain the initial components (i.e., monomers). Both processes are preceded by an initial sorting stage [2] to classify and separate the textiles prior to their subsequent processing, thus maximizing recycling efficiency and textile management. In addition, energy recovery is applied to non-recyclable or reusable fabric garments. These stages are discussed in more depth in their respective sections below.

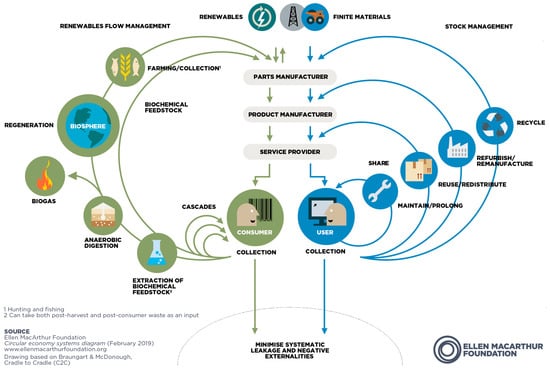

The transition from the current linear system of textile production and consumption to a circular one is a process in which all relevant stakeholders may participate. Contributions would include changes in design, production, marketing, use, collection, and end-of-life management. Circular practices can be achieved through the implementation of circular business models, the development and promotion of recycling technologies, focused policies and regulations, and changes in consumer behavior. The circularity of the textile value chain is shown in Figure 5.

Figure 5.

Value chain from textile feedstock to its end-of-life processes. Figure taken from reference [19].

1.1. Main Stages of Textile Waste Management

In light of what has been previously stated, the importance of developing sustainable recycling techniques for textile materials is becoming increasingly pressing. In the context of textile waste, recycling involves the production of new sustainable materials or fibers. However, as recycled textiles require the addition of non-recycled fibers to achieve the minimum quality, as well as high energy and resource inputs, there are unavoidable environmental impacts associated with recycling, despite its great environmental value [17].

The management of textile waste generally involves classifying textiles based on their condition, such as worn, partially worn, and outdated, which determines their potential for reuse, including direct reuse in second-hand stores, redesign, or renovation, without the need for complex chemical or mechanical processes.

This management involves three main stages: collection, classification, and treatment. Collection is carried out through specific containers, collection points, or donations; classification is based on the condition and composition of the textiles to determine their final destination; and treatment can range from mechanical or chemical recycling to incineration or landfill disposal (see Figure 6).

Figure 6.

Different routes for textile waste.

The recycling process starts with the collection of textiles from different sources, followed by an initial sorting, mainly visual, to identify the corresponding category, like clothes or accessories. Then the textile is separated into two different sub-categories: natural and synthetic, according to its composition. In some cases, there are steps of color sorting and accessory removal to facilitate further processing.

The aim of this pretreatment is to minimize the material complexity of textile fibers and to maximize the efficiency of recycling and reuse. This is challenging due to the presence of different types of fabrics, colors, patterns, and contaminants in the textile waste streams.

In the subsequent recycling stages, textile waste undergoes physical and chemical transformations in order to be used as secondary raw materials for the manufacturing of products (fibers, threads, etc.) for which various mechanical and chemical recycling technologies are being developed.

Regarding processing, chemical recycling can be closed-loop (the material is recycled into an identical product), e.g., for pure polyester (PET) and nylon-6 materials, or open-loop (the material is recycled into a different category of the product), e.g., for cotton materials whose end product is a cellulose pulp that can be regenerated into new cellulose-based fibers such as viscose, lyocell, or other forms of rayon.

For synthetic fibers, the process involves breaking down polymer chains into monomers, which are then separated, purified, and reprocessed into new polymers. Additives are often removed during the purification process by distillation, and recycled fibers usually have the same properties as virgin synthetic fibers. In theory, almost all polymers can be depolymerized, but an efficient, practical process that is applicable for all polymers has not yet been developed [20].

Chemical recycling of certain cellulosic fibers, such as cotton, is possible through a pulping process followed by solution spinning to produce regenerated cellulosic fibers. However, this is not currently possible for viscose and lyocell, which are already regenerated cellulosic fibers. Some additives are removed during the process, and in the case of cotton, the cellulose fibers are completely regenerated and, theoretically, have similar properties to other regenerated cellulose fibers. The only commercially available recycled natural fiber today is a blend of 20% recycled lyocell fibers from cotton and 80% regenerated fibers from virgin forest [21].

A common aspect of both synthetic and cellulose fibers is that the efficiency of the chemical recycling process increases with the purity of the input material. Any content other than the intended fiber for recycling is considered a contaminant, resulting in reduced yield, additional separation/purification steps, and increased costs, both in environmental and economic terms [22].

Mechanical recycling can be used in a closed- or open-loop system for pure synthetic materials and in an open-loop system for all textile materials [20]. This technology involves two main processes:

(1) Synthetic fibers are melted to produce granules that are used to spin new fibers (thermomechanical recycling). The re-melting process has strict requirements, as it cannot tolerate contamination from surface treatments, dust, or dirt. Fiber blends (e.g., nylon 6 and nylon 6.6) and non-melting polymers (e.g., elastane) cannot undergo this type of recycling.

(2) Tearing of the fabric to recover the fibers (mechanical recycling), where the textile material is first separated from metal and plastic components such as zippers and buttons. The material is then cut into smaller pieces, which are fed into a textile tearing machine to open the textile structure and release the fibers. During the recycling process into yarn, the textile fiber mass is carded and may undergo additional steps to remove short fibers [20].

Overall, although recycling involves the production of sustainable materials for the textile industry with a positive environmental impact, in terms of energy and resources, it is more expensive than the reuse process. Consequently, less than 1% of the 10–12% of post-consumer textile waste collected is recycled in a closed loop [23].

In addition, there is a significant economic barrier related to processing costs, which tend to exceed those of manufacturing new garments. As a result, these outlays are reflected in the selling price of recycled fabrics or garments. Despite this economic challenge, there are a growing number of initiatives in this direction, with major textile companies including this process into their production chains and launching lines consisting exclusively of recycled garments.

Efforts Toward Textile Circularity in Spain

In Spain, major textile companies (Decathlon [24], H&M [25], Ikea [26], Inditex [27], Kiabi [28], Mango [27] and Tendam [29]), have formed the Association for Textile Trash Management, with the intention of reducing the amount of waste produced by the Spanish clothing and footwear industry [30]. As for legislation, the Spanish Law 7/2022 of 8 April 2022 on waste and contaminated soils transposes Directive 2008/98/EC [31]. Within its framework of a circular economy, producers, distributors and importers of the textile sector are allowed to form a Collective System of Extended Producer Responsibility (SCRAP as its Spanish acronym), with its main task being the management of textile waste in the country [30].

Furthermore, this law establishes that from 2025 onwards, all municipalities in Spain will have to selectively collect textile waste, prioritize its reuse, and prohibit the destruction of textile surpluses. The main aim is to prepare 55% of textile waste for reuse or recycling by 2025, rising to 60% in 2030 and 65% in 2035. With approximately 1 million tons of clothing being annually discarded in Spain, and about 87% of the total discarded textiles disposed in landfills or incinerations, it is necessary to establish circularity policies not only at the beginning of the value chain (manufacturers and distributors) but also among the entities involved in the end-of-life processes. This highlights the need for fashion brands to manage their surpluses and to promote textile circularity.

The present study comprises an overview of textile waste’s state of the art. This overview aims to explain the main characteristics of the textile waste recycling processes, including collection, pretreatment, mechanical recycling, and chemical recycling. This study presents a comparison of the different techniques based on their description, technology readiness levels (TRLs), investments, and costs. In conclusion, the pros and cons of each technology are presented. Additionally, legislation and existing and future regulations related to textile waste in Europe and Spain are examined to outline the future trends in textile waste recycling.

2. Materials and Methods

A comprehensive literature review of scientific sources was carried out, including research papers, articles, and relevant publications. The first step was to identify key issues in the field of textile waste recycling, such as emerging technologies, challenges, and sustainable practices. The processes selected were sorting, mechanical recycling, and chemical recycling. These topics were organized by similarity, and technologies were critically analyzed through different reported studies. In order to present a coherent overview, the information found was synthesized. In addition, the effectiveness of different recycling techniques was evaluated and gaps in the literature identified, contributing to a thorough and insightful review.

For evaluating the different technologies, the following aspects were included:

- Description of the process.

- Technologies and their description.

- Status of the technologies and future perspectives.

- Advantages and disadvantages.

The literature review is followed by an overview of the main circular economy (CE) strategies.

3. Sorting

3.1. Description

Sorting plays a key role in the economic and environmental aspects of recycling, and it is a mandatory pretreatment for all textile recycling processes, providing the necessary inputs for the subsequent recycling technologies. Focusing on the different stages of post-consumer textile waste, particularly on clothing, which is collected from various sources such as collection centers and donation points and transported to adequate treatment facilities (often owned by wholesalers) where; in order to achieve the highest fiber quality, it is first sorted into two categories: clothing in good condition which can be reused, and worn-out items which can be recycled [2].

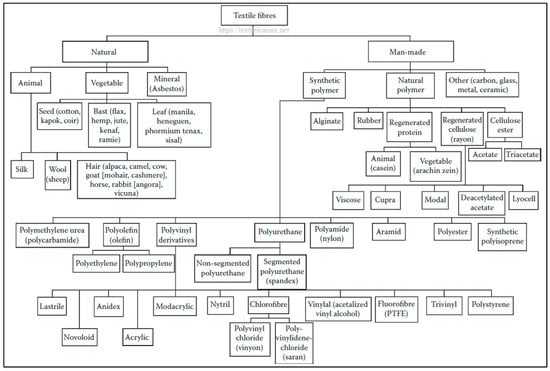

The following steps of this process involve the classification and/or quality control of textile waste to separate them into natural fibers and synthetic/man-made fibers using different recycling techniques. Figure 7 presents a detailed diagram of the different materials that may be found in textile waste.

Figure 7.

Classification of textile fibers. Figure taken from reference [32].

Efficient and specific sorting of textiles into categories increases recyclability by enhancing waste purity, but challenges like unwanted materials and certain treatments (i.e., dyeing, coating) require careful management to maximize success. Currently, most technology providers rely on the manual removal of these unwanted pieces. In this case, a fraction of the textile material is lost as it is not economically viable to spend a significant amount of time on accurate piece extraction. Some metallic parts can be easily removed using a magnet, while non-metallic parts can be separated by centrifugal force based on density after fragmentation. In the case of contaminated textiles (e.g., unwashed clothing, soiled carpets, or soiled workwear), the pretreatment stage may also include sanitization through an industrial cleaning/washing process.

Consumer awareness plays a critical role in recycling textile materials. In another sense (also practiced in some processes), a barcode system based on a small slip within the fabric or textile product must be adhered/stitched so that the machine can easily detect different fiber contents. However, there is another issue related to color associated to textiles of various colors and the sensitivities of spectroscopical techniques/automatic sorting to these materials to.

Sorting processes currently used can be divided into two types: manual sorting and automated sorting. The following sections include a more in-depth description of each [2].

3.2. Manual Sorting

Manual sorting as its name indicates involves the separation and classification of textile waste by manual labor. This process requires more personnel attention, while manual errors are common and consume a lot of time. However, manual sorting is particularly suitable for the identification and separation of high-quality textiles for reuse, and it is critical for the recovery of reuse textiles that cannot be fully automated due to the complexity of assessing the functional quality of each item. Therefore, automated techniques have become inefficient when the textile contains more than one fiber (or mixture), for example, in the case of polycotton (a mixture of polyester and cotton).

The input types treated can be either, used and unsorted textiles, or used and pre-sorted textiles, with the best-quality items removed for sale in local secondhand shops. The process takes place in manual sorting facilities, with an initial step carried out by less-skilled personnel to remove all non-textile waste. Batches of textiles contaminated by rainwater, mold, oil, etc. are also removed [2]. Then, more skilled workers sort textiles into more than a hundred categories based on various criteria such as style, garment type, size, seasonal changes, and end markets.

The next stage is to remove non-reusable clothing and textiles. Non-reusable textiles can be identified by damage (i.e., rips and tears, discoloration, missing components, etc.). The reusable fraction is then passed on, usually via conveyor belts, to the most skilled sorting personnel, who sort it into various categories using their visual and tactile senses. The number and type of categories into which the reusable textiles are sorted depends on the facility and the demand. They can be sorted by style, type, color, season, target group, and condition, and in some cases, further specificity can be reached by sorting by fabric or fiber composition.

Sophisticated assistive technologies like tools, devices, or systems that provide additional capabilities to improve the efficiency, accuracy, or speed of the manual sorting process can significantly improve the manual textile waste sorting process in several ways, including through quick and accurate identification, automatic segregation, improved accuracy, increased efficiency, and reduced contamination. After manual sorting is completed, non-reusable waste is sent to an automated sorting stage, which, in some sites, can take place simultaneously with manual sorting.

In 2020, the separate collection of used textiles in EU-27 was in the range of 1.7 to 2.1 million tons. Forecasts for 2025 onwards predict an annual increase in separate textile collections of 65,000 to 90,000 tons per year. It is assumed that all of the collected material will require manual sorting [2].

The advantages and disadvantages of manual sorting are presented in Table 2.

Table 2.

Advantages and disadvantages of manual sorting (conventional and assisted) [31,33,34,35].

3.3. Automated Sorting

These systems focus on the classification of non-recyclable waste from manual sorting facilities or the sorting of collected textile waste with low recyclable value. Innovative recycling methods, both closed-loop and open-loop, usually have minimal tolerance for impurities from a chemical and mechanical point of view. This requires the use of technological solutions to identify fiber types and material composition.

The preferred method for dealing with non-reusable outputs from manual sorting or the processing of other textile waste (e.g., pre-consumer factory waste without reusable content) is likely to be automated or semi-automated sorting. This approach can effectively and accurately sort various textile wastes by color and fiber type and prepare them for high-quality mechanical or chemical recycling.

The automated process has the potential to provide cost-effective and accurate sorting of non-reusable textile waste by material composition to meet different material needs. The most promising technologies are the following:

- Near-infrared spectroscopy (NIR)

- Radio-frequency identification (RFID)

The advantage is that these are more accurate and inexpensive ways of classifying non-reusable textile wastes compared to manual sorting. In terms of disadvantages, on the one hand, all NIR methods have a severe limitation in surface measurements, which makes them impossible to identify with complete accuracy the composition of the material in the case of multi-layered garments or fabrics composed of different fibers on the front and back sides; thus, a precise determination of material components based on diffuse reflectance spectroscopy techniques is not strictly possible. On the other hand, the fundamental challenge with RFID technologies lies in the exchange and collection of real-time data, which includes wireless communication standards and radio-frequency identification.

3.3.1. Near-Infrared Spectroscopy (NIR)

NIR is a spectroscopic technique based on molecular absorptions measured in the near-infrared part of the spectrum. It is sensitive to organic constituents and can provide both chemical and physical information [33]. NIR relies on the principle that molecules absorb at distinct frequencies based on their inherent structure. The system assesses the absorption of radiation across varying wavelengths. This wavelength spectrum spans from 190 to 900 nm, with a further extension of up to 3300 nm in UV-Vis-NIR equipment. The resulting signals depend largely on the nature of the sample surface, including parameters such as particle size, moisture content, color, brightness, and applied finishing agents [34]. In other words, it relies on the detection of textiles using sensors capable of accurately recognizing NIR spectra (over 90–95%, depending on the type of textile) and determining the presence of cotton, linen, silk, wool, polyester, polyamide, viscose, and up to 13 different fiber fractions, enabling automatic classification [35]. In the case of textile waste, it works by using the near-infrared region of the electromagnetic spectrum to identify different materials based on their unique spectral fingerprints.

In the context of sorting textile waste, this technique is applied in several steps, starting with the emission of NIR light, followed by the interaction with the textile waste (depending on the chemical composition of the textile, as each type of fiber has a specific molecular structure that absorbs and reflects the NIR light) and the detection of the reflected light (the detector is responsible for recording the intensity of the light and producing a spectrum), and ending with a spectral analysis of the different spectra [35].

The large variety of textiles recovered has caused traditional software and sorting machines to fail in this application; therefore, a vast dataset is crucial to ensure accurate sorting.

NIR has been studied in the textile industry [36,37]. It is non-destructive and allows for online measurements once a comprehensive dataset has been established [34]. Several companies in the market have developed sorting systems with NIR technology [38], some of them through European projects such as Autorsort [39], SipTex, or Fibersort [40], which combine NIR used for analyzing fiber composition and RGB (Red, Green, Blue) camera technology to capture and analyze color information using the three primary colors: red, green, and blue [41]. Each component in the RGB triplet can vary from zero to a defined maximum value of 255. If all the three R, G, and B components are at 0, the resulting color is black. At the maximum value of 255 for each of R, G, and B, the result is white [41].

Fibersort is a European project funded by Interreg [40], where a demonstration plant for automated textile classification using NIR spectroscopy was constructed and operated in the outskirts of Amsterdam. The project was coordinated by the Dutch non-profit organization Circle Economy (Circular Economy 2021) and concluded in March 2020, when the demonstration plant transitioned to a commercial operation and now operates in an industrial setting. However, the current capacity is not large enough for Fibersort to be defined as a complete industrial textile automated sorting plant.

The SIPTex sorting technology in Sweden was developed under two projects funded by the Swedish Innovation Agency Vinnova [42]. A test plant was built and operated between 2016 and 2018 in Avesta, northwest of Stockholm (IVL Svenska Miljöinstitutet, 2021). In 2020, an industrial-scale plant was constructed by Staedler and Tomra in Malmö, Sweden, with a potential sorting capacity of 24,000 tonnes of textiles a year [42].

3.3.2. Radio-Frequency Identification (RFID)

RFID uses electromagnetic fields to automatically identify, and track tags attached to textiles, containing information about their composition [40]. This technique is employed to facilitate the identification and tracking of items as they move through the sorting process. This equipment consists of an antenna that emits radio waves and receives signals from the different textile tags. There are two categories of RFID tags: active and passive. An RFID tag has the capacity to store a significant amount of data and is activated when it meets a reader. The tag is applied by the manufacturer and travels with the textile waste until its end of life.

When the textile arrives at the reprocessor, the tag is read to sort the waste into the correct bin. During the reading, the tag can be in the middle of the garment and covered with fabric without affecting the quality of the reading [43]. This greatly facilitates handling compared with, for example, barcode/QR code systems, which cannot be read remotely or carry the same amount of data.

RFID systems can be used in an adaptive way, as they can be used to classify textiles according to specific parameters. For example, the system would allow the separation of textiles containing a particular unwanted chemical substance that has been regulated since the garment was manufactured.

In their review of closed-loop textile supply chains, Govindan et al. [44] argue that RFID can support the transition to closed-loop systems for waste recycling. Furthermore, networked RFID systems help to connect products tagged with an RFID chip to an information network that provides comprehensive product lifecycle information to all connected partners in the network.

In general, the recycling process of textile waste can be easily achieved through the Internet of Things (IoT) technologies [35]. IoT can assist in collecting data provided by various sensors and in connecting stakeholders across the value chain.

3.4. Status of the Technologies and Future Perspectives

Table 3 presents information on the readiness level of current sorting technologies and the prospects for technology development.

Table 3.

TRL of current technologies of sorting.

Both manual and automated sorting will play a crucial role in the future CE for used textiles in Europe [2]. On the one hand, manual sorting serves as an important first step to identify, separate, and categorize reusable textiles into various clothing and textile product types for sale in global reuse markets. On the other hand, automated sorting is the preferred method for handling non-reusable waste generated during the manual sorting process or for processing other types of textile waste that do not have reusable content.

Automated sorting has proven to be highly efficient and accurate in categorizing most textile waste by color and fiber type, including a variety of fiber blends suitable for high-quality mechanical or chemical recycling. While manual sorting personnel can process 100 to 150 kg of textiles per person per hour, advanced automated sorting systems can handle significantly higher volumes, ranging from 900 to 1500 kg per person per hour.

The product of the automated process is usually used as an input for chemical and mechanical recycling and it is therefore of much lower economic value than the product obtained from manual sorting, which is intended for direct reuse. An economic study is shown in Table 4.

Table 4.

Economics of sorting technologies [34,46]. GBP: British pound sterling.

Although automated sorting technologies have recently become ready for industrial-scale upscaling, their current capacity across Europe is limited to a few thousand tons per year. Substantial investments will be required in the coming years to cope with the expected collection of hundreds of thousands of tons of non-reusable textiles per year, especially with the 2025 mandate for the separate collection of textile waste.

4. Mechanical Recycling Technologies: General Description

The mechanical recycling of textiles is based on processes that convert textile fabrics into fibers without the use of chemicals. There are different types of mechanical treatments depending on the type of fibers they focus on, such as wool, cellulose-based fibers, or synthetics [17]. Mechanical recycling technologies consist of various subprocesses involving an initial pretreatment and a series of mechanical actions. These subprocesses can also vary depending on the desired end product and its use, as well as the type, structure, and size of the textile product used as input [47,48].

After pretreatment, two main mechanical recycling processes are currently used [47]:

- Mechanical process: Textile waste is broken down and transformed into new textile products using mechanical processes, without the need for heat or chemicals to dissolve the materials.

- Thermomechanical process: Melting of synthetic fibers before they can be spun into new fibers or form into other shapes [20].

Many forms of mechanical recycling are closed-loop processes, although the material produced is often of lower quality than the original textile.

The quality of the resulting fibers depends on the quality of the original product but is generally lower than that of virgin fibers. While mechanically recycled fibers can be used as a substitute for virgin fibers, blending is required to achieve satisfactory yarn quality. The spinnable fiber fraction includes fibers of sufficient length to be spun once again. In the case of natural fibers, such as cotton, this fraction represents 5–20% of the original textile material. For poly-cotton or polyester, the spinnable fiber fraction is 25–55%. Polyamide is notoriously excluded from mechanical recycling processes.

The remaining output fraction (lint, fillers, and dust) is of lower quality than the spinnable fiber fraction and can be used in the nonwoven industry as a filler or reinforcement in man-made composites or incinerated with energy recovery [17].

While the final products obtained from mechanical recycling often include industrial rags, quilting, automotive fillings, sound and thermal insulation, and nonwoven carpets, those of thermomechanical recycling include (i) textile yarns (such as continuous filaments in cases of high-quality input with uncontaminated or undegraded polymers), (ii) staple fibers in scenarios with lower quality input, and (iii) thermoplastic polymer pellets for various applications (in cases where fiber spinning is not feasible) [46,48].

4.1. Mechanical Process

In this process, physical processes such as shredding, carding, or tearing are used to recover the fibers that make up the textile and to create new fabrics. The recovered fibers can be spun into yarn for woven or knitted fabrics.

After pretreatment, the textile material is cut into smaller pieces that are fed into a textile-tearing machine that opens its structure and releases the fibers. To recycle these fibers into yarn, the mass of textile fiber is carded and may undergo additional steps to remove short fibers. These machines perform carding (Figure 8) and tearing operations on the fabric using a series of strong and sharp teeth mounted on cylinders that tear the fabric into radial planes, transforming it into individual fibers.

Figure 8.

Carding machine [49].

Carding is a mechanical process that disentangles, cleans, and mixes the fibers to produce a continuous web or sliver suitable for further processing. This is archived by guiding the fibers between surfaces with differential movements covered with “card clothing”—a resilient and flexible material embedded with metal pins [49].

This type of machine has been around for decades, but due to its limitations, the end product has always been low-quality yarn, which is then used for items such as rags, carpets, insulation fillings, car seats, etc. However, the development of machinery has made it possible to recover fibers of sufficient quality for spinning yarns for fabrics. Fiber length is the most important factor in yarn fineness, and modern machines such as rotor spinning, air-jet spinning, friction spinning, vortex spinning, electrostatic spinning, core spinning, wrap spinning, and twistless spinning [49] can recover fibers of over 2 cm in length, allowing open-end spinning.

This type of mechanical recycling preserves almost all the properties of the fiber, except for fiber length, which is shortened by the tearing or cutting of the fabric. In terms of the color of the resulting fibers from this process, mixtures of different colors are obtained depending on the prior classification of the raw material. If this classification is effective, re-dyeing can be avoided, thus reducing the environmental impact of the textile product manufacturing process. This type of process is most commonly used for natural textile fabrics and is preferred for monofiber fabrics (such as cotton and wool, but rarely viscose, due to their fiber structure and higher yield).

Other fiber-to-fiber recycling processes are based on chemical recycling technologies, and their processes are often preceded by a mechanical process. Thus, the mechanical process can basically be applied to any textile material, making this type of recycling a fundamental option when planning future fiber recycling strategies [2].

4.2. Thermomechanical Process

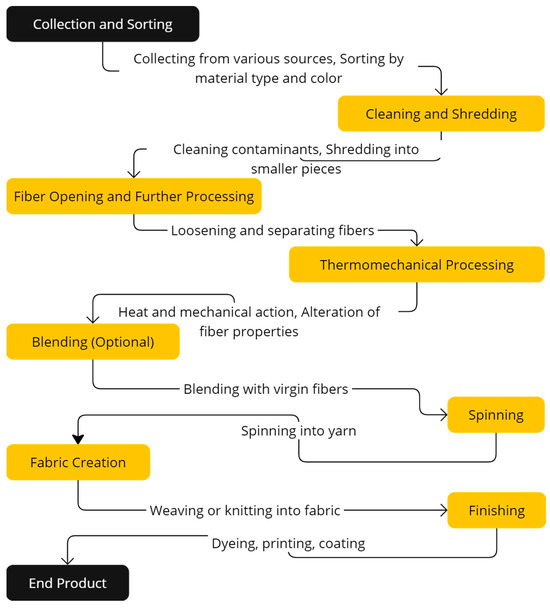

The complete process is shown in Figure 9.

Figure 9.

Step-by-step process of textile recycling using a thermomechanical process.

There are several requirements for the application of this type of recycling process. First, it is essential that the textile material intended for thermomechanical recycling is composed of a single type of polymer or compatible types of polymers. In addition, polymers that cannot be mixed do not melt completely, which weakens the fibers or, in some cases, prevents fiber formation. Other elements such as dyes, prints, cleaning residues, flame retardants, and coatings present in discarded textiles can also interfere with the spinning process and significantly reduce the quality of the final product. In addition, mixing materials of different colors can result in unwanted colors, as dyes and color agents are not removed during the process.

It is therefore essential to know the composition, type, and quantity of the elements present and to separate and classify the material to be used [50]. In general, this method is used to recycle pure synthetic fibers, such as polyesters and polyamides due to their heat resistance, uniform composition, ability to retain quality after recycling, energy efficiency, reduced environmental impact, and compatibility with existing recycling infrastructure [51].

It is important to note that during the thermomechanical process, there is a degradation of the polymer, which can affect its physical, thermal, or mechanical properties, potentially affecting its quality. As a result, while the fibers produced may be suitable for different textile applications, nevertheless, depending on their quality, the properties of the polymer/fiber tend to deteriorate after each recycling cycle [17].

4.3. Status of the Technologies and Future Perspectives

Table 5 presents information on the TRL of current technologies:

Table 5.

TRLs of current mechanical processes.

Mechanical recycling processes are well developed and easy to apply. They are particularly suitable for recycling production waste and some specific post-consumer waste that has been collected and properly sorted at specialized centers [16]. The recycling technology is currently at TRL 9 and is well established on the market, with decades of experience, e.g., for wool in the Prato region in Italy or for other natural fibers (cellulose-based such as cotton, jute, sisal, linen, etc.) and also for synthetic fibers (polyester, polyamide, acrylic, viscose, PP, etc.) in several European regions (Belgium, France, Germany, Sweden, etc.) [16].

New developments, starting from TRL 7, focus mainly on increasing the number of spinnable fibers and improving the quality of the recycled fibers. These developments mainly involve adjustments to the machinery or the configuration of the recycling line, additional (chemical) treatments, and better sorting of the input material [38].

The thermomechanical recycling process is very interesting for the recycling of production waste or scrap. It is estimated that in the next five years, the process will reach TRL 7 for post-industrial textile waste [38]. In the specific case of the thermomechanical recycling of polyester, there is still a long way to go before it can be scaled up to an industrial level, mainly due to the high costs associated with the removal of contaminants [4].

One technology provider, currently capable of processing 5000 tons of material per year, plans to reach TRL 7 for post-industrial textile waste soon. However, this requires the addition of virgin material, and only a limited amount of recycled material will be present in the final fiber. One of the technology holders blends 20% of recycled polyester with virgin material [38].

Further research is being carried out to include the use of chemicals to improve the quality of the polymer. Furthermore, the recycling of blends of thermoplastic materials into hybrid yarn is being investigated, although at low TRLs (2–3), and there are some technology holders, such as Antex, DS Fibres, and Eastman Carbon Renewal Technology [38].

4.4. Advantages and Disadvantages of Mechanical Processes

In Table 6, the advantages and disadvantages of mechanical recycling and thermomechanical recycling can be seen:

Table 6.

Advantages and disadvantages of mechanical processes.

5. Chemical Recycling Technologies

5.1. General Description

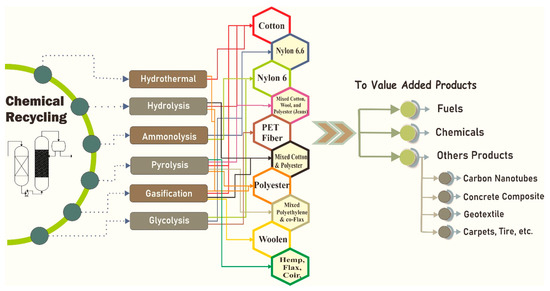

Chemical recycling technologies break down textiles into their basic components (monomers), or basic building blocks, which can then be used to make new polymers. Chemical recycling technologies make it possible to transform textile waste into the same product or other products, and even to obtain a high-value product after the process (upcycling). Depending on the reagents used for the chemical recycling, the processes can be classified as follows [2]:

- Glycolysis

- Methanolysis

- Hydrolysis (acid, alkali)

- Aminolysis

- Hydrothermal process

- Enzymatic hydrolysis

- Gasification

- Ammonolysis

- Pyrolysis

Figure 10 shows a summary of the current chemical recycling technologies for textile waste, the inputs, and their conversion into value-added products.

Figure 10.

The possible pathways to recycling textiles using chemical methods. Figure taken from reference [37].

Given the wide range of technologies within the chemical recycling of textile waste, a more detailed review of some of them (glycolysis, hydrothermal process, enzymatic hydrolysis, and pyrolysis) is included below, as they are considered more interesting from the perspective of this study.

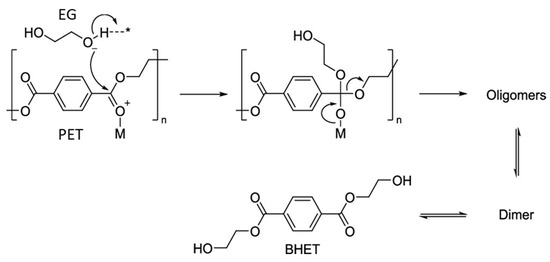

5.2. Glycolysis of PET

Poly(ethylene terephthalate), known as PET in the packaging industry and referred to as “polyester” in the textile industry, is used in a wide range of sectors and applications, including in the manufacture of fibers, packaging, construction materials, and, in particular, plastic bottles. The widespread use of PET is attributed to its low cost, excellent tensile strength, chemical resistance, clarity, processability, and reasonable thermal stability [54]. However, due to its inability to degrade rapidly in the ecosystem, finding a sustainable and economical technique to recycle PET waste becomes essential.

Glycolysis is the most common chemical recycling technology used for PET. Glycolysis is a degradation process used to convert large molecules of a PET polymer into smaller molecules by breaking down covalent bonds. The process temperature is typically between 180 °C and 250 °C, and the reaction time can vary depending on factors such as the type of catalyst, the glycol concentration, and the PET shape. Reaction times go from a few minutes to several hours, with typical times between 1 and 8 h [54].

Normally, it is carried out in a solution of ethylene glycol (EG) at atmospheric pressure with various metallic catalysts. The glycolysis reaction takes place between PET and EG in a batch reactor. The reaction medium can be heated with an electric heater and stirred with a magnetic stirrer, or the reaction can be assisted by microwave irradiation [54].

Mechanism:

PET is depolymerized to its monomer, bis(2-hydroxyethyl) terephthalate (BHET), by glycolysis using ethylene glycol (EG). The reaction starts with the metal (catalyst) attacking the carbonyl oxygen, resulting in the protonation of the EG’s hydrogen. This results in the oxygen having two free electrons that can attack the carbon of the carbonyl group [55]. As a result, the hydroxyethyl group of the EG forms a bond with the carbonyl carbon of the PET, leading to the cleavage of the long chain into short-chain oligomers and, ultimately, BHET (Figure 11).

Figure 11.

Representation of various stages of PET glycolysis using ethylene glycol [55].

In the absence of catalysts, the reaction is slow, leading to the incomplete depolymerization of PET into BHET monomers, but the formation of secondary products (oligomers) increases significantly. Traditionally, PET glycolysis has been carried out in the presence of metal acetates, titanium phosphate, solid super acids and metal oxides such as NiO, Fe2O3, or TiO2, etc. However, these catalysts are toxic and/or corrosive and/or cause severe contamination [54], so the development of an environmentally friendly and highly efficient catalyst as deep eutectic solvents (DES) or ionic liquids (IL) for PET glycolysis is crucial. Table 7 lists some of the catalysts used in the glycolysis of PET and their experimental results, including their BHET yield and rate of PET conversion.

Table 7.

Catalysts used in the glycolysis of PET and their experimental results.

Depolymerization of PET is an essential step in recycling this polymer back into its monomers or other useful materials. Several chemical processes other than glycolysis have been developed for this purpose, each with its own specific mechanisms, advantages, and applications.

- Other Chemical Processes for Depolymerizing PET

The main processes that are used to depolymerize PET include, methanolysis with methanol, and hydrolysis under acidic, basic, or neutral conditions. More recent options include aminolysis, ammonolysis, and hydrogenation. Depending on the chemical recycling process, PET is completely depolymerized into monomers or oligomers such as TPA, bis(hydroxylethylene) terephthalate (BHET), DMT, bis(hydroxylethylene) terephthalamide (BHETA), and other chemicals [58].

The glycolysis process is the most used chemical recycling process for the depolymerization of PET, mainly due to the direct applicability of the recycled products (i.e., bis(2-hydroxyethyl) terephthalate) as a single raw feedstock for the reproduction of PET. On the one hand, this process is versatile, uses milder conditions, and can process various forms of PET waste (including colored and contaminated materials). On the other hand, the purity of the product is not very good, so it always requires post-treatments and high operating costs, and often catalysts and a high energy input [58,59].

However, in hydrolysis, PET reacts with water molecules under neutral, basic and acidic conditions at high temperature and pressure to produce TPA and ethylene glycol, which can be used as the basic building block for PET repolymerization. Its main advantages over the glycolysis process are the use of water (which avoids a toxic solvent and reduces the need to recycle it), the high monomer purity in monomers due to the production of TPA (which can be used directly for the synthesis of new PET), and the flexibility to use acidic, neutral or alkaline conditions depending on the specific reaction requirements [58].

Another PET recycling process is methanolysis, which is a catalytic process using methanol at high temperature and pressure to decompose PET into dimethyl terephthalate (DMT) and EG. Due to its relatively low solubility in water, DMT can be easily purified to a polymer grade that can be used as an alternative feedstock for the production of PET. Its main advantages over the glycolysis process are the production of high-purity DMT and ethylene glycol (EG); the scalability of the process, as it is widely used in industrial PET recycling operations (feasible and economically viable); and the potential for closed-loop recycling, where PET waste is converted back into its original monomers for the production of new PET products, minimizing the need for virgin resources. On the downside, the process involves the use and recovery of methanol, which is flammable and toxic [59].

Ultimately, the choice between all these processes depends on the specific objectives of the recycling process, such as the end products, environmental requirements, and economic factors, amongst others.

5.3. Hydrothermal Process

This is a decomposition process using chemical crystallization techniques at high temperatures and pressures (mild conditions: 100–200 °C, moderate conditions: 200–300 °C) with water as the main reaction component. Under these conditions, water can break chemical bonds, decompose materials, or facilitate reactions between different components of the waste. Organic and inorganic acids, alkalis, and metals catalysts are the most used. After the reaction, the system is gradually cooled, and the pressure is reduced to safe levels; then, the output is separated into three different phases—solid, liquid, and gas. These phases are treated as required, which may include further purification or treatment steps [37,60].

The hydrothermal process does not require pre-treatment. Depending on the water temperature of the process (always below 300 °C), 5 processes can be differentiated: (i) hot water extraction, (ii) pressurized hot water extraction, (iii) liquid hot water treatment, (iv) hydrothermal carbonization and (v) hydrothermal liquefaction.

This type of recycling is particularly suitable for certain types of fibers such as synthetic fibers (polyester, nylon), acrylics and polyolefins (polypropylene, polyethylene), mixed fibers (made from blends of natural and synthetic fibers), biodegradable polymers (polylactic acid), natural fibers (cotton, rayon), and technical textiles (high-performance fibers used in applications such as filtration, automotive, medical textiles, etc.) [37].

Table 8 shows the description of inputs, outputs and description according to some fabrics analyzed.

Table 8.

Description, inputs, and outputs of different hydrothermal processes [2].

5.4. Enzymatic Hydrolysis

Hydrolysis involves the cleavage of a chemical bond by the action of water and is considered enzymatic when hydrolase enzymes act as catalysts. The main objective of enzymatic hydrolysis is to break down textile fibers into their constituent; specifically for those fibers that contains cellulose, into sugars, which can then be fermented to produce biofuels, or used to regenerate new fibers. This process leverages the ability to convert simple sugars into other materials through chemical or biotechnological processes.

First, a collection and sorting process is required to select the preferred fibers for the process. This is followed by a mechanical process to reduce their size and increase their surface area using shredders/cutters and, finally, a chemical pretreatment to remove non-cellulosic parts to make the cellulose more accessible to the enzymes using tanks equipped with mixers. In general, the hydrolysis process requires pretreatment with acids, alkaline liquids, and ionic liquids.

Enzymatic hydrolysis requires bioreactors or fermentation tanks to control the temperature (45° to 55 °C is optimal), pH (4.5–5.5 is optimal), agitation, and the environment. Heating/cooling systems must accurately maintain the temperature set point to ensure the proper performance of the enzymes. Times for this type of recycling can vary from 1–4 h to 24–48 h [37].

Table 9 includes a description of the inputs and outputs according to the cellulosic tissues analyzed, as well as the reaction conditions and yields of the reported experiments.

Table 9.

Description, inputs, and outputs of different enzymatic hydrolysis processes [2].

These types of recycling processes are considered upcycling processes as the output is a product with higher value, quality, or functionality.

5.5. Pyrolysis

Pyrolysis is a promising technology that can be used to break down carbon polymers in solid waste and convert them into three pyrolysis products in solid, liquid, and gaseous states. Pyrolysis can be applied to various textile materials that have not been previously classified or to multi-material textile products that would otherwise only be treated in waste-to-energy conversion facilities. PET is not suitable for pyrolysis because liberates excess of gas (20–40 wt%).

In addition, is necessary to do some pretreatment steps depending on textile waste, which are size reduction, contaminant removal, drying and sorting. It is a technique used to break down organic materials into their basic components, depending on the type of textile waste [67]:

- Oils: These can be used as fuel, lubricants, or chemicals.

- o

- Natural fibers, such as cotton and wool, produce oils containing a mixture of aliphatic and aromatic hydrocarbons, carboxylic acids, and alcohols. Wool, which contains proteins, may also contain nitrogen compounds such as amines and amides.

- o

- Synthetic fibers, such as PET, product oils rich in aromatic hydrocarbons, including terephthalic acid and its derivatives, and polyamide (nylon) oils containing caprolactam or its derivatives.

- o

- Blends and complex textiles produce oils with a wide range of organic compounds.

- Gases: These can be used as an energy source.

- o

- Natural fibers: Rich in CO, CO2, H2, and light hydrocarbons (e.g., methane, ethylene).

- o

- Synthetic fibers: depending on the polymer type, PET pyrolysis tends to produce more CO and CO2. Nylon may generate higher levels of nitrogenous gases such as ammonia or hydrogen cyanide.

- o

- Blends and complex textiles: Result in a complex mixture of CO, CO2, H2, light hydrocarbons, and in the case of lycra, elastane and nylon, possibly nitrogenous or sulfuric gases (SO2, H2S, SO3) if these elements are present in the feedstock.

- Charcoal: it can be reprocessed to generate fine spherical carbon black (CB) particles. CB can be used together with Carbon nanotubes or graphene as fillers in cement composite applications [67].

- o

- Natural fibers: Primarily composed of carbon, with a structure that can retain some of the texture of cellulose or proteinaceous material (although the protein structure itself is typically broken down during the pyrolysis process, the char might retain some of the original texture from these protein-containing materials before being further processed).

- o

- Synthetic fibers: Any solid residue that may contain carbon but with a higher degree of aromaticity, reflecting the synthetic origin.

- o

- Blends and complex textiles: Carbon content and mineral residues (inorganic fillers, metallic compounds, flame retardants, pigments…) reflecting the diversity of the feedstock.

Textile recycling by pyrolysis involves subjecting textiles to high temperatures (usually above 300 °C) in a controlled environment without oxygen to prevent combustion [34]. The first step is the feedstock preparation, with shredders or grinders (to reduce the size of the waste) and dryers (to remove the moisture to improve the process). In addition, the pyrolysis reactor chosen can vary in complexity and scale, from small batch reactors for research and development to large continuous systems for commercial operations. Heating systems are also required, both external (indirect heating through the reactor walls) and internal (direct heating of the reactor contents). Condensers and gas scrubbers/filters are required for cooling and for removing impurities and particulates from the gas stream respectively [68].

Below, there is a table (Table 10) describing some inputs and outputs according to the recycled material.

Table 10.

Description, inputs, and outputs of different pyrolysis processes.

5.6. Status of the Technologies and Future Perspectives

Below is Table 11, with information on the TRL of current technologies, the prospects for technology development, and the possible actors involved [71].

Table 11.

Readiness level of current chemical technologies for textile recycling.

5.7. Advantages and Disadvantages

In Table 12, the advantages and disadvantages of the different chemical processes for recycling textile waste can be seen:

Table 12.

Advantages and disadvantages of chemical recycling technologies [37].

6. Legislation, Regulation, and Other Transversal Aspects

Below, the main policies and legislation at the European and Spanish levels applicable to textile waste are examined:

6.1. Strategy for the Circularity and Sustainability of Textile Products

In March 2022, the European Commission presented an EU strategy for sustainable and circular textiles. The strategy proposes actions for the entire lifecycle of textile products, simultaneously supporting the ecosystem in its ecological and digital transition. It addresses the design and use of textile products and also explores sustainable technological solutions and innovative business models. Some of the measures include the following:

- New Design Requirements: Introduce new design requirements for textile products under the Sustainable Products Design Regulation. These requirements would establish mandatory minimums for the inclusion of recycled fibers in textiles, making them more durable and easier to repair and recycle. According to the proposed regulation, sustainable textile products will become the norm in the EU. The proposal also aims to prohibit the destruction of unsold products under certain conditions, including unsold or returned textile products. This measure is ongoing and due for completion by 2024.

- Clearer Information on Textile Products and a Digital Product Passport: Implement clearer information on textile products and a digital product passport based on mandatory information requirements regarding circularity and other key environmental aspects. Strict eco-bleaching controls: Enforce stricter standards for eco-bleaching with the aim of protecting consumers, linked to the upcoming initiative on ecological claims.

- Measures to Address the Unintended Release of Microplastics from Textile Products: Implement measures to address the unintended release of microplastics, focusing on product design, manufacturing processes, pre-washing in industrial manufacturing plants, labeling, and the promotion of innovative materials.

- Harmonized EU Standards on Extended Producer Responsibility for Textile Products: Establish harmonized EU standards on extended producer responsibility for textile products, along with economic incentives to make products more sustainable (“ecological modulation of fees”), as part of the review of the Waste Framework Directive in 2023.

- Support for Research, Innovation, and Investments: Provide support for research, innovation, investments, and the development of necessary capabilities for ecological and digital transition.

- Addressing Challenges in Ending Textile Waste Exports: Tackle the challenges associated with ending the export of textile waste.

- Joint Creation of a Transition Route for the Textile Ecosystem: Collaboratively create a transition route for the textile ecosystem to establish the path forward and take concrete steps to achieve the 2030 goals set by the Textile Products Strategy.

Within these objectives, the main short-term measures that the European Commission will implement as part of this strategy are shown in Table 13 [5].

Table 13.

The main short-term measures implemented by the EC presented an EU strategy for sustainable and circular textiles. The blue color indicates the type of action or measure.

6.2. Spanish Circular Economy Strategy (2030)—Government of Spain

The main trends in the sector regarding consumer demand involve a shift in search and purchasing habits, driven by current technological advances where social networks and mobile devices play a more significant role [72]. Undoubtedly, the adoption of more ambitious goals for separate packaging collection will lead to an increase in the collection of higher-value plastic materials such as PET. This could impact the availability of secondary raw materials for the production of acrylic or nylon fibers, with a lower water footprint during manufacturing and lower energy requirements during use (lower temperatures during washing and ironing) [71]. Within the Spain Circular Economy Action Plan (2021–2023), which also encompasses some legal requirements derived from European and national policies, the following actions related to textile waste are outlined [72]:

2024–2025:

- Mandatory separate collection for new waste streams: textiles, hazardous domestic waste, used cooking oils, and biowaste (deadline: 31 December 2024).

- The necessary regulations will be developed to apply extended producer responsibility (EPR) to textile waste, ensuring the resources needed for financing the separate collection of textile waste. Progress will be made in preparation for the reuse, recycling, and development of products with recycled materials. Work will be carried out on the implementation of information systems related to the market placement of textile products and their management (deadline: April 2025).

- The European Commission will assess the need for the inclusion of reuse and recycling targets in this waste stream (2024).

6.3. Law 7/2022 of 8 April 2022 on Waste and Contaminated Soils for a Circular Economy

Within this law, new obligations are legislated for waste management:

- −

- Article 18. Prevention Measures: The destruction or disposal of unsold non-perishable products such as textiles, toys, or electrical appliances, among others, through landfill deposit is prohibited.

- −

- Article 25. Separate Collection of Waste for Valorization: Incineration, with or without energy recovery, and landfilling of separately collected waste for preparation for reuse and recycling are prohibited. Local entities will establish the separate collection of, at least, the following waste fractions of local competence:

- (a)

- Paper, metals, plastic, and glass.

- (b)

- Domestic biowaste by 30 June 2022 for local entities with a population above five thousand inhabitants and by 31 December 2023 for the rest. Separate collection of biowaste also includes separation and recycling at the source through domestic or community composting.

- (c)

- Textile waste by 31 December 2024.

- (d)

- Used cooking oils by 31 December 2024.

- (e)

- Hazardous domestic waste by 31 December 2024, to prevent contamination of other local competence waste streams.

- (f)

- Bulky waste (furniture and household items) by 31 December 2024.

- −

- Seventh Final Provision. Within a maximum period of three years from the entry until this law, extended producer responsibility schemes will be developed for textiles, furniture and household items and for non-packaging agricultural plastics.

7. Conclusions

Each year, the EU collects up to 2.1 million tons of textiles for recycling or reuse; however, 62% end up in landfills or incinerators, with a significant amount also exported to countries in Asia and Africa. The fast-fashion trend exacerbates these problems, with leading brands releasing numerous collections annually, resulting in 87% of the fiber input being discarded after the first use. In addition, the textile industry’s reliance on petrochemical-derived fibers and water-intensive cotton contributes to CO2 emissions, water depletion, and pollution.

Although Spain collected more than 108,292 tons of textile waste in 2019 and Europe generated 180,000 tons in 2016, only a small fraction is recycled into new clothing due to the complexity of the materials and the need for efficient recycling processes. Improved traceability of the materials and chemicals used in textiles is needed to improve the efficiency of sorting technologies and, thus, process efficiency.

In terms of pretreatment and different recycling technologies, precise sorting is essential to separate natural from synthetic fibers, as they require different recycling techniques. The sorting process is crucial for the recycling industry as it requires pure fractions for the different recycling processes, including manual and automatic methods to maximize recycling efficiency and reduce the environmental impact. It is important to note that textile recycling technologies vary depending on the type of fiber to be recycled, and efficiency and separation issues arise when the garment to be recycled is made up of a mixture of materials. Mechanical and chemical recycling are common methods in the textile recycling process.

On the one hand, mechanical processes are more suitable for single materials or fibers of natural origin (cotton, wool, etc.), while thermochemical treatments are also viable for synthetic fibers, preferably of a single material. Mechanical recycling involves processes like melting synthetic fibers or tearing fabrics to recover fibers, with limitations due to contamination and the inability to process non-meltable polymers. This is a sustainable method that converts textile fabric into fibers without chemical use, focusing on different fiber types like wool, cellulose, or synthetics. Mechanical recycling produces lower-quality materials used in industrial applications, while thermomechanical recycling melts synthetic fibers for reuse. Despite its environmental benefits, including reduced energy consumption and greenhouse gas emissions, the mechanical recycling process faces challenges such as the quality dependency on input materials, limited recyclability of fibers, and technical limitations in handling contaminated fiber blends and textiles.

On the other hand, chemical textile recycling breaks down textile waste into monomers, or building blocks, to create new polymers or high-value products. The main methods include glycolysis, hydrothermal processes, hydrolysis, gasification, ammonolysis, and pyrolysis, each suitable for different textile materials and aimed at specific recycling outcomes. Each recycling method has its advantages, such as the low energy consumption of glycolysis, the high calorific value of hydrothermal processes, and the versatility in raw materials for pyrolysis. However, challenges include the need for specific catalysts in glycolysis, long reaction times in hydrothermal processes, dependency on feedstock purity in enzymatic hydrolysis, and high energy consumption in pyrolysis.

The maturity of these technologies varies, and glycolysis and enzymatic hydrolysis are expected to reach commercial viability in the near future. Despite their potential, these processes require further development to improve efficiency, reduce costs, and overcome technical limitations.

The EU strategy, introduced in 2022, includes measures such as new design requirements, clearer product information, digital passports, microplastics reduction, harmonized extended producer responsibility standards, and support for innovation. Spain’s Circular Economy Strategy is in line with these goals, with specific measures for textile waste management outlined in its Action Plan (2021–2023) and Law 7/2022, which requires the separate collection of textiles by the end of 2024 and prohibits the destruction of unsold non-perishable products.

In conclusion, the recycling of textile waste is crucial to building a sustainable future, reducing the environmental impact of the fashion industry, and incorporates a circular economy that values resources and incorporates environmental responsibility into every thread of our daily lives.

Author Contributions

Conceptualization, methodology, formal analysis, writing—original draft, I.E.L. and E.L.; writing—review and editing, I.E.L., M.B. and C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was performed within the framework of the REDOL project (Aragon’s REgional hub for circularity: Demonstration Of Local industrial–urban symbiosis initiatives). The REDOL project has received funding from the European Union’s Horizon 2020 Research and Innovation program under Grant Agreement no. 101091668 (https://www.redolproject.eu/; accessed on 29 May 2024).

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors express their gratitude to the REDOL project’s partners for their technical support in defining the barriers’ implications and recommendations.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of the data; in the writing of the manuscript; or in the decision to publish the results.

References

- Parlamento Europeo y el Consejo de la UNIÇON Europea, “Reglamento (UE) No 1007/2011”, Sep. 2011. Available online: http://data.europa.eu/eli/reg/2011/1007/oj (accessed on 29 May 2024).

- Donatello, S.; Danneck, J.; Löw, C.; Watson, D.; Konstantas, A.; Trzepacz, S.; Liu, R.; Köhler, A.; Faraca, G. “Circular Economy Perspectives in the EU Textile sector. Final Report” Luxembourg, June 2021. Available online: https://op.europa.eu/en/publication-detail/-/publication/08cfc5e3-ce4d-11eb-ac72-01aa75ed71a1/language-en (accessed on 29 May 2024).

- Residuos Textiles, Qué Son y Cómo se Reciclan. Available online: https://www.texlimca.com/blog/residuos-textiles-que-son-y-como-se-reciclan (accessed on 2 December 2023).

- A New Textiles Economy: Redesigning Fashion’s Future. Available online: https://www.ellenmacarthurfoundation.org/a-new-textiles-economy (accessed on 2 December 2023).

- EU Strategy for Sustainable and Circular Textiles. Available online: https://environment.ec.europa.eu/strategy/textiles-strategy/eu-strategy-sustainable-and-circular-textiles_en (accessed on 2 December 2023).

- Eppinger, E. Recycling technologies for enabling sustainability transitions of the fashion industry: Status quo and avenues for increasing post-consumer waste recycling. Sustain. Sci. Pract. Policy 2022, 18, 114–128. [Google Scholar] [CrossRef]

- Final Consumption Expenditure of Households by Consumption Purpose (COICOP 3 Digit). Statistics|Eurostat. Available online: https://ec.europa.eu/eurostat/databrowser/view/nama_10_co3_p3__custom_11351103/default/table?lang=en&page=time:2022 (accessed on 14 May 2024).

- Luján-Ornelas, C.; Güereca, L.P.; Franco-García, M.-L.; Heldeweg, M. Sustainability A Life Cycle Thinking Approach to Analyse Sustainability in the Textile Industry: A Literature Review. Sustainability 2020, 12, 10193. [Google Scholar] [CrossRef]

- Manshoven, S.; Christis, M.; Vercalsteren, A.; Arnold, M.; Nicoalu, M.; Lafond, E. “ETC/WMGE Report 6/2019: Textiles and the environment in a circular economy” Eionet Report—ETC/WMGE 2019/6. November 2019. Available online: https://www.eionet.europa.eu/etcs/etc-wmge/products/etc-wmge-reports/textiles-and-the-environment-in-a-circular-economy (accessed on 29 May 2024).

- Investors—Lenzing—Innovative by Nature. Available online: https://www.lenzing.com/investors/ (accessed on 2 January 2024).

- Shen, L.; Worrell, E.; Patel, M.K. Environmental impact assessment of man-made cellulose fibres. Resour. Conserv. Recycl. 2010, 55, 260–274. [Google Scholar] [CrossRef]

- Roos, S.; Sandin, G.; Zamani, B.; Peters, G. Environmental Assessment of Swedish Fashion Consumption Five Garments-Sustainable Futures. Available online: https://refashion.fr/eco-design/sites/default/files/fichiers/Environmental%20assessment%20of%20Swedish%20fashion%20consumption.pdf (accessed on 29 May 2024).

- Allwood, J.M.; Laursen, S.E.; de Rodríguez, C.M.; Bocken, N. “Well Dressed? The Present and Future Sustainability of Clothing and Textiles in the United Kingdom. Technical Annex” Institute for Manufactuing, University of Cambridge. 2006. Available online: https://www.ifm.eng.cam.ac.uk/insights/sustainability/well-dressed/ (accessed on 3 January 2024).

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; de Vries, W.; de Wit, C.A.; et al. Planetary boundaries: Guiding human development on a changing planet. Science 2015, 347, 1259855. [Google Scholar] [CrossRef] [PubMed]

- Sandin, G.; Peters, G.M.; Svanström, M. Using the planetary boundaries framework for setting impact-reduction targets in LCA contexts. Int. J. Life Cycle Assess. 2015, 20, 1684–1700. [Google Scholar] [CrossRef]

- Textiles Recycling: The Sorting Challenge—RECYCLING Magazine. Available online: https://www.recycling-magazine.com/2023/04/12/textiles-recycling-the-sorting-challenge/ (accessed on 3 January 2024).

- Piribauer, B.; Bartl, A. Textile recycling processes, state of the art and current developments: A mini review. Waste Manag. Res. 2019, 37, 112–119. [Google Scholar] [CrossRef]

- Hasanzadeh, E.; Mirmohamadsadeghi, S.; Karimi, K. Enhancing energy production from waste textile by hydrolysis of synthetic parts. Fuel 2018, 218, 41–48. [Google Scholar] [CrossRef]

- The Butterfly Diagram: Visualising the Circular Economy. Available online: https://www.ellenmacarthurfoundation.org/circular-economy-diagram (accessed on 5 January 2024).

- Ribul, M.; Lanot, A.; Pisapia, C.T.; Purnell, P.; McQueen-Mason, S.J.; Baurley, S. Mechanical, chemical, biological: Moving towards closed-loop bio-based recycling in a circular economy of sustainable textiles. J. Clean Prod. 2021, 326, 129325. [Google Scholar] [CrossRef]

- REFIBRATM: Textile Recycling, Sustainable Fabrics|TENCELTM Lyocell Fiber. Available online: https://www.tencel.com/refibra (accessed on 4 January 2024).

- Scott, A. Transforming textiles. CEN Glob. Enterp. 2022, 100, 22–28. [Google Scholar] [CrossRef]

- Textile Recycling: Immediate Challenges for the Industry—Indian Textile Journal. Available online: https://indiantextilejournal.com/textile-recycling-immediate-challenges-for-the-industry/ (accessed on 4 January 2024).

- Our Ecodesign Approach and Criteria. Available online: https://sustainability.decathlon.com/our-ecodesign-approach-and-criteria (accessed on 4 January 2024).

- Collect, Recirculate and Recycle—H&M Group. Available online: https://hmgroup.com/sustainability/circularity-and-climate/recycling/ (accessed on 4 January 2024).

- Transform the Way We Use Recycled Textiles—IKEA Global. Available online: https://www.ikea.com/global/en/newsroom/sustainability/transform-the-way-we-use-recycled-textiles-211006/ (accessed on 4 January 2024).

- Moda de Mujer|Mango España. Available online: https://shop.mango.com/es/mujer (accessed on 4 January 2024).

- Press, E. Kiabi se Compromete a Que el 30% de su Producción Textil en 2025 Será de Materiales Reciclados. Available online: https://www.europapress.es/epsocial/responsables/noticia-kiabi-compromete-30-produccion-textil-2025-sera-materiales-reciclados-20210422174439.html (accessed on 4 January 2024).

- Sostenibilidad|Compromiso con la Sostenibilidad de Tendam. Available online: https://old.tendam.es/sostenibilidad/ (accessed on 4 January 2024).

- Leading Brands Join to Tackle Textile Waste in Spain|Sustainability News Europe. Available online: https://apparelresources.com/business-news/sustainability/leading-brands-join-tackle-textile-waste-spain/ (accessed on 4 January 2024).

- BOE.es—DOUE-L-2008-82319 Directiva 2008/98/CE del Parlamento Europeo y del Consejo, de 19 de Noviembre de 2008, Sobre los Residuos y por la que se Derogan Determinadas Directivas. Available online: https://www.boe.es/buscar/doc.php?id=DOUE-L-2008-82319 (accessed on 4 January 2024).

- Classification of Textile Fibers—Textile Learner. Available online: https://textilelearner.net/classification-of-textile-fibers/ (accessed on 2 December 2023).