Nonwoven Fabrics from Agricultural and Industrial Waste for Acoustic and Thermal Insulation Applications

Abstract

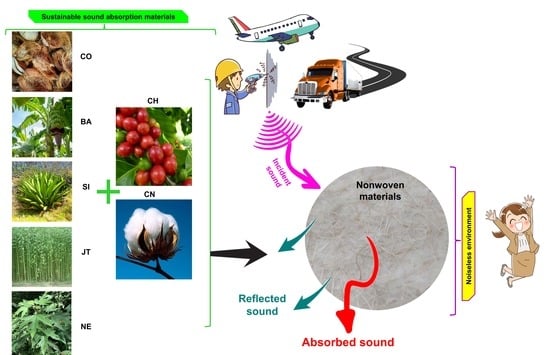

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Extraction of Coffee Husk Fibers

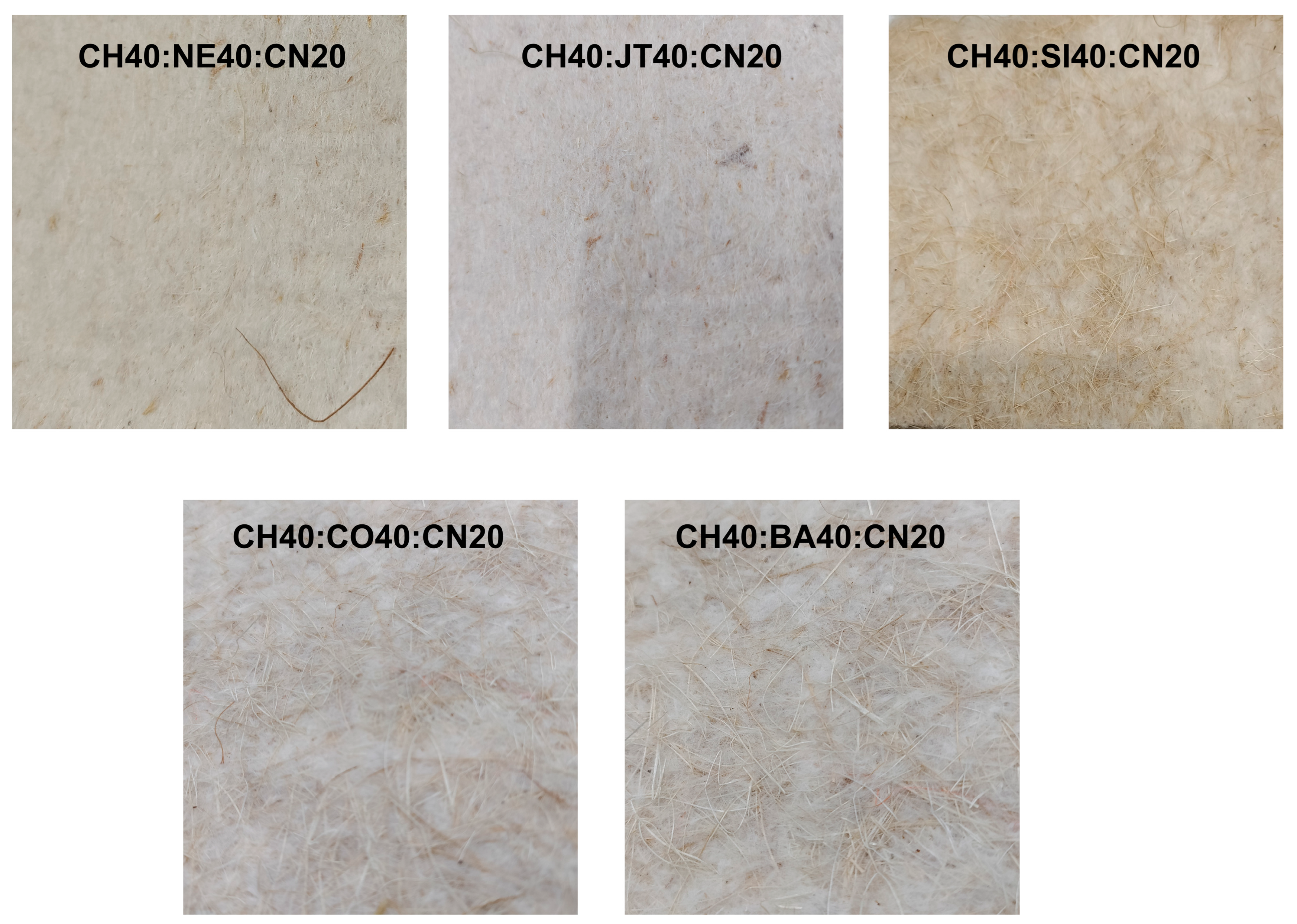

2.3. Nonwoven Fabric Production

2.4. Testing and Characterization

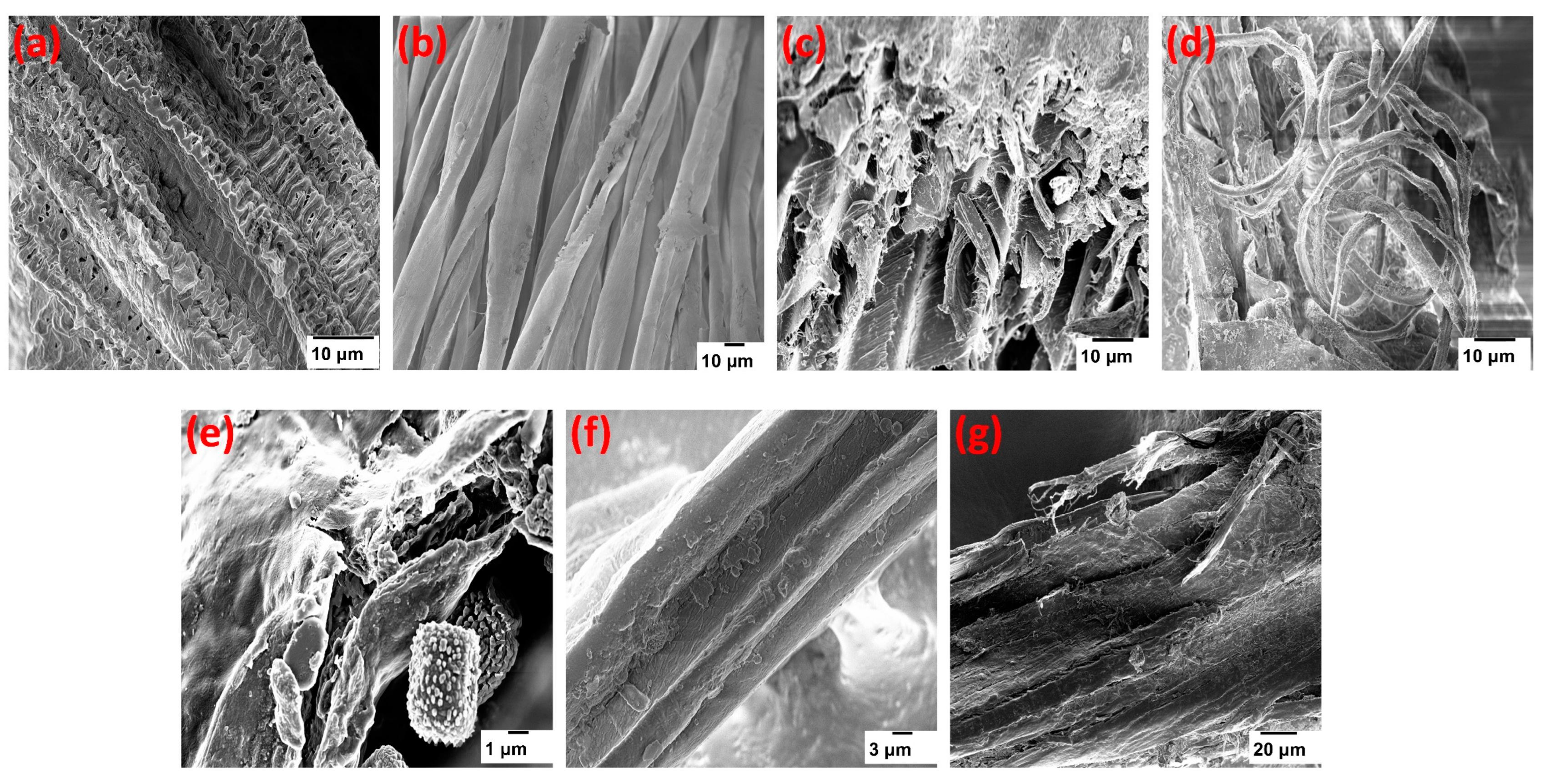

2.4.1. Scanning Electron Microscope (SEM)

2.4.2. Testing of Other Properties of Nonwoven Fabric

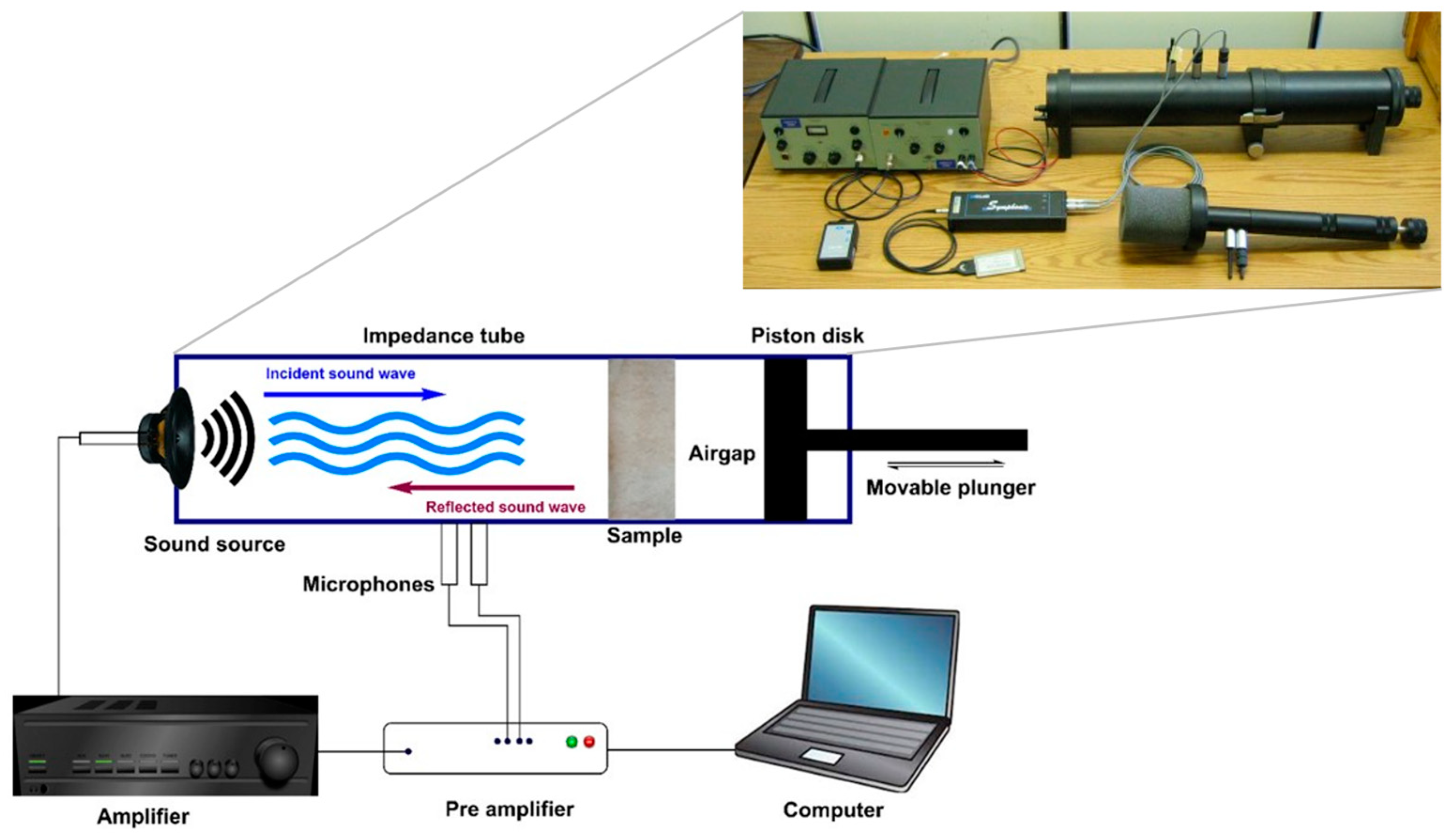

2.4.3. Acoustical Characterization

2.4.4. Empirical Models to Determine the Acoustic Properties

Delany–Bazley Model

Garai and Pompoli (GP) Model

Miki Model

Allard and Champoux Model

3. Results and Discussion

3.1. Surface Morphology

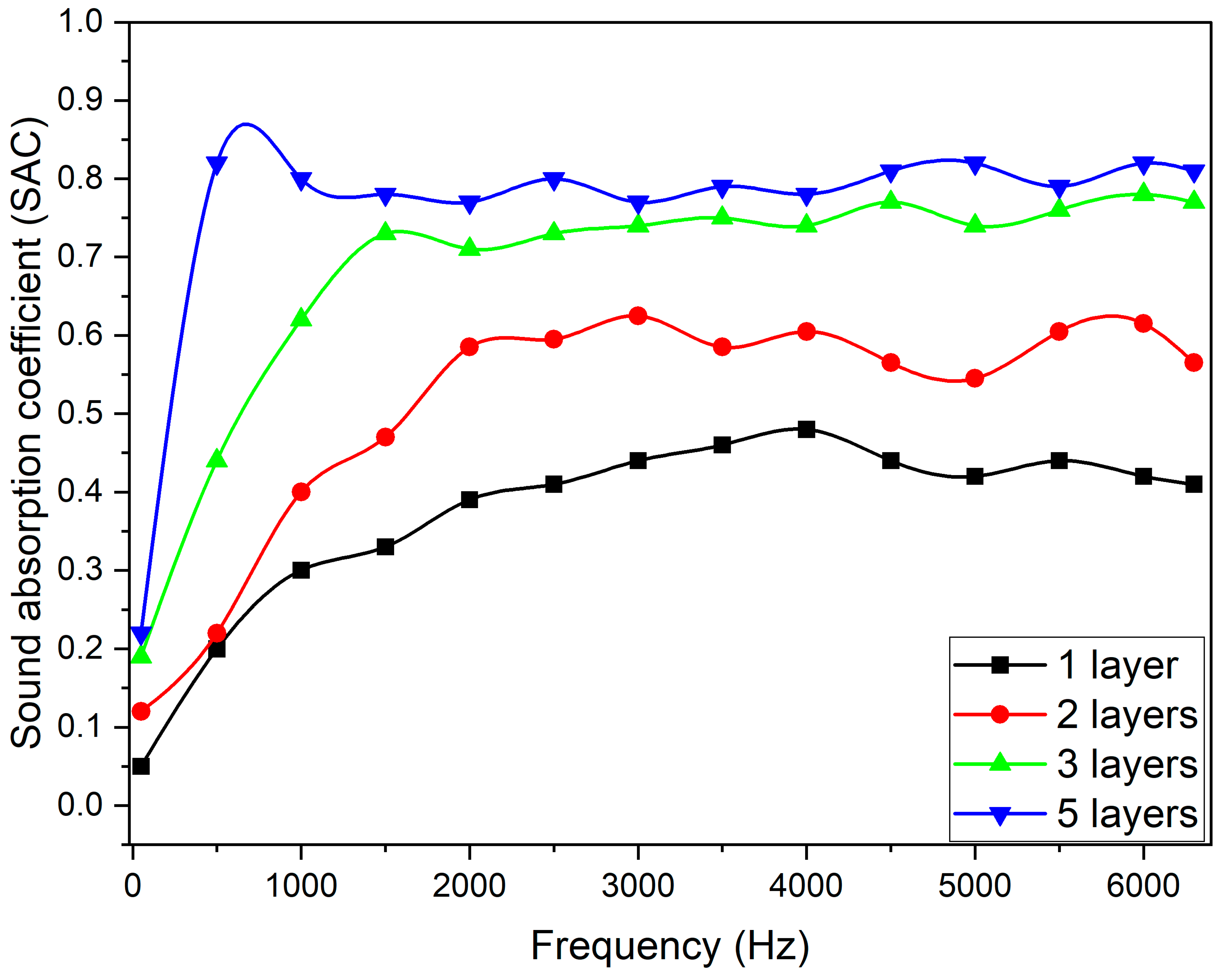

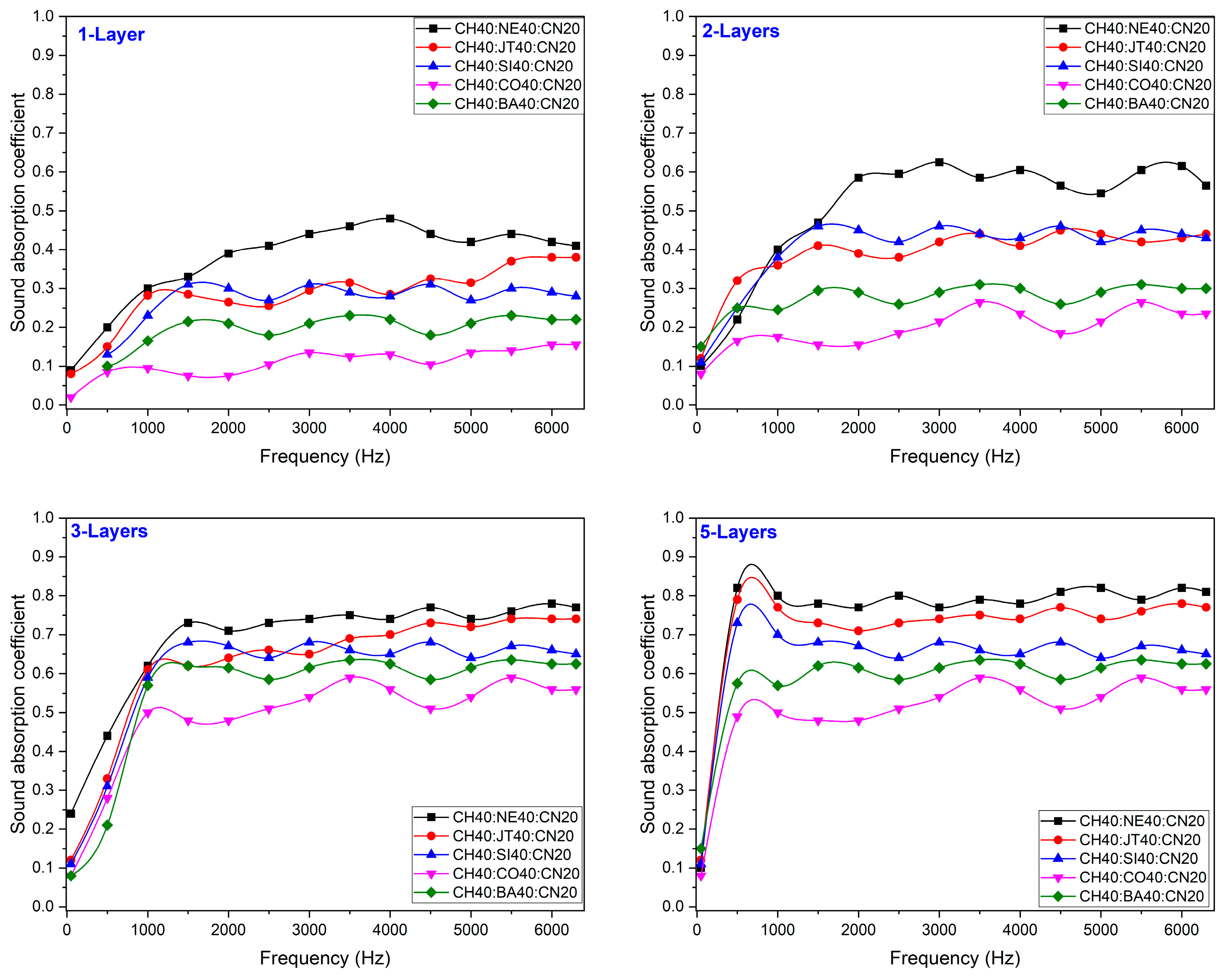

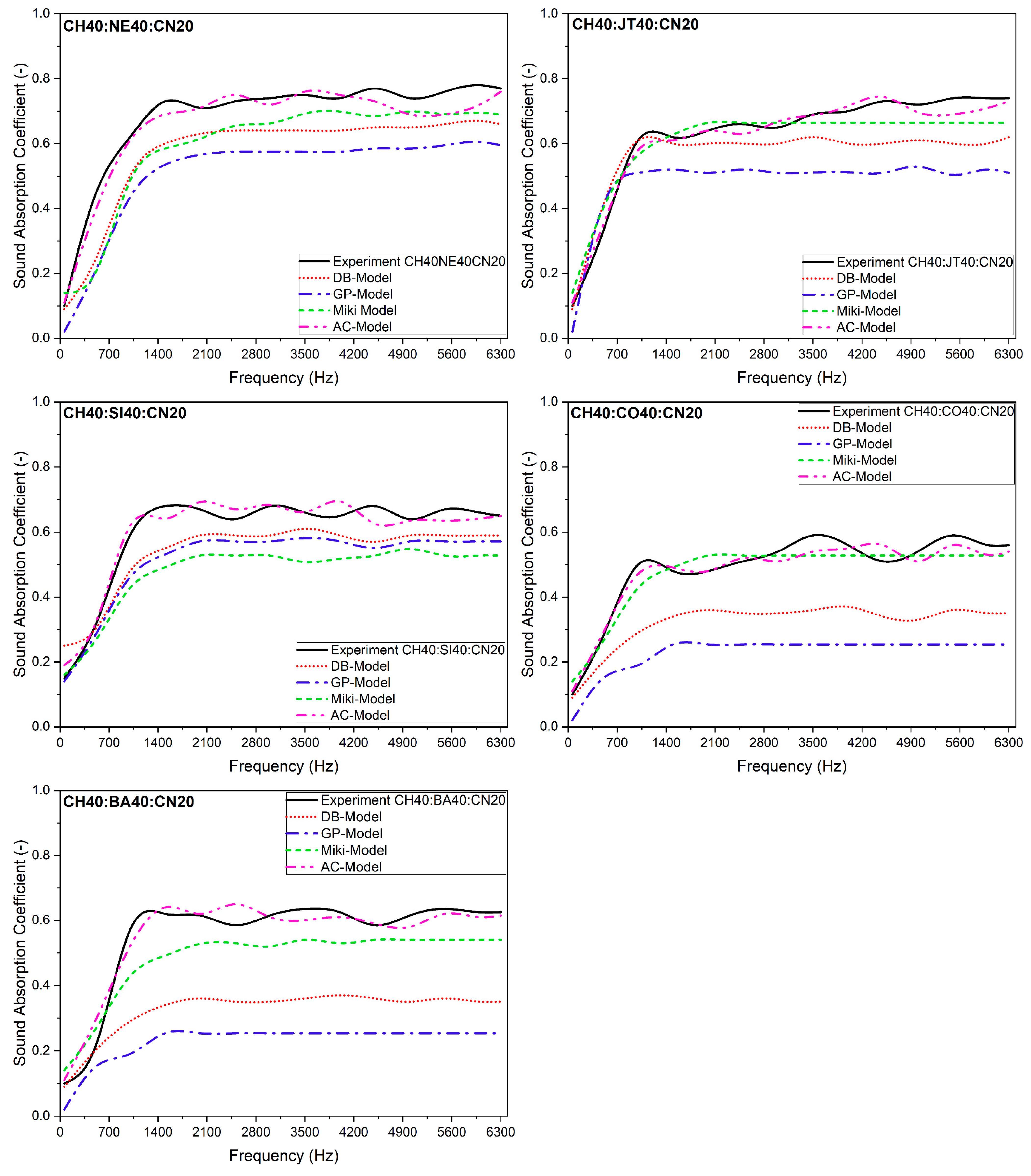

3.2. Results for Sound Absorption Coefficient

- A greater number of fine fibers as opposed to coarser fibers in the same weight of nonwoven, which results in a more convoluted path in the fibrous structure.

- Because the finer fibers had a larger surface area, there was a greater likelihood that they would interact with the sound waves. This resulted in a higher airflow resistance, which was caused by frictional viscosity brought about by the vibrating of the air.

- The ability of finer fibers to vibrate more easily than coarser fibers can result in the loss of acoustic energy, which can then be converted into heat.

3.3. Comparison with some Commercial Products

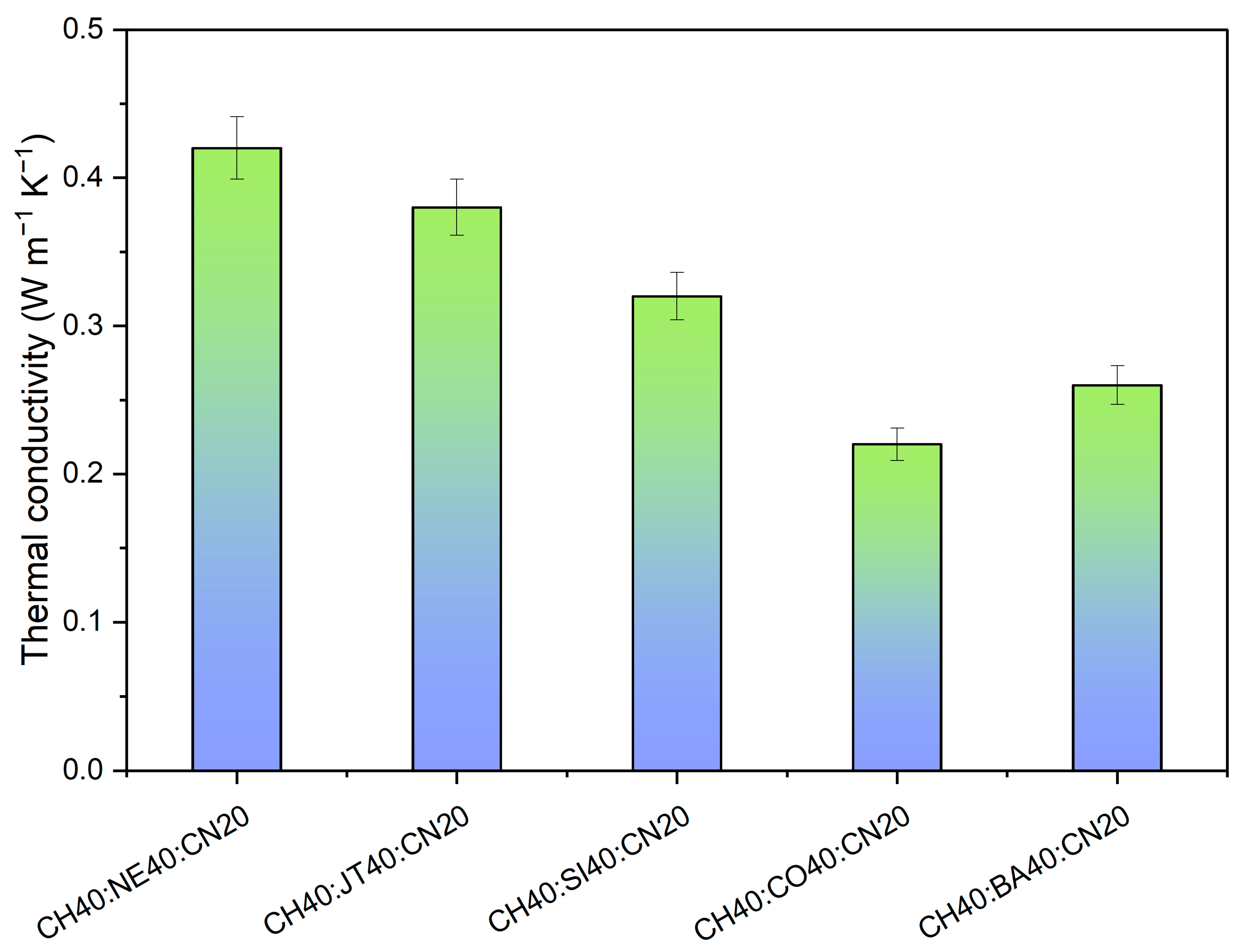

3.4. Thermal and Acoustic Properties

3.5. Air Permeability

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moszynski, P. WHO Warns Noise Pollution Is a Growing Hazard to Health in Europe. BMJ 2011, 342, d2114. [Google Scholar] [CrossRef] [PubMed]

- ShSuneel, D. Status of Ambient Noise Level in India 2017; National Ambient Noise Monitoring Network: New Delhi, India, 2018. [Google Scholar]

- Chepesiuk, R. Decibel Hell: The Effects of Living in a Noisy World. Environ. Health Perspect. 2005, 113, A34–A41. [Google Scholar] [CrossRef]

- Münzel, T.; Sørensen, M. Noise Pollution and Arterial Hypertension. Eur. Cardiol. Rev. 2017, 12, 26. [Google Scholar] [CrossRef]

- Halperin, D. Environmental Noise and Sleep Disturbances: A Threat to Health? Sleep Sci. 2014, 7, 209–212. [Google Scholar] [CrossRef] [PubMed]

- Munzel, T.; Gori, T.; Babisch, W.; Basner, M. Cardiovascular Effects of Environmental Noise Exposure. Eur. Heart J. 2014, 35, 829–836. [Google Scholar] [CrossRef]

- Münzel, T.; Sørensen, M.; Daiber, A. Transportation Noise Pollution and Cardiovascular Disease. Nat. Rev. Cardiol. 2021, 18, 619–636. [Google Scholar] [CrossRef] [PubMed]

- Frenzilli, G.; Ryskalin, L.; Ferrucci, M.; Cantafora, E.; Chelazzi, S.; Giorgi, F.S.; Lenzi, P.; Scarcelli, V.; Frati, A.; Biagioni, F.; et al. Loud Noise Exposure Produces DNA, Neurotransmitter and Morphological Damage within Specific Brain Areas. Front. Neuroanat. 2017, 11, 49. [Google Scholar] [CrossRef] [PubMed]

- Dos Reis, J.M.L. Effect of Textile Waste on the Mechanical Properties of Polymer Concrete. Mater. Res. 2009, 12, 63–67. [Google Scholar] [CrossRef]

- Periyasamy, A.P.; Militky, J. Sustainability in Regenerated Textile Fibers. In Sustainability in the Textile and Apparel Industries; Springer: Cham, Switzerland, 2020; pp. 63–95. [Google Scholar]

- Periyasamy, A.P. Natural Dyeing of Cellulose Fibers Using Syzygium Cumini Fruit Extracts and a Bio-Mordant: A Step toward Sustainable Dyeing. Sustain. Mater. Technol. 2022, 33, e00472. [Google Scholar] [CrossRef]

- Periyasamy, A.P.; Tehrani-Bagha, A. A Review on Microplastic Emission from Textile Materials and Its Reduction Techniques. Polym. Degrad. Stab. 2022, 199, 109901. [Google Scholar] [CrossRef]

- Arenas, J.P.; Asdrubali, F. Eco-Materials with Noise Reduction Properties. In Handbook of Ecomaterials; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–26. [Google Scholar]

- Asdrubali, F.; Schiavoni, S.; Horoshenkov, K.V. A Review of Sustainable Materials for Acoustic Applications. Build. Acoust. 2012, 19, 283–311. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Yatim, J.M.; Sam, A.R.M.; Awal, A.S.M.A. Durability Performance of Green Concrete Composites Containing Waste Carpet Fibers and Palm Oil Fuel Ash. J. Clean. Prod. 2017, 144, 448–458. [Google Scholar] [CrossRef]

- Rao, S.; Riahi, K. The Role of Non-CO₃ Greenhouse Gases in Climate Change Mitigation: Long-Term Scenarios for the 21st Century. Energy J. 2006, 27, 177–200. [Google Scholar]

- Leahy, S.; Clark, H.; Reisinger, A. Challenges and Prospects for Agricultural Greenhouse Gas Mitigation Pathways Consistent with the Paris Agreement. Front. Sustain. Food Syst. 2020, 4, 1–8. [Google Scholar] [CrossRef]

- da Silva, A.R.; Mareze, P.; Brandão, E. Prediction of Sound Absorption in Rigid Porous Media with the Lattice Boltzmann Method. J. Phys. A Math. Theor. 2016, 49, 065501. [Google Scholar] [CrossRef]

- Debnath, B.; Haldar, D.; Purkait, M.K. A Critical Review on the Techniques Used for the Synthesis and Applications of Crystalline Cellulose Derived from Agricultural Wastes and Forest Residues. Carbohydr. Polym. 2021, 273, 118537. [Google Scholar] [CrossRef]

- Coffee Second Only to Oil? Available online: https://www.thefreelibrary.com/Coffee+second+only+to+oil%3F+Is+coffee+really+the+second+largest...-a0198849799 (accessed on 13 July 2022).

- Karunakaran, G.; Periyasamy, A.P.; Tehrani, A. Extraction of Micro, Nanocrystalline Cellulose and Textile Fibers from Coffee Waste. J. Test. Eval. 2023, 51, 20220487. [Google Scholar] [CrossRef]

- Chawalitsakunchai, W.; Dittanet, P.; Loykulnant, S.; Sae-oui, P.; Tanpichai, S.; Seubsai, A.; Prapainainar, P. Properties of Natural Rubber Reinforced with Nano Cellulose from Pineapple Leaf Agricultural Waste. Mater. Today Commun. 2021, 28, 102594. [Google Scholar] [CrossRef]

- Ventura-Cruz, S.; Tecante, A. Nanocellulose and Microcrystalline Cellulose from Agricultural Waste: Review on Isolation and Application as Reinforcement in Polymeric Matrices. Food Hydrocoll. 2021, 118, 106771. [Google Scholar] [CrossRef]

- Vincent, S.; Kandasubramanian, B. Cellulose Nanocrystals from Agricultural Resources: Extraction and Functionalisation. Eur. Polym. J. 2021, 160, 110789. [Google Scholar] [CrossRef]

- Fatima, S.; Mohanty, A.R. Acoustical and Fire-Retardant Properties of Jute Composite Materials. Appl. Acoust. 2011, 72, 108–114. [Google Scholar] [CrossRef]

- Yilmaz, N.D.; Powell, N.B.; Banks-Lee, P.; Michielsen, S. Hemp-Fiber Based Nonwoven Composites: Effects of Alkalization on Sound Absorption Performance. Fibers Polym. 2012, 13, 915–922. [Google Scholar] [CrossRef]

- Hosseini Fouladi, M.; Ayub, M.; Jailani Mohd Nor, M. Analysis of Coir Fiber Acoustical Characteristics. Appl. Acoust. 2011, 72, 35–42. [Google Scholar] [CrossRef]

- Khidir, E.A.; Ali, M.O.M.; Ali, M.M.; Tahir, M.F.B.M.; Zulkifli, R. Analysis of Sound Absorption of Date Palm Fibers Based on Flow Resistivity. Appl. Mech. Mater. 2013, 471, 285–290. [Google Scholar] [CrossRef]

- Thilagavathi, G.; Pradeep, E.; Kannaian, T.; Sasikala, L. Development of Natural Fiber Nonwovens for Application as Car Interiors for Noise Control. J. Ind. Text. 2010, 39, 267–278. [Google Scholar] [CrossRef]

- Rwawiire, S.; Tomkova, B.; Militky, J.; Hes, L.; Kale, B.M. Acoustic and Thermal Properties of a Cellulose Nonwoven Natural Fabric (Barkcloth). Appl. Acoust. 2017, 116, 177–183. [Google Scholar] [CrossRef]

- Asdrubali, F. Green and Sustainable Materials for Noise Control in Buildings. In Proceedings of the 19th International Congress on Acoustics, Madrid, Spain, 2–7 September 2007. [Google Scholar]

- Venkatesan, H.; Periyasamy, A.P. Eco-Fibers in the Textile Industry. In Handbook of Ecomaterials; Springer International Publishing: Cham, Switzerland, 2019; Volume 3, pp. 1413–1433. ISBN 9783319682556. [Google Scholar]

- ASTM D5729-97; Standard Test Method for Thickness of Nonwoven Fabrics. ASTM: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/d5729-97.html (accessed on 13 March 2023).

- Liu, Y.; Lyu, L.; Guo, J.; Wang, Y. Sound Absorption Performance of the Poplar Seed Fiber/PCL Composite Materials. Materials 2020, 13, 1465. [Google Scholar] [CrossRef] [PubMed]

- ASTM D737-18; Standard Test Method for Air Permeability of Textile Fabrics. ASTM: West Conshohocken, PA, USA, 2018. Available online: https://www.astm.org/standards/d737 (accessed on 13 March 2023).

- Hes, L.; Dolezal, I. New Method and Equipment for Measuring Thermal Properties of Textiles. Sen’i Kikai Gakkaishi J. Text. Mach. Soc. Jpn. 1989, 42, T124–T128. [Google Scholar] [CrossRef]

- Mangat, M.M.; Hes, L. Comfort Aspects of Denim Garments. In Denim: Manufacture, Finishing and Applications; Woodhead Publishing: Sawston, UK, 2015; pp. 461–479. ISBN 9780857098498. [Google Scholar]

- Hes, L.; Dolezal, I. Indirect Measurement of Moisture Absorptivity of Functional Textile Fabrics. J. Phys. Conf. Ser. 2018, 1065, 122026. [Google Scholar] [CrossRef]

- ASTM E1050-12; Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphones and a Digital Frequency Analysis System. ASTM: West Conshohocken, PA, USA, 2019. Available online: https://www.astm.org/e1050-12.html (accessed on 11 March 2023).

- Jayamani, E.; Hamdan, S.; Rahman, M.R.; Bin Bakri, M.K.; Kakar, A. An Investigation of Sound Absorption Coefficient on Sisal Fiber Poly Lactic Acid Bio-Composites. J. Appl. Polym. Sci. 2015, 132, 42470. [Google Scholar] [CrossRef]

- Jayamani, E.; Hamdan, S.; Kok Heng, S.; Rahman, M.R.; Bin Bakri, M.K. Acoustical, Thermal, and Morphological Properties of Zein Reinforced Oil Palm Empty Fruit Bunch Fiber Bio-Composites. J. Appl. Polym. Sci. 2016, 133, 44164. [Google Scholar] [CrossRef]

- Bakri, M.K.B. Investigation of Acoustical and Mechanical Properties of Epoxy Based Natural Fibre Composites. Master’s Thesis, Swinburne University of Technology, Melbourne, Australia, 2015. [Google Scholar]

- Delany, M.E.; Bazley, E.N. Acoustical Properties of Fibrous Absorbent Materials. Appl. Acoust. 1970, 3, 105–116. [Google Scholar] [CrossRef]

- Egab, L.; Wang, X.; Fard, M. Acoustical Characterisation of Porous Sound Absorbing Materials: A Review. Int. J. Veh. Noise Vib. 2014, 10, 129. [Google Scholar] [CrossRef]

- Samaei, S.E.; Berardi, U.; Soltani, P.; Taban, E. Experimental and Modeling Investigation of the Acoustic Behavior of Sustainable Kenaf/Yucca Composites. Appl. Acoust. 2021, 183, 108332. [Google Scholar] [CrossRef]

- Garai, M.; Pompoli, F. A Simple Empirical Model of Polyester Fibre Materials for Acoustical Applications. Appl. Acoust. 2005, 66, 1383–1398. [Google Scholar] [CrossRef]

- Kirby, R. On the Modification of Delany and Bazley Fomulae. Appl. Acoust. 2014, 86, 47–49. [Google Scholar] [CrossRef]

- Crocker, M.J. (Ed.) Handbook of Noise and Vibration Control; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; ISBN 9780470209707. [Google Scholar]

- Bonfiglio, P.; Pompoli, F. Inversion Problems for Determining Physical Parameters of Porous Materials: Overview and Comparison Between Different Methods. Acta Acust. United Acust. 2013, 99, 341–351. [Google Scholar] [CrossRef]

- Miki, Y. Acoustical Properties of Porous Materials. Modifications of Delany-Bazley Models. J. Acoust. Soc. Jpn. 1990, 11, 19–24. [Google Scholar] [CrossRef]

- Champoux, Y.; Allard, J. Dynamic Tortuosity and Bulk Modulus in Air-saturated Porous Media. J. Appl. Phys. 1991, 70, 1975–1979. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G.; di Gabriele, M. Characterization of Sheep Wool Panels for Room Acoustic Applications. In Proceedings of the Meetings on Acoustics, Buenos Aires, Argentina, 5–9 September 2016; p. 015001. [Google Scholar]

- Qui, H.; Enhui, Y. Effect of Thickness, Density and Cavity Depth on the Sound Absorption Properties of Wool Boards. Autex Res. J. 2018, 18, 203–208. [Google Scholar] [CrossRef]

- Li, H.; Zhang, N.; Fan, X.; Gong, J.; Zhang, J.; Zhao, X. Investigation of Effective Factors of Woven Structure Fabrics for Acoustic Absorption. Appl. Acoust. 2020, 161, 107081. [Google Scholar] [CrossRef]

- Prahsarn, C.; Klinsukhon, W.; Suwannamek, N.; Wannid, P.; Padee, S. Sound Absorption Performance of Needle-Punched Nonwovens and Their Composites with Perforated Rubber. SN Appl. Sci. 2020, 2, 559. [Google Scholar] [CrossRef]

- Oliveira, T.A. Noise Control Treatments Modeling Using Statistical Energy Analysis and the Transfer Matrix Method. In Multiphysics Simulations in Automotive and Aerospace Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 91–131. [Google Scholar]

- Liu, P.S.; Chen, G.F. Characterization Methods. In Porous Materials; Elsevier: Amsterdam, The Netherlands, 2014; pp. 493–532. [Google Scholar]

- Koruk, H.; Genc, G.; Yuce, H. Jute and Luffa Fibers: Physical, Acoustical, and Mechanical Properties. In Cellulose Fibre Reinforced Composites; Elsevier: Amsterdam, The Netherlands, 2023; pp. 357–378. [Google Scholar]

- Mamtaz, H.; Hosseini Fouladi, M.; Nuawi, M.Z.; Narayana Namasivayam, S.; Ghassem, M.; Al-Atabi, M. Acoustic Absorption of Fibro-Granular Composite with Cylindrical Grains. Appl. Acoust. 2017, 126, 58–67. [Google Scholar] [CrossRef]

- Jitendra Kumar Shukla Coir Products. Available online: http://www.ccriindia.org/cict_bangalore.html (accessed on 22 April 2023).

- Saurabh Bakliwal Thermoplastic Nonwovens and PU Foams. Available online: https://www.dynamicnonwovens.com/profile.html (accessed on 22 April 2023).

- Militky, J.; Kremenakova, D. A Simple Methods for Prediction of Textile Fabrics Thermal Conductivity. In Proceedings of the 5th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, South Africa, 1–4 July 2017; Meyer, J.P., Ed.; University of Pretoria: Sun City, South Africa, 2007; pp. 1–5. [Google Scholar]

- Xiao, X.; hu, J.; Hua, T.; Zeng, X.; Long, A. Through-Thickness Air Permeability of Woven Fabric under Low Pressure Compression. Text. Res. J. 2015, 85, 1732–1742. [Google Scholar] [CrossRef]

| Properties | Coffee Husk Fiber (CH) | Nettle (NE) | Jute (JT) | Sisal (SI) | Coir (CO) | Banana (BA) | Cotton (CN) |

|---|---|---|---|---|---|---|---|

| Fiber length (mm) | 18 ± 15 | 48 ± 18 | 30 ± 12 | 32 ± 4 | 73 ± 35 | 98 ± 34 | 18 ± 2.8 |

| Fiber diameter (μm) | 15.98 ± 21 | 11.2 ± 3 | 12 ± 3.8 | 13 ± 4.4 | 24 ± 14.5 | 16 ± 7.2 | 12 ± 0.8 |

| Moisture regains (%) at 65% R.H | 8.4 | 9.2 | 12.5 | 11 | 10.5 | 13 | 8.5 |

| Tenacity | 3.69 ± 4 g/tex | 18 ± 2 g/tex | 5 ± 1.4 g/den | 9 ± 2.2 g/den | 10 ± 3.1 g/tex | 9 ± 1.5 g/den | 5 ± 1.1 g/den |

| Elongation (%) | 5.2 ± 6 | 4.29 ± 2 | 1.5 ± 0.3 | 4.5 ± 1.4 | 0.8 ± 0.2 | 6.5 ± 2 | 4 ± 0.8 |

| Sample | Blend Ratio (Weight %) | ||||||

|---|---|---|---|---|---|---|---|

| Coffee Husk | Nettle | Jute | Sisal | Coir | Banana | Cotton | |

| CH40:NE40:CN20 | 40 | 40 | - | - | - | - | 20 |

| CH40:JT40:CN20 | 40 | - | 40 | - | - | - | 20 |

| CH40:SI40:CN20 | 40 | - | - | 40 | - | - | 20 |

| CH40:CO40:CN20 | 40 | - | - | - | 40 | - | 20 |

| CH40:BA40:CN20 | 40 | - | - | - | - | 40 | 20 |

| Sample | Fabric Ariel Density (g.m2) | Thickness (mm) | Porosity (%) | |||

|---|---|---|---|---|---|---|

| Mean | σ | Mean | σ | Mean | σ | |

| CH40:NE40:CN20 | 390 | ±12 | 4.8 | ±0.12 | 78.62 | ±1.5 |

| CH40:JT40:CN20 | 430 | ±18 | 5.1 | ±0.18 | 77.58 | ±0.5 |

| CH40:SI40:CN20 | 510 | ±21 | 5.3 | ±0.14 | 75.17 | ±0.4 |

| CH40:CO40:CN20 | 580 | ±19 | 5.8 | ±0.31 | 80.1 | ±1.2 |

| CH40:BA40:CN20 | 520 | ±24 | 5.2 | ±0.18 | 76.29 | ±1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Periyasamy, A.P. Nonwoven Fabrics from Agricultural and Industrial Waste for Acoustic and Thermal Insulation Applications. Textiles 2023, 3, 182-200. https://doi.org/10.3390/textiles3020013

Periyasamy AP. Nonwoven Fabrics from Agricultural and Industrial Waste for Acoustic and Thermal Insulation Applications. Textiles. 2023; 3(2):182-200. https://doi.org/10.3390/textiles3020013

Chicago/Turabian StylePeriyasamy, Aravin Prince. 2023. "Nonwoven Fabrics from Agricultural and Industrial Waste for Acoustic and Thermal Insulation Applications" Textiles 3, no. 2: 182-200. https://doi.org/10.3390/textiles3020013

APA StylePeriyasamy, A. P. (2023). Nonwoven Fabrics from Agricultural and Industrial Waste for Acoustic and Thermal Insulation Applications. Textiles, 3(2), 182-200. https://doi.org/10.3390/textiles3020013