PCM-Impregnated Textile-Reinforced Cementitious Composite for Thermal Energy Storage

Abstract

:1. Introduction

2. Materials and Methods

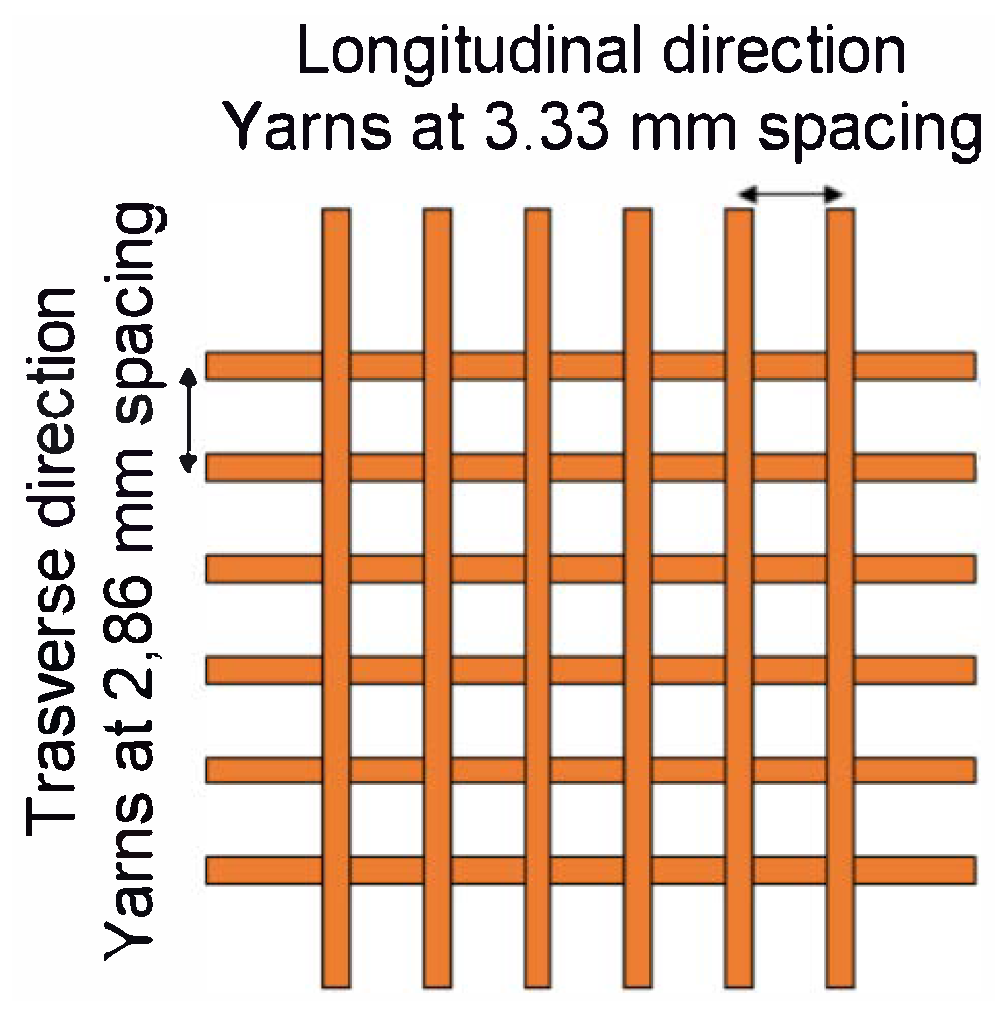

2.1. Materials

2.2. Methods

2.2.1. Scanning Electron Microscopy

2.2.2. Micro-Computed Tomography (Micro-CT) Scans

2.2.3. Immersion of Jute Fabric in Liquid PCM and Polymer Solution

2.2.4. Mechanical Characterization of Jute Fibers

2.2.5. Chemical Characterization of Jute Fibers

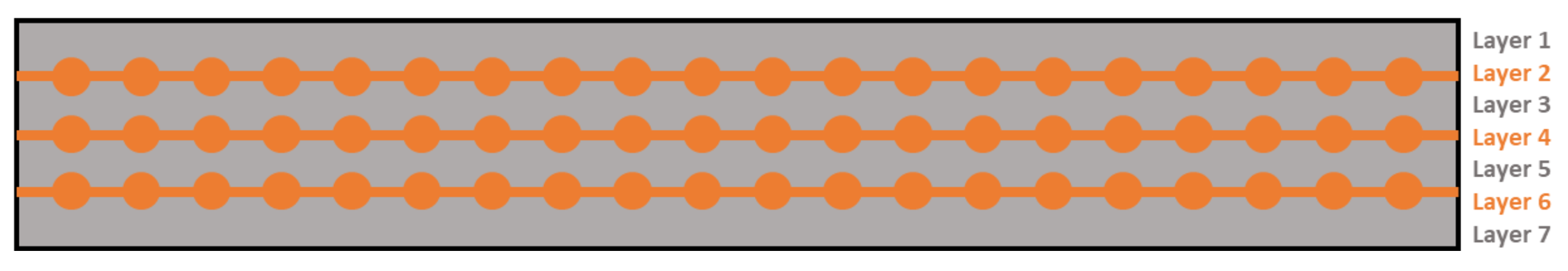

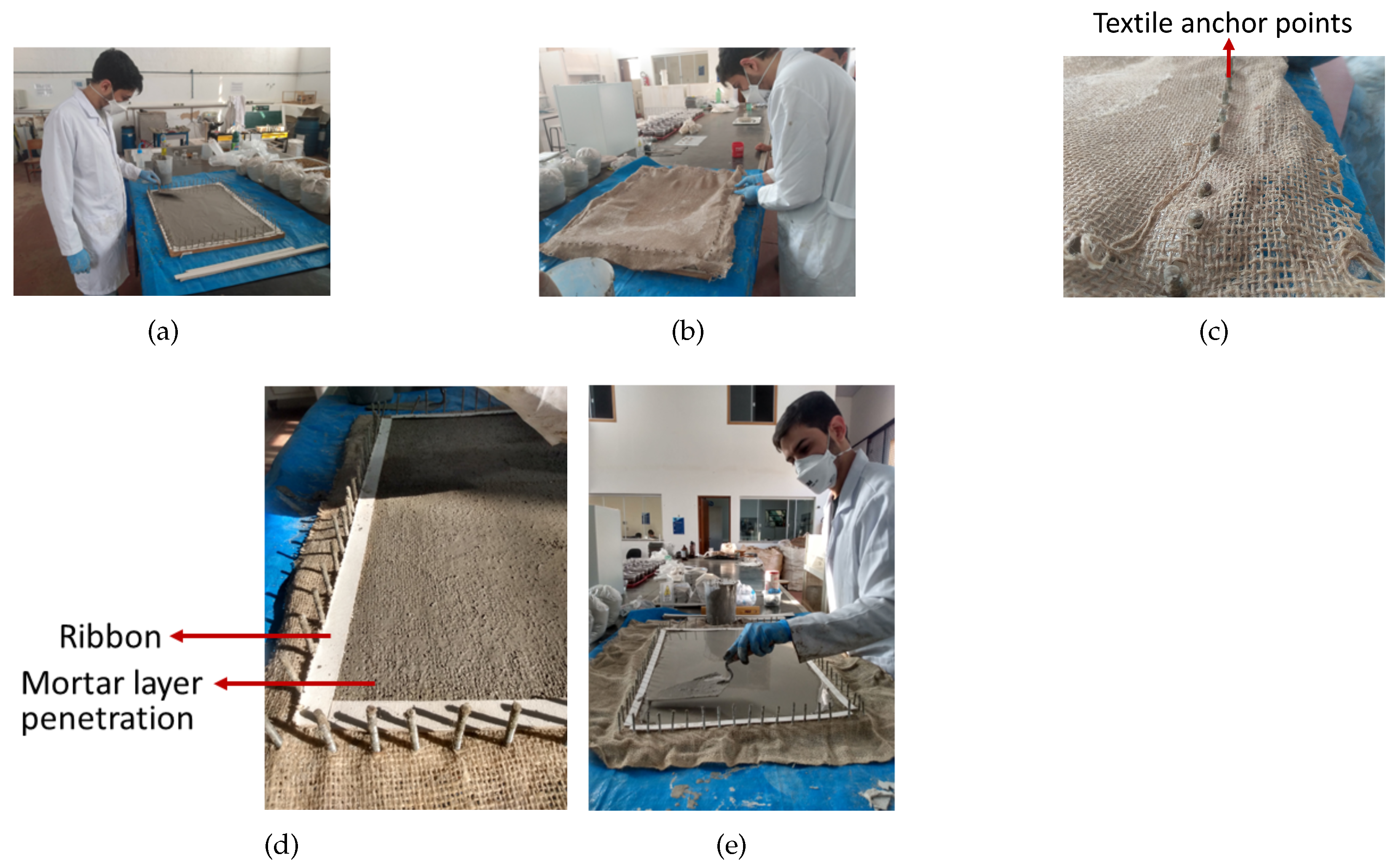

2.2.6. Composite Production

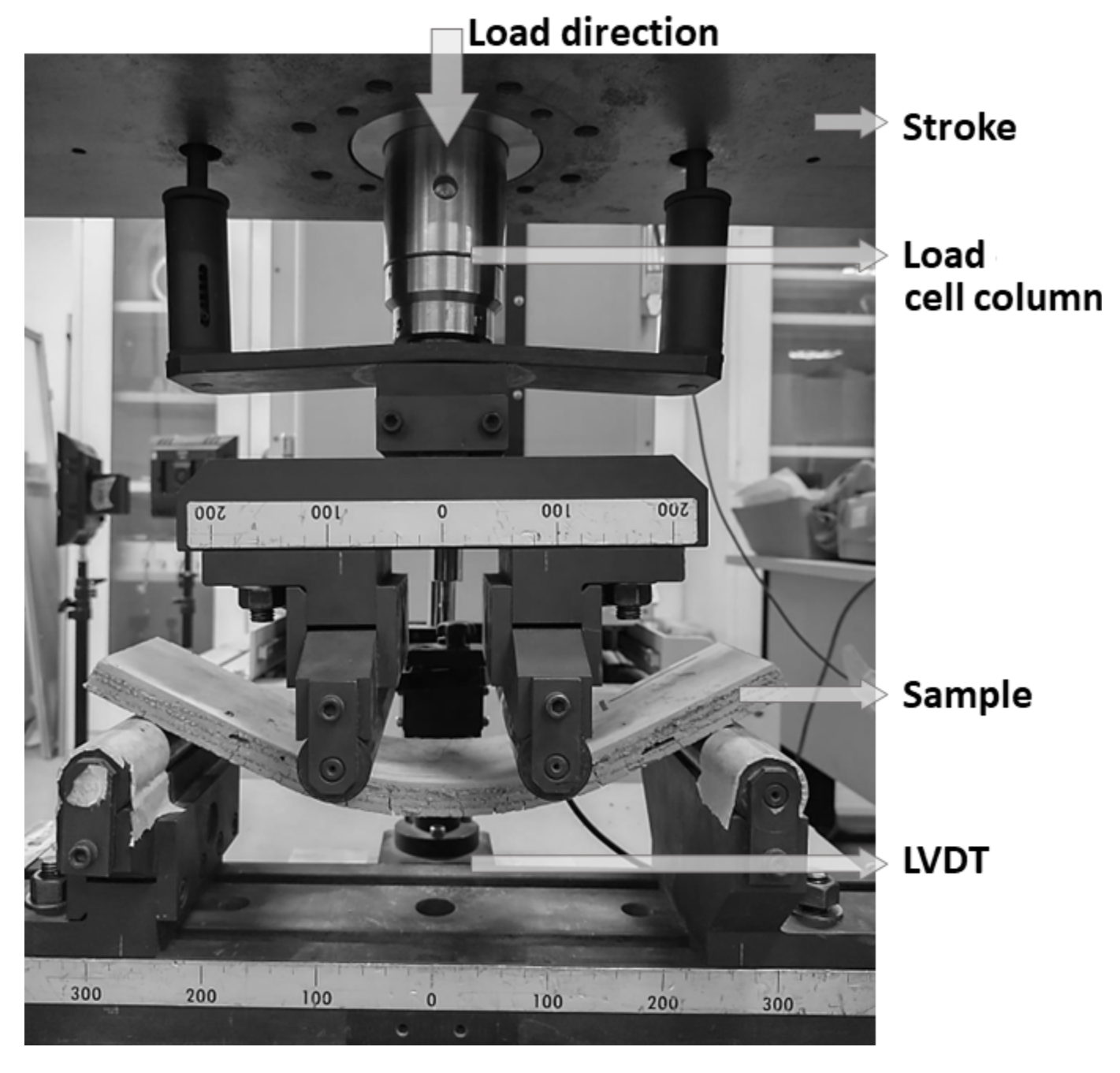

2.2.7. Mechanical Characterization of the Laminated Composites

2.2.8. Thermal Behavior of Composites

3. Results and Discussion

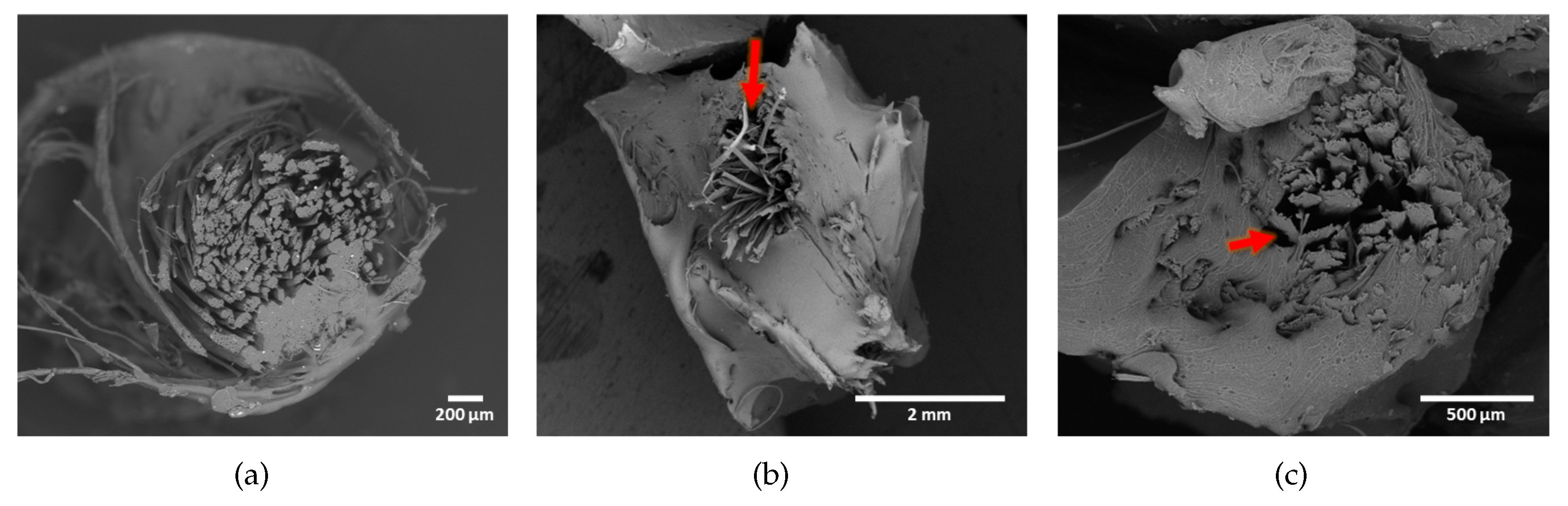

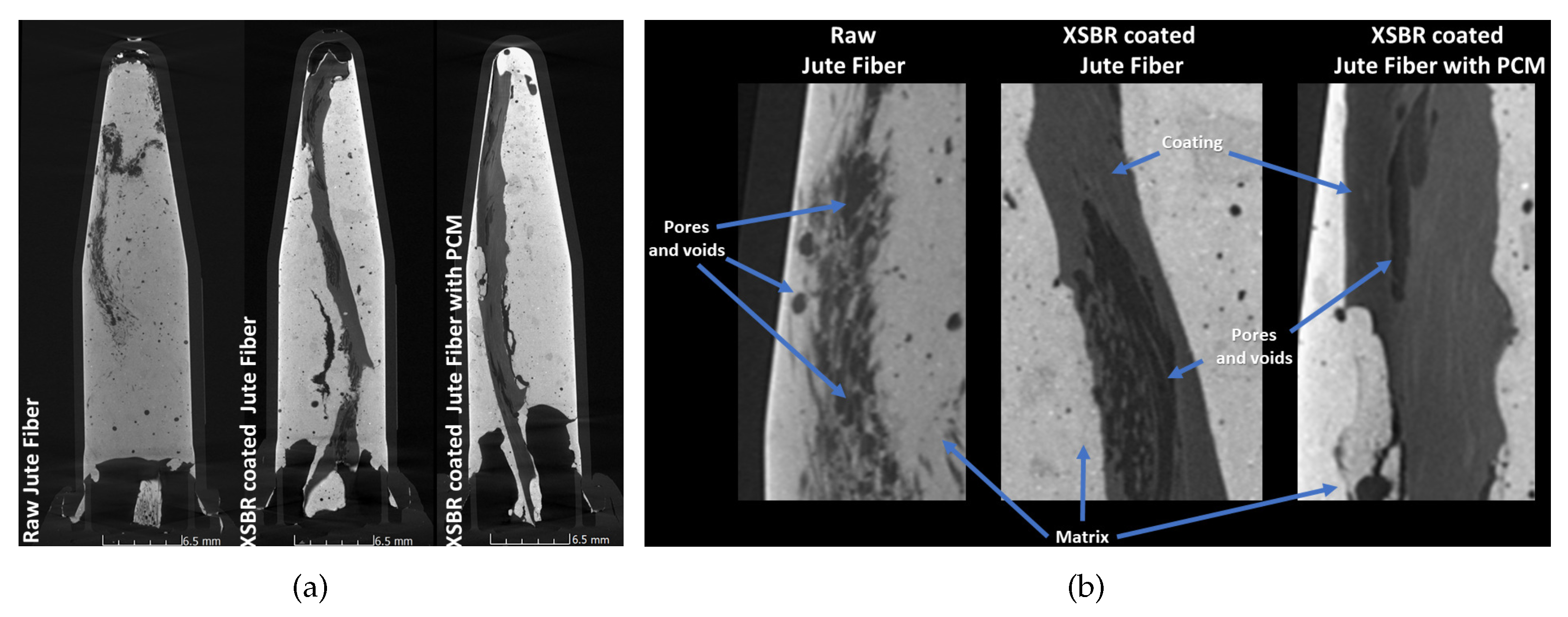

3.1. SEM and Micro-CT Scan Image Analysis

3.2. Jute Fabric PCM Absorption and Polymer Coating Treatment

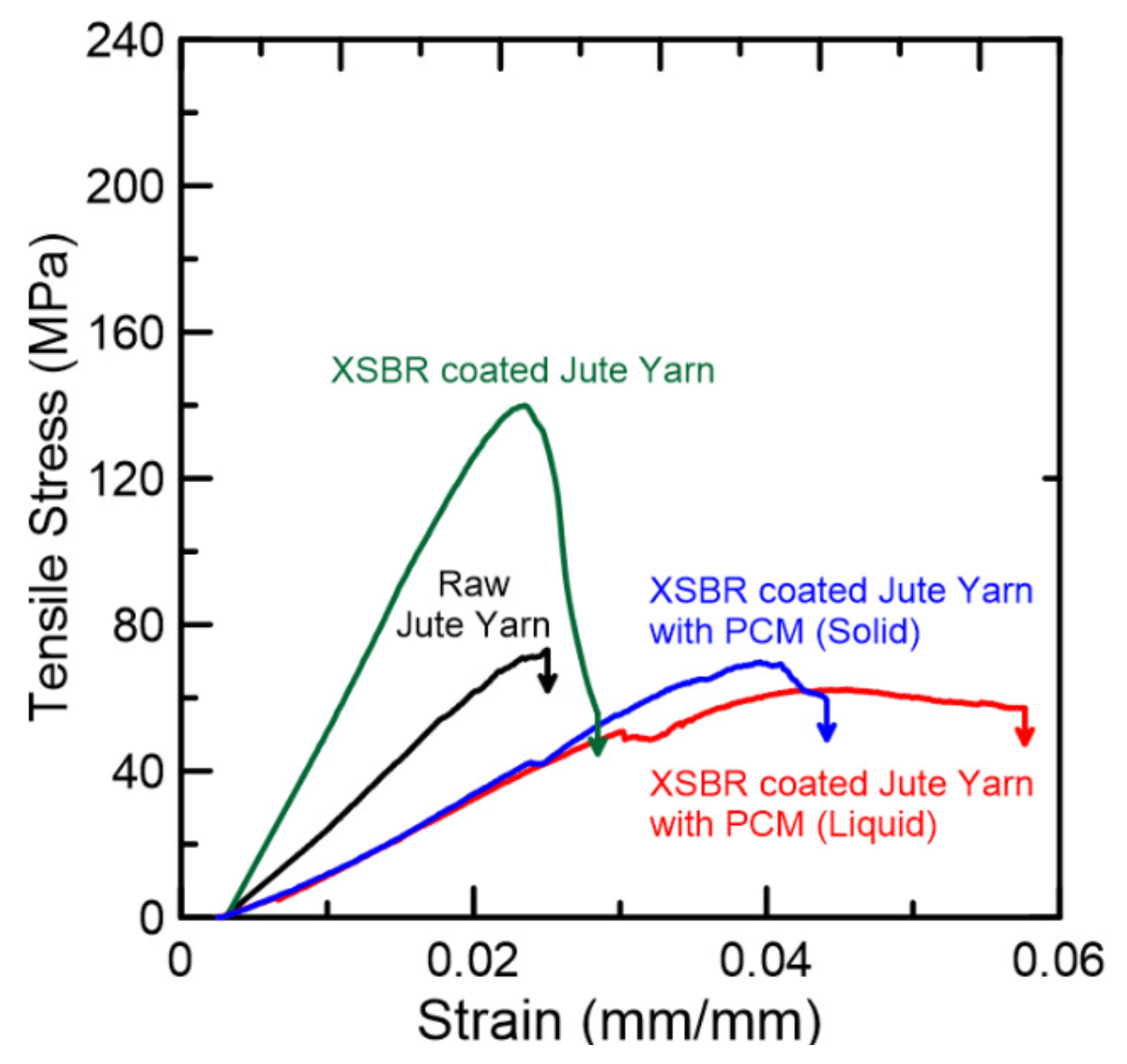

3.3. Mechanical Characterization of Jute Fibers

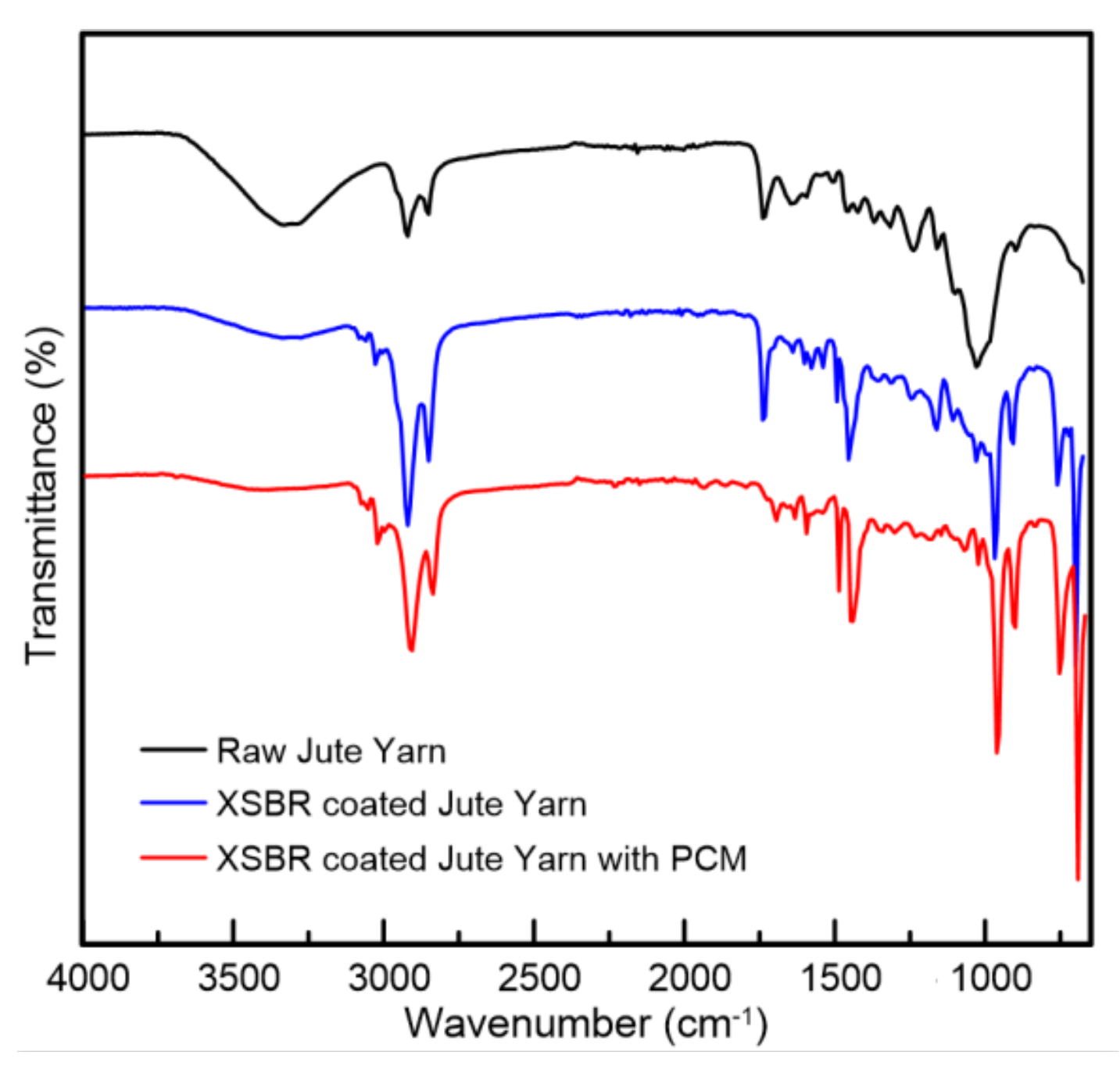

3.4. FTIR

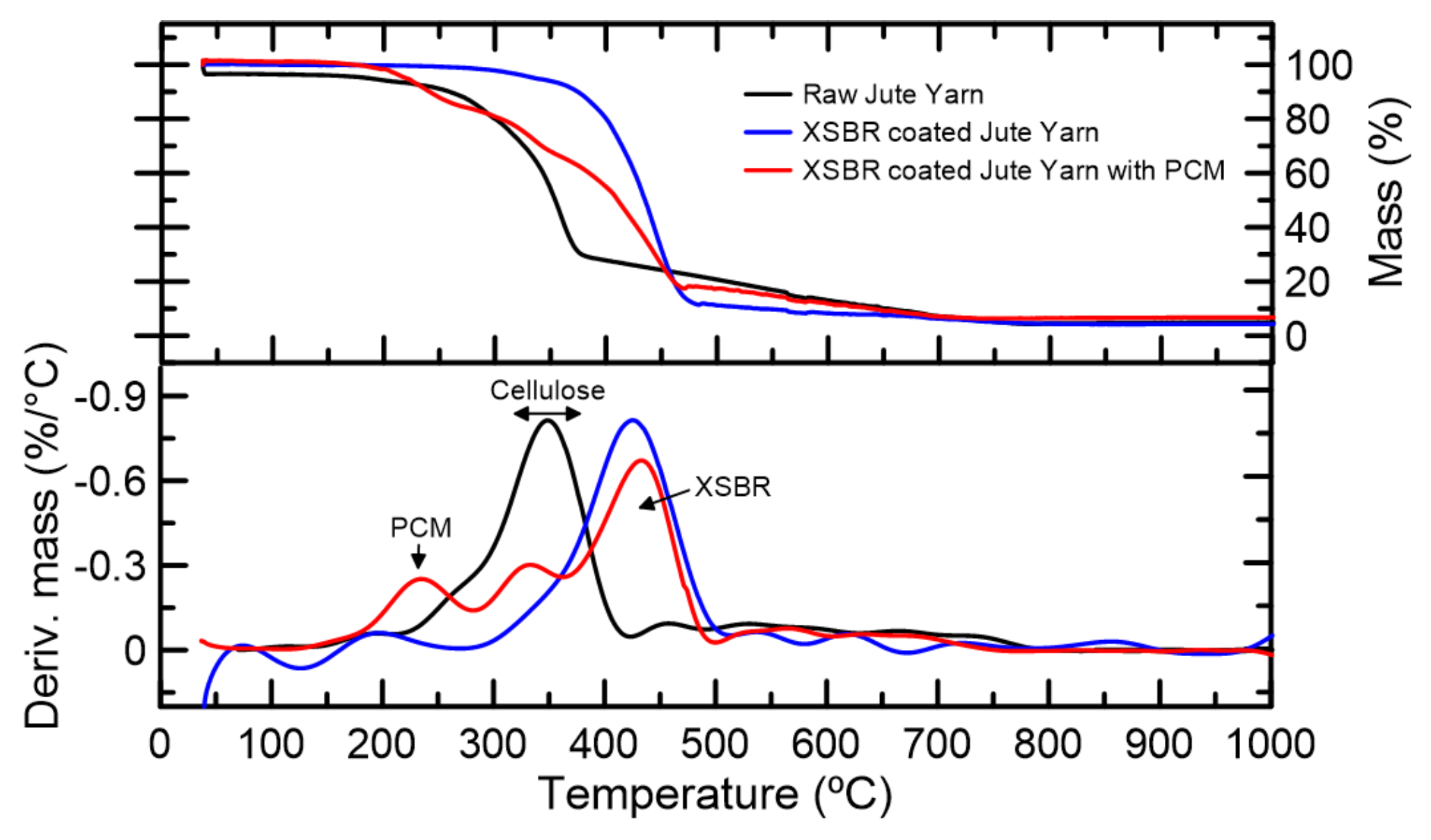

3.5. Thermogravimetric Analysis

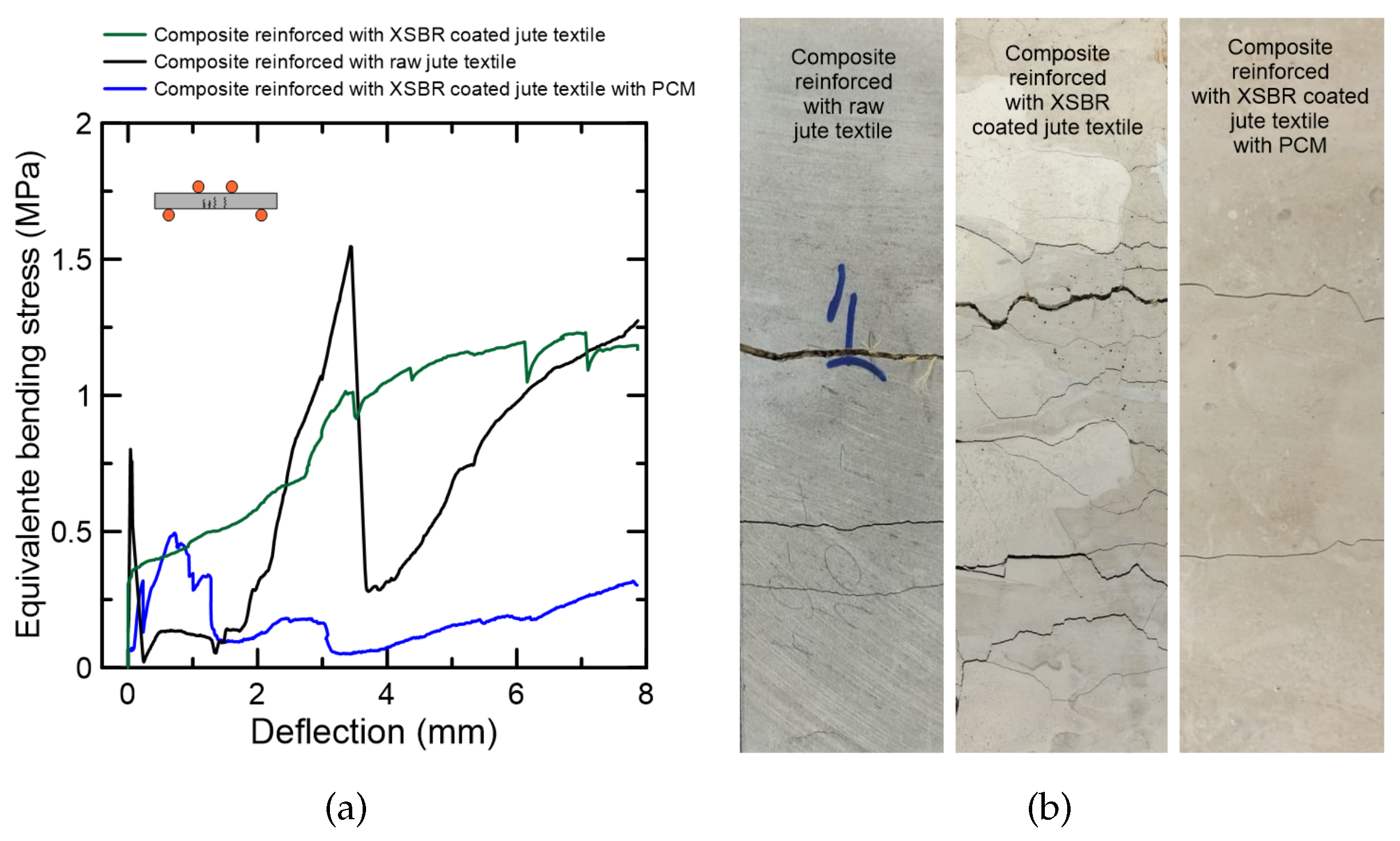

3.6. Mechanical Behavior of Composites

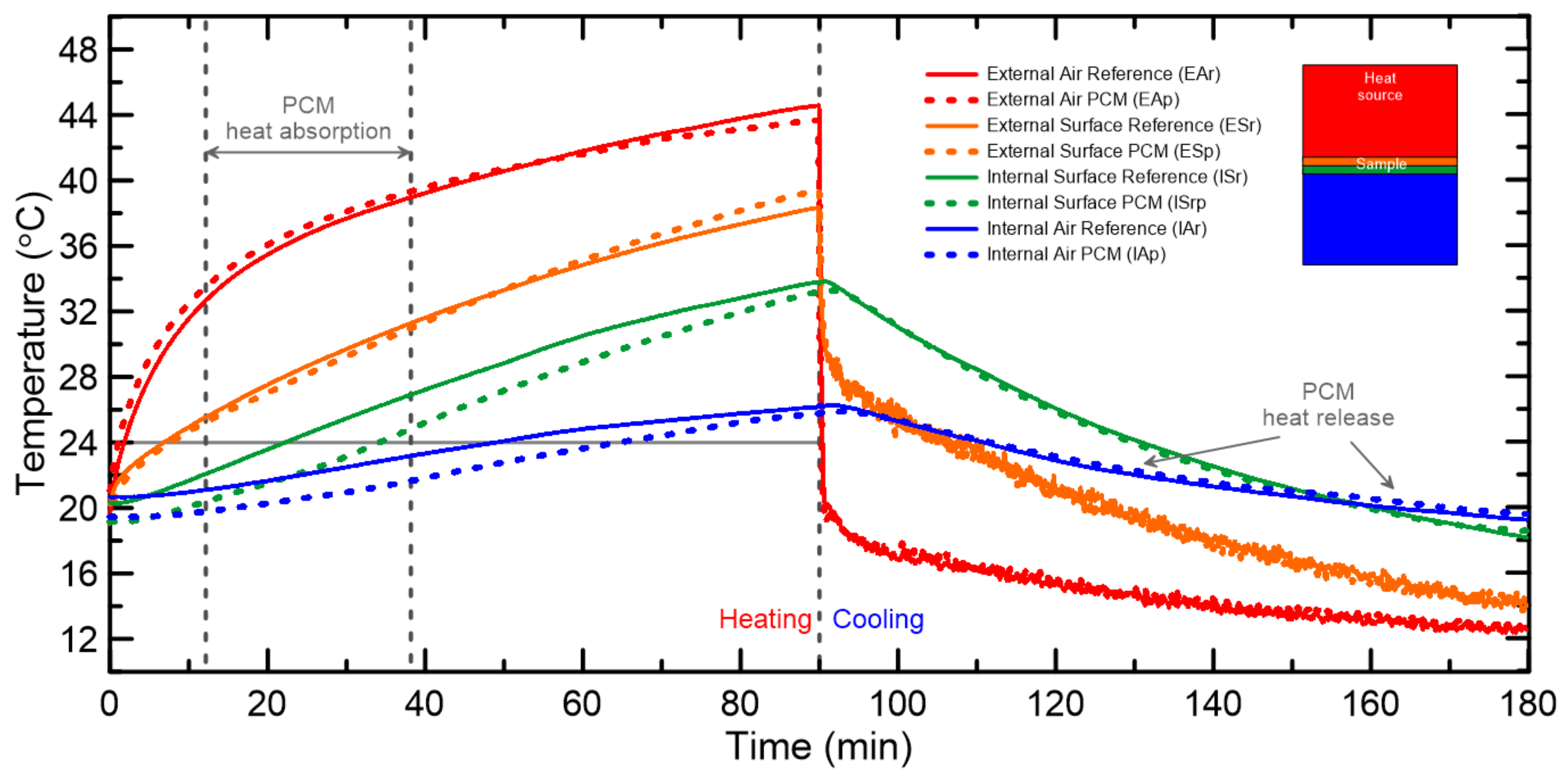

3.7. Thermal Behavior of Composites

4. Conclusions

5. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PCM | Phase Change Material |

| GHG | Greenhouse Gases |

| TES | Thermal Energy Storage |

| LCA | Life Cycle Assessment |

| SDGs | Sustainable Development Goals |

| XSBR | Carboxylated Styrene-Butadiene Rubber |

| SEM | Scanning Electron Microscope |

| Micro-CT | Micro-computed tomography |

| ASTM | American Society for Testing and Materials |

| FTIR | Fourier-transform infrared spectroscopy |

| ATR | Attenuated total reflectance |

| TG | Thermogravimetry |

| DTG | Differential Thermogravimetry |

References

- IEA. Energy Efficiency 2021; Technical Report; IEA: Paris, France, 2021. [Google Scholar]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Phase change materials for building applications: A state-of-the-art review. Energy Build. 2010, 42, 1361–1368. [Google Scholar] [CrossRef]

- da Cunha, S.R.L.; de Aguiar, J.L.B. Phase change materials and energy efficiency of buildings: A review of knowledge. J. Energy Storage 2020, 27, 101083. [Google Scholar] [CrossRef]

- Mankel, C.; Caggiano, A.; Koenders, E. Thermal energy storage characterization of cementitious composites made with recycled brick aggregates containing PCM. Energy Build. 2019, 202, 109395. [Google Scholar] [CrossRef]

- Mankel, C.; Caggiano, A.; König, A.; Schicchi, D.S.; Sam, M.N.; Koenders, E. Modelling the thermal energy storage of cementitious mortars made with PCM-Recycled Brick Aggregates. Materials 2020, 13, 1064. [Google Scholar] [CrossRef] [PubMed]

- Sam, M.N.; Caggiano, A.; Mankel, C.; Koenders, E. A comparative study on the thermal energy storage performance of bio-based and paraffin-based PCMs using DSC procedures. Materials 2020, 13, 1705. [Google Scholar] [CrossRef] [PubMed]

- Fabiani, C.; Pisello, A.L.; Barbanera, M.; Cabeza, L.F. Palm oil-based bio-PCM for energy efficient building applications: Multipurpose thermal investigation and life cycle assessment. J. Energy Storage 2020, 28, 101129. [Google Scholar] [CrossRef]

- Rasta, I.M.; Suamir, I.N. Study on Thermal Properties of Bio-PCM Candidates in Comparison with Propylene Glycol and Salt Based PCM for sub-Zero Energy Storage Applications. IOP Conf. Ser. Mater. Sci. Eng. 2019, 494, 012024. [Google Scholar] [CrossRef]

- Huang, X.; Zhu, C.; Lin, Y.; Fang, G. Thermal properties and applications of microencapsulated PCM for thermal energy storage: A review. Appl. Therm. Eng. 2019, 147, 841–855. [Google Scholar] [CrossRef]

- Mankel, C.; Caggiano, A.; Ukrainczyk, N.; Koenders, E. Thermal energy storage characterization of cement-based systems containing microencapsulated-PCMs. Constr. Build. Mater. 2019, 199, 307–320. [Google Scholar] [CrossRef]

- Singh Rathore, P.K.; Shukla, S.K.; Gupta, N.K. Potential of microencapsulated PCM for energy savings in buildings: A critical review. Sustain. Cities Soc. 2020, 53, 101884. [Google Scholar] [CrossRef]

- Fachinotti, V.D.; Bre, F.; Mankel, C.; Koenders, E.A.; Caggiano, A. Optimization of multilayered walls for building envelopes including pcm-based composites. Materials 2020, 13, 2787. [Google Scholar] [CrossRef] [PubMed]

- Memon, S.A. Phase change materials integrated in building walls: A state of the art review. Renew. Sustain. Energy Rev. 2014, 31, 870–906. [Google Scholar] [CrossRef]

- Sharifi, N.P.; Sakulich, A. Application of phase change materials to improve the thermal performance of cementitious material. Energy Build. 2015, 103, 83–95. [Google Scholar] [CrossRef]

- Jeong, S.G.; Jeon, J.; Seo, J.; Lee, J.H.; Kim, S. Performance evaluation of the microencapsulated PCM for wood-based flooring application. Energy Convers. Manag. 2012, 64, 516–521. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Y.; Yu, Q.; Cao, G.; Yang, R.; Ke, J.; Di, X.; Liu, F.; Zhang, W.; Wang, C. Composite phase change materials with good reversible thermochromic ability in delignified wood substrate for thermal energy storage. Appl. Energy 2018, 212, 455–464. [Google Scholar] [CrossRef]

- Zhang, P.; Xiao, X.; Ma, Z. A review of the composite phase change materials: Fabrication, characterization, mathematical modeling and application to performance enhancement. Appl. Energy 2016, 165, 472–510. [Google Scholar] [CrossRef]

- Safari, A.; Saidur, R.; Sulaiman, F.A.; Xu, Y.; Dong, J. A review on supercooling of Phase Change Materials in thermal energy storage systems. Renew. Sustain. Energy Rev. 2017, 70, 905–919. [Google Scholar] [CrossRef]

- Guan, W.; Li, J.; Qian, T.; Wang, X.; Deng, Y. Preparation of paraffin/expanded vermiculite with enhanced thermal conductivity by implanting network carbon in vermiculite layers. Chem. Eng. J. 2015, 277, 56–63. [Google Scholar] [CrossRef]

- Kenisarin, M.M.; Kenisarina, K.M. Form-stable phase change materials for thermal energy storage. Renew. Sustain. Energy Rev. 2012, 16, 1999–2040. [Google Scholar] [CrossRef]

- Cárdenas-Ramírez, C.; Gómez, M.; Jaramillo, F. Characterization of a porous mineral as a promising support for shape-stabilized phase change materials. J. Energy Storage 2019, 26, 101041. [Google Scholar] [CrossRef]

- Umair, M.M.; Zhang, Y.; Iqbal, K.; Zhang, S.; Tang, B. Novel strategies and supporting materials applied to shape-stabilize organic phase change materials for thermal energy storage—A review. Appl. Energy 2019, 235, 846–873. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, N.; Peng, J.; Fang, X.; Gao, X.; Fang, Y. Preparation and thermal energy storage properties of paraffin/expanded graphite composite phase change material. Appl. Energy 2012, 91, 426–431. [Google Scholar] [CrossRef]

- Qian, T.; Li, J.; Min, X.; Deng, Y.; Guan, W.; Ning, L. Diatomite: A promising natural candidate as carrier material for low, middle and high temperature phase change material. Energy Convers. Manag. 2015, 98, 34–45. [Google Scholar] [CrossRef]

- Wen, R.; Zhang, X.; Huang, Y.; Yin, Z.; Huang, Z.; Fang, M.; Liu, Y.; Wu, X. Preparation and properties of fatty acid eutectics/expanded perlite and expanded vermiculite shape-stabilized materials for thermal energy storage in buildings. Energy Build. 2017, 139, 197–204. [Google Scholar] [CrossRef]

- Song, S.; Dong, L.; Zhang, Y.; Chen, S.; Li, Q.; Guo, Y.; Deng, S.; Si, S.; Xiong, C. Lauric acid/intercalated kaolinite as form-stable phase change material for thermal energy storage. Energy 2014, 76, 385–389. [Google Scholar] [CrossRef]

- Karaipekli, A.; Sari, A. Development and thermal performance of pumice/organic PCM/gypsum composite plasters for thermal energy storage in buildings. Sol. Energy Mater. Sol. Cells 2016, 149, 19–28. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, D.; Liu, F.; Zhang, W.; Di, X.; Wang, C. A polyethylene glycol/hydroxyapatite composite phase change material for thermal energy storage. Appl. Therm. Eng. 2017, 113, 1475–1482. [Google Scholar] [CrossRef]

- Entürk, S.B.; Kahraman, D.; Alkan, C.; Göke, I. Biodegradable PEG/cellulose, PEG/agarose and PEG/chitosan blends as shape stabilized phase change materials for latent heat energy storage. Carbohydr. Polym. 2011, 84, 141–144. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, E.; Li, X.; Zhang, Y.; Qu, J.; Yu, Z.Z. Cellulose/graphene aerogel supported phase change composites with high thermal conductivity and good shape stability for thermal energy storage. Carbon 2016, 98, 50–57. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. The determination of porosity and cellulose content of plant fibers by density methods. J. Mater. Sci. Lett. 2001, 20, 2095–2096. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Pereira, T.V.C.; Gomes, O.D.F.M.; De Andrade Silva, F.; Toledo Filho, R.D. The effect of fiber morphology on the tensile strength of natural fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Toledo Filho, R.D.; de Andrade Silva, F.; Mobasher, B.; Müller, S.; Mechtcherine, V. Interface characteristics of jute fiber systems in a cementitious matrix. Cem. Concr. Res. 2019, 116, 252–265. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Rodrigues Sena Neto, A.; de Andrade Silva, F.; Gomes de Souza, F.; Dias Toledo Filho, R. The influence of carboxylated styrene butadiene rubber coating on the mechanical performance of vegetable fibers and on their interface with a cement matrix. Constr. Build. Mater. 2020, 262, 120770. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; De Andrade Silva, F.; Toledo Filho, R.D. The Influence of fiber treatment on the mechanical behavior of jute textile reinforced concrete. Key Eng. Mater. 2014, 600, 469–474. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Toledo Filho, R.D.; Silva, F.d.A.; Mechtcherine, V.; Butler, M.; Hempel, S. The effect of accelerated aging on the interface of jute textile reinforced concrete. Cem. Concr. Compos. 2016, 74, 7–15. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Pepe, M.; Martinelli, E.; de Andrade Silva, F.; Toledo Filho, R.D. Influence of natural fibers characteristics on the interface mechanics with cement based matrices. Compos. Part B Eng. 2018, 140, 183–196. [Google Scholar] [CrossRef]

- Natalli, J.F.; Thomaz, E.C.S.; Mendesa, J.C.; Peixoto, R.A.F. A review on the evolution of Portland cement and chemical admixtures in Brazil. Rev. IBRACON Estrut. Mater. 2021, 14, e14603. [Google Scholar] [CrossRef]

- Vieira, L.H.; de Souza, T.D.; Enríquez-León, A.J.; Aragão, F.T.S.; Gomes, O.d.F.M.; Leite, L.F.M.; Rezende, L.R.d. Experimental Testing and Analysis Procedure to Determine the Apparent Film Thickness of Asphalt Binder in Fine Aggregate Matrix Mixtures. Transp. Res. Rec. 2021, 2675, 166–179. [Google Scholar] [CrossRef]

- Anonymous. Standard Test Method for Tensile Strength and Young’ s Modulus of Fibers Astm C 1557-14, Annual Book Of Astm Standards; Technical Report; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar] [CrossRef]

- Ferreira, S.R. Influência da Hornificação na Aderência Fibra-Matriz E No Comportamento Mecânico de Compósitos Cimentíceos Reforçados Com Fibras Curtas de Sisal. Ph.D. Thesis, Universidade Estadual de Feira de Santana, Feira de Santana, Brazil, 2012. [Google Scholar]

- Da Fonseca, R.P.; Rocha, J.C.; Cheriaf, M. Mechanical properties of mortars reinforced with Amazon rainforest natural fibers. Materials 2021, 14, 155. [Google Scholar] [CrossRef] [PubMed]

- RILEM Technical Committee 232-TDT (Wolfgang Brameshuber); Brameshuber, W.; Hinzen, M.; Dubey, A.; Peled, A.; Mobasher, B.; Bentur, A.; Aldea, C.; Silva, F.; Hegger, J.; et al. Recommendation of RILEM TC 232-TDT: Test methods and design of textile reinforced concrete. Mater. Struct. 2016, 49, 4923–4927. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, Y.; Kamran, U.; Park, S.J. Improved thermal conductivity and mechanical property of mercapto group-activated boron nitride/elastomer composites for thermal management. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106869. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Silva, F.d.A.; Lima, P.R.L.; Toledo Filho, R.D. Effect of hornification on the structure, tensile behavior and fiber matrix bond of sisal, jute and curauá fiber cement based composite systems. Constr. Build. Mater. 2017, 139, 551–561. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, S.; Kim, H.-J.; Yang, H.S. Thermal properties of bio-flour-filled polyolefin composites with different compatibilizing agent type and content. Thermochim. Acta 2006, 451, 181–188. [Google Scholar] [CrossRef]

- Poletto, M.; Ornaghi, H.; Zattera, A. Native Cellulose: Structure, Characterization and Thermal Properties. Materials 2014, 7, 6105–6119. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Yu, S.; Zhong, H.; Liu, T.; Yao, E.; Zhang, Y.; Zou, H.; Du, W. Gas products generation mechanism during co-pyrolysis of styrene-butadiene rubber and natural rubber. J. Hazard. Mater. 2021, 401, 123302. [Google Scholar] [CrossRef]

| Property | Typical Value | Unit |

|---|---|---|

| Thermal properties by differential scanning calorimetry (DSC) | ||

| Peak melting temperature | 24 | °C |

| Latent heat (melting) | 184 | kJ/kg |

| Peak crystallisation temperature | 22 | °C |

| Latent heat (crystallisation) | −182 | kJ/kg |

| Thermal properties by three-layer calorimetry (3LC) | ||

| Peak melting temperature | 23 | °C |

| Total heat capacity (melting) | 207 | kJ/kg |

| Peak crystallisation temperature | 23 | °C |

| Total heat capacity (crystallisation) | 213 | kJ/kg |

| Other properties | ||

| Bio-based content | 100 | % |

| Density at 20 °C (solid) | 906 | kg/m³ |

| Density at 40 °C (liquid) | 843 | kg/m³ |

| Flash point | 226 | °C |

| Specific heat capacity (solid) | 3.7 | kJ/kg °C |

| Specific heat capacity (liquid) | 2.2 | kJ/kg °C |

| Volume expansion 20–40 °C | 7.5 | % |

| Thermal conductivity (solid) | 0.22 | W/m °C |

| Thermal conductivity (liquid) | 0.16 | W/m °C |

| Thermal cycles without change in properties | 10,000 | cicles |

| Component | Materials Consumption (kg/m³) |

|---|---|

| Cement | 548 |

| Metakaolinite | 438 |

| Fly ash | 108 |

| Sand | 548 |

| Water | 438 |

| Textile Component | Tensile Strength (MPa) | Elastic Modulus (MPa) |

|---|---|---|

| Yarn | 102 ± 18 | 4627 ± 739 |

| Fabric (transverse) | 60 ± 17 | 2938 ± 220 |

| Fabric (longitudinal) | 62 ± 19 | 3208 ± 704 |

| Coated yarn | 118 ± 14 | 5508 ± 427 |

| Coated yarn and PCM (liquid) | 61 ± 11 | 2160 ± 290 |

| Coated yarn and PCM (solid) | 69 ± 9 | 2431 ± 258 |

| Treatment | Ti (°C) 3% Mass Loss | DTG Main Peak (°C) | Residue at 1000 °C (%) |

|---|---|---|---|

| Raw jute | 214 | 350 | 4.8 |

| XSBR | 313 | 425 | 4.3 |

| XSBR + PCM | 195 | 437 | 6.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guimarães, T.C.; Gomes, O.d.F.M.; Oliveira de Araújo, O.M.; Tadeu Lopes, R.; da-Gloria, M.Y.R.; Toledo Filho, R.D.; Koenders, E.; Caggiano, A.; Mankel, C.; Nazari Sam, M.; et al. PCM-Impregnated Textile-Reinforced Cementitious Composite for Thermal Energy Storage. Textiles 2023, 3, 98-114. https://doi.org/10.3390/textiles3010008

Guimarães TC, Gomes OdFM, Oliveira de Araújo OM, Tadeu Lopes R, da-Gloria MYR, Toledo Filho RD, Koenders E, Caggiano A, Mankel C, Nazari Sam M, et al. PCM-Impregnated Textile-Reinforced Cementitious Composite for Thermal Energy Storage. Textiles. 2023; 3(1):98-114. https://doi.org/10.3390/textiles3010008

Chicago/Turabian StyleGuimarães, Túlio Caetano, Otavio da Fonseca Martins Gomes, Olga Maria Oliveira de Araújo, Ricardo Tadeu Lopes, M´hamed Yassin Rajiv da-Gloria, Romildo Dias Toledo Filho, Eddie Koenders, Antonio Caggiano, Christoph Mankel, Mona Nazari Sam, and et al. 2023. "PCM-Impregnated Textile-Reinforced Cementitious Composite for Thermal Energy Storage" Textiles 3, no. 1: 98-114. https://doi.org/10.3390/textiles3010008

APA StyleGuimarães, T. C., Gomes, O. d. F. M., Oliveira de Araújo, O. M., Tadeu Lopes, R., da-Gloria, M. Y. R., Toledo Filho, R. D., Koenders, E., Caggiano, A., Mankel, C., Nazari Sam, M., Mendes de Andrade, R. G., & Ferreira, S. R. (2023). PCM-Impregnated Textile-Reinforced Cementitious Composite for Thermal Energy Storage. Textiles, 3(1), 98-114. https://doi.org/10.3390/textiles3010008