Fibers and Textiles for Personal Protective Equipment: Review of Recent Progress and Perspectives on Future Developments

Abstract

:1. Introduction

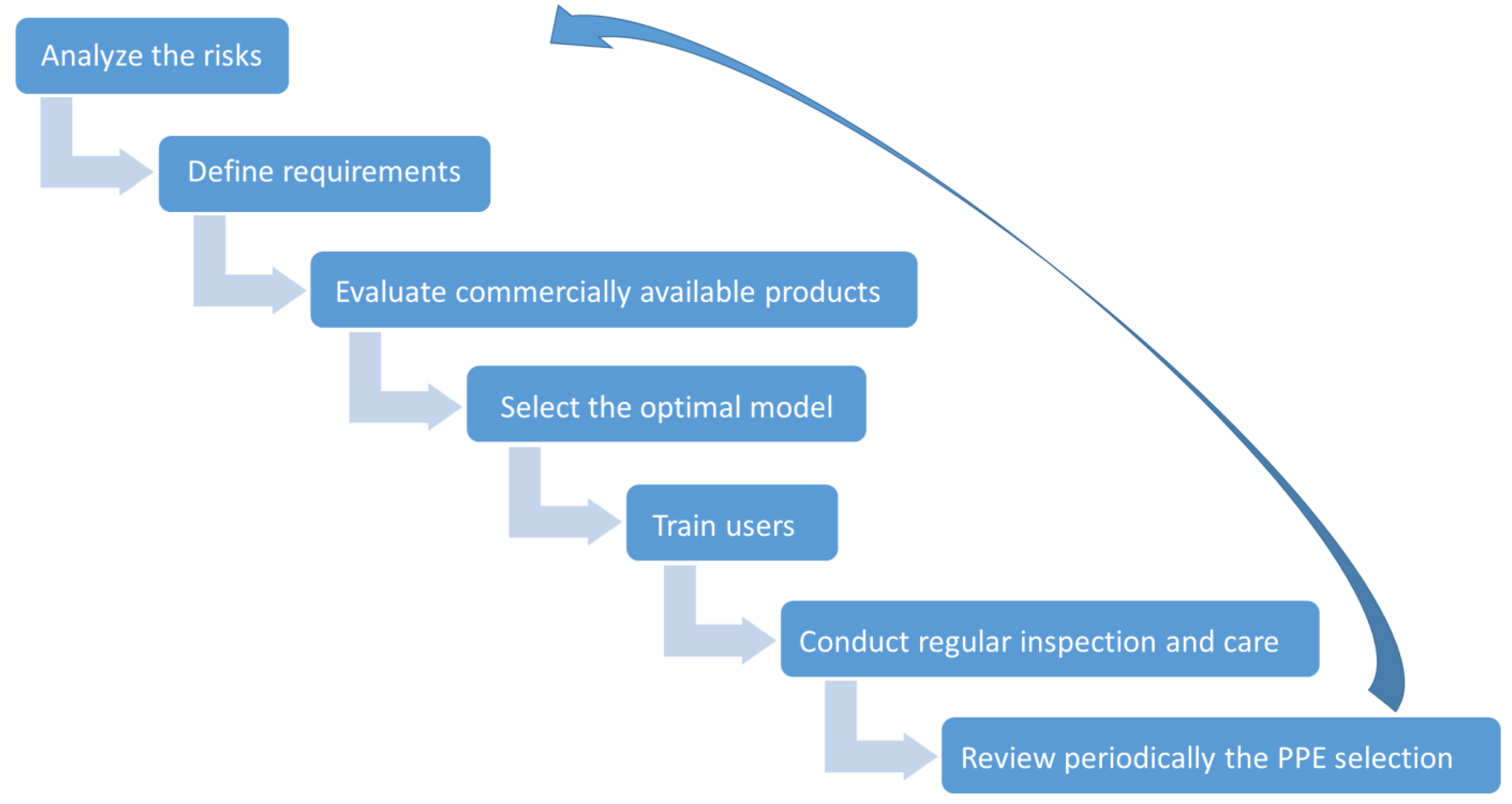

- Analyze the risks and identify those that cannot be avoided through engineering controls and administrative measures;

- Determine the requirements for PPE based on the risks involved, including those resulting from wearing the PPE, and considerations related to the activity to be performed and the environment;

- Assess and compare the characteristics of commercially available PPE;

- Select the optimal PPE based on the protection and functionality requirements as well as other aspects, such as cost and durability;

- Initiate and train users to properly wear the PPE;

- Establish a procedure for the PPE inspection and care;

- Perform a periodic review of the choice of PPE to verify that they still meet requirements and that the level of risk has not changed.

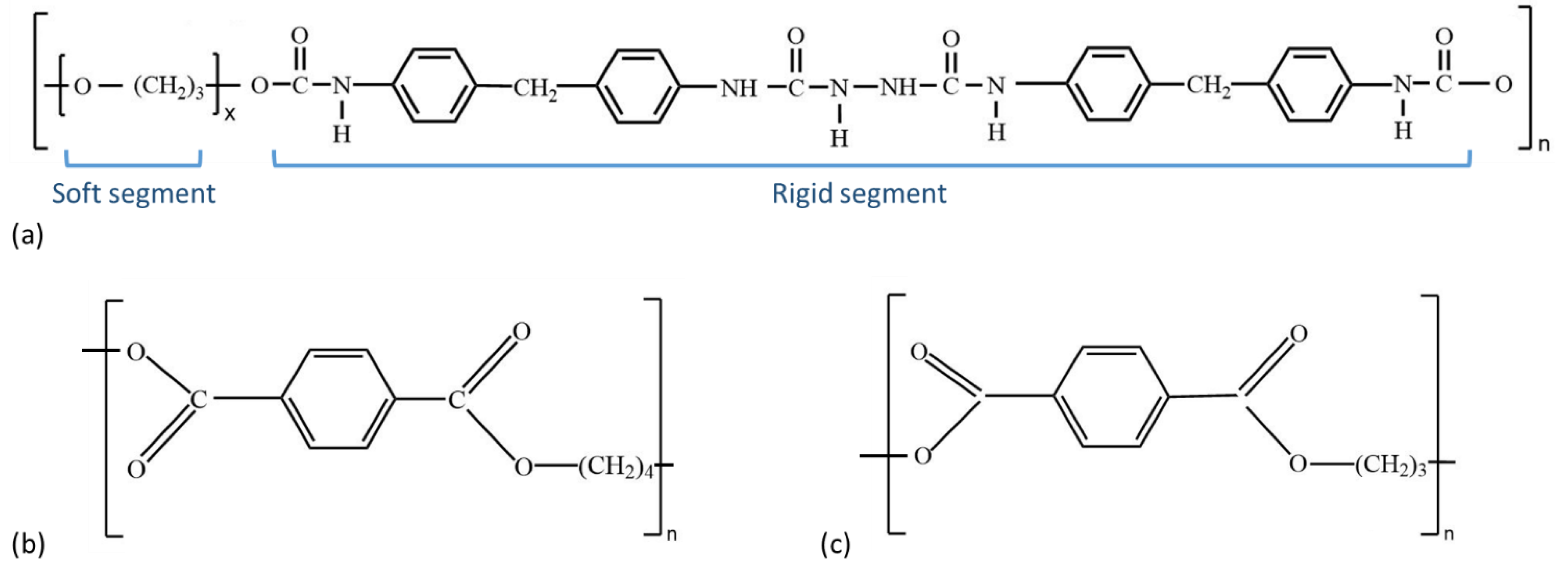

2. Highly Extensible Elastomeric Fibers

3. Cellulose-Based Fibers

3.1. Natural Fibers

3.2. Regenerated Cellulose Fibers

4. Commodity Synthetic Fibers

4.1. Polyolefin Fibers

4.2. Polyester and Polyamide Fibers

4.3. Modacrylic Fibers

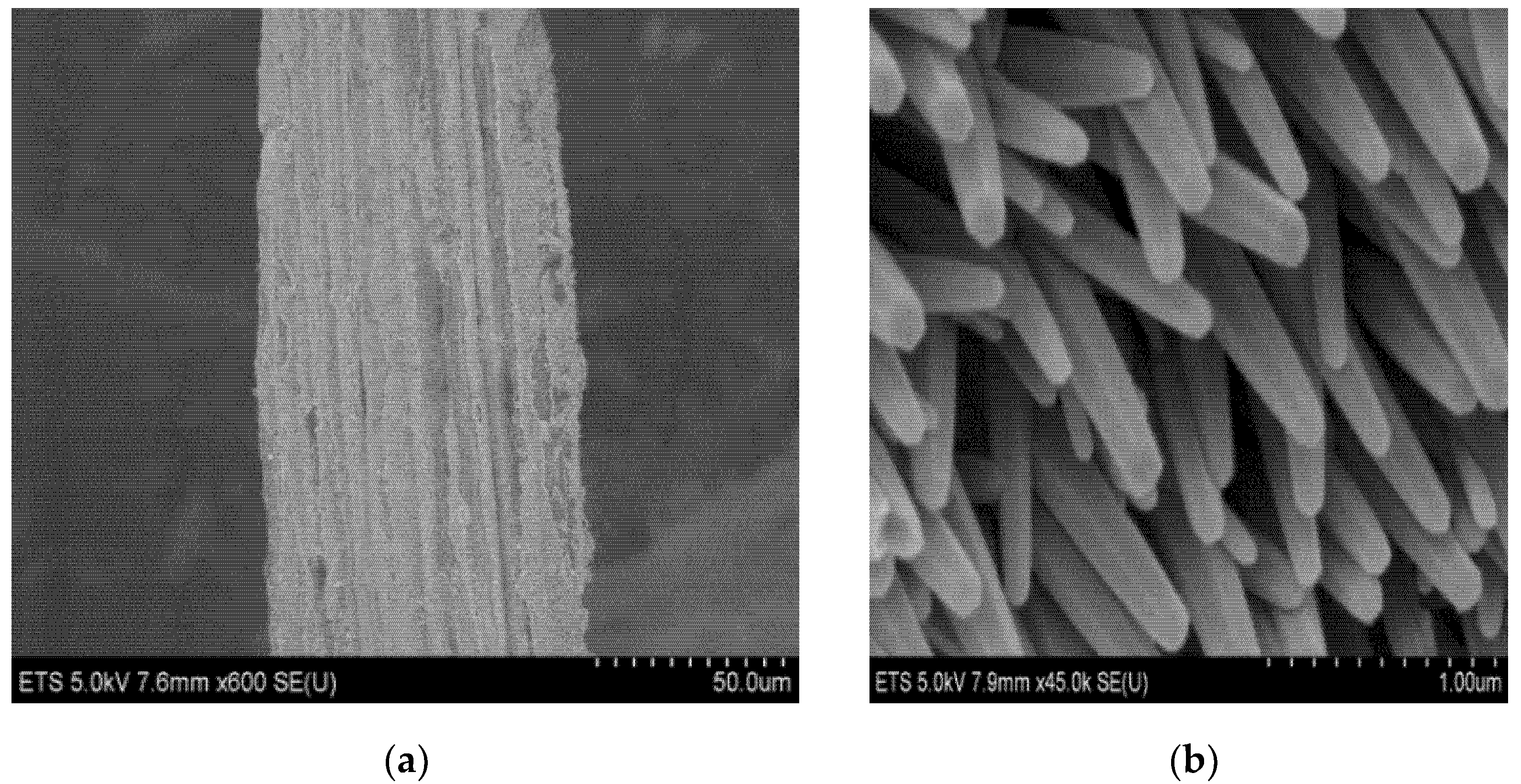

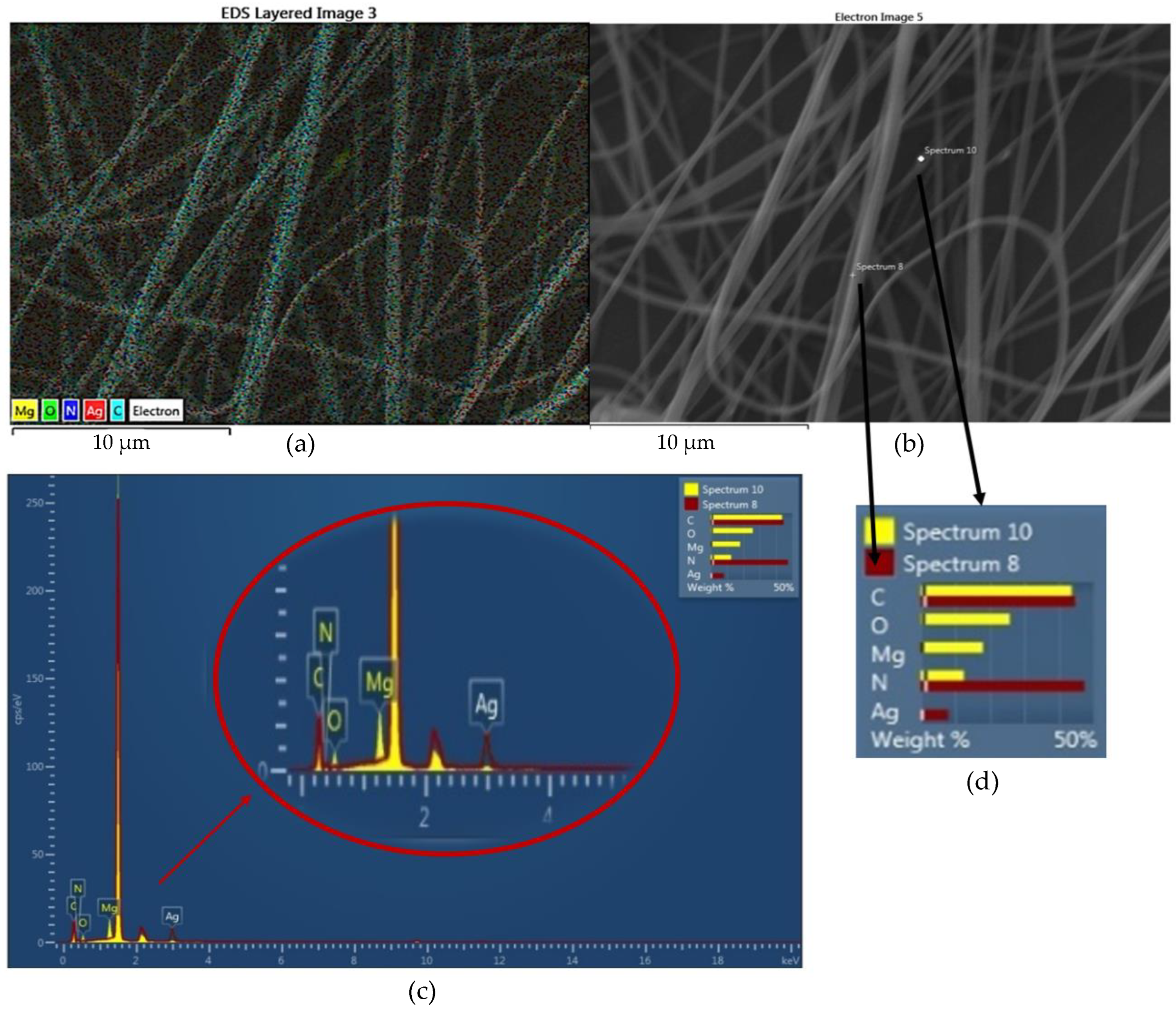

4.4. Nanofibers

5. High-Strength Inorganic Materials

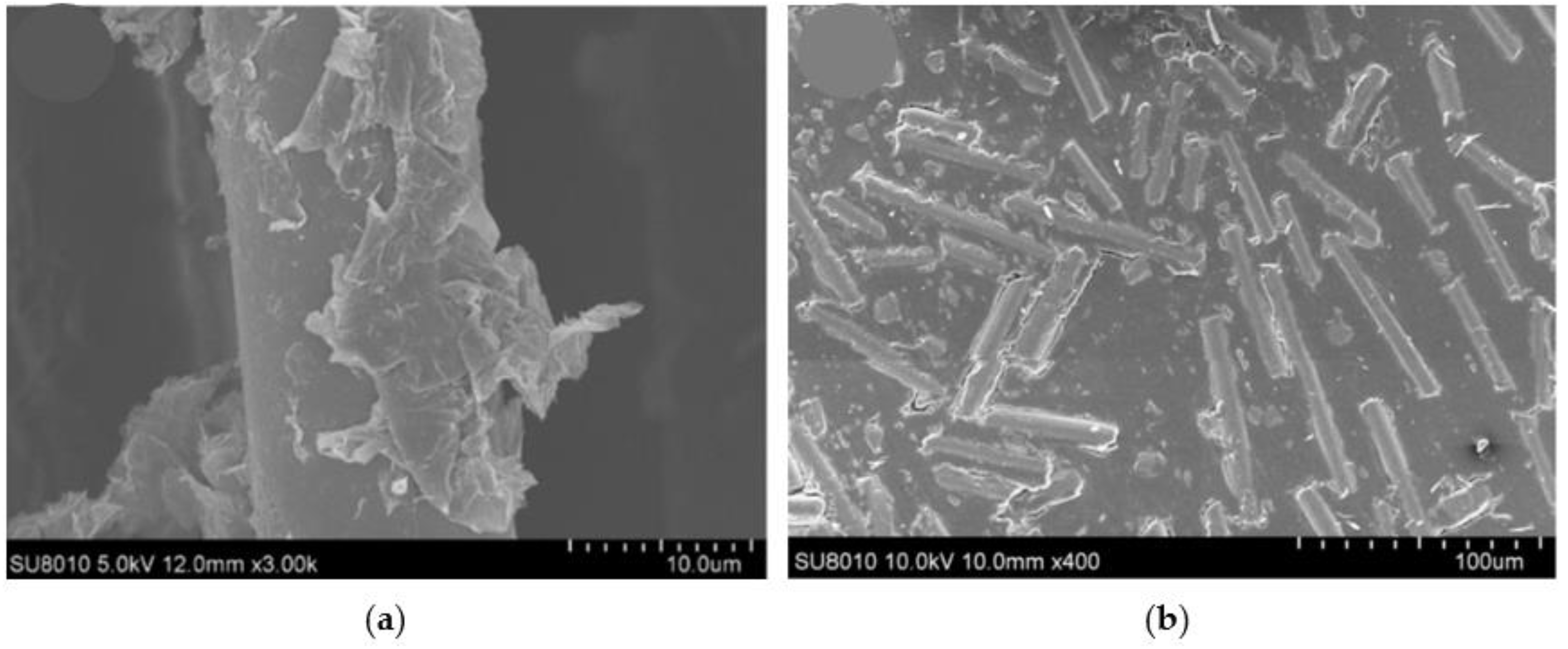

5.1. Basalt Fibers

5.2. Carbon Fibers, Carbon Nanofibers, and Other Carbonaceous Nanomaterials

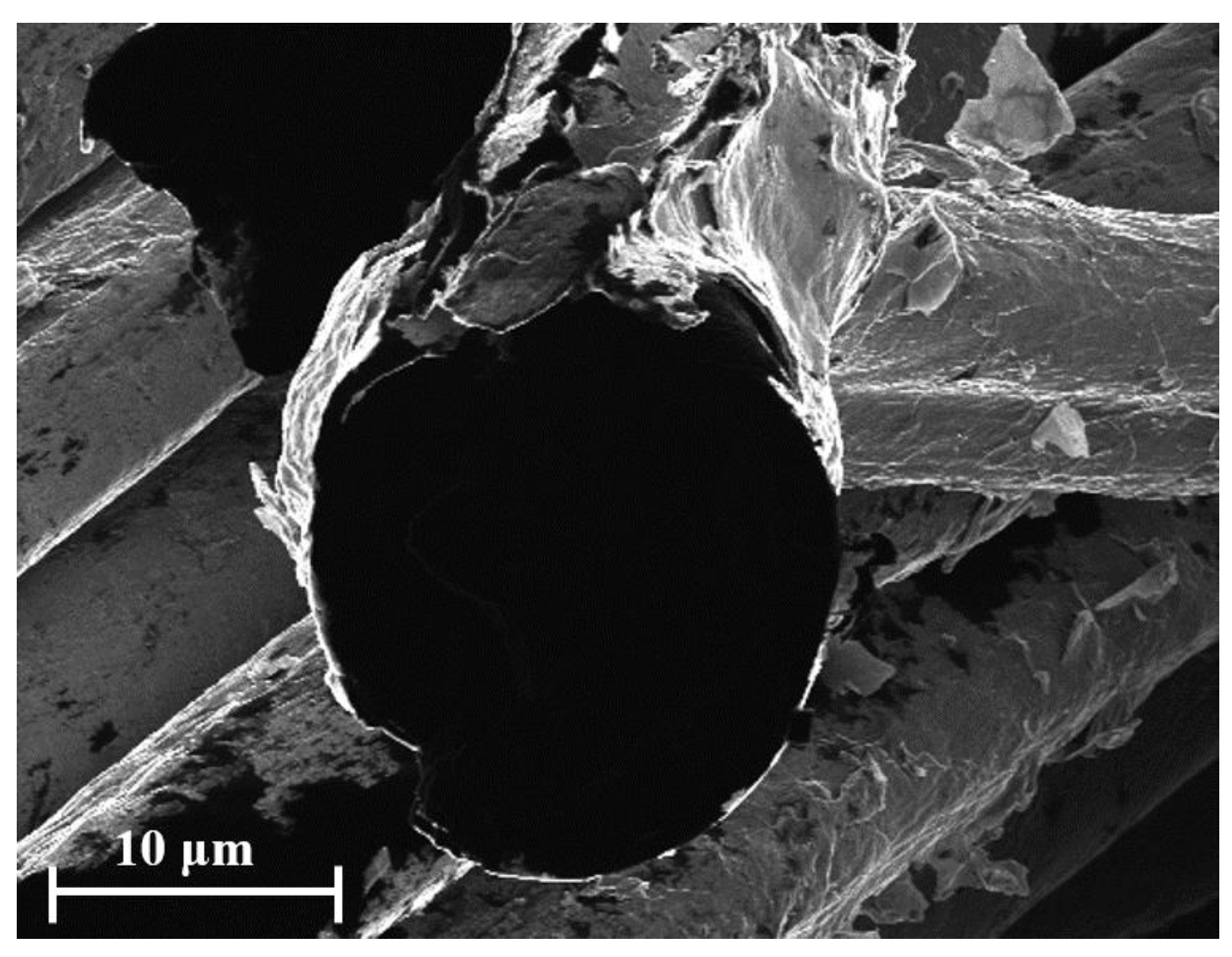

5.3. Metal Fibers and Structures

5.4. Boron Fibers and Other Boron-Containing Materials

5.5. Components for Wearable Electronics and Smart Textiles

6. High-Performance Polymer Fibers

6.1. Para-Aramid Fibers

6.2. Meta-Aramid Fibers

6.3. Other Rigid-Rod Polymer Fibers

6.4. Ultra-High Molecular Weight Polyethylene

6.5. Other High-Performance Polymer Fibers

6.6. Aging of High-Performance Polymer Fibers

7. Special Textile Structures

7.1. Three-Dimensional Textiles

7.2. Auxetic Textiles

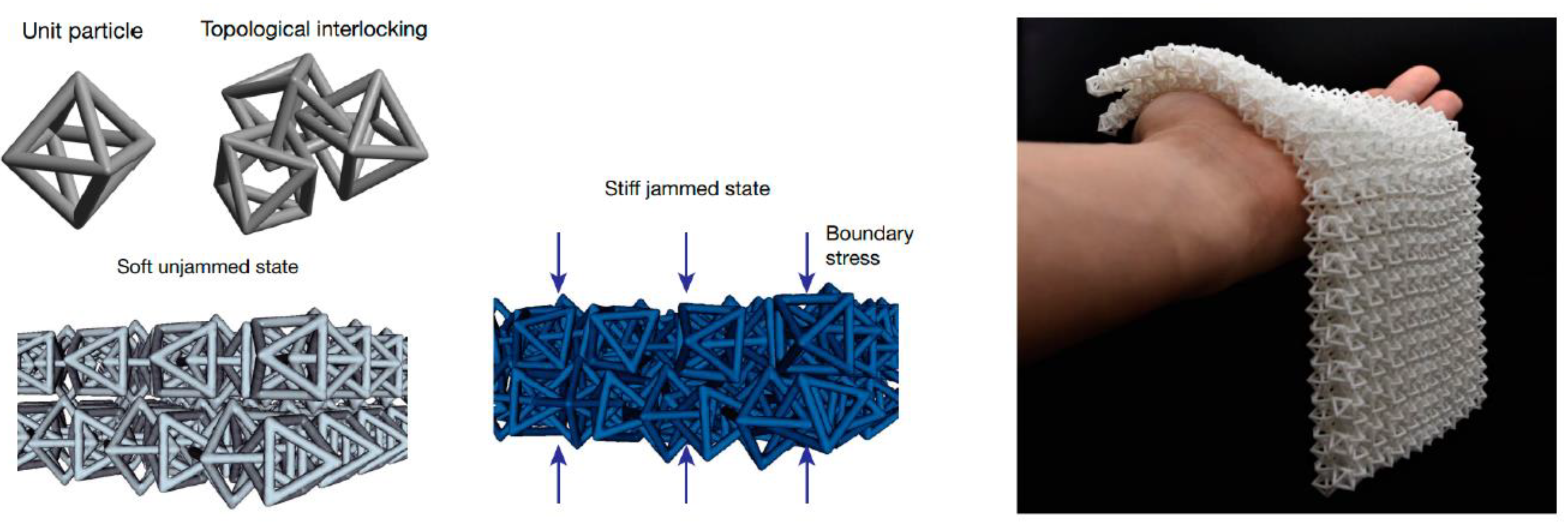

7.3. Shear Thickening Fabrics

7.4. Nanoporous Structures

7.5. Phase Change Materials and Janus Textiles

7.6. Textile-Based Composite Structures for Protection against Cut and Puncture

8. Perspectives on Promising Avenues of Further Development

8.1. Measuring Comfort

8.2. Adopting New Technologies

8.3. Enhancing Sustainability

8.4. Taking an Interdisciplinary Approach

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- OSHA. Personal Protective Equipment. Occupational Safety and Health Administration. 2022. Available online: https://www.osha.gov/personal-protective-equipment (accessed on 21 February 2022).

- Dolez, P.; Soulati, K.; Gauvin, C.; Lara, J.; Vu-Khanh, T. Information Document for Selecting Gloves for Protection against Mechanical Hazards; Publications IRSST, RG-738: Montreal, QC, Canada, 2012; 61p. [Google Scholar]

- ISO 11610; Protective Clothing—Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2004; 93p.

- Thomsen, A. History of Body Armour. Timetoast Timelines. Available online: https://www.timetoast.com/timelines/history-of-body-armour (accessed on 21 February 2022).

- Risteski, S.; Srebrenkoska, V. Appearance of Protective Clothing over the Centuries. Tekst. Ind. 2020, 4, 38–48. [Google Scholar] [CrossRef]

- Watkins, S.M. Development of Protective Clothing. LoveToKnow Media. Available online: https://fashion-history.lovetoknow.com/alphabetical-index-fashion-clothing-history/protective-clothing (accessed on 21 February 2022).

- Blümner, H.; Zimmern, A. The Home Life of the Ancient Greeks; Cassell and Company Limited: London, UK; Paris, France; Melbourne, Australia, 1893; 548p. [Google Scholar]

- Medieval Blacksmith Clothing. Working the Flame. 2019. Available online: https://workingtheflame.com/medieval-blacksmith-clothing/ (accessed on 27 February 2022).

- Lee, A.; Meyer, R. Escape through Time. NOVA. 2000. Available online: https://www.pbs.org/wgbh/nova/escape/timefire.html (accessed on 27 February 2022).

- Feldman, D. Polymer History. Des. Monomers Polym. 2008, 11, 1–15. [Google Scholar] [CrossRef]

- Bourbigot, S.; Flambard, X. Heat resistance and flammability of high performance fibres: A review. Fire Mater. 2002, 26, 155–168. [Google Scholar] [CrossRef]

- Kelly, J.M. Ultra-High Molecular Weight Polyethylene. J. Macromol. Sci. Part C 2002, 42, 355–371. [Google Scholar] [CrossRef]

- MacLaury, J. The Job Safety Law of 1970: Its Passage Was Perilous. Mon. Labor Rev. 1981, 104, 18–24. [Google Scholar]

- ISO/TC 94 Personal Safety—Personal Protective Equipment. International Organization for Standardization. Available online: https://www.iso.org/committee/50580.html (accessed on 27 February 2022).

- Committee F23 on Personal Protective Clothing and Equipment. ASTM International. Available online: https://www.astm.org/get-involved/technical-committees/committee-f23 (accessed on 27 February 2022).

- Hu, J.; Lu, J. Recent developments in elastic fibers and yarns for sportswear. Text. Sportsw. 2015, 53–76. [Google Scholar] [CrossRef]

- Fletcher, J.C.; Howarth, J.T.; Sheth, S.; Sidman, K.R.; Massucco, A.A. Flame Retardant Spandex Type Polyurethanes. U.S. Patent 4,069,212, 17 January 1978. [Google Scholar]

- Aldridge, D. Limited-Stretch, Permanently Fire-Resistant Suspenders. U.S. Patent 5,448,779, 12 September 1995. [Google Scholar]

- Tausif, M.; Cassidy, T.; Butcher, I. Yarn and thread manufacturing methods for high-performance apparel. In High-Performance Apparel; McLoughlin, J., Sabir, T., Eds.; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2018; pp. 33–73. [Google Scholar]

- Sáenz-Pérez, M.; Bashir, T.; Laza, J.M.; García-Barrasa, J.; Vilas, J.L.; Skrifvars, M.; León, L.M. Novel shape-memory polyurethane fibers for textile applications. Text. Res. J. 2019, 89, 1027–1037. [Google Scholar] [CrossRef]

- Safranski, D.L.; Boothby, J.M.; Kelly, C.N.; Beatty, K.; Lakhera, N.; Frick, C.P.; Lin, A.; Guldberg, R.E.; Griffis, J.C. Thermo-mechanical behavior and structure of melt blown shape-memory polyurethane nonwovens. J. Mech. Behav. Biomed. Mater. 2016, 62, 545–555. [Google Scholar] [CrossRef] [Green Version]

- Banikazemi, S.; Rezaei, M.; Rezaei, P.; Babaie, A.; Eyvazzadeh-Kalajahi, A. Preparation of electrospun shape memory polyurethane fibers in optimized electrospinning conditions via response surface methodology. Polym. Adv. Technol. 2020, 31, 2199–2208. [Google Scholar] [CrossRef]

- Otaigbes, J.U.; Madbouly, A. 11-The processing, structure and properties of elastomeric fibers. In Handbook of Textile Fibre Structure; Eichhorn, S.J., Hearle, J.W.S., Jaffe, M., Kikutani, T., Eds.; Woodhead Publishing: Cambridge, UK, 2009; Volume 1, pp. 325–351. [Google Scholar]

- Crown, E.M.; Batcheller, J.C. Technical textiles for personal thermal protection. In Handbook of Technical Textiles, 2nd ed.; Horrocks, A.R., Anand, S.C., Eds.; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2016; Volume 2, pp. 271–285. [Google Scholar] [CrossRef]

- Horrocks, A.R. Technical fibres for heat and flame protection. In Handbook of Technical Textiles, 2nd ed.; Horrocks, A.R., Anand, S.C., Eds.; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2016; Volume 2, pp. 237–270. [Google Scholar] [CrossRef]

- Hoagland, H. Flame resistant textiles for electric arc flash hazards. In Handbook of Fire Resistant Textiles; Kilinc, Ed.; Woodhead Publishing: Cambridge, UK; Philadelphia, PA, USA; New Delhi, India, 2013; pp. 549–580. [Google Scholar]

- Novaković, M.; Popović, D.M.; Mladenović, N.; Poparić, G.B.; Stanković, S.B. Development of comfortable and eco-friendly cellulose based textiles with improved sustainability. J. Clean. Prod. 2020, 267, 122154. [Google Scholar] [CrossRef]

- Kocić, A.; Bizjak, M.; Popović, D.; Poparić, G.B.; Stanković, S.B. UV protection afforded by textile fabrics made of natural and regenerated cellulose fibres. J. Clean. Prod. 2019, 228, 1229–1237. [Google Scholar] [CrossRef]

- Liang, S.; Neisius, N.M.; Gaan, S. Recent developments in flame retardant polymeric coatings. Prog. Org. Coat. 2013, 76, 1642–1665. [Google Scholar] [CrossRef]

- Tian, M.; Du, M.; Qu, L.; Chen, S.; Zhu, S.; Han, G. Electromagnetic interference shielding cotton fabrics with high electrical conductivity and electrical heating behavior via layer-by-layer self-assembly route. R. Soc. Chem. Adv. 2017, 7, 42641–42652. [Google Scholar] [CrossRef] [Green Version]

- Dolez, P.I. Application of nanomaterials in textile coatings and finishes. In Nanomaterials-Based Coatings: Fundamentals and Applications; Nguyen-Tri, R., Plamondon, O., Eds.; Elsevier: Amsterdam, The Netherlands; Oxford, UK; Waltham, MA, USA, 2019; pp. 139–169. [Google Scholar]

- Braga, F.D.O.; Milanezi, T.L.; Monteiro, S.N.; Louro, L.H.L.; Gomes, A.V.; Lima, É.P. Ballistic comparison between epoxy-ramie and epoxy-aramid composites in multilayered armor systems. J. Mater. Res. Technol. 2018, 7, 541–549. [Google Scholar] [CrossRef]

- Venkatesan, H.; Periyasamy, A.P. Eco-fibers in the Textile Industry. In Handbook of Ecomaterials; Martinez, L.M.T., Ed.; Springer International Publishing: Cham, Switzerland, 2019; pp. 1413–1433. [Google Scholar]

- Arfaoui, M.A.; Dolez, P.I.; Dubé, M.; David, É. Development and characterization of a hydrophobic treatment for jute fibres based on zinc oxide nanoparticles and a fatty acid. Appl. Surf. Sci. 2017, 397, 19–29. [Google Scholar] [CrossRef]

- Arafa Badr, A. Anti-microbial and durability characteristics of socks made of cotton and regenerated cellulosic fibers. Alex. Eng. J. 2018, 57, 3367–3373. [Google Scholar] [CrossRef]

- Hardin, I.R.; Wilson, S.S.; Dhandapani, R.; Dhende, V. An assessment of the validity of claims for “Bamboo” fibers. AATCC Rev. 2009, 9, 33–36. [Google Scholar]

- Zhu, Q.; Jin, Y.; Sun, G.; Yan, K.; Wang, D. AQC functionalized CNCs/PVA-co-PE composite nanofibrous membrane with flower-like microstructures for photo-induced multi-functional protective clothing. Cellulose 2018, 25, 4819–4830. [Google Scholar] [CrossRef]

- Guo, L.; Chen, Z.; Lyu, S.; Fu, F.; Wang, S. Highly flexible cross-linked cellulose nanofibril sponge-like aerogels with improved mechanical property and enhanced flame retardancy. Carbohydr. Polym. 2018, 179, 333–340. [Google Scholar] [CrossRef]

- Sharma, A.; Thakur, M.; Bhattacharya, M.; Mandal, T.; Goswami, S. Commercial application of cellulose nano-composites—A review. Biotechnol. Rep. 2019, 21, e00316. [Google Scholar] [CrossRef]

- Tessier, D. Testing thermal properties of textiles. In Advanced Characterization and Testing of Textiles; Dolez, V.I., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 71–92. [Google Scholar]

- Sabir, T. Fibers used for high performance apparel. In High-Performance Apparel; McLoughlin, J., Sabir, T., Eds.; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2018; pp. 7–32. [Google Scholar]

- Lefakane, T.E.; Ndibewu, P.P.; Netshiozwi, T.E. Characterization, chemical phase identification, and performance evaluation of omnipotent, polymers used in the manufacturing of personal protective garments. Polym. Res. J. 2015, 9, 2530. [Google Scholar]

- Kim, Y.K. The use of polyolefins in industrial and medical applications. In Polyolefin Fibres: Structure, Properties and Industrial Applications, 2nd ed.; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2017; pp. 135–155. [Google Scholar] [CrossRef]

- Purchas, D.B.; Sutherland, K. Handbook of Filter Media; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Ishack, S.; Lipner, S.R. Applications of 3D Printing Technology to Address COVID-19−Related Supply Shortages. Am. J. Med. 2020, 133, 771–773. [Google Scholar] [CrossRef] [PubMed]

- Okrasa, M.; Brochocka, A.; Majchrzycka, K. Electret filtering nonwovens with enhanced protective and comfort properties for human protection in heavy working conditions. In International Textile Conference; National Research Institute: Łódź, Poland, 2016; pp. 24–25. [Google Scholar]

- Sibanda, M.; Leuteritz, A.; Brünig, H.; Focke, W. Development of polyolefin bicomponent filaments as controlled release devices of volatile repellents for use in malaria vector control. AIP Conf. Proc. 2019, 2055, 060007. [Google Scholar] [CrossRef]

- Irzmańska, E.; Brochocka, A. Modified polymer materials for use in selected personal protective equipment products. Autex Res. J. 2017, 17, 35–47. [Google Scholar] [CrossRef] [Green Version]

- Demir, B.; Cerkez, I.; Worley, S.D.; Broughton, R.M.; Huang, T.-S. N-Halamine-Modified Antimicrobial Polypropylene Nonwoven Fabrics for Use against Airborne Bacteria. ACS Appl. Mater. Interfaces 2015, 7, 1752–1757. [Google Scholar] [CrossRef]

- Crăciun, N.; Trifu, A. Reducing the risk of slipping on ice by selecting appropriate protective footwear. Qual.-Access Success 2019, 20, 147–152. [Google Scholar]

- Elmaaty, A.T.; Sofan, M.; Elsisi, H.; Kosbar, T.; Negm, E.; Hirogaki, K.; Tabata, I.; Hori, T. Optimization of an eco-friendly dyeing process in both laboratory scale and pilot scale supercritical carbon dioxide unit for polypropylene fabrics with special new disperse dyes. J. CO2 Util. 2019, 33, 365–371. [Google Scholar] [CrossRef]

- Razafimahefa, L.; Chlebicki, S.; Vroman, I.; Devaux, E. Effect of nanoclays on the dyeability of polypropylene nanocomposite fibres. Coloration Technol. 2008, 124, 86–91. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Joshi, R.; Chughtai, A.A.; Macintyre, C.R. Graphene modified multifunctional personal protective clothing. Adv. Mater. Interfaces 2019, 6, 1–27. [Google Scholar] [CrossRef] [Green Version]

- Lomazzo Directa Plus and Alfredo Grassi to Develop Graphene-Enhanced Workwear. Innovation in Textiles. 2017. Available online: https://www.innovationintextiles.com/directa-plus-and-alfredo-grassi-to-develop-grapheneenhanced-workwear/ (accessed on 15 April 2022).

- Wang, H.; Xu, L.; Song, X.; Cai, Z. Facile preparation of acid-resistant polyester fabrics with organic/inorganic nanocomposites. Cloth. Text. Res. J. 2017, 35, 98–110. [Google Scholar] [CrossRef]

- Yao, L.; Wu, L.; Wu, H.; Koo, J.H.; Krifa, M. Design and characterization of flame resistant blended nondrip PA6/Lenzing FR®/PBI fiber nonwoven fabrics. Flame Retard. Therm. Stab. Mater. 2019, 2, 49–59. [Google Scholar] [CrossRef]

- Shabanian, S.; Khatir, B.; Nisar, A.; Golovin, K. Rational design of perfluorocarbon-free oleophobic textiles. Nat. Sustain. 2020, 3, 1059–1066. [Google Scholar] [CrossRef]

- Decaens, J.; Vermeersch, O. Wearable technologies for personal protective equipment: Embedded textile monitoring sensors, power and data transmission, end-life indicators. In Smart Textiles and Their Applications; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2016; pp. 519–537. [Google Scholar] [CrossRef]

- Korpinen, L.; Pirkkalainen, H.; Heiskanen, T.; Pääkkönen, R. The possibility of decreasing 50-HZ electric field exposure near 400-kV power lines with arc flash personal protective equipment. Int. J. Environ. Res. Public Health 2016, 13, 942. [Google Scholar] [CrossRef] [Green Version]

- Grgac, S.F.; Bischof, S.; Pušić, T.; Petrinić, I.; Luxbacher, T. Analytical assessment of the thermal decomposition of cotton-modacryl knitted fabrics. Fibres Text. East. Eur. 2017, 25, 59–67. [Google Scholar] [CrossRef]

- Ackerman, M.Y. Thermal Decomposition of Selected Flame Resistant Clothing Materials. AATCC Rev. 2011, 11, 35–43. [Google Scholar]

- Mackay, C.E.; Reinhardt, T.E.; Vivanco, S.N.; McClure, S.; Vercellone, J. Real-Time Monitoring and Assessment of Thermal and Toxicological Risk Associated with Fire Retardant Textiles in a Full-Size Simulation of an Engulfment Flash Fire. Fire Technol. 2015, 51, 1167–1193. [Google Scholar] [CrossRef] [Green Version]

- Waxman, R.; Seward, P. Flame Resistant Blends. U.S. Patent Application US 2013/0212790 A1, 22 August 2013. [Google Scholar]

- Zhu, M.; Han, J.; Wang, F.; Shao, W.; Xiong, R.; Zhang, Q.; Pan, H.; Yang, Y.; Samal, S.K.; Zhang, F.; et al. Electrospun nanofibers membranes for effective air filtration. Macromol. Mater. Eng. 2017, 302, 1–27. [Google Scholar] [CrossRef]

- Nayak, R. Polypropylene Nanofibers-Melt Electrospinning Versus Meltblowing; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar]

- Mohraz, M.H.; Golbabaei, F.; Yu, I.J.; Ghahri, A. Optimization of the electrospinning process of polyurethane nanofibers and their filtration performance for use in respiratory protection mask filters. J. Mil. Med. 2019, 21, 195–204. [Google Scholar]

- Kao, T.H.; Su, S.K.; Su, C.I.; Lee, A.W.; Chen, J.K. Polyacrylonitrile microscaffolds assembled from mesh structures of aligned electrospun nanofibers as high-efficiency particulate air filters. Aerosol Sci. Technol. 2016, 50, 615–625. [Google Scholar] [CrossRef] [Green Version]

- Lolla, D.; Lolla, M.; Abutaleb, A.; Shin, H.U.; Reneker, D.H.; Chase, G.G. Fabrication, polarization of electrospun polyvinylidene fluoride electret fibers and effect on capturing nanoscale solid aerosols. Materials 2016, 9, 671. [Google Scholar] [CrossRef] [Green Version]

- Akduman, C. Cellulose acetate and polyvinylidene fluoride nanofiber mats for N95 respirators. J. Ind. Text. 2019, 50, 1239–1261. [Google Scholar] [CrossRef]

- Zhang, J.; Gong, S.; Wang, C.; Jeong, D.Y.; Wang, Z.L.; Ren, K. Biodegradable electrospun poly(lactic acid) nanofibers for effective PM 2.5 removal. Macromol. Mater. Eng. 2019, 304, 1900259. [Google Scholar] [CrossRef]

- Gorji, M.; Bagherzadeh, R.; Fashandi, H. Electrospun nanofibers in protective clothing. In Electrospun Nanofibers; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2017; pp. 571–598. [Google Scholar] [CrossRef]

- Sheng, J.; Zhao, J.; Yu, X.; Liu, L.; Yu, J.; Ding, B. Electrospun nanofibers for waterproof and breathable clothing. In Electrospinning: Nanofabrication and Applications; Elsevier: Amserdam, The Netherlands, 2018; pp. 543–570. [Google Scholar] [CrossRef]

- Akshat, T.M.; Misra, S.; Gudiyawar, M.Y.; Salacova, J.; Petru, M. Effect of electrospun nanofiber deposition on thermo-physiology of functional clothing. Fibers Polym. 2019, 20, 991–1002. [Google Scholar] [CrossRef]

- Si, Y.; Zhang, Z.; Wu, W.; Fu, Q.; Huang, K.; Nitin, N.; Ding, B.; Sun, G. Daylight-driven rechargeable antibacterial and antiviral nanofibrous membranes for bioprotective applications. Sci. Adv. 2018, 4, eaar5931. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Li, Y.; Si, Y.; Wang, F.; Liu, Y.; Ma, Y.; Yu, J.; Yin, X.; Ding, B. Rechargeable polyamide-based: N -halamine nanofibrous membranes for renewable, high-efficiency, and antibacterial respirators. Nanoscale Adv. 2019, 1, 1948–1956. [Google Scholar] [CrossRef] [Green Version]

- Kharaghani, D.; Kee Jo, Y.; Khan, M.Q.; Jeong, Y.; Cha, H.J.; Kim, I.S. Electrospun antibacterial polyacrylonitrile nanofiber membranes functionalized with silver nanoparticles by a facile wetting method. Eur. Polym. J. 2018, 108, 69–75. [Google Scholar] [CrossRef]

- Ruan, D.; Qin, L.; Chen, R.; Xu, G.; Su, Z.; Cheng, J.; Xie, S.; Cheng, F.; Ko, F. Transparent PAN:TiO2 and PAN-co-PMA:TiO2 nanofiber composite membranes with high efficiency in particulate matter pollutants filtration. Nanoscale Res. Lett. 2020, 15, 7. [Google Scholar] [CrossRef] [Green Version]

- Wang, N.; Cai, M.; Yang, X.; Yang, Y. Electret nanofibrous membrane with enhanced filtration performance and wearing comfortability for face mask. J. Colloid Interface Sci. 2018, 530, 695–703. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, Q.; Zhang, J.B.; Liu, G.B. Electrospun SiO2 aerogel/polyacrylonitrile composited nanofibers with enhanced adsorption performance of volatile organic compounds. Appl. Surf. Sci. 2020, 512, 145697. [Google Scholar] [CrossRef]

- Hussain, M.; Salam, A.; Arain, M.F.; Ullah, A.; Dao, A.-T.; Vu-Manh, H.; Phan, D.-N.; Ansari, A.S.; Khan, M.Q.; Javed, Z.; et al. Polyacrylonitrile Nanofibers Containing Viroblock as Promising Material for Protective Clothing. Appl. Sci. 2021, 11, 11469. [Google Scholar] [CrossRef]

- Zhu, M.; Xiong, R.; Huang, C. Bio-based and photocrosslinked electrospun antibacterial nanofibrous membranes for air filtration. Carbohydr. Polym. 2019, 205, 55–62. [Google Scholar] [CrossRef] [PubMed]

- Kalantari, M.; Ayranci, C.; Dolez, P.I. Multifunctionalized dual-electrospun nano-fibrous webs for protection against chemical and biological hazards. In Proceedings of the 5th International Congress on Soldiers’ Physical Performance–ICSPP 2020, Quebec City, QC, Canada, 11–14 February 2020. [Google Scholar]

- He, H.; Gao, M.; Illés, B.; Molnar, K. 3D printed and electrospun, transparent, hierarchical polylactic acid mask nanoporous filter. Int. J. Bioprint 2020, 6, 278. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Nie, J.; Han, C.; Jiang, T.; Yang, Z.; Pang, Y.; Xu, L.; Guo, T.; Bu, T.; Zhang, C.; et al. Self-powered electrostatic adsorption face mask based on a triboelectric nanogenerator. ACS Appl. Mater. Interfaces 2018, 10, 7126–7133. [Google Scholar] [CrossRef] [PubMed]

- Frydrych, I.; Cichocka, A.; Gilewicz, P.; Dominiak, J. Thermal Manikin Measurements of Protective Clothing Assemblies. Fibres Text. East. Eur. 2018, 26, 126–133. [Google Scholar] [CrossRef]

- Hrynyk, R.; Frydrych, I. Study on textile assemblies with aluminized basalt fabrics destined for protective gloves. Int. J. Cloth. Sci. Technol. 2015, 27, 705–719. [Google Scholar] [CrossRef]

- Miśkiewicz, P.; Frydrych, I.; Tokarska, M.; Pawlak, W. Study on Some Thermal and Electrical Properties of Basalt Fabric Modified with Metal and Ceramics as a Result of Magnetron Sputtering. Polymers 2019, 11, 2087. [Google Scholar] [CrossRef] [Green Version]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Pucci, M.F.; Seghini, M.C.; Liotier, P.J.; Sarasini, F.; Tirilló, J.; Drapier, S. Surface characterisation and wetting properties of single basalt fibres. Compos. Part B Eng. 2017, 109, 72–81. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Valente, M.; Ferrante, L.; Cioffi, S.; Iannace, S.; Sorrentino, L. Hybrid composites based on aramid and basalt woven fabrics: Impact damage modes and residual flexural properties. Mater. Des. 2013, 49, 290–302. [Google Scholar] [CrossRef]

- Sun, G.; Tong, S.; Chen, D.; Gong, Z.; Li, Q. Mechanical properties of hybrid composites reinforced by carbon and basalt fibers. Int. J. Mech. Sci. 2018, 148, 636–651. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, J.; Wang, S.; Ma, X.; Huang, J.; Zhao, G.; Liu, Y. Facile preparation of multiscale graphene-basalt fiber reinforcements and their enhanced mechanical and tribological properties for polyamide 6 composites. Mater. Chem. Phys. 2018, 217, 315–322. [Google Scholar] [CrossRef]

- Purnomo, H.; Widananto, H.; Sulistio, J. The optimization of soft body armor materials made from carbon-aramid fiber using the Taguchi method. AIP Conf. Proc. 2018, 1977, 020003. [Google Scholar] [CrossRef]

- Kim, S.; Lee, J.; Roh, C.; Eun, J.; Kang, C. Evaluation of carbon fiber and p-aramid composite for industrial helmet using simple cross-ply for protecting human heads. Mech. Mater. 2019, 139, 103203. [Google Scholar] [CrossRef]

- Rosengren, K.S.; Hsiao-Wecksler, E.T.; Horn, G. Fighting fires without falling: Effects of equipment design and fatigue on firefighter’s balance and gait. Ecol. Psychol. 2014, 26, 167–175. [Google Scholar] [CrossRef]

- Devina, E.A.; Bokova, E.S.; Devin, K.L.; Evsyukova, N.V.; Abramova, A.B. Effect of Fibrous-Porous Composite Composition on its Radiophysical Characteristics. Fibre Chem. 2017, 48, 487–490. [Google Scholar] [CrossRef]

- Behnam, R.; Morshed, M.; Tavanai, H.; Ghiaci, M. Destructive adsorption of diazinon pesticide by activated carbon nanofibers containing A12O3 and MgO nanoparticles. Bull. Environ. Contam. Toxicol. 2013, 91, 475–480. [Google Scholar] [CrossRef]

- Storck, J.L.; Wortmann, M.; Brockhagen, B.; Frese, N.; Diestelhorst, E.; Grothe, T.; Hellert, C.; Ehrmann, A. Comparative Study of Metal Substrates for Improved Carbonization of Electrospun PAN Nanofibers. Polymers 2022, 14, 721. [Google Scholar] [CrossRef]

- Fornasiero, F. Water vapor transport in carbon nanotube membranes and application in breathable and protective fabrics. Curr. Opin. Chem. Eng. 2017, 16, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Rebouillat, S.; Steffenino, B.; Miret-Casas, A. Aramid, steel, and glass: Characterization via cut performance testing, of composite knitted fabrics and their constituent yarns, with a review of the art. J. Mater. Sci. 2010, 45, 5378–5392. [Google Scholar] [CrossRef]

- Guevel, J.; Bontemps, G. Cut-Resistant Yarn Intended Especially for the Production Of Protective Garments. U.S. Patent 7,065,949, 27 June 2006. [Google Scholar]

- Mofarah, H.M.; Najar, S.S.; Etrati, S.M. Mechanical properties of copper/cotton core-spun yarns produced by siro and ring spinning methods. Indian J. Fibre Text. Res. 2019, 44, 431–436. [Google Scholar]

- Koren, M. Chainmail, Metal Spikes and Unbreakable Material: Can We Design a ‘Shark-Proof’ Wetsuit? Smithson. Mag. 2013. Available online: https://www.smithsonianmag.com/arts-culture/chainmail-metal-spikes-and-unbreakable-material-can-we-design-a-shark-proof-wetsuit-27310741/ (accessed on 10 June 2022).

- Landau, E. ‘Space Fabric’ Links Fashion and Engineering. Space Tech. Available online: https://www.nasa.gov/feature/jpl/space-fabric-links-fashion-and-engineering (accessed on 18 April 2017).

- Bernard, S.; Chassagneux, F.; Berthet, M.-P.; Vincent, H.; Bouix, J. Structural and mechanical properties of a high-performance BN fibre. J. Eur. Ceram. Soc. 2002, 22, 2047–2059. [Google Scholar] [CrossRef]

- Tam, T.; Bhatnagar, A. High-performance ballistic fibers and tapes. In Lightweight Ballistic Composites: Military and Law-Enforcement Applications, 2nd ed.; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2016; pp. 1–39. [Google Scholar] [CrossRef]

- Nayak, R.; Kanesalingam, S.; Wang, L.; Padhye, R. Stab resistance and thermophysiological comfort properties of boron carbide coated aramid and ballistic nylon fabrics. J. Text. Inst. 2019, 110, 1159–1168. [Google Scholar] [CrossRef]

- Liu, H.; Du, Y.; Lei, S.; Liu, Z. Flame-retardant activity of modified boron nitride nanosheets to cotton. Text. Res. J. 2020, 90, 512–522. [Google Scholar] [CrossRef]

- Umrao, S.; Gupta, T.K.; Kumar, S.; Singh, V.K.; Sultania, M.K.; Jung, J.H.; Oh, I.-K.; Srivastava, A. Microwave-Assisted Synthesis of Boron and Nitrogen co-doped Reduced Graphene Oxide for the Protection of Electromagnetic Radiation in Ku-Band. ACS Appl. Mater. Interfaces 2015, 7, 19831–19842. [Google Scholar] [CrossRef]

- Tekin, H.O.; Altunsoy, E.E.; Kavaz, E.; Sayyed, M.I.; Agar, O.; Kamislioglu, M. Photon and neutron shielding performance of boron phosphate glasses for diagnostic radiology facilities. Results Phys. 2019, 12, 1457–1464. [Google Scholar] [CrossRef]

- Dolez, P.I.; Decaens, J.; Buns, T.; Lachapelle, D.; Vermeersch, O. Applications of smart textiles in occupational health and safety. IOP Conf. Ser. Mater. Sci. Eng 2020, 827, 012014. [Google Scholar] [CrossRef]

- Min, R.; Ortega, B.; Marques, C. Latest Achievements in Polymer Optical Fiber Gratings: Fabrication and Applications. Photonics 2019, 6, 36. [Google Scholar] [CrossRef] [Green Version]

- Zlobina, I.V.; Bekrenev, N.V. Influence of microwave radiation on the strength of aramid filaments. AIP Conf. Proc. 2018, 2053, 040107. [Google Scholar] [CrossRef]

- Zlobina, I.V.; Bekrenev, N.V. Study of the microstructure of aramid fabrics for structural and protective organoplastics modified in a microwave electromagnetic field. IOP Conf. Ser. Mater. Sci. Eng. 2019, 511, 012033. [Google Scholar] [CrossRef]

- Zlobina, I.V.; Bekrenev, N.V. Study of mechanical and protective characteristics of composite materials based on aramid fabrics modified in a microwave electromagnetic field. IOP Conf. Ser. Mater. Sci. Eng. 2019, 511, 012031. [Google Scholar] [CrossRef]

- Safonov, P.E.; Yukhin, S.S. Deformation of aramid fabrics with different structures during low-speed penetration by an indenter. Review. Fibre Chem. 2017, 48, 478–486. [Google Scholar] [CrossRef]

- LaBarre, E.D.; Calderon-Colon, X.; Morris, M.; Tiffany, J.; Wetzel, E.; Merkle, A.; Trexler, M. Effect of a carbon nanotube coating on friction and impact performance of Kevlar. J. Mater. Sci. 2015, 50, 5431–5442. [Google Scholar] [CrossRef]

- Usman Javaid, M.; Militký, J.; Wiener, J.; Jabbar, A.; Salačová, J.; Umair, M. Effect of surface modification and knife penetration angle on the Quasi-Static Knife Penetration Resistance of para-aramid fabrics. J. Text. Inst. 2019, 110, 590–599. [Google Scholar] [CrossRef]

- da Silva, A.O.; Weber, R.P.; Monteiro, S.N.; Lima, A.M.; Faria, G.S.; da Silva, W.O.; Oliveira, S.D.S.A.; Monsores, K.; Pinheiro, W.A. Effect of graphene oxide coating on the ballistic performance of aramid fabric. J. Mater. Res. Technol. 2020, 9, 2267–2278. [Google Scholar] [CrossRef]

- Manaee, P.; Valefi, Z.; Goodarz, M. The effect of bond coat type on the stab resistance of Al2O3–13 wt% TiO2 plasma sprayed ceramic coating on aramid fabrics. Surf. Interfaces 2020, 18, 100432. [Google Scholar] [CrossRef]

- Rodríguez-Millán, M.; Álvarez-Díaz, A.; Aranda-Ruiz, J.; Álvarez-Díaz, J.; Loya, J.A. Experimental analysis for stabbing resistance of different aramid composite architectures. Compos. Struct. 2019, 208, 525–534. [Google Scholar] [CrossRef]

- Lin, T.R.; Lin, T.A.; Lin, M.C.; Lin, Y.Y.; Lou, C.W.; Lin, J.H. Impact resistance of fiber reinforced sandwich-structured nonwoven composites: Reinforcing effect of different fiber length. Mater. Today Commun. 2020, 24, 101345. [Google Scholar] [CrossRef]

- Cheon, J.; Lee, M.; Kim, M. Study on the stab resistance mechanism and performance of the carbon, glass and aramid fiber reinforced polymer and hybrid composites. Compos. Struct. 2020, 234, 111690. [Google Scholar] [CrossRef]

- Gonzalez, G.M.; Ward, J.; Song, J.; Swana, K.; Fossey, S.A.; Palmer, J.L.; Zhang, F.W.; Lucian, V.M.; Cera, L.; Zimmerman, J.F.; et al. Para-aramid fiber sheets for simultaneous mechanical and thermal protection in extreme environments. Matter 2020, 3, 742–758. [Google Scholar] [CrossRef]

- Levit, N.V.; Young, R.H. Flame Resistant Thermal Liner, Composite Fabric, and Garment. U.S. Patent 9,913,504, 13 March 2018. [Google Scholar]

- Oertel, A.; Khenoussi, N.; Schacher, L.; Adolphe, D.C.; Graftieaux, H. Optimization of meta-aramid electrospun nanofibers productivity through wire-based electrospinning setup scale up. J. Ind. Text. 2018, 48, 236–254. [Google Scholar]

- Kim, H.B.; Lee, W.J.; Choi, S.C.; Lee, K.B.; Lee, M.-H. Dependence of the fiber diameter on quality factor of filters fabricated with meta-aramid nanofibers. Sep. Purif. Technol. 2019, 222, 332–341. [Google Scholar] [CrossRef]

- Ryu, S.-Y.; Chung, J.W.; Kwak, S.-Y. Amphiphobic meta-aramid nanofiber mat with improved chemical stability and mechanical properties. Eur. Polym. J. 2017, 91, 111–120. [Google Scholar] [CrossRef]

- Chung, J.; Kwak, S.-Y. Solvent-assisted heat treatment for enhanced chemical stability and mechanical strength of meta-aramid nanofibers. Eur. Polym. J. 2018, 107, 46–53. [Google Scholar] [CrossRef]

- Oh, H.J.; Yeang, B.J.; Park, Y.K.; Choi, H.J.; Kim, J.H.; Kang, Y.S.; Bae, Y.; Kim, J.Y.; Lim, S.J.; Lee, W.; et al. Washable Colorimetric Nanofiber Nonwoven for Ammonia Gas Detection. Polymers 2020, 12, 1585. [Google Scholar] [CrossRef]

- Jung, J.-Y.; Ku, P.; Kim, D.H.; Kwon, M.-J.; Kang, S.; Choi, J.-Y.; Lee, J.-Y. Development of firefighters’ personal protective clothing with Nomex honeycomb fabric and its protective and comfort evaluation. Fash. Text. Res. J. 2019, 21, 606–617. [Google Scholar] [CrossRef]

- Kasper, D. Aramid recycling. In Proceedings of the 116th Scientific Session, Institute of Textile Science, Montreal, QC, Canada; Edmonton, AB, Canada, 3 April 2017. [Google Scholar]

- Dolez, P.; Breton, H.; Paskaluk, S.; Batcheller, J. Predicting the Arc Rating of Fire-Resistant Fabrics Containing Recycled Aramid Fibers. In Proceedings of the Fiber Society Conference, Hong Kong, China, 21–23 May 2019. [Google Scholar]

- Mushtaq, N.; Wang, Q.; Chen, G.; Lao, H.; Zhang, Y.; Sidra, L.R.; Fang, X.; Bashir, B. Synthesis of polyamide-imides with different monomer sequence and effect on transparency and thermal properties. Polymer 2020, 190, 122218. [Google Scholar] [CrossRef]

- Helali, N.; Rastgar, M.; Farhad Ismail, M.; Sadrzadeh, M. Development of underwater superoleophobic polyamide-imide (PAI) microfiltration membranes for oil/water emulsion separation. Sep. Purif. Technol. 2020, 238, 116451. [Google Scholar] [CrossRef]

- Dawkins, B.G.; Qin, F.; Gruender, M.; Copeland, G.S. Polybenzimidazole (PBI) high temperature polymers and blends. High Temp. Polym. Blends 2014, 174–212. [Google Scholar] [CrossRef]

- Lee, S.; Cho, A.R.; Park, D.; Kim, J.K.; Han, K.S.; Yoon, I.-J.; Lee, M.H.; Nah, J. Resuable polybenzimidazole nanofiber membrane filter for highly breathable PM2.5 dust proof mask. ACS Appl. Mater. Interfaces 2019, 11, 2750–2757. [Google Scholar] [CrossRef]

- Lee, S.; Han, K.S.; Kim, M.; Kim, M.C.; Anh, C.V.; Nah, J. Polybenzimidazole-benzophenone composite nanofiber window air filter with superb UV resistance and high chemical and thermal durability. ACS Appl. Mater. Interfaces 2020, 12, 23914–23922. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, Y. Technical textiles for ballistic protection. In Handbook of Technical Textiles-V2: Technical Textile Applications; Woodhead Publishing: Duxford, UK, 2016; pp. 169–192. [Google Scholar]

- Hart, S.V. Third Status Report to the Attorney General on Body Armor Safety Initiative Testing and Activities; National Institute of Justice: Washington, DC, USA, 2005. [Google Scholar]

- Dolez, P.; Malajati, Y. Resistance of Fire Protective Fabrics to Repeated Launderings. In Performance of Protective Clothing and Equipment: Innovative Solutions to Evolving Challenges; (STP 1624); ASTM International: West Conshohocken, PA, USA, 2020; 14p. [Google Scholar]

- Fu, Q.; Zhang, H.; Song, B.; Liu, X.; Zhuang, Q.; Han, Z. Mechanism of Degradation of Poly(P-Phenylene Benzobisoxazole) under Hydrolytic Conditions. J. Appl. Polym. Sci. 2011, 121, 1734–1739. [Google Scholar] [CrossRef]

- Liu, J.; Liu, X.; Wang, D.; Wang, H. An important factor affecting the UV aging resistance of PBO fiber foped with nano-TiO2: The number of amorphous regions. Polymers 2019, 11, 869. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Obermann, M.; Aumann, S.; Heimlich, F.; Weber, M.O.; Schwarz-Pfeiffer, A. Comparison of flat-knitted structures made of poly(P-phenylene-2,6-benzobisoxazole) and para-aramid referring to their stab resistance. IOP Conf. Ser. Mater. Sci. Eng. 2016, 141, 012004. [Google Scholar] [CrossRef] [Green Version]

- Vlasblom, M.P.; Van Dingenen, J.L.J. The manufacture, properties and applications of high strength, high modulus polyethylene fibers. In Handbook of Tensile Properties of Textile and Technical Fibres; Bunsell, A.R., Ed.; Woodhead Publishing: Cambridge, UK; New Delhi, India; Boca Raton, FL, USA, 2009; pp. 437–485. [Google Scholar]

- Van Der Werff, H.; Heisserer, U. High-performance ballistic fibers: Ultra-high molecular weight polyethylene (UHMWPE). In Advanced Fibrous Composite Materials for Ballistic Protection; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2016; pp. 71–107. [Google Scholar] [CrossRef]

- Firouzi, D.; Ching, C.Y.; Rizvi, S.N.; Selvaganapathy, P.R. Development of oxygen-plasma-surface-treated UHMWPE fabric coated with a mixture of SiC/polyurethane for protection against puncture and needle threats. Fibers 2019, 7, 46. [Google Scholar] [CrossRef] [Green Version]

- Chukov, D.I.; Kharitonov, A.P.; Tcherdyntsev, V.V.; Zherebtsov, D.D.; Maksimkin, A.V. Structure and mechanical properties of self-reinforced ultra-high molecular weight polyethylene. J. Compos. Mater. 2018, 52, 1689–1698. [Google Scholar] [CrossRef]

- Zherebtsov, D.; Chukov, D.; Torokhov, V.; Statnik, E. Manufacturing of single-polymer composite materials based on ultra-high molecular weight polyethylene fibers by hot compaction. J. Mater. Eng. Perform. 2020, 29, 1522–1527. [Google Scholar] [CrossRef]

- Lepage, M.L.; Simhadri, S.; Liu, C.; Takaffoli, M.; Bi, L.; Crawford, B.; Milani, A.S.; Wulff, J.E. A broadly applicable cross-linker for aliphatic polymers containing C–H bonds. Science 2019, 366, 875–878. [Google Scholar] [CrossRef]

- Ivanov, S.; Kuznetsov, S.; Volkov, A.; Terekhin, P.; Dmitriev, S.; Tcherdyntsev, V.; Gorshenkov, M.; Boykov, A. Photons transport through ultra-high molecular weight polyethylene based composite containing tungsten and boron carbide fillers. J. Alloy. Compd. 2014, 586 (Suppl. 1), 2012–2015. [Google Scholar] [CrossRef]

- Ertekin, M.; Erhan Kirtay, H. Cut resistance of hybrid para-aramid fabrics for protective gloves. J. Text. Inst. 2016, 107, 1276–1283. [Google Scholar] [CrossRef]

- da Silva, L.F.; Lavoratti, A.; Pereira, I.M.; Dias, R.R.; Amico, S.C.; Zattera, A.J. Development of multilaminar composites for vehicular ballistic protection using ultra-high molecular weight polyethylene laminates and aramid fabrics. J. Compos. Mater. 2019, 53, 1907–1916. [Google Scholar] [CrossRef]

- Kocer, H.B.; Ozkan, F.; Broughton, R.M.; Worley, S.D. Treatment of melamine formaldehyde fibers for decontaminating biological and chemical warfare agents. J. Appl. Polym. Sci. 2015, 132, 42799. [Google Scholar] [CrossRef]

- Zhu, F.; Xu, Y.; Feng, Q.; Yang, Q. Thermal kinetics study and flammability evaluation of polyimide fiber material. J. Therm. Anal. Calorim. 2018, 131, 2579–2587. [Google Scholar] [CrossRef]

- Serbezeanu, D.; Popa, A.M.; Stelzig, T.; Sava, I.; Rossi, R.M.; Fortunato, G. Preparation and characterization of thermally stable polyimide membranes by electrospinning for protective clothing applications. Text. Res. J. 2015, 85, 1763–1775. [Google Scholar] [CrossRef]

- Yi, B.; Zhao, Y.; Tian, E.; Li, J.; Ren, Y. High-performance polyimide nanofiber membranes prepared by electrospinning. High Perform. Polym. 2019, 31, 438–448. [Google Scholar] [CrossRef]

- Wen, Y.; Meng, X.; Wang, Z.; Yan, J. Surface modification of high-performance polyimide fibers by oxygen plasma treatment. High Perform. Polym. 2017, 29, 1083–1089. [Google Scholar] [CrossRef]

- Sloan, F. Liquid crystal aromatic polyester-arylate (LCP) fibers: Structure, properties, and applications. In Structure and Properties of High-Performance Fibers; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2017; pp. 113–140. [Google Scholar] [CrossRef]

- Bertocchi, M.J.; Simbana, R.A.; Wynne, J.H.; Lundin, J.G. Electrospinning of Tough and Elastic Liquid Crystalline Polymer–Polyurethane Composite Fibers: Mechanical Properties and Fiber Alignment. Macromol. Mater. Eng. 2019, 304, 1900186. [Google Scholar] [CrossRef]

- Balagna, C.; Irfan, M.; Perero, S.; Miola, M.; Maina, G.; Crosera, M.; Santella, D.; Simone, A.; Ferraris, M. Antibacterial nanostructured composite coating on high performance Vectran™ fabric for aerospace structures. Surf. Coat. Technol. 2019, 373, 47–55. [Google Scholar] [CrossRef]

- Li, J.; Zhu, Y.; Yu, H.; Dai, B.; Jun, Y.-S.; Zhang, F. Microbially Synthesized Polymeric Amyloid Fiber Promotes β-Nanocrystal Formation and Displays Gigapascal Tensile Strength. ACS Nano 2021, 15, 11843–11853. [Google Scholar] [CrossRef]

- Bowen, C.H.; Sargent, C.J.; Wang, A.; Zhu, Y.; Chang, X.; Li, J.; Mu, X.; Galazka, J.M.; Jun, Y.-S.; Keten, S.; et al. Microbial production of megadalton titin yields fibers with advantageous mechanical properties. Nat. Commun. 2021, 12, 5182. [Google Scholar] [CrossRef]

- McQuerry, M.; Klausing, S.; Cotterill, D.; Easter, E. A Post-use Evaluation of Turnout Gear Using NFPA 1971 Standard on Protective Ensembles for Structural Fire Fighting and NFPA 1851 on Selection, Care and Maintenance. Fire Technol. 2015, 51, 1149–1166. [Google Scholar] [CrossRef]

- Dolez, P.I.; Tomer, N.S.; Malajati, Y. A quantitative method to compare the effect of thermal aging on the mechanical performance of fire protective fabrics. J. Appl. Polym. Sc. 2018, 135, 47045. [Google Scholar] [CrossRef]

- Arrieta, C.; David, E.; Dolez, P.; Vu-Khanh, T. Hydrolytic and photochemical aging studies of a Kevlar-PBI blend. Polym. Degrad. Stab. 2011, 96, 1411–1419. [Google Scholar] [CrossRef]

- Hoque, M.S.; Saha, A.; Chung, H.-J.; Dolez, P.I. Hydrothermal aging of fire-protective fabrics. J. Appl. Polym. Sci. 2022, e52666. [Google Scholar] [CrossRef]

- Dolez, P.I.; Tomer, N.S.; Malajati, Y. Aging of aramid fabrics: Effect of exposure to high temperature, UV, and laundering on mechanical performance. In Proceedings of the 5th International Congress on Soldiers’ Physical Performance—ICSPP, Quebec City, QC, Canada, 11–14 February 2020. [Google Scholar]

- Dolez, P.; Chung, H.-J.; Cho, C. End-of-Life Sensors for Fabrics. PCT International Patent Application PCT/CA2022/000006, 3 March 2022. [Google Scholar]

- Cho, C.; Elias, A.; Batcheller, J.; Dolez, P.; Chung, H.-J. Electrical conduction of reduced graphene oxide coated meta-aramid textile and its evolution under aging conditions. J. Ind. Text. 2021, 50, 1330–1347. [Google Scholar] [CrossRef]

- Cho, C.; Nam, S.L.; de la Mata, P.A.; Harynuk, J.J.; Elias, A.; Chung, H.-J.; Dolez, P.I. Investigation of the accelerated thermal aging behavior of polyetherimide and lifetime prediction at elevated temperature. J. Appl. Polym. Sci. 2021, 139, e51955. [Google Scholar] [CrossRef]

- Braun, C.; Nam, S.L.; de la Mata, P.A.; Harynuk, J.J.; Chung, H.-J.; Dolez, P.I. Hydrothermal Aging of Polyimide Film. J. Appl. Polym. Sci. 2022, 139, e52183. [Google Scholar] [CrossRef]

- Behera, B.K.; Dash, B.P. An experimental investigation into structure and properties of 3D-woven aramid and PBO fabrics. J. Text. Inst. 2013, 104, 1337–1344. [Google Scholar] [CrossRef]

- Gu, B. Modelling of 3D woven fabrics for ballistic protection. In Advanced Fibrous Composite Materials for Ballistic Protection; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2016; pp. 145–197. [Google Scholar] [CrossRef]

- Chu, T.L.; Ha-Minh, C.; Imad, A. Analysis of local and global localizations on the failure phenomenon of 3D interlock woven fabrics under ballistic impact. Compos. Struct. 2017, 159, 267–277. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Engineering of 3D warp interlock p-aramid fabric structure and its energy absorption capabilities against ballistic impact for body armour applications. Compos. Struct. 2019, 225, 111179. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Enhancing the ballistic performances of 3D warp interlock fabric through internal structure as new material for seamless female soft body armor development. Appl. Sci. 2020, 10, 4873. [Google Scholar] [CrossRef]

- Mahbub, R.; Nayak, R.; Wang, L.; Arnold, L. Comfort properties of 3D-knitted seamless female body armour vests. J. Text. Inst. 2017, 108, 1997–2005. [Google Scholar] [CrossRef]

- Palani Rajan, T.; Ramakrishnan, G.; Kandhavadivu, P. Permeability and impact properties of warp-knitted spacer fabrics for protective application. J. Text. Inst. 2016, 107, 1079–1088. [Google Scholar] [CrossRef]

- Nayak, R.; Kanesalingam, S.; Vijayan, A.; Wang, L.; Padhye, R.; Arnold, L. Design of 3D knitted structures for impact absorption in sportswear. KnE Eng. 2017, 2, 127. [Google Scholar] [CrossRef] [Green Version]

- Storck, J.L.; Ehrmann, G.; Uthoff, J.; Diestelhorst, E.; Blachowicz, T.; Ehrmann, A. Investigating inexpensive polymeric 3D printed materials under extreme thermal conditions. Mater. Futures 2022, 1, 015001. [Google Scholar] [CrossRef]

- Ugbolue, S.C.; Kim, Y.K.; Warner, S.B.; Fan, Q.; Yang, C.-L.; Feng, Y.; Kyzymchuk, O. Formation and Performance of Auxetic Textiles. Natl. Text. Cent. Annu. Rep. 2008, 101, 660–667. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Xiao, X. Deformation behaviors of three-dimensional auxetic spacer fabrics. Text. Res. J. 2014, 84, 1361–1372. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H. Tensile and forming properties of auxetic warp-knitted spacer fabrics. Text. Res. J. 2017, 87, 1925–1937. [Google Scholar] [CrossRef]

- Steffens, F.; Rana, S.; Fangueiro, R. Development of novel auxetic textile structures using high performance fibres. Mater. Des. 2016, 106, 81–89. [Google Scholar] [CrossRef]

- Sun, Y.; Xu, W.; Wei, W.; Ma, P.; Xia, F. Stab-resistance of auxetic weft-knitted fabric with Kevlar fibers at quasi-static loading. J. Ind. Text. 2019, 50, 1384–1396. [Google Scholar] [CrossRef]

- Ali, M.; Zeeshan, M.; Ahmed, S.; Qadir, B.; Nawab, Y.; Anjum, A.S.; Riaz, R. Development and comfort characterization of 2D-woven auxetic fabric for wearable and medical textile applications. Cloth. Text. Res. J. 2018, 36, 199–214. [Google Scholar] [CrossRef]

- Goncalves, C.; Magalhaes, R.; Rana, S.; Fangueiro, R.; Nunes, J.; Dias, G. Novel high performance auxetic fibrous structures for composite reinforcement. IOP Conf. Ser. Mater. Sci. Eng. 2018, 406, 012046. [Google Scholar] [CrossRef]

- Lolaki, A.; Shanbeh, M. Variation of Poisson’s ratio of fabrics woven with helical composite auxetic weft yarns in relation to fabric structural parameters. J. Ind. Text. 2019, 50, 149–169. [Google Scholar] [CrossRef]

- Chen, J.; Du, Z.; Li, T. Structural design and characterization of highly elastic woven fabric containing helical auxetic yarns. Text. Res. J. 2020, 90, 809–823. [Google Scholar] [CrossRef]

- Zielinska, D.; Delczyk-Olejniczak, B.; Wierzbicki, L.; Wilbik-Hałgas, B.; Struszczyk, M.H.; Leonowicz, M. Investigation of the effect of para-aramid fabric impregnation with shear thickening fluid on quasi-static stab resistance. Text. Res. J. 2014, 84, 1569–1577. [Google Scholar] [CrossRef]

- Baharvandi, H.R.; Alebooyeh, M.; Alizadeh, M.; Khaksari, P.; Kordani, N. Effect of silica weight fraction on rheological and quasi-static puncture characteristics of shear thickening fluid-treated Twaron® composite. J. Ind. Text. 2016, 46, 473–494. [Google Scholar] [CrossRef]

- Santos, T.F.; Santos, C.M.S.; Aquino, M.S.; Ionesi, D.; Medeiros, J.I. Influence of silane coupling agent on shear thickening fluids (STF) for personal protection. J. Mater. Res. Technol. 2019, 8, 4032–4039. [Google Scholar] [CrossRef]

- Li, W.; Xiong, D.; Zhao, X.; Sun, L.; Liu, J. Dynamic stab resistance of ultra-high molecular weight polyethylene fabric impregnated with shear thickening fluid. Mater. Des. 2016, 102, 162–167. [Google Scholar] [CrossRef]

- Majumdar, A.; Laha, A. Effects of fabric construction and shear thickening fluid on yarn pull-out from high-performance fabrics. Text. Res. J. 2016, 86, 2056–2066. [Google Scholar] [CrossRef]

- Haris, A.; Lee, H.P.; Tay, T.E.; Tan, V.B.C. Shear thickening fluid impregnated ballistic fabric composites for shock wave mitigation. Int. J. Impact Eng. 2015, 80, 143–151. [Google Scholar] [CrossRef]

- Fowler, J.N.; Pallanta, A.A.; Swanik, C.B.; Wagner, N.J. The use of shear thickening nanocomposites in impact resistant materials. J. Biomech. Eng. 2015, 137, 054504. [Google Scholar] [CrossRef]

- Haris, A.; Lee, H.P.; Tan, V.B.C. An experimental study on shock wave mitigation capability of polyurea and shear thickening fluid based suspension pads. Def. Technol. 2018, 14, 12–18. [Google Scholar] [CrossRef]

- Li, S.; Wang, Y.; Ding, J.; Wu, H.; Fu, Y. Effect of shear thickening fluid on the sound insulation properties of textiles. Text. Res. J. 2014, 84, 897–902. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Y.; Fu, X.; Fu, Y. Effect of TW-ZnO/SiO2-compounded shear thickening fluid on the sound insulation property of glass fiber fabric. Text. Res. J. 2015, 85, 980–986. [Google Scholar] [CrossRef]

- Cwalina, C.D.; McCutcheon, C.M.; Dombrowski, R.D.; Wagner, N.J. Engineering enhanced cut and puncture resistance into the thermal micrometeoroid garment (TMG) using shear thickening fluid (STF)-ArmorTM absorber layers. Compos. Sci. Technol. 2016, 131, 61–66. [Google Scholar] [CrossRef]

- Wei, R.; Dong, B.; Wang, F.; Yang, J.; Jiang, Y.; Zhai, W.; Li, H. Effects of silica morphology on the shear-thickening behavior of shear thickening fluids and stabbing resistance of fabric composites. J. Appl. Polym. Sci. 2020, 137, 1–7. [Google Scholar] [CrossRef]

- Zhang, X.; Li, T.T.; Peng, H.K.; Wang, Z.; Huo, J.; Lou, C.W.; Lin, J.H. Effects of bi-particle-sized shear thickening fluid on rheological behaviors and stab resistance of Kevlar fabrics. J. Ind. Text. 2020, 1–16. [Google Scholar] [CrossRef]

- Gürgen, S. Numerical modeling of fabrics treated with multi-phase shear thickening fluids under high velocity impacts. Thin-Walled Struct. 2020, 148, 106573. [Google Scholar] [CrossRef]

- Majumdar, A.; Laha, A.; Bhattacharjee, D.; Biswas, I. Tuning the structure of 3D woven aramid fabrics reinforced with shear thickening fluid for developing soft body armour. Compos. Struct. 2017, 178, 415–425. [Google Scholar] [CrossRef]

- Xu, W.; Yan, B.; Hu, D.; Ma, P. Preparation of auxetic warp-knitted spacer fabric impregnated with shear thickening fluid for low-velocity impact resistance. J. Ind. Text. 2020. [Google Scholar] [CrossRef]

- Wang, Y.; Li, L.; Hofmann, D.; Andrade, J.E.; Daraio, C. Structured fabrics with tunable mechanical properties. Nature 2021, 596, 238–243. [Google Scholar] [CrossRef]

- Linhares, T.; Pessoa de Amorim, M.T.; Durães, L. Silica aerogel composites with embedded fibres: A review on their preparation, properties and applications. J. Mater. Chem. A 2019, 7, 22768–22802. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, X.; Wu, X.; Lu, C. Flame retardant, heat insulating cellulose aerogels from waste cotton fabrics by in situ formation of magnesium hydroxide nanoparticles in cellulose gel nanostructures. ACS Sustain. Chem. Eng. 2015, 3, 1853–1859. [Google Scholar] [CrossRef]

- Liu, Z.; Lyu, J.; Fang, D.; Zhang, X. Nanofibrous kevlar aerogel threads for thermal insulation in harsh environments. ACS Nano 2019, 13, 5703–5711. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, Y.; Shao, Z.; Gao, W.; Bai, H.; Fan, W.; Liu, T. Multifunctional polyimide aerogel textile inspired by polar bear hair for thermoregulation in extreme environments. Chem. Eng. J. 2020, 390, 124623. [Google Scholar] [CrossRef]

- Qiao, S.; Zhang, H.; Kang, S.; Quan, J.; Hu, Z.; Yu, J.; Wang, Y.; Zhu, J. Hydrophobic, Pore-Tunable Polyimide/Polyvinylidene Fluoride Composite Aerogels for Effective Airborne Particle Filtration. Macromol. Metarials Eng. 2020, 305, 2000129. [Google Scholar] [CrossRef]

- Maksoud, F.J.; Lameh, M.; Fayyad, S.; Ismail, N.; Tehrani-Bagha, A.R.; Ghaddar, N.; Ghali, K. Electrospun waterproof breathable membrane with a high level of aerosol filtration. J. Appl. Polym. Sci. 2018, 135, 45660. [Google Scholar] [CrossRef]

- Park, Y.S.; Lee, J.W.; Nam, Y.S.; Park, W.H. Breathable properties of m-Aramid nanofibrous membrane with high thermal resistance. J. Appl. Polym. Sci. 2015, 132, 41515. [Google Scholar] [CrossRef]

- Iqbal, K.; Khan, A.; Sun, D.; Ashraf, M.; Rehman, A.; Safdar, F.; Basit, A.; Maqsood, H.S. Phase change materials, their synthesis and application in textiles—a review. J. Text. Inst. 2019, 110, 625–638. [Google Scholar] [CrossRef] [Green Version]

- Gao, C. Phase-change materials (PCMs) for warming or cooling in protective clothing. In Protective Clothing: Managing Thermal Stress; Woodhead Publishing: Cambridge, MA, USA; Waltham, MA, USA; Kidlington, UK, 2014; pp. 227–249. [Google Scholar]

- Chen, W.; Ni, S.; Weng, W.; Fu, M. The preparation and characterization of ultrafine fatty acid ester/poly(meta-phenylene isophthalamide) phase change fibers designed for thermo-regulating protective clothing. Fibers Polym. 2018, 19, 498–506. [Google Scholar] [CrossRef]

- Saraç, E.G.; Öner, E.; Kahraman, M.V. Microencapsulated organic coconut oil as a natural phase change material for thermo-regulating cellulosic fabrics. Cellulose 2019, 26, 8939–8950. [Google Scholar] [CrossRef]

- Sheng, N.; Rao, Z.; Zhu, C.; Habazaki, H. Enhanced thermal performance of phase change material stabilized with textile-structured carbon scaffolds. Sol. Energy Mater. Sol. Cells 2020, 205, 110241. [Google Scholar] [CrossRef]

- Han, N.; Zhang, W.; Wang, X.; Zhang, X.; Li, W.; Yu, W. Preparation and properties of shape-stabilized phase change material cellulose benzoate-g-polyoxyethylene (2) hexadecyl ether with potential for thermal energy storage. Text. Res. J. 2019, 89, 1512–1521. [Google Scholar] [CrossRef]

- Chen, W.; Fu, M.; Weng, W. Electrospinning of continuous nanofiber hollow yarns for thermal storage and insulation by a multi-step twisting method. Text. Res. J. 2020, 90, 1045–1056. [Google Scholar] [CrossRef]

- Hsu, P.-C.; Liu, C.; Song, A.Y.; Zhang, Z.; Peng, Y.; Xie, J.; Liu, K.; Wu, C.-L.; Catrysse, P.B.; Cai, L.; et al. A dual-mode textile for human body radiative heating and cooling. Sci. Adv. 2017, 3, e170089. [Google Scholar] [CrossRef] [Green Version]

- Abebe, M.G.; De Corte, A.; Rosolen, G.; Maes, B. Janus-Yarn Fabric for Dual-Mode Radiative Heat Management. Phys. Rev. Appl. 2021, 16, 054013. [Google Scholar] [CrossRef]

- Koohestani, A.S.; Bashari, A. Advanced bulletproof and stab-and spike-resistant textiles. In Advances in Functional and Protective Textiles; Woodhead Publishing: Duxford, UK; Cambridge, MA, USA; Kidlington, UK, 2020; pp. 261–289. [Google Scholar] [CrossRef]

- Kim, Y.H.; Smith, N.; Ji, H. Penetration Resistant Fabric with Multiple Layer Guard Plate Assemblies and Method of Making the Same. U.S. Patent 7,018,692; United States Patent Office, 28 March 2006. [Google Scholar]

- SuperFabric® A Cut Above. HexArmor. 2020. Available online: https://www.hexarmor.com/technologies/superfabric (accessed on 10 June 2022).

- Dolez, P.I.; Nguyen, C.T.; Guero, G.; Gauvin, C.; Lara, J. Influence of medical needle characteristics on the resistance to puncture of protective glove materials. J. ASTM Int. 2008, 5, 12. [Google Scholar]

- Boorsma, J.; Smith, N. Cut, Abrasion and/or Puncture Resistant Knitted Gloves. U.S. Patent 10,455,875; United States Patent Office, 29 October 2019. [Google Scholar]

- Vu-Khanh, T.; Dolez, P.; Nguyen, C.T.; Gauvin, C.; Lara, J. Needlestick Resistance of Protective Gloves-Development of a Test Method; Publications IRSST: Montréal, QC, Canada, 2012; ISBN 978-2-89631-638-0. [Google Scholar]

- Howland, C.A.; Hannigan, M.A. Protective Garment and Glove Construction and Method for Making Same. U.S. Patent 7,007,308; United States Patent Office, 7 March 2006. [Google Scholar]

- Jones, R.J.; Linsner, A.; Wyatt, S.; Scheir, C.; Muller, G.; Sung, J.; Hewes, L.; Graziosi, D. Enhancements to the ISS Phase VI Glove Design. In Proceedings of the 44th International Conference on Environmental Systems, Tucson, AZ, USA, 13–17 July 2014; pp. 1–11. [Google Scholar]

- Nguyen, C.; Dolez, P.; Vu-Khanh, T.; Gauvin, C.; Lara, J. Resistance of protective gloves materials to puncture by medical needles. J. ASTM Int. 2010, 7, 1–16. [Google Scholar]

- Nguyen, C.T.; Dolez, P.I.; Vu-Khanh, T.; Gauvin, C.; Lara, J. Effect of protective glove use conditions on their resistance to needle puncture. Plast. Rubber Compos. 2013, 42, 187–193. [Google Scholar] [CrossRef]

- Firouzi, D.; Russel, M.K.; Rizvi, S.N.; Ching, C.Y.; Selvaganapathy, P.R. Development of flexible particle-laden elastomeric textiles with improved penetration resistance to hypodermic needles. Mater. Des. 2018, 156, 419–428. [Google Scholar] [CrossRef]

- Gartmann, V.; Lottenbach, R.; Hibner, H.J. Textiles Having a Protective Function Against Abrasion and Contact Heat. Patent Application US 2014/0255664 A1; United States Patent Office, 11 September 2014. [Google Scholar]

- Optimum Protection from Abrasion. Schoeller Textiles. 2020. Available online: https://www.schoeller-textiles.com/en/technologies/ceramic-coating (accessed on 10 June 2022).

- Blakely, K.S. Apparel with Heat Retention Layer and Method of Making the Same. U.S. Patent 9,719,206; United States Patent Office, 1 August 2017. [Google Scholar]

- Das, A.; Alagirusamy, R. Science in Clothing Comfort; Woodhead Publishing: New Delhi, India; Cambridge, UK; Oxford, UK, 2010. [Google Scholar]

- Classen, E. Comfort testing of textiles. In Advanced Characterization and Testing of Textiles; Elsevier: Amsterdam, The Netherlands, 2017; pp. 59–69. [Google Scholar]

- NFPA 1971; Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting. National Fire Protection Association: Quincy, MA, USA, 2018.

- Wang, F. Udayraj Human Wear Trials for Assessing Comfort Performance of Firefighter Protective Clothing. In Firefighters’ Clothing and Equipment; Song, G., Wang, F., Eds.; CRC Press: Boca Raton, FL, USA, 2018; pp. 217–268. [Google Scholar]

- ASTM F1154-11; Standard Practices for Qualitatively Evaluating the Comfort, Fit, Function, and Durability of Protective Ensembles and Ensemble Components. ASTM International: West Conshohocken, PA, USA, 2018; 7p.

- Harrabi, L.; Dolez, P.I.; Vu-Khanh, T.; Lara, J.; Tremblay, G.; Nadeau, S.; Larivière, C. Characterization of protective gloves stiffness: Development of a multidirectional deformation test method. Saf. Sci. 2008, 46, 1025–1036. [Google Scholar] [CrossRef]

- Gauvin, C.; Airoldi, A.; Proulx-Croteau, S.; Dolez, P.I.; Lara, J. A new test method to characterize the adherence of protective glove materials. In Performance of Protective Clothing and Equipment: Emerging Issues and Technologies; Shepherd, A.M., Ed.; ASTM International: West Conshohocken, PA, USA, 2012; pp. 392–406. [Google Scholar]

- Bradley, J.V. Glove characteristics influencing control manipulability. Hum. Factors 1969, 11, 21–35. [Google Scholar] [CrossRef]

- Dolez, P.; Mlynarek, J. Smart Materials for PPE: Tendencies and Recent Developments. In Smart Textiles and their Applications; Koncar, V., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 497–517. [Google Scholar]

- Dolez, P. Smart barrier membranes for protective clothing. In Smart Textiles for Protection; Chapman, R., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2012; pp. 148–189. [Google Scholar]

- Hambling, D. The Overloaded Soldier: Why, U.S. Infantry Now Carry More Weight than Ever. Hearst Magazine Media. 26 December 2018. Available online: https://www.popularmechanics.com/military/research/a25644619/soldier-weight/ (accessed on 24 July 2021).

- Dolez, P.I. Energy Harvesting Materials and Structures for Smart Textile Applications: Recent Progress and Path Forward. Sensors 2021, 21, 6297. [Google Scholar] [CrossRef] [PubMed]

- Nazif, K.N.; Daus, A.; Hong, J.; Lee, N.; Vaziri, S.; Kumar, A.; Nitta, F.; Chen, M.E.; Kananian, S.; Islam, R.; et al. Cambridge High-specific-power flexible transition metal dichalcogenide solar cells. Nat. Commun. 2021, 12, 7034. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Zhao, X.; Xu, J.; Fang, Y.; Chen, G.; Song, Y.; Li, S.; Chen, J. Giant magnetoelastic effect in soft systems for bioelectronics. Nat. Mater. 2021, 20, 1670–1676. [Google Scholar] [CrossRef]

- Komatsu, N.; Ichinose, Y.; Dewey, O.S.; Taylor, L.W.; Trafford, M.A.; Yomogida, Y.; Wehmeyer, G.; Pasquali, M.; Yanagi, K.; Kono, J. Macroscopic weavable fibers of carbon nanotubes with giant thermoelectric power factor. Nat. Commun. 2021, 12, 4931. [Google Scholar] [CrossRef] [PubMed]

- Khudiyev, T.; Grena, B.; Loke, G.; Hou, C.; Jang, H.; Lee, J.; Lee, J.T. Thermally drawn rechargeable battery fiber enables pervasive power. Mater. Today 2022, 52, 80–89. [Google Scholar] [CrossRef]

- Yang, P.; Li, J.; Lee, S.W.; Fan, H.J. Printed Zinc Paper Batteries. Adv. Sci. 2022, 9, 2103894. [Google Scholar] [CrossRef]

- Ammendolia, J.; Saturno, J.; Jacobs, S. Environmental Concern Emerges from COVID-19 Pandemic: PPE Waste by the Public; Canadian Science Policy Centre: Richmond Hill, ON, Canada, 2020. [Google Scholar]

- Dolez, P.I. When Protective Clothing and PPE Become Sustainable. In Proceedings of the International e-Conference on Sustainable Growth in Textiles (SGT-2021), Kanpur, India, 19–21 August 2021. [Google Scholar]

- Trupp, S. Colour-changing gloves for toxic-substance detection. Smart Text. Nanotechnol. 2013, 9, 11. [Google Scholar]

- COVID-19–What We Know So Far about…Reuse of Personal Protective Equipment. Ontario Agency for Health Protection and Promotion. Public Health Ontario, Toronto, ON: Queens’s Printer for Ontario. 2020. 10p. Available online: https://www.publichealthontario.ca/-/media/documents/ncov/covid-wwksf/what-we-know-reuse-of-personal-protective-equipment.pdf?la=en (accessed on 16 April 2022).

| Fiber/Textile Category | Strategy Used | Applications/Improvements |

|---|---|---|

| Highly extensible elastomeric fibers | Polyester-based elastic fibers [16] Olefin-based elastic fibers [16] Bicomponent fibers [16] Shape-memory polyurethane, e.g., [20] | Enhanced sustainability Improved resistance to chemicals and UV Switchable tightness |

| Cellulose-based fibers | Hemp as an alternative to cotton, e.g., [27] Ramie as alternative to high-performance fibers [32] Recycling of used products [25] Nano-enabled coating, e.g., [31] Cellulose nanostructures, e.g., [37] | Enhanced sustainability Electromagnetic shielding Antibacterial activity Chemical detoxification Thermal protection Lower cost |

| Commodity synthetic fibers | Surface functionalization [31] Nano-enabled coatings, e.g., [81] Core-sheath structures [47] Nanocomposite structures, e.g., [56] 3D printing [83] Nanofibers, e.g., [73] Dual electrospinning [82] Environmentally friendly processes, e.g., [51] | Improved filtration efficiency Biological and chemical activity Superhydro/oleo-phobicity UV protection Heat and flame protection Abrasion resistance Electrical properties Multifunctionality Improved comfort Enhanced sustainability |

| High-strength inorganic materials | Basalt as an alternative to glass fibers, e.g., [85] Carbon and boron fibers as a reinforcement for composites, e.g., [106] Carbon and boron nanomaterials as coating and additive, e.g., [53] Nano-enabled coatings, e.g., [92] Nanofibers, e.g., [97] Conductive inks [111] Conductive yarns [111] Recycling of composite products [89] | Heat and flame protection Radiation protection Improved strength Impact protection Chemical detoxification Enhanced sustainability Lower weight Lower cost Power and data transmission Sensors and actuators |

| High-performance polymer fibers | Electromagnetic radiation treatment, e.g., [113] Nano-enabled coatings, e.g., [117] Sandwich/hybrid structures, e.g., [121] Crosslinkers [150] Nanocomposite fibers, e.g., [143] Nanofibers, e.g., [126] Biomimetics, e.g., [162] End-of-life sensors [169] Recycling of used garments [132] | Improved strength Increased impact resistance Thermal protection Heat and flame resistance Antibacterial activity UV resistance FR filter media Improved comfort Degradation monitoring during use Enhanced sustainability |

| Special textile structures | 3D weaving/knitting, e.g., [176] 3D printing, e.g., [181] Auxetic woven/knitted textiles, e.g., [190] Shear thickening fabrics, e.g., [193] Polymer and cellulose aerogels, e.g., [211] Nanofibrous membranes, e.g., [214] Nanocomposite coatings, e.g., [234] Solid–solid PCMs, e.g., [220] Janus textiles, e.g., [223] | Increased impact resistance Resistance to needle puncture Thermal protection Improved thermophysiological comfort |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dolez, P.I.; Marsha, S.; McQueen, R.H. Fibers and Textiles for Personal Protective Equipment: Review of Recent Progress and Perspectives on Future Developments. Textiles 2022, 2, 349-381. https://doi.org/10.3390/textiles2020020

Dolez PI, Marsha S, McQueen RH. Fibers and Textiles for Personal Protective Equipment: Review of Recent Progress and Perspectives on Future Developments. Textiles. 2022; 2(2):349-381. https://doi.org/10.3390/textiles2020020

Chicago/Turabian StyleDolez, Patricia I., Sabrina Marsha, and Rachel H. McQueen. 2022. "Fibers and Textiles for Personal Protective Equipment: Review of Recent Progress and Perspectives on Future Developments" Textiles 2, no. 2: 349-381. https://doi.org/10.3390/textiles2020020

APA StyleDolez, P. I., Marsha, S., & McQueen, R. H. (2022). Fibers and Textiles for Personal Protective Equipment: Review of Recent Progress and Perspectives on Future Developments. Textiles, 2(2), 349-381. https://doi.org/10.3390/textiles2020020