Abstract

Since the 1970s and 1980s, a major effort has been made to study UHMWPE (Ultra-High Molecular Weight PolyEthylene) fibers with remarkable mechanical properties, based on a basic polymer such as PE (PolyEthylene). These performances are above all associated with a very strong alignment of the molecules and the microfibrillar structures formed using various processes. However, they vary greatly depending on many parameters, and particularly on the draw ratio. Thus, these characteristics have been extensively analyzed by dynamic, static tensile, and creep tests, and are predominantly viscoelastic. The behavior appears to be associated with physical considerations and with the characteristic orthorhombic-hexagonal solid phase transition. The presence of a hexagonal phase is detrimental to the behavior because the chains slide easily relative to each other. Shifting this transition to higher temperatures is a challenge and many factors influence it and the temperature at which it takes place, such as the application of stress or annealing. The objective here is to give an overview of what has been done so far to understand the behavior of UHMWPE yarns. This is important given future numerical modeling work on the dimensioning of structural parts in which these UHMWPE yarns will be reinforcements within composites.

1. Introduction

1.1. Context

The use of polymers in structural parts is generally done for economic reasons. When replacing metal parts, lightweight considerations are added to the low cost. However, polymers are sometimes limited in their use or not used at all in certain industries (automotive, aeronautics). They are intended primarily for use in cladding parts and, in the case of stiffer polymers, for lightly filled structural elements. In highly filled parts, composites sometimes compete with metals, in which case the polymers act as a matrix that maintains the coherence of the composites and protects the fibers. Thermoplastic matrices are increasingly used, whereas thermosetting matrices previously dominated the composites market. The appearance of thermoplastic prepregs has contributed to an increase in the use of this family of polymers in composites since 1980. This interest is also based on faster processes and, above all, the possible reuse of thermoplastics by melting them [].

The automotive industry is subject to requirements in terms of lighter structures as well as environmental impact. Also, using carbon or glass fiber reinforcements raises questions. Laws are pushing manufacturers to consider more carefully the impact of their products at each stage of the life cycle, including recycling and end-of-life disposal. Indeed, manufacturers are trying to ensure that every part is recyclable. Between 2015 and 2018, EU countries had to achieve reuse and recycling rates of more than 85% and reuse and recovery rates of more than 95% for individual vehicles, based on the average weight per vehicle []. When glass or carbon reinforcements are reused, their mechanical properties are degraded, and they cannot be burnt. It is important to underline that 95% of the composites produced are reinforced with glass fibers on the European market [], and the reuse of carbon fibers is marginal. Furthermore, the fields of application of these recycled fibers are therefore restricted. One possibility is to use natural fibers such as hemp or flax, which are recyclable and can be burned, but whose mechanical properties are reduced when recycled because of their low thermal stability. Whatever the nature of the reinforcing fiber, when it is different from that of the matrix, recycling seems to be compromised or very expensive to implement. To summarize, on the one hand, the separation of the components is very expensive or even impossible or ecologically devastating (dissolving chemicals), and on the other hand, the reuse as shred often leads to a loss of properties that worsens with each cycle. The method of shredding and the size of the pellets, influence the properties of the recycled material.

The concept of self-reinforced polymers (later called SRP) was then introduced by Capiati and Porter in 1975 []. It is a composite material whose matrix and reinforcement are made from the same polymer or the same chemical family. Thus, unlike more conventional composites, an SRP is much easier to recycle []. If the morphology differs between the reinforcement (fibrillar microstructure due to the drawing process) and the matrix (spheroidal morphology), the chemical structures are close and therefore a strong chemical adhesion is possible between the fibers and the matrix [,]. This structural homogeneity then has no impact on biocompatibility and biodegradation, as no chemical agents are added to promote reinforcement or adhesion of the matrix []. These composites are used in fields such as automotive (engine crankcase, bumpers, door panels, among others), audio (loudspeakers), medical (prosthesis parts), ballistic (armoring and bullet-proof vests), consumer products (luggage, orthoses, sports equipment (hockey and football)), construction (architectural panels, among others), and nautical (reinforcement for sailing), but also for valves, pipelines, and containers [,,,,,,,,].

In the literature, many authors have focused on studying the behavior of SRP, regardless of the nature of the constituent polymer. The behavior of SRP differs from that of non-reinforced polymers in terms of greater rigidity and tensile strength [,,] and compressive strength [], greater longitudinal bending performance [,], improved tenacity [], impact strength [,], and creep resistance [,]. The behavior of SRPs compared to composites with glass, carbon, or natural fiber reinforced matrices was also investigated. The specific modulus and strength of SRPs compete with those of composites with glass-fiber reinforced polymers []. But SRPs stand out above all for their high energy absorption capacity and therefore their impact resistance, which is superior to any conventional composite [,,,]. These studies demonstrate that SRPs are plausible alternatives to current composites with better prospects in terms of large-scale recyclability. The viscoelastic reinforcements are the principal reason for the attractive use of SRPs in industry. A major disadvantage of traditional composites is their low strain at break under stress in the direction of the fiber [], and taking advantage of viscoelastic fibers as reinforcements brings these ductility properties to composites. This type of fiber also guarantees vibration damping in certain structural elements []. However, some polymer fibers, e.g., PE, are compatible with only a few matrices because their molecular polarity is low, so self-reinforcement is one of the only solutions to overcome this problem [,].

So, given the attractiveness of these composites for lightweight and strong structural parts, understanding their behavior is essential. The use of such composites could, for example, reduce the thickness of parts that are currently made of unreinforced polymer. However, to design such parts, it is necessary to understand the behavior of composites, and the complete knowledge of the reinforcement behavior is essential.

The advantage of PE is its low cost and its biological neutrality, but it allows, in addition, very high drawing ratios with a limited number of defects and consequently very high mechanical properties and a damping capacity due to a viscous part in their mechanical behavior. The specific stiffness far exceeds those of glass and their recyclability is much higher. The use of SRPE composites with such fibers can be considered to compete with glass-fiber reinforced epoxy composites, but with the disadvantage of a proven limitation concerning temperature and creep resistance in hot environments. However, a better knowledge of the mechanical behavior of these fibers is a prerequisite for their use in SRPEs and to extend their use in mass-produced structures with a need for an increasingly high recycling rate.

In the 1980s, fibers have been commercially developed by several companies, including Spectra® (Honeywell (formerly Allied-Signal Inc.), Colonial Heights, VA, USA), Dyneema® (DSM, Geleen, The Netherlands), Tenfor® (Snia Fiber, Milan, Italy), Hifax®, Doyentrontex® (BJTYZ, Beijing, China), and Tekmilon® (Mitsui Petrochemical, Tokyo, Japan). However, most studies focused on Dyneema® [,,,,,,,,,,,,,] or Spectra® fibers [,,,], or even Hifax® [,,,].

Consequently, different types of PE reinforcements are available on the market, both fabrics and fibers. In the literature, several terms are used. To create a frame of reference, the terminology used in this review considers a fiber, also called a filament by some authors, as the smallest entity. A filament bundle is then referred to as a yarn, a strand, or a tow. Fabrics can be made from these strands or yarns.

Many authors have focused on studying unique fiber [,,,,,,,]. For several reasons related to experimental difficulties, which will be explained below, and because composite reinforcements are made of yarns or fabrics, some authors focus on yarns and not fibers [,,,,,,,,].

In addition to the remarkable properties that can be achieved with stretched PE reinforcements, and their compatibility with very few matrices, the reason this review focuses on PE reinforcements is the subject of the next section.

1.2. Focus on PE Fibers

PolyEthylene (PE) has always been of great interest because it is one of the most important basic polymers for scientists but also for industry. The ambition to obtain a mechanically performing polymer material by taking advantage of the intrinsic properties of covalent bonds was first observed in 1932 by Carothers and Hill [] on polyester and polyamide, notably processed by cold drawing. Thus, PE fibers were quickly introduced to the market and were subsequently used in many areas, as they show real potential as reinforcement. Low density and high tensile strength make the use of PE reinforcements interesting. In his review, Ohta [] compared different tenacities obtained on commercial fibers from several polymers and it is PE, one of the most basic polymers, that has the highest tenacity. UHMWPE (Ultra-High Molecular Weight PolyEthylene) has a good set of properties, good abrasion resistance, a low density, the highest impact resistance of all plastics at cryogenic temperatures, good corrosion resistance, a low friction coefficient, and good impact and noise reduction properties. These industrial fibers have high strength, a more moderate modulus, compared to glass fibers, but a higher elongation at break.

However, their low melting temperature compared to other reinforcements may also be an obstacle to their use for certain applications. Due to its properties, UHMWPE reinforcement is today used in limited fields such as ballistics (bullet-proof vest []), medicine (prosthetic joints []) for protective equipment (helmets []), or towing lines []. These fibers have not been integrated into the primary structures in the automotive and aeronautic industry. To widen their use in these fields of activity, it would be mandatory to know and control their thermomechanical behavior under different load paths (loads at different speeds, fatigue, creep, load fluctuations coupled with temperature fluctuations) and the field of knowledge of this behavior is by no means exhaustive today.

PE is a viscoelastic material and is in its rubbery state at room temperature, which favors time-dependent processes. Reinforcements are therefore very sensitive to creep due to the low cohesive energy density of PE and structural irregularities []. To explore new applications or to design structural parts, the influence of temperature and time on the mechanical performance of PE reinforcements must, therefore, be better known. This is all the more true concerning fibers, which are the main elements of SRPs. For example, the behavior of glass and carbon fibers is well known and is linearly elastic, and the creep of glass fiber is very small, so exploiting glass or carbon reinforcements is easy, and engineers handle the behavior. In conclusion, a precise characterization of SRPs and fibers is necessary to simulate and dimension parts, because often, the values given by the manufacturers and those published are different and the performance of the reinforcements is then not mastered []. As reinforcement is the fundamental element that affects the stiffness and breakage of the composite part, it is essential to perfectly know its mechanical characteristics. Moreover, understanding yarn behavior is a necessary step in predicting the response of fabrics within a matrix of the same nature.

In the current context which imposes the use of reusable lightweight composites, and following what has just been discussed, it seems interesting to make an inventory of the current state of knowledge on UHMWPE yarns given their future use in structures supporting significant mechanical loads. More precisely, the objective of this review is to bring together the different studies and conclusions, obtained on the analysis of the mechanical and thermal behavior of PE reinforcements.

In the first section, how remarkable properties can be obtained from basic PE and the associated processes are briefly described. Then, on a very fine scale, the representation of the molecular structure and its formation during the process are detailed. The different phases that can be distinguished are depicted. After explaining the main ways of testing UHMWPE reinforcements and the associated difficulties, an important, but non-exhaustive literature synthesis of the thermal and mechanical characterization results is proposed. Tensile, creep, and DMA (Dynamic Mechanical Analysis) performances are given at the macroscopic scale but are mostly related to morphological considerations at a smaller scale. The influence of time and temperature on its behavior is also examined.

2. Basic Principles of Property Enhancement

2.1. Outstanding Performance from a Basic Polymer

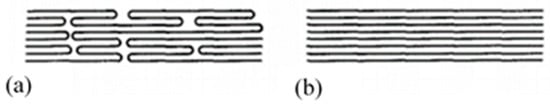

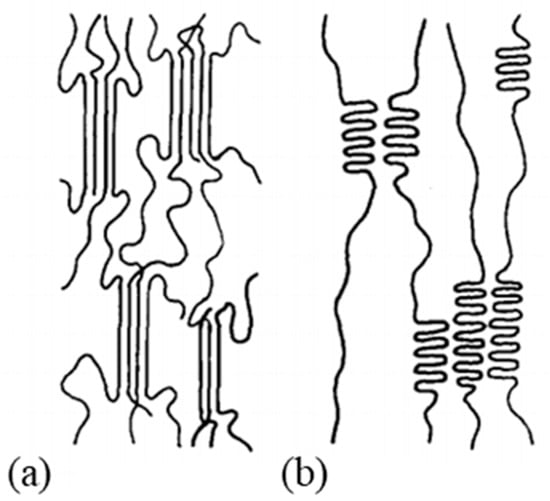

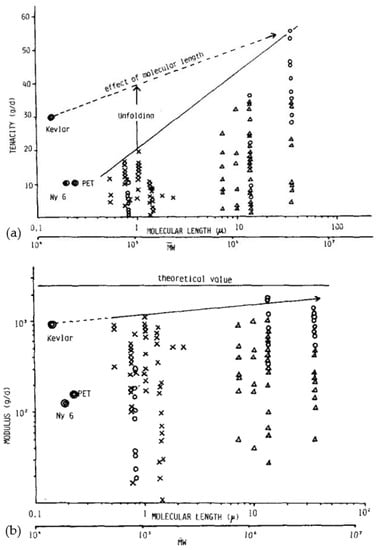

For applications exploiting SRP composites, if remarkable properties are desired, the reinforcement is only the component that takes up the load and ensures the mechanical performance of the part. To achieve superior properties from a basic polymer such as PE, it is necessary to orient and align the molecules (Figure 1a,b) []. By nature, all linear polymers can be solid and rigid due to the covalent bonds present. Concerning the optimum theoretical modulus achievable under ideal molecular alignment conditions, several values were proposed based on theoretical calculations and experiments on the calculation of crystallite stiffness [,]. Yeh et al. [] suggested that for a perfect PE crystal, a modulus of 324 GPa is attainable. However, many fibers on the market have properties that are about two orders of magnitude lower than the theoretical maximum properties, which would then be achieved if all the molecules chains were perfectly aligned and extended. The difference between theoretical and actual resistance can mainly be attributed to the presence of structural irregularities and the widespread tendency for chains to slip [].

Figure 1.

Sketch of moderately (a) and completely extended molecular chains (b), respectively without and with molecular drawing (reprinted with permission from ref. []. 2021 Roiron.).

In particular, the ultimate strength, not necessarily achievable, is governed by the rupture of the carbon-carbon bonds and can be calculated as follows []:

with the molecular cross-sectional area, which is 0.193. The value taken for the density is 0.96. To convert it to a more widely used unit, such as GPa, the following conversion must be made:

The theoretical resistance calculated in this way is just over 30 GPa. Song and Hu [] proposed a method for predicting strength based on kinetic equations of bond breaks of over-stressed taut tie molecules (TTM) and/or trapped entanglements (TEC) present in the domain defined as the disordered domain. A correlation was finally obtained between tensile strength, primary molecular weight, process, test conditions, and durability. By extrapolating the molecular weight and draw ratio to infinity, the theoretical strength can then be estimated to be between 30 and 40 GPa. This theoretical resistance can also be predicted by an energy potential function, which describes the forces between atoms from the distance between them. However, the values of the theoretical resistance are very dependent on this function. Smook et al. [] made a small synthesis of the functions that can be used for a good estimation, and the values obtained are between 19 and 25 GPa at room temperature and 66 GPa at 0 K.

2.2. Processes

Processes were then developed to be as close as possible to this theoretical maximum and numerous studies were carried out to highlight the key process and initial polymer parameters (such as molecular weight, for example) that impede the achievement of theoretical optimum performance. Depending on the intended application, it is then possible, when the process is well controlled and the influence of its parameters is well understood, to produce fibers with a suitable modulus or a good energy absorption capacity.

Numerous articles focused on the processes and their impact on the structure and properties of UHMWPE fibers used in the industry. Some reviews dealt with them [,,] and others [,] provided a summary of the various processes for obtaining PE reinforcements with good mechanical performance. Only a brief presentation of these articles will be made.

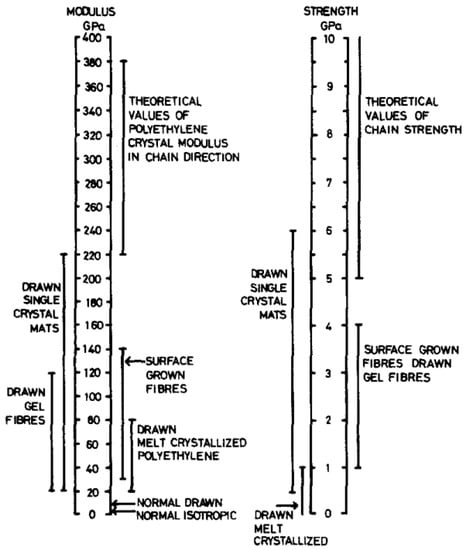

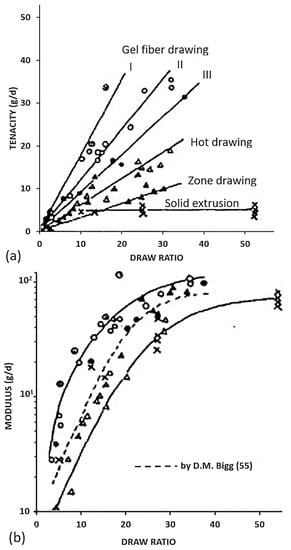

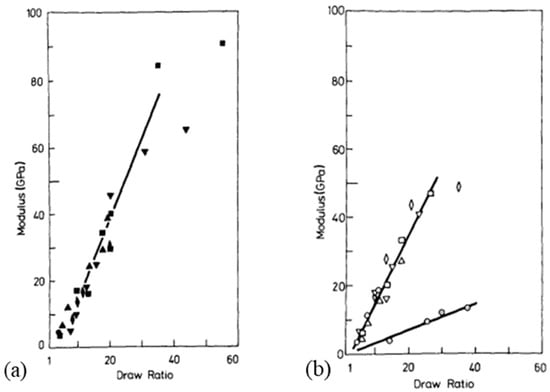

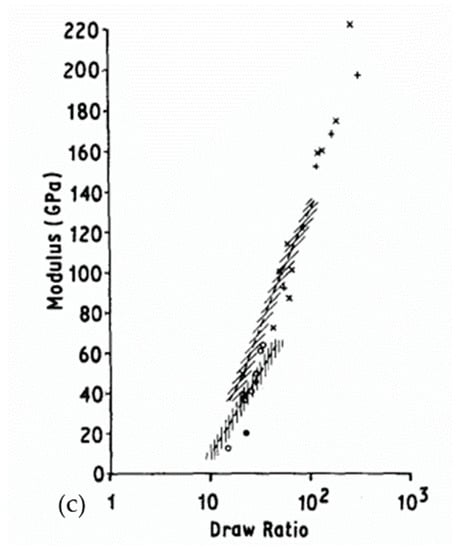

Several families of processes are used and all of them consist of a high drawing. What differentiates them is the state of the material at the beginning of the process. Quite different technologies certainly result. The hot drawing consists of stretching an extrudate, made from a molten polymer. The drawing temperature must be higher than the crystalline dispersion temperature, otherwise, ultra-stretched reinforcements (i.e., with a ratio higher than 20) are not possible. Chains folded into lamellae can then be stretched. The zone drawing technique is close to the previous one, but the heating of the stretched reinforcement is done locally with a device that moves along the fiber. This avoids the bending of the extended chains and prevents as much as possible the degradation of the polymer. Peterlin [] in his review was more interested in the molecular approach of drawing or extrusion. Barham and Keller [] proposed in their review a chronological history of the process of gel drawing from a solution. The first to attempt to stretch polymers to maximize their performance was a group of researchers at the University of Leeds in the 1970s [,,]. To create a frame of reference, Barham and Keller in their review [] proposed a scale that relates the mechanical properties to the kind of stretching (Figure 2). This one provided an idea of the theoretical values that could be achieved, and the real performance obtained.

Figure 2.

Modulus and strength scales for PE (reprinted with permission from ref. []. 2021 Roiron.).

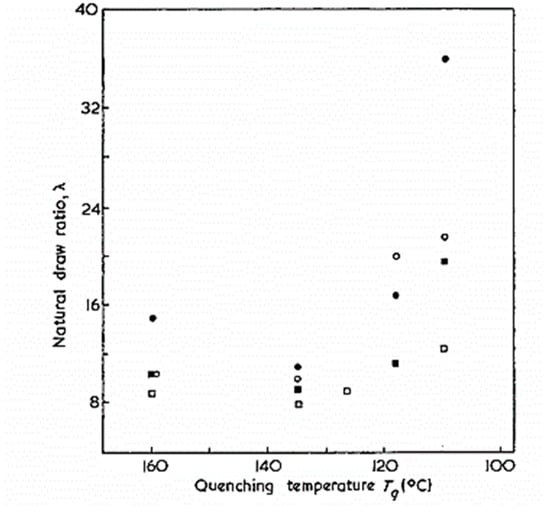

Solid-state extrusion is done from already formed billets, through a conical device at a temperature close to the melting temperature of the polymer. This process is often done in two stages. The first stage involves rapid drawing, has a ratio that does not exceed 7, and is called natural drawing. The second stage, or super-drawing, is done at a lower draw rate and controlled temperature.

Gel drawing appears to also be a promising process in the literature. Indeed, this technique makes it possible to align polymers such as PE quite easily by transforming a dilute gel entanglement network into a highly oriented crystalline structure. The prepared solution initially contains between 2 and 5 wt.% PE in the solvent [,]. These gels correspond to very disorganized networks. The drawing process can be divided into two parts: firstly, the preparation of a non-oriented gel filament and, secondly, the treatment of this filament to form a rigid and resistant highly oriented fiber.

Depending on the nature of the polymer to be stretched, not all techniques are feasible [,]. For example, melt drawing is complex when the polymer is highly viscous. Whereas this technique of drawing from a gel state is possible even for large molecular weights (greater than 4,000,000). Dessain et al. [] explained in more detail the differences between gel and melt drawing. For a drawing from a gel solution, the control of the solvent extraction, as well as the recycling of the solvent, is important. The extraction is done either by heating or by solvent exchange, either upstream or at the same time as the drawing. The way the solvent is removed does not affect the behavior of hot-drawing films [].

Finally, the last process that can be used is fibrillar crystal growth, which is developed for PE to form fibers with the widest possible chains. Fluid solutions consisting of between 0.1 and 0.5% wt.% of PE in the solvent are the source of crystal growth. Again, polymers with high initial molecular weights can be used []. The two main techniques used are solid-state extrusion and drawing from solution (gel or crystal growth) []. In their review, Barham and Keller [] synthesized many works concerning the latter group of processes in a rather comprehensive manner. The two processes constituting this group have as a common denominator the dissolution of the polymer. This one is a good means of disentangling the polymer which will allow the very large deformation necessary during the drawing process to align and lengthen the chains, to produce solid and rigid fibers. Industrially speaking, continuous processes are preferred, and one or the other of the gel drawing techniques could then be suitable.

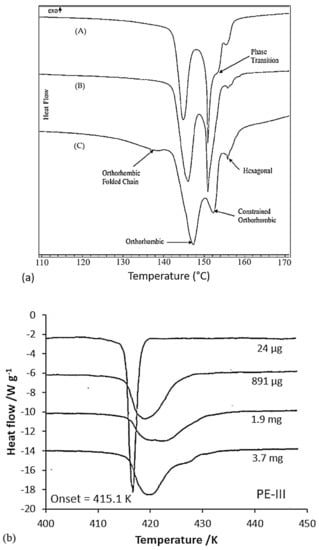

Processes deeply affect morphology. The endotherms resulting from DSC (Differential Scanning Calorimetry) tests differ depending on the process used to draw the UHMWPE fibers. Comparing different results obtained in the literature, Chodak [] pointed out that for melt-spun fibers, a single endotherm is discernible, whereas, for gel-spun fibers, three peaks were observed [,].

In summary, different processes can be used to engender this fibrillar microstructure, and consequently, the generated microstructures can differ and lead to variable properties. In the following paragraph, the structure resulting from these processes is discussed according to the parameters inherent to each technology.

3. Molecular Structure

3.1. Microstructural Model

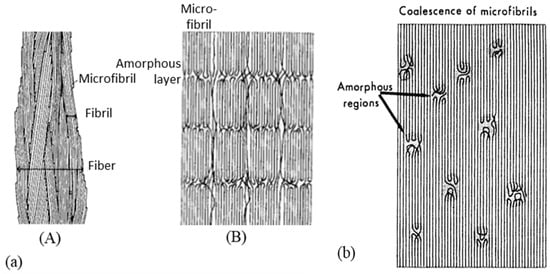

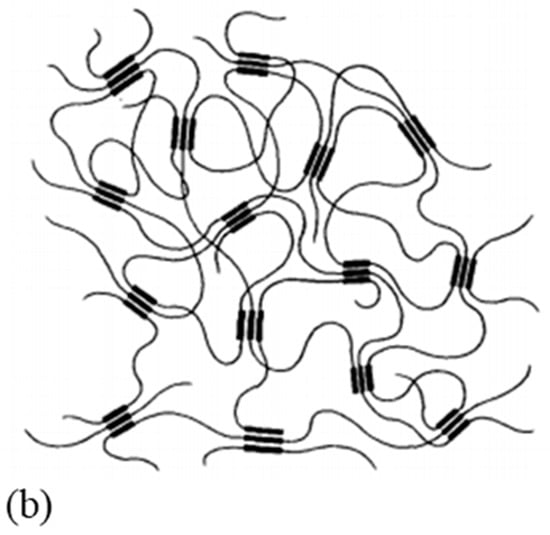

The specific performance induced during the drawing process is related to the modification of the morphology and, in particular, to specific configuration patterns of the carbon skeleton. The complex structural organization of macromolecules is partly responsible for the unique properties obtained. Several microstructural models are proposed for drawn polymers in the literature. These models are often generic, as suggested by the work of Taylor and Clark [] who found a similar fibrillar structure in the case of PP filaments to those of the PE. In their attempt to describe mathematically the evolution of Young’s modulus in the fiber axis, Irvine and Smith [] modeled the molecular chains of fibers using two elements. The helix elements are oriented in the draw axis while the coils are not oriented. Porter and Wang mentioned these models in one article []. In the same spirit, a microfibrillar model is proposed composed of a series of crystalline blocks with highly oriented and amorphous crystals. Peterlin [] suggested one specific schematization to represent such a structure. He describes the fibers as a bundle of fibrils that are oriented along the axis of the fiber. Each of these fibrils is composed of bundles of microfibrils that are parallel to the axis of the fibrils. The latter are made up of chains folded in the crystalline parts. The individual crystalline parts are bonded together with taut tie molecules. These bonds occur both between the microfibrils and adjacent fibrils and within each of the microfibrils (Figure 3a).

Figure 3.

(a) Fiber (A) (reprinted with permission from []) and fibrils (reprinted with permission from ref. []. 2021 Roiron.) (B) structure model for a natural draw ratio; (b) Model of a continuous crystalline structure at the ultra-drawing stage (reprinted with permission from ref. []. 2021 Roiron.).

It is then possible to deduce that the resumption of tensile stress in fiber with such a structure is due to the taut tie molecules, which act as connectors. The processes listed above aim to maximize the number of taut tie molecules while reducing the number of folded chains in the crystalline parts. This maximization of taut tie molecules is done during the super-drawing step. The greater the crystallization rate and molecular weight, the greater the number of taut tie molecules. They play on the tenacity but also on the ease of being plastically deformed. However, as they create bonds between the microfibrils, they limit the achievable draw ratio for the microfibrils in the cold drawing process []. In the super-drawing process that follows drawing at a lower ratio, the natural draw ratio, two mechanisms compete: the unfolding of the chains to form additional taut tie molecules and the shear displacement of the microfibrils relative to each other []. While the former promotes the continuity of the covalent bonds, the latter allows the draw ratio to be increased without greatly altering the structure of the microfibrils. The predominance of one process over the other depends on several factors such as temperature and speed during the super-drawing stage. The low lateral consistency of the strong segments of the chains offers great potential for low-temperature processing and is an essential condition for rubber elastic and viscoelastic behavior []. On a smaller scale, NMR analyses have highlighted the presence of fibrillar crystals. These crystals are composed of both crystalline and non-crystalline material in series [,,].

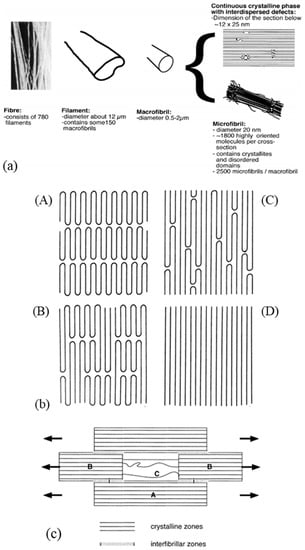

On a higher scale, to represent the microstructure of a macro fibril, two types of models seem to be mainly suggested (Figure 4a) according to Berger et al. []. In the first, it is indicated that microfibrils, composed of very extensive crystalline chains, form macro fibrils. In a continuous crystalline model authors [,,,] suggested for a super drawing process, macro fibrils are assumed to consist of a more or less continuous crystalline phase with some scattered defects. The movement of the defects allows the deployment of the folded chains within a microfibril; this movement can only be generated at an optimal temperature []. The range of drawing speed is restricted because if the drawing is done at a speed higher than that which allows for possible defectsmovement, the sample will break. The final structure sought is a continuous crystal structure (Figure 3b). In this model, it seems that the discontinuities between neighboring microfibrils have been depreciated by their coalescence. This could be explained by the arrangement of the taut tie molecules between the fibrils.

Figure 4.

(a) Description of the microstructure of a Dyneema SK60 fiber (reprinted with permission from ref. []. 2021 Roiron.), (b) Schematization of four models ((A) Lamella folded chain model for rigid elastic fibers; (B) Lamella block model for a drawn fibril; (C) Continuous crystalline matrix with folded chain defects; (D) Extended chain model for a drawn fibril) (reprinted with permission from ref. []. 2021 Roiron.)), and (c) Two-dimensional mechanical model of a macro fibril of UHMWPE (reprinted with permission from ref. []. 2021 Roiron.).

Clark and Scott [] pointed out the need to propose four different models which they have simplified—for ease of understanding, the amorphous part is not shown. The first model shows the “row” lamellar structure, in the case of hard elastic fibers [,] (Figure 4(bA)). The second model is the one Peterlin worked on (Figure 4(bB)). The third is a more continuous structure with folded chains that are defects [] (Figure 4(bC)). The last model with extended chains can be observed when polymerization is induced by radiation from single crystals [] or within the central region of a polymer as it is extruded under certain conditions. Indeed, it undergoes high pressure and shear in the pressure capillary viscometer [,,] (Figure 4(bD)).

A description of a drawn macro fibril as a series of large crystal blocks interspersed with smaller, more disordered areas was put forward and taken up by several authors [,,,,]. This representation is shown in Figure 4c. These messier areas include entanglements and other defects such as chain ends and twists. The strength is thus attributed to the taut tie molecules in the disordered domain and the crystalline fraction that spreads the load. The elongation of the fiber at break is established by the elongation at break of the disordered domains but also of the crystal blocks. Finally, the tensile modulus can be defined as the ratio between the length of the crystal block and the disordered domains as well as the fraction of taut tie molecules []. As a result of experimental considerations, regions with defects are added to a model that includes extended chains and crystal regions in series []. The intensity of the charge transfer between the microfibrils is perceived in different ways. On the condition that the cohesion within them is more important than the lateral interactions between them, they act as structural entities. Gibson et al. [] suggested a crystalline tie model that accounts for this. Berger et al. [] provided an interesting schematic (Figure 4c) of the structural elements of a fibril where crystalline regions with stretched chains are connected by non-crystalline segments. The charge is then transmitted by shear at the interface between the blocks and thus probably not to adjacent crystals [,]. During the drawing step, crystalline perfection increases with the draw ratio and small, unstable fibrils break and reorganize. The structures’ diameters homogenize, to allow uniform load distribution across the diameter [].

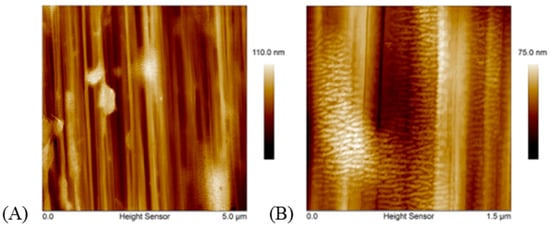

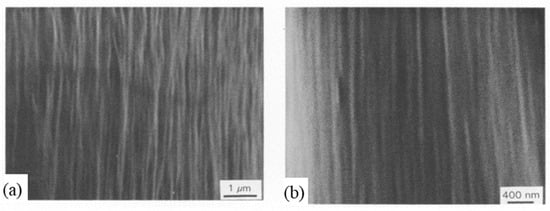

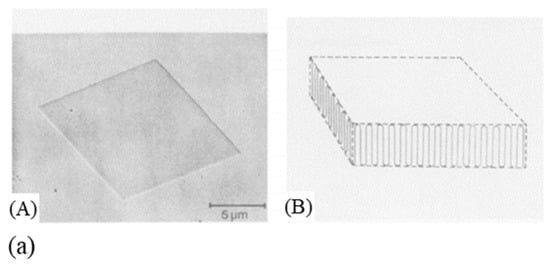

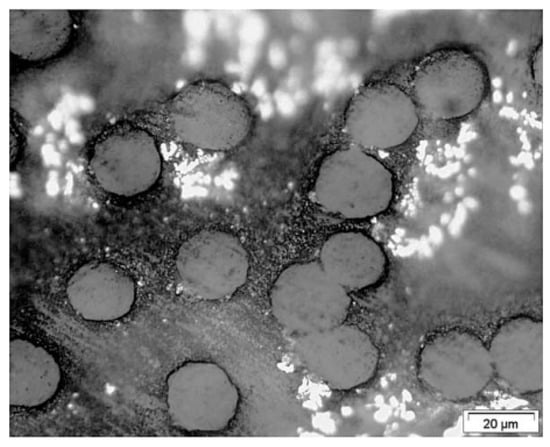

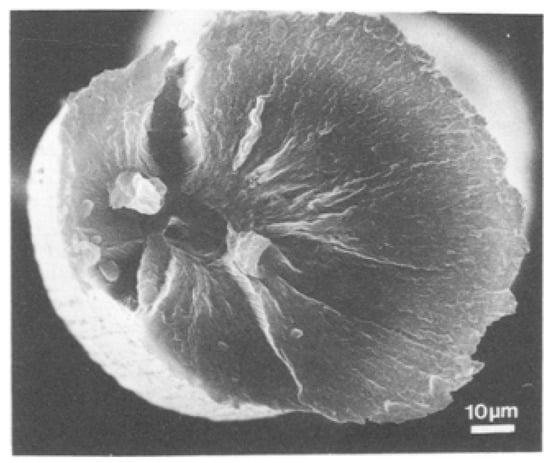

As explained in the previous section, the gel drawing process, for example, consists of several steps that complicate its morphological structure. Analysis of the nanostructure of commercial fibers, using WAXS (Wide-Angle X-ray Scattering) and AFM (Atomic Force Microscope) [] or dark-field electron microscopy, allows the quantification of the size of the characteristic elements. Thus, for fibers with an effective diameter of 25 to 40 µm, the macro fibrils measure between 100 nm and 3 µm, and the microfibrils constituting them measure between 8 nm and 100 nm []. The bundles they form are of the order of a hundred nanometers and a few micrometers wide. According to Peterlin [], the closely aligned microfibrils measure a few hundred angstroms in width and several tens of microns in length for a cold-drawn polyethylene. For gel-drawn fibers with a diameter of 55 µm, the diameter of the macro fibrils is estimated to be 0.5 µm [,]. The diameter of the constituent microfibrils is estimated to be between 15 and 20 nm. As the draw ratio increases, the width distribution of these structures is narrower, according to NMR analyses []. On the surface of the fiber, epitaxial patterns are visible (Figure 5). These are ordered structures that appear perpendicular to the fiber and extend across several microfiber widths. They are on the order of tenths to hundredths of a nanometer. These structures thicken when annealed at a temperature above 120 °C. The patterns begin to grow from lamellae of folded chains that then nucleate on the microfibrils. These epitaxial crystals can only form if there are sufficient voids to grow. Thus, these patterns do not appear in the case of post-drawn fiber because the stretching and melting have consolidated the voids between the filaments. Using WAXS analysis and dark-field electron microscopy [], gel-drawn fiber crystal blocks were measured and estimated to be at least 70 nm long and 20 nm wide, exactly the diameter of the microfibrils according to the authors. The more disordered domain that intersects the crystal blocks is estimated at 4 nm.

Figure 5.

Observation of (A) the fibrillar structure on a surface of an S130 fiber (5 µm scan) and of (B) epitaxial patterns on the surface of the macro fibrils (1.5 µm scan) (reprinted with permission from ref. []. 2021 Roiron.).

3.2. Structure Formation during the Process

The PE initially used for processing has a crystalline part and an amorphous part in which lamellae are randomly dispersed. The space between the spherulites is less organized than in the crystalline part. Short lamellae are taken from the amorphous part of the material (Figure 6a). When the PE is drawn, the spherulites originally present will align in the stretching axis. Li and Lee [] described in detail the evolution of morphology during the die drawing process, solid-state extrusion from a billet. From the beginning of the drawing process, these structures become more aligned in the direction of the drawing. The lamellae between them grow and are more numerous, due to the recrystallization induced by the deformation during drawing. Small oriented spherulites also emerge between the large ones. If the drawing process carries on, these structures change in shape and become ordered in rows in the direction of the stretching axis. This arrangement is constrained by the melting of the short lamellae, which are located around the spherulites, under the thermal effect of the extrusion process. The spherulites are smaller and aligned. The lamellae become thinner and longer. Kawai et al. [] also pointed this out for drawing from the molten state, noting a melting temperature that increases with the drawing of the polymer, so cooling must be greater, and the lamellae are thinner. The stack of lamellae is due to intramolecular nucleation within the same molecule from segments that have been brought together. The nuclei grow along the molecular chain and agglomerate into a bundle. These formed are then able to orient themselves in the direction of the molecular orientation. A second crystallization takes place. This is the crystallization of the taut tie molecules that grow laterally between the adjacent lamellae.

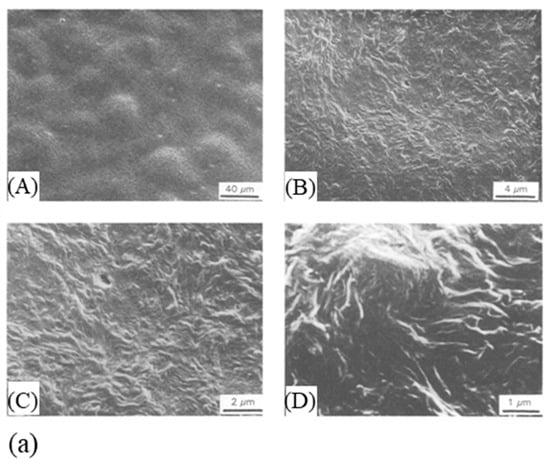

Figure 6.

(a) Electron microscopic observations of the structure of an undrawn billet ((A) entire spherulites, (B,C) sheaf-like lamellae and (D) the core) (reprinted with permission from ref. []. 2021 Roiron.) (b) Electron micrographs of a drawn billet (disintegration of the spherulites at a draw ratio of 6 (A) and 7.5 (B), (C) zoom of (B), and (D) details of the lamellae) (reprinted with permission from ref. []. 2021 Roiron.).

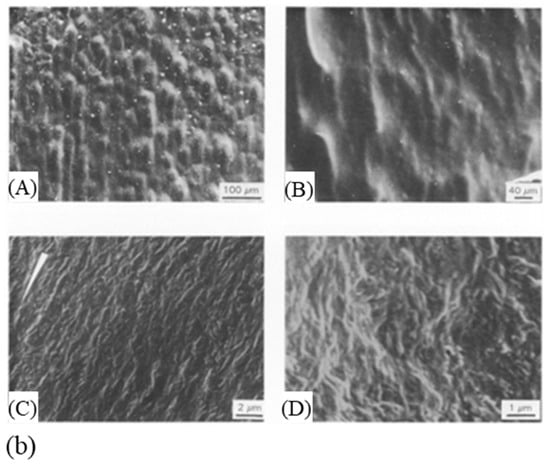

If a draw ratio of 7 is reached (Figure 6b), complete spherulites are few and the ordered rows disappear []. This results in a sample that becomes transparent due to the reduction in the size of the crystalline phase. Only predominantly oriented lamellae persist and some merge. The lamellae are more oriented, thinner, and longer than in the initial plot. Beyond a draw ratio of 12.6 (Figure 7), the lamellae undergo plastic strain allowing the appearance of microfibrils []. Some of them retain small waves that tend to disappear further down the die. Thus, thanks to the recrystallization induced by the strain during drawing, local melting, and plastic strain of the lamellae, fibrils can then be formed. During crystallization, the disordered chains thus change their structure to adopt a regular conformation in the crystalline phase [].

Figure 7.

Electron microscopic observations of the structure of a billet drawn at a ratio of 12.6, (a) at about 100 mm and (b) 200 mm from the exit of the die, with the drawing direction downwards (reprinted with permission from ref. []. 2021 Roiron.).

Peterlin [] also proposed a model to describe the deformation process in the cold drawing process. He considered three steps to form the microfibrils of the oriented material, which are:

- The continuous plastic deformation of the spherulites before necking, which occurs in the entire sample at approximately the same low stress;

- The transformation of the spherulites into fibrils, which he attributes to the breaking of the small crystal blocks that are present in the lamella packs, the reorientation, and rearrangement into stacks. This discontinuous transformation of the spherulitic into fiber structure is done by micro-necking. Indeed, the formation of bundles of microfibrils is encouraged by the cracking of the folded chain lamellae and by the presence of many micro-necks at the crack;

- The plastic deformation of these fibrils after the neck. The sliding of the microfibrils relative to each other stretches the taut tie molecules. The chain sections by which these molecules are attached to the crystalline blocks can then unfold. The density, crystallinity, and draw resistance then increase. The strain-hardening process then continues until breakage.

Thus, the mechanism underlying the deformation is defined. It is associated with the phase transformation, the twinning, the inclination of the chain, and its sliding. This leads to the complete breakage of the initial crystals into smaller blocks which are incorporated into the stretched fibrils []. It is the tilting and sliding of the chains that allow the very large crystal deformation. The latter takes advantage of the presence of linear defects and makes possible the formation of fibrils which are strongly aligned macromolecular chains that are extracted from the strongly inclined crystalline lattice []. The molecular model suggested by Peterlin [] to represent plastic deformation can also be applied to polypropylene.

According to this representation into three steps of the deformation process for a cold-drawn specimen, the natural draw ratio thus corresponds to the draw ratio of the microneckage process. The model described can be applied to the hot drawing process but with some reservations. Indeed, the addition of temperature during the process leads to the random distribution of the destruction zones, a decrease of the tie molecules, a healing of the crystalline defects, and more mobile chains. Consequently, no yield strength is present. Li and Lee [] did not observe the plastic strain of spherulites. During solid-state extrusion drawing, the spherulitic structure initially present in the amorphous phase was transformed into a final structure composed of coalesced microfibrils separated by the amorphous phase.

As a reminder, the c axis is parallel to the macromolecular chain. The a and b axes, on the other hand, are arranged in directions transverse to the chains. Concerning the orientation of the molecular chains with the drawing process, Peterlin [] noticed, using wide-angle X-ray diagrams, that the displacement of the a and b axis with the drawing direction and the orientation of the c axis are progressive in this direction. A small-angle scattering analysis allows the suppression of the lamellae perpendicular to the drawing axis to be observed. The strong inclination of the lamellae facilitates the sliding of the chains. Judge and Stein [] were more specifically interested in the growth of crystals according to the draw ratio (Figure 8a,b) for a melt-state process. In the case of a high draw ratio, the crystals will grow with a c-axis in the direction of elongation to form crystallite bundles while for a lower draw ratio they assumed a growth mode with the a-axis parallel to the draw axis to allow the formation of lamellae.

Figure 8.

The model proposed by Judge and Stein for the growth of crystals for crystallization at (a) high and (b) more moderate orientation (reprinted with permission from ref. []. 2021 Roiron.).

In the case of drawing from solution, chains crystallize by the formation of lamellae, within which the chains are folded []. For stationary solutions, the precipitation of the crystals takes place during cooling. The platelets then remain in suspension and have a folded configuration (Figure 9a). Another mode of crystallization is possible for flowing solutions. It is induced by chain stretching and this is done by stirring the solution []. The solution must be stirred at a sufficiently high temperature so that the folded crystals that usually form do not appear. The crystals may, however, precipitate on the stirrer in the form of fibrous networks. The fibrous structure is characterized by a platelet-fiber assembly also called shish-kebab. This type of crystallization is facilitated by high molecular weights. The third mode of crystallization highlighted leads to the formation of gels. These are swollen networks in which junctions are formed between crystalline regions. These junctions can take several forms: platelet chains, fibrous crystals (shish-kebab), or tiny micelles (Figure 9b) []. Again, gelling crystallization is aided by high molecular weights but also by the concentration of the initial solution. In both lamellar single crystal and gel crystallization, the chains are neither extended nor oriented. This alignment step is necessary to obtain fibers with good performance. Monocrystalline mats, characterized by suspended platelets, are composed of separate lamellar entities but with high cohesion between the different layers. It is then possible to stretch them.

Figure 9.

Illustration of (a) a polyethylene single crystal ((A) electron micrograph and (B) a sketch of the molecular arrangement), and (b) a gel with micellar junctions (reprinted with permission from ref. []. 2021 Roiron.).

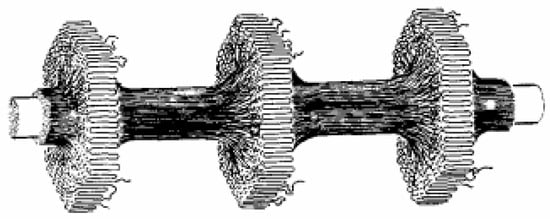

3.3. Particular Structure of Shish-Kebab

The characteristic shish-kebab structure of the microfibrils generated during drawing is important to emphasize and explain. The shish structures are represented as extended chains while the kebab structures are associated with crystalline platelets of lamellae (Figure 10). During stretching, the lamellae are elongated and then merge with the extended chains. Li and Lee [] did not observe this structure in the case of solid-state extrusion drawing of slugs, either because of limitations in the microscopic equipment or because the microfibrils are a continuous crystalline phase, formed by strain-induced recrystallization during drawing. These extended chain morphologies are dependent on the gel drawing process parameters, such as temperature and the draw ratio achieved []. Thus, over a certain temperature range, above the crystallization temperature of the single crystals, the formation of aggregates of shish-kebab structures can be obtained on the stirrer during drawing from an S solution []. These particular structures can only occur when vortices are generated during stirring. As explained upstream, a high molecular weight facilitates crystallization into fibrous structures. Indeed, agitation that lengthens chains is more efficient on long molecules []. Chains that are shorter than a certain length, and this for a given agitation speed, cannot be stretched in shish and then lead to the creation of platelets, in the form of folded lamellae—part of the structure called kebab. To optimize the performance of the fibers used, it is interesting to minimize the formation of these platelets. This can be achieved by filtration at stirring temperature, as platelets are more soluble than shish structures. Shish structures are never perfectly smooth [,] and are also in themselves shish-kebab structures. A distinction between structures with removable (macro shish-kebab) and permanent platelets with a strong molecular connection (micro shish-kebab) can be made.

Figure 10.

Schematic representation of a micro shish-kebab structure, connection between the platelets (reprinted with permission from ref. []. 2021 Roiron.).

The cooling type as well as the length of time the material remains at the maximum temperature affects the size and spaces in the structure []. These latter characteristic parameters of the platelets can also be influenced after their development by storage at a given temperature below the initial fiber formation temperature. The formed fibers are “hairy” with loose hairs that are pendulous and capable of crystallizing into chains under the influence of cooling conditions. The hairs can metamorphose into platelets consisting of folded chains or smooth fibers []. A particular elongation flow in the case of drawing from a solution creates the conditions for the continuous growth of the fibers, which is necessary to produce shish-kebab structures. These conditions are not necessarily met in the case of traditional spinning where the draw ratios are not very high.

Thus, two mechanisms can lead to the formation of high-performance fibers. The “free growth” method [], the surface growth method, and wet gel drawing under agitation [] meet the practical requirements of continuous production of a parallel assembly of shish-kebabs at high temperatures such that single crystals cannot form or survive. The second mechanism is the large-scale deformation of single crystals. This mechanism can occur during the drawing of all gels in which single crystals have been able to grow.

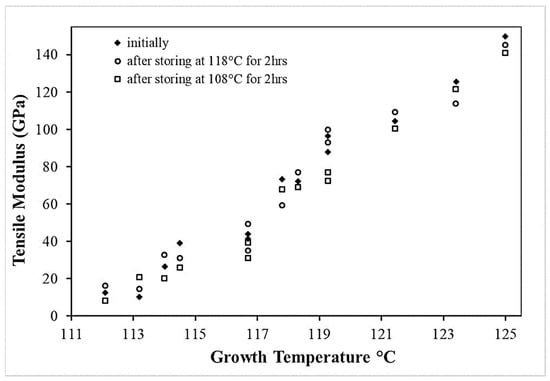

These structures appear to be strongly related to the performance of the fibers used (Figure 11) []. The process conditions and the characteristics of the initial polymer allowing their development must therefore be known and analyzed. The influence of the conditions and these characteristics will be detailed later in a paragraph.

Figure 11.

Dependence of the module on the growth temperature of shish-kebab structures, symbols refer to three different morphologies which can be obtained depending on the treatment after the formation (reprinted with permission from ref. []. 2021 Roiron.).

3.4. Morphology Study and Polymorphism

Fiber morphology depends on the initial material (chain length, entanglements, and crystal morphology) and the drawing process, from solution or solid-state extrusion. Song and Hu [] considered that fibers were made up of four elements, the stretched chains, the folded crystallites, the taut tie molecules, and the entangled and trapped chains. The fractions of the first two can be obtained by DSC analyses as they correspond to the fibrillar and lamellar morphology, respectively. The crystallinity is then calculated as the sum of the lamellar and fibrillar fractions. At room temperature, UHMWPE fibers consist of three phases: a crystalline phase, an amorphous phase, and a moderately oriented phase [,]. The latter consists of moving chains that have a preferred direction but not periodically. The mechanical properties are dominated by crystalline and moderately oriented phases. As an indication, the degree of fiber crystallinity for Dyneema® SK60 fibers is reported to be 71% [] and 82% for Spectra® 1000 []. The main crystalline phases present are an orthorhombic phase, at 85%, and a monoclinic phase, at 15%, often present on the fiber skin for these same fibers. The amorphous phase represents less than 5% []. It includes conformation irregularities, taut tie molecules, and defects of the crystalline phases. The rest is made up of crystalline segments, entanglements, and folds. Similarly, but for non-commercial gel-drawn fibers, the signal associated with NMR with the amorphous phase is very weak [], as revealed by the WAXS [] and HTWAXD (High-Temperature Wide-Angle X-ray Diffraction) [] analyses. The main NMR signal is associated with the orthorhombic crystalline phase. The monoclinic phase corresponds to a weaker signal. Mc Daniel et al. [] estimated this phase to be less than 4% by WAXD. These last two phases are transformed into each other by a simple change of side chains, which are perpendicular to an orthorhombic phase and parallel in the other case. A model representing the transformation mechanism was proposed []. The boundary between the monoclinic and orthorhombic phases is defined by a plane parallel to the monoclinic plane (010) and the orthorhombic plane (110). A reorientation of the molecules in the monoclinic plane (010) occurs around the molecular axis and these molecules are transformed into molecules in the orthorhombic plane (110). Besides, an oriented amorphous phase was observed []. In this phase, the conformations of the polymer chains are trans zigzag. However, their lateral package is not the same as in a crystal.

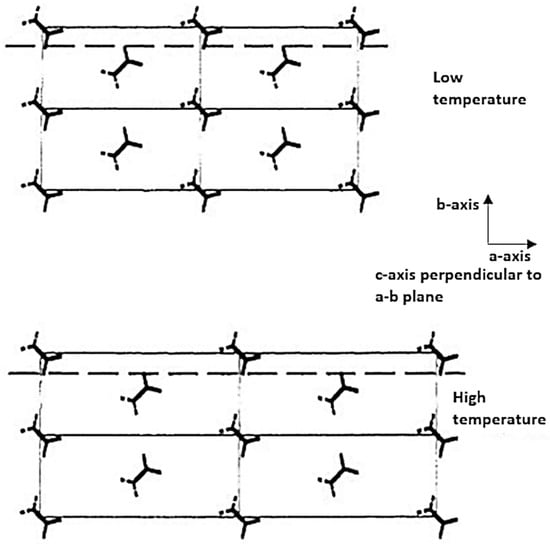

The fusion of the fiber center begins in defects due to chain ends, bent or trapped entanglements, among others. The main orthorhombic structure melts and then transforms into a pseudo-hexagonal structure that melts at higher temperatures. The melting of the molecules crystals thus occurs in two stages: a transition and the melting or formation of dislocations which is comparable to the melting of atomic crystals and which gives rise to minor changes in the chain conformation. This last hexagonal phase is generated by the fusion of the orthorhombic phase under stress. The characteristics of the hexagonal phase have been approximated by X-ray and FTIR (Fourier Transform InfraRed) analysis []. It then appears that this phase is composed of parallel bundles of molecules of disordered conformation. Within these packets, trans-gauche isomers are randomly distributed. The average orientation of the molecular chains is rather preserved except near the melting temperature. The transformation of the orthorhombic phase into a hexagonal or pseudo-hexagonal phase is only possible when the expansion of the unit cell in direction a is √3 times greater than the expansion in direction b, according to WAXD analysis []. Orthorhombic cells grow linearly with temperature []. The total volume of the gel-drawn fibers increases non-linearly and deviates from the volume expansion of the orthorhombic cells. This is less visible for less crystallized reinforcements. Concerning the monoclinic phase present in the fiber sheath, Ratner et al. [] noted a peak at 135 °C for Dyneema® fibers. Crystalline lamellae melt and this melting is followed by that of thicker lamellae. Sometimes this peak may be hidden under the larger peak associated with the melting of the orthorhombic phase. This monoclinic phase can still be detected by WAXS analyses []. A monoclinic peak was also noticed by Hsieh and Hu [] through WAXD studies of Spectra® fibers.

Several endotherms are thus identified during the DSC analysis of UHMWPE fibers. They were associated with different phases. Attached Table A1 summarizes the different melting temperatures observed according to various parameters such as the type of fibers, whether they are stressed or not, the heating rate and the mass of the sample as well as the molecular weight when they are known. All these parameters have an impact on the position and size of the peaks.

Peak values of the endotherms are strongly related to the heating rate in the DSC tests [,]. Hellmuth and Wunderlich [] studied the time dependence of the melting of the different crystals that form polyethylene. As the heating rate increases, the melting temperature of extended chains increases while that of the lamellar crystals decreases. In DSC, the tested fiber length in the capsule also impacts the peaks observed [], as well as the fixed elongation of the sample and the crystallization temperature [].

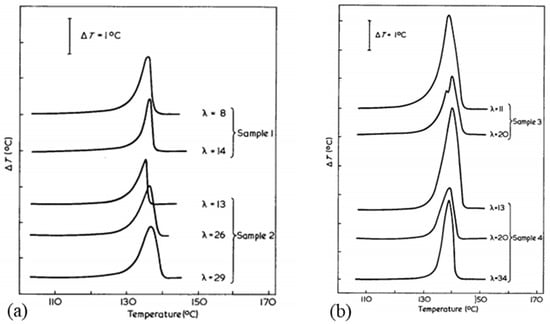

The drawing process plays a role in the morphology obtained. Smook and Pennings [] noted a single discernible peak for undrawn fibers at around 137 °C, which then disappears in favor of two peaks at higher temperatures after drawing. The proportions of these two peaks, sometimes three, are modified according to the draw ratio. The peaks are associated with transitions and fusions of the orthorhombic, hexagonal, or pseudo-hexagonal phases. Comparing different results from the literature, the presence of these peaks is also a function of the process used []. Indeed, the endotherms of melt-spun and gel-spun fibers show differences. For the first process, a single peak even after drawing is visible [], whereas more peaks can be observed in the second case [,]. However, Dijkstra et al. [], only got one main endotherm for constrained gel-spun hot-drawn fibers.

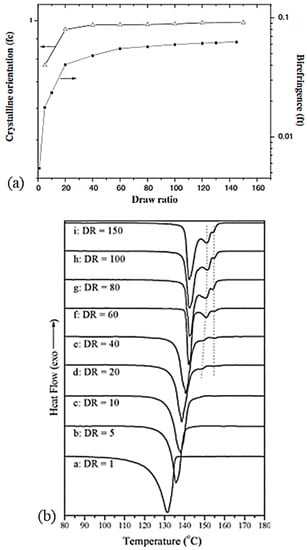

The crystallinity and orientation of the crystals increases in the samples at increasing draw ratios in the range of 20 to 40 (Figure 12a) which has an impact on the mechanical properties []. Folded chains in kebab crystals appear to convert to shish shape with a more pronounced alignment and orientation. Above a ratio of 20, only shish crystals are visible. For ratios in the range of 40 to 150, monoclinic crystals grow gradually to replace orthorhombic crystals. Better thermal stability is therefore distinguishable with high draw ratios []. Tenacity and modulus are influenced by the draw ratio and this is the consequence of a change in morphology. The influence of process conditions on mechanical behavior will be further detailed in the following section. More precisely, Capaccio and Ward [] and Yeh et al. [,] noted that the main peak observed in DSC testing of UHMWPE films shifts to higher temperatures as the draw ratio increases (Figure 12b). A second endotherm appears around 148 °C, and it becomes more important and observable for ratios above 20 []. A similar observation was made by Capaccio and Ward []. It is associated with the transition of orthorhombic crystals which are the main guarantors of the remarkable properties of UHMWPE reinforcements into hexagonal or pseudo-hexagonal crystal phase. With an increasing draw ratio, these two peaks are practically not shifted for all that. The melting of monoclinic crystals is not discernible because the larger peak of the melting of orthorhombic crystals is superimposed on it. As the draw ratio increases, some molecules initially present in the amorphous phase have probably crystallized under stress and transformed into orthorhombic oriented crystals, which impacts mechanical properties.

Figure 12.

Influence of the draw ratio on (a) crystal orientation (∆) and birefringence (■) and also (b) on endotherms (reprinted with permission from ref. []. 2021 Roiron.).

The polymorphism of the PE fibers shows up well in DSC analyses. The presence and proportion of a given phase, influenced by process parameters such as the draw ratio or the initial characteristics of the polymer used, has an impact on the mechanical properties of the fibers. This effect will be further developed in a future section. However, to fully understand the structure/properties relationship, it is necessary to know the geometry and spatial distribution at the meso/nanoscale because the basis of the performance of these fibers derives from the meso-nanostructural components. The optimization of the processing, chain alignment, and the formation of structures such as shish-kebabs, but also of the material to be used initially, makes it possible to obtain fibers with interesting mechanical and thermal properties for the use of UHMWPE fibers as reinforcements in composites on structural parts.

In brief, the various drawing processes presented in the previous section make it possible to obtain fibers whose mechanical performance is of interest with different microstructures or phases. Drawing from a gel solution is efficient to generate a good microstructure and the history of the temperature conditions defines the final properties. More precisely, the influence of the orthorhombic phase, predominant over the other crystalline phases, contributes mainly to the mechanical properties []. According to the authors, the melting of this phase, which prevails at room temperature, takes place between 141 and 146 °C (see the section on the morphology study), limiting the use of these fibers for certain fields of application. However, the characteristic orthorhombic-hexagonal phase transition that follows the melting endotherm can be detrimental to the performance of the fibers and thus sets an upper limit on the use of the fibers in terms of temperature [].

3.5. Consequence of a Stress on the Fiber Morphology

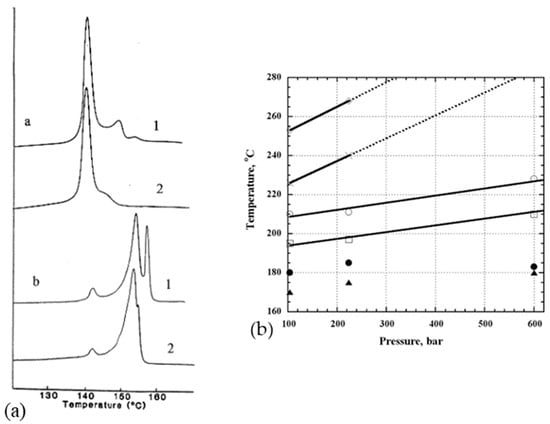

Constraining the fibers could be a means of increasing this limiting melting temperature. It seems that pressure increases the melting temperature and the onset of recrystallization. Indeed, several authors have analyzed the effect of hydrostatic pressure on phase transitions and the morphology of PE [,] in particular. More precisely, phase transition behavior is more or less affected by the history of the sample, depending on the setup and the way the sample is constrained. Thus, endotherms resulting from calorimetric tests are sensitive to the stress distribution in the sample. Also, they differ depending on whether or not the fiber, obtained from a gel, is stressed during the test. Tsubakihara et al. [] noted for the unconstrained sample a large pic around 143–144 °C (Figure 13a). It is related to the melting of extended chains under their unconstrained state. Whereas with the addition of a constraint, three peaks are observable: a small one at 143 °C, and two others at 155 and 159 °C, and it shows up more or less markedly with the molecular weight of the sample. So, constraining the specimen inhibits this melting process (Figure 13a), and Kwon et al. [] observed the same trends. This small peak is seen because of the melting of the stress-free taut tie molecules []. Complementary X-ray analyses have been performed, and they allow one to affirm that this peak at 155 °C is associated with the transition from the orthorhombic phase to the hexagonal phase. These two phases coexist between the second and third peaks. The temperature range over which they are both present depends on the molecular weight of the sample (Figure 13a). The main endotherm is shifted by 10 to 15 K with the addition of stress []. A brief thermal contraction and breakage of the sample are noticeable when the hexagonal phase melts. The hexagonal phase has a thermodynamic origin. As described briefly in a previous section, the heating rate influences also the calorimetric results. A decrease in the area of the transition and melting peaks of the hexagonal phase is especially noticeable. And the shift due to the overheating phenomenon, between heating rates of 0.3 and 5 K/min, is only 2 K [].

Figure 13.

(a) Endotherms of constrained and unconstrained gel-drawn fibers with two different molecular weights ([1; 2] × 106, [2; 7] × 105) (reprinted from ref. []. Copyright 1998 Elsevier/INIST-CNRS), data from ref. []; (b) Influence of pressure on the temperature at the heating and present phases (●: appearance of the hexagonal reflection, ○: disappearance of the orthorhombic reflections, ◊: disappearance of the hexagonal reflection (sample melting) and at the sequential cooling, ×: reappearance of the hexagonal reflection, □: reappearance of the orthogonal reflections, and ▲: disappearance of the hexagonal reflection, dotted lines represent extrapolation) (reprinted with permission from ref. []. 2021 Roiron.); (c) Evaluation of the effect of lateral compression and its duration (reprinted with permission from ref. []. 2021 Roiron.).

Also, crystallization at elevated pressure and temperature influences the morphology of the folded chains. At very high pressure, extended chain crystals can even be formed. Using X-ray diffraction analysis at the synchrotron, Rein et al. [] estimated that the melting temperature increased by 35.2 °C every kilobar. For example, at 100 bars, the reflections of the monoclinic (100) and orthorhombic (110 and 200) phases are visible at 100 °C. The monoclinic phase disappears at 177 °C and the hexagonal phase (100) appears at 179 °C. At 209 °C, the orthorhombic phase is no longer present, but traces of the hexagonal phase remain up to 250 °C. At 260 °C, the sample is fully amorphous. According to Figure 13b, stress can therefore stabilize the fibers against melting and thus increase the previously restricted application interval of the fibers since the orthorhombic to hexagonal transition occurs at higher temperatures as soon as pressure is applied []. However, other authors do not observe changes in the endotherms obtained for lateral pressures of several kilobars in DSC []. The melting process of constrained fibers can be described throughout a free energy diagram [].

Even at low pressure, the hexagonal phase is observed during melting and recrystallization. Torfs and his colleague [] measured a difference of 4 °C in the phase transition temperature when a stress of 0.8 GPa was applied. This difference is due to stress relaxation. It is a metastable phase over a certain temperature range, which is pressure-dependent. Only the complete melting of this phase is highly dependent on pressure. This metastable characteristic allows sufficient mobility for the melting of the fibers without causing a great loss of orientation of the extended chains. An intermediate hexagonal phase appears predominantly on the surface of the fibers. In the case of the use of UHMWPE fibers in SRPE composites, this phase promotes good fiber bonding while preserving the core-orientated fiber structure when a hot-compaction process is used []. In the case of compression-stressed fibers, Ratner et al. [] observed a double peak, the first at 145 °C associated with the transition from the orthorhombic to the hexagonal phase and then the melting of the hexagonal phase at 159 °C. WAXS analyses [] also highlighted the significant increase in dimensions (200) and (110) of the majority orthorhombic structure of Spectra® fibers when compressed in the direction perpendicular to the fiber axis. These analyses also showed an increase in monoclinic forms, probably a part of the amorphous, which reduced the degree of transition into the hexagonal phase. Thus, the formation of a monoclinic shape prevents the structural transformation characteristic of UHMWPE fibers []. The stresses in the sample that prevent the molecules from reaching perfect isotropy may explain these shifts []. An additional peak around 138 °C also appears, associated with the melting of the folded chains obtained by recrystallization, if the temperature during processing is excessive []. A triple endotherm is also sometimes reported [], with an additional triclinic phase. In similar analyses, Kwon et al. [] on Spectra® fibers noted two peaks at 142 and 149 °C and Van Aerle and Lemstra [] at 153 °C and 176 °C for stressed fibers and that all fibers remain generally orthorhombic until the main melting. They pointed out, however, that a quantity of orthorhombic fibrillar crystals transformed into the hexagonal phase, as did Clough [,] around 177 °C. This occurs only in stressed fibers, which implies that this hexagonal phase is a phase that is not initially present in the original fiber. It is thereby an out-of-equilibrium phase. Similarly, for Hsieh and Hu [], axial stress with heating to 110 °C may explain the structural transformation between an orthorhombic and a pseudo-hexagonal phase.

The impact of the duration of the lateral stress was studied [], and it is presented in Figure 13c. The longer the duration, the more the enthalpy is reduced, up to 2 min for which the enthalpy stabilizes but then the second peak tends to disappear. The transformation into the hexagonal phase then seems no longer allowed. The widening of the peak suggests a decrease in the size of the original crystals.

Tsubakihara et al. [] concluded that there is little influence of sample types and constrained methods. Therefore, a significant increase in the transition point cannot be expected. A chemical method could be more hard-hitting. Indeed, in the case where PE is cross-linked and compressed [], a shift in these endotherms can be seen in Figure 14a, which was supported by Yeh et al. []. An additional endotherm was reported by Clough [,] around 150 °C for slightly cross-linked, stress-crystallized PE. The characteristic transition of linear PE is also less pronounced even if the material is just irradiated [,].

Figure 14.

(a) DSC test to analyze the effect of fiber compaction and cross-linking on the endotherms ((A) non-crosslinked sample prepared at 145 °C, (B) a cross-linked sample prepared at 145 °C, (C) a cross-linked sample prepared at 150 °C) (reprinted with permission from ref. []. 2021 Roiron.); (b) DSC test to assess the influence of the mass of the sample (Spectra 900) in a cold-welded pan on the endotherms, heated at 10 K·min−1 (reprinted with permission from ref. []. 2021 Roiron.).

3.6. Effect of Sample Mass

Besides, associated with a phase transition and a process to make the fiber anisotropic, the two peaks considered can also be related to the fusion of lamellae of two different thicknesses [,] or the excessive growth of lamellae []. The different peaks are influenced by the mass effects of the test samples, and by the arrangement in the capsule and thermal conductivity. For very low fiber masses in the capsule (between 25 µg and 1.15 mg), the highest peak disappears []. It is then suggested that the double peak is caused by higher lateral stress when a higher mass is introduced into the constant volume of the capsule. If these stresses are removed, the highest peak in temperature is no longer present [] (Figure 14b). Kwon et al. [] did the same experiments and a double peak is observed for each mass. Only the ratio of sizes of the two endotherms is affected by the sample mass. Boller and Wunderlich [] noted the broadening of the melting peak and the development of a bump that turns into a secondary peak as soon as the sample mass increases, as can be seen in Figure 14b. The enthalpy of fusion also decreases with the mass of the sample. They even attribute the multiple peaks to an artifact due to the conditioning of the sample in the capsule, such as the non-uniform positioning of the sample in the capsule, or the instrumentation. One suggested solution is to decrease the mass of the sample or improve thermal conductivity. A change in experimental conditions seems to induce the disappearance of the double peak. As soon as the fiber is well placed at the bottom of the capsule or when the capsule is filled with alumina powder, a single peak persists. This corroborates the artifact theory of Boller and Wunderlich [] for the double peak. Fibers hanging in the capsule may also lead to aberrations in the DSC results. The sample preparation then appears to be a decisive step. The mass of the sample should not be too large, but the very thin fiber should be in sufficient quantity to ensure a good heat transfer with the capsule. A single peak was also observed by Rudnik and Dobkowski [] in the case of the study of a UHMWPE powder and the peak value increased with the mass of the tested sample.

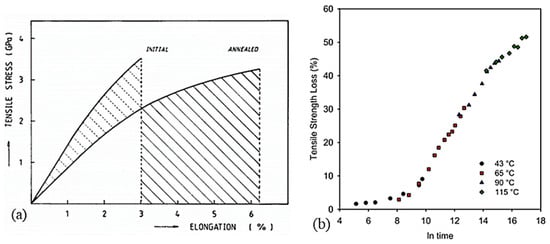

3.7. Consequence of Annealing on the Fiber Morphology

Since the unique structure of UHMWPE fibers is temperature-controlled during the process, the effect of annealing on the morphology needs to be analyzed. Fouad et al. [] highlighted the effect of heat treatments on the degree of crystallinity upstream of calorimetric and micro-hardness tests. The influence of the temperature of this annealing and the duration is studied. It seems then that for annealing at 50, 80, and 100 °C between 2 and 4 h, the degree of crystallinity increases with the temperature and the duration of the annealing. It rises from 55% for a virgin sample to 67% crystallinity for a sample maintained 4 h at 100 °C before testing. For annealing temperatures between 115 and 130 °C [], with 15 min of temperature stabilization after 3 min of rising, the effect of annealing is congruent with the annealing of crystals of lamellae consisting of folded chains. Indeed, a shift in thickness distributions is observed for each annealing temperature with larger changes at 130 °C.

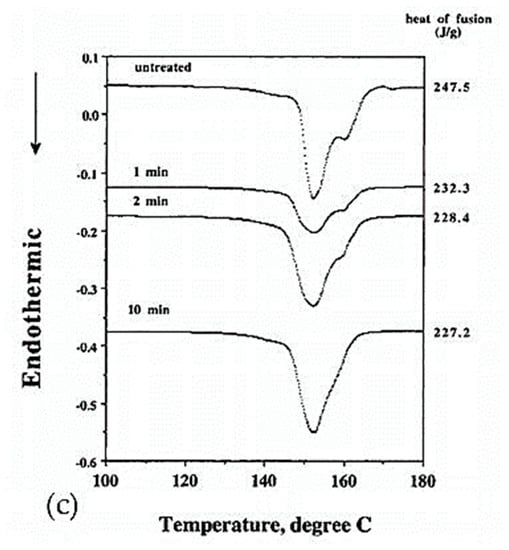

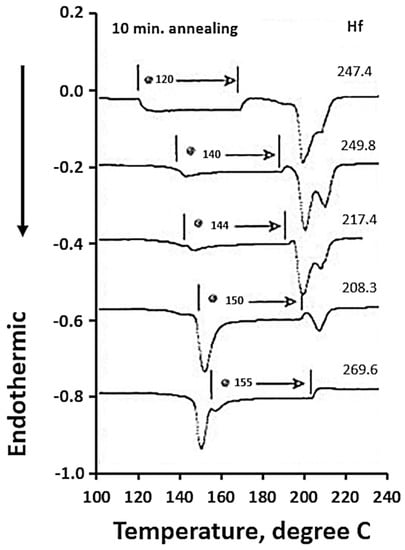

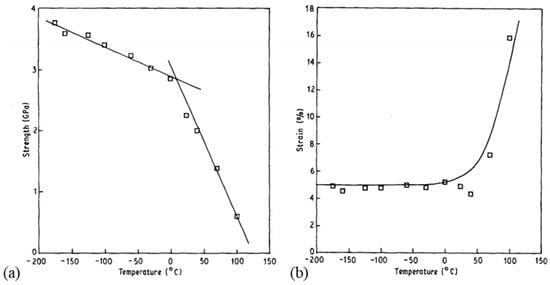

Higher annealing temperatures were analyzed by Hsieh and Ju [] at 120, 140, 144, 150, and 155 °C for ten minutes (Figure 15). Annealing at 120 °C does not seem to have any effect since this temperature is lower than the melting temperature of the less stable phase. Small endotherms appear for annealing between 140 and 144 °C, close to these temperatures. For this temperature range, the relaxation of the inter-crystalline chains is then allowed. For annealing at 150 °C, the double endotherm separates. The reduction of stresses in the fibrils and between the crystals by annealing can explain the reduction of the heat of fusion for annealing between 141 and 151 °C, melting temperatures associated with the melting of crystals between the fibrils, and orthorhombic crystals. At 155 °C, endothermic peaks and enthalpies decrease further as the deformed chains have relaxed and the orthorhombic crystals have almost completely melted, preventing possible recrystallization. As the annealing temperature increases, the total heat enthalpy and the size of the main endotherm decreases []. The structural transformation between the orthorhombic and pseudo-hexagonal phases then seems to be reduced. With increasing temperatures, the thermal expansion coefficients increase in directions a and b, directions transverse to the direction of the macromolecular chains. If the coefficient of thermal expansion becomes substantial, the transformation of orthorhombic crystals into the pseudo-hexagonal phase is facilitated. The annealing caused by the extended annealing time and the holding time in a HTWAXD test prevents phases transition. When heating is accompanied by tension along the axis, in the case of HTWAXD tests, this leads to the increased structural transformation between the orthorhombic and monoclinic forms []. Based on X-ray diffraction measurements taken during annealing at 80 °C for 30 min, the reflection of the monoclinic phase loses intensity in favor of the orthorhombic phase. Thus, a monoclinic-to-orthorhombic phase transition takes place and the transformation rate increases with increasing annealing temperature []. As a reminder, the monoclinic phase prevents the characteristic structural transformation of UHMWPE fibers between orthorhombic and hexagonal. The transition from the orthorhombic to the hexagonal phase can be achieved not only by stress but also by heating under hydrostatic pressure [].

Figure 15.

Thermograms following DTA tests to study the effect of annealing on morphology (reprinted with permission from ref. []. 2021 Roiron.).

For some authors, the apparent PE polymorphism is due to an artifact during sample preparation. The highlighted phase transitions may be affected by sample preparation and experimental conditions, even if it is originally the same fiber. Indeed, when a weak constraint is applied, and this will be the case as soon as these fibers are used as reinforcements in composites, the formation of a hexagonal phase, out-of-equilibrium, seems inevitable. This stress may be the consequence, not necessarily desired, of a too-large mass of fibers introduced into a capsule during a calorimetric test. The greater the stress, the more the phase transition takes place at high temperatures. Therefore, stress could allow the fibers to be thermally stabilized over a longer temperature range. This stabilization can also be achieved chemically (cross-linking by irradiation), by reducing the free volume (stress in DSC capsules), by adding hydrostatic pressure or annealing, within a given temperature range, or a combination of these factors. Embedding in a matrix could be a means of preventing the fibers’ relaxation and thus allowing the fibers to be used at temperatures above 155 °C, although the orthorhombic to hexagonal transition is an intrinsic property of the fibers, a property which is reversible in the configuration of embedded in a matrix []. If the phase transitions appear identical by X-ray diffraction [] with and without the addition of epoxy resin, impregnation of the fibers may however allow a more uniform distribution of pressure on the sample to further stabilize them thermally.

3.8. Physical Properties: An Overview

A variety of processes exists for the manufacture of fibers from PE. The main ones are as follows: hot drawing and zone drawing techniques made from a molten polymer, solid-state extrusion from a billet, gel drawing, and the fibrillar crystal growth from a solution. They align the chains of molecules that are initially disoriented and thus allow the theoretical maximum of PE properties to be approached. In particular, drawing from the gel state seems to be promising but the preference of one process over another depends on several parameters and in particular on the viscosity and molecular weight of the PE, whereas hot drawing is very complex for high molecular weights. The microstructures obtained then vary according to the process used. A fibrillar structure is put forward for the different processes. Depending on the processes used from molten polymers, the drawing ratios achieved, and the molecular weight of the grade, the plastic strain of the spherulites, and their transformation into fibrils took place to a greater or lesser extent. In the case of extraction from a solution, the chains crystallize through the formation of lamellae, within which the chains are folded. In the case of gel-spun fibers or fibers processed by the surface growth method, the microfibrils described have a particular structure called shish-kebab. To describe the microstructure, several models have been suggested. Some models are based on helix and coil elements to represent the parts that are oriented during the drawing process and those that remain disoriented. Other models are based on the representation of bundled fibrils oriented in the direction of the fiber. On a smaller scale, these fibrils (macro fibrils) are made up of microfibrils, composed of chains folded in the crystalline parts. The latter is bound by taut tie molecules and also binds the microfibrils and fibrils together. Another category of models proposes the representation of macro fibrils as a continuous crystalline phase with defects. A lamellar row structure is also suggested. Defects, which can take the form of entanglements, chain ends, or twists, are created during the PE orientation process and have an impact on the draw ratio that can be achieved and thus have a direct influence on the mechanical properties. At low temperatures, entanglements are considered to be the weak bonds of the fibers. Also, process conditions such as drawing rate, gelation conditions, and the initial concentration of the oriented polymer, among others, have an impact on the number of entanglements. However, they seem to be reduced when a process of drawing from a gel solution is used, compared to, for example, a melt crystallization process.

The fibers are polymorphic and the main phases are monoclinic, orthorhombic, and pseudo-hexagonal. The process parameters used affect the presence of these phases and their proportion. The draw ratio affects the thermal stability of the fibers. Indeed, the main peak observed in DSC shifts to higher temperatures for higher draw ratios. One explanation may be the crystallization under the stress of molecules present in the amorphous part during the drawing process. Besides, the initial characteristics of the drawn PE grade have an influence. The temperature range in which the transition takes place and thus that the orthorhombic and hexagonal phases coexist depends on the molecular weight of the oriented sample. DSC tests highlight them, but the conditions of these tests (mass of the sample and heating rate) influence the melting temperatures obtained as well as the presence of the different peaks. As these parameters impact the morphology, they then have a consequence on the mechanical properties. PE reinforcements with outstanding mechanical properties are characterized by a high draw ratio.

An overview of the physical properties of PE-based reinforcements and in particular of highly stretched UHMWPE reinforcements was given. The knowledge of the structure of such reinforcements is important because physical properties and mechanical properties are intimately linked as will be detailed in the next section.

4. Mechanical Behavior

4.1. Test Protocol

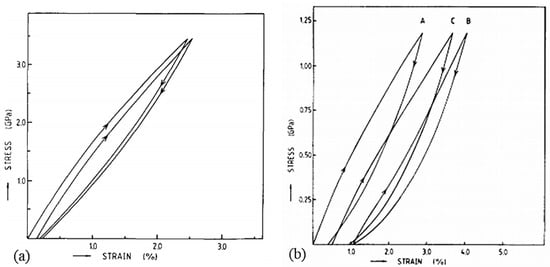

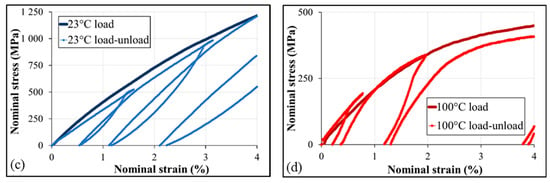

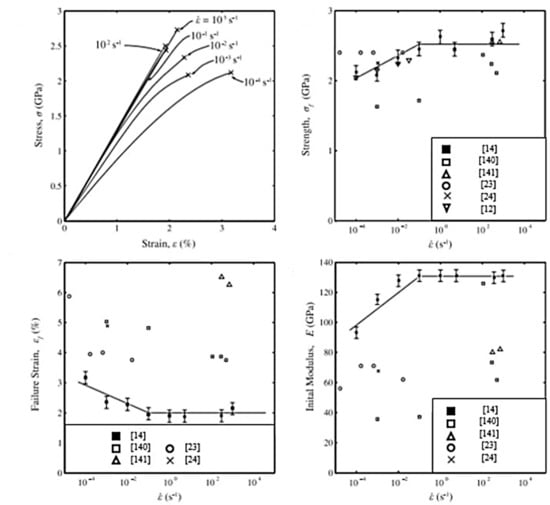

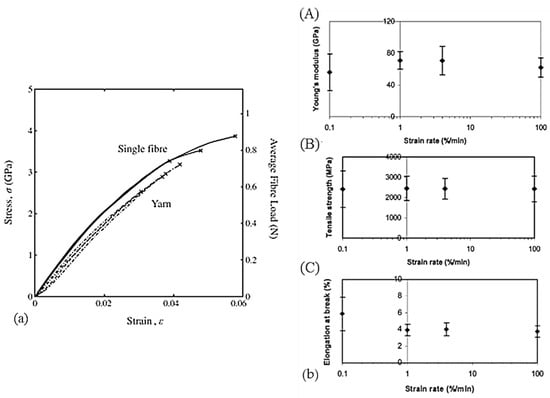

Concerning the way to test the UHMWPE material, many approaches to tensile or creep testing are described in the literature. For tensile tests, the way to set up the sample differs according to the authors. Indeed, Kromm et al. [] tested specimens bonded with epoxy resin to a stiff frame, whereas in the case of Dessain et al. [] fibers were simply gripped in the jaws between pieces of thin cardboard to prevent damage. In creep tests, yarns are also mostly bonded with cardboard tabs [,,]. Special devices are sometimes added to standard tensile test machines. Schwartz et al. [] developed capstan inserts that fit pneumatic jaws. Russell et al. [] created a device for testing between 10−4 and 103 s−1, consisting of a semi-circular anchor. Pneumatic clamps are widely used because sample slippage is then prevented by adjusting the air pressure [,,]. For temperature tests, the oven used is thermostatically controlled [,]. A system was also proposed by Dijkstra et al. [], consisting of a brass cylinder that surrounds the clamps and sample, and which is itself surrounded by glass. The brass cylinder can then be cooled through a nitrogen flow between the two cylinders. For tests at temperatures above room temperature, heating is done employing two heated brass blocks, which encircle the sample. Part of the creep tests consisted of dead-load tests [,,,]. Berger et al. [] carried out these tests using an in-house-built machine, just as Wilding and Ward [] designed a purpose-built system for carrying out stress relaxation tests. A summary table of the different tests that will be introduced in this review and the associated conditions is presented in Table A2, given in Appendix A. The intervals of values of the mechanical characteristics are always given in ascending order and not according to the range of temperature, strain rate, or gauge length studied. The protocols are quite varied as many experimental difficulties must be overcome.

4.2. Experimental Difficulties

Data reported in the literature or by manufacturers are averaged data with a large standard deviation. This is related to many experimental difficulties associated with measuring cross-sections. However, the recording of displacement with accuracy during the test is a challenge. The validity of this test is not evident, even more so when using the scale effect to determine the behavior of yarns. Moreover, the mechanical parameters depend on chemical aspects and the kind of process on a larger scale [], thus defining a unique value has no sense. These difficulties are presented in the following section.