Abstract

The manufacture of Portland cement (PC) emits a significant amount of CO2 into the atmosphere. Therefore, the partial replacement of PC by supplementary cementitious materials (SCMs) possessing pozzolanic properties is considered a viable strategy to reduce its environmental impact. Recently, waste glass (WG) has been explored as a potential SCM. However, due to the wide variety of glass types and their differing physical and chemical properties, not all WG can be universally considered suitable for this purpose; therefore, this study investigates the use of recycled WG as an SCM for the partial replacement of PC. Two types of WG were evaluated: green waste glass from wide bottles (GWG) and laboratory waste glass (LWG), and their performance was compared to that of fly ash (FA). The physical, mechanical, and pozzolanic properties of the materials were assessed. Results show that both types of WG exhibit particle size distributions comparable to PC and have contents of SiO2, Al2O3, and Fe2O3 exceeding 70%. Chemical, mineralogical, and pozzolanic analyses revealed that both GWG and LWG presented higher pozzolanic activity than FA, particularly at later ages. Notably, LWG demonstrated the most significant contribution to mechanical strength development. These findings suggest that recycled waste glass, especially LWG, can serve as a viable and sustainable SCM, contributing to the reduction of the environmental footprint associated with Portland cement production.

1. Introduction

The manufacture of Portland cement (PC) for the construction industry is a major contributor to environmental degradation, primarily due to its high carbon footprint [1,2]. The calcination of limestone and the combustion of fossil fuels during clinker production release substantial quantities of CO2, accounting for approximately 7–8% of global CO2 emissions [3]. Mitigating these impacts requires the adoption of alternative materials, energy-efficient technologies, and carbon capture strategies within the production process.

Among alternative materials, ecological concretes have been developed through the partial replacement of PC with supplementary cementitious materials (SCMs), such as fly ash (FA), ground granulated blast-furnace slag, silica fume, sugarcane bagasse ash, and metakaolin, with effective replacement rates ranging from 20% to 80% [4,5]. These SCMs act as partial substitutes due to their pozzolanic properties. Specifically, the amorphous silica (SiO2) and alumina (Al2O3) present in SCMs react with portlandite (Ca(OH)2) to form secondary cementitious compounds, mainly calcium silicate hydrates (C-S-H), which significantly contribute to the mechanical strength and durability of PC-based materials [6].

The efficiency of the pozzolanic reaction depends on several factors, including the fineness, chemical composition, degree of amorphousness, and the capacity of SCMs to react with portlandite, as well as the replacement level, curing temperature, and calcium availability in the concrete mixture. Numerous studies have demonstrated that the incorporation of SCMs not only reduces the carbon footprint of concrete by lowering the clinker content but also enhances its long-term performance, making it a sustainable and effective alternative in modern construction [7,8,9]. In the last few years, FA has been the most used SCM used to manufacture ecological concretes; however, recent studies have reported a decrease in the availability of FA for use in meeting climate targets to reduce of coal usage by about 75% by 2030 [10,11]. For example, The Netherlands aims to phase out all coal-based power generation by 2030, and in the United States, nearly 40% of coal-fired power plants have been shut down over the past five years [12]. The above is significantly reducing FA generation volumes, and, therefore, PC producers are increasingly seeking alternative SCM sources such as calcined clays, biomass ashes, and recycled glass to maintain performance and sustainability of PC-based materials.

In this context, other SCMs have been studied; however, in order to promote the sustainability of the cement industry, it is preferable that such materials come from agro-industrial and urban waste; for example, glass waste (WG). From an environmental perspective, discarded glass fragments can disrupt soil ecosystems and pose physical hazards to wildlife. Moreover, broken glass waste increases the risk of injuries, particularly in urban areas where waste management practices are inadequate [13,14,15]. Additionally, the energy-intensive process of producing new glass amplifies carbon emissions, making the recycling of glass a critical but underutilized practice in many regions [16].

In light of the above, several studies have focused on the partial replacement of fine and coarse aggregates with WG [17,18,19]. However, when WG is used as an aggregate, alkali–silica reactions (ASR) can occur in PC-based materials, negatively affecting their mechanical and durability properties [20,21]. Consequently, the use of WG as an SCM is considered a more viable alternative, as supported by several investigations [22,23,24].

Recent studies have emphasized the environmental benefits of using WG as an SCM through life-cycle assessment (LCA) approaches. These assessments reveal that incorporating WG in PC-based materials can significantly reduce CO2 emissions by about 31% when 20% WG is used as a partial replacement of PC in concretes [25]. For instance, research by Letelier et al. [26] demonstrated that replacement of PC by WG can decrease CO2 by about 68 kg per ton of concrete production; whereas Patel et al. [27] affirms that replacing 20% of PC by WG can reduce ozone depletion potential by 20%.

WG as an SCM is commonly classified according to its chemical composition and physical properties. In this context, Qin et al. [28] carried out a comprehensive overview of WG chemistry. The most widely studied type is soda-lime glass, comprising roughly 68–75% SiO2, 8–15% CaO and Na2O, and minor oxides such as Al2O3 and MgO, and well suited as an SCM. Less-common types include borosilicate or fused silica glass, which may originate from laboratory or solar-panel waste and vary in composition. Particle size is critical: typical SCM-grade WG is ground to below 600 µm; however, optimal reactivity is achieved at ≤75 µm. WG performance as a partial replacement for PC shows enhancements in strength and durability in cementitious composites at percentages of about 10–20%. Similarly, Wang et al. [29] demonstrated that both finely ground and higher-granularity WG can substitute for up to 30% of the cement in mortar, improving mechanical properties at moderate replacement rates (5–15%). In geopolymer systems, also known as geopolymers, recent studies have explored the use of WG as a precursor due to its high amorphous silica content and reactivity in alkaline environments. For instance, Çelik et al. [30] reported that geopolymers synthesized from soda-lime WG and FA activated with sodium hydroxide and sodium silicate achieved compressive strength CS values up to 55 MPa after 28 days of curing at ambient temperature. Similarly, Tahwia et al. [31] demonstrated that WG-based geopolymers can attain early CS above 40 MPa with optimized curing and activator concentrations.

Despite the promising results of using WG as an SCM, studies that have evaluated the pozzolanic potential of WG reported contrasting findings. While some research highlights significant pozzolanic activity, mainly attributed to the high content of amorphous SiO2 and its high chemical reactivity in alkaline environments [32], other studies have found that certain types of WG, such as cathode ray tube glass and waste E-glass [33,34,35], exhibit limited or negligible pozzolanic reactivity. This is primarily due to their unfavorable chemical compositions or higher degrees of crystallinity.

This disparity in results suggests that the pozzolanic activity of WG is not a universally applicable property, which complicates its reliable use in PC-based materials. Therefore, further research is essential to clarify this variability and to establish well-defined criteria for its effective use as a pozzolanic material in construction engineering, particularly when introducing new sources of WG, such as laboratory waste glass.

From this perspective, the present study aims to assess the physical, chemical, and pozzolanic properties of two types of WG: one derived from green wide bottles (GWG) and the other from laboratory glassware (LWG). Furthermore, these properties were compared with those of FA to provide a more comprehensive evaluation and to determine the potential of each type of WG as a reliable SCM. This study did not address ASR, since it focuses on pozzolanic behavior of two types of WG used as a partial substitute for PC, rather than its performance as an aggregate.

2. Materials and Methods

2.1. Materials

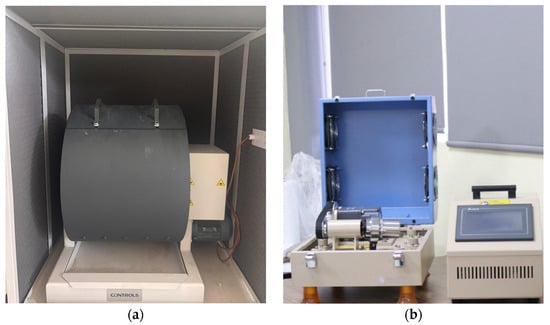

Blended Portland cement (CPC-30R), available in the southern region of Mexico and conforming to NMX-C-414-ONNCCE [36], was used to produce the pastes and mortars in this study. Two types of recycled WG were employed: one derived from green wine bottles (GWG) collected from a recycling center located in Oaxaca, Mexico and the other from laboratory glassware (LWG) collected from universities also located in Oaxaca, Mexico. The bottles were thoroughly cleaned with soap and water. Subsequently, the labels and markers on both WGs were removed with acetone, and the WGs were cleaned again with soap and water. Both were initially ground in a Los Angeles abrasion machine to 30 rpm with stainless steel (SS) balls of Ø19 mm for 1 h (Figure 1a) to obtain particles passing the No. 100 mesh sieve. Subsequently, the ground WG materials were further dry milled in a high-energy 3D ball mill MSK-SFM-3-F to 500 rpm for 30 min (Figure 1b) using a 500 mL SS jar with SS milling balls of Ø10 mm. The ratio of balls/WG of 10:1 by weight was used according to Wei et al. [37]. Finally, the WGs obtained were sieved through No 200 mesh. Fly ash (FA) was sourced from the Plutarco Elías Calles coal-fired power plant located in Petacalco, Guerrero, Mexico, and was also sieved to pass ASTM No. 200 mesh. The specific gravities (SG) of CPC, GWG, LWG, and FA were determined in accordance with ASTM C188 [38] and were found to be 2.98, 2.55, 2.53, and 2.26, respectively.

Figure 1.

(a) Los Angeles abrasion machine and (b) MSK-SFM-3-F high-energy 3D movement ball mill used to obtain GWG and LWG.

2.2. Characterization of Cementitious Materials

2.2.1. Particle Size Distribution and Morphological

The particle size distribution of the cementitious materials was determined by means of laser ray diffraction with a laser diffractometer, Mastersizer 2000 with a Scirocco 2000 dry powder feeder (Worcestershire, UK). The equipment was operated in the wet mode using isopropyl alcohol as a dispersant and applying ultrasonic energy of 40 watts over 60 s. The morphology of the cementitious materials particles was observed using a high vacuum Scanning Electron Microscope (SEM), JOEL model JSM-6510LV (Tokyo, Japan), equipped with Energy-Dispersive X-ray Spectroscopy (EDS), from Oxford Instruments (Abingdon, UK).

2.2.2. Determination of Chemical and Mineralogical Composition

Quantification oxides from cementitious materials were determined by X-ray fluorescence using a spectrometer, PAN-alytical® Epsilon3-XL (Almelo, The Netherlands). The loss on ignition (LOI) of PC was determined at 950 °C according to ASTM C 144 [39], while for GWG, LWG, and FA, their LOIs were determined at 750 °C according to ASTM D 7348 [40]. Mineralogical phases of cementitious materials were determined by X-ray diffraction (XRD) using an Empyrean® diffractometer (Almelo, The Netherlands). The equipment used a Cu anode, and it was operated with a voltage of 45 kV and a current of 40 mA. XRD tests were carried out from 10° to 70° (2θ) at a scanning speed of 0.5 s and increments of 0.026°. Mineral phases were identified using the software EVA version 11.0.03®. Moreover, a semiquantitative quantification of amorphous phase in the SCMs was estimated by means of the determination of area under the curve from XRD patterns.

2.3. Methods to Evaluate the Pozzolanic Activity

2.3.1. Chapelle Method

The pozzolanic activities of GWG, LWG, and FA were also evaluated using the modified Chapelle method [41]. This method involves preparing a solution containing 1.00 g of the mentioned SCM and 1.00 g of CaO in 250.0 mL of distilled water. The solution was maintained in an oven at 90 °C for 16 h. Subsequently, the remaining CaO content was determined by titration with a hydrochloric acid (HCl) solution, using phenolphthalein as an indicator. The results were calculated as the difference between the 1.00 g of CaO and the mass of CaO measured during the titration.

2.3.2. Pozzolanic Index with Lime

The pozzolanic index with lime was determined using mortar cubes of 50 mm × 50 mm × 50 mm, which were manufactured with hydrated lime as recommended by Ali et al. [42]. The mixture consisted of Ottawa® silica sand in the ratio 1:2SG:9 by weight, where SG is the ratio of specific gravity of the SCM to that of hydrated lime. The water/cementitious material ratio was 0.5 in all mixtures. After casting, the specimens were covered with greased glass plates and kept under wet gunny bags for 48 h. After demolding, specimens were cured at 50 °C for eight days, after which the CS at 7 days was determined. Lime reactivity is represented as the strength of lime and pozzolan mixture.

2.3.3. Strength Activity Index Tests

The Strength Activity Index (SAI) of SCMs studied was evaluated according to ASTM C 311 [43]. For mortar control, 500 g of PC, 1.375 g of Ottawa® silica sand and 242 mL of bidistilled water were used. In the case of mortars with GWG, LWG, and FA, 20% of the PC was replaced with each SCM. For each mixture, cubes of 50 mm × 50 mm × 50 mm were cast and demolded after 24 h. Next, cubes were cured in a saturated solution of Ca(OH)2 at ambient temperature until the testing. The CSs of six cubes for mixtures at 14, 28, and 90 days were determined using a compression testing machine, Controls® model Compact-Line PILOT Pro (Liscate, Italy), with a loading rate of 1000 N/s. The above is according to standard ASTM C109/C109M-22 [44], and the SAI was calculated as the ratio between SCM-mortar and control, expressed in percentage.

3. Results and Discussion

3.1. Particle Size Distribution and Morphological Analysis

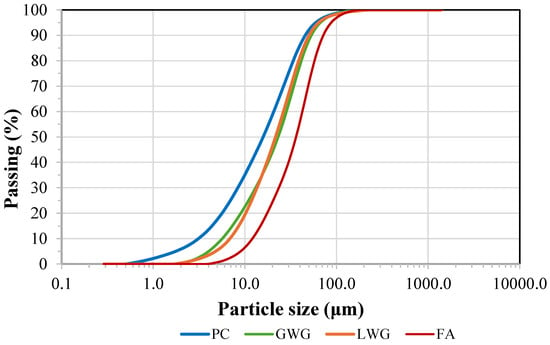

Figure 2 illustrates the particle size distribution of PC, GWG, LWG, and FA. Among the cementitious materials evaluated, PC exhibited the finest particle size distribution. Both types of waste glass (GWG and LWG) showed slightly coarser distributions compared to PC; however, their particle sizes remained below 200 μm. Several studies have reported particle size ranges for WG used as a partial replacement for PC of typically between 45 μm and 500 μm [45,46,47]. In the present study, the adopted grinding procedure successfully produced WG particles below 200 μm, which confirms that the process is adequate for obtaining particle sizes comparable to those reported in the literature. In the case of FA, this exhibited the coarsest particle size distribution among the materials analyzed. This can be attributed to the fact that, unlike the WG samples, FA did not undergo any additional grinding treatment.

Figure 2.

Particle size distribution of PC and SCMs.

Continuing with the analysis, Table 1 presents the average particle sizes of the cementitious materials. PC exhibited the smallest average size, while the average particle sizes of GWG and LWG were 5.80 μm and 7.32 μm, respectively, only slightly larger than that of PC. Compared to values reported in the literature, where the average particle size of WG used as SCM ranges between 0.90 μm and 70 μm [45,46], the results obtained in this study fall within that range. Thus, both the particle size distribution and the average particle sizes of GWG and LWG are consistent with those reported for other waste glasses used as SCMs. The scope of this research did not include alkali–silica reaction (ASR), since the focus was not on the performance of WG as an aggregate, but rather on its pozzolanic behavior when used in finely ground form as a partial replacement for PC. In this context, both WGs presented average particle sizes lower than 200 µm, the maximum value reported in the literature [22] for WG used as SCMs in PC-based materials, which presented ASR values lower than that established by the standard ASTM C1260 [48].

Table 1.

Average particle size of PC and SCMs.

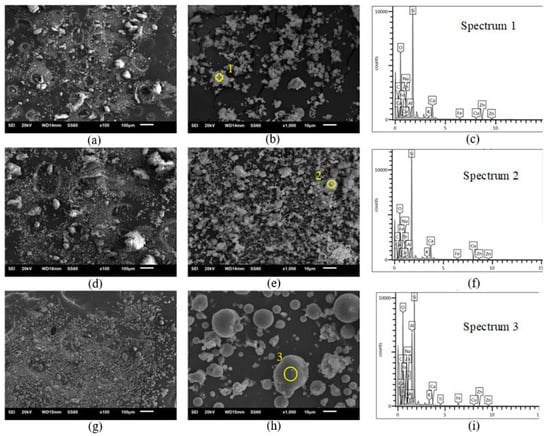

The morphologies of GWG, LWG, and FA are shown in Figure 3. GWG particles (Figure 3a–c) and LWG particles (Figure 3d–f) appear agglomerated, with sizes ranging from approximately 10 μm to 100 μm, consistent with the results of the particle size distribution analysis. In both WG types, the particles exhibit undefined shapes, primarily due to the mechanical grinding process. EDS analysis revealed that WG particles (Spectrum 1 and Spectrum 2) are primarily composed of Si, Na, O, Al, Ca, and Fe. In contrast, FA particles display predominantly spherical morphology (Figure 3g–i), containing cenospheres and plerospheres, along with some unburned carbon particles. These are mainly composed of Si, Al, Fe, and O (Spectrum 3). The morphology of WG particles has been reported to depend on both the type of glass and the grinding process. For example, Bouchikhi et al. [49] and Nassar & Soroushian [50] observed prismatic, angular, cubic, irregular, and semi-spherical particles in WG with particle sizes between 45 and 75 μm. Similarly, Chen et al. [34] reported cylindrical morphologies in WG obtained from crushed electronic-grade fiber scrap.

Figure 3.

SEM images and EDS analysis of particles from SCMs.

3.2. Chemical and Mineralogical Composition

The chemical compositions of PC and the SCMs are presented in Table 2. It can be observed that both GWG and LWG are primarily composed of SiO2; however, LWG shows a higher SiO2 content compared to both GWG and FA. Additionally, the combined content of SiO2 + Al2O3 + Fe2O3 in GWG, LWG, and FA exceeds 70%, which is the minimum threshold established by ASTM C 618 [51] to classify a material as pozzolanic. Among the evaluated materials, LWG demonstrates the highest percentage of SiO2, surpassing that of other WG types reported in the literature, which suggests its potential for superior pozzolanic performance.

Table 2.

Chemical composition of PC and SCMs.

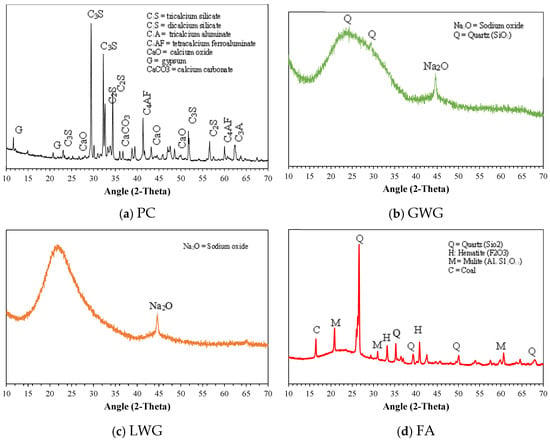

The mineralogical compositions of PC and the SCMs are illustrated in Figure 4. PC displays characteristic crystalline phases of tricalcium silicate (C3S), dicalcium silicate (C2S), tricalcium aluminate (C3A), and tetracalcium aluminoferrite (C4AF), which are typical of PC and contribute to the formation of cementitious hydration products such as C-S-H, Ca(OH)2, ettringite, and monosulfate upon reaction with water. Additionally, gypsum and calcium carbonate were identified in PC. In the case of GWG, crystalline phases of quartz and sodium oxide were identified, while LWG showed only the presence of sodium oxide. This suggests that LWG possesses a more homogeneous and predominantly amorphous structure. In this context, Pacewska et al. [52] mention that a higher degree of amorphism enhances pozzolanic reactivity, as amorphous silica is more reactive than crystalline silica, such as quartz, which is chemically inert under normal hydration conditions. For FA, quartz, hematite, mullite, and unburned carbon were detected, consistent with the SEM observations presented in Section 3.1. Like WG, FA also exhibited an amorphous halo in its XRD pattern, although its intensity was lower.

Figure 4.

XRD patterns of PC and SCMs.

In order to compare the amorphous content of the SCMs, a semi-quantitative analysis was performed based on the area under the XRD curve. The estimated amorphous contents were 60.2% for GWG, 63.6% for LWG, and 43.3% for FA. These results correspond to the relative intensity of the amorphous halo observed in the 2θ range of 10–30°. This is particularly relevant, as the amorphous phase plays a critical role in pozzolanic reactivity, leading to the formation of secondary cementitious compounds such as C-S-H, which enhance the mechanical and durability properties of PC-based materials [53,54,55]. Based on the findings from Section 3.1 and Section 3.2, it can be concluded that both GWG and LWG exhibit promising pozzolanic potential. Their particle size distributions are comparable to those of PC, their SiO2 + Al2O3 + Fe2O3 content exceeds the ASTM threshold, and their XRD patterns confirm the presence of a significant amorphous phase. This pozzolanic potential will be further analyzed and discussed in the following sections.

3.3. Pozzolanic Activity

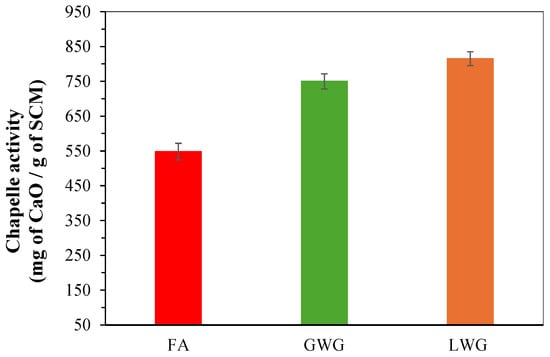

3.3.1. Analysis of the Chapelle Method

Figure 5 illustrates the Chapelle activity of FA, GWG, and LWG. It can be observed that the pozzolanic activity of FA is the lowest of the three SCMs evaluated, with a value close to 550 mg CaO/g. This indicates that although it has pozzolanic properties, its capacity for chemical reaction with Ca(OH)2 is limited compared to WGs. In the case of GWG, the results show an increase in pozzolanic activity compared to FA, with a value close to 750 mg CaO/g. This suggests that GWG has a better chemical interaction as an SCM. Regarding the Chapelle activity of LWG, this SCM exhibits the highest pozzolanic activity among the SCMs analyzed, reaching approximately 800 mg CaO/g.

Figure 5.

Chapelle activity of the SCM.

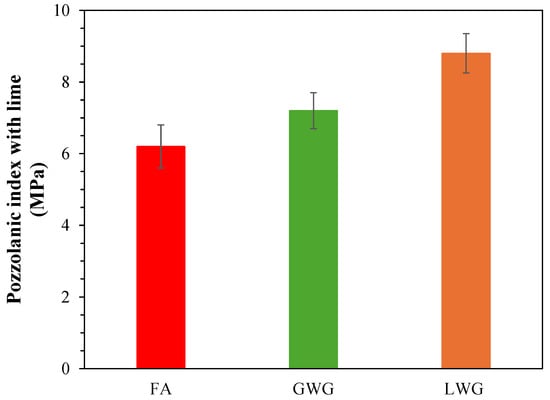

3.3.2. Analysis of the Pozzolanic Index with Lime

The pozzolanic index with lime for SCMs studied is shown in Figure 6, which indicates the ability of each material to contribute to the mechanical strength through pozzolanic reactions in combination with lime [56]. Results show that FA has a pozzolanic index of approximately 6 MPa, being the lowest value among the three SCMs evaluated. This indicates that, although it has some capacity to react with lime, its contribution to mechanical strength is limited compared with WG. Continuous with analysis, GWG shows a slight improvement over FA, with an index close to 7 MPa. This suggests greater chemical interaction with lime, making it a more effective option to improve the mechanical properties of PC-based materials. LWG presented the highest pozzolanic index, reaching approximately 8 MPa. This highlights its high reactivity and its superior capacity to contribute to the development of mechanical strength in combination with lime, which positions it as the most promising studied material. The results of this test were obtained in curing conditions of 50 °C for 8 days in order to accelerate the pozzolanic reaction and simulate longer-term behavior within a shorter period. Though this approach follows the methodology reported by Ali et al. [42], which is commonly used to enhance the interaction between lime and the pozzolanic materials, it is important to mention that the results shown do not consider pozzolanic performance at late ages or curing under ambient conditions. However, the SAI results considering the aforementioned conditions are presented and analyzed below.

Figure 6.

Pozzolanic index with lime of the SCMs.

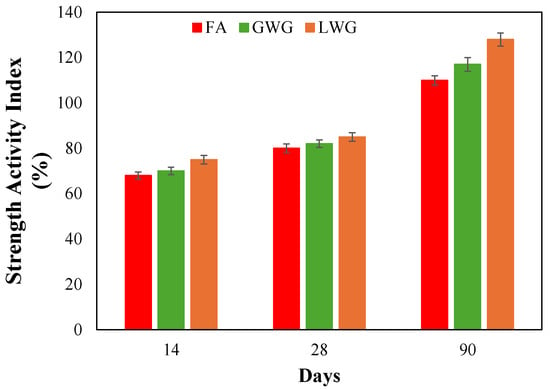

3.3.3. Strength Activity Index

Figure 7 presents the Strength Activity Index (SAI) at 14, 28, and 90 days for the SCMs evaluated. At 14 days, the SAI values for FA, GWG, and LWG are approximately 80%, indicating that partial replacement of PC with these SCMs does not significantly reduce early compressive strength. It is important to mention that LWG exhibited the highest Chapelle activity (~800 mg CaO/g); however, all SCMs showed similar SAI values (~80%) at 14 days. This apparent inconsistency can be explained by the nature and sensitivity of the two tests. The Chapelle test evaluates the chemical reactivity of the SCMs under accelerated conditions, where high temperature at 90 °C and prolonged contact with CaO facilitate the dissolution and reaction of amorphous silica. On the other hand, the SAI test shows the contribution of the SCMs to strength development under standard curing conditions, which are less favorable for the rapid progression of pozzolanic reactions. Moreover, early-age strength development is strongly influenced by the hydration of Portland cement, with SCMs contributing more significantly at long-term ages. In this context, LWG showed higher chemical reactivity in the Chapelle test, its contribution to early strength is still limited by the relatively slow kinetics of pozzolanic reactions under ambient conditions. The above behavior is typical of SCMs, as their pozzolanic reactions, which contribute to strength development, proceed more slowly than the early hydration of PC [8,9].

Figure 7.

SAI of the SCMs.

By 28 days, the increase in the SAI suggests pozzolanic activity. LWG exhibits slightly better performance than FA and GWG, indicating a higher degree of reactivity at this age. Although the SAI values remain below 100%, the pozzolanic reaction is clearly progressing. Notably, both GWG and LWG achieve SAI values exceeding 85%, which meets the minimum threshold defined in ASTM C1866/C1866 [57] for classifying WG as a pozzolanic material. At 90 days, the SAI values for GWG, LWG, and FA all exceed 100%, indicating that partial replacement of PC with these SCMs results in higher long-term compressive strength than that of the control mortar. LWG stands out with the highest SAI, highlighting its superior contribution to long-term development. Importantly, both types of WG demonstrate pozzolanic behavior comparable to FA in terms of reaction kinetics. For instance, while SCMs like silica fume exhibit early pozzolanic reactivity [58], FA and WGs showed delayed pozzolanic activity, as reflected in the SAI values at later ages. The superior performance of LWG across all pozzolanic activity tests aligns with its chemical characteristics. LWG exhibited the highest content of major oxides and the greatest proportion of amorphous phases. This enhanced reactivity may be attributed to its high purity and lack of coloring agents. In contrast, GWG likely contains metallic oxides such as Fe, Cr, and Mn (see Table 2), along with additives or contaminants that can reduce the availability of reactive amorphous silica and introduce impurities or crystalline phases that hinder pozzolanic reactivity [59,60].

It is important to mention that, to ensure the reliability of the characterization and pozzolanic activity results, all tests were conducted using standardized and widely accepted and used methods in the literature, including the Chapelle method, pozzolanic index with lime, and SAI. The analytical results were validated by comparison with threshold values established by ASTM C618 [51] and ASTM C1866 [57], as well as with previously published data. For instance, the SiO2 + Al2O3 + Fe2O3 contents exceeded 70% in all SCMs [51], and the SAI values were higher than the limits established by ASTM C1866/C1866 [51] for pozzolanic classification. Furthermore, the agreement observed between the chemical (XRF and XRD), physical (PSD and SEM/EDS), and mechanical (lime index and SAI) evaluations supports the consistency and robustness of the experimental results. Therefore, although no novel test was introduced, the convergence of multiple standardized methods and cross-referencing with benchmark data validates the experimental outcomes presented in this study.

Finally, it is possible to affirm that, based on the results from all pozzolanic activity assessments, both WG types demonstrated higher reactivity than FA, with LWG consistently showing the best performance. The SAI values at 90 days confirm that LWG not only supports improved long-term mechanical performance but also represents a viable and sustainable alternative for partially replacing PC. This contributes to strength development while promoting the valorization of waste materials and the reduction of CO2 emissions in the construction industry.

4. Conclusions

The results regarding the pozzolanic activity of GWG and LWG, as well as their comparison with a conventional SCM such as FA, lead to the following conclusions:

- The average particle size and distribution of both GWG and LWG are similar to those of Portland cement.

- The combined content of SiO2, Al2O3, and Fe2O3 in GWG and LWG exceeds 70%, meeting the minimum requirement established by ASTM C618-19 for classifying a material as pozzolanic.

- The XRD patterns of GWG and LWG exhibit an amorphous halo in the 2θ range of 10–30°, indicating the presence of amorphous material, which is essential for pozzolanic reactivity.

- The results obtained from the Chapelle test, lime reactivity, and Strength Activity Index (SAI) confirm that both GWG and LWG exhibit pozzolanic properties, outperforming FA. Moreover, the pozzolanic reaction kinetics of GWG and LWG are comparable to those of FA, with the most significant chemical reactions with Ca(OH)2 occurring at later curing ages.

- The experimental methods carried out in this study are standardized and widely recognized for assessing the pozzolanic performance of SCMs. Results from physical, mineralogical, morphological, chemical, and mechanical assessments not only validated the reliability of the data but also revealed differences in reactivity and performance between the two WGs. These findings underscore the significance of glass origin and composition in determining pozzolanic behavior, particularly the superior reactivity of LWG. This contributes valuable new insights for the sustainable valorization of glass waste in cement-based materials.

Author Contributions

Conceptualization, S.R.-A. and F.M.-A.; Data curation, S.R.-A.; Formal analysis, H.C.-M. and H.R.-C.; Investigation, J.M.M.-R. and V.A.F.-L.; Writing—original draft, V.A.F.-L.; Writing—review and editing, H.C.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Tecnológico Nacional de México, grant number 20689.24-P and 22609.25-P.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to express their gratitude to Instituto Tecnológico del Valle de Etla and Universidad Autónoma de Nuevo Leon for the use of their facilities during testing carried out in this investigation.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Benhelal, E.; Shamsaei, E.; Rashid, M.I. Challenges against CO2 Abatement Strategies in Cement Industry: A Review. J. Environ. Sci. 2021, 104, 84–101. [Google Scholar] [CrossRef]

- Hayek, M.; El Bitouri, Y.; Bouarab, K.; Yahia, A. Structural Build-Up of Cement Pastes: A Comprehensive Overview and Key Research Directions. Constr. Mater. 2025, 5, 31. [Google Scholar] [CrossRef]

- Antunes, M.; Santos, R.L.; Pereira, J.; Rocha, P.; Horta, R.B.; Colaço, R. Alternative Clinker Technologies for Reducing Carbon Emissions in Cement Industry: A Critical Review. Materials 2021, 15, 209. [Google Scholar] [CrossRef] [PubMed]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary Cementitious Materials: New Sources, Characterization, and Performance Insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Hassannezhad, K.; Akyol, Y.; Dursun, M.C.; Ow-Yang, C.W.; Gulgun, M.A. Effect of Metakaolin and Lime on Strength Development of Blended Cement Paste. Constr. Mater. 2022, 2, 297–313. [Google Scholar] [CrossRef]

- Sarangi, S.; Suganya, O.M. A Comprehensive Review of the Physical and Mechanical Characteristics of Agricultural By-Products as Cementitious Alternatives in the Production of Sustainable Concrete. Mater. Today Sustain. 2024, 27, 100882. [Google Scholar] [CrossRef]

- Andersson, A.; Brander, L.; Lennartsson, A.; Roos, Å.; Engström, F. Ground Granulated Iron Silicate Slag as Supplementary Cementitious Material: Effect of Prolonged Grinding and Granulation Temperature. Clean. Mater. 2023, 10, 100209. [Google Scholar] [CrossRef]

- Bharadwaj, K.; Burkan Isgor, O.; Jason Weiss, W. Pozzolanic Reactivity of Supplementary Cementitious Materials. Mater. J. 2023, 120, 63–76. [Google Scholar] [CrossRef]

- Xu, X.; Wang, F.; Gu, X.; Zhao, Y. Mechanism of Different Mechanically Activated Procedures on the Pozzolanic Reactivity of Binary Supplementary Cementitious Materials. Minerals 2022, 12, 1365. [Google Scholar] [CrossRef]

- Benhelal, E.; Shamsaei, E.; Rashid, M.I. Novel Modifications in a Conventional Clinker Making Process for Sustainable Cement Production. J. Clean Prod. 2019, 221, 389–397. [Google Scholar] [CrossRef]

- Amir Raza, M.; Karim, A.; Aman, M.M.; Ahmad Al-Khasawneh, M.; Faheem, M. Global Progress towards the Coal: Tracking Coal Reserves, Coal Prices, Electricity from Coal, Carbon Emissions and Coal Phase-Out. Gondwana Res. 2025, 139, 43–72. [Google Scholar] [CrossRef]

- McCarthy, M.J.; Robl, T.; Csetenyi, L.J. 14—Recovery, Processing, and Usage of Wet-Stored Fly Ash. In Coal Combustion Products (CCP’s); Robl, T., Oberlink, A., Jones, R.B.T., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 343–367. ISBN 978-0-08-100945-1. [Google Scholar]

- Chandra Paul, S.; Šavija, B.; Babafemi, A.J. A Comprehensive Review on Mechanical and Durability Properties of Cement-Based Materials Containing Waste Recycled Glass. J. Clean Prod. 2018, 198, 891–906. [Google Scholar] [CrossRef]

- Lu, J.X.; Zhan, B.J.; Duan, Z.H.; Poon, C.S. Using Glass Powder to Improve the Durability of Architectural Mortar Prepared with Glass Aggregates. Mater. Des. 2017, 135, 102–111. [Google Scholar] [CrossRef]

- Solahuddin, B.A. A Comprehensive Review on Waste Paper Concrete. Results Eng. 2022, 16, 100740. [Google Scholar] [CrossRef]

- Nodehi, M.; Mohamad Taghvaee, V. Sustainable Concrete for Circular Economy: A Review on Use of Waste Glass. Glass Struct. Eng. 2022, 7, 3–22. [Google Scholar] [CrossRef]

- Arabi, N.; Meftah, H.; Amara, H.; Kebaïli, O.; Berredjem, L. Valorization of Recycled Materials in Development of Self-Compacting Concrete: Mixing Recycled Concrete Aggregates—Windshield Waste Glass Aggregates. Constr. Build. Mater. 2019, 209, 364–376. [Google Scholar] [CrossRef]

- Lu, J.X.; Zhan, B.J.; Duan, Z.H.; Poon, C.S. Improving the Performance of Architectural Mortar Containing 100% Recycled Glass Aggregates by Using SCMs. Constr. Build. Mater. 2017, 153, 975–985. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef] [PubMed]

- Afshinnia, K.; Rangaraju, P.R. Influence of Fineness of Ground Recycled Glass on Mitigation of Alkali–Silica Reaction in Mortars. Constr. Build. Mater. 2015, 81, 257–267. [Google Scholar] [CrossRef]

- Zheng, K. Pozzolanic Reaction of Glass Powder and Its Role in Controlling Alkali–Silica Reaction. Cem. Concr. Compos. 2016, 67, 30–38. [Google Scholar] [CrossRef]

- Franco-Luján, V.A.; Ramírez-Arellanes, S.; Gomez-Sanchez, A.; Pérez-Ramos, A.E.; Cruz-García, E.S.; Cruz-Martínez, H. Properties of Fresh and Hardened Cement-Based Materials with Waste Glass as Supplementary Cementitious Material: A Review. J. Build. Eng. 2024, 95, 110137. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.C.; Mo, K.H.; Shi, C. A Critical Review of Waste Glass Powder—Multiple Roles of Utilization in Cement-Based Materials and Construction Products. J. Environ. Manag. 2019, 242, 440–449. [Google Scholar] [CrossRef]

- Rashid, K.; Hameed, R.; Ahmad, H.A.; Razzaq, A.; Ahmad, M.; Mahmood, A. Analytical Framework for Value Added Utilization of Glass Waste in Concrete: Mechanical and Environmental Performance. Waste Manag. 2018, 79, 312–323. [Google Scholar] [CrossRef] [PubMed]

- Soliman, N.A.; Tagnit-Hamou, A. Development of Ultra-High-Performance Concrete Using Glass Powder—Towards Ecofriendly Concrete. Constr. Build. Mater. 2016, 125, 600–612. [Google Scholar] [CrossRef]

- Letelier, V.; Henríquez-Jara, B.I.; Manosalva, M.; Parodi, C.; Ortega, J.M. Use of Waste Glass as A Replacement for Raw Materials in Mortars with a Lower Environmental Impact. Energies 2019, 12, 1974. [Google Scholar] [CrossRef]

- Patel, D.; Tiwari, R.P.; Shrivastava, R.; Yadav, R.K. Effective Utilization of Waste Glass Powder as the Substitution of Cement in Making Paste and Mortar. Constr. Build. Mater. 2019, 199, 406–415. [Google Scholar] [CrossRef]

- Qin, D.; Hu, Y.; Li, X. Waste Glass Utilization in Cement-Based Materials for Sustainable Construction: A Review. Crystals 2021, 11, 710. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Zhang, P.; Ma, Y. Effective Utilization of Waste Glass as Cementitious Powder and Construction Sand in Mortar. Materials 2020, 13, 707. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Tunç, U.; Bahrami, A.; Karalar, M.; Othuman Mydin, M.A.; Alomayri, T.; Özkılıç, Y.O. Use of Waste Glass Powder toward More Sustainable Geopolymer Concrete. J. Mater. Res. Technol. 2023, 24, 8533–8546. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Heniegal, A.M.; Abdellatief, M.; Tayeh, B.A.; Elrahman, M.A. Properties of Ultra-High Performance Geopolymer Concrete Incorporating Recycled Waste Glass. Case Stud. Constr. Mater. 2022, 17, e01393. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Karalar, M.; Çelik, A.İ.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of Replacing Cement with Waste Glass on Mechanical Properties of Concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef]

- Bignozzi, M.C.; Saccani, A.; Barbieri, L.; Lancellotti, I. Glass Waste as Supplementary Cementing Materials: The Effects of Glass Chemical Composition. Cem. Concr. Compos. 2015, 55, 45–52. [Google Scholar] [CrossRef]

- Chen, C.H.; Huang, R.; Wu, J.K.; Yang, C.C. Waste E-Glass Particles Used in Cementitious Mixtures. Cem. Concr. Res. 2006, 36, 449–456. [Google Scholar] [CrossRef]

- Khmiri, A.; Chaabouni, M.; Samet, B. Chemical Behaviour of Ground Waste Glass When Used as Partial Cement Replacement in Mortars. Constr. Build. Mater. 2013, 44, 74–80. [Google Scholar] [CrossRef]

- NMX-C-414-ONNCCE-2017; Industria de la Construcción–Cementos Hidráulicos–Especificaciones y Métodos de Prueba. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación, S.C.: Mexico City, Mexico, 2017; pp. 1–2. (In Spanish)

- Wei, L.K.; Abd Rahim, S.Z.; Al Bakri Abdullah, M.M.; Yin, A.T.M.; Ghazali, M.F.; Omar, M.F.; Nemeș, O.; Sandu, A.V.; Vizureanu, P.; Abdellah, A.E. hadj Producing Metal Powder from Machining Chips Using Ball Milling Process: A Review. Materials 2023, 16, 4635. [Google Scholar] [CrossRef] [PubMed]

- ASTM C188-17; Standard Test Method for Density of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C144; Test Methods for Chemical Analysis of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D 7348; Standard Test Methods for Loss on Ignition (LOI) of Solid Combustion Residues. ASTM International: West Conshohocken, PA, USA, 2023.

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R. Pozzolanic Activity and Filler Effect of Sugar Cane Bagasse Ash in Portland Cement and Lime Mortars. Cem. Concr. Compos. 2008, 30, 410–418. [Google Scholar] [CrossRef]

- Ali, H.A.; Xuan, D.; Poon, C.S. Assessment of Long-Term Reactivity of Initially Lowly-Reactive Solid Wastes as Supplementary Cementitious Materials (SCMs). Constr. Build. Mater. 2020, 232, 117192. [Google Scholar] [CrossRef]

- ASTM C311/C311M-24; Standard Test Methods for Sampling and Testing Coal Ash or Natural Pozzolans for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C109/C109M-22; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-Mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2022.

- Jiang, X.; Xiao, R.; Bai, Y.; Huang, B.; Ma, Y. Influence of Waste Glass Powder as a Supplementary Cementitious Material (SCM) on Physical and Mechanical Properties of Cement Paste under High Temperatures. J. Clean Prod. 2022, 340, 130778. [Google Scholar] [CrossRef]

- Jochem, L.F.; Casagrande, C.A.; Onghero, L.; Venâncio, C.; Gleize, P.J.P. Effect of Partial Replacement of the Cement by Glass Waste on Cementitious Pastes. Constr. Build. Mater. 2021, 273, 121704. [Google Scholar] [CrossRef]

- Pereira-De-Oliveira, L.A.; Castro-Gomes, J.P.; Santos, P.M.S. The Potential Pozzolanic Activity of Glass and Red-Clay Ceramic Waste as Cement Mortars Components. Constr. Build. Mater. 2012, 31, 197–203. [Google Scholar] [CrossRef]

- ASTM C1260-22; Standard Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method). ASTM International: West Conshohocken, PA, USA, 2022.

- Bouchikhi, A.; Benzerzour, M.; Abriak, N.E.; Maherzi, W.; Mamindy-Pajany, Y. Study of the Impact of Waste Glasses Types on Pozzolanic Activity of Cementitious Matrix. Constr. Build. Mater. 2019, 197, 626–640. [Google Scholar] [CrossRef]

- Nassar, R.U.D.; Soroushian, P. Strength and Durability of Recycled Aggregate Concrete Containing Milled Glass as Partial Replacement for Cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar] [CrossRef]

- ASTM C 618-19; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- Pacewska, B.; Wilińska, I. Usage of Supplementary Cementitious Materials: Advantages and Limitations. J. Therm. Anal. Calorim. 2020, 142, 371–393. [Google Scholar] [CrossRef]

- Berenguer, R.; Lima, N.; Pinto, L.; Monteiro, E.; Povoas, Y.; Oliveira, R.; Lima, N.B.D. Cement-Based Materials: Pozzolanic Activities of Mineral Additions Are Compromised by the Presence of Reactive Oxides. J. Build. Eng. 2021, 41, 102358. [Google Scholar] [CrossRef]

- Toutanji, H.; Delatte, N.; Aggoun, S.; Duval, R.; Danson, A. Effect of Supplementary Cementitious Materials on the Compressive Strength and Durability of Short-Term Cured Concrete. Cem. Concr. Res. 2004, 34, 311–319. [Google Scholar] [CrossRef]

- Zhuang, W.; Li, S.; Yu, Q. The Effect of Supplementary Cementitious Material Systems on Dynamic Compressive Properties of Ultra-High Performance Concrete Paste. Constr. Build. Mater. 2022, 321, 126361. [Google Scholar] [CrossRef]

- Walker, R.; Pavía, S. Physical Properties and Reactivity of Pozzolans, and Their Influence on the Properties of Lime-Pozzolan Pastes. Mater. Struct./Mater. Constr. 2011, 44, 1139–1150. [Google Scholar] [CrossRef]

- ASTM C1866/C1866M-20; Standard Specification for Ground-Glass Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- Sahoo, S.; Parhi, P.K.; Chandra Panda, B. Durability Properties of Concrete with Silica Fume and Rice Husk Ash. Clean Eng. Technol. 2021, 2, 100067. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Y.; Riefler, C.; Wang, H. Characteristics and Pozzolanic Reactivity of Glass Powders. Cem. Concr. Res. 2005, 35, 987–993. [Google Scholar] [CrossRef]

- Shao, Y.; Lefort, T.; Moras, S.; Rodriguez, D. Studies on Concrete Containing Ground Waste Glass. Cem. Concr. Res. 2000, 30, 91–100. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).