The Effects of Reclaimed Asphalt Pavement Modification on the Delta Tc Parameter for PG58-XX and PG64-XX Asphalt Binders

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- RAP1: Variable-depth cold milling, composed of a combination of chip seal, crack sealant, surface recycle, and hot mix asphalt (HMA).

- RAP2: 2-inch cold mill removal, containing 2012 crack sealant, ~2005 SM-9.5T PG 70-28 HMA (1.5-inch layer), and ~2005 SM-19A PG 70-28 HMA (0.5-inch layer).

- RAP3: 1-inch cold mill removal from two locations:

- Haskell Co.: Some 2014 crack sealant, 2013 SR-12.5A PG 58-28 (1-inch layer).

- Gray Co.: 2017 UBAS-Novachip (~5/8-inch layer), 2012 surface recycle (~3/8-inch layer).

- RAP4: 2.5-inch cold mill removal, containing 2013 chip seal, 2008 UBAS-Novachip (~5/8-inch layer), 2006 UBAS-Novachip (~5/8-inch layer), and ~2002 SM-9.5T PG 70-28 HMA (1.25-inch layer).

2.2. Experimental Procedures

2.3. Parameter Calculation

3. Results

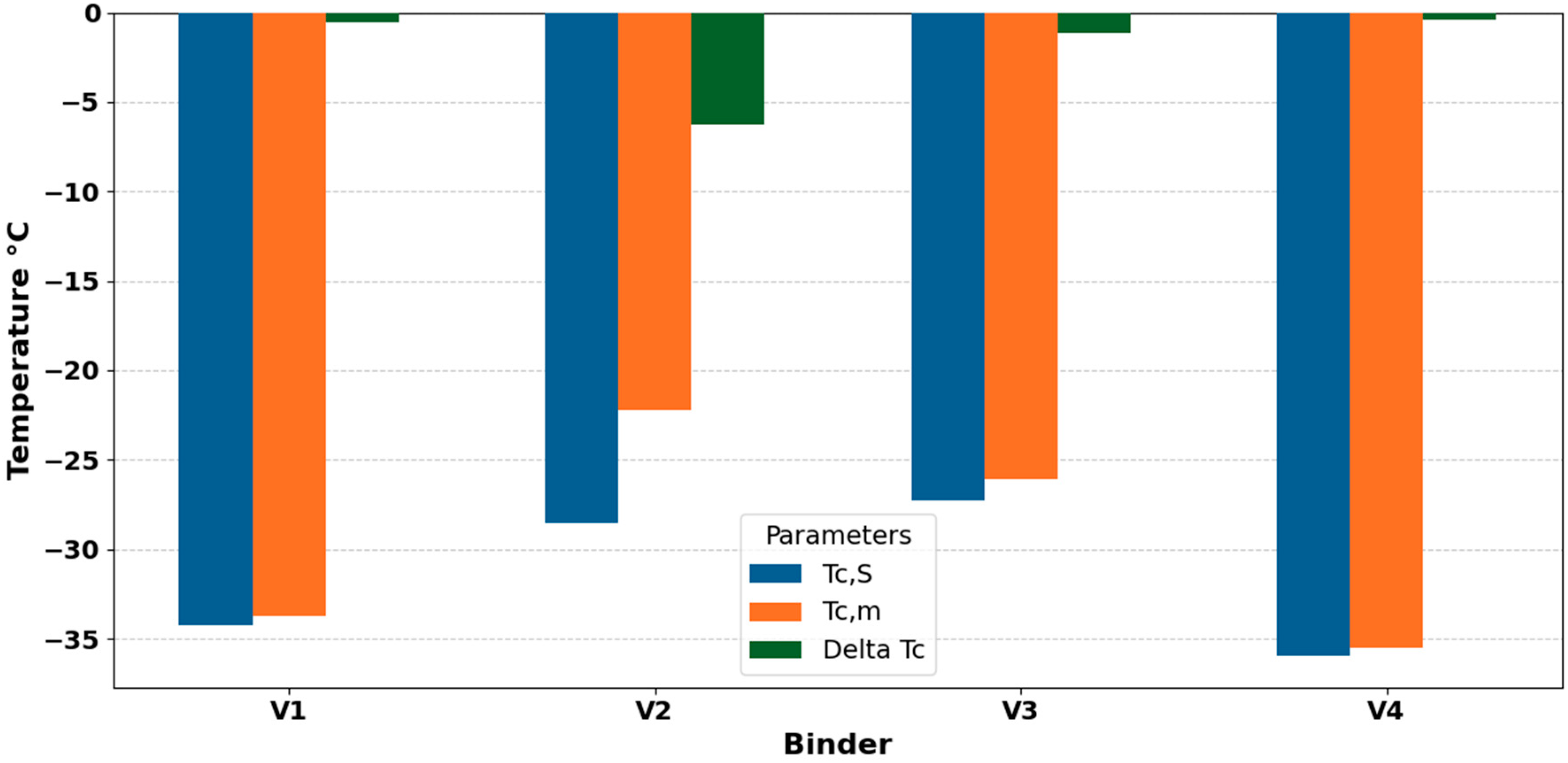

3.1. Pure Virgin Binders

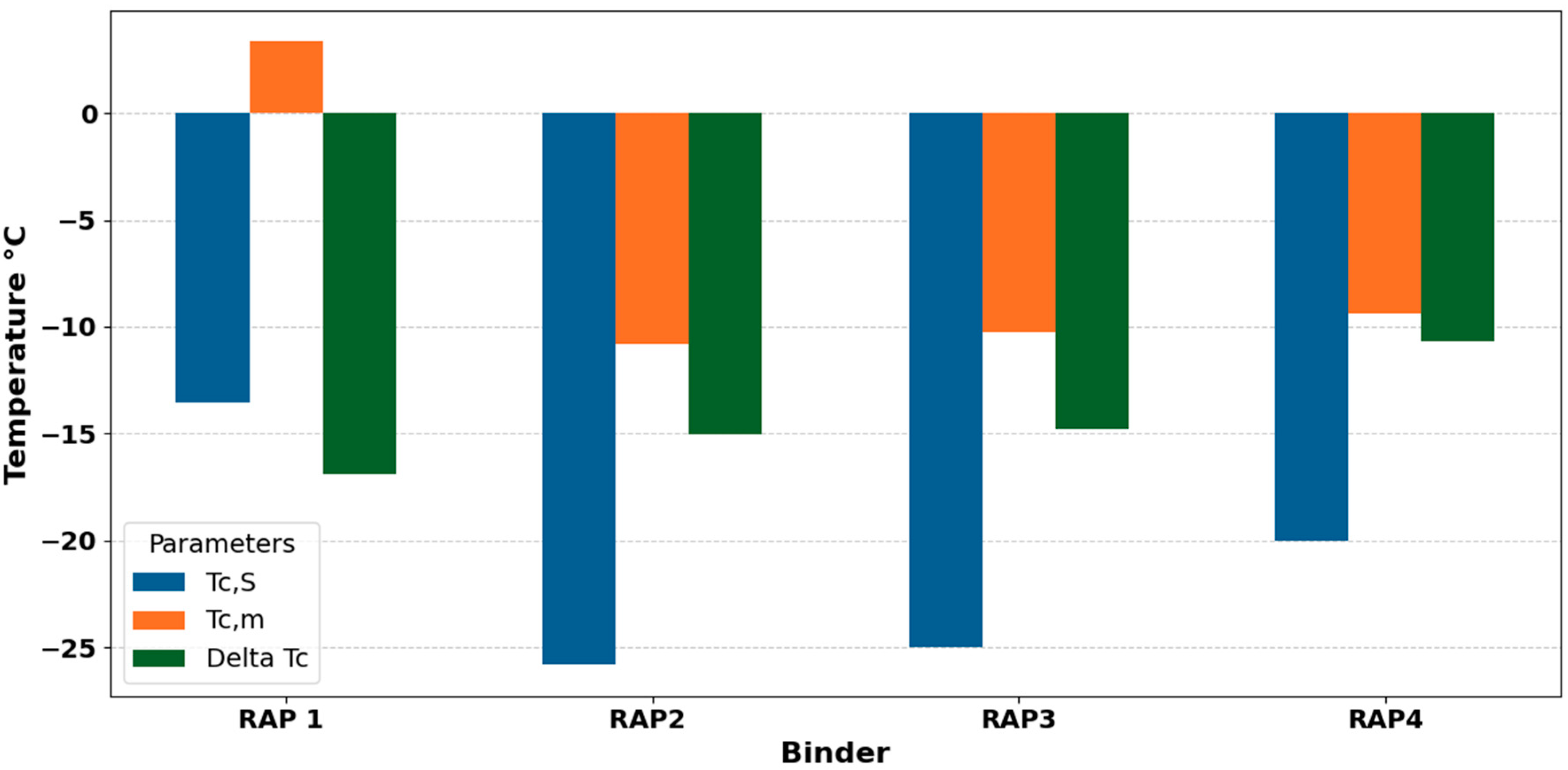

3.2. Pure RAP Binders

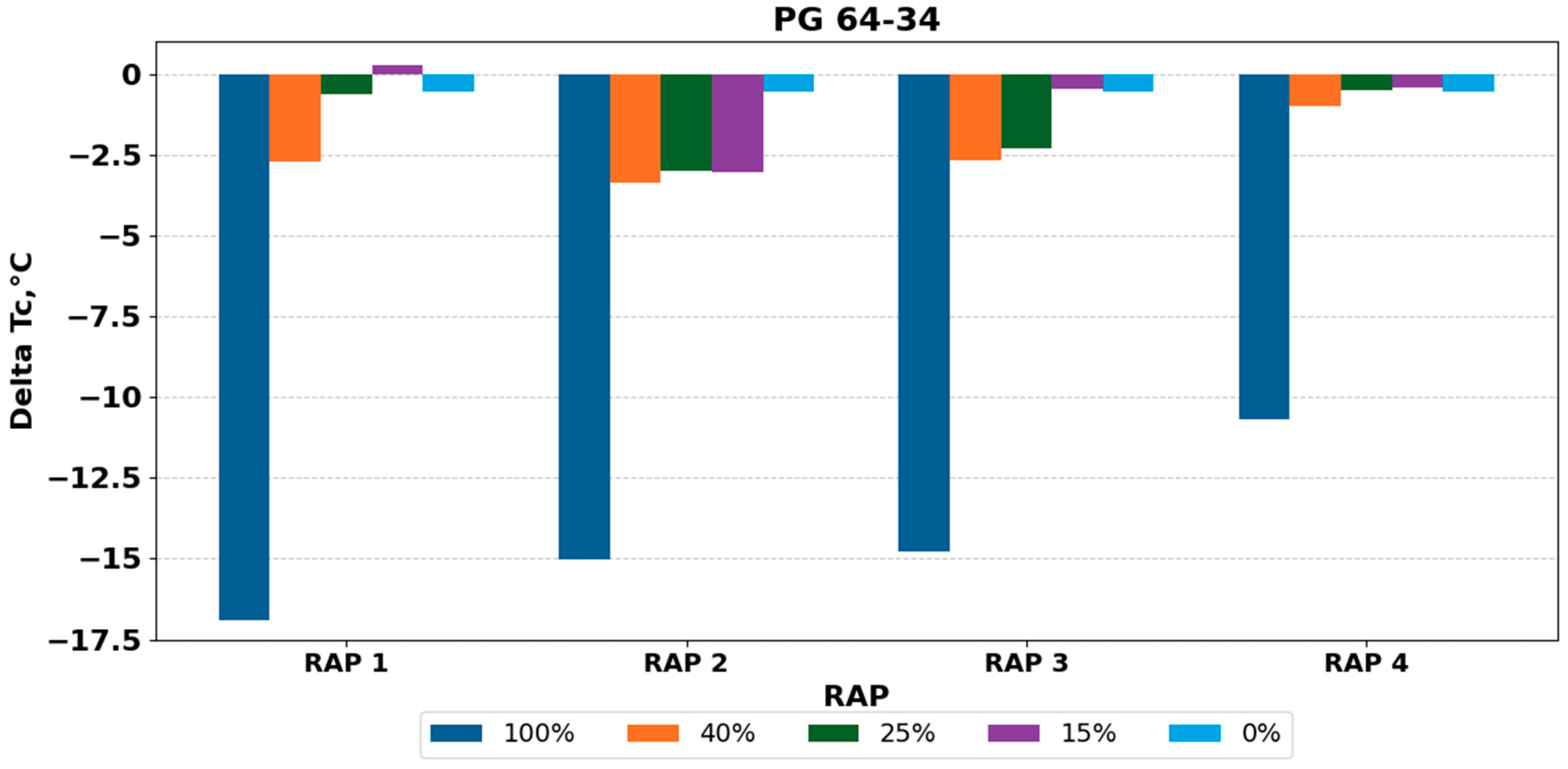

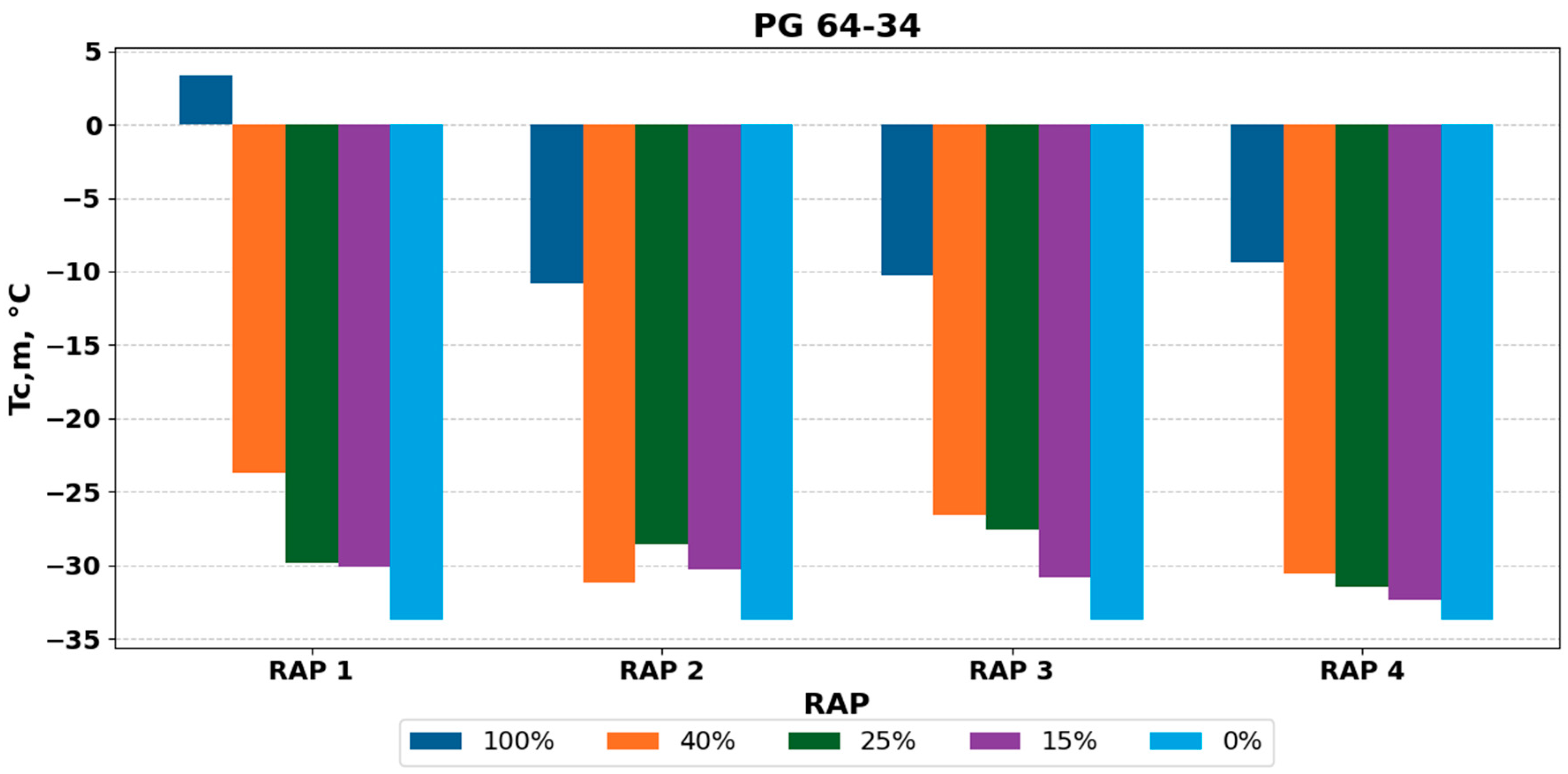

3.3. Blended Mixtures

- Fourteen samples were categorized as safe, reflecting adequate relaxation properties.

- Twenty-two samples fell within the watch category, indicating increased susceptibility to low-temperature cracking.

- Twelve samples were classified in the critical category, showing significant risks for cracking due to poor relaxation capacity.

4. Discussion

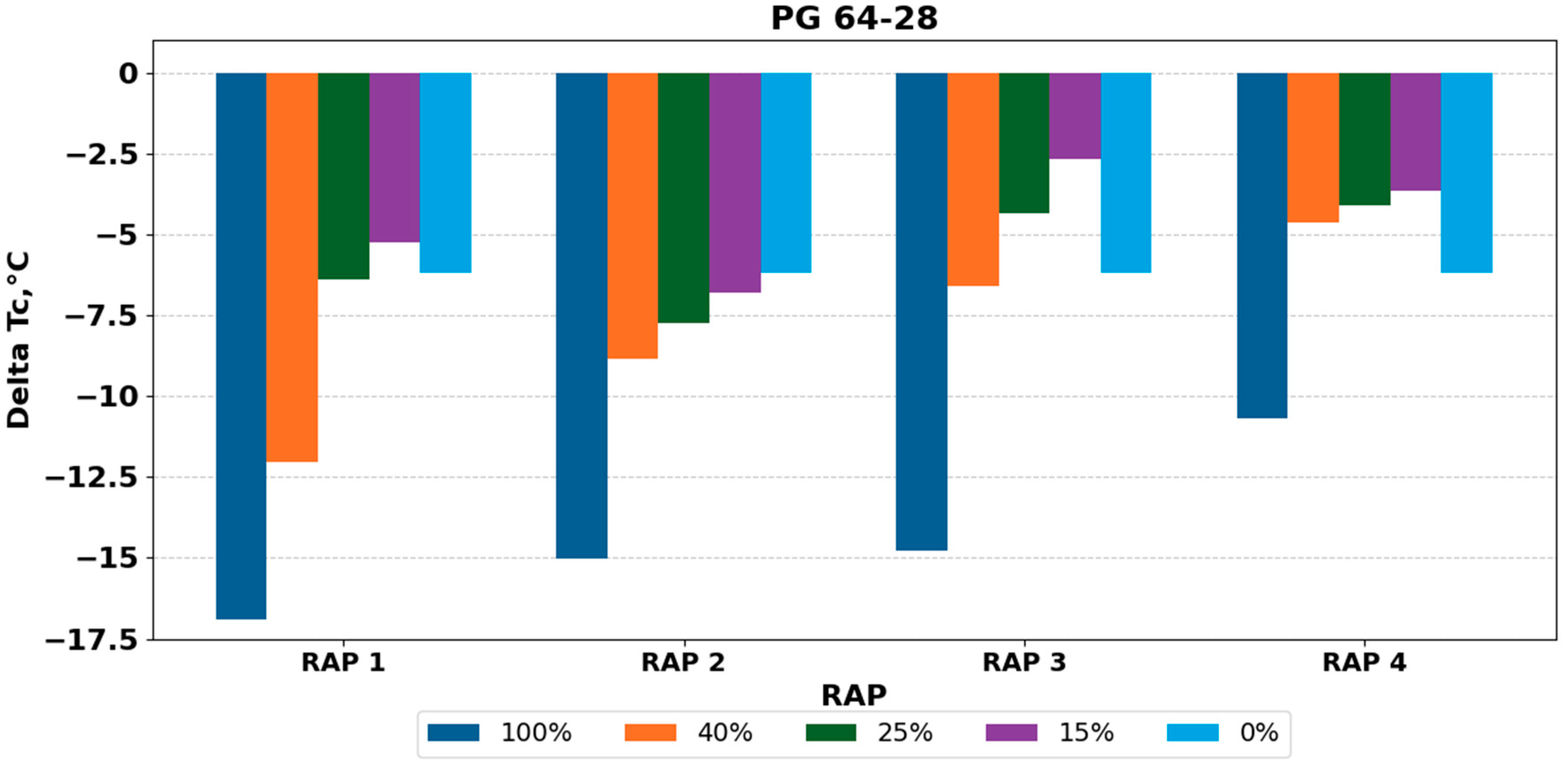

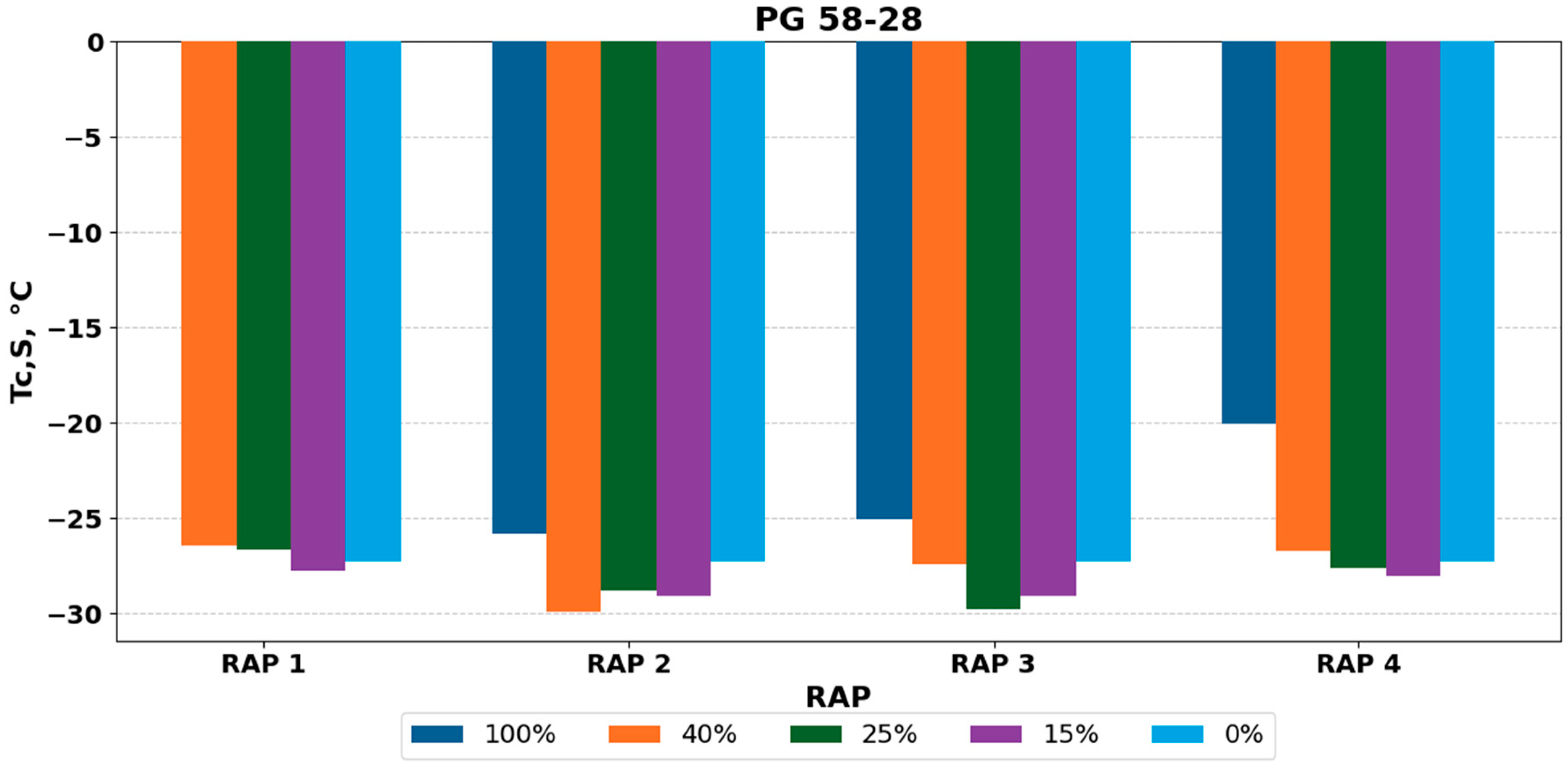

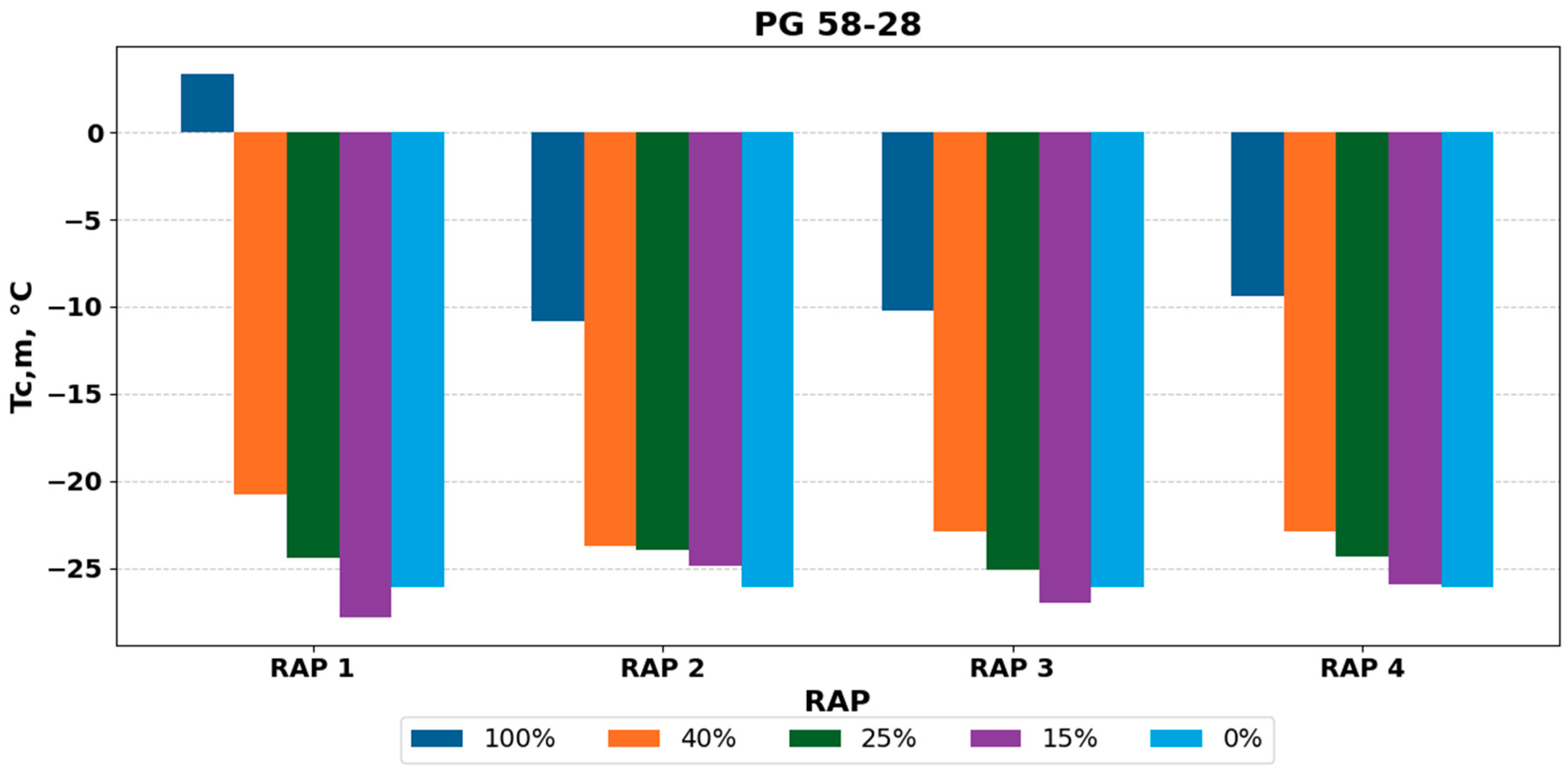

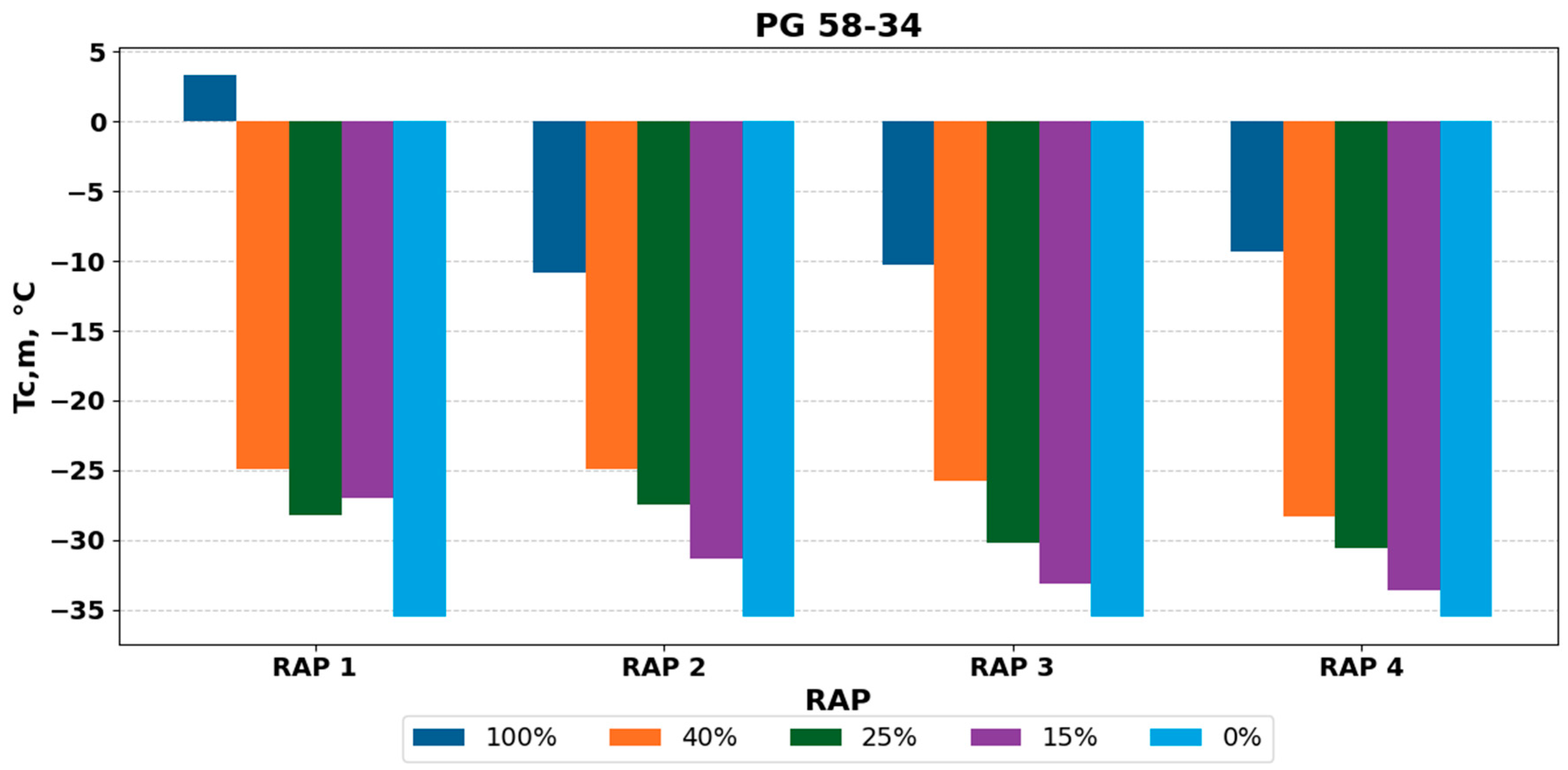

4.1. Impact of RAP Content on Binder Performance

- Material Age: Older RAP materials, such as RAP2 (2005–2012 pavement layers), showed the most severe deterioration, leading to significantly lower values and greater cracking susceptibility.

- Milling Depth: RAP4, removed from a deeper 2.5-inch milling, incorporated less aged materials, resulting in higher values and better relaxation capacity than RAP1, RAP2, and RAP3. Conversely, RAP3, with a shallower 1-inch milling depth, likely included more aged materials, worsening its low-temperature performance at higher RAP contents.

- Binder Source and Composition: The presence of highly oxidized surface layers, crack sealants, and recycled treatments in RAP1 and RAP2 contributed to their poor performance, whereas RAP4’s UBAS-Novachip layers helped retain better stress relaxation properties.

- RAP Percentage in Blends: Higher RAP content (40%) had a pronounced effect on , especially in RAP1, RAP2, and RAP3 blends, whereas lower RAP percentages (15–25%) mitigated some of these negative effects.

4.2. Evaluation of as a Specification Parameter

4.3. Practical Implications

5. Conclusions and Recommendations

- Among the virgin binders, V2 exhibited a critical value of −6.27 °C, indicating a high risk of cracking. The remaining virgin binders demonstrated acceptable performance, with values above −2.5 °C. In contrast, all RAP binders fell into the critical category, with values ranging from −10.67 °C to −16.91 °C, reflecting their poor relaxation capacity and higher stiffness.

- RAP source significantly influenced of blended binders. RAP2 (containing highly oxidized 2005–2012 pavement layers) exhibiting the most negative values, while RAP4 (milled from deeper, less aged layers) had the least impact. These differences highlight that is influenced by both RAP content and source properties, such as age, composition, and milling depth.

- Blended samples with V2 consistently fell into the watch or critical categories, attributed to its already low value, which made it more susceptible to performance deterioration when combined with RAP.

- RAP replacement at 40% consistently resulted in critical values across all binders and sources (except V1 + RAP4), indicating that high RAP levels are generally unsuitable unless the RAP source exhibits favorable properties.

- RAP replacement levels should be limited to 25% unless the RAP source demonstrates favorable performance, such as RAP4. Binder specifications should also include thresholds (−2.5 °C and −5.0 °C) to classify binder performance and reduce low-temperature cracking risks.

- RAP sources should be evaluated based on their aging history, milling depth, and material composition before use to optimize mixture performance and mitigate cracking susceptibility.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- AASHTO M320-23; Standard Specification for Performance-Graded Asphalt Binder. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2023.

- McDaniel, R.S.; Shah, A. Investigation of Delta Tc for Implementation in Indiana (Joint Transportation Research Program Publication No. FHWA/IN/JTRP-2019/14); Purdue University: West Lafayette, IN, USA, 2019. Available online: https://rosap.ntl.bts.gov/view/dot/54401 (accessed on 11 March 2024). [CrossRef]

- Anderson, R.M.; King, G.N.; Hanson, D.I.; Blankenship, P.B. Evaluation of the relationship between asphalt binder properties and non-load related cracking. J. Assoc. Asph. Paving Technol. 2011, 80, 615–664. [Google Scholar]

- West, R.C. Best Practices for RAP and RAS Management; Report #QIP 129; National Asphalt Pavement Association: Lanham, MD, USA, 2015. [Google Scholar]

- McDaniel, R.S.; Anderson, R.M. Recommended Use of Reclaimed Asphalt Pavement in the Superpave Mix Design Method: Technician’s Manual; Report #D9-12 FY ’97; National Research Council (US), Transportation Research Board: Washington, DC, USA, 2001. Available online: https://rosap.ntl.bts.gov/view/dot/15417 (accessed on 11 March 2024).

- Al-Qadi, I.L.; Elseifi, M.; Carpenter, S.H. Reclaimed Asphalt Pavement—A Literature Review. FHWA-ICT-07-001. 2007. Available online: https://www.ideals.illinois.edu/items/46016 (accessed on 11 March 2024).

- Copeland, A. Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice; FHWA-HRT-11-021; Federal Highway Administration: Washington, DC, USA, 2011. Available online: https://rosap.ntl.bts.gov/view/dot/40918 (accessed on 11 March 2024).

- Tran, N.H.; Taylor, A.; Willis, R. Effect of rejuvenator on performance properties of HMA mixtures with high RAP and RAS contents. NCAT Rep. 2012, 1, 12–15. [Google Scholar]

- Krishna Swamy, A.; Mitchell, L.F.; Hall, S.J.; Daniel, J.S. Impact of RAP on the volumetric, stiffness, strength, and low-temperature properties of HMA. J. Mater. Civ. Eng. 2011, 23, 1490–1497. [Google Scholar] [CrossRef]

- Li, X.; Clyne, T.R.; Marasteanu, M.O. Recycled Asphalt Pavement (RAP) Effects on Binder and Mixture Quality; MN/RC–2005-02; Minnesota Department of Transportation: Saint Paul, MN, USA, 2004. [Google Scholar]

- Yan, T.; Mariette, E.; Turos, M.; Marasteanu, M. Evaluation of physical hardening and oxidative aging effects on Delta Tc of asphalt binders. Road Mater. Pavement Des. 2023, 24 (Suppl. 1), 626–639. [Google Scholar] [CrossRef]

- Sharma, B.K.; Ma, J.; Kunwar, B.; Singhvi, P.; Ozer, H.; Rajagopalan, N. Modeling the Performance Properties of RAS and RAP Blended Asphalt Mixes Using Chemical Compositional Information; Illinois Center for Transportation Series No. 17-002; FHWA-ICT-17-001; University of Illinois at Urbana-Champaign, Illinois Center for Transportation: Rantoul, IL, USA, 2017. Available online: https://rosap.ntl.bts.gov/view/dot/32024 (accessed on 11 March 2024).

- Asphalt Institute Advisory Board. State-of-the-Knowledge: Use of the Delta Tc Parameter to Characterize Asphalt Binder Behavior; Asphalt Institute Technical Document, IS-240; Asphalt Institute Advisory Board: Lexington, KY, USA, 2019; ISBN 978-1-934154-77-9. [Google Scholar]

- Deef-Allah, E.; Abdelrahman, M. Evaluating the low-temperature properties of asphalt binders extracted from mixtures containing recycled materials. Period. Polytech. Civ. Eng. 2022, 66, 593–602. [Google Scholar] [CrossRef]

- AASHTO T240-23; Standard Method of Test for Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling Thin-Film Oven Test) (ASTM Designation: D2872-22). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2023.

- AASHTO R28-22; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO T313-22; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

| Original Binders (Virgin) | |

| Binder ID | PG Grading |

| V1 | PG 64-34 (FHR) |

| V2 | PG 64-28 (P66) |

| V3 | PG 58-28 (Valero) |

| V4 | PG 58-34 (FHR) |

| Reclaimed Asphalt Pavement (RAP) | |

| RAP ID | Source |

| R1 | 21-2159 31 KA 5850-01 |

| R2 | 21-2158 50-028 KA 5886 |

| R3 | 21-2157 54-106 KA 5843-01 |

| R4 | 21-2156 70-028 KA 5507-01 |

| V1 | V2 | V3 | V4 | ||

|---|---|---|---|---|---|

| RAP1 | 40% | W | C | C | W |

| 25% | S | C | S | W | |

| 15% | S | C | S | W | |

| RAP2 | 40% | W | C | C | C |

| 25% | W | C | W | C | |

| 15% | W | C | W | W | |

| RAP3 | 40% | W | C | W | C |

| 25% | S | W | W | W | |

| 15% | S | W | S | S | |

| RAP4 | 40% | S | W | W | W |

| 25% | S | W | W | S | |

| 15% | S | W | S | S |

| V1 | V2 | V3 | V4 | ||

|---|---|---|---|---|---|

| RAP1 | 40% | 355 | 396 | 410 | 261 |

| 25% | 207 | 318 | 367 | 170 | |

| 15% | 264 | 265 | 309 | 210 | |

| RAP2 | 40% | 197 | 228 | 248 | 153 |

| 25% | 179 | 249 | 272 | 146 | |

| 15% | 161 | 232 | 269 | 144 | |

| RAP3 | 40% | 265 | 250 | 322 | 212 |

| 25% | 238 | 274 | 249 | 145 | |

| 15% | 235 | 218 | 256 | 108 | |

| RAP4 | 40% | 245 | 294 | 353 | 230 |

| 25% | 202 | 271 | 314 | 150 | |

| 15% | 147 | 317 | 299 | 133 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darabi, M.; Matalkeh, B. The Effects of Reclaimed Asphalt Pavement Modification on the Delta Tc Parameter for PG58-XX and PG64-XX Asphalt Binders. Constr. Mater. 2025, 5, 17. https://doi.org/10.3390/constrmater5010017

Darabi M, Matalkeh B. The Effects of Reclaimed Asphalt Pavement Modification on the Delta Tc Parameter for PG58-XX and PG64-XX Asphalt Binders. Construction Materials. 2025; 5(1):17. https://doi.org/10.3390/constrmater5010017

Chicago/Turabian StyleDarabi, Masoud, and Bisher Matalkeh. 2025. "The Effects of Reclaimed Asphalt Pavement Modification on the Delta Tc Parameter for PG58-XX and PG64-XX Asphalt Binders" Construction Materials 5, no. 1: 17. https://doi.org/10.3390/constrmater5010017

APA StyleDarabi, M., & Matalkeh, B. (2025). The Effects of Reclaimed Asphalt Pavement Modification on the Delta Tc Parameter for PG58-XX and PG64-XX Asphalt Binders. Construction Materials, 5(1), 17. https://doi.org/10.3390/constrmater5010017