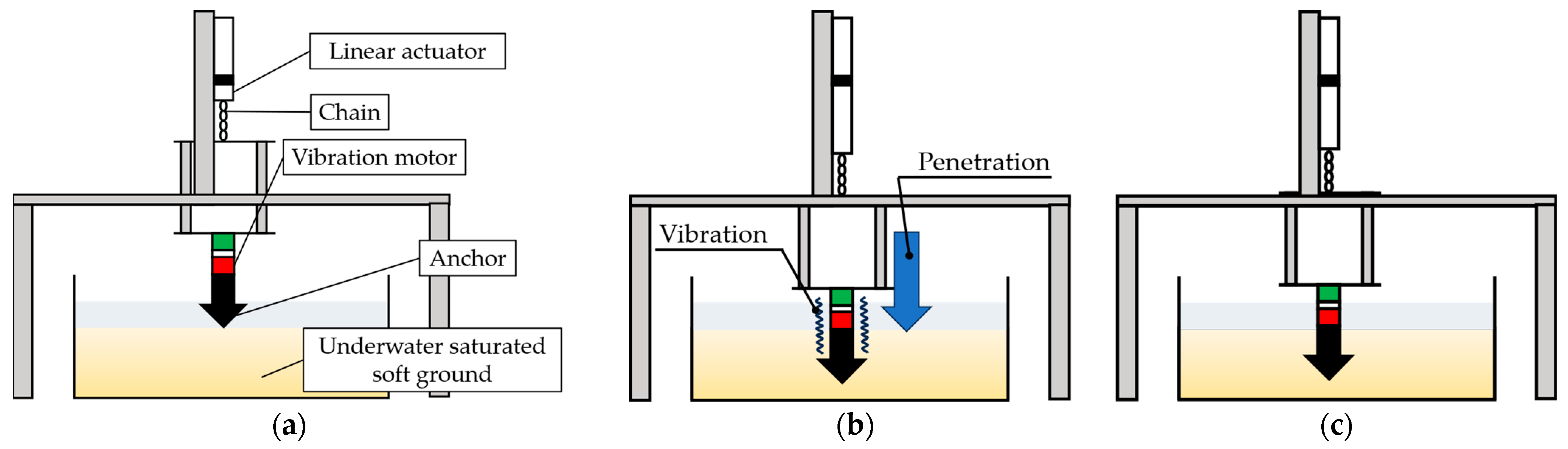

4.1. Experimental Setups and Procedures of Vibratory Penetration Experiments

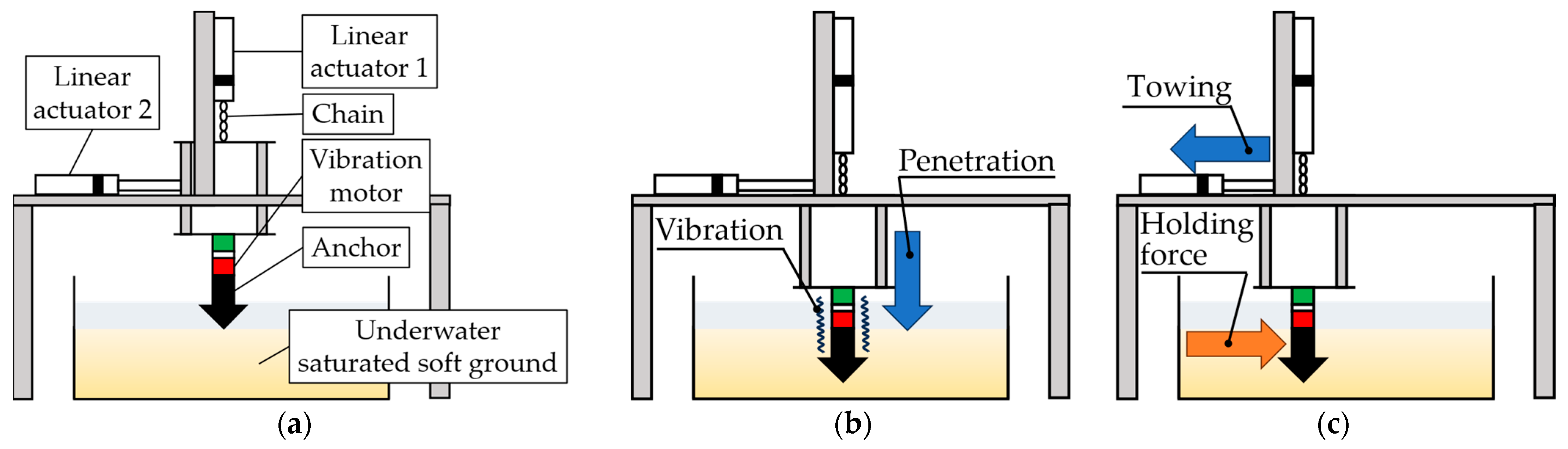

To investigate the influence of vibration on the penetration of composite-shaped anchors in underwater saturated soft soil, the experimental setup shown in

Figure 9 was used. As illustrated in

Figure 9a, the system consists of composite-shaped anchors with different tip angles, a linear actuator to control the vertical position of the anchor, a chain connecting the actuator to the anchor, a vibration motor attached to the anchor, and a soil container filled with a mixture of water and sand to simulate saturated soft ground.

The experimental procedure is summarized as follows: First, the anchor was positioned at the initial location (

Figure 9a). Next, the anchor was embedded into the saturated soft soil while applying vibration (

Figure 9b). After a specified time, both the vibration and penetration were stopped, and the final penetration depth was measured (

Figure 9c).

In addition, the time-dependent penetration resistance was recorded to evaluate the effect of vibration during penetration.

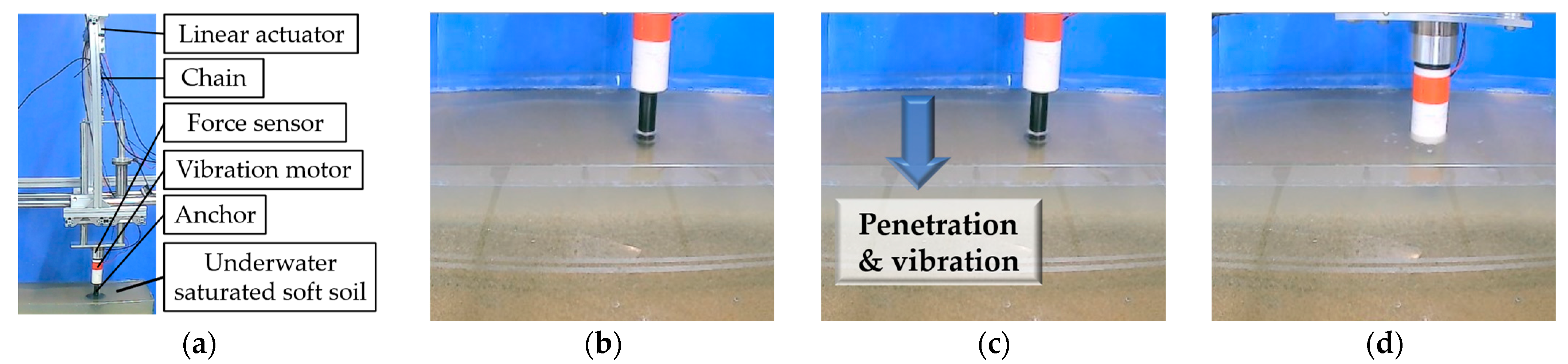

Based on the schematic of the experimental apparatus shown in

Figure 9a, the actual experimental setup is illustrated in

Figure 10a. The setup consisted of a PLA anchor with tip angles of 45, 60, 75, and 90°, suspended from a linear actuator via a chain. The actuator controlled the vertical motion of the anchor, and the chain length determined the initial position. The anchors were attached to a vibration motor and a force sensor. The vibration motor applied vibration to the anchors, and its intensity was regulated by the supplied voltage. The force sensor measured penetration resistance. The experiments were conducted on underwater saturated soft ground prepared with tap water and No. 5 silica sand. In addition, penetration resistance depends on the effective unit weight of sand and is therefore not influenced by water depth, provided that the sand is fully saturated. Accordingly, in this study, the soil bed was prepared with a water depth of 400 mm and a sand bed thickness of 350 mm to ensure full saturation. The specifications of the experimental apparatus are summarized in

Table 4.

Step 1: The anchor is positioned just above the soil surface (

Figure 10b). The anchor is suspended from the actuator by chains.

Step 2: Vibration is initiated by applying voltages of 0, 20, and 30 V to the motor. The corresponding vibration accelerations are 0, 8.99, and 14.4 m/s

2, respectively, and are summarized in

Table 5 together with other vibration parameters.

Step 3: The linear actuator extends downward while vibration is maintained, loosening the chain. This allows the anchor to penetrate the soil under its own weight of 36 N (

Figure 10c). The penetration process lasts for 30 s.

Step 4: After 30 s, the vibration motor and the linear actuator are stopped (

Figure 10d). The final penetration depth is then measured.

Step 5: The anchor returns to its initial position, and the soil surface is leveled.

Following the procedure above, five repeated trials were conducted for each test condition, defined by combinations of anchor shape and vibration. In addition, the variation in penetration resistance over time is also measured using the force sensor.

4.2. Experimental Results and Consideration of Vibratory Penetration Experiments

The results of the previous experiments are shown in

Figure 11 and

Figure 12 and

Table 6.

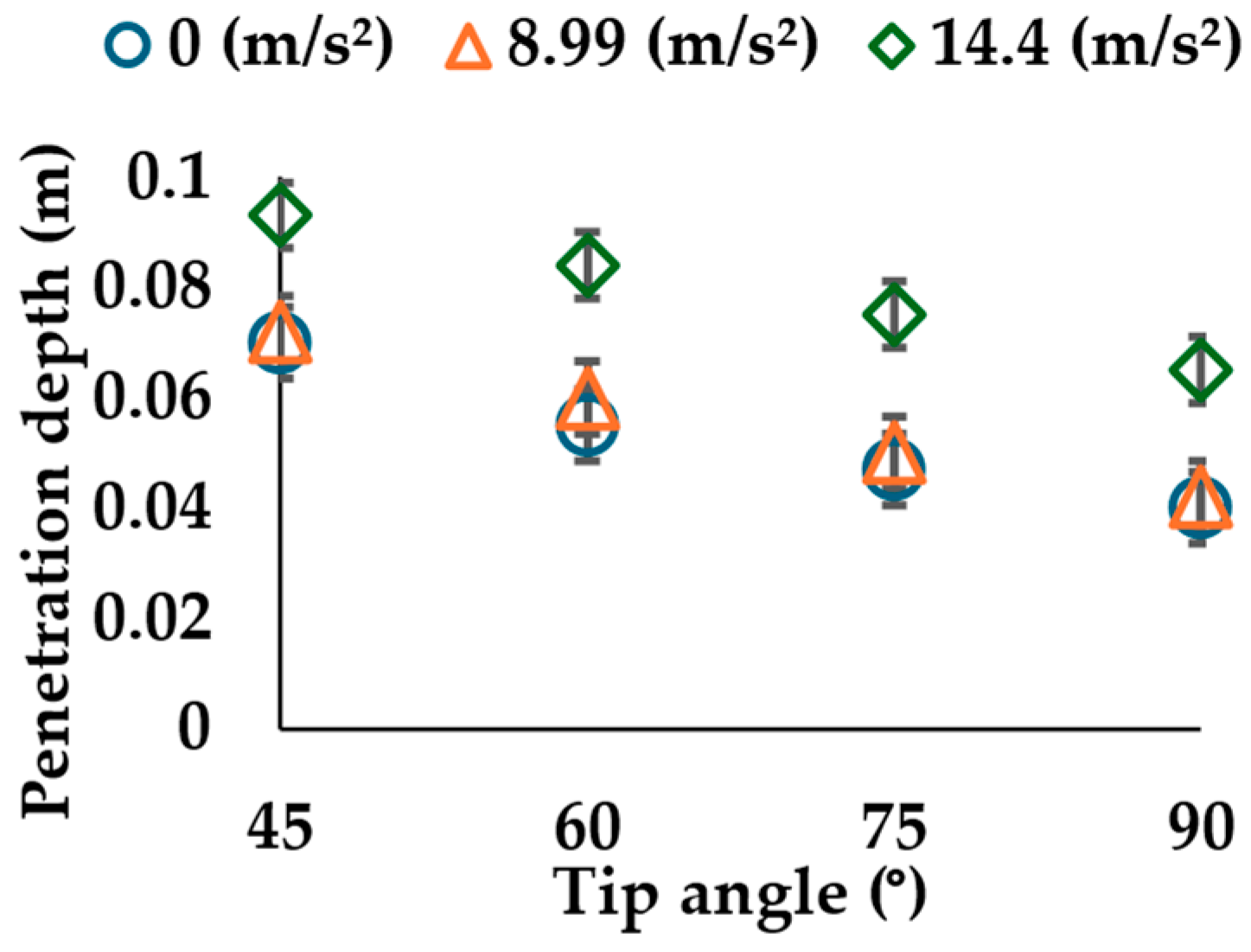

Figure 11 illustrates the relationship between tip angle and penetration depth under different vibration accelerations. Additionally,

Table 6 summarizes the results of

Figure 11 together with the target depth required for the anchor to achieve a holding force of 15.5 N and the theoretical depth achievable under a thrust of 36 N, as calculated in

Section 3.3. Furthermore,

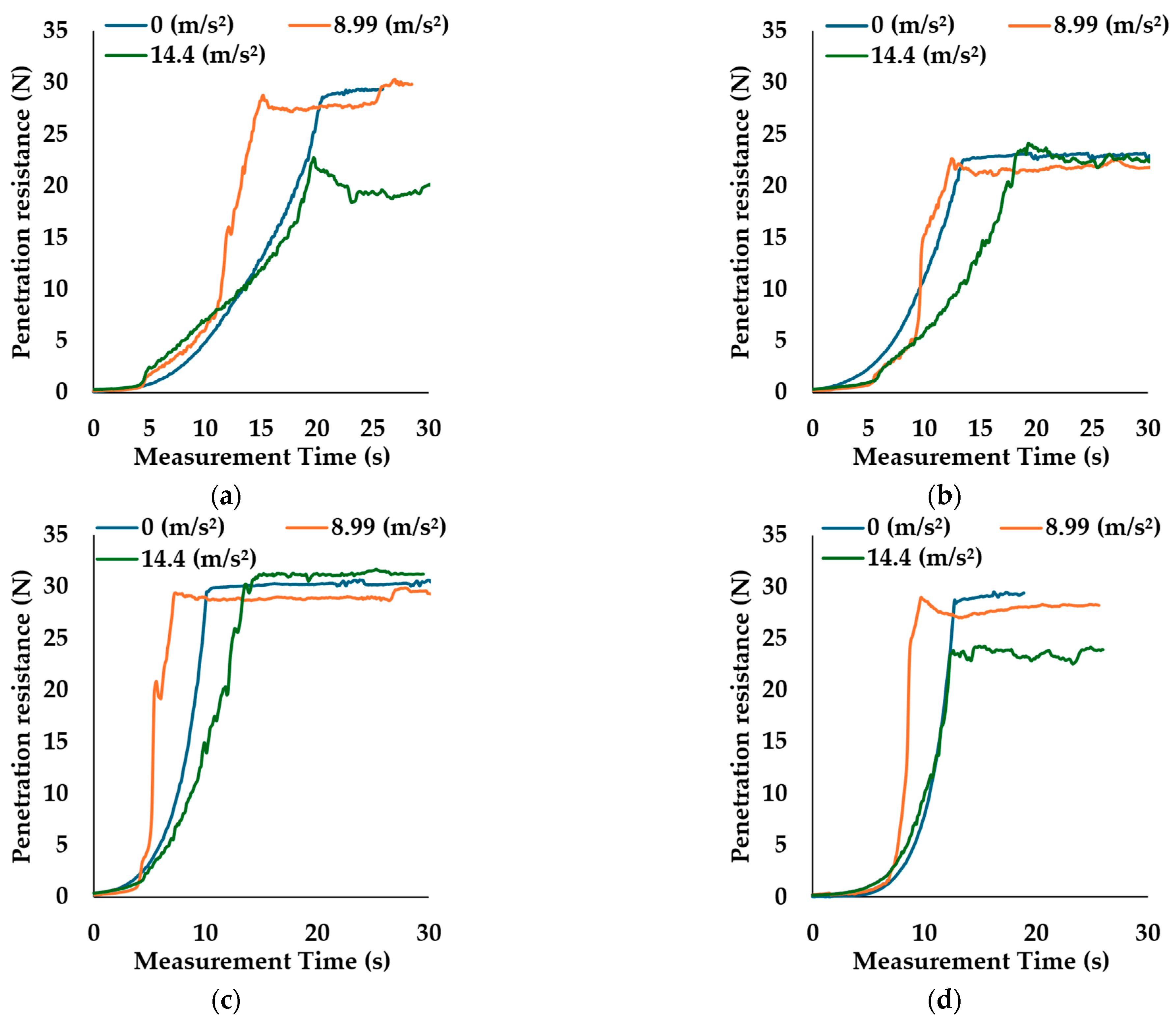

Figure 12 illustrates the relationship between the measurement time and penetration resistance under different vibration accelerations. Specifically,

Figure 12a–d correspond to tip angles of 45, 60, 75, and 90°, respectively.

These figures and the table show the following results.

Figure 11 shows that penetration depth decreases with increasing tip angle, indicating that sharper tips embed more effectively. In addition, vibration enhances penetration. This increase becomes larger at higher vibrations, as observed from the difference between the depths of 8.99 m/s

2 and the depths of 14.4 m/s

2. These findings indicate that the penetration depth increases with decreasing tip angle and increasing vibration intensity.

Table 6 shows that all anchors reach the target depth with 14.4 m/s

2. In contrast, all anchors failed to reach the target depth for anchoring under 0 m/s

2 and 8.99 m/s

2. This means that sufficient penetration depth is difficult to achieve under non-vibratory or weak vibratory conditions. Additionally, the anchors with tip angles of 45, 60, and 75° failed to reach the theoretical depth under any vibration level. This result suggests that additional factors may have raised penetration resistance, thereby limiting the embedment depth. In contrast, the angle of 90° can penetrate over the theoretical depth even without the application of vibration, implying that another factor reduces resistance.

Figure 12 presents some results on the effect of vibration on penetration resistance, which differ from those in

Figure 11 and

Table 6. The slope of the increase in resistance varies with vibration level. 8.99 m/s

2 condition shows relatively steep slopes, indicating that vibration increased the penetration speed. Conversely, 14.4 m/s

2 condition results in gentler slopes, indicating that vibration continuously reduces penetration resistance. Moreover, the final resistance values differed by tip angle. For example, 60 and 75° anchors show similar final resistance under both 0 m/s

2 and 14.4 m/s

2 conditions, as shown in

Figure 12b,c. In contrast, 45 and 90° anchors exhibit a significant difference in final resistance between 0 m/s

2 and 14.4 m/s

2, as shown in

Figure 12a,d. 60° anchor consistently converges to a lower resistance of approximately 25 N, further highlighting its unique penetration behavior. These differences show that tip angles affect vibratory penetration.

These experimental results allow for several considerations.

First, the results show that vibration lowers penetration resistance and may increase penetration speed. This effect becomes more pronounced with stronger vibration. In other words, strong vibration is considered to enable sufficient penetration with a smaller thrust.

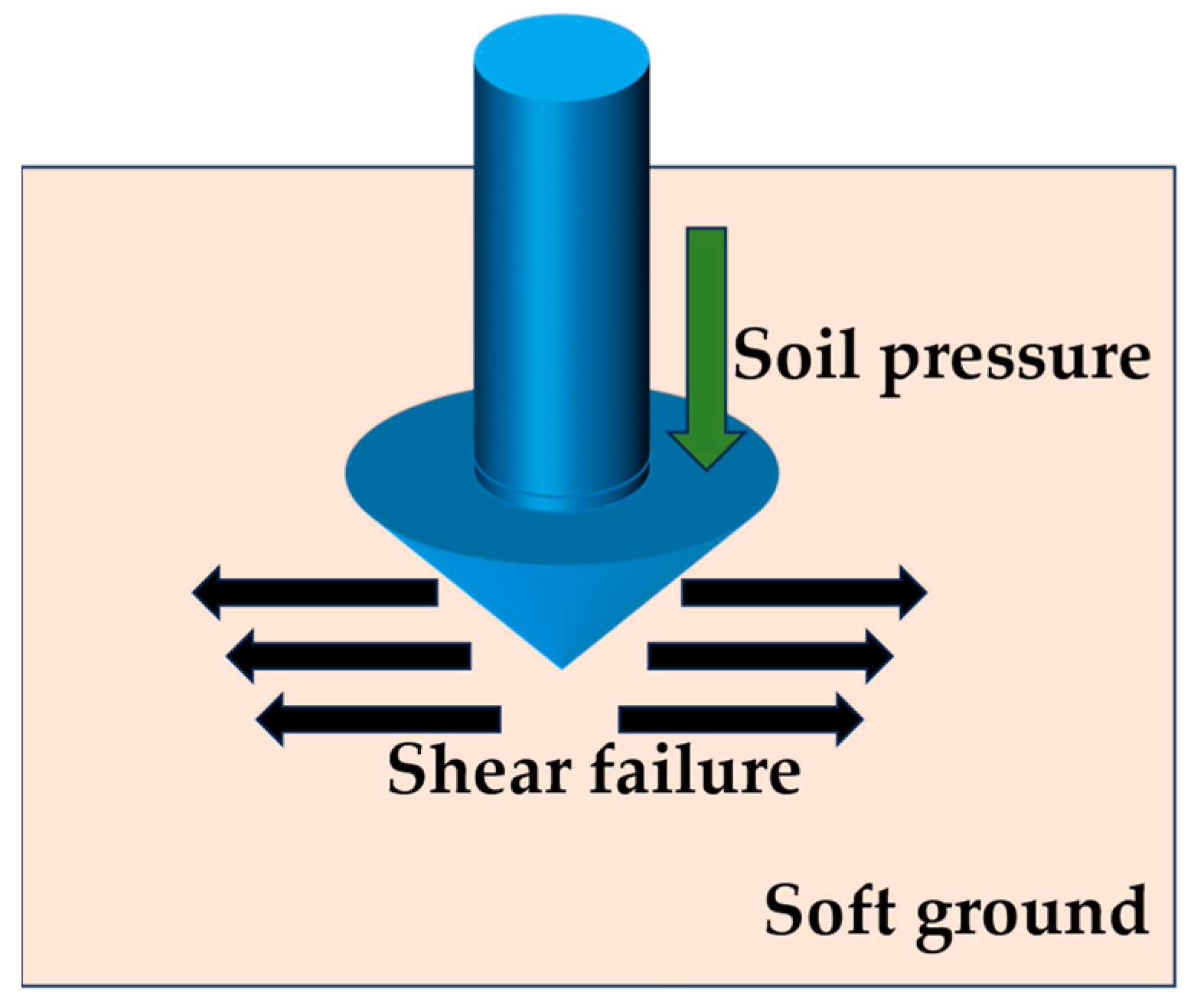

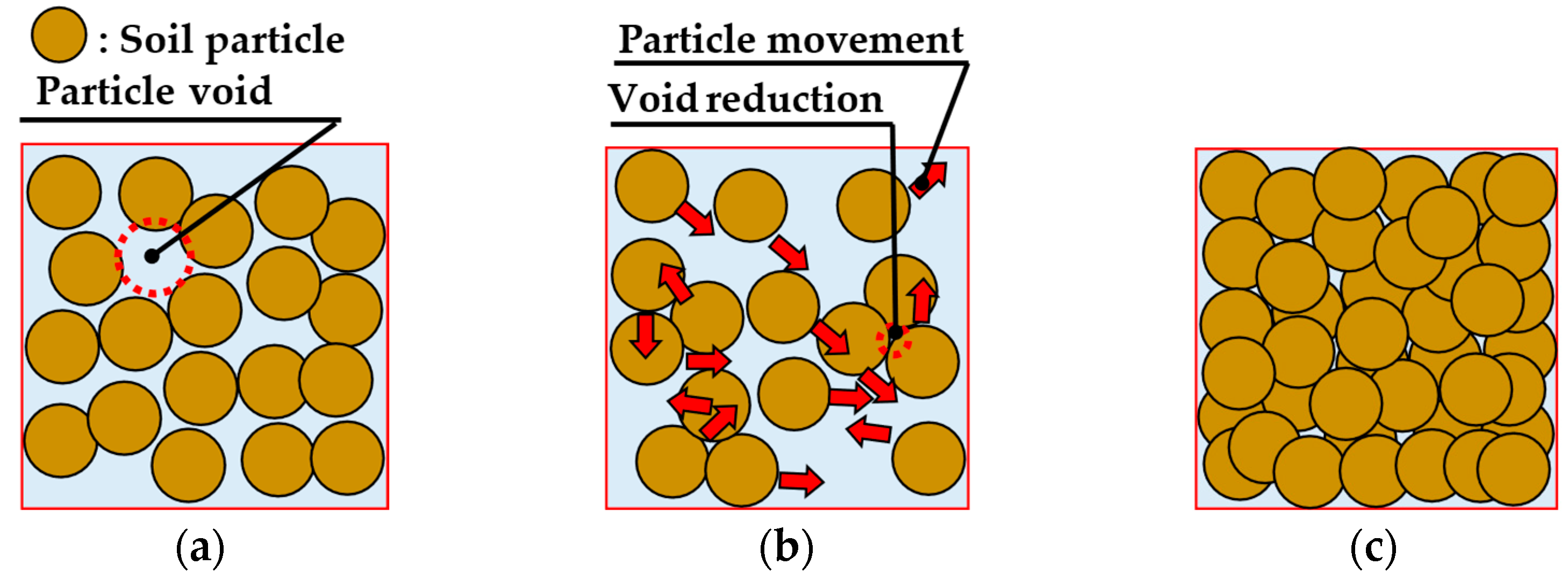

Next, the reasons for the discrepancy between the theoretical and experimental penetration depths are considered. One possible explanation is the lack of consideration of certain factors in the theoretical model. Among these factors, soil compression can be considered significant. During penetration, the soil beneath the anchor tip is subjected to force from the anchor, causing the soil to compress. This compression increases both the internal friction angle and the effective unit weight of the soil, thereby raising the penetration resistance and reducing the achievable penetration depth. On the other hand, in the case of the 90° anchor, the experimental penetration depth exceeded the theoretical value. This can be attributed to the omission of pore water pressure effects in the model, leading to an overestimation of effective stress. In the highly saturated surface layer of the soil, excessive pore pressure can significantly reduce effective stress, turning the soil into a fluid-like muddy state. This drastically weakened the strength of the surface layer and likely allowed the 90° anchor to penetrate deeper than expected. These results suggest that to accurately predict anchor penetration behavior in saturated soft soils, future analytical models should account for soil compressibility and moisture content per unit volume.

Finally, the differences in terminal penetration resistance due to tip angle are examined. As shown in

Figure 12b, the anchor with a tip angle of 60° consistently exhibited lower maximum resistance than those with other angles. This is considered to be attributable to the fact that the 60° anchor has a geometrically intermediate shape. Compared with sharper anchors such as 45°, stress concentration at the tip was smaller, making it difficult to induce sufficient shear failure. On the other hand, compared with blunter anchors such as 75° and 90°, the contact area with the soil was smaller, limiting the lateral displacement of the surrounding soil mass. As a result, neither stress concentration nor lateral deformation became dominant, leading to shallower penetration. At such shallow embedment depths, the soil resistance could not be fully mobilized, and consequently, the terminal resistance was reduced. Furthermore,

Figure 12a,c show that anchors with tip angles of 45 and 90° exhibited clear differences in terminal resistance between 0 m/s

2 and 14.4 m/s

2. This suggests that, even at the end of the experiments under vibration, the penetration process had not yet reached equilibrium, and the reduction in effective stress was still active. It is therefore inferred that deeper penetration could have been achieved if vibration had been applied for a longer duration. In contrast, anchors with tip angles of 60 and 75° showed almost no difference in terminal resistance between 0 m/s

2 and 14.4 m/s

2. This indicates that the effect of vibration had either already reached its limit or was constrained by the geometric characteristics of these anchors. From these results, it can be concluded that anchors with geometrically balanced shapes are less capable of sufficiently inducing soil failure mechanisms such as stress concentration and lateral displacement and therefore tend to reach the limit of vibratory effects at an earlier stage. Consequently, when vibratory penetration is employed, anchors with extreme geometries—either sharper or blunter—are more advantageous, as they are more likely to exhibit greater penetration effect.

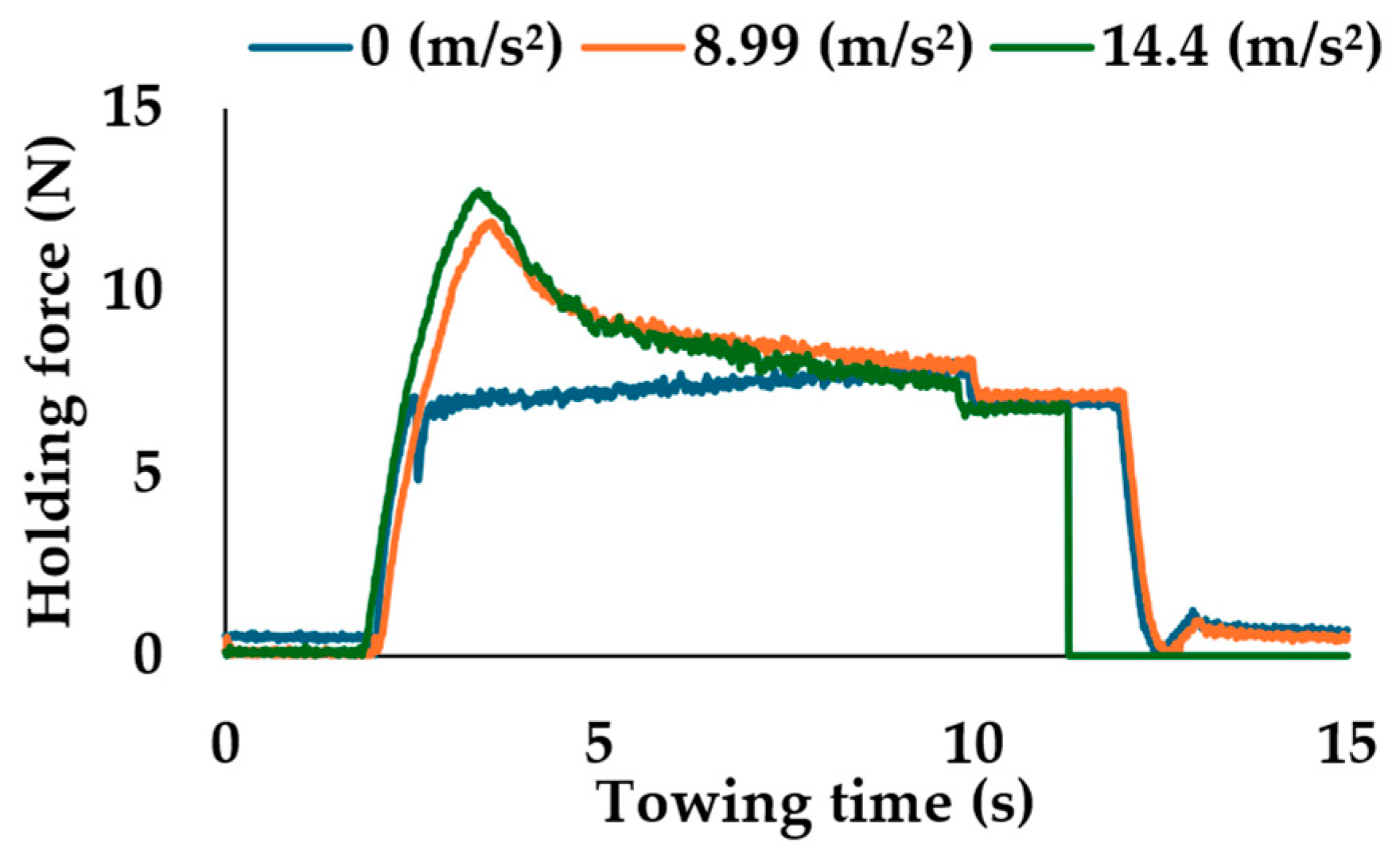

The next section examines whether the application of vibration enables sufficient penetration and provides the necessary force to secure the robot through towing tests. Additionally, the tests investigate whether tip angles affect the holding force.