1. Introduction

Nuclear energy continues to play a pivotal role in addressing energy shortages and reducing carbon emissions. Despite its contributions to energy production, nuclear energy faces the following significant challenge: the safe and enduring management of radioactive waste. With increasing awareness of environmental safety and the risks posed by radioactive materials, the importance of secure waste containment solutions has only heightened. The disposal of high-level waste (HLW), which contains long-lived radionuclides, requires stringent containment strategies spanning hundreds of thousands to millions of years to prevent harmful exposure to the environment and human health. Recognizing this urgency, governments and international bodies have established strict guidelines for the isolation and disposal of nuclear waste in deep geological repositories [

1].

Disposal requirements vary based on factors such as waste type, radionuclide inventory, and activity levels per unit of mass or volume, necessitating different time scales (as illustrated in

Table 1). High-level waste (HLW) requires significantly longer storage durations than low- or intermediate-level waste, with a widely accepted time horizon extending up to 1 million years (1 Ma) [

2]. If the radioactive waste is not managed appropriately and radionuclides are released into the environment, it will be harmful to humans and the ecosystem. Therefore, the disposal of radioactive waste to ensure its long-term safety is an important and urgent research topic.

The concept of geological repositories relies on a multi-barrier system designed to isolate radioactive waste, incorporating engineered barriers and natural barriers (host rocks), constituting a multi-barrier system (as shown in

Table 2) [

2]. The long-term management of radioactive waste often entails its disposal in deep geological repositories situated in low-permeability rock formations, like granite, claystone, or salt. The waste is securely enclosed in copper or steel canisters and stored in repositories constructed 250 to 1000 m beneath the Earth’s surface [

3].

Gas production arises from the decomposition of radioactive waste and the corrosion of canisters. Thus, underground repositories are usually located in geological media with low permeability to minimize hydraulic conductivity and manage gas generation and migration within both engineered and natural barriers. This control is essential to limit radionuclide movement, as gas-induced fractures could otherwise compromise barrier integrity. Consequently, a comprehensive understanding of clay-rich formations and minerals is critical to ensuring long-term containment effectiveness [

4].

Several countries have identified low-permeability geological formations suitable for waste containment, including clays, crystalline rocks, and salt deposits, as follows:

Belgium: In Belgium, the plastic Boom Clay serves as a potential host rock. At the Mol-Dessel nuclear site, the Boom Clay, deposited approximately 30 million years ago, lies 190–290 m beneath the surface. The undisturbed Boom Clay formation, characterized by extremely low hydraulic conductivity and a minimal hydraulic gradient, primarily facilitates the migration of liquids, dissolved gases, and solutes through diffusion. Between the host rock and the canister, it was planned to be filled with clay-rich blocks. Compacted MX80 bentonite was chosen as the sealing element for a demonstration experiment [

5].

France: In the 1990s, the French National Radioactive Waste Management Agency (Andra) initiated studies on the Callovo-Oxfordian claystone (COx) as a potential host rock, citing its extremely low hydraulic conductivity. In 2000, Andra started constructing the Meuse/Haute-Marne underground research laboratory (MHM URL) to study COx claystone, located 420 to 550 m underground. The goals were to characterize the claystone’s confining properties and demonstrate that constructing and operating a geological repository would not create pathways for radionuclide migration. The repository layout involves horizontally drilled storage cells with multiple canisters arranged consecutively and sealed with COx clay and a cement plug. Mineralogical changes are expected at the interface between the bentonite and cement [

6].

Germany: Considerations encompass salt, argillaceous rocks, and crystalline rocks as potential host rocks. Hoth et al. [

7] conducted an evaluation of Germany’s argillaceous rock formations for high-level waste (HLW) disposal. Salt formations, proposed in both Germany and the United States, exhibit even lower hydraulic conductivity than clay rocks, alongside favorable properties such as creep and self-sealing. Additionally, salt possesses considerably higher thermal conductivity, thereby facilitating efficient heat transfer [

2].

Sweden: The Swedish Nuclear Fuel and Waste Management Company (SKB) developed technology aiming to isolate the metal canister from crystalline host rock using highly compacted bentonite blocks. In their repository concept, canisters are vertically positioned on the bentonite blocks and completely encircled by bentonite rings. A cement block seals the upper bentonite plug, and the galleries are subsequently filled with backfill material. For an extensive period, SKB concentrated on investigating the Wyoming bentonite MX80 [

8,

9].

Finland: Posiva Oy in Finland manages the site selection, construction, and operation of a permanent repository. The Finnish repository concept closely resembles the Swedish model, with site investigations carried out at the underground rock characterization facility in Olkiluoto [

2].

Switzerland: Three geological siting regions—Zürich Nordost, North of Lägern, and Jura Ost—are identified as potential sites for high-level waste repository, all featuring Opalinus Clay as the host rock [

10]. According to the disposal concept proposed by the national cooperative for radioactive waste [

11], canisters rest on a foundation of densely compacted bentonite blocks, while the remaining space above is filled with pellets of highly compacted bentonite. Nagra [

11] considers bentonite an appropriate interface between disposal containers and the host rock, possessing advantageous radionuclide retention properties that contribute to the long-term stability of the disposal containers.

The study of gas generation within nuclear waste repositories and its impact on repository integrity has been a long-standing focus in radioactive waste management [

12]. Gas generation arises from various processes, including anaerobic corrosion of metal canisters, which produces hydrogen (H

2); organic matter degradation, releasing carbon dioxide (CO

2) and methane (CH

4); and radiolysis of water, yielding primarily H

2 [

13,

14]. Over time, the accumulation of these gases could eventually generate pressures that may compromise the integrity of engineered barriers or the surrounding host rock. Therefore, understanding gas migration within low-permeability geological media is essential for accurately predicting repository behavior over extended timescales and ensuring long-term containment integrity [

4].

A detailed assessment of the gas kinetics near the source is crucial to determining the potential for gas formation and hydrogen evolution within the repository. As part of the Fate Of Repository Gases (FORGE) project, researchers specifically investigated hydrogen generation resulting from the corrosion of carbon steel components. The results show that hydrogen generation rates can be extremely high during the early phase of corrosion, until a protective layer develops on the metal surface [

15]. In addition, factors such as oxygen content, temperature, and water/solid chemistry still introduce uncertainties affecting both corrosion and hydrogen production rates [

16].

Gas buildup and its release within the repository system can impact vital processes that govern long-term safety. Elevated gas pressures may eventually impair the engineered barrier system or the host rock and alter the flow of groundwater, potentially impacting the movement of dissolved radionuclides. Additionally, some of the gases generated may be radioactive, posing a radiological hazard if released into the biosphere. Therefore, comprehensive evaluation of all processes related to repository performance and safety is crucial to instilling confidence in safety assessments [

17].

Clays, especially bentonites, are well-suited as engineered barriers in host rocks due to their favorable properties. Gas permeability in clay materials have been extensively studied. For example, Zhang and Rothfuchs [

18] investigated steady-state gas flow in air-dried Callovo-Oxfordian argillite samples, finding that gas permeability varied by an order of magnitude between flows parallel and perpendicular to bedding planes. Similarly, Renner et al. [

19] conducted steady-state gas flow tests on cretaceous marls and tertiary shales from the Alps, observing a significant 1.5-order-of-magnitude change in permeability with a 30 MPa increase in confining stress. Additionally, Uehara and Shimamoto [

20] reported permeability changes of two orders of magnitude under shear stress in cataclastic rocks.

Furthermore, Harrington et al. [

21] conclusively demonstrated the formation of temporary, dilatant gas pathways in Boom Clay, a proposed clay-based host rock. The researchers injected nanoparticulate tracers with helium gas into the Boom Clay sample and observed the presence of these dilatant pathways using visual and optical microscopes. This technique constitutes a novel diagnostic tool for identifying multiphase flow processes, which is invaluable for robust, long-term assessments of repository performance.

Following the formation of dilatant pathways, the behavior of gas within low-permeability clay shows additional complexities. Once gas injection is stopped, gas pressure declines to a finite asymptotic threshold value, below which no flow occurs. Upon re-establishment of flow, breakthrough pressure is much lower than in undisturbed clay, indicating the presence of residual gas-filled voids along the migration path [

12]. In addition, bubbly gas seepage flow in a porous matrix is an intriguing phenomenon, particularly for discrete gas migration through water-saturated, loosely compacted soils near the surface. Ma et al. [

22] developed a mathematical model to simulate bubbly gas seepage flow in a porous matrix. The model incorporates the effects of bubble size, gas–liquid interactions, and the influence of matrix permeability to better understand and predict the behavior of gas seepage in porous materials.

Projects like FORGE and DECOVALEX have substantially advanced experimental techniques and numerical modeling, deepening our understanding of gas migration and fracture development in low-permeability media. Integrating experimental data with numerical simulations using tools like TOUGH and CODE_BRIGHT enhances prediction accuracy for gas flow, fracture pathways, and repository performance under varied scenarios. As nuclear energy remains essential to the global energy mix, safe radioactive waste disposal fuels interdisciplinary collaboration and drives innovation to tackle these complex challenges.

This review paper is systematically organized into five sections. The introduction highlights the importance of nuclear waste containment and the challenges posed by gas generation and migration in engineered and natural barriers. The

Section 2 explores the four main gas transport mechanisms—diffusion, visco-capillary flow, dilatancy-controlled flow, and tensile fractures. The

Section 3 critically examines large-scale projects like GMT, FORGE, and DECOVALEX, analyzing their methodologies, findings, and limitations. The

Section 4 evaluates advanced numerical tools (TOUGH, phase-field method, and CODE_BRIGHT) and their capabilities in simulating coupled thermo-hydro-mechanical processes, heterogeneity, and fracture dynamics. Finally, the conclusion part synthesizes key insights, identifies knowledge gaps, and proposes directions for further research, emphasizing interdisciplinary collaboration and innovative modeling approaches.

3. Field Testing and Experiments

3.1. Gas Migration Test

The gas migration test (GMT) is a pioneering large-scale in situ experiment that explores the migration of gas generated from low- and intermediate-level waste in a silo-type disposal system [

37,

38]. It aims to understand how gas interacts with the engineered barrier system (EBS) and migrates through both the EBS and the excavation damaged zone (EDZ). The excavation damaged zone refers to the region of rock surrounding an underground excavation where the mechanical and hydraulic properties have been altered due to stress redistribution, fracturing, and microstructural damage caused during construction. The GMT project involves saturating the geotechnical barrier with water and then injecting gas into the storage chamber. Using appropriate instrumentation, the two-phase flow is analyzed, and the data are used to understand the processes and calibrate numerical simulation models. Note that the GMT experiment employed a comprehensive sensor network to monitor gas migration pathways, pressure, saturation, and mechanical responses in the EBS and surrounding geosphere. Key components include pressure sensors, temperature sensors, time-domain reflectometers, multi-packer systems, gas tracers, and borehole instrumentation. The primary goals of GMT are the following:

- (1)

Evaluate the overall performance of the EBS and surrounding geosphere as a system concerning repository-generated gas migration;

- (2)

Assess conceptual and numerical models of gas migration through barriers under realistic in situ conditions;

- (3)

Gather data to enhance EBS design for managing gas migration, including vent integration;

- (4)

Demonstrate the construction and emplacement of an ILW-silo system under realistic in situ conditions.

The GMT field test, spanning six years from 1998, involved multiple stages, as follows: (1) excavating the access drift and silo cavern, (2) construction and instrumentation, (3) EBS saturation, (4) water testing, (5) long-term nitrogen gas injection at varying rates, (6) post-gas water testing, (7) gas injection using a tracer “cocktail”, and (8) depressurization followed by dismantling.

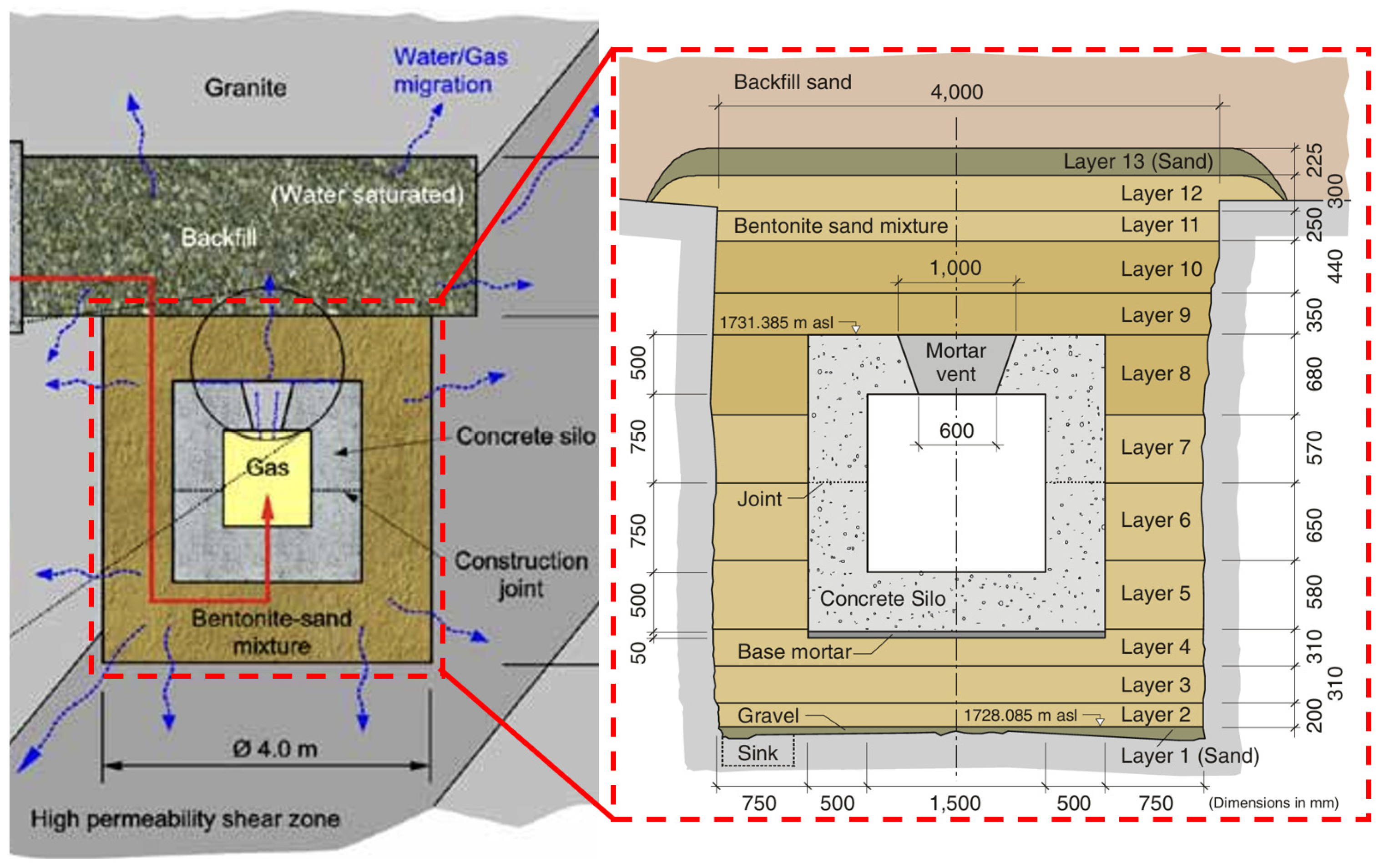

The components of the field experiment (as shown in

Figure 2) included a 4.5 m deep, 4.0 m diameter silo cavern; a 2.5 m high concrete silo with a 2.5 m external diameter; a vent atop the concrete silo; bentonite/sand backfill surrounding the silo; and sand/gravel backfill in the cavern’s upper section. The bentonite/sand was placed in compacted layers, with monitoring instruments positioned at various levels. Gas was injected at the concrete silo’s center, and its breakthrough and migration through the engineered barriers and surrounding geosphere were monitored [

38].

The GMT field test demonstrated key behaviors of gas migration in engineered barriers, where nitrogen injection at a 4.5 MPa overpressure led to breakthrough in a sand/bentonite buffer (20% bentonite and 80% sand). Gas preferentially migrated along interfacial pathways due to stress-dependent permeability changes, with flow rates stabilizing at 0.1–0.3 mL/min post-breakthrough, suggesting limited pathway dilation. Notably, less than 1% of the porewater was displaced, confirming the buffer’s low hydraulic conductivity. These results indicate that the EBS effectively restricted gas migration, primarily through interfacial flow rather than bulk matrix penetration. However, the test’s 6-year duration insufficiently captured long-term gas accumulation effects, and the simplified homogeneous buffer design overlooked field-scale heterogeneity (e.g., density variations), highlighting a need for extended and more realistic experimental conditions.

The GMT experiment revealed complex two-phase flow behavior, indicating coupled hydromechanical processes involved in gas migration through the sand/bentonite buffer. The EBS responses revealed significant interaction with the surrounding geosphere, influenced by the balance of water injection and loss from the upper cavern and gas escape. The key findings of the GMT experiment are summarized as follows [

40]:

The disposal system:

- (1)

The bentonite/sand mixture formed a stable, low-permeability buffer;

- (2)

Gas escaped the EBS with relatively low overpressure;

- (3)

Minimal water was expelled from the concrete silo.

Geosphere:

- (1)

Natural sealing processes reduced leakage from the GMT cavern during the experiment;

- (2)

Although some gas may have migrated into sections of the geosphere, it largely acted as a barrier to gas migration;

- (3)

Heterogeneity within the geosphere had a limited effect on EBS saturation.

Gas migration in a composite system:

- (1)

Interfaces played a significant role in gas migration, associated with channeled flow;

- (2)

Interpreting results requires considering coupled two-phase flow and mechanical processes.

However, some aspects still need further investigation. For instance, the pressure difference between the silo and the upper cavern and sand/bentonite requires clarification. Additionally, the reduced permeability observed in the sand/bentonite buffer might result from compaction due to pressure decline after the initial gas test. A numerical model of the GMT was developed using the two-phase flow code TOUGH2, which is described in the next chapter.

3.2. FORGE

The FORGE project is a pan-European initiative involving international radioactive waste management organizations, regulators, and academia that tackles critical research topics related to gas generation and migration in repositories. It has supplied experimental data to help reduce uncertainties in the quantitative analysis of gas in performance assessments. This was accomplished through a series of laboratory and field-scale experiments conducted at multiple European underground research facilities, along with modeling and the development of new up-scaling methods to optimize repository concepts through detailed scenario analysis. Overall, the primary focus of the FORGE Project is to deepen understanding of gas behavior in radioactive waste disposal.

The Large-Scale Gas Injection Test (Lasgit) was a full-scale experiment conducted in the Äspö Hard Rock Laboratory (

Figure 3). Current knowledge of gas movement in bentonite barriers largely comes from small-scale lab studies focused on specific issues. While these studies have greatly advanced understanding, uncertainties remain, especially regarding the scale effects on gas migration mechanisms within bentonite. Lasgit was conducted to investigate these scale effects, closely following the Swedish concept of vertical borehole emplacement. Gas was injected into the bentonite barrier through a copper container, with hydraulic and mechanical processes monitored by various sensors. Lasgit aimed to conduct gas injection tests in a full-scale KBS-3 deposition hole, generating quantitative data to improve process understanding and validate modeling approaches for potential use in performance assessments.

The Lasgit experiment spanned 5782 days (over 15 years) and comprised the following three phases: installation, hydration, and gas injection. The installation phase (2003–2005) involved designing, constructing, and emplacing the necessary infrastructure [

42]. The hydration phase began on 1 February 2005, with the closure of the deposition hole to fully saturate and equilibrate the buffer. Once fully hydrated, the main gas injection phase began in 2007, featuring detailed gas injection tests to examine gas flow processes within the bentonite barrier. Lasgit was conducted in deposition hole DA3147G01, measuring 8.5 m in length and 1.75 m in diameter. A full-scale KBS-3 canister was modified with twelve circular filters of different sizes to serve as point sources for gas injection, simulating potential canister defects. These filters facilitated water injection during hydration and gas injection during testing.

A total of seven gas injection tests were performed, with tests GT1, GT2, GT4, and GT6 conducted near the base of the canister in filter FL903 and tests GT3 and GT5 in filter FU910 toward the top. The seventh FCT test was performed through a filter at the base of the canister. Early tests (GT1 and GT2) indicated small precursor gas flows into the bentonite during a state of porewater pressure and stress disequilibrium. However, gas inflow rates were significantly reduced when the gas pressure was held constant, suggesting limited pathway growth. In all tests, gas injection led to increased gas pressure. As the bentonite matured and approached hydraulic equilibrium, the peak gas pressure systematically increased, typically equaling or exceeding local total stress.

The FORGE project’s Lasgit experiment revealed critical insights into gas migration through compacted bentonite, where breakthrough required injection pressures exceeding local total stress (≥8 MPa) to initiate pathways. Episodic flow dynamics were observed, characterized by pressure peaks (9–10 MPa) followed by abrupt declines, indicative of self-sealing behavior in dilatant pathways (

Figure 3). Pre-hydration of the bentonite significantly reduced gas permeability by two orders of magnitude, underscoring the role of clay swelling in inhibiting flow. These findings confirm that gas migration in bentonite is highly localized and transient, without inducing sustained desaturation of the buffer material. However, the experiment’s 15-year duration remains insufficient to fully assess repository-relevant timescales (≥1000 years), and the potential for particle detachment (colloid loss) during gas migration was not quantified, representing a key limitation for long-term safety assessments.

The Lasgit experiment confirmed the coupling between gas, stress, and pore-water pressure for flow before and after major gas entry at the field scale. Observations suggest that pathway propagation and dilatancy mechanisms predominate. Gas migration took place via localized pathways, typically moving downward in the deposition hole following the dominant stress gradient. Evidence indicates a highly dynamic, complex network of pressure-induced pathways within the clay that evolve over time and space, opening and closing in response to local variations in gas pressure or effective stress.

The main conclusions of the Lasgit experiment can be summarized as follows:

Peak gas pressure is influenced by the buffer’s hydraulic permeability and how easily gas can escape from the deposition hole;

Gas moves through a few dilatant pathways, which are small relative to the total buffer volume and temporally variable;

No desaturation of the bentonite buffer due to gas transport was observed;

Gas pathways are anticipated to gradually close once a finite “shut-in” pressure is reached;

Gas migration through bentonite is unlikely to significantly affect the barrier’s favorable hydromechanical properties.

However, the following several aspects remain unclear:

The effect of long-lasting heterogeneities within the bentonite on gas pressure is still uncertain.

The process of clay particles attachment to a gas phase and a subsequent loss of buffer material was not studied.

Self-sealing behaviors of the tested bentonite sample need to be further examined.

3.3. DECOVALEX

The DECOVALEX (Development of COupled models and their VALidation against EXperiments) project was initiated in 1992 to address the modeling challenges related to coupled thermal, hydrological, mechanical, and chemical (THMC) processes. This international collaborative project brings together nuclear waste organizations, including implementers, regulators, and supporting research and modeling teams. The project runs in four-year phases, each tackling key modeling challenges essential to radioactive waste disposal through theoretical, numerical, laboratory, and field studies.

During the first six phases, the project focuses on (1) supporting the development of numerical simulators for THM and THMC processes in geological systems; (2) investigating and implementing effective algorithms for THM and THMC modeling; (3) comparing model predictions with field and laboratory experimental results; (4) designing new experiments to advance code and model development; and (5) applying THM and THMC modeling to assess the performance and safety of nuclear waste repositories [

43]. Research on gas migration in low-permeability clay materials has primarily been conducted in the DECOVALEX-2019 (2016–2019) and DECOVALEX-2023 (2020–2023).

In DECOVALEX-2019, task A aims to deepen understanding of the processes governing gas advective movement in two low-permeability materials: (i) compacted bentonite and (ii) natural host rock. To support this task, new numerical models for predicting gas fluxes have been developed and tested through staged laboratory experiments, each increasing in complexity in both experimental setup and modeling approach. These models provide valuable tools for assessing the impact of gas flow on barrier and host materials, offering insights relevant to the design of future repositories. In addition, experience gained from task A has direct applications to other clay-based engineering challenges involving advective gas flow [

44].

This task incorporated two experiments conducted by the British Geological Survey (BGS), with the gas migration apparatus illustrated in

Figure 4. The first experiment involved a 1D gas injection test on a compacted bentonite sample, while the second experiment featured a spherical gas injection test on a similar sample [

45,

46]. A key difference between the 1D and spherical injection tests is the outflow for the spherical flow case is via three isolated ports on the radial outer surface rather than across a single continuous end-plate. Both tests are composed of the following two stages: hydration followed by gas testing. Throughout these stages, stresses and pore pressures were continuously monitored, providing data for teams to evaluate their modeling strategies.

The results of these gas injection tests reveal a mix of stochastic and deterministic behaviors. Both the initial gas breakthrough following a pressure increase and bulk gas flow through a dominant pathway were observed in the 1D and 3D experiments. In the 3D test, instability and pathway switching occurred before a primary flow path was established, indicating that the timing of the gas breakthrough and related flows may have a stochastic nature. Consequently, numerical modeling must differentiate between experimental features that are consistently reproducible and those unique to specific tests.

Eight teams in total worked on modeling gas movement in plastic clays using 1D and 3D experiments conducted under controlled laboratory conditions. Various modeling approaches serve distinct objectives based on their intended applications. Consequently, model outcomes ought to be assessed in relation to their defined objectives rather than against the entire complexity of the experimental setups. Nonetheless, these models fail to represent certain fundamental physical mechanisms, such as the formation of dilatant pathways that are essential for advective gas flow. Consequently, they cannot comprehensively capture the complexity of these processes in low-permeability materials. Furthermore, the models demand extensive calibration of fitting parameters and do not accurately reproduce the stochastic behaviors observed in experimental data.

DECOVALEX-2023 represents the eighth phase of the project, spanning from 2020 to 2023. Task A addresses fluid pressurization within the Callovo-Oxfordian claystone (COx) and its resulting fracturing. Several field-scale gas injection tests (PGZ—Perturbation induite par les GaZ) were performed at the Meuse/Haute-Marne Underground Research Laboratory (MHM URL) through packed-off sections of 28 m long boreholes to study gas migration mechanisms into the COx. The description and observations described below for the PGZ experiment are taken from articles in de La Vaissière et al. [

47].

Nitrogen-gas injection tests were conducted at flow rates ranging from 1 to 500 mLn/min in parallel inclined boreholes (PGZ1201 and PGZ1202) drilled into the GMR drift wall. These boreholes were outfitted with multiple packer systems to monitor water and gas pressures across three isolated intervals. Additionally, a third borehole (PGZ1031) was drilled into the GEX drift wall and equipped with a multi-point magnetic extensometer probe to measure potential axial deformation. PGZ1 focuses on identifying the gas migration mechanisms into the COx claystone at different pressure levels. To this end, a series of gas injection tests at different flows was conducted.

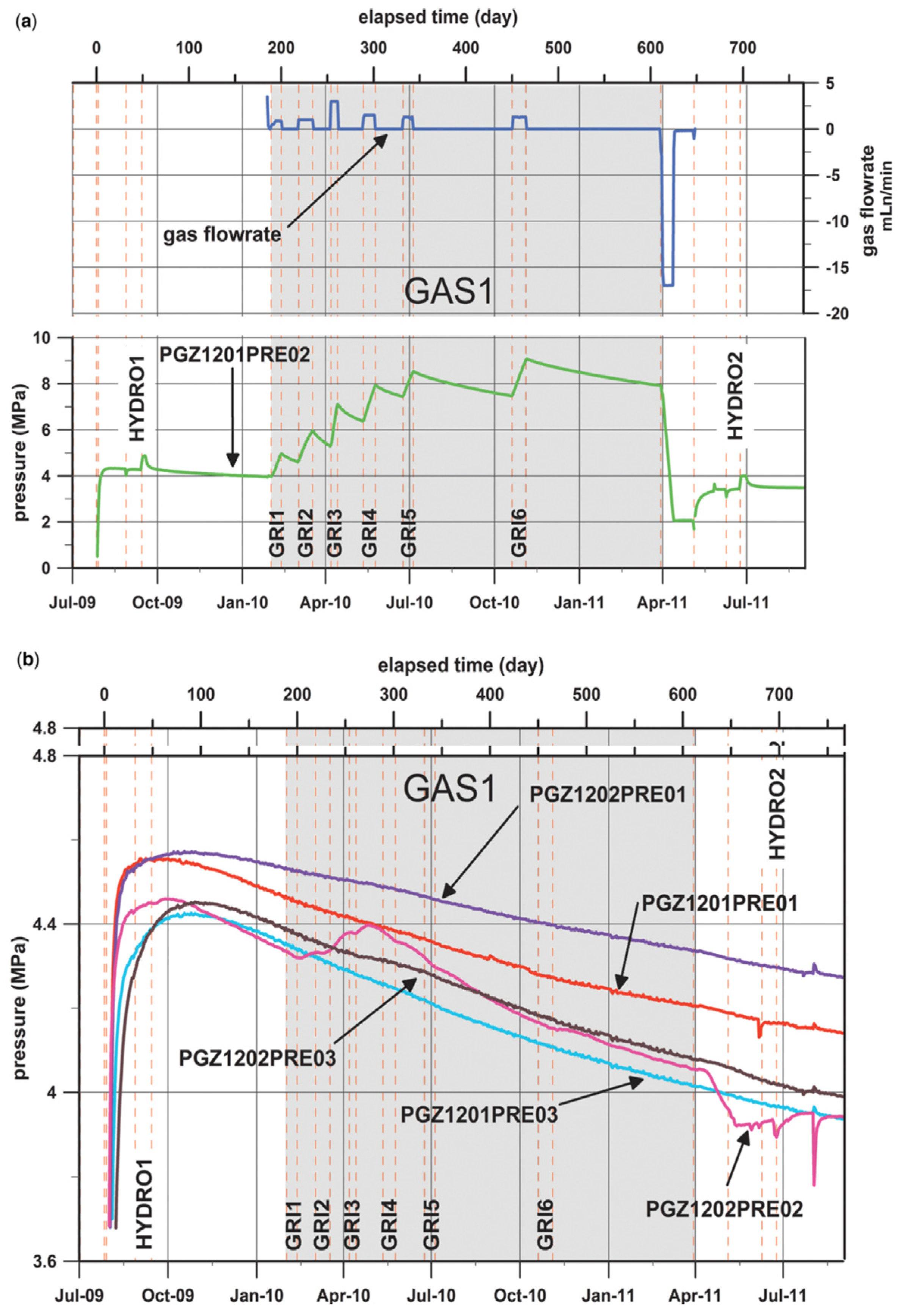

Figure 5 presents a representative phase of GAS1, showcasing data obtained from boreholes PGZ1201 and PGZ1202.

The test phases included the following:

GAS1: This phase consisted of six constant-rate gas injection steps, each lasting between 7 and 15 days, followed by a pressure recovery period. During the final injection step (GRI6), the pressure buildup peaked at 9.1 MPa, with gas flow rates ranging from 1 to 3 mLn/min.

GAS2: started with a constant injection rate at 1 mLn/min and then transitioned to constant injection pressure for eleven months at 9.8 MPa.

GAS3: Consisted of different constant-rate gas injection steps (GRIx) followed by pressure recovery phases. Starting in August 2014 and stopping in August 2015, GAS3-GRI1 began with a constant injection flow rate test at 1 mLn/min until the pressure reached 10.45 MPa. An increase in the gas percolation rate was observed, indicating an increase in the gas outflow. A sudden pressure drop coincided with a drastic increase in the injected gas flow rate, reaching the maximum capacity of the flowmeter (10 mLn/min). A new gas injection phase (GAS3-GRI3) in March 2015 involved a high constant injection flow rate at 250 mLn/min, using a gas mixture (95% nitrogen and 5% helium). The gas pressure stabilized at 10.03 MPa, with no displacement detected by the extensometer string.

The measurements carried out during the PGZ1 experiment, over a period of about ten years, have provided significant insights into gas percolation in very-low-permeability clay rock under various pressure levels. Two different gas transfer mechanisms were observed, as follows: (1) two-phase flow controlled by the generalized Darcy equation for liquid and gas and (2) rock fracturing by gas for the highest pressure levels. The fracturing threshold pressure depends on the kinetics of the pressure rise, and the damage zone created during drilling must be considered in the analysis of the tests.

Further analysis is underway to understand the role of gas injection kinetics on the fracturing process, particularly the influence of the borehole damaged zone and the stress applied by the packers. New borehole and gas injection tests will be performed in the future to better characterize the gas fracturing process. An important safety consideration for radioactive waste repository projects is that even if a gas fracture is generated, it will naturally close when the pressure drops, as evidenced by the permeability measurements made before and after gas fracturing.

3.4. Comparative Analysis of Experimental Works on Gas Migration

Based on a comprehensive review of the GMT, FORGE, and DECOVALEX projects, a comparative analysis of their experimental works is presented below, highlighting the respective advantages and limitations of each initiative.

Advantages:

Comprehensive Scope: explores gas interaction with both engineered and natural barriers in a full-scale silo-type system

Innovative Instrumentation: extensive monitoring with a sensor network enabled detailed analysis of two-phase flow and mechanical responses.

Key Insights: demonstrated the effectiveness of sand–bentonite buffers in restricting gas migration with minimal water displacement.

- (2)

FORGE

Extended Duration: the 15-year study provided robust data on temporal changes in gas migration processes.

Scale-Appropriate Insights: full-scale tests mimicked repository-relevant conditions, improving the understanding of bentonite’s self-sealing behavior and episodic flow mechanisms.

Localized Gas Pathways: confirmed that gas transport is highly localized and transient, preserving buffer hydromechanical properties.

- (3)

DECOVALEX

Multidisciplinary Approach: integrated modeling, laboratory, and field studies addressed complex coupled processes (THMC).

Model Development: advanced numerical tools provided predictive capabilities for gas migration and host material behavior.

Long-Term Perspective: focused on low-permeability clays and long-term repository safety, addressing scaling effects and stochastic behavior.

Limitations:

Insufficient Duration: six years of data were inadequate to fully assess long-term effects.

Simplified Design: homogeneous buffer design failed to account for field-scale heterogeneities.

- (2)

FORGE

Unresolved Issues: did not address colloid detachment or persistent heterogeneities in bentonite that may affect long-term gas migration.

Model Validation Challenges: episodic and transient behavior is difficult to reproduce and validate using current models.

- (3)

DECOVALEX

Complexity of Processes: current models do not fully capture dilatant pathways critical to advective gas flow.

Fracturing Dynamics: limited understanding of fracturing thresholds and the role of borehole damage in gas migration.

4. Modeling Insights

Owing to the rapid advancement of computer technology, researchers have been able to simulate the gas injection process with increasing efficiency and sophistication. This chapter will present three representative numerical approaches, which have made significant progress in simulating the development of preferential pathways in geological media.

4.1. TOUGH

TOUGH (Transport of Unsaturated Groundwater and Heat) is a suite of numerical simulation programs developed by the Lawrence Berkeley National Laboratory (LBNL) for modeling fluid and heat flow in porous and fractured media [

49]. It is primarily designed for simulating subsurface processes, such as groundwater flow, heat transfer, and multiphase fluid flow in geologic formations.

TOUGH employs numerical methods such as finite difference or finite element discretization schemes to solve governing equations for fluid flow, heat transfer, and mass transport in porous media. It utilizes sophisticated algorithms to handle complex boundary conditions, including fully coupled multiphysics processes.

The TOUGH suite of simulators has been pivotal in modeling gas migration in low-permeability media, enabling accurate predictions of two-phase flow and fracture development. Recent work has shown that integrating discrete fracture network models can further enhance the predictive power of these tools, particularly in heterogeneous environments. However, there remains a need for better handling of permeability variations and material heterogeneities, as well as improved computational efficiency for large-scale 3D simulations.

Rutqvist et al. [

50] introduced the Rigid Body-Spring Network (RBSN), a discrete fracture network (DFN) model developed by LBNL to simulate the formation of preferential pathways in bentonite. LBNL explored two complementary methods for modeling gas migration as part of DECOVALEX-2019 task A, as follows:

- (1)

Continuum modeling approach using TOUGH-FLAC simulator [

51];

- (2)

Discrete fracture modeling approach using TOUGH-RBSN simulator [

52].

The continuum approach using TOUGH-FLAC simulates the long-term thermal-hydraulic-mechanical (THM) behavior of nuclear waste repositories in clay host rocks. Previously, TOUGH2 and other continuum models were applied to gas migration in clay, accounting for the heterogeneous clay properties and pressure-dependent permeability, though without incorporating geomechanical coupling [

53,

54].

The discrete fracture modeling approach with TOUGH-RBSN explicitly simulates the opening of grain boundaries to represent dilatant gas migration, employing fracture mechanics principles. This method has been used to model fluid-induced hydraulic fracturing and complex fracture development in clay host rocks [

52]. This approach is well-suited for simulating complex flow pathways related to dilatant gas migration within clay formations.

It is noteworthy that TOUGH2 successfully simulated the GMT experiment mentioned in the previous chapter. Throughout the GMT experiment, each stage was computationally modeled to forecast the anticipated pressure and saturation dynamics. The simulated outcomes, depicting gas saturation and flow patterns (left diagram) alongside pressure and water movement (right diagram) during the gas injection phase (

Figure 6), reveal the progression of gas migration from the silo into the adjacent sand/bentonite layer and, ultimately, into the upper cavern.

The numerical simulations of the GMT experiment demonstrated that essential features and processes occurring during various stages were successfully replicated using the TOUGH2 two-phase flow modeling framework. Simulations with properties calibrated from water tests could well reproduce the gas injection phases when a pressure-dependent permeability increase was implemented at the horizontal interface at the top of the concrete silo and the vertical interface between the host rock and the sand/bentonite layer. This permeability increase could be related to interface opening or pathway dilation associated with the minima in vertical and horizontal stresses.

The stress-dependent interface opening results in preferential gas flow from the concrete silo through the sand/bentonite buffer into the backfill of the upper cavern. During the recovery phase after the initial gas injection sequence, the observed reduction in the permeability of the sand/bentonite layers was attributed to the pressure decrease in the upper cavern, despite the absence of any discernible stress variation. The inferred permeability reduction in sand/bentonite layers matched values measured during the EBS excavation, accurately reproducing the second gas injection phase [

39,

53,

55].

In summary, TOUGH is an advanced and comprehensive tool for simulating gas injection processes. It can simulate the simultaneous flow of multiple fluid phases (e.g., gas, liquid, and supercritical fluids) through porous and fractured media. This is critical for accurate gas injection simulations, where the interactions between gas, water, and oil phases are complex. It incorporates thermal effects, which are essential for understanding the behavior of injected gases in geothermal and subsurface environments where temperature variations play a significant role. It is designed to handle large-scale simulations and can be run on parallel computing platforms, making it suitable for extensive field-scale models. However, its computational demands, complexity, and the need for detailed input data can pose significant challenges.

4.2. Phase-Field Method

The phase-field method (PFM) provides a continuous representation for simulating fracturing processes, seamlessly integrated into the conventional finite element method framework. The study employs equal low-order finite elements. To avoid pore pressure oscillations (common in low-permeability materials), a stabilization technique (polynomial pressure projection) is applied. For fracture propagation, the domain is finely meshed near expected fracture paths and coarsely elsewhere to balance accuracy and computational cost. The coupled hydro-mechanical (HM) and phase-field (PF) system is solved via weak forms derived from mass balance equations (for water and gas), momentum balance equations, and phase-field equation. In this approach, sharp discontinuities are smoothed into diffusive crack regions through the introduction of a scalar auxiliary variable known as the PF [

56]. Unlike discontinuous approaches that introduce either interface elements or new shape functions, the PF method can be straightforwardly implemented using the standard FEM [

57]. The PF method characterizes crack initiation, propagation, and branching by employing a governing equation grounded in the principles of minimum potential energy or thermodynamic theory [

58]. Therefore, the PFM presents a robust framework for modeling gas-induced fracturing in initially saturated porous media, with its adaptation to unsaturated conditions being relatively straightforward [

59,

60].

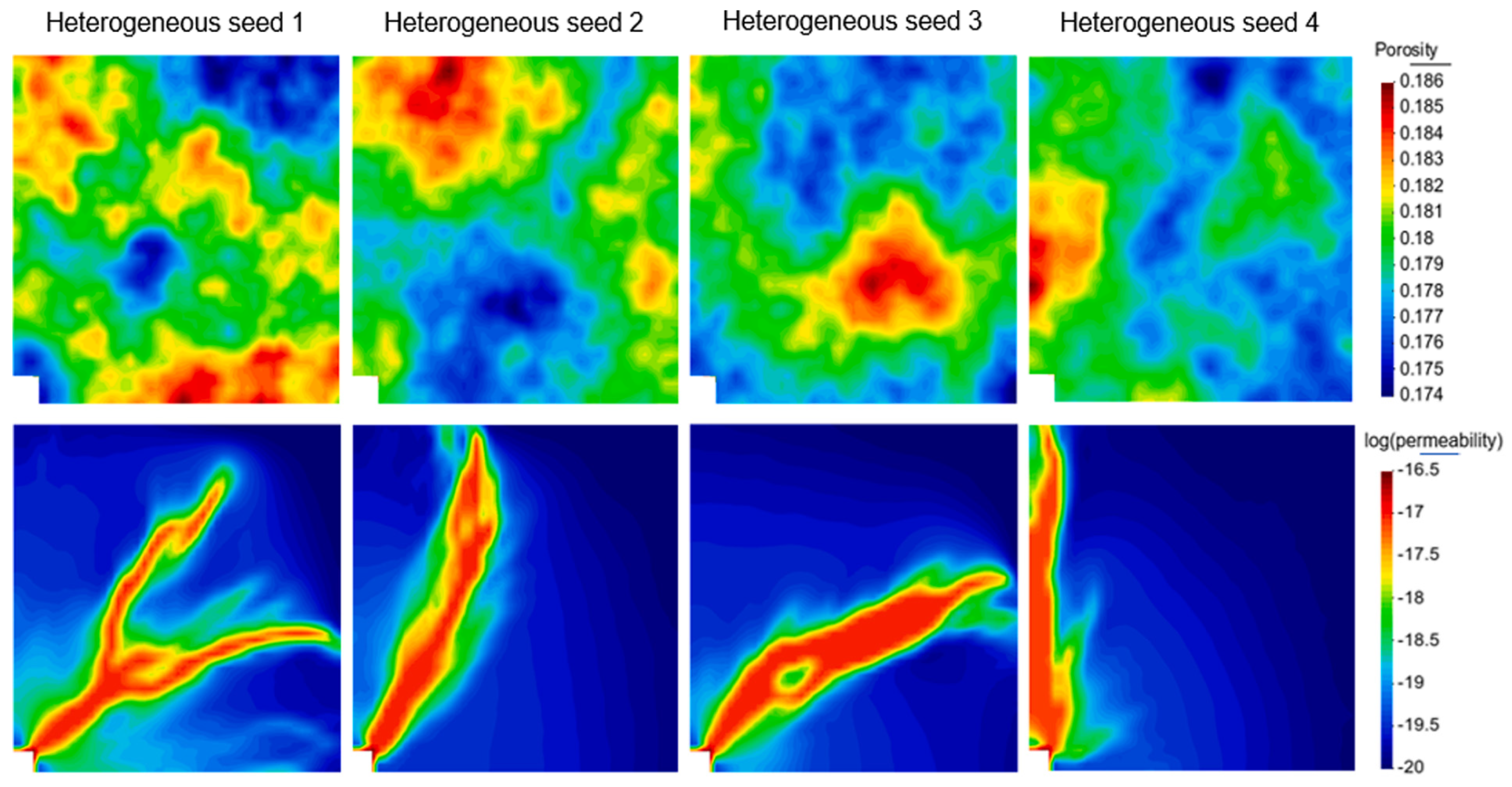

Cajuhi et al. [

61] integrated the classical poromechanical formulation with a phase-field approach, effectively modeling fractures in variably saturated porous media. Guo and Fall [

59] implemented the phase-field approach within a coupled hydro-mechanical model to investigate preferential gas migration in saturated bentonite. Additionally, the model successfully captures arbitrary fracture propagation and branching by incorporating heterogeneous distributions of hydro-mechanical properties (as shown in

Figure 7). Guo and Fall [

62] further improved the coupled HM-PF model based on Coussy’s thermodynamic theory for saturated soils and microforce balance law. Yang et al. [

63] extended the method to an equivalent THM model for gas migration in saturated rocks. Their fracture spacing sensitivity analysis revealed that microcracking induced by highly pressurized gas significantly impacts the coupled process.

The phase-field method is highly versatile, adaptable across scales from pore-level to field-scale simulations, making it suitable for a wide range of gas injection scenarios. It can naturally handle complex interface morphologies and topological changes (e.g., merging and splitting of fluid phases), offering detailed insights into gas injection and fluid displacement dynamics. Additionally, PFM allows for coupling various physical processes, including fluid flow, heat transfer, and chemical reactions, enabling comprehensive simulations that capture interactions among different phenomena. Generally robust, the PFM can handle complex boundary conditions and geometries, maintaining numerical stability in challenging simulation scenarios. However, it is computationally intensive, especially for three-dimensional simulations or high-resolution applications, making large-scale or long-term simulations resource-demanding and time-consuming.

4.3. CODE_BRIGHT

CODE_BRIGHT is a finite element method (FEM) simulation program developed at the Universitat Politècnica de Catalunya (UPC) for coupled analyses of stress equilibrium, water mass conservation, gas mass conservation, energy conservation, and conservative/reactive transport. The program treats displacement, liquid pressure, gas pressure, temperature, and chemical species as the principal unknown variables. A comprehensive formulation of the governing equations implemented in CODE_BRIGHT has been documented in prior studies [

64].

Recent studies have highlighted CODE_BRIGHT’s capabilities. Mo et al. [

65] conducted six types of benchmark exercises using the heat and gas fracking model (HGFRAC), achieving successful simulation of the gas fracturing pathway in saturated clay. Mo et al. [

66] presented a comprehensive comparison of the following three numerical strategies: standard FEM, standard FEM with selective integration, and mixed FEM. In mixed FEM, displacements and strains were treated as independent unknowns, which enhanced result accuracy and achieved mesh independence.

Rodriguez-Dono et al. [

67] proposed a novel methodology for addressing coupled thermo-hydro-mechanical (THM) challenges in geomaterials exhibiting heterogeneous properties, highlighting its significance in the development of gas migration pathways. As shown in

Figure 8, various heterogeneous porosity distributions were considered, and the gas branching cracking phenomenon was effectively captured. Rodriguez-Dono et al. [

68] further extended this approach by incorporating embedded fractures and heterogeneous material properties in a gas injection experiment. The study emphasizes that accounting for material heterogeneity critically impacts gas injection scenarios, especially in the presence of hydraulic fracture development.

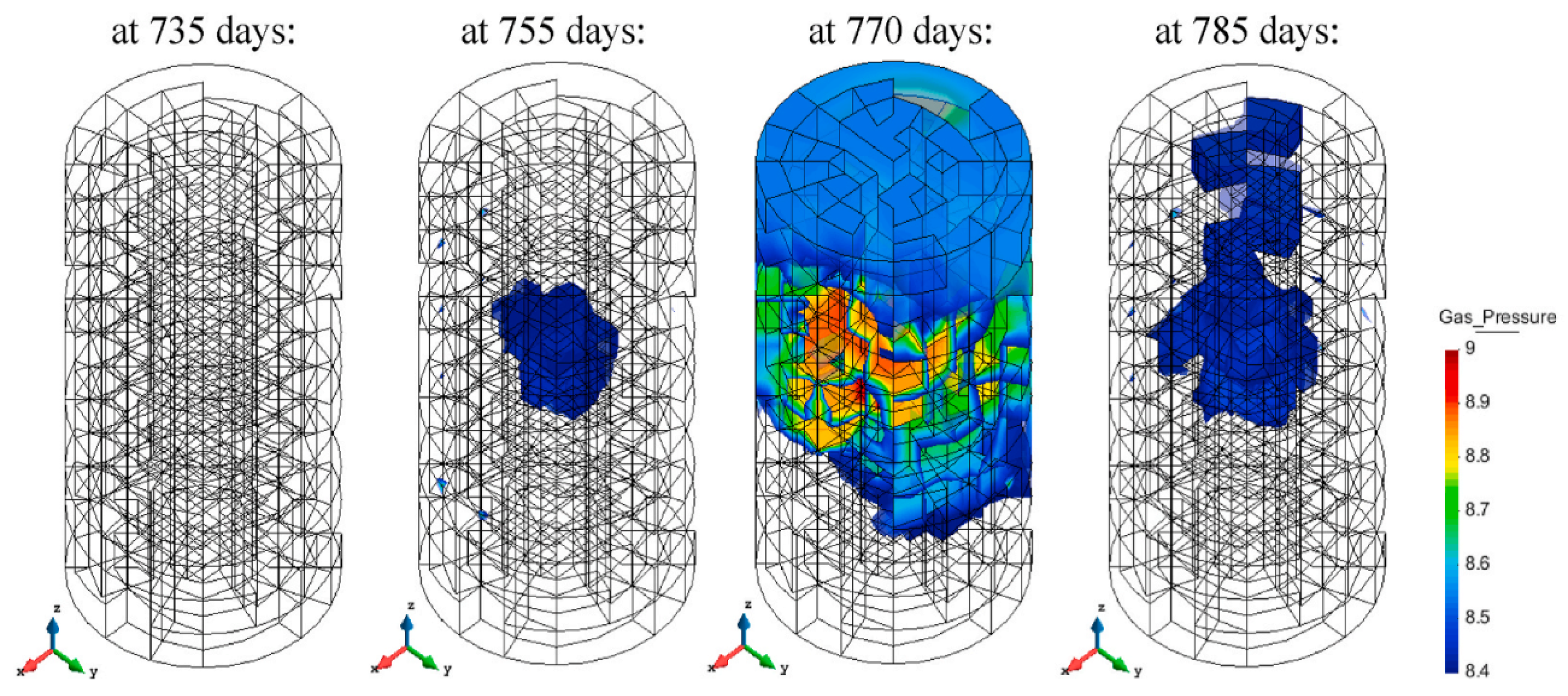

Damians et al. [

69] formulated a 3D coupled hydro-gas-mechanical model to simulate both axial and spherical gas flows within saturated Mx80 bentonite under constant volume constraints, as shown in

Figure 9. Damians et al. extended this work by constructing a 3D model that assumes heterogeneous initial permeability and material anisotropy throughout the specimen, also incorporating embedded fractures into the formulation. This enhanced model successfully reproduced the behavior observed in gas injection tests.

Noghretab et al. [

70] further modeled gas flow in pre-compacted Mx80 bentonite, accounting for material heterogeneity and embedded fractures while considering three different scenarios for gap closure. Some preliminary findings from the gas transport experiment in the Large Scale Gas Injection Test (Lasgit) project are represented.

Overall, CODE_BRIGHT is a robust FEM program in the field of geotechnical engineering, with its primary advantage being the efficient integration of various soil constitutive models. CODE_BRIGHT is designed to be extended and customized as needed, enabling the addition of new constitutive models or analysis modules. This flexibility allows CODE_BRIGHT to continually adjust to evolving engineering and research demands. The CODE_BRIGHT team has made substantial progress in several aspects, which is presented in detail in the following sections.

4.3.1. Embedded Fracture Model

The embedded fracture model is proposed by Olivella and Alonso [

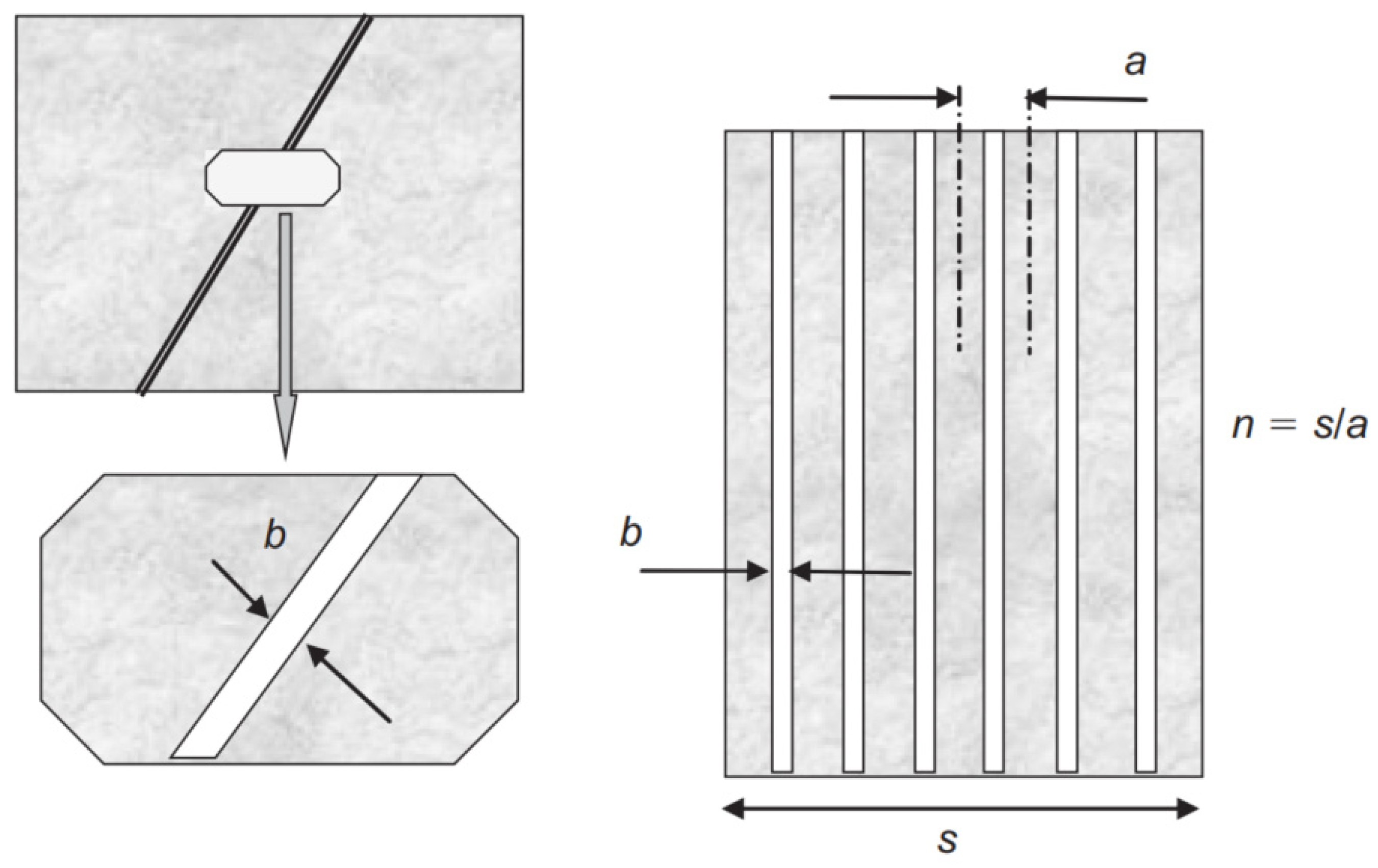

71]. The basic idea of the embedded fracture model is shown in

Figure 10. On the left, the model depicts a single fracture within a porous medium, defined by its aperture

. On the right, a finite element comprises a rock matrix—typically a porous medium—containing multiple fractures,

in total. The quantity of fractures within an element is determined by the fracture width,

, regarded as a characteristic material dimension, and the element size,

, measured perpendicular to the orientation of the discontinuities.

When modeling complex fluid injection problems, it is important to note that the intrinsic permeability can be expressed as the sum of two terms, as shown in Equation (14). The first component,

, is a function of the porosity,

, of the material’s matrix, following Kozeny’s law (Equation (15)) [

71,

72,

73]. The second component,

, corresponds to the permeability associated with the aperture,

, of embedded fractures, according to a cubic law (Equation (16)). By combining Equations (15) and (16), Equation (17) can be derived, where

represents the intrinsic permeability at a reference porosity,

of the matrix, and

a denotes the spacing between fractures.

The aperture,

, is calculated as shown in Equations (18) and (19), where

and

refer to the strain and threshold strain, and

and

denote the initial and maximum apertures, respectively.

In addition, the capillary pressure can be formulated as in Equation (20):

where

is the surface tension of the water,

is the initial permeability, and

is the initial capillary pressure.

4.3.2. Heterogeneity

In natural environments, geomaterials such as soils, rocks, and concrete exhibit intrinsic heterogeneity [

74]. Under thermo-hydro-mechanical (THM) conditions, attributes such as thermal conductivity, intrinsic permeability, and Young’s modulus are significantly influenced by the spatial arrangement and characteristics of the constituent minerals, along with the material’s bulk density [

75,

76]. Therefore, accounting for heterogeneity in geotechnical simulations is essential.

Damians et al. [

69] developed a heterogeneity model based on permeability variations. This model consists of 12 layers (

Figure 11), each of which is assigned a random permeability distribution with three possible permeability values, assuming equal probability. In spite of this, the anisotropy of clay material was also examined to assess its impact on gas flow.

Rodriguez-Dono et al. [

67] introduce an innovative modeling framework that accounts for spatial heterogeneity in geomaterials, a significant advancement in thermo-hydro-mechanical (THM) simulation. Recognizing that properties like porosity, intrinsic permeability, and mechanical attributes vary naturally within geomaterials, this model employs spatially correlated heterogeneous fields, which better reflect the irregularities observed in real-world geological formations. This approach was implemented in CODE_BRIGHT and was successfully validated with experiment results [

68].

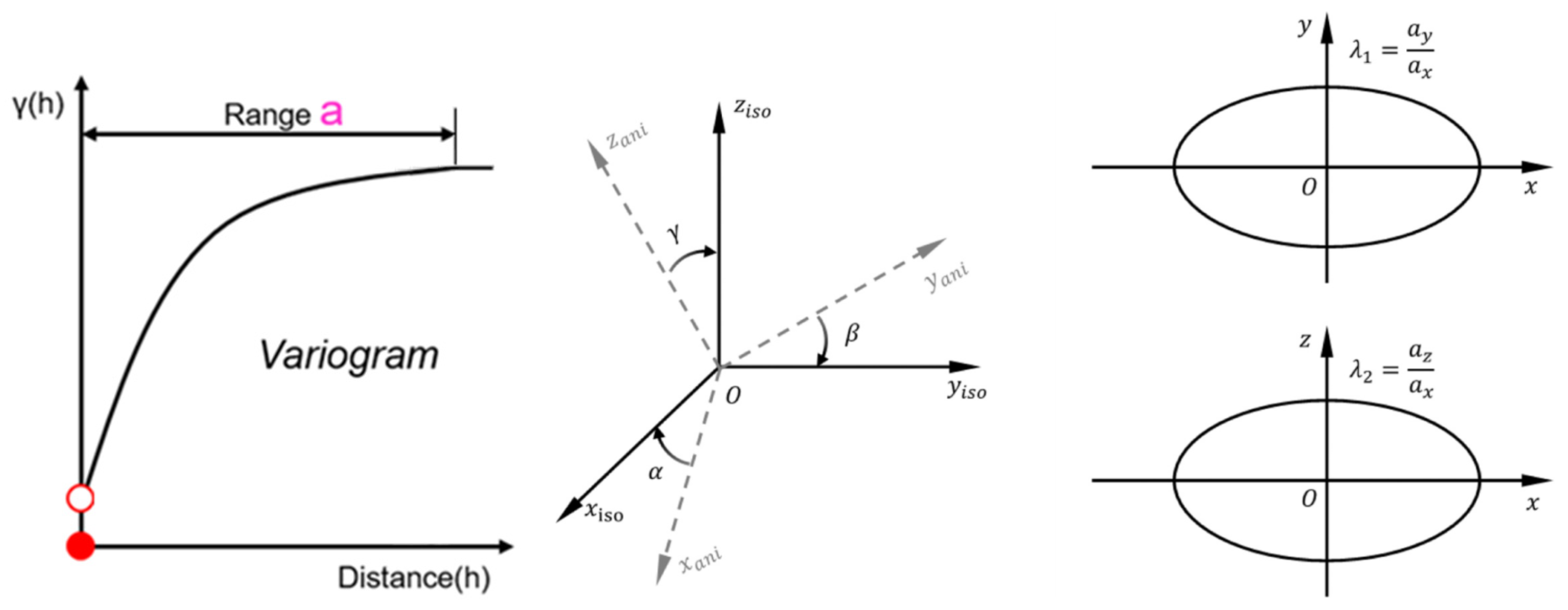

The authors selected a spherical semi-variogram as the foundation for the implementation in CODE_BRIGHT to simulate these spatial correlations due to its widespread use as a variogram model [

77,

78].

Figure 12 illustrates the spherical semi-variogram. The range,

, indicates the radius within which data values correlate.

The phenomenon under investigation is termed “anisotropic” when the modulus of the property,

(distance vector between two elements), varies in different directions [

79]. In these instances, the directional graph of the range,

, assumes the shape of an ellipsoid in three-dimensional space (3D). Deriving the anisotropic covariance function begins with rotating the coordinate system by the angles

α,

β, and

γ (

Figure 12), thereby aligning the axes with the principal directions of the ellipsoid. Following this, the ellipsoid’s axes are defined, corresponding to the ranges in the three principal directions. The major range of the ellipsoid is

, while the other ranges are derived using the ratios

and

, where

,

, and

are the ranges for the rotated axes x, y, and z, respectively [

68].

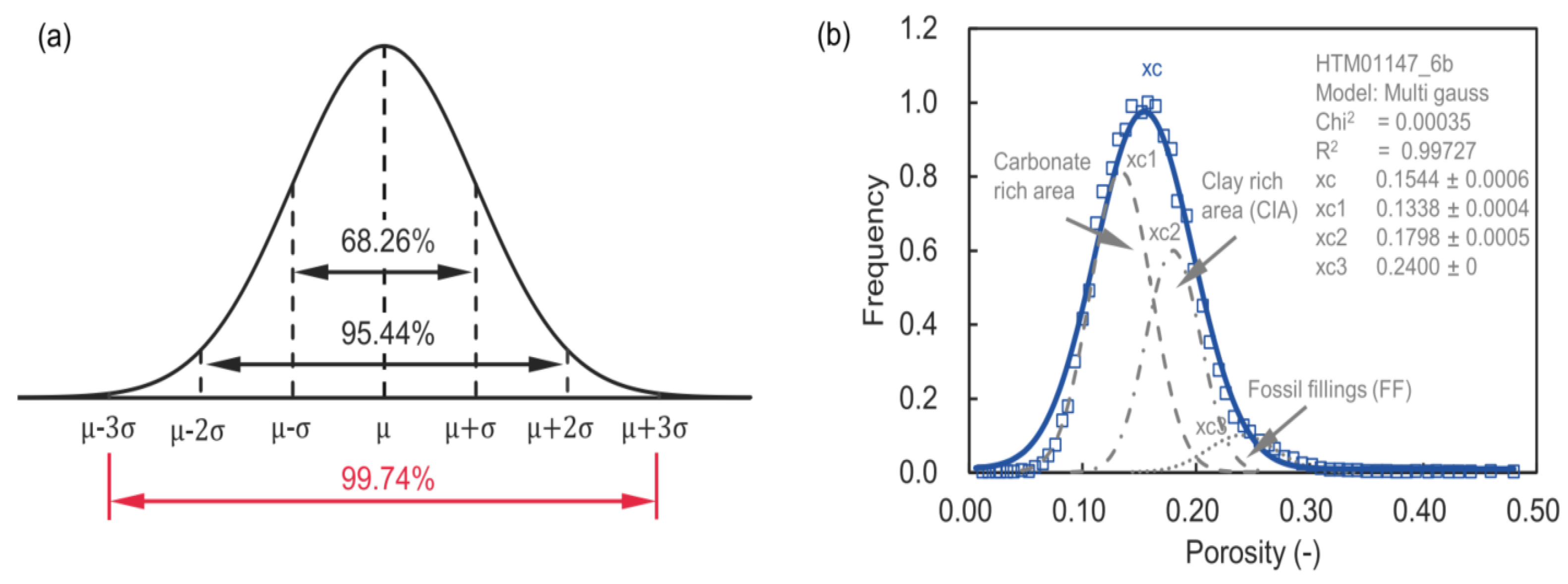

The CODE_BRIGHT framework allows for multiple parameters to depend on porosity, inherently incorporating heterogeneity when porosity is treated as a non-uniform property. Furthermore, analyses reveal that the pore size distribution in specific geological formations, such as COx clay rock, tends to exhibit an approximately normal distribution, as shown in

Figure 13b. Consequently, porosity was chosen as the variable for generating a spatially correlated field based on a normal distribution [

80,

81,

82].

A dedicated module within CODE_BRIGHT was designed to generate spatially correlated heterogeneous porosity fields [

67], employing a Gaussian random distribution characterized by a mean,

μ, and standard deviation,

σ (

Figure 13a). The resulting porosity values are subsequently allocated to the elements within the finite element mesh. Furthermore, to maintain spatial correlation, the variogram model’s range,

, must be at least twice the dimension of the mesh elements; ranges smaller than this threshold result in the absence of spatial correlation.

In their simulations, the model was validated by applying it to materials commonly encountered in nuclear waste repositories, like compacted clays and other low-permeability formations. By comparing homogeneous and heterogeneous THM responses, the study found that introducing spatial variability allowed for a more accurate representation of stress distribution, deformation, and fluid flow. Specifically, heterogeneity affected pore pressure dissipation, crack formation, and gas migration, underscoring the need for such variability in realistic THM analysis. Their approach holds particular relevance for repository design and management, where understanding long-term material behavior under varying stress, thermal, and fluid conditions is essential.

In 2024, Rodriguez-Dono and colleagues further developed their model to examine gas injection within fractured and heterogeneous materials, an important aspect for subsurface gas storage and nuclear waste containment. This work extends the previous heterogeneity model by incorporating embedded fractures, which dynamically alter permeability, as they open and close in response to stress changes. These fractures are simulated as discontinuities within the finite element mesh, allowing for the assessment of complex gas migration pathways that account for both the material’s inherent heterogeneity and fracture network geometry.

The study used CODE_BRIGHT to run gas injection simulations in low-permeability clays, such as Callovo-Oxfordian clay. The model demonstrated that fracture spacing, aperture, and connectivity significantly influence gas migration paths, with fractures creating high-permeability pathways that can alter fluid pressure distributions across the material. A sensitivity analysis showed that properties, such as gas saturation, intrinsic permeability, and diffusion coefficients, greatly impact the gas flow behavior, especially when fractures are widely spaced or oriented in specific directions. This insight is crucial for predicting long-term gas behavior in repositories, where fractures could act as pathways for radionuclide transport if left unmanaged.

4.3.3. Different Element Types

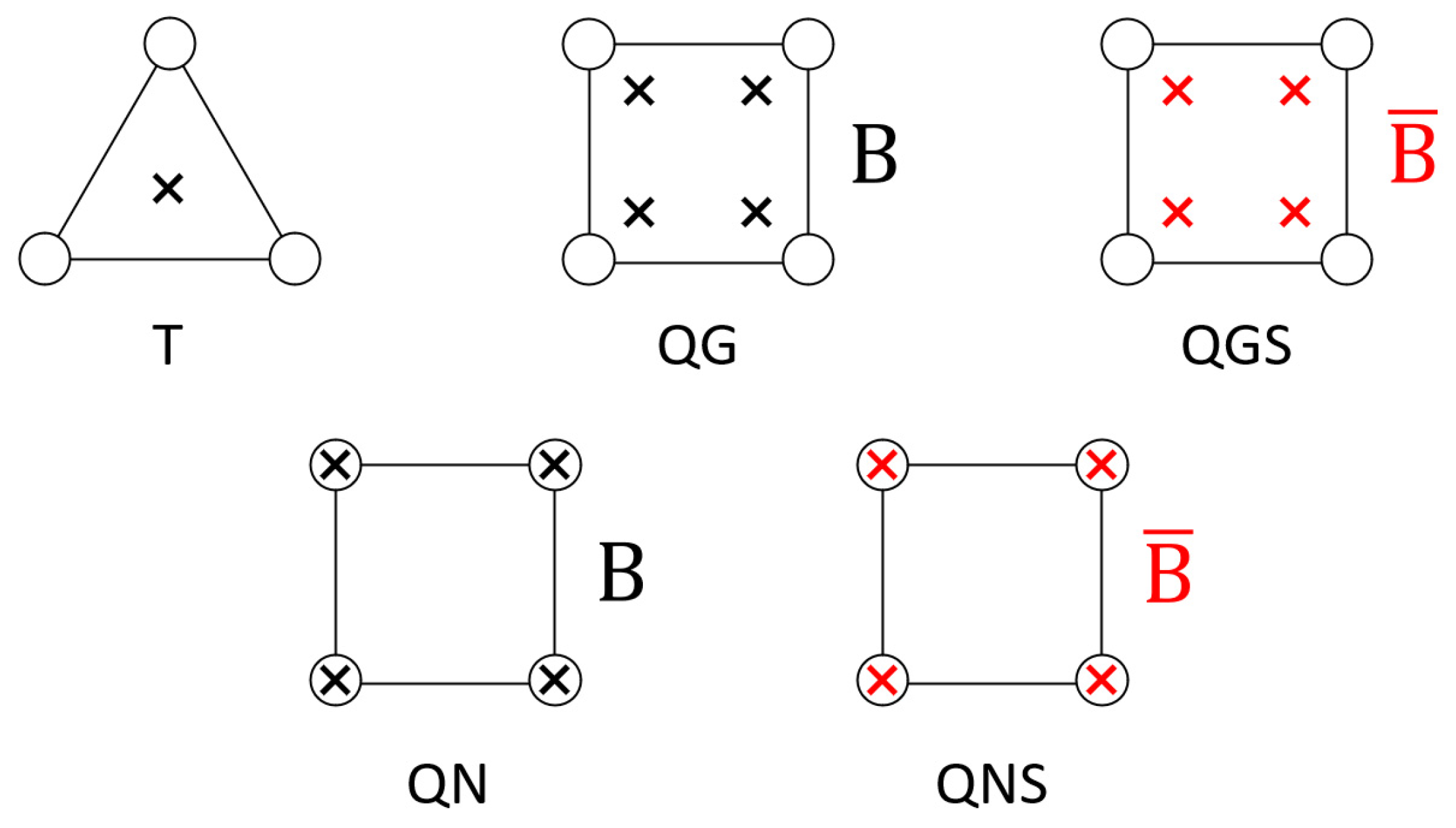

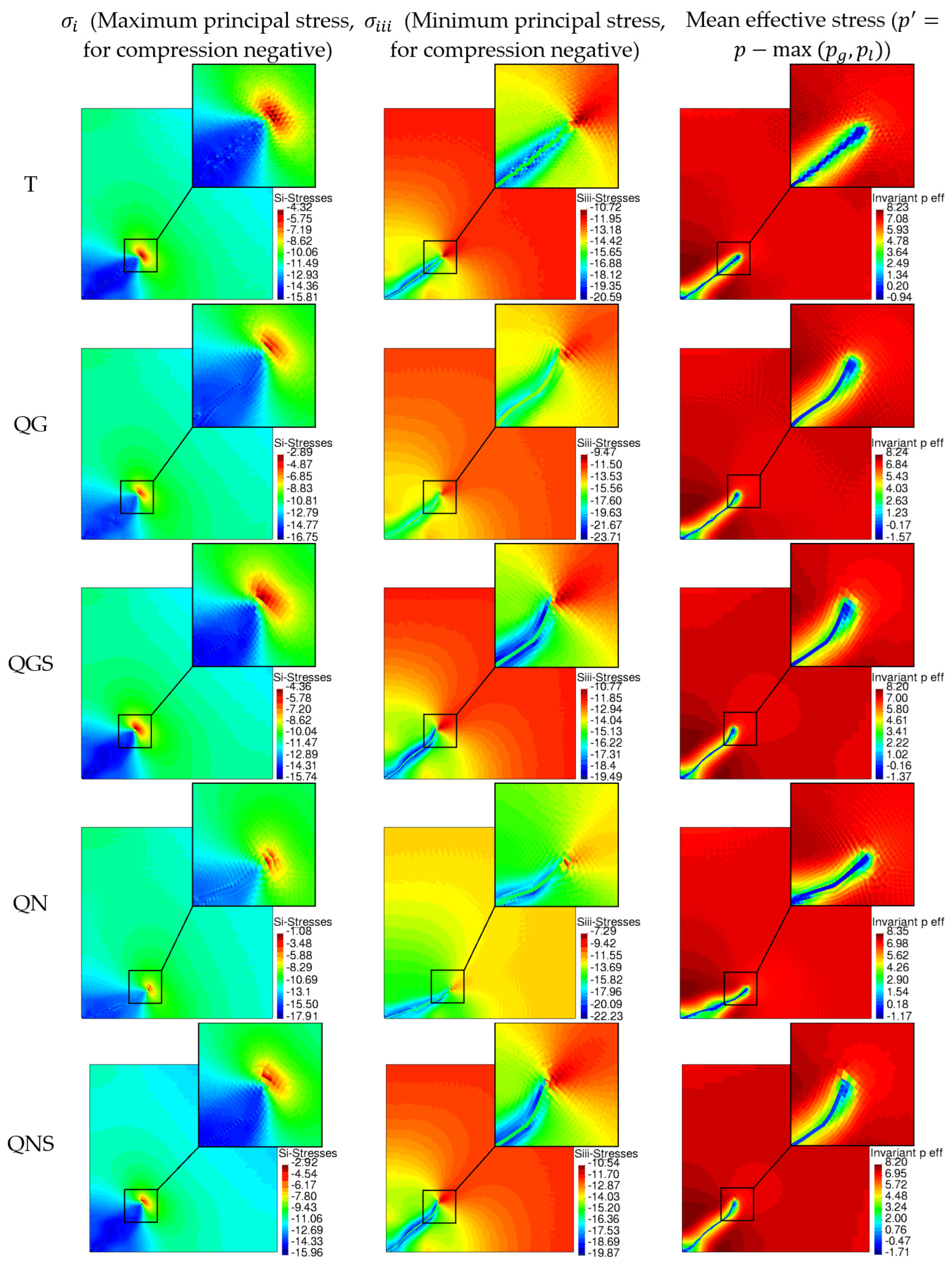

Mo et al. [

65] compare the performance of triangle and quadrilateral elements in HM coupled gas injection simulations. It is important to note that quadrilateral elements are subdivided into four types based on their integration methods and position, as illustrated in

Figure 14. According to the integration methods, it is classified into the following two categories: “standard integration” and “selective integration”. Additionally, depending on the integration positions, they are further divided into the following two forms: “integrated at Gauss points” and “integrated at the nodes”. The calculation results of the maximum stress, minimum stress and mean effective stress for the five element types is shown in

Figure 15.

Note that, the selective integration method involves a crucial step of splitting the stiffness matrix into two components: volumetric and deviatoric. The volumetric part is then computed using lower-order integration rules, which helps alleviate the issue of an overstiff response [

83,

84]. The corresponding equations and manipulations have been elaborated elsewhere [

65].

Furthermore, the triangular element model is susceptible to volumetric locking, especially in regions exhibiting steep gradient variations near the preferential gas flow path. This locking phenomenon arises from the overly restrictive constraints applied to incompressible materials, which substantially limit the deformation capacity of triangular elements. Among the four quadrilateral element types evaluated, the incorporation of selective integration markedly enhances the accuracy of the stress field. Specifically, the QGS and QNS elements demonstrate superior performance in capturing the mean effective stress, whereas the QG and QN elements continue to exhibit locking issues.

4.4. Comparative Analysis of Modeling Approaches on Gas Migration

Based on the comprehensive review of TOUGH, PFM, and CODE_BRIGHT, a comparative analysis of their features is presented below, highlighting the respective advantages and limitations of each method.

Advantages

- (1)

TOUGH

Proven capability for large-scale, multiphase flow (gas/water/heat) in porous/fractured media.

Parallel computing support enables field-scale simulations (e.g., GMT experiment replication).

Discrete fracture network (DFN) integration (TOUGH-RBSN) improves fracture pathway modeling.

- (2)

PFM

Explicit fracture modeling without predefined crack paths (handles branching/merging).

Seamless coupling with hydro-mechanical (HM) processes.

Versatile across scales (pore-to-field) and complex geometries.

- (3)

CODE_BRIGHT

Fully coupled THM with embedded fractures and heterogeneity/anisotropy.

Advanced material models (e.g., spatially correlated porosity fields).

Limitations:

Limited geomechanical coupling.

Calibration-heavy for complex processes (e.g., dilatant pathways).

- (2)

PFM

Extreme computational demands (especially for 3D/THMC).

Stochastic behavior (e.g., pathway switching) hard to replicate.

- (3)

CODE_BRIGHT

Mesh sensitivity (e.g., locking effects with triangular elements).

Limited chemical coupling compared to TOUGH.

5. Conclusions and Future Work

This article reviews the latest research on gas migration in various clay types across several countries that can potentially serve as host rocks for underground radioactive waste repositories. Bentonite, or a mixture of sand and bentonite, is widely considered to be an appropriate interface between disposal containers and the host rock due to its advantageous radionuclide retention properties, which contribute to the long-term stability of the disposal containers. Additionally, it is essential to consider that the mineral composition and fabric of clay significantly impact its gas migration behavior. Clays with a higher proportion of expansive minerals exhibit significantly different responses to gas injection compared with those composed primarily of non-expansive minerals. Moreover, clay microstructure can realign or compress under sustained injection pressures, which may enhance the connectivity of gas pathways through reorientation of platelets. Such behavior is critical to understanding the long-term performance of clay barriers, as continuous injection or high pressures may induce a reorganization of particles, potentially leading to preferential flow paths over time.

Four primary gas migration mechanisms are reviewed, with attention given to the conditions under which they are applicable. Special emphasis is placed on the tensile fractures induced by excessive gas, as the presence of preferential paths profoundly affects the properties of low-permeability clays and further affects various processes in the THM multi-field coupling. The presence of fractures in clay materials modifies fluid transport pathways, alters stress distribution, and influences thermal conduction within the clay matrix. In THM modeling for fractured clays, it is essential to consider these factors to accurately predict gas migration patterns, assess fracture stability, and evaluate the long-term behavior of clay as a barrier material.

Additionally, this article examines major research projects (GMT, FORGE, and DECOVALEX), highlighting their methodologies, findings, and contributions to advancing the field. These landmark initiatives provide a multidimensional perspective on gas migration phenomena and emphasize the importance of integrating in situ field data, scalable laboratory tests, and advanced modeling techniques. Such integration is crucial for developing comprehensive and predictive frameworks that ensure the long-term safety of underground repository. The capabilities and limitations of current numerical simulation tools, including TOUGH, the phase-field method, and CODE_BRIGHT, are also reviewed. Although previous studies on this topic have established a robust coupled THM framework for simulating the gas migration process, further enhancements are needed. Considering the current state of research in this field, several key aspects should be addressed in future work, as follows:

- (1)

The development of 3D numerical models is imperative. While both vertical and horizontal sections of the models have been simulated in 2D models, these two approaches reveal different gas flow patterns. In the horizontal section of the model, a preferential gas fracture is generated. However, in the vertical section of the model, no gas flow paths are observed. Therefore, extending these models from 2D to 3D would offer a more comprehensive understanding of gas migration dynamics.

- (2)

During gas flow, the attachment of clay particles (colloids) to the gas phase and the subsequent loss of buffer material remains potential concerns. This process has yet to be fully studied, as the mass of bentonite in the tests is usually very large, making it impossible to detect any material loss. However, clay particle attachment to a gas phase is more likely to occur if the gas migrates in the form of bubbles.

- (3)

The study of the self-sealing behavior of clay materials, such as bentonite, has not received sufficient attention in the context of gas migration. Bentonite’s self-sealing may involve complex interactions among clay minerals, absorbed water, and gas phase at the microscopic level. Future numerical approaches need to effectively account for these interactions to achieve a thorough understanding of the self-sealing process.

- (4)

The influence of heterogeneity on gas migration faces limitations due to high computational demands for 3D simulations and dependence on data quality and may not be ideal for low-porosity materials where porosity is not the primary factor in heterogeneity. Future work aims to address these limitations by exploring more efficient algorithms and to allow for model heterogeneity based on other parameters different than porosity. Further research and validation will help refine this approach and expand its applicability. In addition, it may be necessary to consider the influence of heterogeneity in pore shape and size on gas injection studies.

- (5)

The importance of multiscale investigations should be emphasized, encompassing not only the macroscale, continuum-scale, and representative elementary volume (REV) scale but also the mesoscale, microscale, and pore scale. Pore-scale or microscale explorations can provide deeper physical insights into the underlying phenomena. However, their practical application in engineering requires effective upscaling techniques. Such upscaling must integrate the effects of local heterogeneities and pore-scale multiphase physics into REV-scale constitutive relationships. These critical aspects have yet to be addressed and should be a priority in future research efforts.