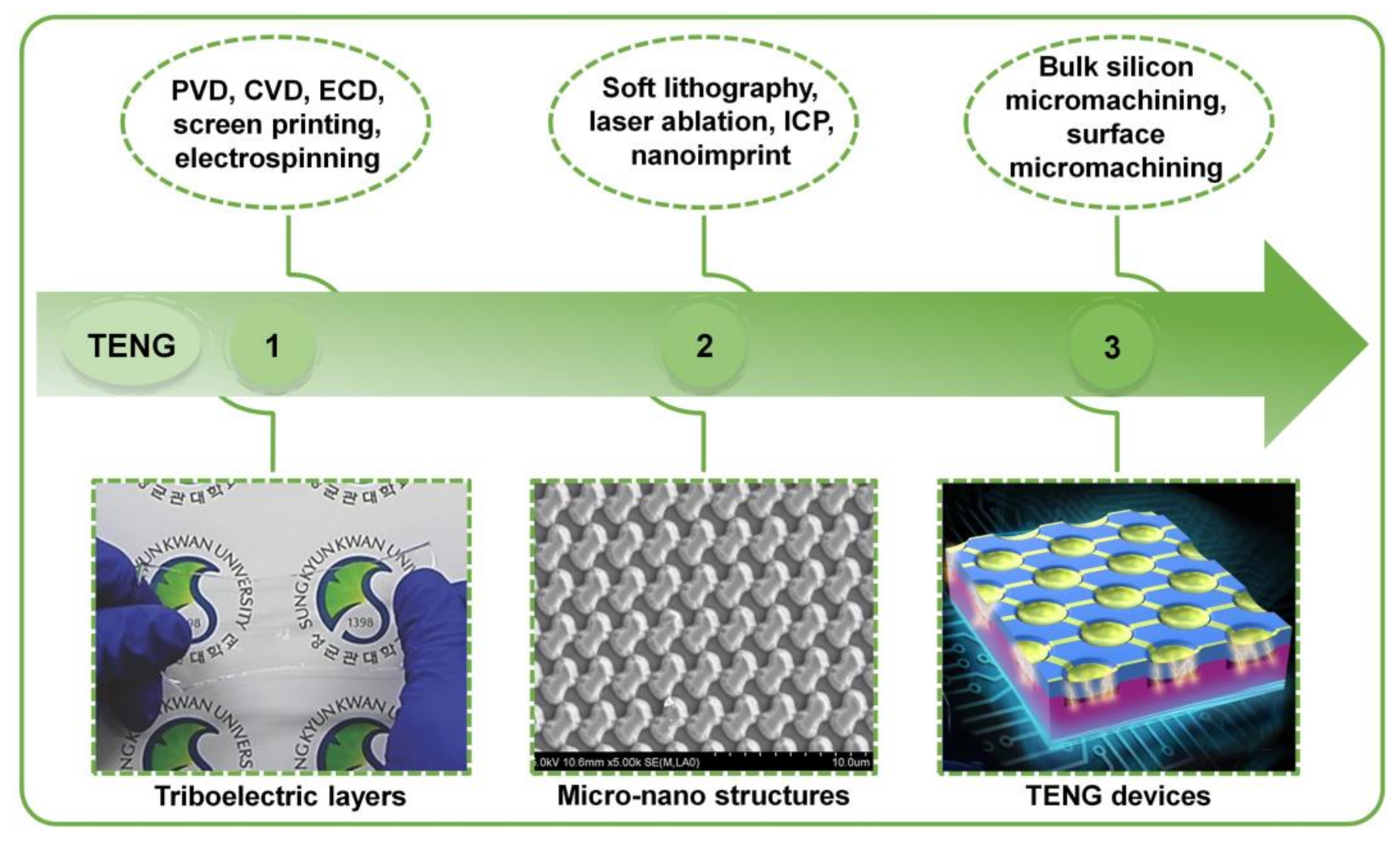

Overview of Advanced Micro-Nano Manufacturing Technologies for Triboelectric Nanogenerators

Abstract

1. Introduction

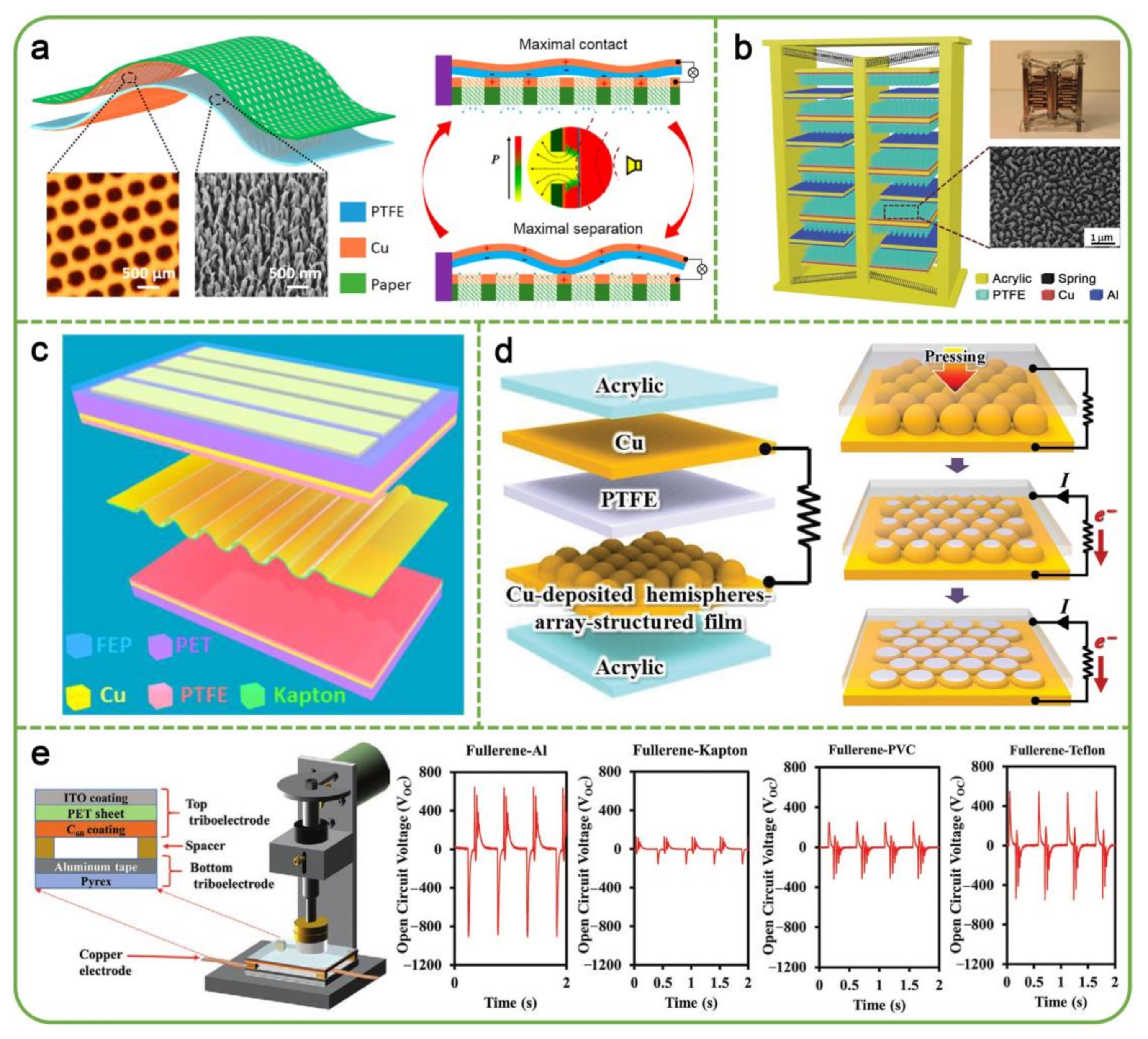

2. Film Preparation for Triboelectric Layers

2.1. Physical Vapor Deposition

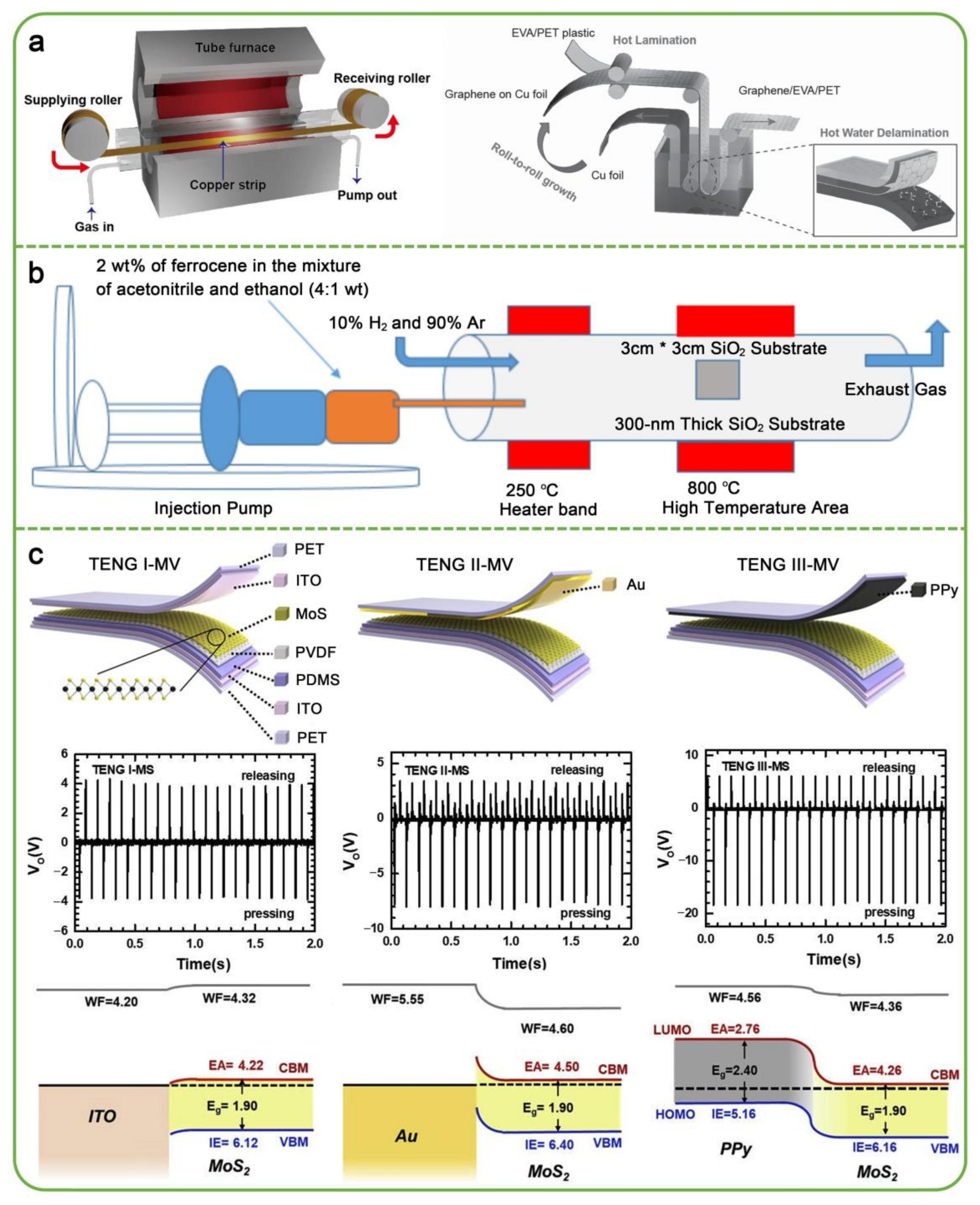

2.2. Chemical Vapor Deposition

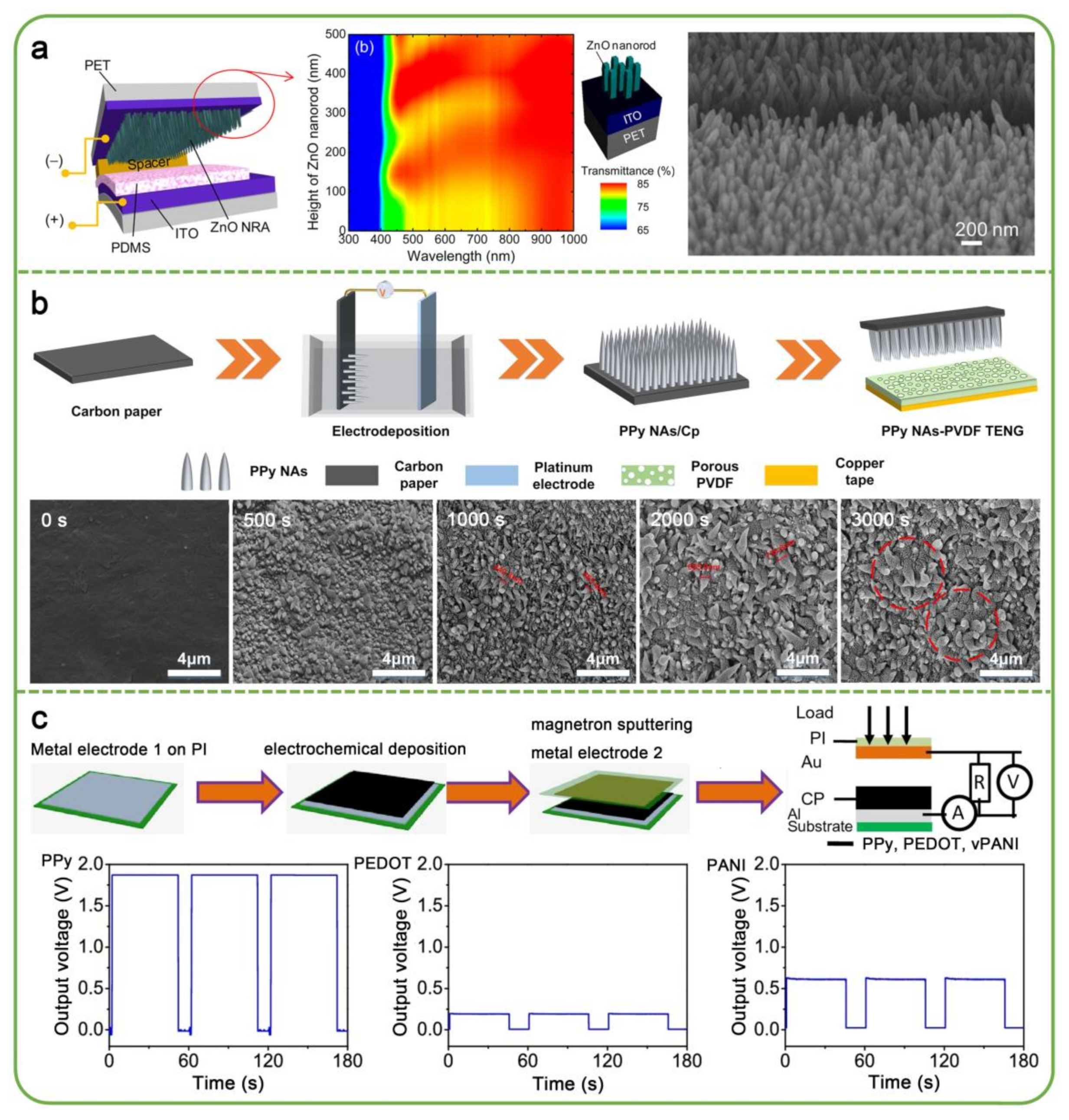

2.3. Electrochemical Deposition

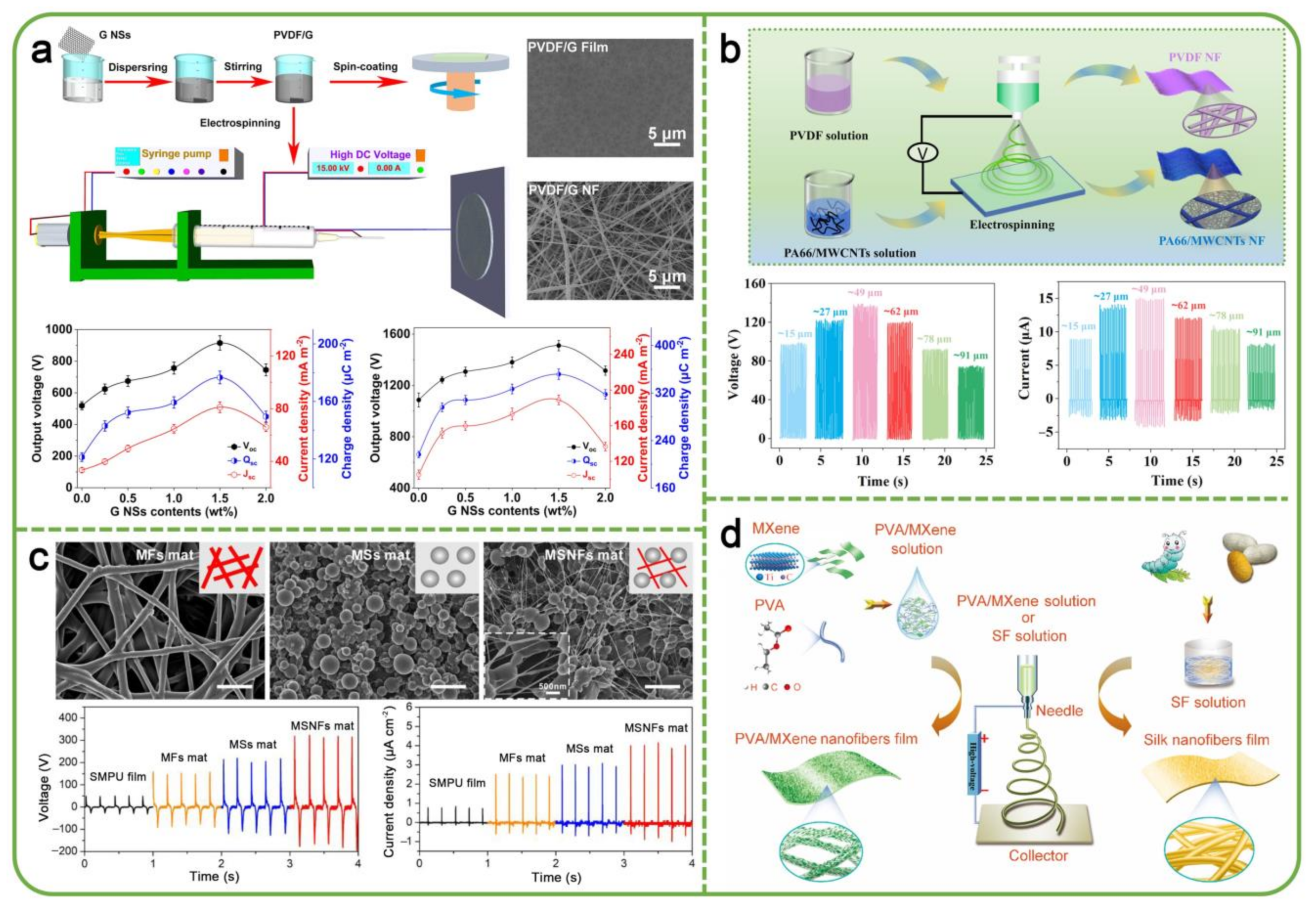

2.4. Electrospinning

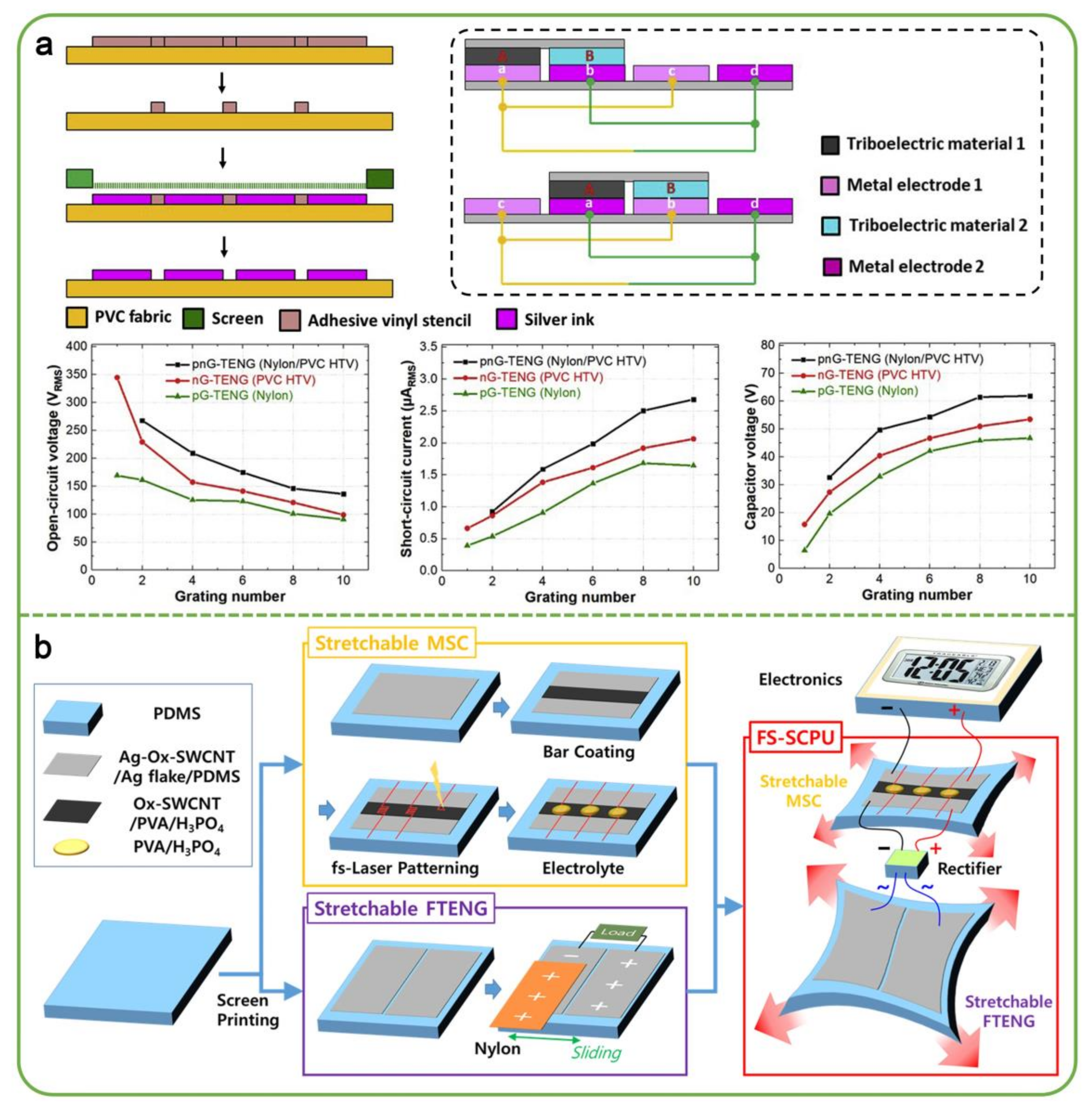

2.5. Screen Printing

3. Surface Processing for Micro-Nano Structures

3.1. Soft Lithography

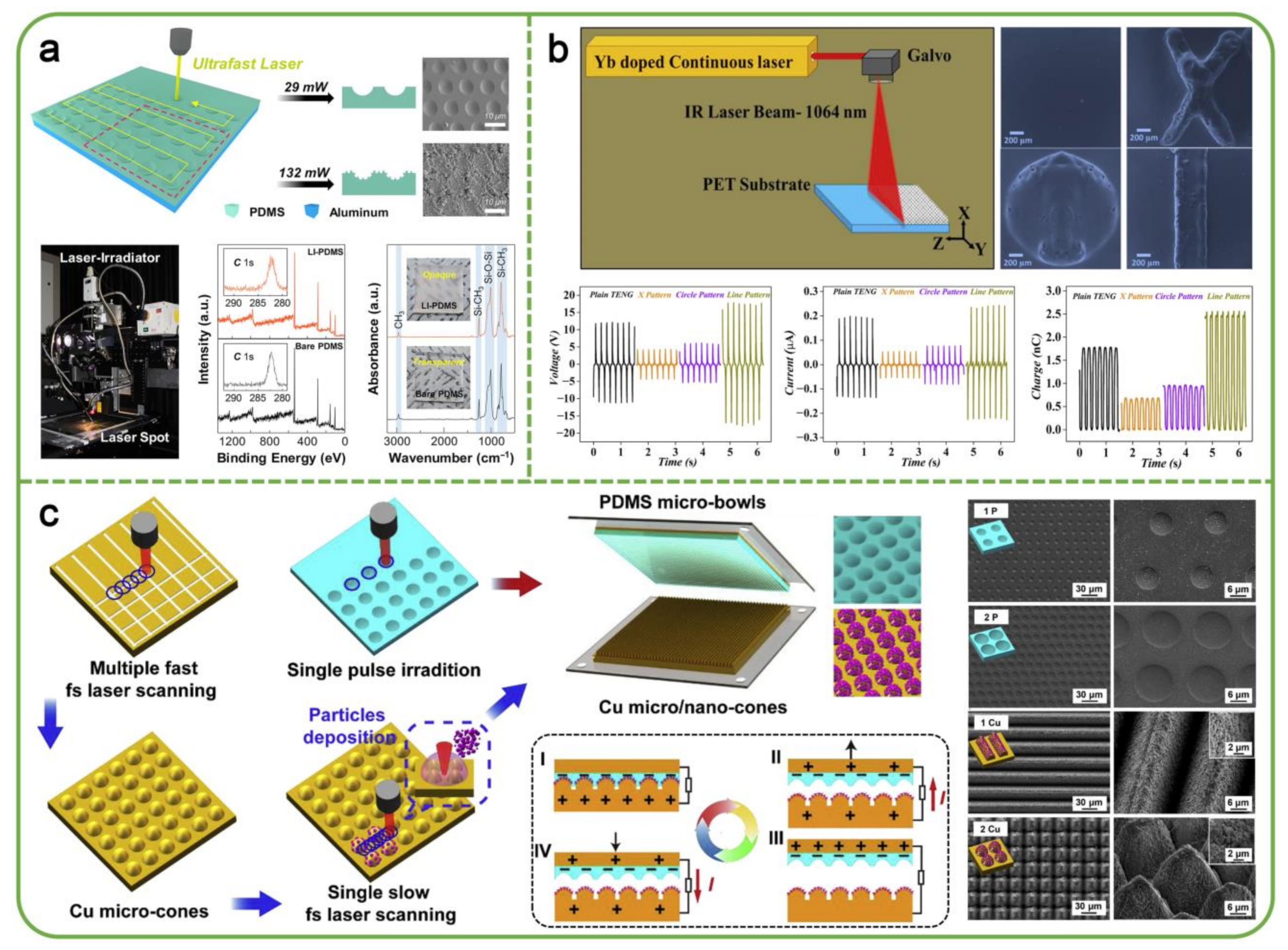

3.2. Laser Ablation

3.3. Inductively Coupled Plasma

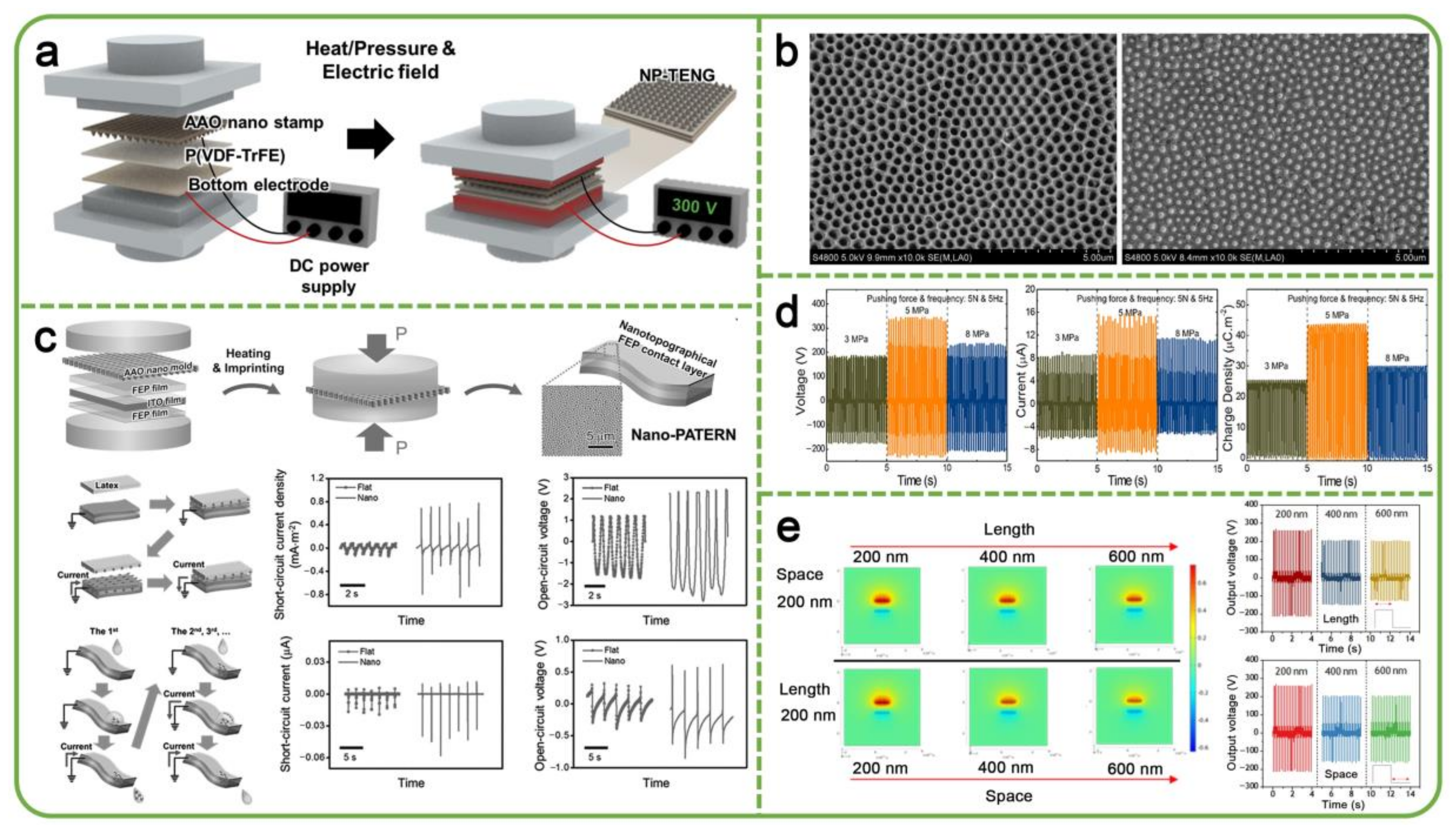

3.4. Nanoimprint

4. MEMS Fabrication for TENG Devices

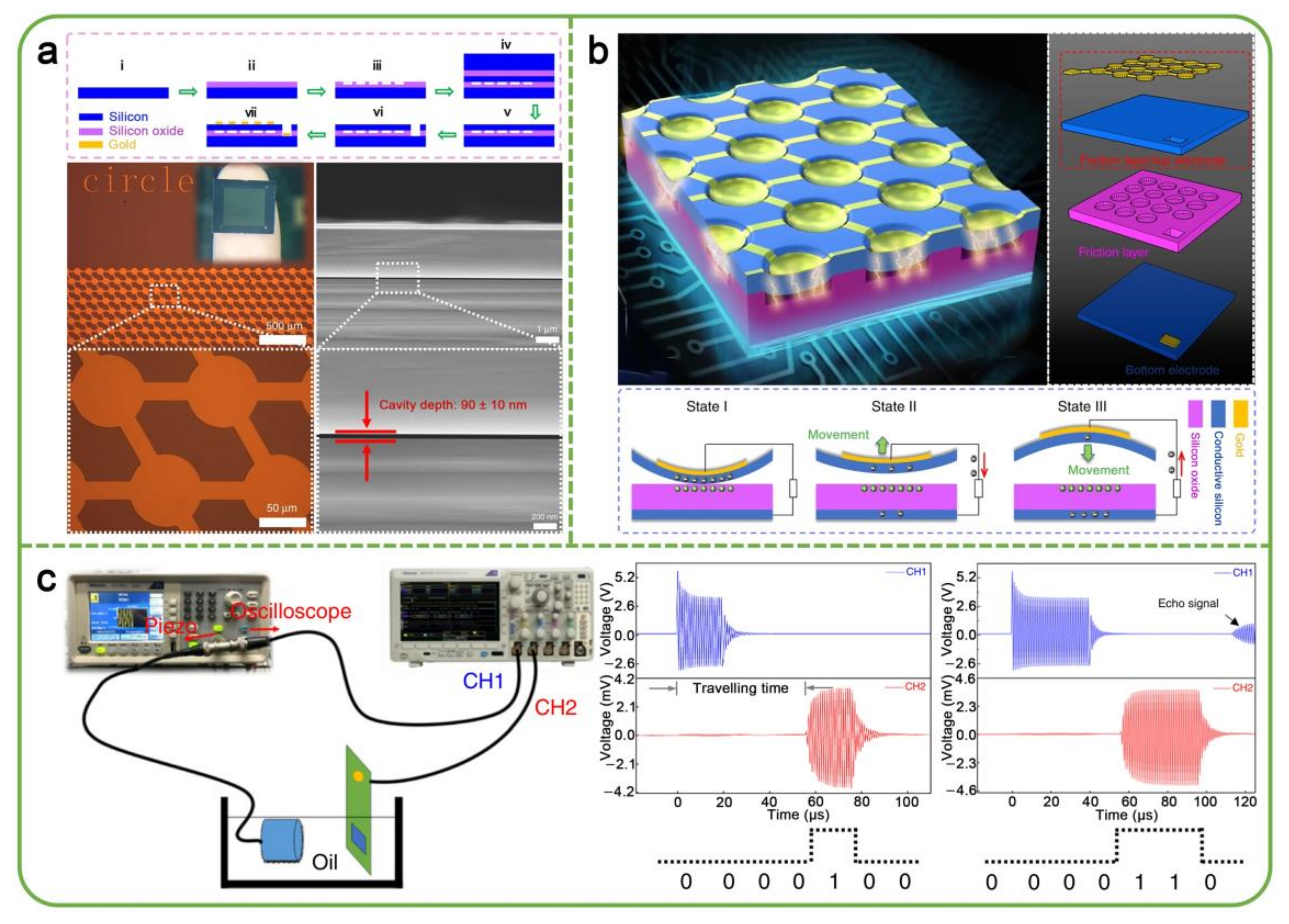

4.1. MEMS Acoustic Sensors

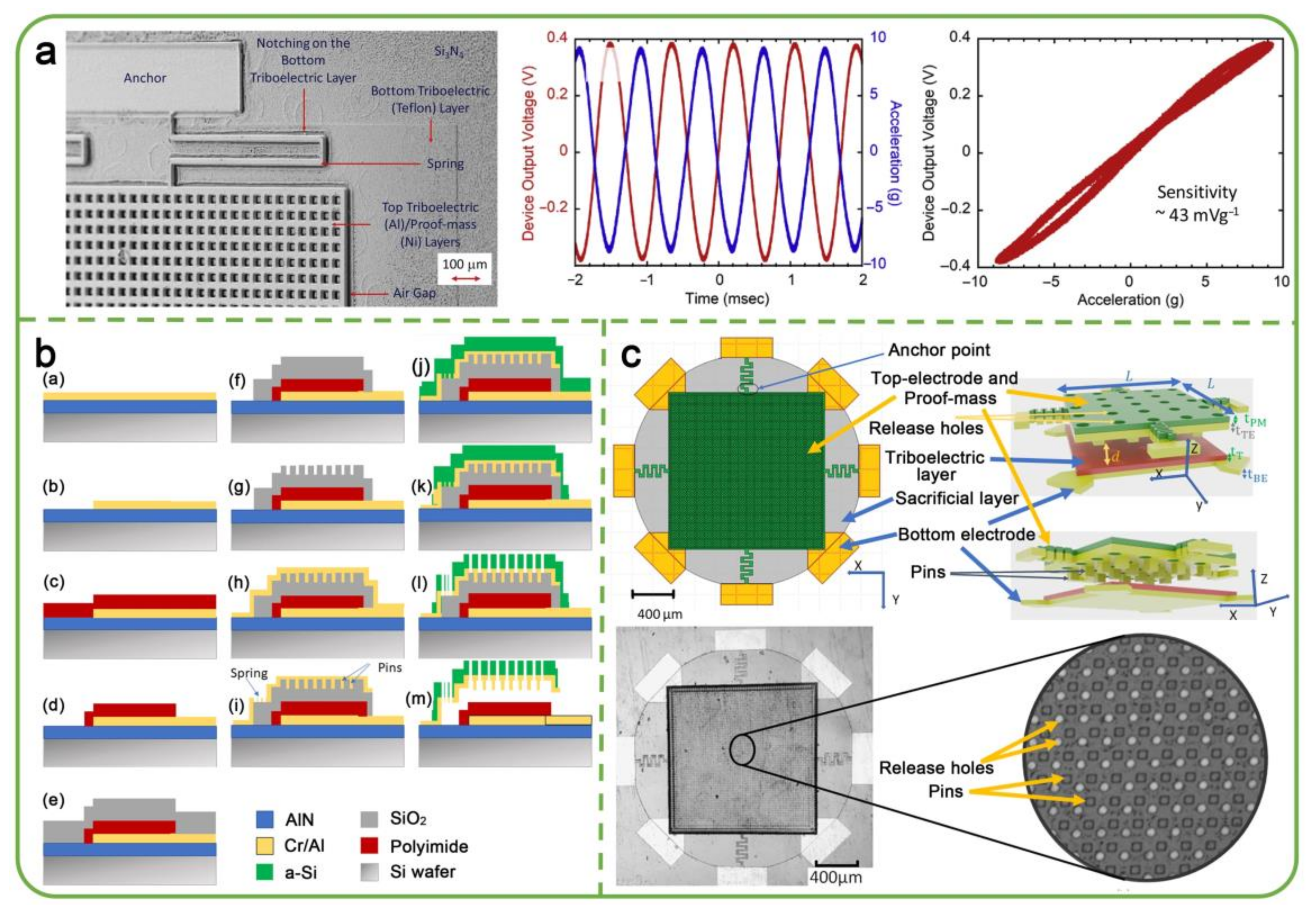

4.2. MEMS Vibration Sensors

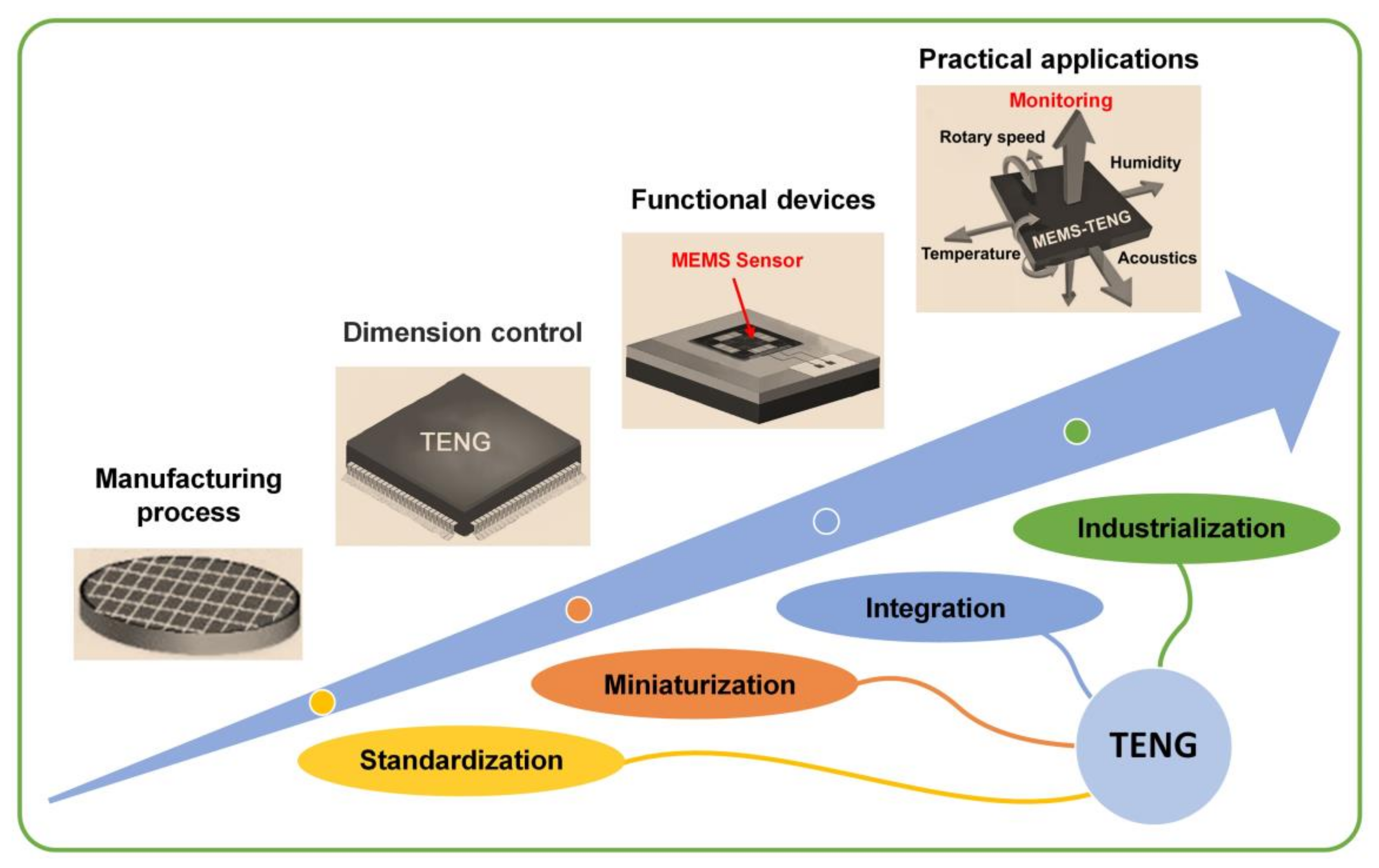

5. Conclusions and Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Wang, Z.L. Entropy theory of distributed energy for internet of things. Nano Energy 2019, 58, 669–672. [Google Scholar] [CrossRef]

- Kim, W.-G.; Kim, D.-W.; Tcho, I.-W.; Kim, J.-K.; Kim, M.-S.; Choi, Y.-K. Triboelectric Nanogenerator: Structure, Mechanism, and Applications. ACS Nano 2021, 15, 258–287. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Luo, J.; Wang, Z.L. Recent progress of triboelectric nanogenerators: From fundamental theory to practical applications. EcoMat 2020, 2, e12059. [Google Scholar] [CrossRef]

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Liang, X.; Jiang, T.; Liu, G.; Feng, Y.; Zhang, C.; Wang, Z.L. Spherical triboelectric nanogenerator integrated with power management module for harvesting multidirectional water wave energy. Energy Environ. Sci. 2019, 13, 277–285. [Google Scholar] [CrossRef]

- Chen, H.; Lu, Q.; Cao, X.; Wang, N.; Wang, Z.L. Natural polymers based triboelectric nanogenerator for harvesting biomechanical energy and monitoring human motion. Nano Res. 2021, 15, 2505–2511. [Google Scholar] [CrossRef]

- Zhao, H.; Xiao, X.; Xu, P.; Zhao, T.; Song, L.; Pan, X.; Mi, J.; Xu, M.; Wang, Z.L. Dual-Tube Helmholtz Resonator-Based Triboelectric Nanogenerator for Highly Efficient Harvesting of Acoustic Energy. Adv. Energy Mater. 2019, 9, 1902824. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, L.; Zheng, Y.; Wang, D.; Zhou, F.; Liu, W. Leaves based triboelectric nanogenerator (TENG) and TENG tree for wind energy harvesting. Nano Energy 2019, 55, 260–268. [Google Scholar] [CrossRef]

- Zhang, Q.; Jiang, C.; Li, X.; Dai, S.; Ying, Y.; Ping, J. Highly Efficient Raindrop Energy-Based Triboelectric Nanogenerator for Self-Powered Intelligent Greenhouse. ACS Nano 2021, 15, 12314–12323. [Google Scholar] [CrossRef]

- Zi, Y.; Guo, H.; Wen, Z.; Yeh, M.-H.; Hu, C.; Wang, Z.L. Harvesting Low-Frequency (<5 Hz) Irregular Mechanical Energy: A Possible Killer Application of Triboelectric Nanogenerator. ACS Nano 2016, 10, 4797–4805. [Google Scholar] [CrossRef]

- Xu, J.; Zou, Y.; Nashalian, A.; Chen, J. Leverage Surface Chemistry for High-Performance Triboelectric Nanogenerators. Front. Chem. 2020, 8, 577327. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Wang, Y.; Wang, H.; Wang, H.; Zhang, S.L.; Zhao, T.; Xu, M.; Wang, Z.L. Flexible seaweed-like triboelectric nanogenerator as a wave energy harvester powering marine internet of things. ACS Nano 2021, 15, 15700–15709. [Google Scholar] [CrossRef]

- Fu, X.; Xu, S.; Gao, Y.; Zhang, X.; Liu, G.; Zhou, H.; Lv, Y.; Zhang, C.; Wang, Z.L. Breeze-Wind-Energy-Powered Autonomous Wireless Anemometer Based on Rolling Contact-Electrification. ACS Energy Lett. 2021, 6, 2343–2350. [Google Scholar] [CrossRef]

- Xu, C.; Fu, X.; Li, C.; Liu, G.; Gao, Y.; Qi, Y.; Bu, T.; Chen, Y.; Wang, Z.L.; Zhang, C. Raindrop energy-powered autonomous wireless hyetometer based on liquid–solid contact electrification. Microsystems Nanoeng. 2022, 8, 30. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zheng, W.; Zhang, H.; Wang, H.; Cai, H.; Zhang, Y.; Yang, Z. Electron transfer mechanism of graphene/Cu heterostructure for improving the stability of triboelectric nanogenerators. Nano Energy 2020, 70, 104540. [Google Scholar] [CrossRef]

- Fan, B.; Liu, G.; Fu, X.; Wang, Z.; Zhang, Z.; Zhang, C. Composite film with hollow hierarchical silica/perfluoropolyether filler and surface etching for performance enhanced triboelectric nanogenerators. Chem. Eng. J. 2022, 446, 137263. [Google Scholar] [CrossRef]

- Varghese, H.; Chandran, A. A facile mechanical energy harvester based on spring assisted triboelectric nanogenerators. Sustain. Energy Fuels 2021, 5, 5287–5294. [Google Scholar] [CrossRef]

- Liu, D.; Liu, J.; Yang, M.; Cui, N.; Wang, H.; Gu, L.; Wang, L.; Qin, Y. Performance enhanced triboelectric nanogenerator by taking advantage of water in humid environments. Nano Energy 2021, 88, 106303. [Google Scholar] [CrossRef]

- Kim, S.; Gupta, M.K.; Lee, K.Y.; Sohn, A.; Kim, T.Y.; Shin, K.-S.; Kim, D.; Kim, S.K.; Lee, K.H.; Shin, H.-J.; et al. Transparent flexible graphene triboelectric nanogenerators. Adv. Mater. 2014, 26, 3918–3925. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Xia, L.; Dang, S.; Shi, L.; Cao, A.; Du, C. Self-powered flexible pressure sensors based on nanopatterned polymer films. Sens. Rev. 2020, 40, 629–635. [Google Scholar] [CrossRef]

- Chen, C.; Wen, Z.; Shi, J.; Jian, X.; Li, P.; Yeow, J.T.W.; Sun, X. Micro triboelectric ultrasonic device for acoustic energy transfer and signal communication. Nat. Commun. 2020, 11, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Abegunde, O.O.; Akinlabi, E.T.; Oladijo, O.P.; Akinlabi, S.; Ude, A.U. Overview of thin film deposition techniques. AIMS Mater. Sci. 2019, 6, 174–199. [Google Scholar] [CrossRef]

- Fan, X.; Chen, J.; Yang, J.; Bai, P.; Li, Z.; Wang, Z.L. Ultrathin, Rollable, Paper-Based Triboelectric Nanogenerator for Acoustic Energy Harvesting and Self-Powered Sound Recording. ACS Nano 2015, 9, 4236–4243. [Google Scholar] [CrossRef]

- Yang, W.; Chen, J.; Jing, Q.; Yang, J.; Wen, X.; Su, Y.; Zhu, G.; Bai, P.; Wang, Z.L. 3D Stack Integrated Triboelectric Nanogenerator for Harvesting Vibration Energy. Adv. Funct. Mater. 2014, 24, 4090–4096. [Google Scholar] [CrossRef]

- Su, Y.; Wen, X.; Zhu, G.; Yang, J.; Chen, J.; Bai, P.; Wu, Z.; Jiang, Y.; Wang, Z.L. Hybrid triboelectric nanogenerator for harvesting water wave energy and as a self-powered distress signal emitter. Nano Energy 2014, 9, 186–195. [Google Scholar] [CrossRef]

- Lee, K.Y.; Yoon, H.-J.; Jiang, T.; Wen, X.; Seung, W.; Kim, S.-W.; Wang, Z.L. Fully packaged self-powered triboelectric pressure sensor using hemispheres-array. Adv. Energy Mater. 2016, 6, 1502566. [Google Scholar] [CrossRef]

- Zhang, W.; Diao, D.; Sun, K.; Fan, X.; Wang, P. Study on friction-electrification coupling in sliding-mode triboelectric nanogenerator. Nano Energy 2018, 48, 456–463. [Google Scholar] [CrossRef]

- Parajuli, P.; Sharma, B.; Behlow, H.; Rao, A.M. Fullerene-Enhanced Triboelectric Nanogenerators. Adv. Mater. Technol. 2020, 5, 2000295. [Google Scholar] [CrossRef]

- Xu, C.; Liu, Y.; Liu, Y.; Zheng, Y.; Feng, Y.; Wang, B.; Kong, X.; Zhang, X.; Wang, D. New inorganic coating-based triboelectric nanogenerators with anti-wear and self-healing properties for efficient wave energy harvesting. Appl. Mater. Today 2020, 20, 100645. [Google Scholar] [CrossRef]

- Jones, A.C.; Hitchman, M.L. Overview of chemical vapour deposition. In Chemical Vapour Deposition: Precursors, Processes and Applications; Royal Society of Chemistry: London, UK, 2009; Chapter 1; pp. 1–36. [Google Scholar] [CrossRef]

- Carlsson, J.-O.; Martin, M.P. Handbook of deposition technologies for films and coatings (Third Edition). Sci. Appl. Technol. 2010, 314–363. [Google Scholar] [CrossRef]

- Chandrashekar, B.N.; Deng, B.; Smitha, A.S.; Chen, Y.; Tan, C.; Zhang, H.; Peng, H.; Liu, Z. Roll-to-Roll Green Transfer of CVD Graphene onto Plastic for a Transparent and Flexible Triboelectric Nanogenerator. Adv. Mater. 2015, 27, 5210–5216. [Google Scholar] [CrossRef]

- Shankaregowda, S.A.; Nanjegowda, C.B.; Cheng, X.-L.; Shi, M.-Y.; Liu, Z.-F.; Zhang, H.-X. A flexible and transparent graphene-based triboelectric nanogenerator. IEEE Trans Nanotechnol. 2016, 15, 435–441. [Google Scholar] [CrossRef]

- Khan, S.A.; Zhang, H.L.; Xie, Y.; Gao, M.; Shah, M.A.; Qadir, A.; Lin, Y. Flexible Triboelectric Nanogenerator Based on Carbon Nanotubes for Self-Powered Weighing. Adv. Eng. Mater. 2016, 19, 1600710. [Google Scholar] [CrossRef]

- Kim, M.; Kim, S.H.; Park, M.U.; Lee, C.; Kim, M.; Yi, Y.; Yoo, K.-H. MoS2 triboelectric nanogenerators based on depletion layers. Nano Energy 2019, 65, 104079. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, Z.; Zeng, X.; Fu, X.; Hu, Y. Ultrathin, flexible and transparent graphene-based triboelectric nanogenerators for attachable curvature monitoring. J. Phys. D Appl. Phys. 2019, 52, 314002. [Google Scholar] [CrossRef]

- Chen, P.-J.; Rodger, D.C.; Meng, E.; Hwnmayun, M.S.; Tail, Y.-C. Implantable unpowered parylene MEMS intraocular pressure sensor. In Proceedings of the 206 International Conference on Microtechnologies in Medicine and Biology, Okinawa, Japan, 9–12 May 2006; pp. 256–259. [Google Scholar] [CrossRef][Green Version]

- Li, P.-Y.; Givrad, T.K.; Holschneider, D.P.; Maarek, J.-M.I.; Meng, E. A Parylene MEMS Electrothermal Valve. J. Microelectromech. Syst. 2009, 18, 1184–1197. [Google Scholar] [CrossRef]

- Kim, J.Y.-H.; Liu, Y.; Scianmarello, N.; Tai, Y.C. Piezoelectric parylene-C MEMS microphone. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 October 2013; pp. 39–42. [Google Scholar] [CrossRef]

- Kim, B.J.; Gutierrez, C.A.; Meng, E. Parylene-Based Electrochemical-MEMS Force Sensor for Studies of Intracortical Probe Insertion Mechanics. J. Microelectromech. Syst. 2015, 24, 1534–1544. [Google Scholar] [CrossRef]

- Wu, C.-H.; Kang, D.; Chen, P.-H.; Tai, Y.-C. MEMS thermal flow sensors. Sensors Actuators A Phys. 2016, 241, 135–144. [Google Scholar] [CrossRef]

- Ortigoza-Diaz, J.; Scholten, K.; Larson, C.; Cobo, A.; Hudson, T.; Yoo, J.; Baldwin, A.; Hirschberg, A.W.; Meng, E. Techniques and Considerations in the Microfabrication of Parylene C Microelectromechanical Systems. Micromachines 2018, 9, 422. [Google Scholar] [CrossRef] [PubMed]

- Mariello, M.; Scarpa, E.; Algieri, L.; Guido, F.; Mastronardi, V.M.; Qualtieri, A.; De Vittorio, M. Novel Flexible Triboelectric Nanogenerator based on Metallized Porous PDMS and Parylene C. Energies 2020, 13, 1625. [Google Scholar] [CrossRef]

- Wang, Q.; Xue, Q.; Chen, T.; Li, J.; Liu, Y.; Shan, X.; Liu, F.; Jia, J. Recent advances in electrochemical sensors for antibiotics and their applications. Chin. Chem. Lett. 2020, 32, 609–619. [Google Scholar] [CrossRef]

- Ko, Y.H.; Nagaraju, G.; Lee, S.H.; Yu, J.S. PDMS-based Triboelectric and Transparent Nanogenerators with ZnO Nanorod Arrays. ACS Appl. Mater. Interfaces 2014, 6, 6631–6637. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Zhang, P.; Deng, L.; Zhang, W.; Liu, B.; Ren, D.; Yang, Z. Three-Dimensional Polypyrrole Nanoarrays for Wearable Triboelectric Nanogenerators. ACS Appl. Nano Mater. 2022, 5, 11219–11228. [Google Scholar] [CrossRef]

- Meng, Y.; Zhang, L.; Xu, G.; Wang, H. Direct-current generators based on conductive polymers for self-powered flexible devices. Sci. Rep. 2021, 11, 1–10. [Google Scholar] [CrossRef]

- Mariappan, V.K.; Krishnamoorthy, K.; Pazhamalai, P.; Natarajan, S.; Sahoo, S.; Nardekar, S.S.; Kim, S.-J. Antimonene dendritic nanostructures: Dual-functional material for high-performance energy storage and harvesting devices. Nano Energy 2020, 77, 105248. [Google Scholar] [CrossRef]

- Yang, G.; Yang, H.; Wang, M.; Sun, Y.; Wang, M. Application of Nanofiber Material Based on Electrospinning Technology in Sports Rehabilitation of Basketball Player’s Wrist Joint. J. Nanomater. 2022, 2022, 1–9. [Google Scholar] [CrossRef]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef]

- Lu, T.; Cui, J.; Qu, Q.; Wang, Y.; Zhang, J.; Xiong, R.; Ma, W.; Huang, C. Multistructured Electrospun Nanofibers for Air Filtration: A Review. ACS Appl. Mater. Interfaces 2021, 13, 23293–23313. [Google Scholar] [CrossRef]

- Huang, T.; Wang, C.; Yu, H.; Wang, H.; Zhang, Q.; Zhu, M. Human walking-driven wearable all-fiber triboelectric nanogenerator containing electrospun polyvinylidene fluoride piezoelectric nanofibers. Nano Energy 2014, 14, 226–235. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, J.; Du, X.; Wang, J.; Cao, R.; Yin, Y.; Zhang, X.; Yuan, Z.; Xing, Y.; Pui, D.Y.H.; et al. All-Nanofiber-Based Ultralight Stretchable Triboelectric Nanogenerator for Self-Powered Wearable Electronics. ACS Appl. Energy Mater. 2018, 1, 2326–2332. [Google Scholar] [CrossRef]

- Ye, Q.; Wu, Y.; Qi, Y.; Shi, L.; Huang, S.; Zhang, L.; Li, M.; Li, W.; Zeng, X.; Wo, H.; et al. Effects of liquid metal particles on performance of triboelectric nanogenerator with electrospun polyacrylonitrile fiber films. Nano Energy 2019, 61, 381–388. [Google Scholar] [CrossRef]

- Li, Y.; Xiong, J.; Lv, J.; Chen, J.; Gao, D.; Zhang, X.; Lee, P.S. Mechanically interlocked stretchable nanofibers for multifunctional wearable triboelectric nanogenerator. Nano Energy 2020, 78, 105358. [Google Scholar] [CrossRef]

- Shi, L.; Jin, H.; Dong, S.; Huang, S.; Kuang, H.; Xu, H.; Chen, J.; Xuan, W.; Zhang, S.; Li, S.; et al. High-performance triboelectric nanogenerator based on electrospun PVDF-graphene nanosheet composite nanofibers for energy harvesting. Nano Energy 2020, 80, 105599. [Google Scholar] [CrossRef]

- Sun, N.; Wang, G.-G.; Zhao, H.-X.; Cai, Y.-W.; Li, J.-Z.; Li, G.-Z.; Zhang, X.-N.; Wang, B.-L.; Han, J.-C.; Wang, Y.; et al. Waterproof, breathable and washable triboelectric nanogenerator based on electrospun nanofiber films for wearable electronics. Nano Energy 2021, 90, 106639. [Google Scholar] [CrossRef]

- Gu, G.Q.; Han, C.B.; Lu, C.X.; He, C.; Jiang, T.; Gao, Z.L.; Li, C.J.; Wang, Z.L. Triboelectric Nanogenerator Enhanced Nanofiber Air Filters for Efficient Particulate Matter Removal. ACS Nano 2017, 11, 6211–6217. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Luo, H.; Gao, D.; Zhou, X.; Cui, P.; Thangavel, G.; Parida, K.; Lee, P.S. Self-restoring, waterproof, tunable microstructural shape memory triboelectric nanogenerator for self-powered water temperature sensor. Nano Energy 2019, 61, 584–593. [Google Scholar] [CrossRef]

- Jang, S.; Kim, H.; Kim, Y.; Kang, B.J.; Oh, J.H. Honeycomb-like nanofiber based triboelectric nanogenerator using self-assembled electrospun poly(vinylidene fluoride-co-trifluoroethylene) nanofibers. Appl. Phys. Lett. 2016, 108, 143901. [Google Scholar] [CrossRef]

- Huang, J.; Hao, Y.; Zhao, M.; Li, W.; Huang, F.; Wei, Q. All-Fiber-Structured Triboelectric Nanogenerator via One-Pot Electrospinning for Self-Powered Wearable Sensors. ACS Appl. Mater. Interfaces 2021, 13, 24774–24784. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Huang, J.; Liao, S.; Chen, D.; Wei, Q. All-electrospun performance-enhanced triboelectric nanogenerator based on the charge-storage process. J. Mater. Sci. 2022, 57, 5334–5345. [Google Scholar] [CrossRef]

- Huang, T.; Lu, M.; Yu, H.; Zhang, Q.; Wang, H.; Zhu, M. Enhanced Power Output of a Triboelectric Nanogenerator Composed of Electrospun Nanofiber Mats Doped with Graphene Oxide. Sci. Rep. 2015, 5, srep13942. [Google Scholar] [CrossRef]

- Huang, T.; Yu, H.; Wang, H.; Zhang, Q.; Zhu, M. Hydrophobic SiO2 Electret Enhances the Performance of Poly(vinylidene fluoride) Nanofiber-Based Triboelectric Nanogenerator. J. Phys. Chem. C 2016, 120, 26600–26608. [Google Scholar] [CrossRef]

- Ozen, A.; Ozel, F.; Kınas, Z.; Karabiber, A.; Polat, S. Spring assisted triboelectric nanogenerator based on sepiolite doped polyacrylonitrile nanofibers. Sustain. Energy Technol. Assessments 2021, 47, 101492. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, C.; Li, X.; Yao, Y.; Lan, L.; Zhao, F.; Ye, Z.; Ying, Y.; Ping, J. All-electrospun flexible triboelectric nanogenerator based on metallic MXene nanosheets. Nano Energy 2019, 59, 268–276. [Google Scholar] [CrossRef]

- Chu, Z.; Peng, J.; Jin, W. Advanced nanomaterial inks for screen-printed chemical sensors. Sens. Actuators B Chem. 2017, 243, 919–926. [Google Scholar] [CrossRef]

- Gong, X.; Huang, K.; Wu, Y.-H.; Zhang, X.-S. Recent progress on screen-printed flexible sensors for human health monitoring. Sensors Actuators A Phys. 2022, 345, 113821. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Y.; Zheng, S.; Zhang, L.; Shi, X.; He, J.; Chou, X.; Wu, Z.-S. Ink formulation, scalable applications and challenging perspectives of screen printing for emerging printed microelectronics. J. Energy Chem. 2021, 63, 498–513. [Google Scholar] [CrossRef]

- Cao, R.; Wang, J.; Zhao, S.; Yang, W.; Yuan, Z.; Yin, Y.; Du, X.; Li, N.-W.; Zhang, X.; Li, X.; et al. Self-powered nanofiber-based screen-print triboelectric sensors for respiratory monitoring. Nano Res. 2018, 11, 3771–3779. [Google Scholar] [CrossRef]

- Sagar, H.P.; Meti, S.; Bhat, U.K.; Gupta, D. Triboelectric effect based self-powered compact vibration sensor for predictive maintenance of industrial machineries. Meas. Sci. Technol. 2021, 32, 095119. [Google Scholar] [CrossRef]

- Meti, S.; Sagar, H.P.; Rahman, M.R.; Bhat, K.U. Assessment of triboelectricity in colossal-surface-area-lanthanum oxide nanocrystals synthesized via low-temperature hydrothermal process. J. Mater. Sci. Mater. Electron. 2021, 32, 20351–20361. [Google Scholar] [CrossRef]

- Paosangthong, W.; Wagih, M.; Torah, R.; Beeby, S. Textile-based triboelectric nanogenerator with alternating positive and negative freestanding grating structure. Nano Energy 2019, 66, 104148. [Google Scholar] [CrossRef]

- Liu, H.; Xu, Y.; Xiao, Y.; Zhang, S.; Qu, C.; Lv, L.; Chen, H.; Song, G. Highly Adaptive Liquid–Solid Triboelectric Nanogenerator-Assisted Self-Powered Water Wave Motion Sensor. ACS Appl. Electron. Mater. 2022, 4, 3870–3879. [Google Scholar] [CrossRef]

- Prutvi, S.H.; Korrapati, M.; Gupta, D. Self-powering vibration sensor based on a cantilever system with a single-electrode mode triboelectric nanogenerator. Meas. Sci. Technol. 2022, 33, 075115. [Google Scholar] [CrossRef]

- Yang, H.J.; Lee, J.-W.; Seo, S.H.; Jeong, B.; Lee, B.; Do, W.J.; Kim, J.H.; Cho, J.Y.; Jo, A.; Jeong, H.J.; et al. Fully stretchable self-charging power unit with micro-supercapacitor and triboelectric nanogenerator based on oxidized single-walled carbon nanotube/polymer electrodes. Nano Energy 2021, 86, 106083. [Google Scholar] [CrossRef]

- Scharnweber, T.; Truckenmüller, R.; Schneider, A.M.; Welle, A.; Reinhardt, M.; Giselbrecht, S. Rapid prototyping of microstructures in polydimethylsiloxane (PDMS) by direct UV-lithography. Lab Chip 2011, 11, 1368–1371. [Google Scholar] [CrossRef]

- Xue, C.-Y.; Zhang, W.; Choo, W.H.S.; Yang, K.-L. Simplest Method for Creating Micropatterned Nanostructures on PDMS with UV Light. Langmuir 2011, 27, 13410–13414. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Wang, X.; Li, H.; Wu, J.; Hu, Y.; Li, Z.; Liu, H. Fundamental research on the effective contact area of micro-/nano-textured surface in triboelectric nanogenerator. Nano Energy 2019, 57, 41–47. [Google Scholar] [CrossRef]

- Fan, F.-R.; Lin, L.; Zhu, G.; Wu, W.; Zhang, R.; Wang, Z.L. Transparent Triboelectric Nanogenerators and Self-Powered Pressure Sensors Based on Micropatterned Plastic Films. Nano Lett. 2012, 12, 3109–3114. [Google Scholar] [CrossRef]

- Zhang, L.; Su, C.; Cheng, L.; Cui, N.; Gu, L.; Qin, Y.; Yang, R.; Zhou, F. Enhancing the Performance of Textile Triboelectric Nanogenerators with Oblique Microrod Arrays for Wearable Energy Harvesting. ACS Appl. Mater. Interfaces 2019, 11, 26824–26829. [Google Scholar] [CrossRef]

- Dhakar, L.; Tay, F.E.H.; Lee, C. Development of a Broadband Triboelectric Energy Harvester With SU-8 Micropillars. J. Microelectromech. Syst. 2014, 24, 91–99. [Google Scholar] [CrossRef]

- Hong, S.; Lee, H.; Yeo, J.; Ko, S.H. Digital selective laser methods for nanomaterials: From synthesis to processing. Nano Today 2016, 11, 547–564. [Google Scholar] [CrossRef]

- Palneedi, H.; Park, J.H.; Maurya, D.; Peddigari, M.; Hwang, G.-T.; Annapureddy, V.; Kim, J.-W.; Choi, J.-J.; Hahn, B.-D.; Priya, S.; et al. Laser irradiation of metal oxide films and nanostructures: Applications and advances. Adv. Mater. 2018, 30, 1705148. [Google Scholar] [CrossRef]

- Hu, H.; Li, Q.; Li, L.; Teng, X.; Feng, Z.; Zhang, Y.; Wu, M.; Qiu, J. Laser Irradiation of Electrode Materials for Energy Storage and Conversion. Matter 2020, 3, 95–126. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Z.; Chen, D.; Liu, F.; Yang, Z.; Li, X.; Yu, H.; Liu, H.; Zhou, W. Laser Synthesis and Microfabrication of Micro/Nanostructured Materials Toward Energy Conversion and Storage. Nano-Micro Lett. 2021, 13, 1–48. [Google Scholar] [CrossRef]

- Xiao, X.; Lü, C.; Wang, G.; Xu, Y.; Wang, J.; Yang, H. Flexible triboelectric nanogenerator from micro-nano structured polydimethylsiloxane. Chem. Res. Chin. Univ. 2015, 31, 434–438. [Google Scholar] [CrossRef]

- Kim, D.; Tcho, I.-W.; Jin, I.K.; Park, S.-J.; Jeon, S.-B.; Kim, W.-G.; Cho, H.-S.; Lee, H.-S.; Jeoung, S.C.; Choi, Y.-K. Direct-laser-patterned friction layer for the output enhancement of a triboelectric nanogenerator. Nano Energy 2017, 35, 379–386. [Google Scholar] [CrossRef]

- Muthu, M.; Pandey, R.; Wang, X.; Chandrasekhar, A.; Palani, I.; Singh, V. Enhancement of triboelectric nanogenerator output performance by laser 3D-Surface pattern method for energy harvesting application. Nano Energy 2020, 78, 105205. [Google Scholar] [CrossRef]

- Cho, H.; Jo, S.; Kim, I.; Kim, D. Film-Sponge-Coupled Triboelectric Nanogenerator with Enhanced Contact Area Based on Direct Ultraviolet Laser Ablation. ACS Appl. Mater. Interfaces 2021, 13, 48281–48291. [Google Scholar] [CrossRef]

- Wang, S.; Xie, G.; Tai, H.; Su, Y.; Yang, B.; Zhang, Q.; Du, X.; Jiang, Y. Ultrasensitive flexible self-powered ammonia sensor based on triboelectric nanogenerator at room temperature. Nano Energy 2018, 51, 231–240. [Google Scholar] [CrossRef]

- Phan, H.; Hoa, P.; Tam, H.; Thang, P. Q-switched pulsed laser direct writing of aluminum surface micro/nanostructure for triboelectric performance enhancement. J. Sci. Adv. Mater. Devices 2020, 6, 84–91. [Google Scholar] [CrossRef]

- Huang, J.; Fu, X.; Liu, G.; Xu, S.; Li, X.; Zhang, C.; Jiang, L. Micro/nano-structures-enhanced triboelectric nanogenerators by femtosecond laser direct writing. Nano Energy 2019, 62, 638–644. [Google Scholar] [CrossRef]

- Phan, H.; Hoa, P.; Tam, H.; Thang, P.; Duc, N. Multi-directional triboelectric nanogenerator based on industrial Q-switched pulsed laser etched Aluminum film. Extreme Mech. Lett. 2020, 40, 100886. [Google Scholar] [CrossRef]

- Chung, C.; Ke, K. High contact surface area enhanced Al/PDMS triboelectric nanogenerator using novel overlapped microneedle arrays and its application to lighting and self-powered devices. Appl. Surf. Sci. 2020, 508, 145310. [Google Scholar] [CrossRef]

- Pradel, K.C.; Fukata, N. Systematic optimization of triboelectric nanogenerator performance through surface micropatterning. Nano Energy 2021, 83, 105856. [Google Scholar] [CrossRef]

- Zhang, H.; Cui, X.; Cao, S.; Zhang, Q.; Sang, S.; Zhang, W. Human Body as a Power Source for Biomechanical Energy Scavenging Based on Electrode-Free Triboelectric Nanogenerators. Energy Technol. 2018, 6, 2053–2057. [Google Scholar] [CrossRef]

- Chen, G.; Xu, L.; Zhang, P.; Chen, B.; Wang, G.; Ji, J.; Pu, X.; Wang, Z.L. Seawater Degradable Triboelectric Nanogenerators for Blue Energy. Adv. Mater. Technol. 2020, 5, 2000455. [Google Scholar] [CrossRef]

- Li, C.; Wang, Z.; Shu, S.; Tang, W. A Self-Powered Vector Angle/Displacement Sensor Based on Triboelectric Nanogenerator. Micromachines 2021, 12, 231. [Google Scholar] [CrossRef]

- Shin, Y.; Cho, S.; Han, S.; Jung, G.Y. Omni-directional wind-driven triboelectric nanogenerator with cross-shaped dielectric film. Nano Converg. 2021, 8, 25. [Google Scholar] [CrossRef]

- Prada, T.; Harnchana, V.; Lakhonchai, A.; Chingsungnoen, A.; Poolcharuansin, P.; Chanlek, N.; Klamchuen, A.; Thongbai, P.; Amornkitbamrung, V. Enhancement of output power density in a modified polytetrafluoroethylene surface using a sequential O2/Ar plasma etching for triboelectric nanogenerator applications. Nano Res. 2022, 15, 272–279. [Google Scholar] [CrossRef]

- Cheng, G.-G.; Jiang, S.-Y.; Li, K.; Zhang, Z.-Q.; Wang, Y.; Yuan, N.-Y.; Ding, J.-N.; Zhang, W. Effect of argon plasma treatment on the output performance of triboelectric nanogenerator. Appl. Surf. Sci. 2017, 412, 350–356. [Google Scholar] [CrossRef]

- Wang, M.; Li, W.; You, C.; Wang, Q.; Zeng, X.; Chen, M. Triboelectric nanogenerator based on 317L stainless steel and ethyl cellulose for biomedical applications. RSC Adv. 2017, 7, 6772–6779. [Google Scholar] [CrossRef]

- Jeon, S.-B.; Kim, S.; Park, S.-J.; Seol, M.-L.; Kim, D.; Chang, Y.K.; Choi, Y.-K. Self-powered electro-coagulation system driven by a wind energy harvesting triboelectric nanogenerator for decentralized water treatment. Nano Energy 2016, 28, 288–295. [Google Scholar] [CrossRef]

- Chen, S.W.; Cao, X.; Wang, N.; Ma, L.; Zhu, H.R.; Willander, M.; Jie, Y.; Wang, Z.L. An Ultrathin Flexible Single-Electrode Triboelectric-Nanogenerator for Mechanical Energy Harvesting and Instantaneous Force Sensing. Adv. Energy Mater. 2016, 7, 1601255. [Google Scholar] [CrossRef]

- Wang, S.; He, M.; Weng, B.; Gan, L.; Zhao, Y.; Li, N.; Xie, Y. Stretchable and Wearable Triboelectric Nanogenerator Based on Kinesio Tape for Self-Powered Human Motion Sensing. Nanomaterials 2018, 8, 657. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Dong, K.; Li, X.; An, J.; Wu, D.; Peng, X.; Yi, J.; Ning, C.; Cheng, R.; Yu, P.; et al. Stretchable, washable, and ultrathin triboelectric nanogenerators as skin-like highly sensitive self-powered haptic sensors. Adv. Funct. Mater. 2020, 31, 2005584. [Google Scholar] [CrossRef]

- Lin, L.; Xie, Y.; Niu, S.; Wang, S.; Yang, P.-K.; Wang, Z.L. Robust Triboelectric Nanogenerator Based on Rolling Electrification and Electrostatic Induction at an Instantaneous Energy Conversion Efficiency of ∼55%. ACS Nano 2015, 9, 922–930. [Google Scholar] [CrossRef]

- Cheng, X.; Meng, B.; Chen, X.; Han, M.; Chen, H.; Su, Z.; Shi, M.; Zhang, H. Single-Step Fluorocarbon Plasma Treatment-Induced Wrinkle Structure for High-Performance Triboelectric Nanogenerator. Small 2015, 12, 229–236. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett. 1995, 67, 3114–3116. [Google Scholar] [CrossRef]

- Guo, L.J. Recent progress in nanoimprint technology and its applications. J. Phys. D Appl. Phys. 2004, 37, R123–R141. [Google Scholar] [CrossRef]

- Guo, L.J. Nanoimprint Lithography: Methods and Material Requirements. Adv. Mater. 2007, 19, 495–513. [Google Scholar] [CrossRef]

- Yoo, D.; Lee, S.; Lee, J.-W.; Lee, K.; Go, E.Y.; Hwang, W.; Song, I.; Cho, S.B.; Kim, D.W.; Choi, D.; et al. Reliable DC voltage generation based on the enhanced performance triboelectric nanogenerator fabricated by nanoimprinting-poling process and an optimized high efficiency integrated circuit. Nano Energy 2019, 69, 104388. [Google Scholar] [CrossRef]

- Zhang, M.; Xia, L.; Dang, S.; Shi, L.; Cao, A.; Deng, Q.; Du, C. A flexible single-electrode-based triboelectric nanogenerator based on double-sided nanostructures. AIP Adv. 2019, 9, 075221. [Google Scholar] [CrossRef]

- Choi, D.; Yoo, D.; Kim, D.S. One-Step Fabrication of Transparent and Flexible Nanotopographical-Triboelectric Nanogenerators via Thermal Nanoimprinting of Thermoplastic Fluoropolymers. Adv. Mater. 2015, 27, 7386–7394. [Google Scholar] [CrossRef]

- Mahmud, M.P.; Lee, J.; Kim, G.; Lim, H.; Choi, K.-B. Improving the surface charge density of a contact-separation-based triboelectric nanogenerator by modifying the surface morphology. Microelectron. Eng. 2016, 159, 102–107. [Google Scholar] [CrossRef]

- Dudem, B.; Kim, D.H.; Mule, A.R.; Yu, J.S. Enhanced Performance of Microarchitectured PTFE-Based Triboelectric Nanogenerator via Simple Thermal Imprinting Lithography for Self-Powered Electronics. ACS Appl. Mater. Interfaces 2018, 10, 24181–24192. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.; Kim, J.; Ahn, J.; Jeong, J.; Park, I.; Kim, D.; Oh, I. Collectively Exhaustive Hybrid Triboelectric Nanogenerator Based on Flow-Induced Impacting-Sliding Cylinder for Ocean Energy Harvesting. Adv. Energy Mater. 2021, 12, 2103076. [Google Scholar] [CrossRef]

- La, M.; Choi, J.H.; Choi, J.-Y.; Hwang, T.Y.; Kang, J.; Choi, D. Development of the Triboelectric Nanogenerator Using a Metal-to-Metal Imprinting Process for Improved Electrical Output. Micromachines 2018, 9, 551. [Google Scholar] [CrossRef]

- Mishra, M.K.; Dubey, V.; Mishra, P.M.; Khan, I. MEMS Technology: A Review. J. Eng. Res. Rep. 2019, 4, 1–24. [Google Scholar] [CrossRef]

- Coppola, G.; Iodice, M.; Finizio, A.; De Nicola, S.M.; Pierattini, G.; Ferraro, P., Jr.; Magro, C.; Spoto, G. Digital holography microscope as tool for microelectromechanical systems characterization and design. J. Micro/Nanolithography MEMS MOEMS 2005, 4, 013012. [Google Scholar] [CrossRef]

- Tilli, M.; Paulasto-Krockel, M.; Petzold, M.; Theuss, H.; Motooka, T.; Lindroos, V. Handbook of Silicon Based MEMS Materials and Technologies; Elsevier: Amsterdam, The Netherlands, 2020; p. xxi. [Google Scholar]

- Ali, W.R.; Prasad, M. Piezoelectric MEMS based acoustic sensors: A review. Sensors Actuators A Phys. 2019, 301, 111756. [Google Scholar] [CrossRef]

- Prasad, M.; Sahula, V.; Khanna, V.K. Design and Fabrication of Si-Diaphragm, ZnO Piezoelectric Film-Based MEMS Acoustic Sensor Using SOI Wafers. IEEE Trans. Semicond. Manuf. 2013, 26, 233–241. [Google Scholar] [CrossRef]

- Ali, W.R.; Prasad, M. Fabrication of microchannel and diaphragm for a MEMS acoustic sensor using wet etching technique. Microelectron. Eng. 2021, 253, 111670. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, Y.; Guo, L.; Wang, P.; He, X.; Dai, G.; Zheng, H.; Chen, C.; Wang, A.C.; Xu, C.; et al. Quantifying the triboelectric series. Nat. Commun. 2019, 10, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Hamid, H.M.A.; Celik-Butler, Z. Design and Optimization of a MEMS Triboelectric Energy Harvester for Nano-sensor Applications. In Proceedings of the 2019 IEEE Sensors Applications Symposium (SAS), Sophia Antipolis, France, 11–13 March 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Hamid, H.M.A.; Çelik-Butler, Z. A novel MEMS triboelectric energy harvester and sensor with a high vibrational operating frequency and wide bandwidth fabricated using UV-LIGA technique. Sensors Actuators A Phys. 2020, 313, 112175. [Google Scholar] [CrossRef]

- Alzgool, M.; Mousavi, M.; Davaji, B.; Towfighian, S. Micro-triboelectric generator for zero-power shock detection. Nano Energy 2022, 103, 107758. [Google Scholar] [CrossRef]

| TENGs | Technologies | Materials | Film Thickness/Micro-Nano Structures/TENG Size | Output Performance | Ref. |

|---|---|---|---|---|---|

| 3D-TENG | PVD | Al | 100 nm | VOC = 303 V, ISC = 1140 μA, 104.6 W/m2 | [25] |

| GSEC-based TENG | PVD | GSEC | 100 nm, 25 mm × 25 mm | VOC = 13.5 V, JSC = 0.35 μA/cm2, 6.3 W/m2 | [28] |

| C60-based TENG | PVD | C60 | 200 nm | VOC = 1600 V, ISC = 100 µA, 38 W/m2 | [29] |

| Graphene-based TENG | CVD | Graphene | 30 mm × 40 mm | VOC = 22 V, ISC = 0.9 µA | [33] |

| CS-TENG | CVD | Parylene | 2 µm, 20 mm × 20 mm | VOC = 3 V | [37] |

| S-TENG | CVD | Parylene C | 1 µm, 20 mm × 20 mm | VOC = 1.6 V, ISC = 0.15 µA, 0.00224 W/m2 | [44] |

| ZnO-based TENG | ECD | ZnO | 360 nm, 20 mm × 20 mm | VOC = 5.34 V, ISC = 0.1814 µA | [46] |

| PPy-PVDF TENG | ECD | PPy | 20 mm × 20 mm | VOC = 20.2 V, ISC = 1.3 μA, 0.0124 W/m2 | [47] |

| Sb-TENG | ECD | Antimonene | 20 nm | VOC = 54 V, ISC = 0.87 μA, 0.0685 W/m2 | [49] |

| PVDF/G-PA6 TENG | Electrospinning | PVDF/Graphene | 50 µm, 20 mm × 20 mm | VOC = 1511 V, JSC = 18.9 μA/cm2, 130.2 W/m2 | [57] |

| NF-TENG | Electrospinning | PA66/MWCNTs | 49 µm, 20 mm × 20 mm | VOC = 142 V, ISC = 15.5 µA, 1.30 W/m2 | [58] |

| MSNFs mat-TENG | Electrospinning | SMPU | 40 μm | VOC = 320 V, JSC = 4 μA/cm2 | [60] |

| La2O3-TENG | Screen printing | La2O3 | 10 µm, 25 mm × 25 mm | VOC = 120 V, ISC = 23.7 μA, 7.125 W/m2 | [73] |

| pnG-TENG | Screen printing | Ag | VOC = 136 V, ISC = 2.68 μA, 0.0388 W/m2 | [74] | |

| S-TENG | Screen printing | ZnO | 7 µm | VOC = 25 V, ISC = 10 µA, 1.38 W/m2 | [76] |

| Pyramid-TENG | Soft lithography | PDMS | Pyramid, 45 mm × 12 mm × 460 μm | VOC = 18 V, ISC = 0.7 μA | [81] |

| WTNG | Soft lithography | PDMS | Oblique microrod | VOC = 1014.2 V, JSC =3.24 μA/cm2, 2.117 W/m2 | [82] |

| TEH | Soft lithography | Au | Micropillar | 0.0023 W/m2 | [83] |

| Line-patterned TENG | Laser ablation | PET | Line | VOC = 36 V, ISC = 0.46 μA, 0.008 W/m2 | [90] |

| Cu-PDMS TENG | Laser ablation | Cu, PDMS | Micro/nano-cone, micro-bowl | VOC = 22.04 V, 0.21 W/m2 | [94] |

| SA-TENG | Laser ablation | Al | Groove, 50 mm × 50 mm | VOC = 66 V, ISC = 5.1 µA, 350 µW | [95] |

| PTFE-based TENG | ICP | PTFE | Nanowire | VOC = 110.3 V, ISC = 8.8 μA, 9.9 W/m2 | [102] |

| PDMS-based TENG | ICP | PDMS | Micro-pillar, 10 mm × 10 mm | VOC = 72 V, ISC = 8.3 μA | [103] |

| EC-based TENG | ICP | EC | Micro-patterns, 20 mm × 30 mm | VOC = 245 V, ISC = 50 μA | [104] |

| S-TENG | Nanoimprint | PDMS | Nanopillar arrays | VOC = 160 V, ISC = 3 μA, 0.4238 W/m2 | [115] |

| PDMS-PMMA TENG | Nanoimprint | PDMS, PMMA | Hexagonal, 40 mm × 40 mm | VOC = 451.75 V, JSC = 237.28 μA/m2, 0.10719 W/m2 | [117] |

| PTFE-based TENG | Nanoimprint | PTFE | Microgroove, 50 mm × 50 mm | VOC = 625 V, ISC = 50.5 μA, 252 W/m2 | [118] |

| µTUD | MEMS fabrication | Si, SiO2 | VOC = 0.0168 V, 0.297 μW | [22] | |

| MEMS-TENG | MEMS fabrication | Al, PTFE | 5 mm × 3 mm × 8.5 µm | VOC = 26.9 V, ISC = 0.56 µA, 0.0131 W/m2 | [128] |

| MEMS-TENG | MEMS fabrication | Al, PTFE | 5 mm × 3 mm × 15.1 µm | 0.0398 W/m2 | [129] |

| MEMS-TENG | MEMS fabrication | Al, PI | 1.5 mm × 1.5 mm × 1.1 µm | VOC = 0.4 V | [130] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, X.; Qi, Y.; Bu, T.; Li, X.; Liu, G.; Zeng, J.; Fan, B.; Zhang, C. Overview of Advanced Micro-Nano Manufacturing Technologies for Triboelectric Nanogenerators. Nanoenergy Adv. 2022, 2, 316-343. https://doi.org/10.3390/nanoenergyadv2040017

Huang X, Qi Y, Bu T, Li X, Liu G, Zeng J, Fan B, Zhang C. Overview of Advanced Micro-Nano Manufacturing Technologies for Triboelectric Nanogenerators. Nanoenergy Advances. 2022; 2(4):316-343. https://doi.org/10.3390/nanoenergyadv2040017

Chicago/Turabian StyleHuang, Xinlong, Youchao Qi, Tianzhao Bu, Xinrui Li, Guoxu Liu, Jianhua Zeng, Beibei Fan, and Chi Zhang. 2022. "Overview of Advanced Micro-Nano Manufacturing Technologies for Triboelectric Nanogenerators" Nanoenergy Advances 2, no. 4: 316-343. https://doi.org/10.3390/nanoenergyadv2040017

APA StyleHuang, X., Qi, Y., Bu, T., Li, X., Liu, G., Zeng, J., Fan, B., & Zhang, C. (2022). Overview of Advanced Micro-Nano Manufacturing Technologies for Triboelectric Nanogenerators. Nanoenergy Advances, 2(4), 316-343. https://doi.org/10.3390/nanoenergyadv2040017