Synthetic polymers and biodegradable and biobased polymers are currently the largest class of materials studied and used for various applications due to their unique and peculiar properties. For manufactured products made of non-biodegradable polymers, effective end-of-life management through mechanical and chemical recycling is crucial for their future consumption, especially in the case of products with short lifetimes that generate large volumes of waste. For biodegradable polymers, often obtained from renewable sources, the additional opportunity for organic recycling by composting or anaerobic digestion for the end-of-life of such products is a very beneficial element that fits well with the circular economy principles [1]. This can be particularly advantageous for widespread products such as packaging, personal care, cosmetics, and sanitary products that could be gradually replaced with renewable and biodegradable materials. Another exciting aspect is that many renewable materials exhibit high biocompatibility, which could facilitate their use in various applications associated with body and skin contact [2].

In addition to their primary function (protection, containment, preservation, etc.), consumer goods must often possess additional properties that enhance product performance. To this end, several approaches have been proposed to endow polymers with specific functionalities, such as antioxidant, antimicrobial, and anti-inflammatory properties. For example, incorporating functional additives into polymer matrices by extrusion or solvent casting [3,4] or the deposition of additives on the surface of the finished product [5] are effective methods that improve the performance of biobased materials and significantly increase their efficiency and competitiveness compared with fossil-derived materials.

Many molecules and biomaterials from terrestrial or marine environments can be considered for formulating or modifying short-lived polymeric products. A wide range of natural molecules from the marine environment, for example, exhibit antimicrobial properties and could potentially be used in cosmeceutical and nutraceutical applications due to their depigmenting, UV-filtering, anti-inflammatory, anti-wrinkle, anti-ageing, moisturizing, anti-acne, as well as antioxidant and cytoprotective properties [6,7]. However, molecules of plant origin have some limitations because plants grow slowly, and their chemical composition varies from region to region and season to season. In any case, molecules extracted from different terrestrial plants may be of interest because they are already widely available and can be accumulated in different plants [8]. Another significant advantage is that these molecules can often be obtained from agricultural wastes or by-products [9]. For example, waste materials from agri-food industries represent an easily accessible source of phenolic compounds that have recognized antioxidant properties and that, in addition to their use as dietary supplements or as additives in functional foods, have also become increasingly attractive technologically for their possible exploitation in materials science [10,11]. Incorporating polyphenols into polymers, either for stabilization or functionalization purposes, is particularly relevant for active food packaging to prevent or slow oxidative deterioration of food [12]. For example, several articles have reported that polyphenols from by-products of the agribusiness industry, including grape pomace, spent coffee grounds, orange peels, pomegranate processing waste, and walnut shells, can exert powerful stabilizing action on various polymers, proving to be competitive and low-cost additives for active packaging and food preservation [13,14,15,16].

In recent years, biomolecules have also emerged as a promising tool to confer antimicrobial resistance and inhibit biofilm formation, which is the preferred growth strategy for the expansion and survival of many clinically and environmentally relevant microorganisms. Chemical biocides are commonly used to control microbial contamination and biofilm. However, several concerns are related to these substances' intensive and prolonged use. Long-term exposure to antimicrobial agents, for example, can increase the tolerance of microorganisms to certain compounds and lead to antimicrobial cross-resistance [17]. In addition, the most used biocides can impact the environment and human health. Therefore, interest in additional or alternative compounds has increased, and identifying biobased compounds from natural sources as new disinfectant products is one of the most current challenges. It has been shown that polyphenols can inhibit biofilm formation or even eradicate it. In addition, several works have suggested using biomolecules to impart antimicrobial and antioxidant properties to fibers and nonwoven fabrics. For example, poly(vinyl alcohol) fibers containing liquorice root extracts (with antimicrobial properties) were obtained by electrospinning [18], antiviral polymerization fibers were prepared with cranberry extracts [19], and mixtures of polyphenols extracted from cloves, green tea, and olive leaves were deposited on the surface of nonwoven face masks showing virucidal properties [20].

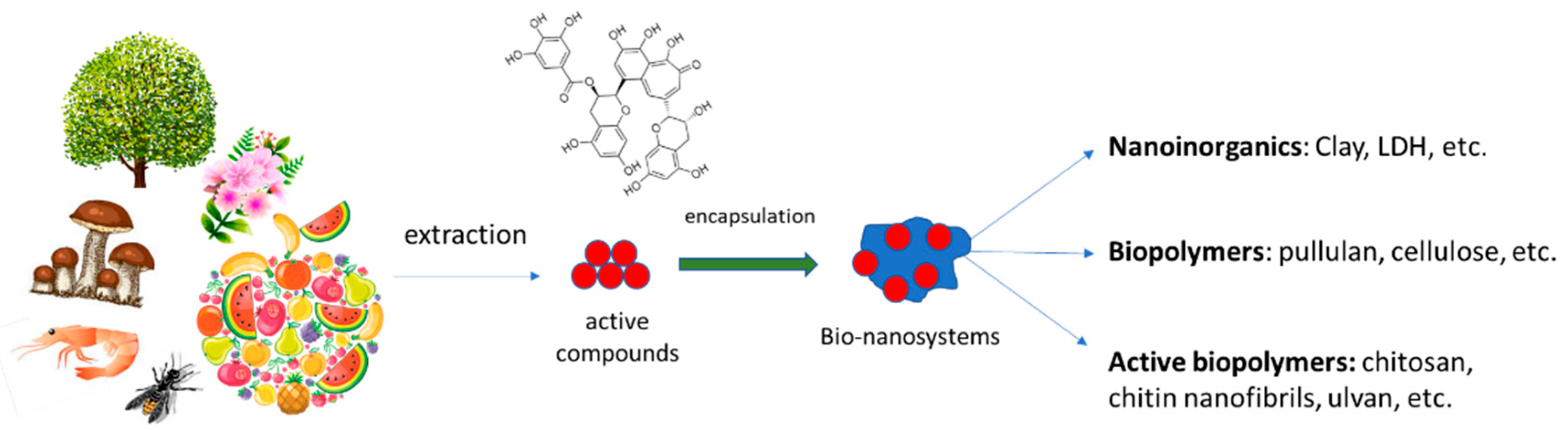

However, biomolecules are vulnerable to oxygen, light, heat, and pH. Therefore, encapsulation of these molecules can be helpful for better modulation of their properties and easier integration of functional molecules into the final product [21]. In particular, combination with nanostructured materials can lead to the preparation of stable bio-nanosystems [22] that can improve the solubility and bioavailability of these substances, protect them from environmental conditions, and enable their controlled release and targeted delivery. Biopolymers or nanoinorganics are often considered to encapsulate active molecules. An example of nanoinorganics is layered double hydroxides (LDH), which were used to encapsulate salicylic acid and rosmarinic acid [23]. Biopolymers obtained by biotechnology that are useful as carriers of functional compounds are pullulan [24] or bacterial cellulose [25]. Renewable biopolymers can be used, for instance, as active encapsulants, as in the case of chitin nanofibril–nanolignin complexes [26], which are both antimicrobial and antioxidant. These complexes were used to encapsulate vitamin E or C, lutein, glycyrrhetinic acid, and nicotinamide. Ulvan [27] can be considered another encapsulant for active biomolecules. Researchers are particularly engaged in studying the synergistic actions of such bio-nanosystems [26,28,29] and investigating techniques to apply them on polymeric substrates [29].

Nevertheless, encapsulation followed by coating is not the unique methodology for modifying polymeric substrates (Figure 1). For instance, grafting enhanced by plasma or electron beam technologies is also widely considered [30]. After all, the chemical nature and surface morphology of polymeric substrate also play a crucial role in the modification process and its effectiveness.

Figure 1.

Example of production of encapsulated active molecules that can be suitable for the modification of polymeric substrates.

This short editorial does not pretend to be exhaustive on all possible topics related to the preparation and characterization of functional polymeric materials using active biomolecules. It only gives some input to the authors to propose their research. By collecting valuable manuscripts for this Special Issue, we intend to focus the attention of polymer scientists on the advantages that can be obtained in using biomolecules from the marine or terrestrial environment, including as waste or by-products, to endow polymeric materials with functional properties by discussing their possible applications and prospects for use.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Briassoulis, D.; Pikasi, A.; Hiskakis, M. Organic recycling of post-consumer /industrial bio-based plastics through industrial aerobic composting and anaerobic digestion—Techno-economic sustainability criteria and indicators. Polym. Degr. Stab. 2021, 190, 109642. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Danti, S. Biobased materials for skin-contact products promoted by POLYBIOSKIN project. J. Funct. Biomater. 2020, 11, 77. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, A.M.; Estevinho, B.N.; Rocha, F. Preparation and incorporation of functional ingredients in edible films and coatings. Food Bioproc. Technol. 2021, 4, 209. [Google Scholar] [CrossRef]

- Nogueira, G.F.; Oliveira, R.A.D.; Velasco, J.I.; Fakhouri, F.M. Methods of incorporating plant-derived bioactive compounds into films made with agro-based polymers for application as food packaging: A brief review. Polymers 2020, 12, 2518. [Google Scholar] [CrossRef] [PubMed]

- Goddard, J.M.; Hotchkiss, J.H. Polymer surface modification for the attachment of bioactive compounds. Prog. Polym. Sci. 2007, 32, 698. [Google Scholar] [CrossRef]

- Alves, A.; Sousa, E.; Kijjoa, A.; Pinto, M. Marine-derived compounds with potential use as cosmeceuticals and nutricosmetics. Molecules 2020, 25, 2536. [Google Scholar] [CrossRef]

- Faccio, G. Plant complexity and cosmetic innovation. iScience 2020, 23, 101358. [Google Scholar] [CrossRef]

- Osorio, L.L.D.R.; Flórez-López, E.; Grande-Tovar, C.D. The potential of selected agri-food loss and waste to contribute to a circular economy: Applications in the food, cosmetic and pharmaceutical industries. Molecules 2021, 26, 515. [Google Scholar] [CrossRef]

- Faustino, M.; Veiga, M.; Sousa, P.; Costa, E.M.; Silva, S.; Pintado, M. Agro-food byproducts as a new source of natural food additives. Molecules 2019, 24, 1056. [Google Scholar] [CrossRef]

- Zuin, V.G.; Ramin, L.Z. Green and sustainable separation of natural products from agro-industrial waste: Challenges, potentialities, and perspectives on emerging approaches. Topics Curr. Chem. 2018, 376, 1. [Google Scholar] [CrossRef]

- Kammerer, D.R.; Kammerer, J.; Valet, R.; Carle, R. Recovery of polyphenols from the by-products of plant food processing and application as valuable food ingredients. Food Res. Int. 2014, 65, 2–12. [Google Scholar] [CrossRef]

- Ambrogi, V.; Panzella, L.; Persico, P.; Cerruti, P.; Lonz, C.A.; Carfagna, C.; Verotta, L.; Caneva, E.; Napolitano, A.; d’Ischia, M. An antioxidant bioinspired phenolic polymer for efficient stabilization of polyethylene. Biomacromolecules 2014, 15, 302. [Google Scholar] [CrossRef] [PubMed]

- Panzella, L.; Cerruti, P.; Ambrogi, V.; Agustin-Salazar, S.; D’Errico, G.; Carfagna, C.; Goya, L.; Ramos, S.; Martin, M.A.; Napolitano, A.; et al. A superior all-natural antioxidant biomaterial from spent coffee grounds for polymer stabilization, cell protection, and food lipid preservation. ACS Sustain. Chem. Eng. 2016, 4, 1169. [Google Scholar] [CrossRef]

- Jin, Q.; Neilson, A.P.; Stewart, A.C.; O’Keefe, S.F.; Kim, Y.-T.; McGuire, M.; Wilder, G.; Huang, H. An integrated approach for the valorization of red grape pomace: Production of oil, polyphenols, and acetone−butanol−ethanol (ABE). ACS Sustain. Chem. Eng. 2018, 6, 16279. [Google Scholar] [CrossRef]

- Rehan, M.; Abdel-Wahed, N.A.M.; Farouk, A.; El-Zawahry, M.M. Extraction of valuable compounds from orange peel waste for advanced functionalization of cellulosic surfaces. ACS Sustain. Chem. Eng. 2018, 6, 5911. [Google Scholar] [CrossRef]

- Moccia, F.; Agustin-Salazar, S.; Berg, A.L.; Setaro, B.; Micillo, R.; Pizzo, E.; Weber, F.; Gamez-Meza, N.; Schieber, A.; Cerruti, P.; et al. Pecan (Carya illinoinensis (Wagenh.) K. Koch) nut shell as an accessible polyphenol source for active packaging and food colorant stabilization. ACS Sustain. Chem. Eng. 2020, 8, 6700–6712. [Google Scholar] [CrossRef]

- Glinel, K.; Thebault, P.; Humblot, V.; Pradier, C.M.; Jouenne, T. Antibacterial surfaces developed from bio-inspired approaches. Acta Biomat. 2012, 8, 1670. [Google Scholar] [CrossRef]

- Chowdhury, M.A.; Shuvho, M.B.A.; Shahid, M.A.; Haque, A.M.; Kashem, M.A.; Lam, S.S.; Ong, H.C.; Uddin, M.A.; Mofijur, M. Prospect of biobased antiviral face mask to limit the coronavirus outbreak. Environ. Res. 2021, 192, 110294. [Google Scholar] [CrossRef]

- Takayama, K.; Tuñón-Molina, A.; Cano-Vicent, A.; Muramoto, Y.; Noda, T.; Aparicio-Collado, J.L.; Serra, R.S.; Martí, M.; Serrano-Aroca, Á. Non-woven infection prevention fabrics coated with biobased cranberry extracts inactivate enveloped viruses such as SARS-CoV-2 and multidrug-resistant bacteria. Int. J. Mol. Sci. 2021, 22, 12719. [Google Scholar] [CrossRef]

- Passaglia, E.; Campanella, B.; Coiai, S.; Cicogna, F.; Carducci, A.; Verani, M.; Federigi, I.; Casini, B.; Tuvo, B.; Bramanti, E. Agri-Food Extracts Effectiveness in Improving Antibacterial and Antiviral Properties of Face Masks: A Proof-of-Concept Study. ChemistrySelect 2021, 6, 2288. [Google Scholar] [CrossRef]

- Casanova, F.; Santos, L. Encapsulation of cosmetic active ingredients for topical application—A review. J. Microencapsul. 2016, 33, 1. [Google Scholar] [CrossRef] [PubMed]

- Nagamune, T. Biomolecular engineering for nanobio/bionanotechnology. Nano Converg. 2017, 4, 9. [Google Scholar] [CrossRef] [PubMed]

- Coiai, S.; Cicogna, F.; Pinna, S.; Spiniello, R.; Onor, M.; Oberhauser, W.; Coltelli, M.-B.; Passaglia, E. Antibacterial LDPE-based nanocomposites with salicylic and rosmarinic acid-modified layered double hydroxides. Appl. Clay Sci. 2021, 214, 106276. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Danti, S.; De Clerck, K.; Lazzeri, A.; Morganti, P. Pullulan for Advanced Sustainable Body- and Skin-Contact Applications. J. Funct. Biomater. 2020, 11, 20. [Google Scholar] [CrossRef]

- Gregory, D.A.; Tripathi, L.; Fricker, A.T.R.; Asare, E.; Orlando, I.; Raghavendran, V.; Roy, I. Bacterial cellulose: A smart biomaterial with diverse applications. Mater. Sci. Eng. R Rep. 2021, 145, 100623. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Morganti, P.; Castelvetro, V.; Lazzeri, A.; Danti, S.; Benjelloun-Mlayah, B.; Gagliardini, A.; Fusco, A.; Donnarumma, G. Chitin Nanofibril-Nanolignin Complexes as Carriers of Functional Molecules for Skin Contact Applications. Nanomaterials 2022, 12, 1295. [Google Scholar] [CrossRef]

- Coiai, S.; Campanella, B.; Paulert, R.; Cicogna, F.; Bramanti, E.; Lazzeri, A.; Pistelli, L.; Coltelli, M.-B. Rosmarinic Acid and Ulvan from Terrestrial and Marine Sources in Anti-Microbial Bionanosystems and Biomaterials. Appl. Sci. 2021, 11, 9249. [Google Scholar] [CrossRef]

- Danti, S.; Trombi, L.; Fusco, A.; Azimi, B.; Lazzeri, A.; Morganti, P.; Coltelli, M.-B.; Donnarumma, G. Chitin Nanofibrils and Nanolignin as Functional Agents in Skin Regeneration. Int. J. Mol. Sci. 2019, 20, 2669. [Google Scholar] [CrossRef]

- Teno, J.; Pardo-Figuerez, M.; Hummel, N.; Bonin, V.; Fusco, A.; Ricci, C.; Donnarumma, G.; Coltelli, M.-B.; Danti, S.; Lagaron, J.M. Preliminary Studies on an Innovative Bioactive Skin Soluble Beauty Mask Made by Combining Electrospinning and Dry Powder Impregnation. Cosmetics 2020, 7, 96. [Google Scholar] [CrossRef]

- Iqbal, M.; Dinh, D.K.; Abbas, Q.; Imran, M.; Sattar, H.; Ul Ahmad, A. Controlled Surface Wettability by Plasma Polymer Surface Modification. Surfaces 2019, 2, 349–371. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).