Nanocontainers for Energy Storage and Conversion Applications: A Mini-Review

Abstract

1. Introduction

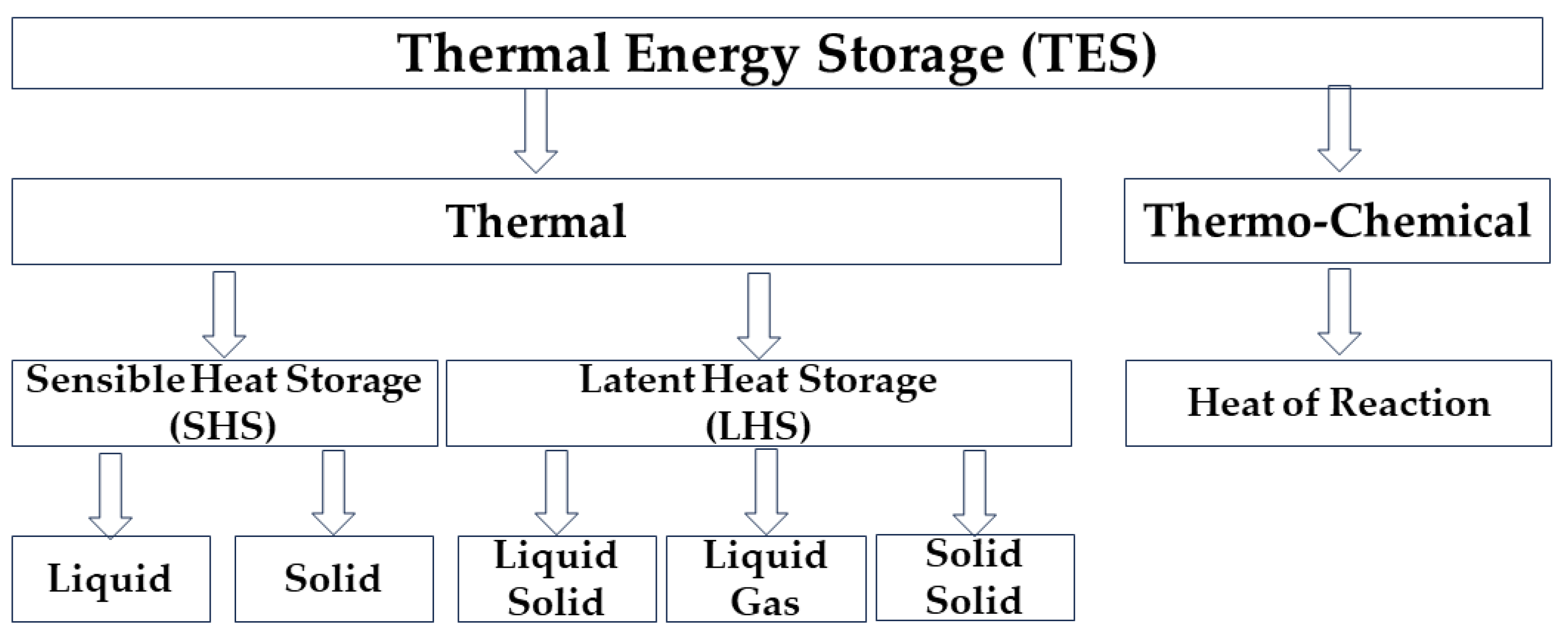

2. Thermal Energy Storage (TES)

2.1. Sensible Heat Storage (SHS)

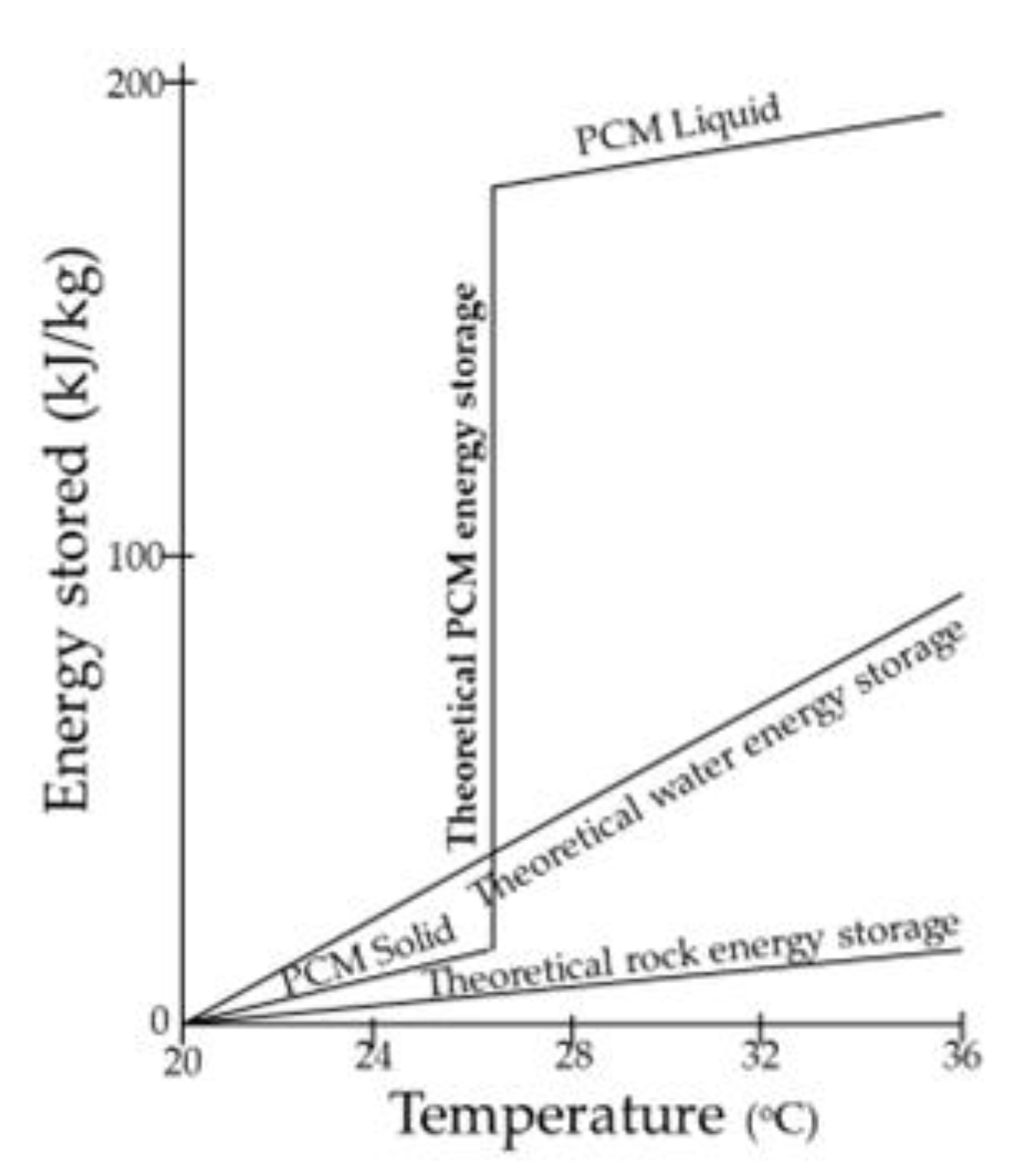

2.2. Latent Heat Storage (LHS)

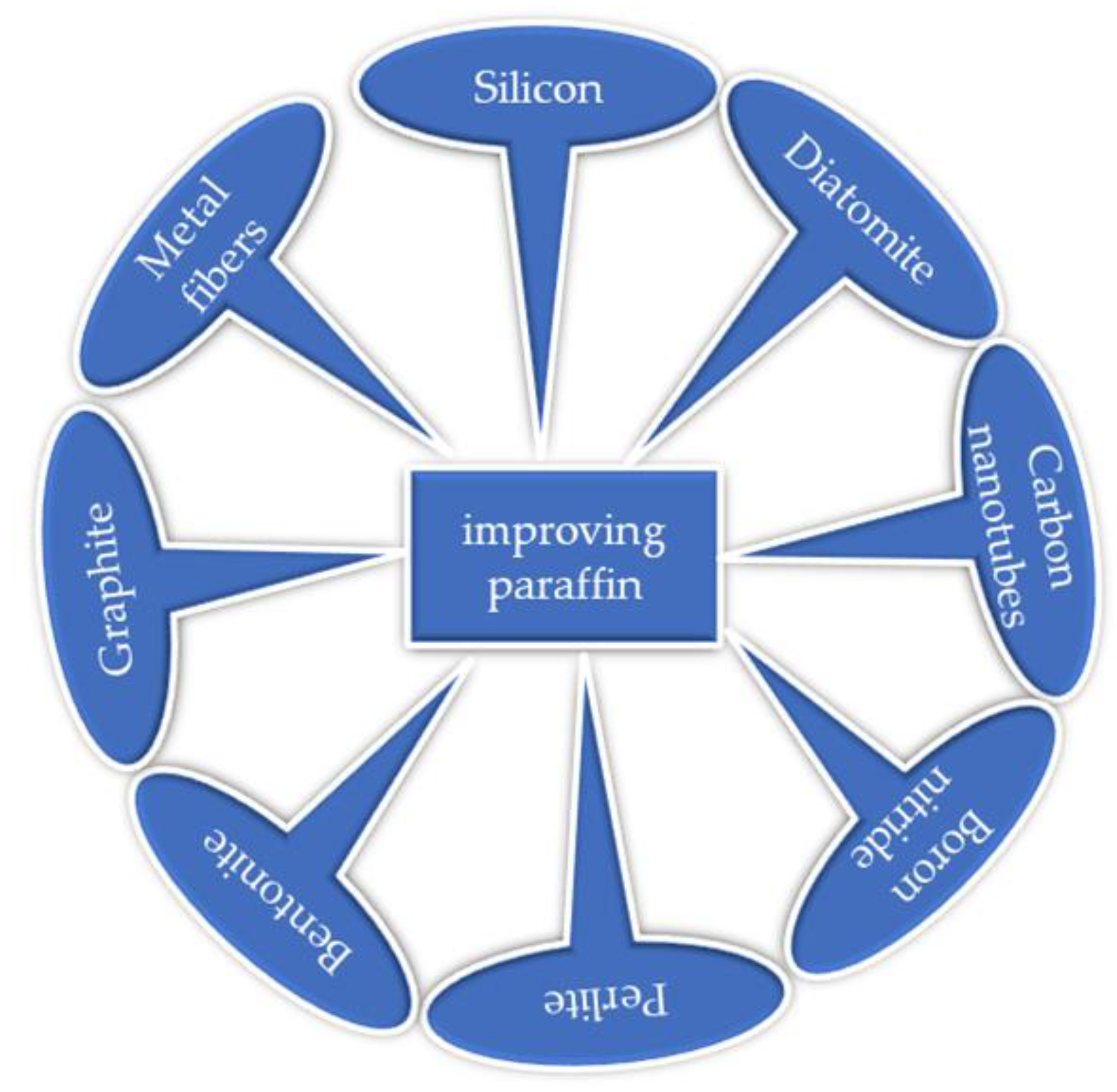

2.3. Paraffin

2.4. Non-Paraffins

2.5. Inorganic Phase Change Materials

2.6. Phase Change Materials (PCMs)

2.7. Classification

2.8. Techniques for Measuring the Latency of Melting Heat and Melting Temperature

- Differential thermal analysis (DTA);

- Differential scanning calorimeter (DSC).

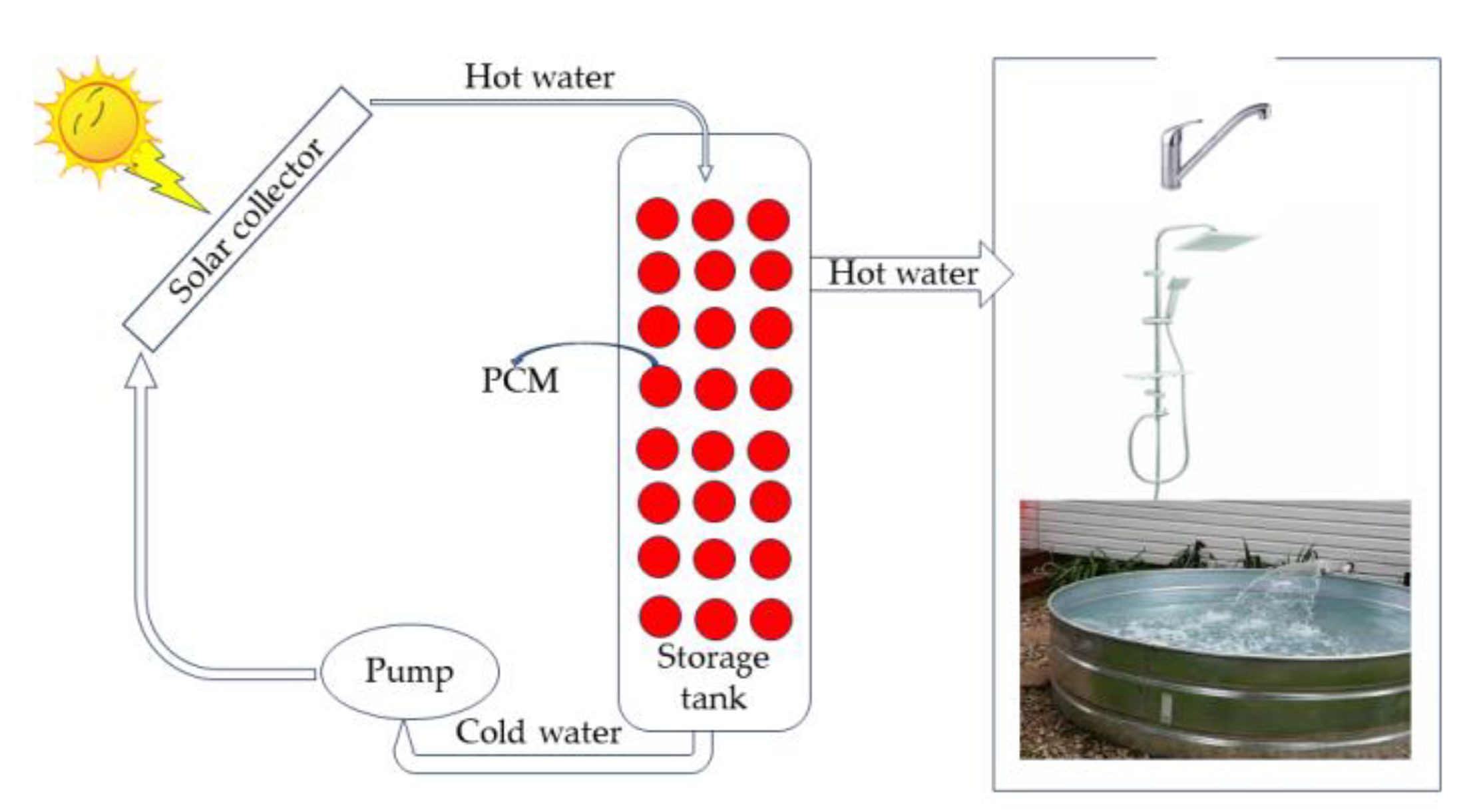

3. Solar Water Heating Systems

4. Solar Cookers

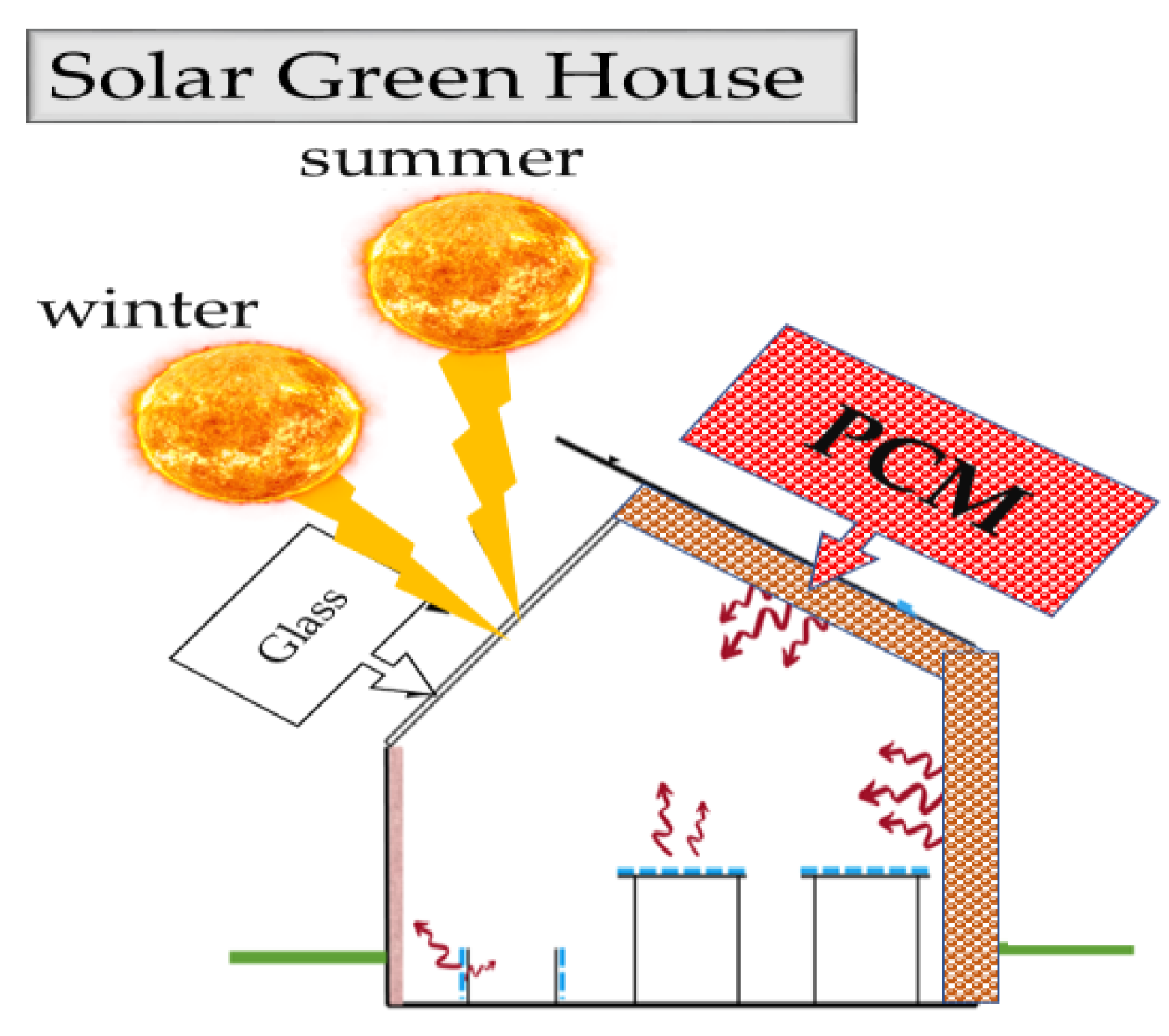

5. Solar Green House

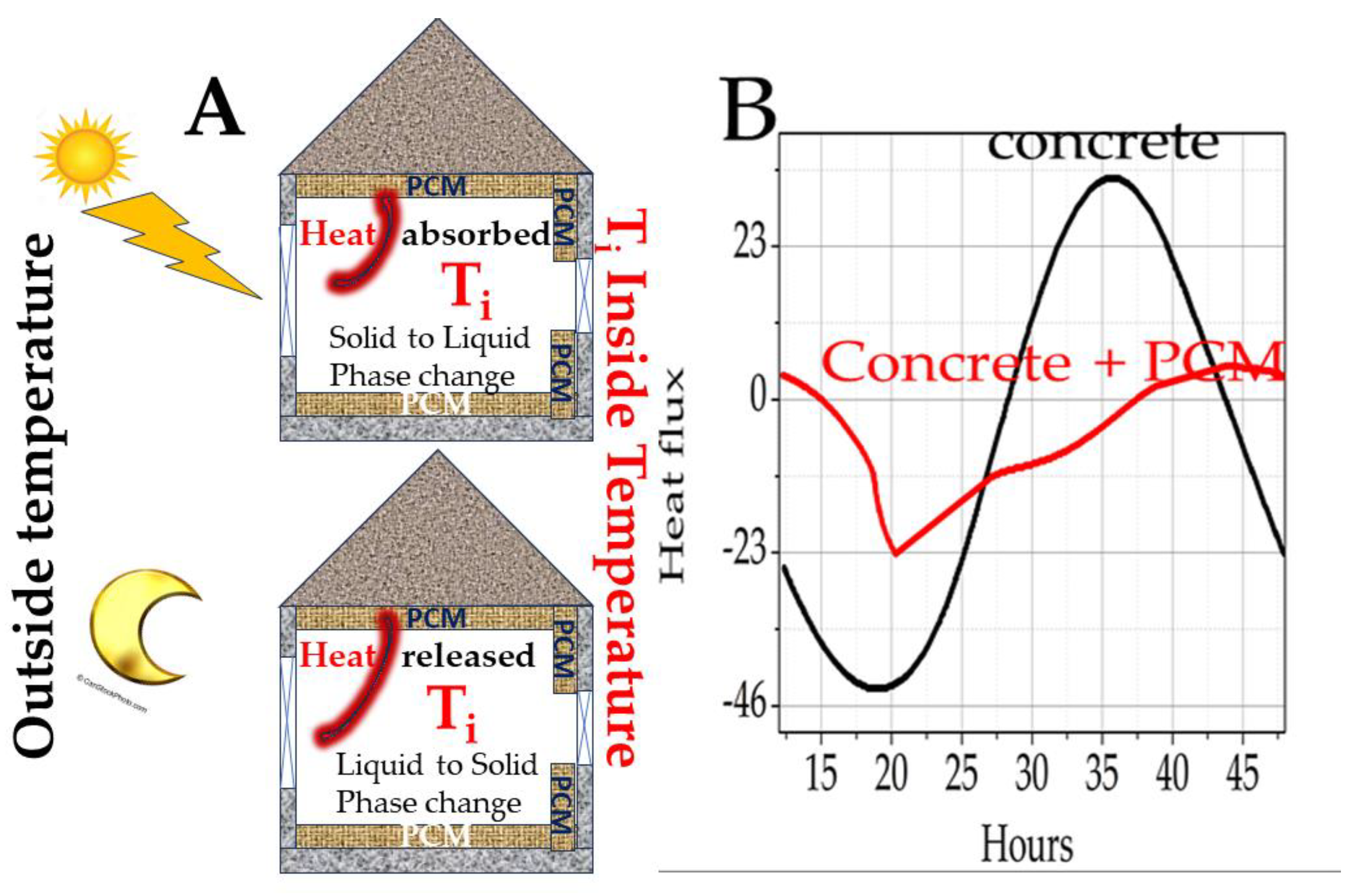

6. Buildings

7. Textiles

8. Nano- and Micro-Encapsulation of PCM

9. Heat Generation

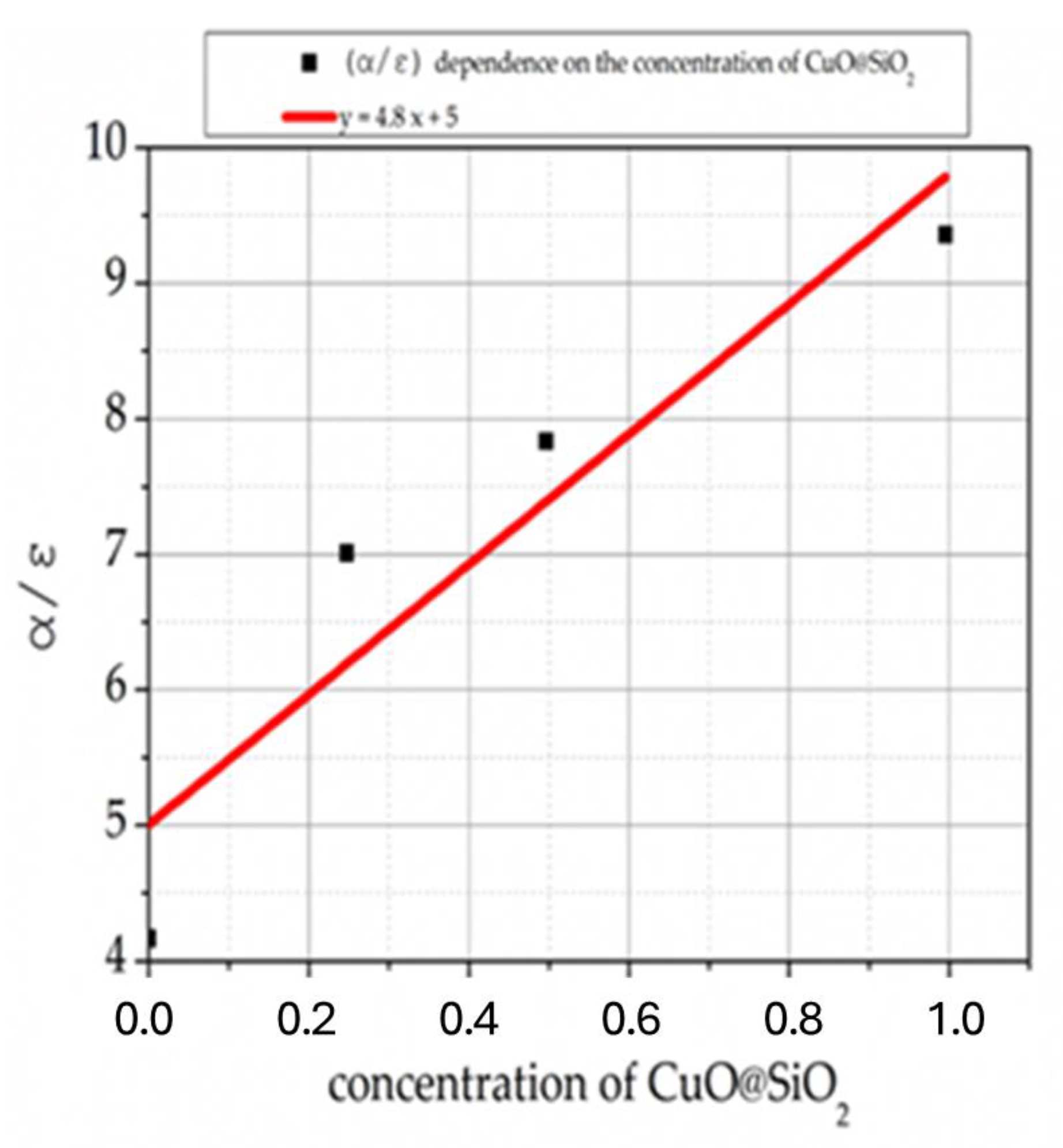

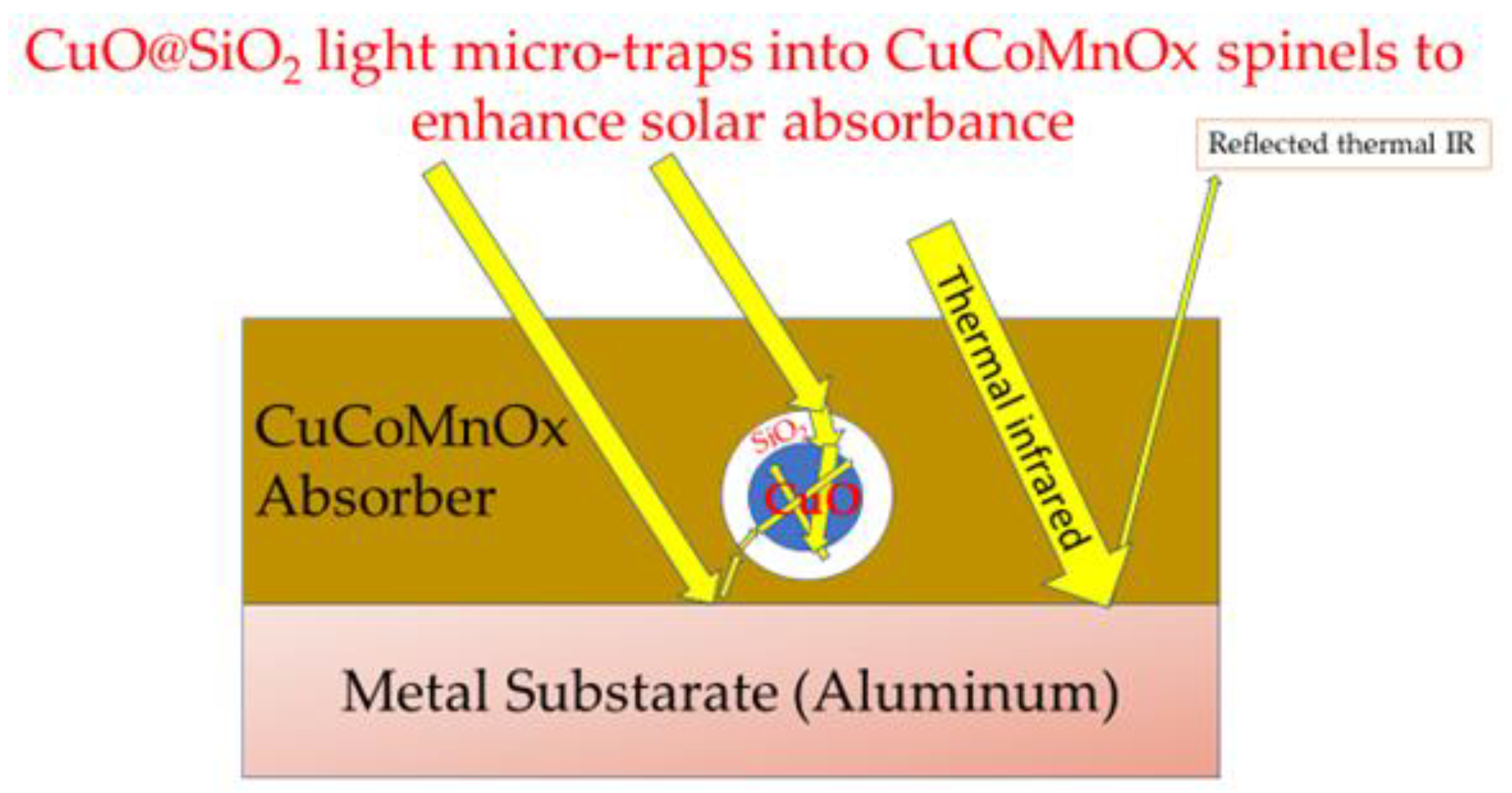

10. Electricity Generation

11. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kenisarin, M.; Mahkamov, K. Solar energy storage using phase change materials. Renew. Sustain. Energy Rev. 2007, 11, 1913–1965. [Google Scholar] [CrossRef]

- Feynman, R.P.; Leighton, R.B.; Sands, M.; Hafner, E.M. The Feynman Lectures on Physics; Vol. I. Am. J. Phys. 1965, 33, 750–752. [Google Scholar] [CrossRef]

- Thaler, S.; Hauser, R. Energy storage through phase change materials (PCM). Komunal. Energy/Power Eng. 2014, 23, 1–7. [Google Scholar]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. A review on phase change materials for thermal energy storage in buildings: Heating and hybrid applications. J. Energy Storage 2021, 33, 101913. [Google Scholar] [CrossRef]

- Mofijur, M.; Meurah, T.; Mahlia, I.; Silitonga, A.S.; Ong, H.C.; Silakhori, M.; Hasan, M.H.; Putra, N.; Rahman, S.M.A. Phase Change Materials (PCM) for Solar Energy Usages and Storage: An Overview. Energies 2019, 12, 3167. [Google Scholar] [CrossRef]

- Gracia, D. Analysis of Microencapsulated Phase Change Material Slurries and Phase Change Material Emulsions as Heat Transfer Fluid and Thermal Storage Material; Universidad de Zaragoza—Zaguan: Zaragoza, Spain, 2013. [Google Scholar]

- Sarbu, I.; Sebarchievici, C. A comprehensive review of thermal energy storage. Sustainability 2018, 10, 191. [Google Scholar] [CrossRef]

- Drissi, S.; Ling, T.C.; Mo, K.H.; Eddhahak, A. A review of microencapsulated and composite phase change materials: Alteration of strength and thermal properties of cement-based materials. Renew. Sustain. Energy Rev. 2019, 110, 467–484. [Google Scholar] [CrossRef]

- Kordas, G. Incorporation of spherical-shaped CuO@SiO2 light microtraps into CuCoMnOx spinels to enhance solar absorbance. J. Am. Ceram. Soc. 2020, 103, 1536–1541. [Google Scholar] [CrossRef]

- Lizana, J.; Chacartegui, R.; Barrios-Padura, A.; Valverde, J.M.; Ortiz, C. Identification of best available thermal energy storage compounds for low-to-moderate temperature storage applications in buildings. Mater. Constr. 2018, 68. [Google Scholar] [CrossRef]

- Lefebvre, D.; Tezel, F.H. A review of energy storage technologies with a focus on adsorption thermal energy storage processes for heating applications. Renew. Sustain. Energy Rev. 2017, 67, 116–125. [Google Scholar] [CrossRef]

- Tatsidjodoung, P.; Le Pierrès, N.; Luo, L. A review of potential materials for thermal energy storage in building applications. Renew. Sustain. Energy Rev. 2013, 18, 327–349. [Google Scholar] [CrossRef]

- Kordas, G. Nanocontainers to increase the absorption of energy and heat conversion. In Advanced Ceramics for Energy and Environmental Applications; Kumar, A., Ed.; CRC Press: New York, NY, USA, 2021; pp. 104–115. ISBN 9781000404715. [Google Scholar]

- Crespo, A.; Barreneche, C.; Ibarra, M.; Platzer, W. Latent thermal energy storage for solar process heat applications at medium-high temperatures—A review. Sol. Energy 2019, 192, 3–34. [Google Scholar] [CrossRef]

- Mehling, H.; Cabeza, L.F. Design of latent heat storages. In Heat and Cold Storage with PCM; Springer: Berlin/Heidelberg, Germany, 2008; pp. 137–179. [Google Scholar] [CrossRef]

- Jamekhorshid, A.; Sadrameli, S.M.; Farid, M. A review of microencapsulation methods of phase change materials (PCMs) as a thermal energy storage (TES) medium. Renew. Sustain. Energy Rev. 2014, 31, 531–542. [Google Scholar] [CrossRef]

- Yang, G.; Yim, Y.J.; Lee, J.W.; Heo, Y.J.; Park, S.J. Carbon-filled organic phase-change materials for thermal energy storage: A review. Molecules 2019, 24, 2055. [Google Scholar] [CrossRef]

- Drissi, S.; Ling, T.C.; Mo, K.H. Thermal efficiency and durability performances of paraffinic phase change materials with enhanced thermal conductivity—A review. Thermochim. Acta 2019, 673, 198–210. [Google Scholar] [CrossRef]

- Cai, W.; Yang, W.; Jiang, Z.; He, F.; Zhang, K.; He, R.; Wu, J.; Fan, J. Numerical and experimental study of paraffin/expanded graphite phase change materials with an anisotropic model. Sol. Energy Mater. Sol. Cells 2019, 194, 111–120. [Google Scholar] [CrossRef]

- Liu, Z.; Zang, C.; Hu, D.; Zhang, Y.; Lv, H.; Liu, C.; She, W. Thermal conductivity and mechanical properties of a shape-stabilized paraffin/recycled cement paste phase change energy storage composite incorporated into inorganic cementitious materials. Cem. Concr. Compos. 2019, 99, 165–174. [Google Scholar] [CrossRef]

- Guo, Y.; Yang, W.; Jiang, Z.; He, F.; Zhang, K.; He, R.; Wu, J.; Fan, J. Silicone rubber/paraffin@silicon dioxide form-stable phase change materials with thermal energy storage and enhanced mechanical property. Sol. Energy Mater. Sol. Cells 2019, 196, 16–24. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, X.; Wu, D. Silica encapsulation of n-octadecane via sol-gel process: A novel microencapsulated phase-change material with enhanced thermal conductivity and performance. J. Colloid Interface Sci. 2010, 343, 246–255. [Google Scholar] [CrossRef]

- Belessiotis, G.V.; Papadokostaki, K.G.; Favvas, E.P.; Efthimiadou, E.K.; Karellas, S. Preparation and investigation of distinct and shape stable paraffin/SiO2 composite PCM nanospheres. Energy Convers. Manag. 2018, 168, 382–394. [Google Scholar] [CrossRef]

- Sakhrieh, A.; Abdullat, Y.; Hamdan, M.A. Enhancement of Thermal Energy Storage Using Phase-Change Material under Jordanian Climate. J. Infrastruct. Syst. 2016, 22, A4014001. [Google Scholar] [CrossRef]

- Weinstein, R.D.; Kopec, T.C.; Fleischer, A.S.; D’Addio, E.; Bessel, C.A. The experimental exploration of embedding phase change materials with graphite nanofibers for the thermal management of electronics. J. Heat Transf. 2008, 130, 042405. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, X.; Chen, P.; Huang, Z.; Xu, T.; Fang, Y.; Zhang, Z. Preparation and thermal performance of paraffin/Nano-SiO2 nanocomposite for passive thermal protection of electronic devices. Appl. Therm. Eng. 2016, 96, 699–707. [Google Scholar] [CrossRef]

- Mishra, D.K.; Bhowmik, C.; Bhowmik, S.; Pandey, K.M. Property-enhanced paraffin-based composite phase change material for thermal energy storage: A review. Environ. Sci. Pollut. Res. 2022, 29, 43556–43587. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.Y.; Lu, W.; Tian, Y. Heat transfer enhancement for thermal energy storage using metal foams embedded within phase change materials (PCMs). Sol. Energy 2010, 84, 1402–1412. [Google Scholar] [CrossRef]

- Bahrami, S.; Mizani, M.; Honarvar, M.; Noghabi, M.A. Low molecular weight paraffin, as phase change material, in physical and micro-structural changes of novel LLDPE/LDPE/paraffin composite pellets and films. Iran. Polym. J. 2017, 26, 885–893. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Sanjayan, J. Thermal enhancement of paraffin/hydrophobic expanded perlite granular phase change composite using graphene nanoplatelets. Energy Build. 2018, 169, 206–215. [Google Scholar] [CrossRef]

- Xu, B.; Ma, H.; Lu, Z.; Li, Z. Paraffin/expanded vermiculite composite phase change material as aggregate for developing lightweight thermal energy storage cement-based composites. Appl. Energy 2015, 160, 358–367. [Google Scholar] [CrossRef]

- Zalba, B.; Ma Marı́n, J.M.; Cabeza, L.F.; Harald Mehling, H. Review on thermal energy storage with phase change: Materials, heat transfer analysis and applications. Appl. Therm. Eng. 2003, 23, 251–283. [Google Scholar] [CrossRef]

- Castell, A.; Martorell, I.; Medrano, M.; Pérez, G.; Cabeza, L.F. Experimental study of using PCM in brick constructive solutions for passive cooling. Energy Build. 2010, 42, 534–540. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Buddhi, D. PCM thermal storage in buildings: A state of art. Renew. Sustain. Energy Rev. 2007, 11, 1146–1166. [Google Scholar] [CrossRef]

- Fan, Y.F.; Zhang, X.X.; Wang, X.C.; Li, J.; Zhu, Q.B. Super-cooling prevention of microencapsulated phase change material. Thermochim. Acta 2004, 413, 1–6. [Google Scholar] [CrossRef]

- Fang, G.; Chen, Z.; Li, H. Synthesis and properties of microencapsulated paraffin composites with SiO2 shell as thermal energy storage materials. Chem. Eng. J. 2010, 163, 154–159. [Google Scholar] [CrossRef]

- Kartsonakis, I.A.; Kordas, G. Synthesis and characterization of cerium molybdate nanocontainers and their inhibitor complexes. J. Am. Ceram. Soc. 2010, 93, 65–73. [Google Scholar] [CrossRef]

- Kartsonakis, I.A.; Danilidis, L.L.; Pappas, G.S.; Kordas, G.C. Encapsulation and release of corrosion inhibitors into titania nanocontainers. J. Nanosci. Nanotechnol. 2010, 10, 5912–5920. [Google Scholar] [CrossRef]

- Fuensanta, M.; Paiphansiri, U.; Romero-Sánchez, M.D.; Guillem, C.; López-Buendía, Á.M.; Landfester, K. Thermal properties of a novel nanoencapsulated phase change material for thermal energy storage. Thermochim. Acta 2013, 565, 95–101. [Google Scholar] [CrossRef]

- Rathod, M.K.; Banerjee, J. Thermal stability of phase change materials used in latent heat energy storage systems: A review. Renew. Sustain. Energy Rev. 2013, 18, 246–258. [Google Scholar] [CrossRef]

- Mehling, H. Solid-Liquid Phase Change Materials; Mehling, H., Cabeza, L.F., Eds.; Heat and Cold Storage with PCM; Springer: Berlin/Heidelberg, Germany, 2008; Volume 3, ISBN 9783540685562. [Google Scholar]

- Alva, G.; Liu, L.; Huang, X.; Fang, G. Thermal energy storage materials and systems for solar energy applications. Renew. Sustain. Energy Rev. 2017, 68, 693–706. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhang, N.; Tao, W.; Cao, X.; He, Y. Fatty acids as phase change materials: A review. Renew. Sustain. Energy Rev. 2014, 29, 482–498. [Google Scholar] [CrossRef]

- del Barrio, E.P.; Godin, A.; Duquesne, M.; Daranlot, J.; Jolly, J.; Alshaer, W.; Kouadio, T.; Sommier, A. Characterization of different sugar alcohols as phase change materials for thermal energy storage applications. Sol. Energy Mater. Sol. Cells 2017, 159, 560–569. [Google Scholar] [CrossRef]

- Aldoss, T.K.; Rahman, M.M.; Sarwar, J.; Mansoor, B.; Ghadim, H.B.; Shahbaz, K.; Al-Shannaq, R.; Farid, M.M.; Ren, Y.; Xu, C.; et al. Nano-enhanced phase change materials: A review of thermo-physical properties, applications, and challenges. Renew. Sustain. Energy Rev. 2014, 120, 905–919. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; De Gracia, A.; Fernández, A.I. Materials used as PCM in thermal energy storage in buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Kong, X.; Lu, S.; Huang, J.; Cai, Z.; Wei, S. Experimental research on using phase change materials in perforated brick rooms for cooling storage. Energy Build. 2013, 62, 597–604. [Google Scholar] [CrossRef]

- Sayyar, M.; Weerasiri, R.R.; Soroushian, P.; Lu, J. Experimental and numerical study of shape-stable phase-change nanocomposite toward energy-efficient building constructions. Energy Build. 2014, 75, 249–255. [Google Scholar] [CrossRef]

- Konuklu, Y.; Unal, M.; Paksoy, H.O. Microencapsulation of caprylic acid with different wall materials as phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cells 2014, 120, 536–542. [Google Scholar] [CrossRef]

- Wickramaratne, C.; Dhau, J.S.; Kamal, R.; Myers, P.; Goswami, D.Y.; Stefanakos, E. Macro-encapsulation and characterization of chloride-based inorganic Phase change materials for high-temperature thermal energy storage systems. Appl. Energy 2018, 221, 587–596. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhao, B.; Lin, J.; Zhang, F.; Wang, H.; Zhu, Z.; Dai, Z. Encapsulation of high-temperature inorganic phase change materials using graphite as heat transfer enhancer. Renew. Energy 2019, 133, 240–247. [Google Scholar] [CrossRef]

- Milián, Y.E.; Gutiérrez, A.; Grágeda, M.; Ushak, S. A review on encapsulation techniques for inorganic phase change materials and the influence on their thermophysical properties. Renew. Sustain. Energy Rev. 2017, 73, 983–999. [Google Scholar] [CrossRef]

- Al-Abbasi, O.; Abdelkefi, A.; Ghommem, M. Modeling and assessing thermochemical energy storage using salt hydrates. Int. J. Energy Res. 2017, 41, 2149–2161. [Google Scholar] [CrossRef]

- Ryu, H.W.; Woo, S.W.; Shin, B.C.; Kim, S.D. Prevention of supercooling and stabilization of inorganic salt hydrates as latent heat storage materials. Sol. Energy Mater. Sol. Cells 1992, 27, 161–172. [Google Scholar] [CrossRef]

- Ferrer, G.; Solé, A.; Barreneche, C.; Martorell, I.; Cabeza, L.F. Review the methodology used in thermal stability characterization of phase change materials. Renew. Sustain. Energy Rev. 2015, 50, 665–685. [Google Scholar] [CrossRef]

- Pielichowska, K.; Pielichowski, K. Phase change materials for thermal energy storage. Prog. Mater. Sci. 2014, 65, 67–123. [Google Scholar] [CrossRef]

- Pereira da Cunha, J.; Eames, P. Thermal energy storage for low and medium temperature applications using phase change materials—A review. Appl. Energy 2016, 177, 227–238. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Kenisarin, M.M. Short-time solar energy accumulation. 1. Low-temperature phase transition materials. Appl. Sol. Energy 1993, 29, 48–65. [Google Scholar]

- Graham, M.; Shchukina, E.; De Castro, P.F.; Shchukin, D. Nanocapsules containing salt hydrate phase change materials for thermal energy storage. J. Mater. Chem. A 2016, 4, 16906–16912. [Google Scholar] [CrossRef]

- Liu, C.; Wang, C.; Li, Y.; Rao, Z. Preparation and characterization of sodium thiosulfate pentahydrate/silica microencapsulated phase change material for thermal energy storage. RSC Adv. 2017, 7, 7238–7249. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, S.S.; Zhang, S.D.; Tao, Q.H.; Pan, L.; Wang, Z.Y.; Zhang, Z.P.; Lei, Y.; Yang, S.K.; Zhao, H.P. In situ synthesis and phase change properties of Na2SO 4·10H2O@SiO2 solid nanobowls toward smart heat storage. J. Phys. Chem. C 2011, 115, 20061–20066. [Google Scholar] [CrossRef]

- Huang, J.; Wang, T.; Zhu, P.; Xiao, J. Preparation, characterization, and thermal properties of the microencapsulation of a hydrated salt as phase change energy storage materials. Thermochim. Acta 2013, 557, 1–6. [Google Scholar] [CrossRef]

- Hassan, N.; Minakshi, M.; Ruprecht, J.; Liew, W.Y.H.; Jiang, Z.T. A Binary Salt Mixture LiCl–LiOH for Thermal Energy Storage. Materials 2023, 16, 1434. [Google Scholar] [CrossRef]

- Hassan, N.; Minakshi, M.; Liew, W.Y.H.; Amri, A.; Jiang, Z.-T. Thermal Characterization of Binary Calcium-Lithium Chloride Salts for Thermal Energy Storage at High Temperature. Energies 2023, 16, 4715. [Google Scholar] [CrossRef]

- Evers, A.C.; Medina, M.A.; Fang, Y. Evaluation of the thermal performance of frame walls enhanced with paraffin and hydrated salt phase change materials using a dynamic wall simulator. Build. Environ. 2010, 45, 1762–1768. [Google Scholar] [CrossRef]

- Principi, P.; Fioretti, R. Thermal analysis of the application of PCM and low emissivity coating in hollow bricks. Energy Build. 2012, 51, 131–142. [Google Scholar] [CrossRef]

- Cui, Y.; Xie, J.; Liu, J.; Wang, J.; Chen, S. A review on phase change material application in building. Adv. Mech. Eng. 2017, 9, 1687814017700828. [Google Scholar] [CrossRef]

- Cui, Y.; Xie, J.; Liu, J.; Pan, S. Review of Phase Change Materials Integrated in Building Walls for Energy Saving. Procedia Eng. 2015, 121, 763–770. [Google Scholar] [CrossRef]

- Trigui, A. Techniques for the Thermal Analysis of PCM. IntechOpen 2022, 11, 1–20. [Google Scholar]

- Al-Hinti, I.; Al-Ghandoor, A.; Maaly, A.; Abu Naqeera, I.; Al-Khateeb, Z.; Al-Sheikh, O. Experimental investigation on the use of water-phase change material storage in conventional solar water heating systems. Energy Convers. Manag. 2010, 51, 1735–1740. [Google Scholar] [CrossRef]

- Syahruddin, A.S.; Jalaluddin, J.; Hayat, A. Performance Analysis of Solar Water Heating System with Plate Collector Integrated PCM Storage. EPI Int. J. Eng. 2021, 3, 143–149. [Google Scholar] [CrossRef]

- Murali, G.; Mayilsamy, K. An overview of PCM usage to enhance solar water heating system. Int. J. ChemTech Res. 2015, 7, 1802–1807. [Google Scholar]

- Castell, A.; Solé, C.; Medrano, M.; Roca, J.; Cabeza, L.F.; García, D. Natural convection heat transfer coefficients in phase change material (PCM) modules with external vertical fins. Appl. Therm. Eng. 2008, 28, 1676–1686. [Google Scholar] [CrossRef]

- Koca, A.; Oztop, H.F.; Koyun, T.; Varol, Y. Energy and exergy analysis of a latent heat storage system with phase change material for a solar collector. Renew. Energy 2008, 33, 567–574. [Google Scholar] [CrossRef]

- Murali, G.; Mayilsamy, K. Effect of Circular Fins on Latent Heat Storage to Enhance Solar Water Heater, an Experimental Study. Appl. Mech. Mater. 2015, 787, 13–17. [Google Scholar] [CrossRef]

- Bédécarrats, J.P.; Strub, F.; Falcon, B.; Dumas, J.P. Phase-change thermal energy storage using spherical capsules: Performance of a test plant. Int. J. Refrig. 1996, 19, 187–196. [Google Scholar] [CrossRef]

- Ival, O. Salyer Phase Change Materials Incorporated throughout the Structure of Polymer. Fibers. Patent No. US5885475A, 23 March 1999. [Google Scholar]

- Eames, I.W.; Adref, K.T. Freezing and melting of water in spherical enclosures of the type used in thermal (ice) storage systems. Appl. Therm. Eng. 2002, 22, 733–745. [Google Scholar] [CrossRef]

- Streicher, W.; Cabeza, L.; Heinz, A. Inventory of Phase Change Materials (PCM); IEA SHC-Task 32-Advenced Storage Concepts Solar Low Energy Building; International Energy Agency: Paris, France, 2005; p. 17. [Google Scholar]

- Regin, A.F.; Solanki, S.C.; Saini, J.S. Heat transfer characteristics of thermal energy storage system using PCM capsules: A review. Renew. Sustain. Energy Rev. 2008, 12, 2438–2458. [Google Scholar] [CrossRef]

- Morrison, D.J.; Abdel-Khalik, S.I. Effects of phase-change energy storage on the performance of air-based and liquid-based solar heating systems. Sol. Energy 1978, 20, 57–67. [Google Scholar] [CrossRef]

- Köll, R.; van Helden, W.; Engel, G.; Wagner, W.; Dang, B.; Jänchen, J.; Kerskes, H.; Badenhop, T.; Herzog, T. An experimental investigation of a realistic-scale seasonal solar adsorption storage system for buildings. Sol. Energy 2017, 155, 388–397. [Google Scholar] [CrossRef]

- Khadiran, T.; Hussein, M.Z.; Zainal, Z.; Rusli, R. Advanced energy storage materials for building applications and their thermal performance characterization: A review. Renew. Sustain. Energy Rev. 2016, 57, 916–928. [Google Scholar] [CrossRef]

- Galazutdinova, Y.; Grágeda, M.; Cabeza, L.F.; Ushak, S. Novel inorganic binary mixture for low-temperature heat storage applications. Int. J. Energy Res. 2017, 41, 2356–2364. [Google Scholar] [CrossRef]

- Sharma, S.D.; Buddhi, D.; Sawhney, R.L.; Sharma, A. Design, development and performance evaluation of a latent heat storage unit for evening cooking in a solar cooker. Energy Convers. Manag. 2000, 41, 1497–1508. [Google Scholar] [CrossRef]

- Habeebullah, M.B.; Khalifa, A.M.; Olwi, I. The oven receiver: An approach toward the revival of concentrating solar cookers. Sol. Energy 1995, 54, 227–237. [Google Scholar] [CrossRef]

- Balzar, A.; Stumpf, P.; Eckhoff, S.; Ackermann, H.; Grupp, M. A solar cooker using vacuum-tube collectors with integrated heat pipes. Sol. Energy 1996, 58, 63–68. [Google Scholar] [CrossRef]

- Wu, W.; Bostanci, H.; Chow, L.C.; Hong, Y.; Wang, C.M.; Su, M.; Kizito, J.P. Heat transfer enhancement of PAO in microchannel heat exchanger using nano-encapsulated phase change indium particles. Int. J. Heat Mass Transf. 2013, 58, 348–355. [Google Scholar] [CrossRef]

- Arshad, A.; Jabbal, M.; Yan, Y.; Darkwa, J. The micro-/nano-PCMs for thermal energy storage systems: A state of art review. Int. J. Energy Res. 2019, 43, 5572–5620. [Google Scholar] [CrossRef]

- Tasnim, S.H.; Hossain, R.; Mahmud, S.; Dutta, A. Convection effect on the melting process of nano-PCM inside porous enclosure. Int. J. Heat Mass Transf. 2015, 85, 206–220. [Google Scholar] [CrossRef]

- Sharma, R.K.; Ganesan, P.; Tyagi, V.V.; Metselaar, H.S.C.; Sandaran, S.C. Developments in organic solid-liquid phase change materials and their applications in thermal energy storage. Energy Convers. Manag. 2015, 95, 193–228. [Google Scholar] [CrossRef]

- Soni, V.; Kumar, A.; Jain, V.K. Performance evaluation of nano-enhanced phase change materials during discharge stage in waste heat recovery. Renew. Energy 2018, 127, 587–601. [Google Scholar] [CrossRef]

- Tan, W.S.; Hassan, M.Y.; Majid, M.S.; Abdul Rahman, H. Optimal distributed renewable generation planning: A review of different approaches. Renew. Sustain. Energy Rev. 2013, 18, 626–645. [Google Scholar] [CrossRef]

- Souayfane, F.; Fardoun, F.; Biwole, P.H. Phase change materials (PCM) for cooling applications in buildings: A review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

- Berroug, F.; Lakhal, E.K.; El Omari, M.; Faraji, M.; El Qarnia, H. Thermal performance of a greenhouse with a phase change material north wall. Energy Build. 2011, 43, 3027–3035. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Zhu, Y.; Li, D.; Ma, L. Experimental investigation of optical and thermal performance of a PCM-glazed unit for building applications. Energy Build. 2018, 158, 794–800. [Google Scholar] [CrossRef]

- da Cunha, S.R.L.; de Aguiar, J.L.B. Phase change materials and energy efficiency of buildings: A review of knowledge. J. Energy Storage 2020, 27, 101083. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castellón, C.; Nogués, M.; Medrano, M.; Leppers, R.; Zubillaga, O. Use of microencapsulated PCM in concrete walls for energy savings. Energy Build. 2007, 39, 113–119. [Google Scholar] [CrossRef]

- Boskovic, S.; Reddy, B.V.; Basu, P. Encapsulated phase change materials for thermal energy storage: Experiments and simulation. Int. J. Energy Res. 2002, 26, 159–171. [Google Scholar] [CrossRef]

- Salaün, F. Phase Change Materials for Textile Application. IntechOpen 2019, 1–25. [Google Scholar] [CrossRef]

- Demirbağ, S.; Aksoy, S.A. Encapsulation of phase change materials by complex coacervation to improve thermal performances and flame retardant properties of the cotton fabrics. Fibers Polym. 2016, 17, 408–417. [Google Scholar] [CrossRef]

- Monllor, P.; Bonet, M.A.; Cases, F. Characterization of the behaviour of flavour microcapsules in cotton fabrics. Eur. Polym. J. 2007, 43, 2481–2490. [Google Scholar] [CrossRef]

- Sarier, N.; Onder, E. The manufacture of microencapsulated phase change materials suitable for the design of thermally enhanced fabrics. Thermochim. Acta 2007, 452, 149–160. [Google Scholar] [CrossRef]

- Cao, L.; Tang, F.; Fang, G. Synthesis and characterization of microencapsulated paraffin with titanium dioxide shell as shape-stabilized thermal energy storage materials in buildings. Energy Build. 2014, 72, 31–37. [Google Scholar] [CrossRef]

- Chen, Z.; Cao, L.; Shan, F.; Fang, G. Preparation and characteristics of microencapsulated stearic acid as composite thermal energy storage material in buildings. Energy Build. 2013, 62, 469–474. [Google Scholar] [CrossRef]

- Sari, A.; Alkan, C.; Altintaş, A. Preparation, characterization and latent heat thermal energy storage properties of micro-nanoencapsulated fatty acids by polystyrene shell. Appl. Therm. Eng. 2014, 73, 1160–1168. [Google Scholar] [CrossRef]

- Jiang, F.; Wang, X.; Wu, D. Design and synthesis of magnetic microcapsules based on n-eicosane core and Fe3O4/SiO2 hybrid shell for dual-functional phase change materials. Appl. Energy 2014, 134, 456–468. [Google Scholar] [CrossRef]

- Kahraman Döğüşcü, D.; Damlıoğlu, Y.; Alkan, C. Poly(styrene-co-divinylbenzene-co-acrylamide)/n-octadecane microencapsulated phase change materials for thermal energy storage. Sol. Energy Mater. Sol. Cells 2019, 198, 5–10. [Google Scholar] [CrossRef]

- Sarı, A.; Bicer, A.; Alkan, C.; Özcan, A.N. Thermal energy storage characteristics of myristic acid-palmitic eutectic mixtures encapsulated in PMMA shell. Sol. Energy Mater. Sol. Cells 2019, 193, 1–6. [Google Scholar] [CrossRef]

- Pappas, G.S.; Liatsi, P.; Kartsonakis, I.A.; Danilidis, I.; Kordas, G. Synthesis and characterization of new SiO2-CaO hollow nanospheres by sol-gel method: Bioactivity of the new system. J. Non-Cryst. Solids 2008, 354, 755–760. [Google Scholar] [CrossRef]

- Su, J.; Ren, L.; Wang, L. Preparation and mechanical properties of thermal energy storage microcapsules. Colloid Polym. Sci. 2005, 284, 224–228. [Google Scholar] [CrossRef]

- Wang, L.; Meng, D. Fatty acid eutectic/polymethyl methacrylate composite as form-stable phase change material for thermal energy storage. Appl. Energy 2010, 87, 2660–2665. [Google Scholar] [CrossRef]

- Sari, A.; Alkan, C.; Bilgin, C. Micro/nano encapsulation of some paraffin eutectic mixtures with poly(methyl methacrylate) shell: Preparation, characterization and latent heat thermal energy storage properties. Appl. Energy 2014, 136, 217–227. [Google Scholar] [CrossRef]

- Sari, A.; Alkan, C.; Karaipekli, A. Preparation, characterization and thermal properties of PMMA/n-heptadecane microcapsules as novel solid-liquid microPCM for thermal energy storage. Appl. Energy 2010, 87, 1529–1534. [Google Scholar] [CrossRef]

- Salaün, F.; Devaux, E.; Bourbigot, S.; Rumeau, P. Development of a precipitation method intended for the entrapment of hydrated salt. Carbohydr. Polym. 2008, 73, 231–240. [Google Scholar] [CrossRef]

- Yi, Q.; Sukhorokov, G.B.; Ma, J.; Yang, X.; Gu, Z. Encapsulation of phase change materials using layer-by-layer assembled polyelectrolytes. Int. J. Polym. Sci. 2015, 2015, 756237. [Google Scholar] [CrossRef][Green Version]

- Zhang, H.; Wang, X. Synthesis and properties of microencapsulated n-octadecane with polyurea shells containing different soft segments for heat energy storage and thermal regulation. Sol. Energy Mater. Sol. Cells 2009, 93, 1366–1376. [Google Scholar] [CrossRef]

- Zhou, X.; Yamashita, S.; Kubota, M.; Kita, H. Encapsulated Copper-Based Phase-Change Materials for High-Temperature Heat Storage. ACS Omega 2022, 7, 5442–5452. [Google Scholar] [CrossRef]

- Zhang, G.; Li, J.; Chen, Y.; Xiang, H.; Ma, B.; Xu, Z.; Ma, X. Encapsulation of copper-based phase change materials for high temperature thermal energy storage. Sol. Energy Mater. Sol. Cells 2014, 128, 131–137. [Google Scholar] [CrossRef]

- Tabor, H.Z. Receiver for Solar Energy Collectors. U.S. Patent No. 291,7817, 1959. [Google Scholar]

- Shanker, K.; Holloway, P.H. Electrodeposition of black chrome selective solar absorber coatings with improved thermal stability. Thin Solid Film. 1985, 127, 181–189. [Google Scholar] [CrossRef]

- Alanod Absorption Surfaces. 2022, pp. 1–8. Available online: https://alanod.com/en/products/our-surfaces/absorption-surfaces (accessed on 1 May 2023).

- Mihelčič, M.; Francetič, V.; Kovač, J.; Šurca Vuk, A.; Orel, B.; Kunič, R.; Peros, D. Novel sol–gel based selective coatings: From coil absorber coating to high power coating. Sol. Energy Mater. Sol. Cells 2015, 140, 232–248. [Google Scholar] [CrossRef]

- Vince, J.; Šurca Vuk, A.; Opara Krašovec, U.; Orel, B.; Köhl, M.; Heck, M. Solar absorber coatings based on CoCuMnOx spinels prepared via the sol-gel process: Structural and optical properties. Sol. Energy Mater. Sol. Cells 2003, 79, 313–330. [Google Scholar] [CrossRef]

- El Mahallawy, N.; Shoeib, M.; Ali, Y. Application of CuCoMnOx coat by sol gel technique on aluminum and copper substrates for solar absorber application. J. Coat. Technol. Res. 2014, 11, 979–991. [Google Scholar] [CrossRef]

- He, C.X.; Lei, B.X.; Wang, Y.F.; Su, C.Y.; Fang, Y.P.; Kuang, D. Bin Sonochemical preparation of hierarchical ZnO hollow spheres for efficient dye-sensitized solar cells. Chem.—A Eur. J. 2010, 16, 8757–8761. [Google Scholar] [CrossRef]

- Dong, Z.; Lai, X.; Halpert, J.E.; Yang, N.; Yi, L.; Zhai, J.; Wang, D.; Tang, Z.; Jiang, L. Accurate control of multishelled ZnO hollow microspheres for dye-sensitized solar cells with high efficiency. Adv. Mater. 2012, 24, 1046–1049. [Google Scholar] [CrossRef]

- Yu, L.; Li, Z. Building triple shelled ZnO hollow microspheres decorated TiO2 nanotree to boost light harvesting and reduced charges recombination in dye sensitized solar cell. Mater. Sci. Semicond. Process. 2022, 149, 106881. [Google Scholar] [CrossRef]

- Yu, L.; Hao, W.; Li, Z.; Ren, X.; Yang, H.; Ma, H. Synthesis of ZnO core/shell hollow microspheres to boost light harvesting capability in quantum dots-sensitized solar cell. Chem. Phys. Lett. 2021, 764, 138283. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Wu, D. Tailoring of bifunctional microencapsulated phase change materials with CdS/SiO2 double-layered shell for solar photocatalysis and solar thermal energy storage. Appl. Therm. Eng. 2018, 134, 603–614. [Google Scholar] [CrossRef]

| Material | Temperature °C | Density (kg/m3) | Specific Heat Capacity (kJ/kg) |

|---|---|---|---|

| Stone | 20 | 2560 | 879 |

| Water | 0–100 | 1000 | 4190 |

| Engine oil | Till 160 | 888 | 1880 |

| Propanol | Till 97 | 800 | 2500 |

| Octane | Till 126 | 704 | 2400 |

| PCM | Melting Temp. (°C) | The Heat of Fusion (kJ/kg) | Thermal Conductivity (w/mk) | Density (kg/m3) | Ref. |

|---|---|---|---|---|---|

| Paraffin C13–C24 | 22–24 | 189 | 0.21 (liquid) | 760 (liquid) 900 (solid) | [32] |

| Paraffin RT-27 | 28 | 179 | 0.2 | 800 | [33] |

| Paraffin RT-18 | 15–19 | 134 | 0.2 | 756 | [33] |

| Paraffin C18 | 28 | 244 | 0.148 (liquid) | [34] |

| PCM | Melting Temp. (°C) | The Heat of Fusion (kJ/kg) | Thermal Conductivity (w/mk) | Density (kg/m3) | Ref. |

|---|---|---|---|---|---|

| Capric acid | 30.2 | 142.7 | 0.2 (liquid) 0.12 (solid) | 815 (liquid) 752 (solid) | [47] |

| CA and 1-dodecanol (CADE) | 26.5 | 126.9 | 0.2 (liquid) 0.12 (solid) | 817 (liquid) 754 (solid) | [47] |

| Capric acid and palmitic acid | 26.2 | 177 | 2.2 | 784 | [48] |

| Capric acid | 30 | 142.7 | 815 (liquid) 752 (solid) | [48] | |

| CA and 1-dodecanol (CADE) | 27 | 126.9 | 817 (liquid) 754 (solid) | [49] |

| PCM | Melting Temp. (°C) | The Heat of Fusion (kJ/kg) | Thermal Conductivity (w/mk) | Density (kg/m3) | Ref. |

|---|---|---|---|---|---|

| Hydrated salt | 29 | 175 | 1.0 | 1490 | [66] |

| CaCl2·6H2O | 29 | 187.49 | 0.54 (liquid) 1.09 (solid) | 560 (liquid) 1800 (solid) | [66] |

| Mn(NO3)2·6H2O + MnCl2·4H2O | 27 | 125.9 | 0.6 | 1700 | [66] |

| SP25A8 hydrate salt | 26 | 180 | 0.6 | 1380 | [33] |

| sodium sulfate decahydrate | 32.5 | 180 | 0.6 | 1600 | [67] |

| Thermal Properties | The Suitable Phase Transition Temperature | High Latent Heat of the Transition | Good Heat Transition |

|---|---|---|---|

| Physical properties | The suitable phase transition temperature | High latent heat of the transition | Good heat transmission |

| Chemical properties | Long-term chemical stability | Compatibility with materials of manufacture | Non-toxic and non flamable |

| Kinetic properties | No subcooling | Sufficient crystallization rate | |

| Economic criteria | Abundance | Aivelanility | Low cost |

| PCM | ||

|---|---|---|

| ↓ | ↓ | ↓ |

| Organic | Inorganic | Eutectic |

| ↓ | ↓ | ↓ |

| ParaffinNon-Paraffin | Salt-HydratesMetal | Organic-Organic |

| Organic-Inorganic | ||

| Inorganic-Inorganic |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kordas, G. Nanocontainers for Energy Storage and Conversion Applications: A Mini-Review. Nanomanufacturing 2023, 3, 356-380. https://doi.org/10.3390/nanomanufacturing3030023

Kordas G. Nanocontainers for Energy Storage and Conversion Applications: A Mini-Review. Nanomanufacturing. 2023; 3(3):356-380. https://doi.org/10.3390/nanomanufacturing3030023

Chicago/Turabian StyleKordas, George. 2023. "Nanocontainers for Energy Storage and Conversion Applications: A Mini-Review" Nanomanufacturing 3, no. 3: 356-380. https://doi.org/10.3390/nanomanufacturing3030023

APA StyleKordas, G. (2023). Nanocontainers for Energy Storage and Conversion Applications: A Mini-Review. Nanomanufacturing, 3(3), 356-380. https://doi.org/10.3390/nanomanufacturing3030023