Microstructure and Mechanical Performance of Cu and Gr/Cu Composites: Experimental and Ab Initio Insights

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Methods

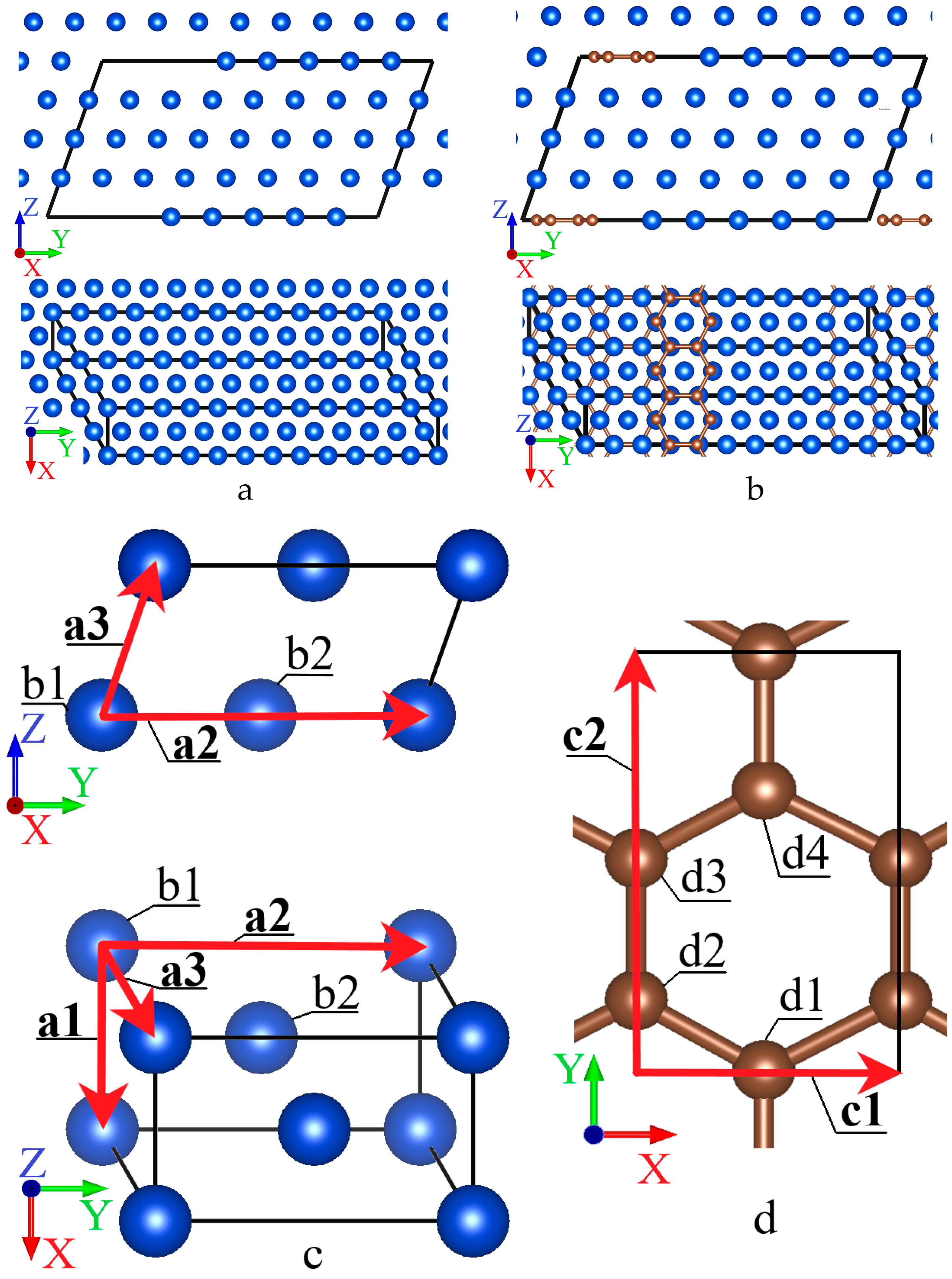

2.2. Theoretical Methods

3. Results

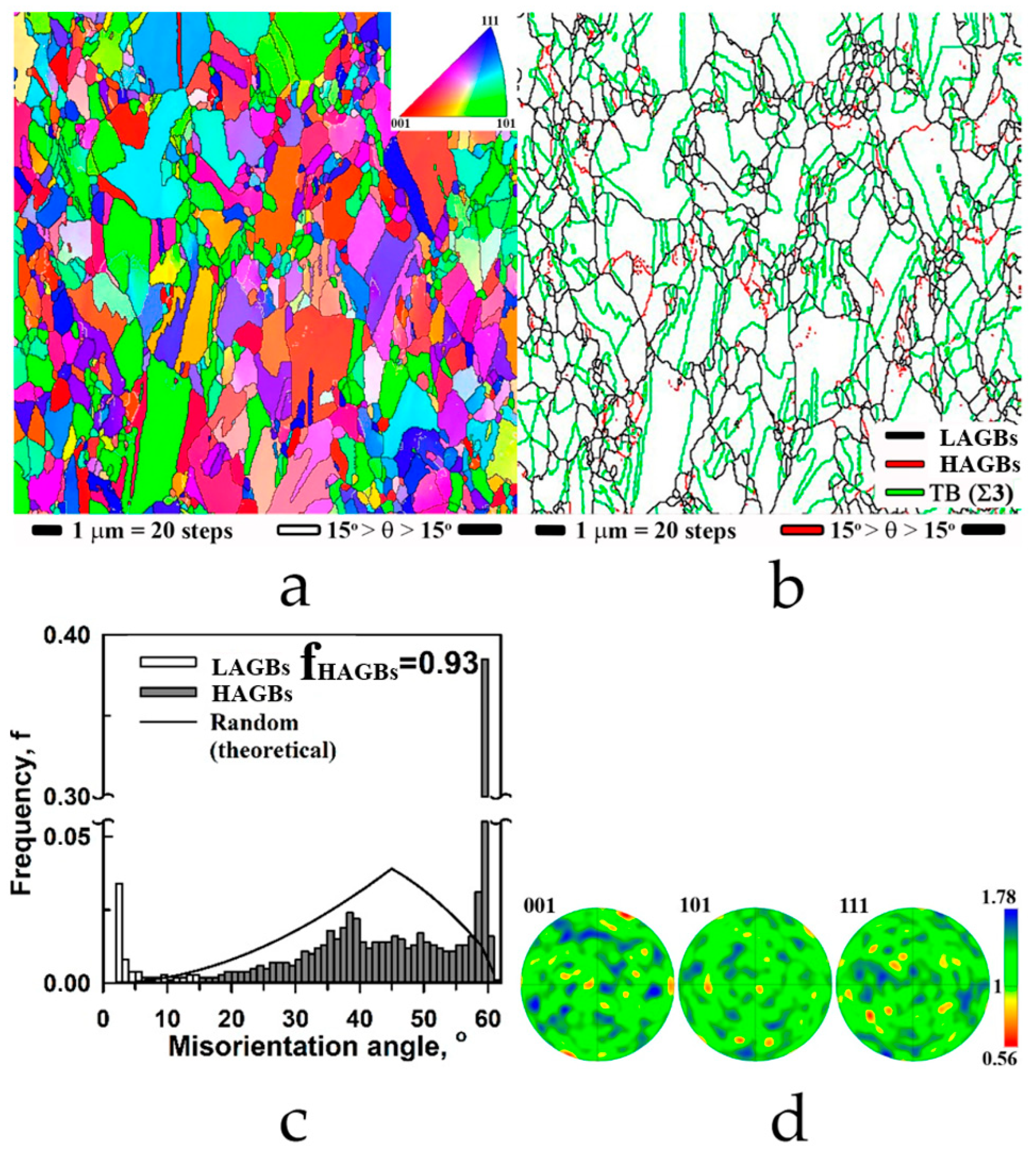

3.1. Microstructure Prior to HPT

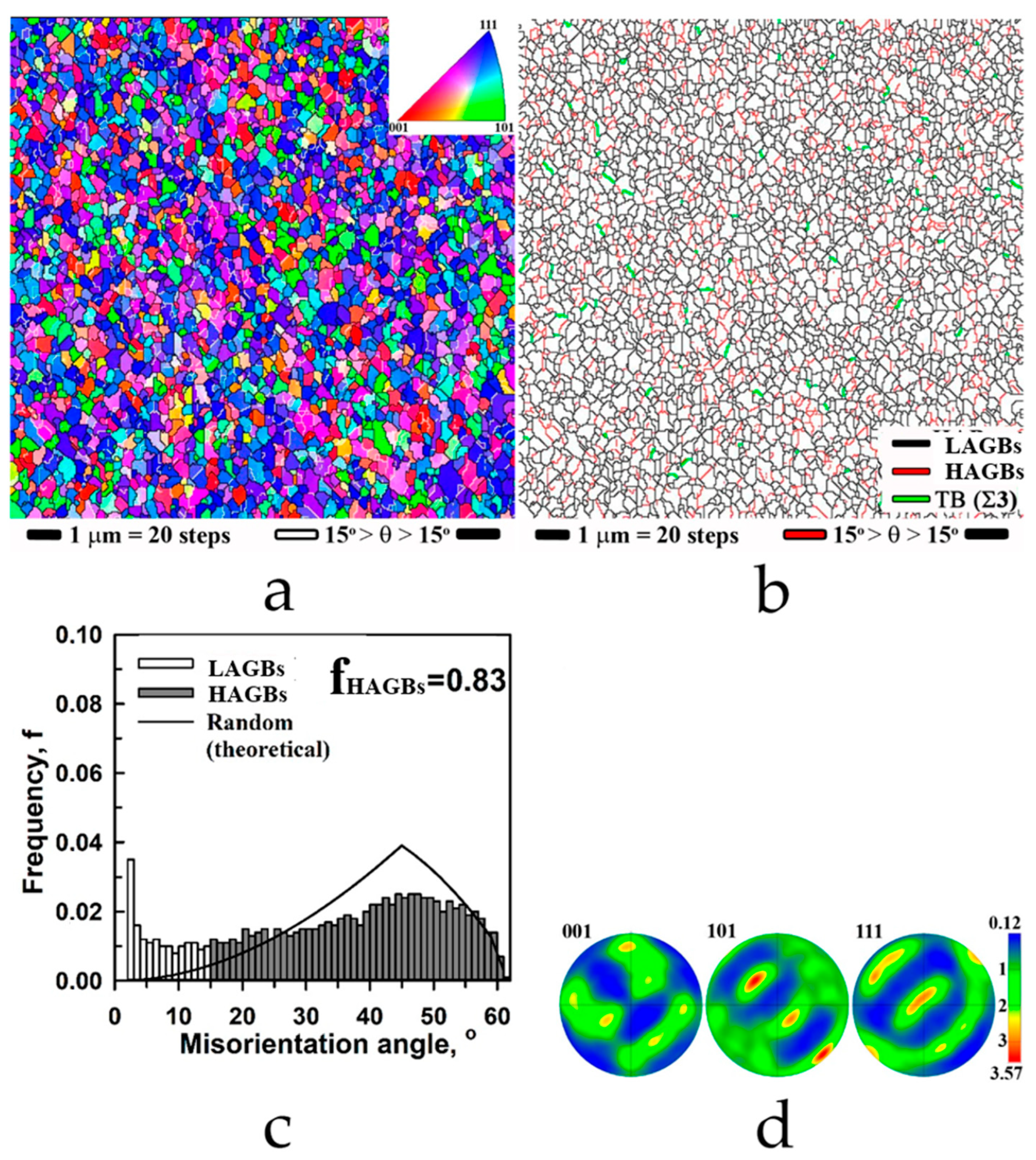

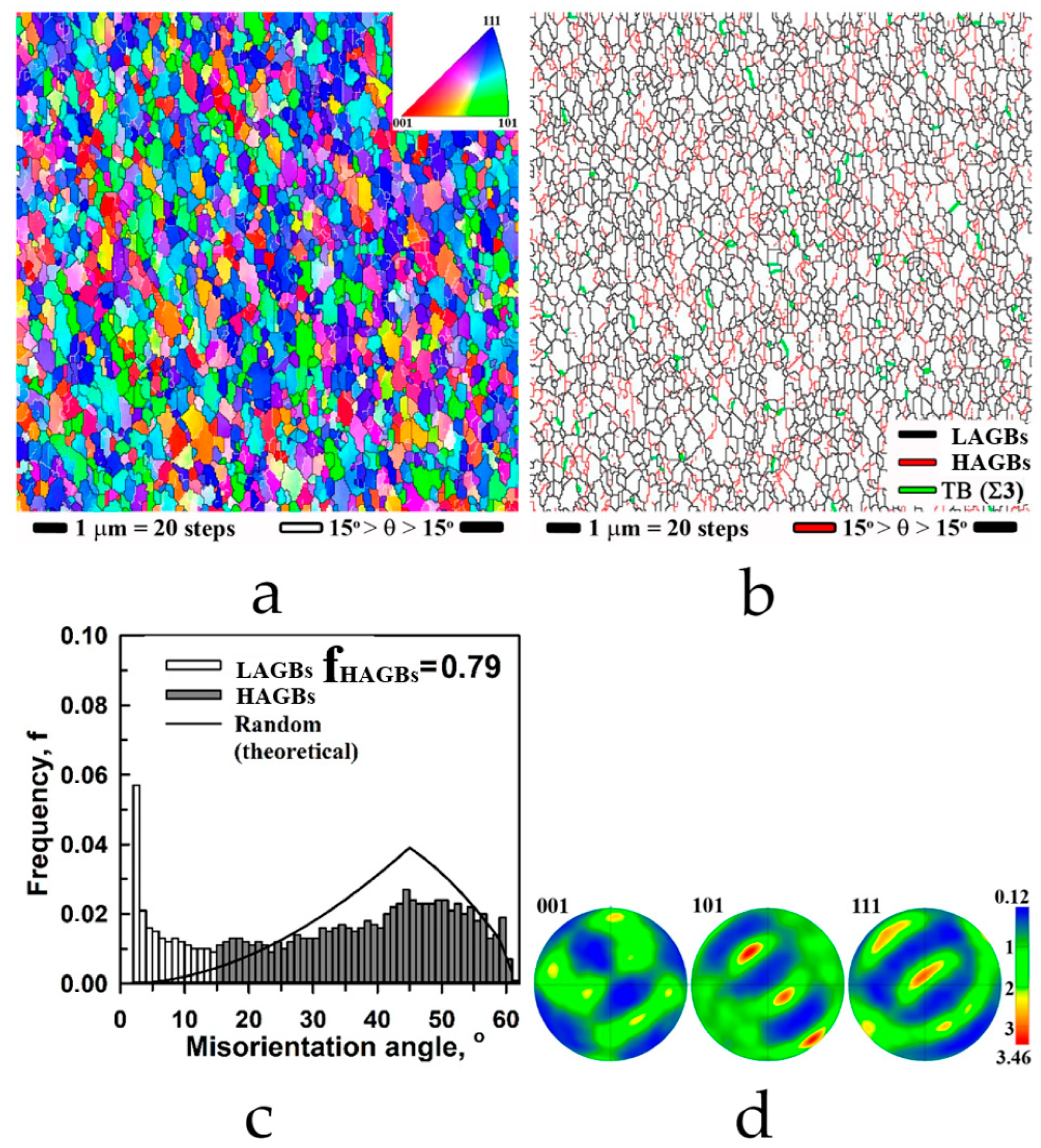

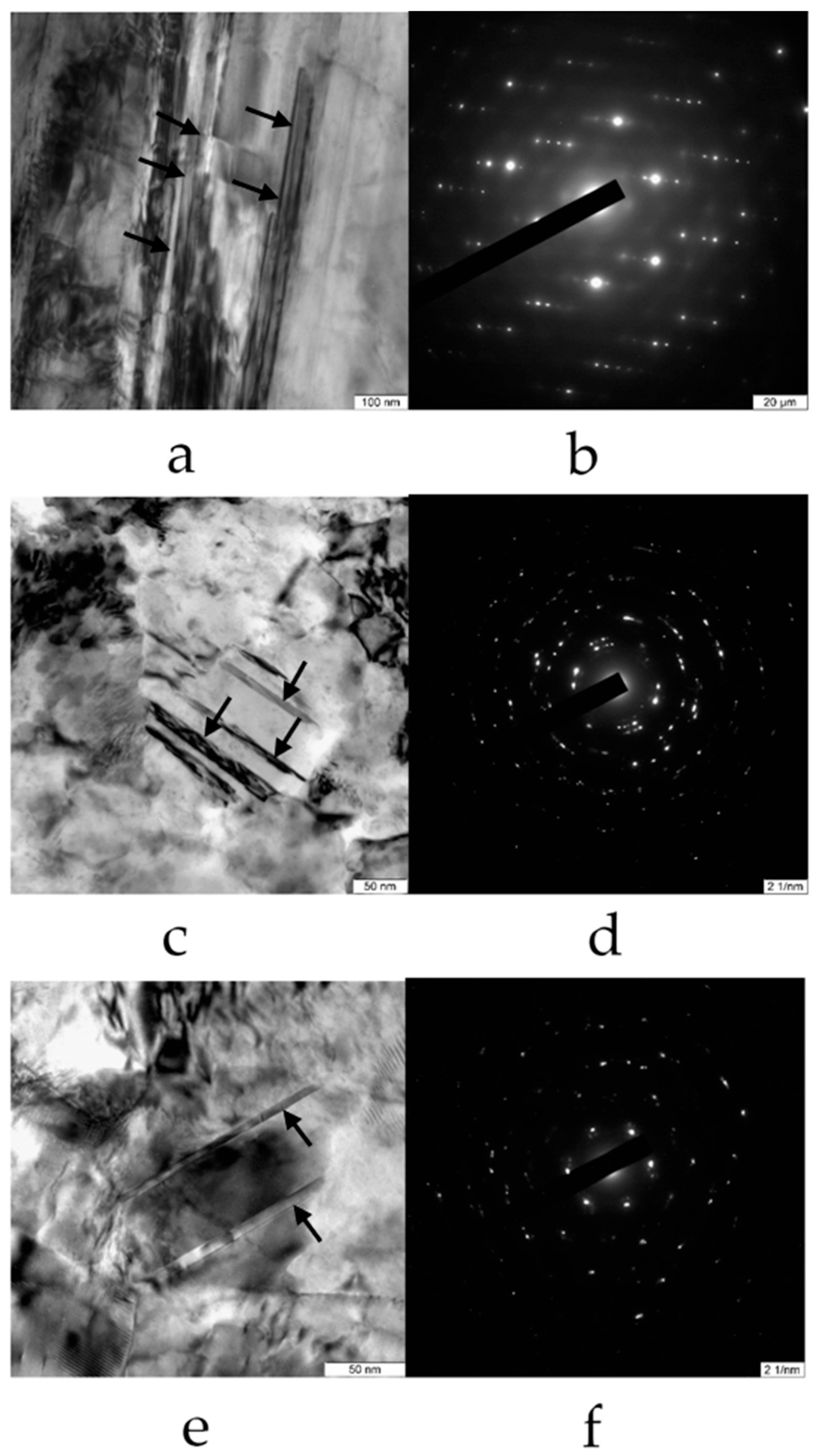

3.2. Characterizations of Composites Processed by HPT

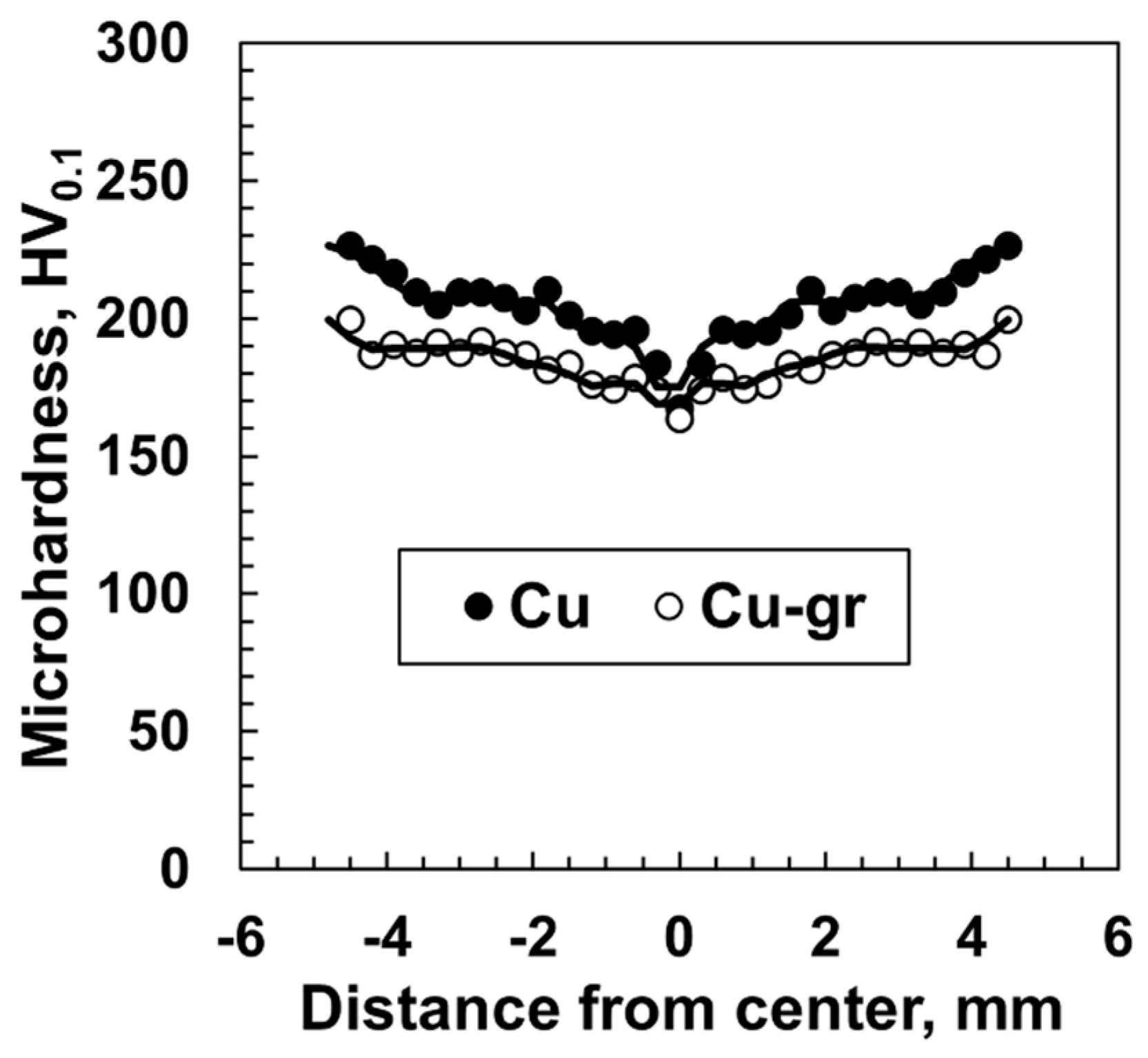

3.3. Mechanical Properties of the Composites

3.4. Stacking Fault Energy Calculation by Ab Initio Simulations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TBs | Twin boundaries |

| HPT | High-pressure torsion |

| HAGBs | High-angle grain boundaries |

| LAGBs | Low-angle boundaries |

| QE | Quantum Espresso |

| DFT | Density functional theory |

| XRD | X-ray diffraction |

| SFE | Stacking fault energy |

| CNTs | Carbon nanotubes |

References

- Mao, Q.; Liu, Y.; Zhao, Y. A review on copper alloys with high strength and high electrical conductivity. J. Alloys Compd. 2024, 990, 174456. [Google Scholar] [CrossRef]

- Champion, Y.; Couzine, J.P.; Tusseau Nenez, S.; Bréchet, Y.; Islamgaliev, R.K.; Valiev, R. High strength and electrical conductivity of UFG copper alloys. Mater. Sci. Forum 2010, 667–669, 755–759. [Google Scholar] [CrossRef]

- Lu, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Lee, K.-P.; Chen, B.-Y.; Lin, Y.-Q.; Hung, Y.-W.; Hsu, W.-Y.; Chen, Y.-H.; Chen, C. High-strength and high-conductivity nanotwinned Cu lightly doped with Ni. Mater. Sci. Eng. A 2024, 891, 145990. [Google Scholar] [CrossRef]

- Lu, L.; Chen, X.; Huang, X.; Lu, K. Revealing the maximum strength in nanotwinned copper. Science 2009, 323, 607–610. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Lei, L.; Ku, L. Hardness and strain rate sensitivity of nanocrystalline Cu. Scr. Mater. 2006, 54, 1913–1918. [Google Scholar] [CrossRef]

- Zhilyaev, A.; Langdon, T. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Czeppe, T.; Korznikova, G.; Korznikov, A.; Wróbel, M. Properties of the Cu-graphene composites produced by high pressure torsion. Mechanik 2016, 5–6, 500–501. [Google Scholar] [CrossRef]

- Mutlu, A.; Çavdar, U. Investigation of mechanical properties of Copper-Graphene composites in terms of production methods and additive ratios: A review. Sigma J. Eng. Nat. Sci. 2024, 42, 600–613. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, C.; Pei, L.; Li, J.; Wang, R.; Tieu, K. The negative Poisson’s ratio and strengthening mechanism of nanolayered graphene/Cu composites. Carbon 2019, 143, 125–137. [Google Scholar] [CrossRef]

- Korznikova, G.; Kabirov, R.; Nazarov, K.; Khisamov, R.; Shayakhmetov, R.; Korznikova, E.; Khalikova, G.; Mulyukov, R. Influence of constrained high-pressure torsion on microstructure and mechanical properties of an aluminum-based metal matrix composite. JOM 2020, 72, 2898–2911. [Google Scholar] [CrossRef]

- Giannozzi, P.; Baroni, S.; Bonini, N.; Calandra, M.; Car, R.; Cavazzoni, C.; Wentzcovitch, R.M. QUANTUM ESPRESSO: A modular and open-source software project for quantum simulations of materials. J. Phys. Condens. Matter 2009, 21, 395502. [Google Scholar] [CrossRef] [PubMed]

- Giannozzi, P.; Andreussi, O.; Brumme, T.; Bunau, O.; Nardelli, M.B.; Calandra, M.; Baroni, S. Advanced capabilities for materials modelling with Quantum ESPRESSO. J. Phys. Condens. Matter 2017, 29, 465901. [Google Scholar] [CrossRef] [PubMed]

- Vanderbilt, D. Soft self-consistent pseudopotentials in a generalized eigenvalue formalism. Phys. Rev. B 1990, 41, 7892. [Google Scholar] [CrossRef] [PubMed]

- Garrity, K.F.; Bennett, J.W.; Rabe, K.M.; Vanderbilt, D. Pseudopotentials for high-throughput DFT calculations. Comput. Mater. Sci. 2014, 81, 446–452. [Google Scholar] [CrossRef]

- Prandini, G.; Marrazzo, A.; Castelli, I.E.; Mounet, N.; Marzari, N. Precision and efficiency in solid-state pseudopotential calculations. npj Comput. Mater. 2018, 4, 72. [Google Scholar] [CrossRef]

- Lejaeghere, K.; Bihlmayer, G.; Björkman, T.; Blaha, P.; Blügel, S.; Blum, V.; Cottenier, S. Reproducibility in density functional theory calculations of solids. Science 2016, 351, aad3000. [Google Scholar] [CrossRef]

- Azzeddine, H.; Bradai, D.; Baudin, T.; Langdon, T.G. Texture evolution in high-pressure torsion processing. Prog. Mater. Sci. 2022, 125, 100886. [Google Scholar] [CrossRef]

- Cao, J.; Li, Y.; Liu, J.; Zhan, K.; Zhao, B.; Ji, V. Engineering texture and twins of Cu foils preparing by pulse electrodeposition and their properties. Mater. Charact. 2024, 218, 114477. [Google Scholar] [CrossRef]

- Reed, R.P.; Schramm, R.E. Relationship between stacking fault energy and x-ray measurements of stacking fault probability and microstrain. J. Appl. Phys. 1974, 45, 4705. [Google Scholar] [CrossRef]

- Sadoun, A.M.; Abdallah, A.W.; Najjar, I.M.R.; Basha, M.; Elmahdy, M. Effect of lattice structure evolution and stacking fault energy on the properties of Cu–ZrO2/GNP nanocomposites. Ceram. Int. 2021, 47, 29598–29606. [Google Scholar] [CrossRef]

- Kunčická, L.; Jambor, M.; Král, P. High-pressure torsion of copper; Effect of processing temperature on structural features, microhardness and electric conductivity. Materials 2023, 16, 2738. [Google Scholar] [CrossRef]

- Rijal, A.; Singh, S.P.; Han, J.; Kawasaki, M.; Kumar, P. Effect of HPT processing followed by long term natural ageing on mechanical and electrical properties of commercially pure Cu. Lett. Mater. 2019, 9, 561–565. [Google Scholar] [CrossRef]

- Korznikova, G.; Czeppe, T.; Khalikova, G.; Gunderov, D.; Korznikova, E.; Litynska-Dobrzynska, L.; Szlezynger, M. Microstructure and mechanical properties of Cu-graphene composites produced by two high pressure torsion procedures. Mater. Charact. 2020, 161, 110122. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Z.; Cui, Y.; Wei, B.; Xu, S.; Sheng, J.; Wang, M.; Zhu, Y.; Fei, W. Graphene-copper composite with micro-layered grains and ultrahigh strength. Sci. Rep. 2017, 7, 41896. [Google Scholar] [CrossRef]

- da Cruz, R.A.; de Andrade Mendes Filho, A.; Santos, S.L.d.; Santos, V.T.d.; da Silva, M.R.; Lobo, F.G.; Santos, G.A.d.; Couto, A.A. Microstructure and mechanical properties of copper/graphene composites fabricated via accumulative roll bonding and heat treatment without a controlled atmosphere. Metals 2024, 14, 4. [Google Scholar] [CrossRef]

- Hidalgo-Manrique, P.; Lei, X.; Xu, R.; Zhou, M.; Kinloch, I.A.; Young, R.J. Copper/graphene composites: A review. J. Mater. Sci. 2019, 54, 12236–12289. [Google Scholar] [CrossRef]

- Lugo, N.; Llorca, N.; Cabrera, J.M.; Horita, Z. Microstructures and mechanical properties of pure copper deformed severely by equal-channel angular pressing and high pressure torsion. Mater. Sci. Eng. A 2008, 477, 366–371. [Google Scholar] [CrossRef]

- Arblaster, J.W. Selected Values of the Crystallographic Properties of Elements; ASM International: Almere, The Netherlands, 2018. [Google Scholar]

- Zhou, L.P.; Wang, M.P.; Kun, P.E.N.; Zhu, J.J.; Zhen, F.U.; Zhou, L.I. Structure characteristic and its evolution of Cu-W films prepared by dual-target magnetron sputtering deposition. Trans. Nonferrous Met. Soc. China 2012, 22, 2700–2706. [Google Scholar] [CrossRef]

- Trong, D.N.; Long, V.C.; Saraç, U.; Quoc, V.D.; Ţălu, Ş. First-principles calculations of crystallographic and electronic structural properties of Au-Cu alloys. J. Compos. Sci. 2022, 6, 383. [Google Scholar] [CrossRef]

- Gray, D.; McCaughan, A.; Mookerji, B. Crystal structure of graphite, graphene and silicon. Phys. Solid State Appl. 2009, 6, 730. [Google Scholar]

- Zhang, Y.; An, Q.; Li, J.; Lu, B.; Wu, W.; Xia, R. Strengthening mechanisms of graphene in copper matrix nanocomposites: A molecular dynamics study. J. Mol. Model. 2020, 26, 335. [Google Scholar] [CrossRef] [PubMed]

- Weng, S.; Ning, H.; Fu, T.; Hu, N.; Zhao, Y.; Huang, C.; Peng, X. Molecular dynamics study of strengthening mechanism of nanolaminated graphene/Cu composites under compression. Sci. Rep. 2018, 8, 3089. [Google Scholar] [CrossRef]

- Yankovskaya, U.I.; Sharapova, Y.R.; Zakharov, P.V. Influence of carbon nanotubes on mechanical properties of Ni3Al polycrystal. Mater. Technol. Des. 2022, 4, 76–81. [Google Scholar]

- Baimova, J.A.; Korznikova, E.A.; Lobzenko, I.P.; Dmitriev, S.V. Discrete breathers in carbon and hydrocarbon nanostructures. Rev. Adv. Mater. Sci. 2015, 42, 68–82. [Google Scholar] [CrossRef]

- Rysaeva, L.K.; Bachurin, D.V.; Murzaev, R.T.; Mulyukov, R.R.; Dmitriev, S.V. Evolution of the carbon nanotube bundle structure under biaxial and shear strains. Facta Univ. Ser. Mech. Eng. 2020, 18, 525–536. [Google Scholar] [CrossRef]

- Babicheva, R.I.; Dahanayaka, M.; Liu, B.; Korznikova, E.A.; Dmitriev, S.V.; Wu, M.S.; Zhou, K. Characterization of two carbon allotropes, cyclicgraphene and graphenylene, as semi-permeable materials for membranes. Mater. Sci. Eng. B 2020, 259, 114569. [Google Scholar] [CrossRef]

| Material | Lattice Parameter, a, (nm) | Coherent Scattering Regions, CSR, (nm) | Microstrain, e, % |

|---|---|---|---|

| HPT Gr/Cu | 0.3616984 ± 0.0000052 | 60.63 ± 0.47 | e = 0.21587 |

| HPT Pure Cu | 0.3616962 ± 0.0000049 | 68.29 ± 0.39 | e = 0.17972 |

| Material | Process | Tensile Strength (MPa) | Ductility (%) | Microhardness (HV) | Reference |

|---|---|---|---|---|---|

| Cu/graphene (this work) | HPT (N = 5 rev.) | 674 | 13.7 | 210 | This work |

| Pure Cu (this work) | HPT (N = 5 rev.) | 689 | 12.1 | 190 | This work |

| Pure Cu | HPT (RT, N = 1 rev.) | 387 | 8.2 | 105 | Ref. [23] |

| Pure Cu | HPT (ε = 1000) | – | – | 142 | Ref. [24] |

| Cu-0.1 wt% Gr | Powder metallurgy | 315 | 5.8 | 131 | Ref. [25] |

| Cu-5 vol% RGO | SPS + layered | 608 | 7.5 | – | Ref. [26] |

| Cu-0.5 wt% Gr | Hot pressing | 308 | 4.2 | – | Ref. [27] |

| Cu-8 vol% GNPs | HPT | 485 | <5 | – | Ref. [10] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korznikova, G.; Khalikova, G.; Kosarev, I.; Wei, W.; Semenov, A.; Korznikova, E. Microstructure and Mechanical Performance of Cu and Gr/Cu Composites: Experimental and Ab Initio Insights. Solids 2025, 6, 57. https://doi.org/10.3390/solids6040057

Korznikova G, Khalikova G, Kosarev I, Wei W, Semenov A, Korznikova E. Microstructure and Mechanical Performance of Cu and Gr/Cu Composites: Experimental and Ab Initio Insights. Solids. 2025; 6(4):57. https://doi.org/10.3390/solids6040057

Chicago/Turabian StyleKorznikova, Galiia, Gulnara Khalikova, Igor Kosarev, Wei Wei, Alexander Semenov, and Elena Korznikova. 2025. "Microstructure and Mechanical Performance of Cu and Gr/Cu Composites: Experimental and Ab Initio Insights" Solids 6, no. 4: 57. https://doi.org/10.3390/solids6040057

APA StyleKorznikova, G., Khalikova, G., Kosarev, I., Wei, W., Semenov, A., & Korznikova, E. (2025). Microstructure and Mechanical Performance of Cu and Gr/Cu Composites: Experimental and Ab Initio Insights. Solids, 6(4), 57. https://doi.org/10.3390/solids6040057