On Ballooning and Burst Behavior of Nuclear Fuel Clad Considering Heating Rate Effect: Development of a Damage Model, a Burst Correlation and Experimental Validation

Abstract

1. Introduction

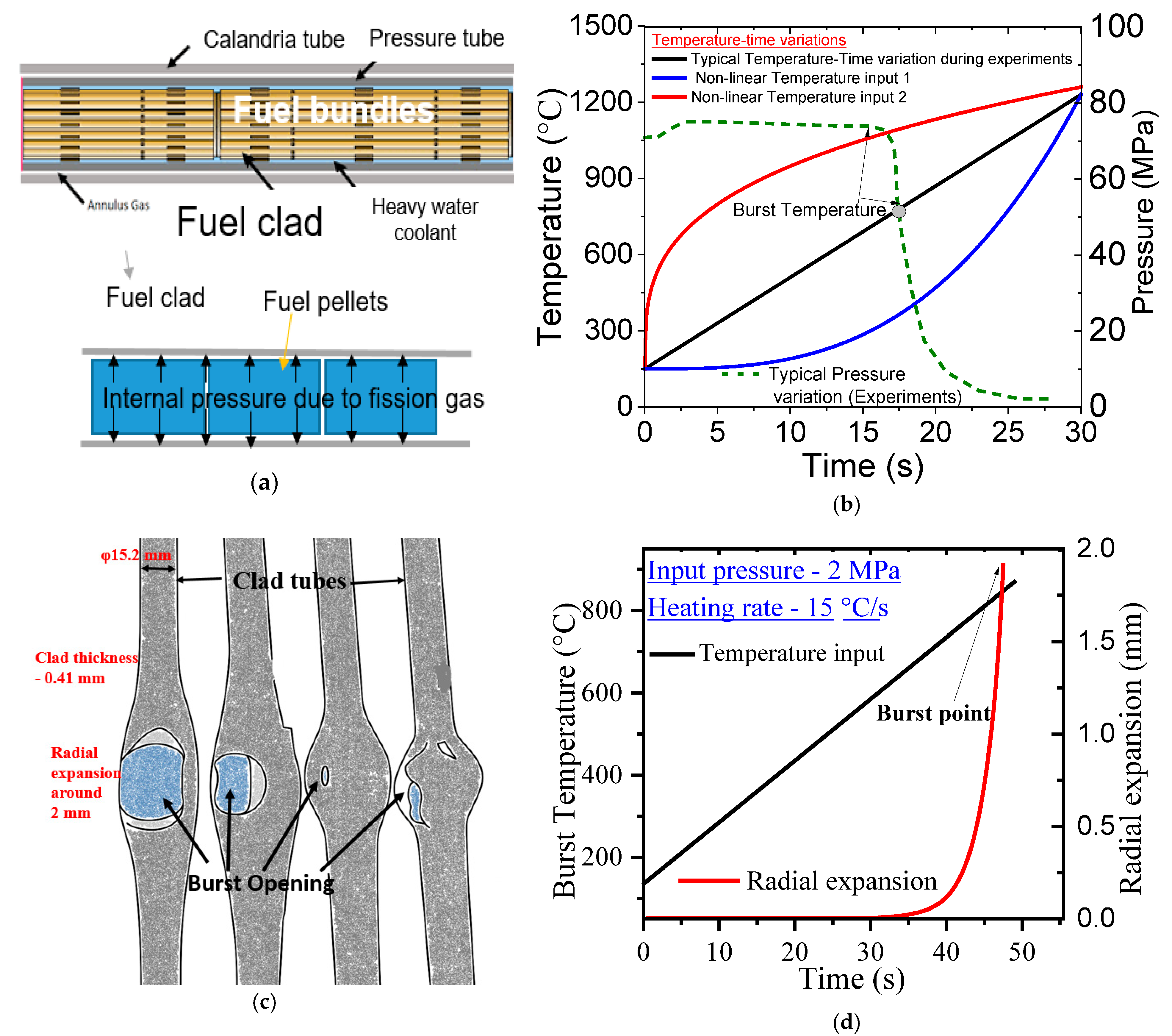

2. Reactor Channel Configuration and Experimental Approach

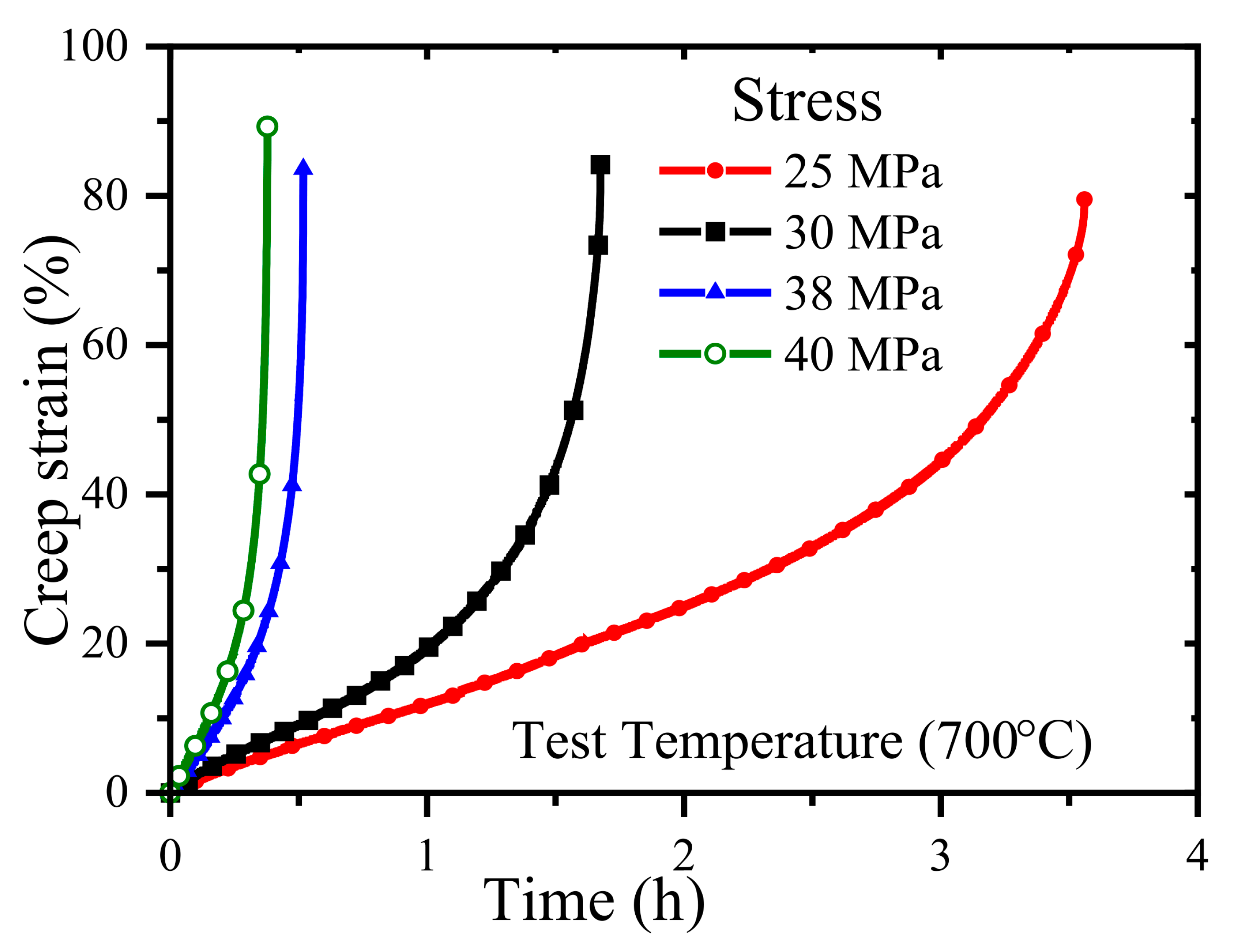

3. Material Data Used in Finite Element Analysis of Fuel Clad Deformation

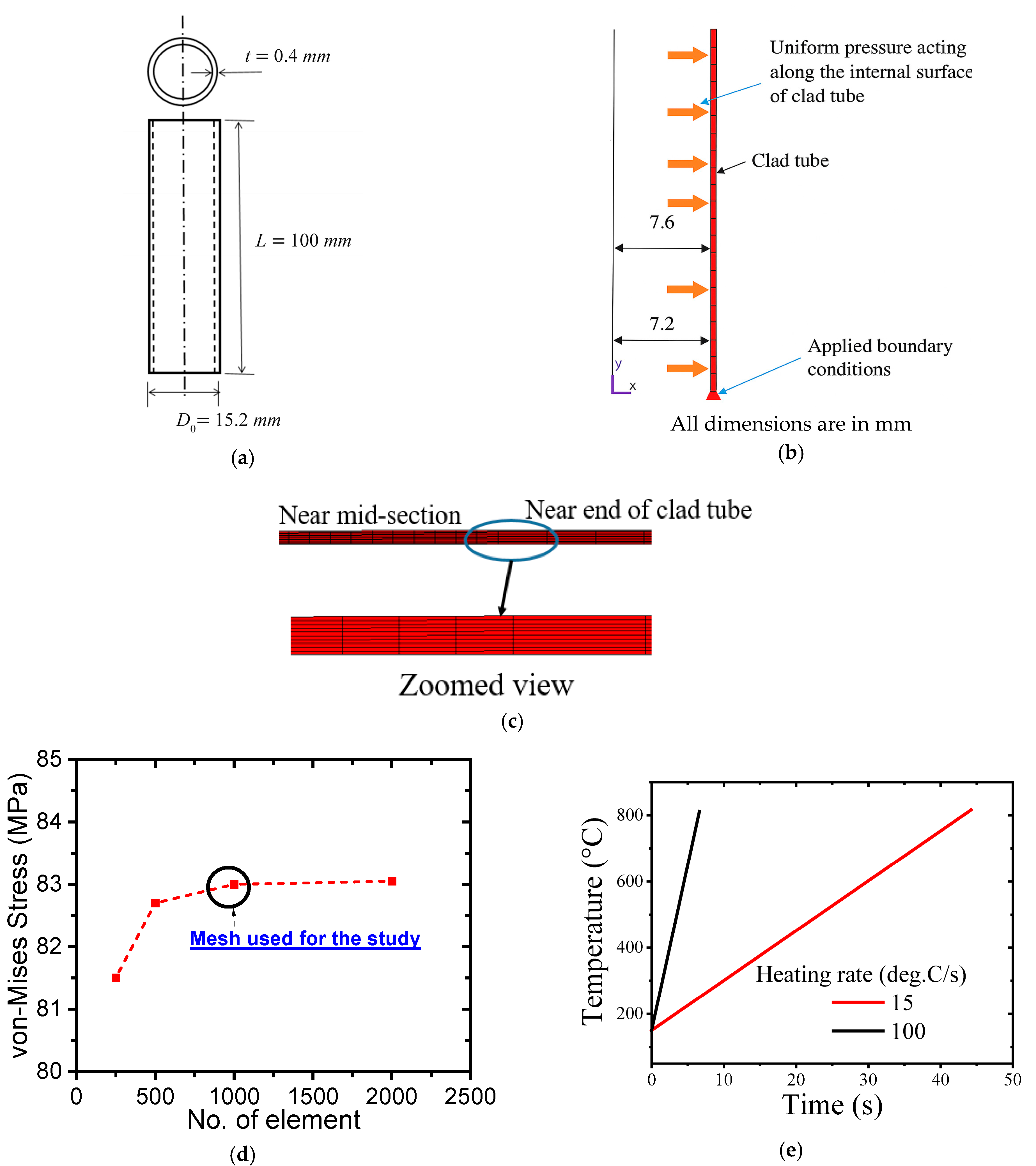

4. Description of Finite Element Model Used in Simulation of Ballooning and Burst Behavior of Fuel Clad

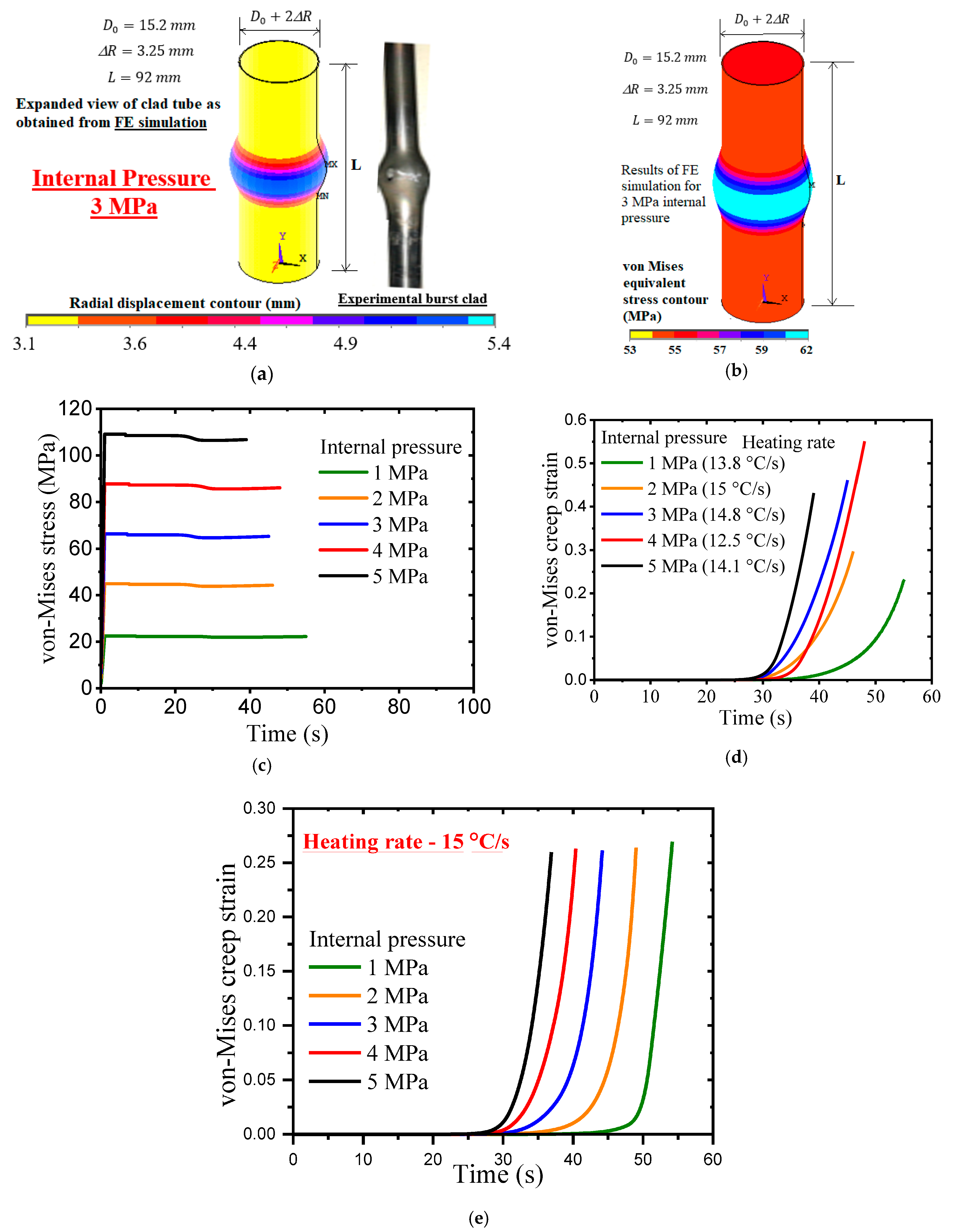

5. Results of FE Analysis, Prediction of Burst Initiation and Experimental Validation

6. Discussion

7. Conclusions

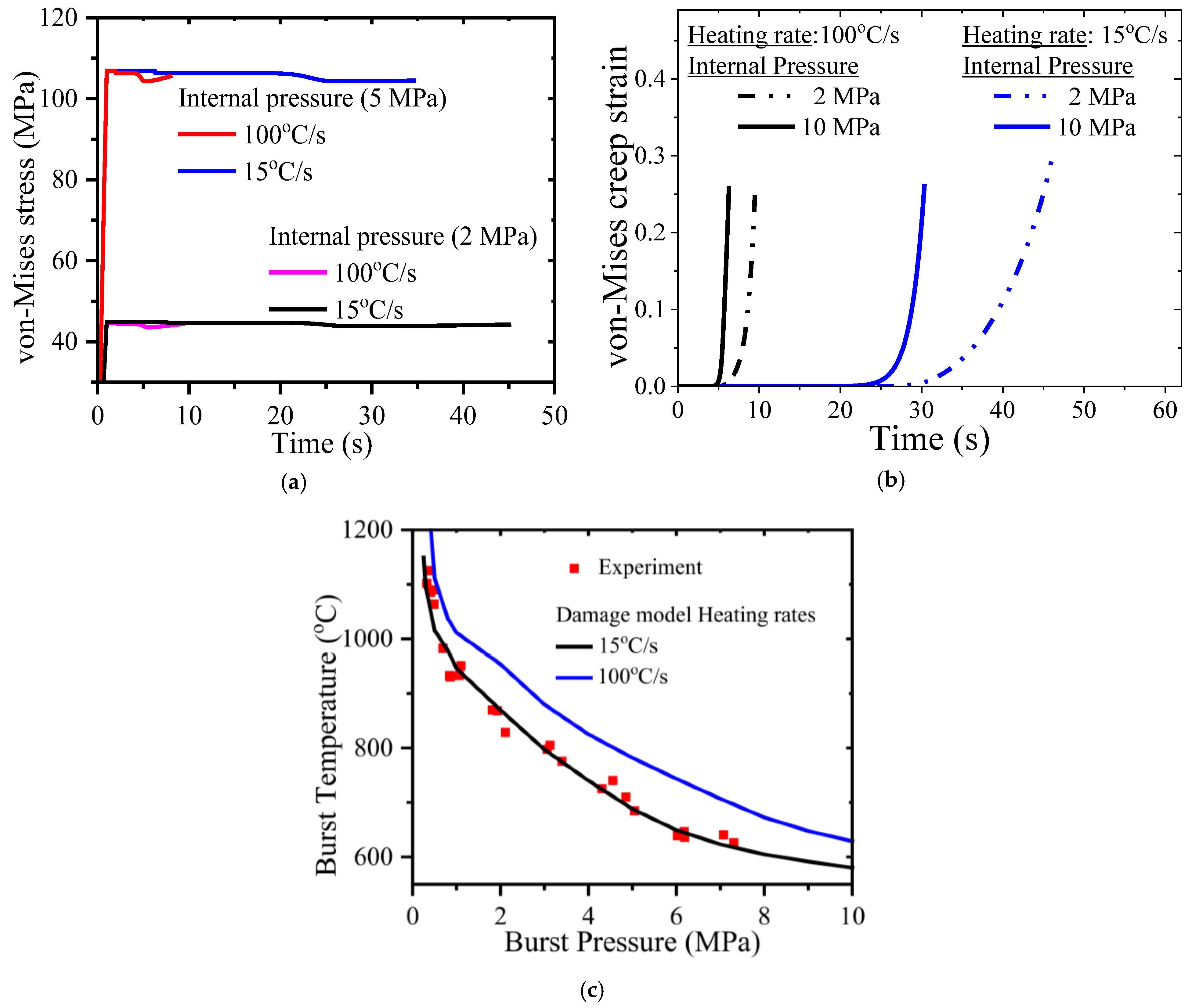

- The creep damage accumulation depends upon the history of temperature and stress variation in the clad and the stress triaxiality in the clad is an important factor, which promotes creep damage accumulation in the material.

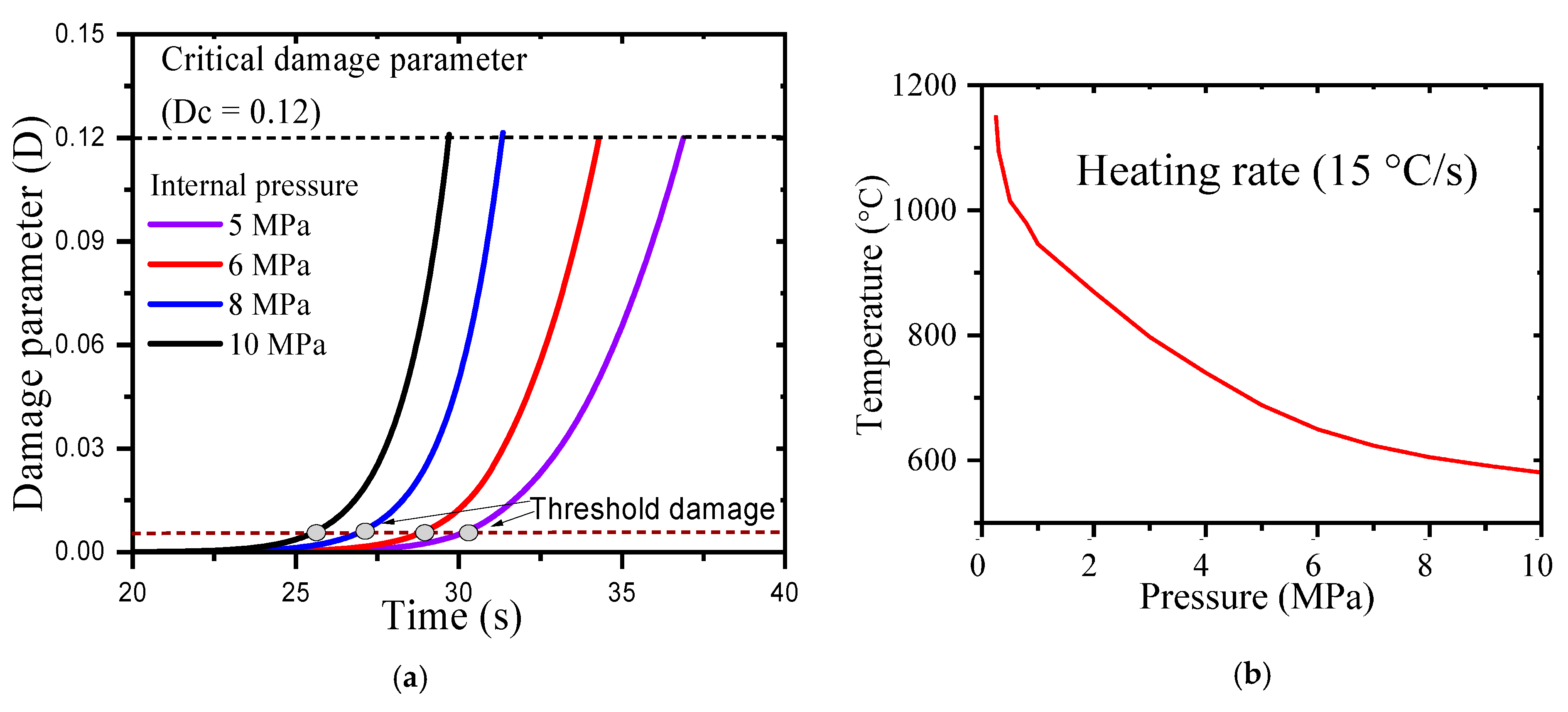

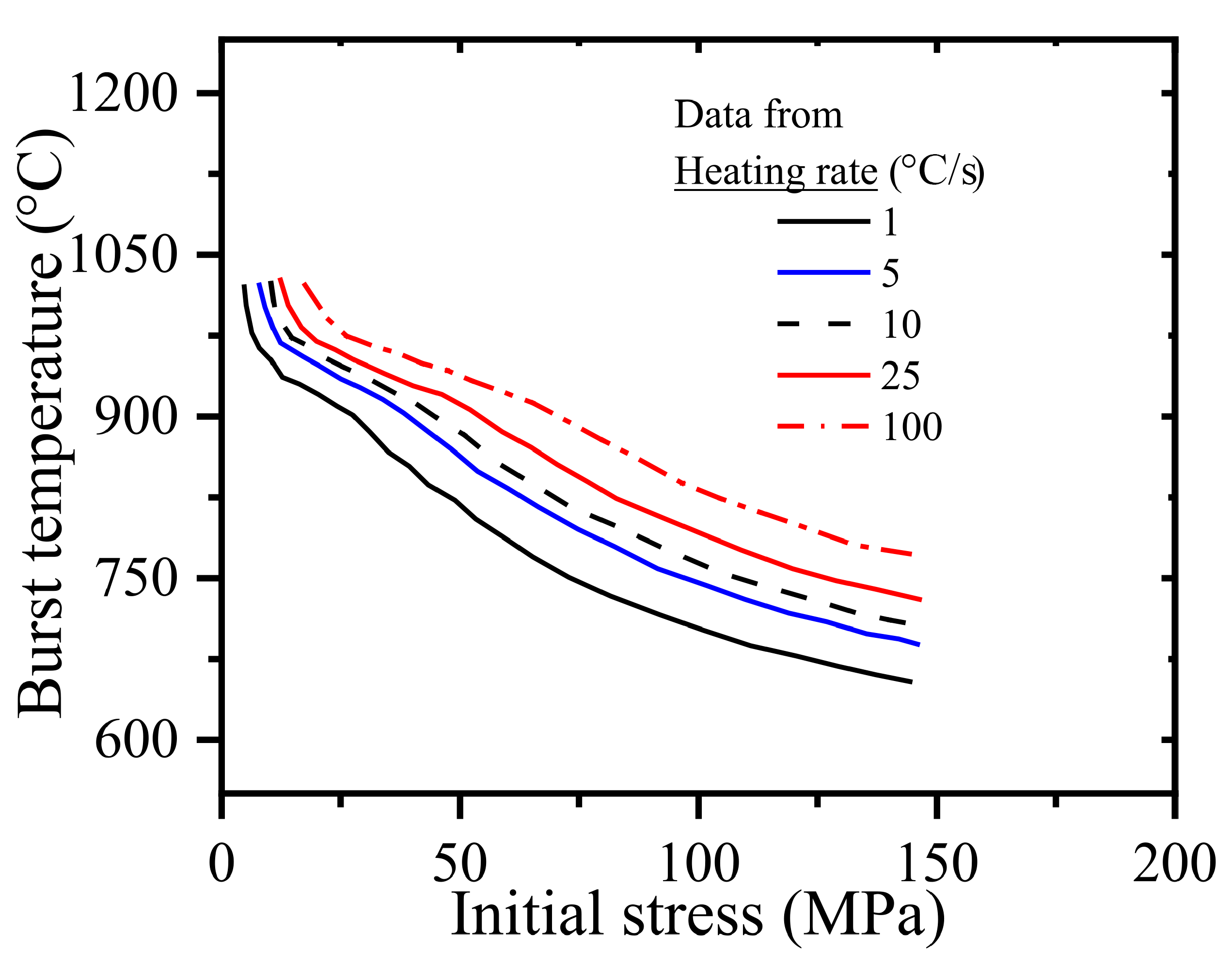

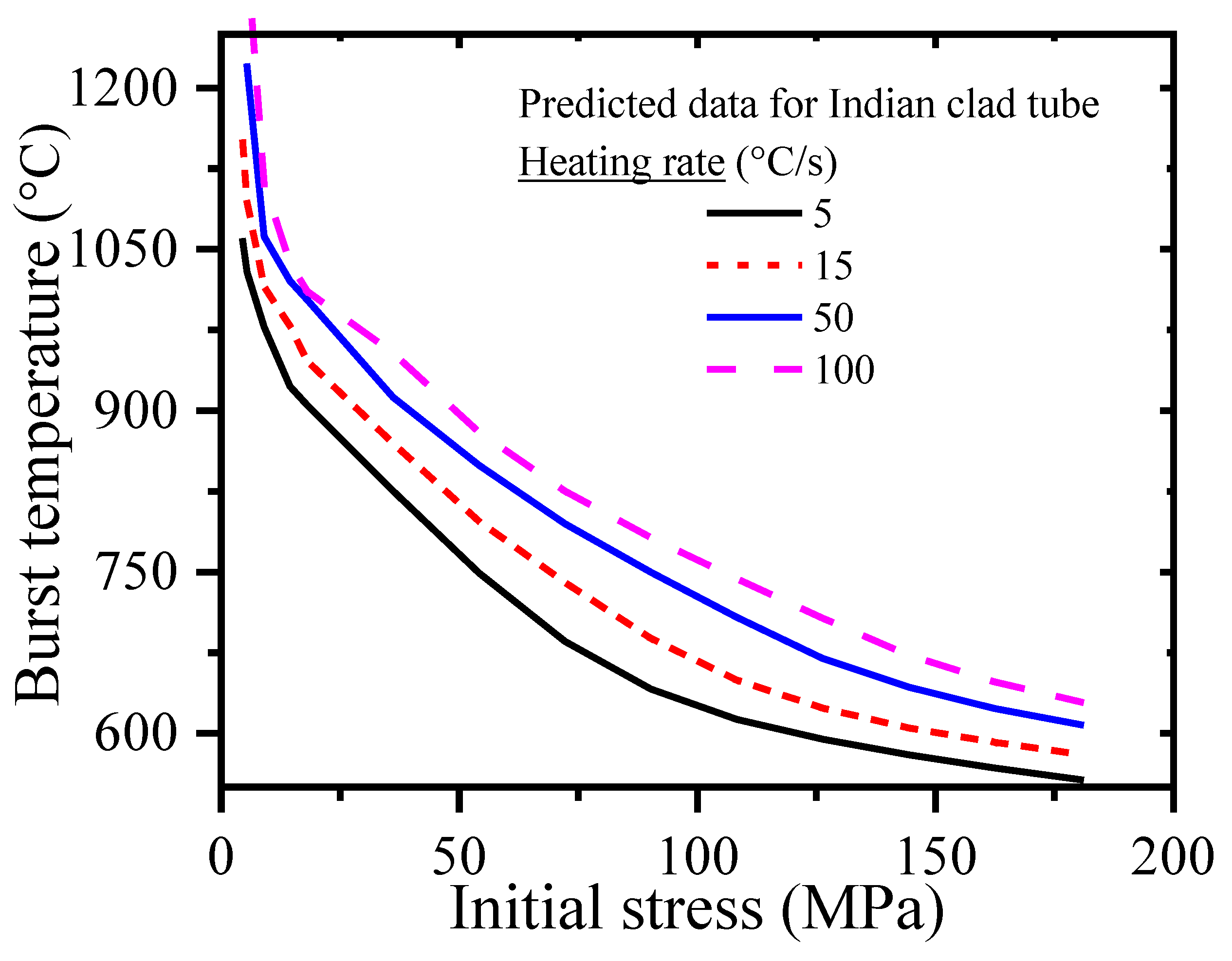

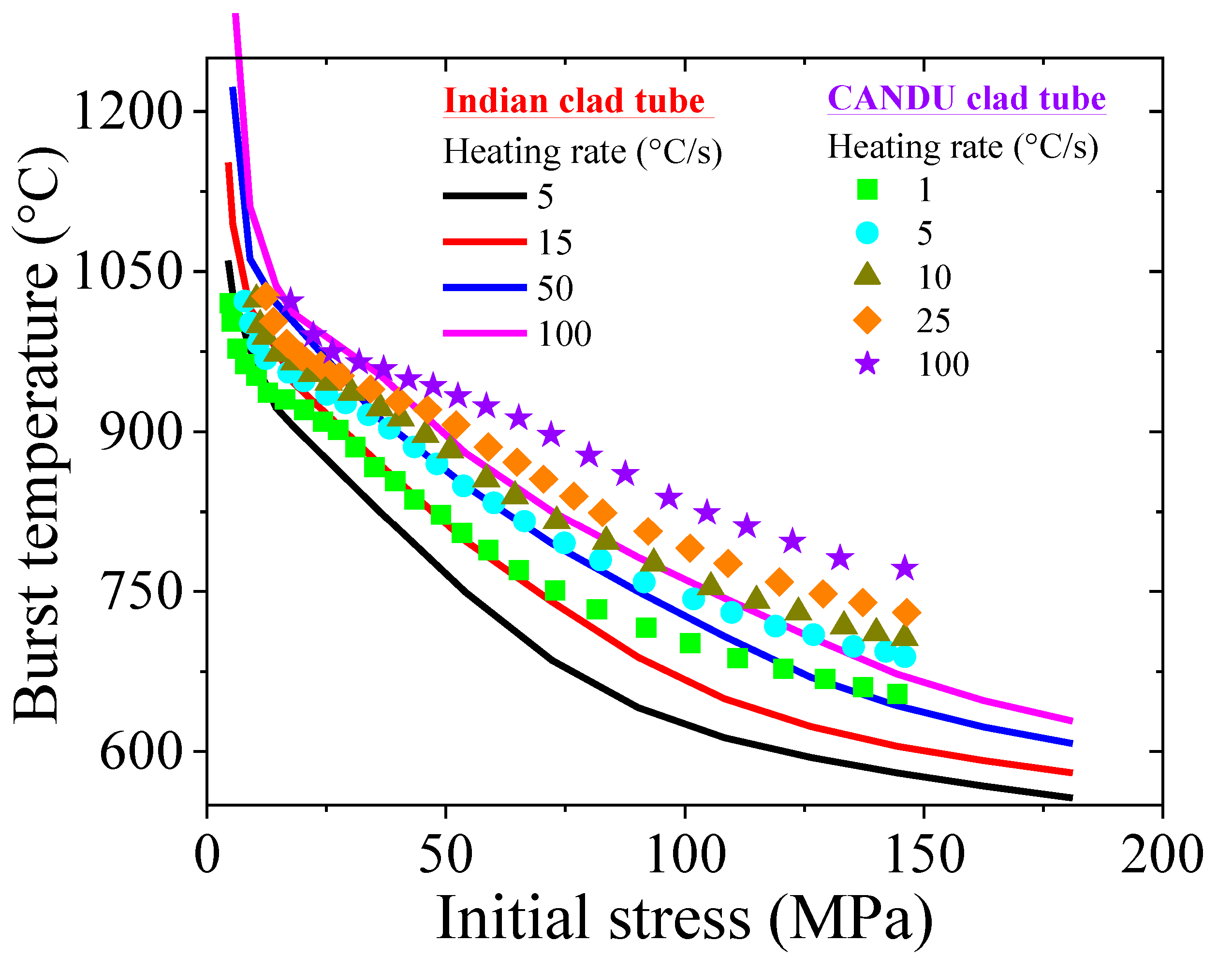

- For a given heating rate, higher applied pressure results in lower temperature at clad burst as the applied stress is higher, which can lead to higher creep strain accumulation at a given temperature.

- A threshold magnitude of burst time and burst temperature is observed, both in experimental data from the literature, and from the results of the current simulation, which corresponds to the clad temperature of the order of 600 °C, approximately. This corresponds to the temperature below which creep deformation of Indian PHWR Zircaloy-4 fuel clad is negligible.

- Clad burst temperature increases with heating rate for a given value of applied stress. This can be explained based on temperature variation with time for different heating rates. For a higher heating rate, there is less time available for creep deformation at a given temperature range, and hence, the clad needs to attain higher temperature in order to accumulate creep damage corresponding to the critical value needed for initiation of clad burst.

- A new heating-rate-dependent correlation has been developed in this work, which can be used by the practitioners as well as by the engineers using the severe accident analysis program in order to simulate the clad deformation and burst behavior in a realistic manner, when heating rate varies during the accident progression.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feria, F.; Aragón, P.; Herranz, L. Assessment of cladding ballooning during DBA-LOCAs with FRAPTRAN. Ann. Nucl. Energy 2023, 195, 110194. [Google Scholar] [CrossRef]

- Aragón, P.; Feria, F.; Herranz, L.E.; Schubert, A.; Van Uffelen, P. Enhancing cladding mechanical modelling during DBA/LOCA accidents with FRAPTRAN: The TUmech one-dimensional model. Prog. Nucl. Energy 2024, 171, 105189. [Google Scholar] [CrossRef]

- Massey, C.P.; Terrani, K.A.; Dryepondt, S.N.; Pint, B.A. Cladding burst behavior of Fe-based alloys under LOCA. J. Nucl. Mater. 2016, 470, 128–138. [Google Scholar] [CrossRef]

- Campello, D.; Tardif, N.; Moula, M.; Baietto, M.; Coret, M.; Desquines, J. Identification of the steady-state creep behavior of Zircaloy-4 claddings under simulated Loss-Of-Coolant Accident conditions based on a coupled experimental/numerical approach. Int. J. Solids Struct. 2017, 115–116, 190–199. [Google Scholar] [CrossRef]

- Narukawa, T.; Kondo, K.; Fujimura, Y.; Kakiuchi, K.; Udagawa, Y.; Nemoto, Y. Behavior of FeCrAl-ODS cladding tube under loss-of-coolant accident conditions. J. Nucl. Mater. 2023, 582, 154467. [Google Scholar] [CrossRef]

- Aragón, P.; Feria, F.; Herranz, L.E.; Schubert, A.; Van Uffelen, P. Fuel performance modelling of Cr-coated Zircaloy cladding under DBA/LOCA conditions. Ann. Nucl. Energy 2024, 211, 110950. [Google Scholar] [CrossRef]

- Sweet, R.; Mouche, P.; Bell, S.; Kane, K.; Capps, N. Chromium-coated cladding analysis under simulated LOCA burst conditions. Ann. Nucl. Energy 2022, 176, 109275. [Google Scholar] [CrossRef]

- Kim, J.; Yoon, J.W.; Kim, H.; Lee, S.-U. Prediction of ballooning and burst for nuclear fuel cladding with anisotropic creep modeling during Loss of Coolant Accident (LOCA). Nucl. Eng. Technol. 2021, 53, 3379–3397. [Google Scholar] [CrossRef]

- Li, W.; Chen, H.; Wu, X.; Duan, Q.; Su, G. Simulation of nuclear fuel clad high-temperature ballooning under loss-of-coolant accident conditions considering anisotropic creep. Ann. Nucl. Energy 2024, 203, 110500. [Google Scholar] [CrossRef]

- Capps, N.; Ridley, M.; Yan, Y.; Bell, S.; Kane, K. BISON validation to in situ cladding burst test and high-burnup LOCA experiments. Ann. Nucl. Energy 2023, 191, 109905. [Google Scholar] [CrossRef]

- Pastore, G.; Williamson, R.; Gardner, R.; Novascone, S.; Tompkins, J.; Gamble, K.; Hales, J. Analysis of fuel rod behavior during loss-of-coolant accidents using the BISON code: Cladding modeling developments and simulation of separate-effects experiments. J. Nucl. Mater. 2021, 543, 152537. [Google Scholar] [CrossRef]

- Sweet, R.; Massey, C.; Hirschhorn, J.; Bell, S.; Kane, K. Wrought FeCrAl alloy (C26M) cladding behavior and burst under simulated loss-of-coolant accident conditions. Nucl. Eng. Des. 2024, 431, 113712. [Google Scholar] [CrossRef]

- Lee, S.K.; Capps, N.A.; Brown, N.R. BISON analysis of FeCrAl and Zircaloy cladding deformation during simulated BWR cyclic dryout conditions. J. Nucl. Mater. 2023, 576, 154243. [Google Scholar] [CrossRef]

- Rossiter, G.; Peakman, A. Development and validation of Loss of Coolant Accident (LOCA) simulation capability in the ENIGMA fuel performance code for zirconium-based cladding materials. Nucl. Eng. Des. 2023, 416, 112767. [Google Scholar] [CrossRef]

- Verma, L.; Clifford, I.; Konarski, P.; Scolaro, A.; Ferroukhi, H. OFFBEAT V&V studies for REBEKA tests on cladding ballooning and burst during LOCA conditions. Ann. Nucl. Energy 2024, 208, 110773. [Google Scholar] [CrossRef]

- Garrison, B.; Cinbiz, M.; Gussev, M.; Linton, K. Burst characteristics of advanced accident-tolerant FeCrAl cladding under temperature transient testing. J. Nucl. Mater. 2022, 560, 153488. [Google Scholar] [CrossRef]

- Joshi, P.; Kombaiah, B.; Cinbiz, M.; Murty, K. Characterization of stress-rupture behavior of nuclear-grade C26M2 FeCrAl alloy for accident-tolerant fuel cladding via burst testing. Mater. Sci. Eng. A 2020, 791, 139753. [Google Scholar] [CrossRef]

- Kane, K.; Bell, S.; Capps, N.; Garrison, B.; Shapovalov, K.; Jacobsen, G.; Deck, C.; Graening, T.; Koyanagi, T.; Massey, C. The response of accident tolerant fuel cladding to LOCA burst testing: A comparative study of leading concepts. J. Nucl. Mater. 2022, 574, 154152. [Google Scholar] [CrossRef]

- Jailin, T.; Tardif, N.; Desquines, J.; Chaudet, P.; Coret, M.; Baietto, M.-C.; Georgenthum, V. Thermo-mechanical behavior of Zircaloy-4 claddings under simulated post-DNB conditions. J. Nucl. Mater. 2020, 531, 151984. [Google Scholar] [CrossRef]

- Ma, Z.; Shirvan, K.; Wu, Y.; Su, G. Numerical investigation of ballooning and burst for chromium coated zircaloy cladding. Nucl. Eng. Des. 2021, 383, 111420. [Google Scholar] [CrossRef]

- Zhang, X.; Li, G.; Gao, R.; Zhao, X.; Yao, P. Numerical study on PWR fuel rod cladding ballooning and burst behavior with the thermo-mechanical coupling finite element method. Int. J. Adv. Nucl. React. Des. Technol. 2025, 7, 7–18. [Google Scholar] [CrossRef]

- Yano, Y.; Sekio, Y.; Tanno, T.; Kato, S.; Inoue, T.; Oka, H.; Ohtsuka, S.; Furukawa, T.; Uwaba, T.; Kaito, T.; et al. Ultra-high temperature creep rupture and transient burst strength of ODS steel claddings. J. Nucl. Mater. 2019, 516, 347–353. [Google Scholar] [CrossRef]

- Massey, C.P.; Kane, K.A.; Sweet, R.T.; Bell, S.B.; Dryepondt, S.N.; Burns, J.; Nelson, A.T. Microstructure dependent burst behavior of oxide dispersion–strengthened FeCrAl cladding. Mater. Des. 2023, 234, 112307. [Google Scholar] [CrossRef]

- Kamerman, D. The deformation and burst behavior of Zircaloy-4 cladding tubes with hydride rim features subject to internal pressure loads. Eng. Fail. Anal. 2023, 153, 107547. [Google Scholar] [CrossRef]

- Bell, S.; Kane, K.; Ridley, M.; Garrison, B.; Johnston, B.; Capps, N. In-situ determination of strain during transient burst testing and the temperature dependence of Zircaloy-4 claddings. J. Nucl. Mater. 2024, 591, 154910. [Google Scholar] [CrossRef]

- Choi, G.-H.; Kim, D.-H.; Shin, C.-H.; Kim, J.Y.; Kim, B.J. In-situ deformation measurement of Zircaloy-4 cladding tube under various transient heating conditions using optical image analysis. Nucl. Eng. Des. 2020, 370, 110859. [Google Scholar] [CrossRef]

- Gussev, M.; Byun, T.; Yamamoto, Y.; Maloy, S.; Terrani, K. In-situ tube burst testing and high-temperature deformation behavior of candidate materials for accident tolerant fuel cladding. J. Nucl. Mater. 2015, 466, 417–425. [Google Scholar] [CrossRef]

- Kim, D.-H.; Choi, G.-H.; Kim, H.; Lee, C.; Lee, S.-U.; Hong, J.-D.; Kim, H.-S. Measurement of Zircaloy-4 cladding tube deformation using a three-dimensional digital image correlation system with internal transient heating and pressurization. Nucl. Eng. Des. 2020, 363, 110662. [Google Scholar] [CrossRef]

- Ridley, M.; Massey, C.; Bell, S.; Capps, N. High temperature creep model development using in-situ 3-D DIC techniques during a simulated LOCA transient. Ann. Nucl. Energy 2023, 193, 110012. [Google Scholar] [CrossRef]

- Yin, C.; Su, G.; Qian, L.; Xiong, Q.; Liu, Y.; Wu, Y.; Du, S.; Zhang, J.; Xiao, Z. Research progress in high-temperature thermo-mechanical behaviors for modelling Cr-coated cladding under loss-of-coolant accident condition. Nucl. Eng. Des. 2025, 439, 114125. [Google Scholar] [CrossRef]

- Qian, L.; Liu, Y.; Huang, T.; Chen, W.; Du, S.; Yin, C.; Xiong, Q. Research progress in high-temperature thermo-mechanical behavior for modelling FeCrAl cladding under loss-of-coolant accident condition. Prog. Nucl. Energy 2023, 164, 104848. [Google Scholar] [CrossRef]

- Murty, K.L.; Seok, C.; Kombaiah, B. Burst and Biaxial Creep of Thin-Walled Tubing of Low c/a-Ratio HCP Metals. Procedia Eng. 2013, 55, 443–450. [Google Scholar] [CrossRef]

- Xin, J.; Yuyu, L.; Libin, Z. Thermal creep behavior of CZ cladding under biaxial stress state. Nucl. Eng. Technol. 2020, 52, 2901–2909. [Google Scholar] [CrossRef]

- Sklenicka, V.; Kral, P.; Kucharova, K.; Kvapilova, M.; Dvorak, J.; Kloc, L. Thermal creep fracture of a Zr1%Nb cladding alloy in the α and (α + β) phase regions. J. Nucl. Mater. 2021, 553, 152950. [Google Scholar] [CrossRef]

- Moore, B.; Topping, M.; Long, F.; Daymond, M. Stress and temperature dependence of irradiation creep in zircaloy-4 studied using proton irradiation. J. Nucl. Mater. 2024, 603, 155383. [Google Scholar] [CrossRef]

- Choi, G.-H.; Shin, C.-H.; Kim, J.Y.; Kim, B.J. Circumferential steady-state creep test and analysis of Zircaloy-4 fuel cladding. Nucl. Eng. Technol. 2021, 53, 2312–2322. [Google Scholar] [CrossRef]

- Limon, R.; Lehmann, S. A creep rupture criterion for Zircaloy-4 fuel cladding under internal pressure. J. Nucl. Mater. 2004, 335, 322–334. [Google Scholar] [CrossRef]

- Han, M.; Liu, H.; Zhang, W.; Zhang, Y.; Luo, S. A failure criterion for nuclear fuel cladding due to internal gas. Nucl. Eng. Des. 2025, 434, 113909. [Google Scholar] [CrossRef]

- Deng, Y.; Liao, H.; He, Y.; Yin, Y.; Pellegrini, M.; Su, G.; Okamoto, K.; Wu, Y. Investigation on hydrogen embrittlement and failure characteristics of Zr-4 cladding based on the GTN method. Nucl. Mater. Energy 2023, 36, 101463. [Google Scholar] [CrossRef]

- Schappel, D.; Capps, N. Impact of LWR assembly structural features on cladding burst behavior under LOCA conditions. Nucl. Eng. Des. 2024, 418, 112887. [Google Scholar] [CrossRef]

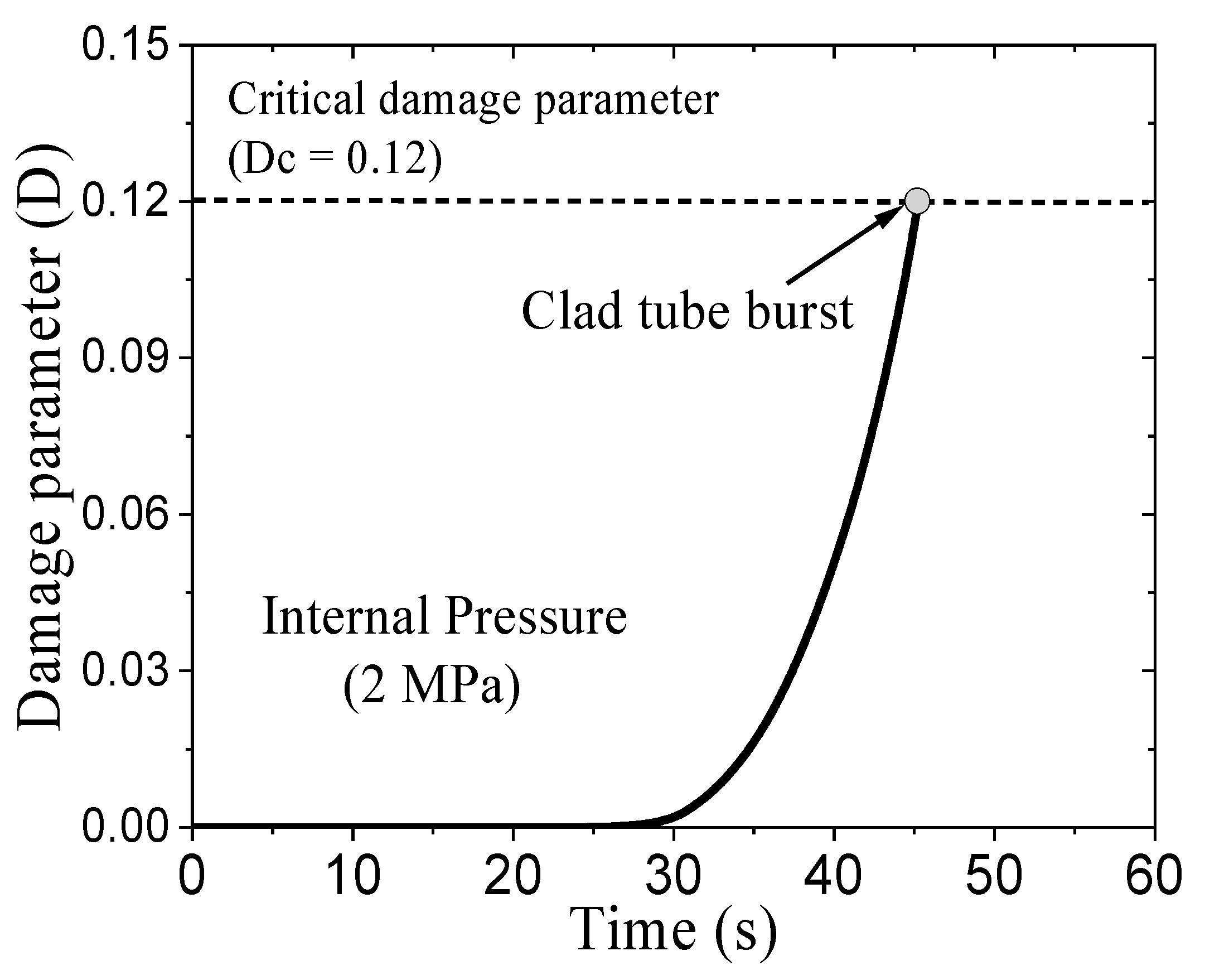

- Syed, A.; Samal, M.; Chattopadhyay, J. Determination of critical material damage parameter for Indian clad tube burst behavior under severe accident scenario. Procedia Struct. Integr. 2024, 60, 195–202. [Google Scholar] [CrossRef]

- Sawarn, T.K.; Banerjee, S.; Pandit, K.; Anantharaman, S. Study of clad ballooning and rupture behavior of fuel pins of Indian PHWR under simulated LOCA condition. Nucl. Eng. Des. 2014, 280, 501–510. [Google Scholar] [CrossRef]

- Chung, H.M.; Kassner, T.F. Deformation Characteristics of Zircaloy Cladding in Vacuum and Steam Under Transient Heating Conditions: Summary Report; Argonne National Laboratory: Lemont, IL, USA, 1978. [Google Scholar]

- Rosinger, H. A model to predict the failure of zircaloy-4 fuel sheathing during postulated loca conditions. J. Nucl. Mater. 1984, 120, 41–54. [Google Scholar] [CrossRef]

- Samal, M.K.; Sanyal, G.; Chakravartty, J.K. An experimental and numerical study of the fracture behaviour of tubular specimens in a pin-loading-tension set-up. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2009, 224, 1–12. [Google Scholar] [CrossRef]

- Samal, M.; Sanyal, G.; Chakravartty, J. Estimation of fracture behavior of thin walled nuclear reactor fuel pins using Pin-Loading-Tension (PLT) test. Nucl. Eng. Des. 2010, 240, 4043–4050. [Google Scholar] [CrossRef]

- Sanyal, G.; Samal, M.; Chakravartty, J.; Ray, K.; Suri, A.; Banerjee, S. Prediction of J–R curves of thin-walled fuel pin specimens in a PLT setup. Eng. Fract. Mech. 2011, 78, 1029–1043. [Google Scholar] [CrossRef]

- Sanyal, G.; Samal, M.K. Fracture behavior of thin-walled Zircaloy fuel clad tubes of Indian pressurized heavy water reactor. Int. J. Fract. 2012, 173, 175–188. [Google Scholar] [CrossRef]

- Syed, A.; Samal, M.K.; Chattopadhyay, J.; Dutta, P. Fracture toughness evaluation of axially-cracked tubular thin-walled specimens of Zircaloy-4 and its implications for integrity analysis of nuclear fuel clad. Theor. Appl. Fract. Mech. 2019, 106, 102449. [Google Scholar] [CrossRef]

- Samal, M.; Syed, A.; Chattopadhyay, J.; Ram, A.; Paul, B.; Reddy, M. Effect of texture on crack initiation toughness and the corresponding anisotropy in ductile fracture resistance of thin Zircaloy-4 sheets of Indian PHWR core component. J. Nucl. Mater. 2020, 535, 152189. [Google Scholar] [CrossRef]

- Rice, J.R.; Tracey, D.M. On the ductile enlargement of voids in triaxial stress fields. J. Mech. Phys. Solids 1969, 17, 201–217. [Google Scholar] [CrossRef]

| Temperature, T (°C) | n | C | A |

|---|---|---|---|

| (T < 600) | 4.86 | 31,620 | 1.2 × 104 |

| (600 < T < 650) | 4.68 | 31,620 | 1.2 × 104 |

| (650 < T < 700) | 4.45 | 31,620 | 1.2 × 104 |

| (700 < T < 750) | 4.35 | 31,620 | 1.2 × 104 |

| (750 < T < 800) | 4.29 | 31,620 | 1.2 × 104 |

| (800 < T < 850) | 4.25 | 31,620 | 1.2 × 104 |

| (850 < T < 900) | 2.35 | 22,600 | 9750 |

| (900 < T < 950) | 2.20 | 22,600 | 9750 |

| (950 < T < 1000) | 2.11 | 22,600 | 9750 |

| (1000 < T < 1050) | 3.45 | 16,300 | 15 |

| (1050 < T < 1100) | 3.37 | 16,300 | 15 |

| (1100 < T < 1150) | 3.31 | 16,300 | 15 |

| (1150 < T < 1200) | 3.24 | 16,300 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Syed, A.; Samal, M.K. On Ballooning and Burst Behavior of Nuclear Fuel Clad Considering Heating Rate Effect: Development of a Damage Model, a Burst Correlation and Experimental Validation. Solids 2025, 6, 56. https://doi.org/10.3390/solids6040056

Syed A, Samal MK. On Ballooning and Burst Behavior of Nuclear Fuel Clad Considering Heating Rate Effect: Development of a Damage Model, a Burst Correlation and Experimental Validation. Solids. 2025; 6(4):56. https://doi.org/10.3390/solids6040056

Chicago/Turabian StyleSyed, Ather, and Mahendra Kumar Samal. 2025. "On Ballooning and Burst Behavior of Nuclear Fuel Clad Considering Heating Rate Effect: Development of a Damage Model, a Burst Correlation and Experimental Validation" Solids 6, no. 4: 56. https://doi.org/10.3390/solids6040056

APA StyleSyed, A., & Samal, M. K. (2025). On Ballooning and Burst Behavior of Nuclear Fuel Clad Considering Heating Rate Effect: Development of a Damage Model, a Burst Correlation and Experimental Validation. Solids, 6(4), 56. https://doi.org/10.3390/solids6040056