Effect of Stoichiometry on Shape Memory Properties of Ti-Ni-Hf-Cu-Nb Shape Memory Alloys Manufactured by Suspended Droplet Alloying

Abstract

:1. Introduction

2. Materials and Experimental Methods

3. Results and Discussions

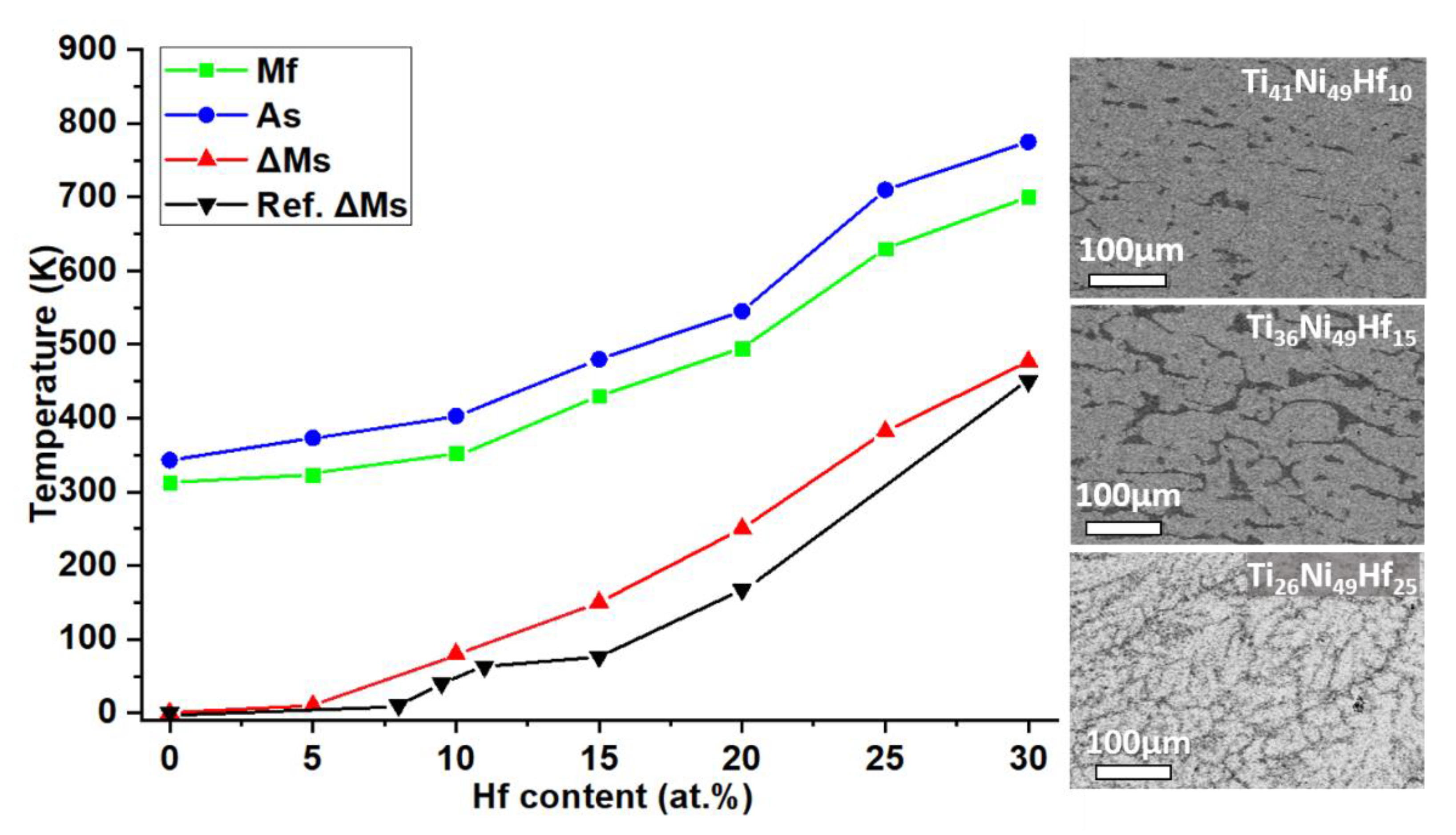

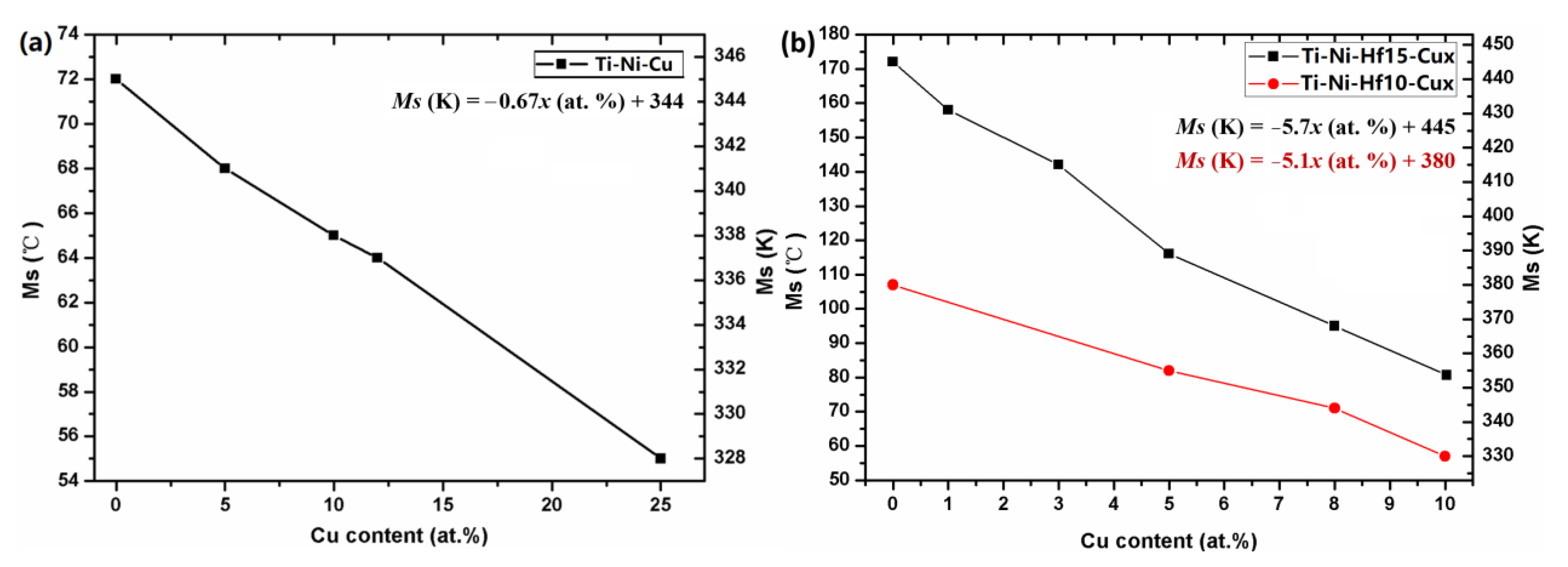

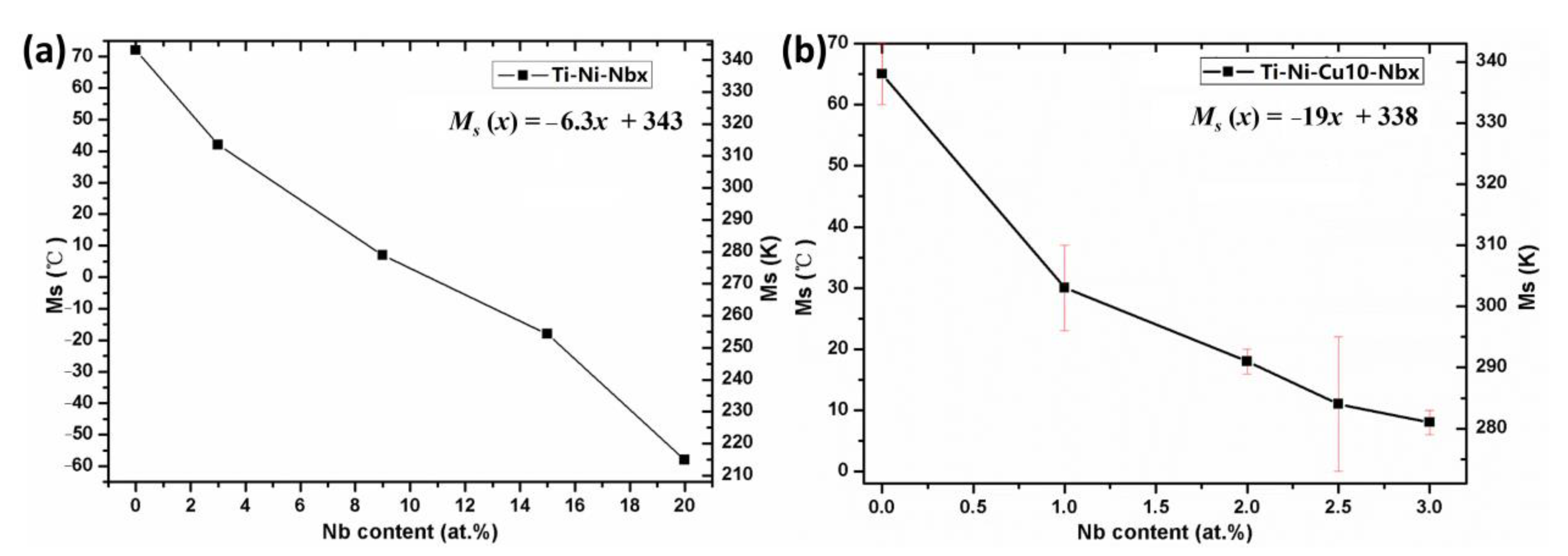

3.1. Influence of Hf and Cu Content on Transformation Temperature of Ti-Ni Based Shape Memory Alloys

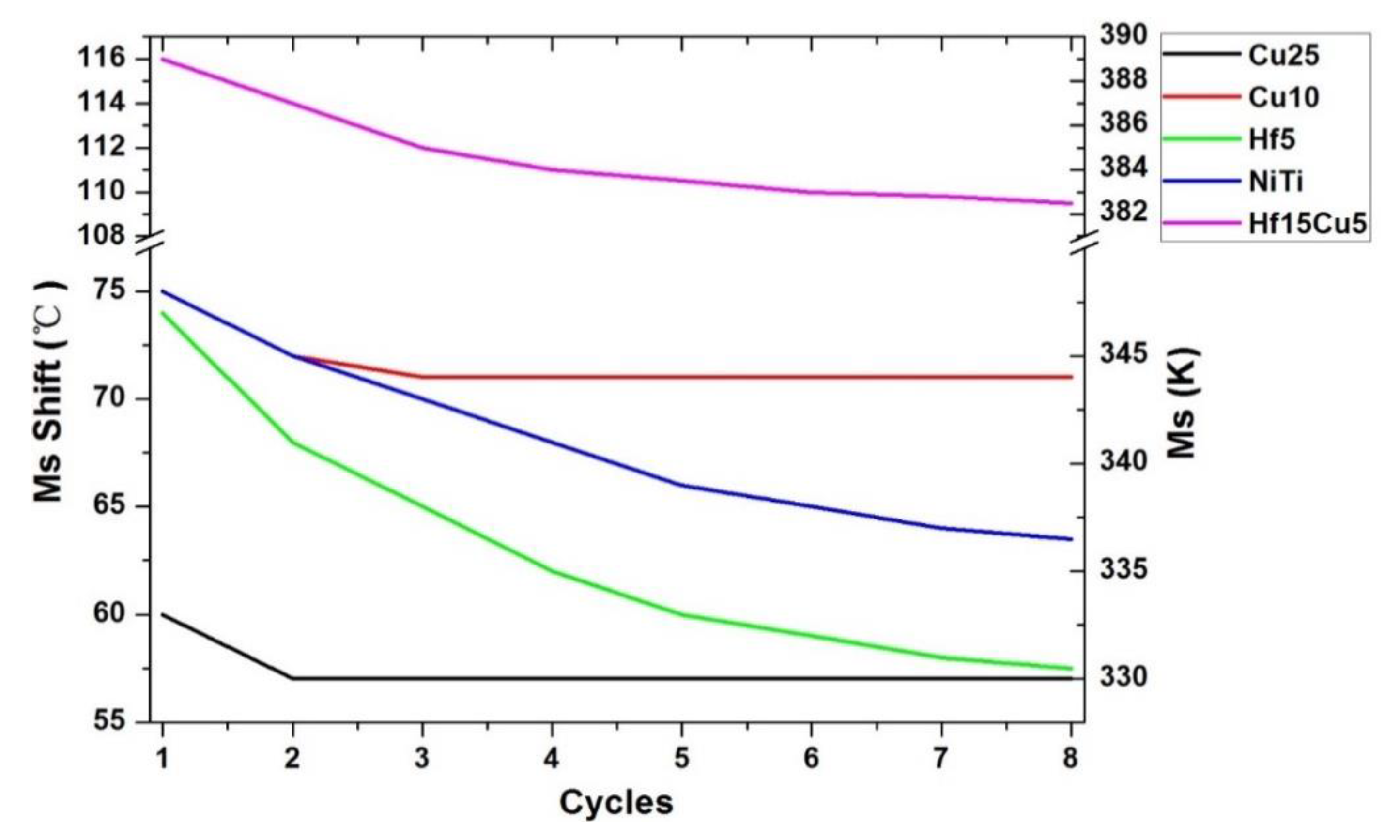

3.2. Improving the Thermal Stability of Quaternary and Quinary Shape Memory Alloys

3.3. Microstructure and Shape Memory Behaviours of Ti-Ni-Hf-Cu-Nb Alloys

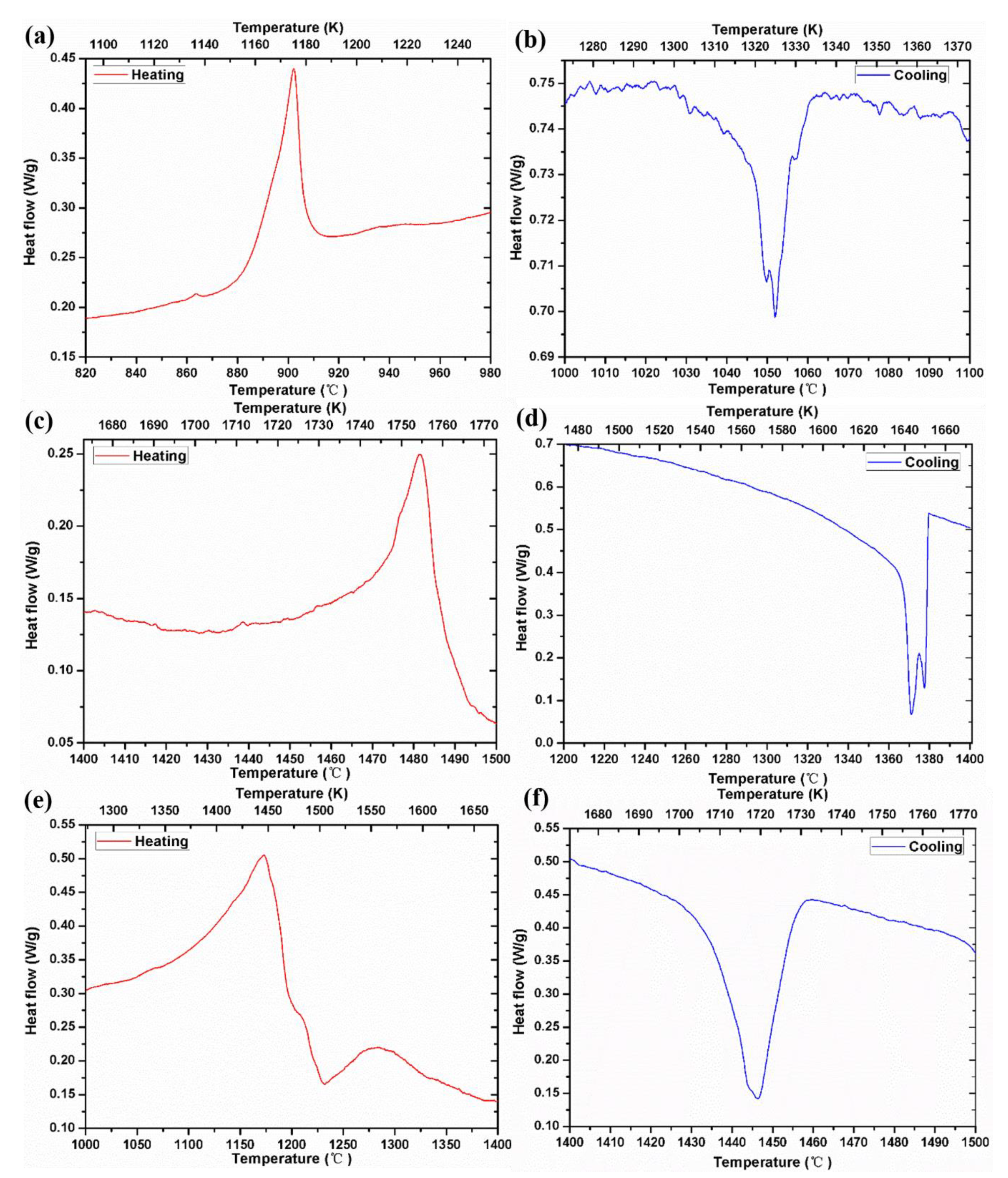

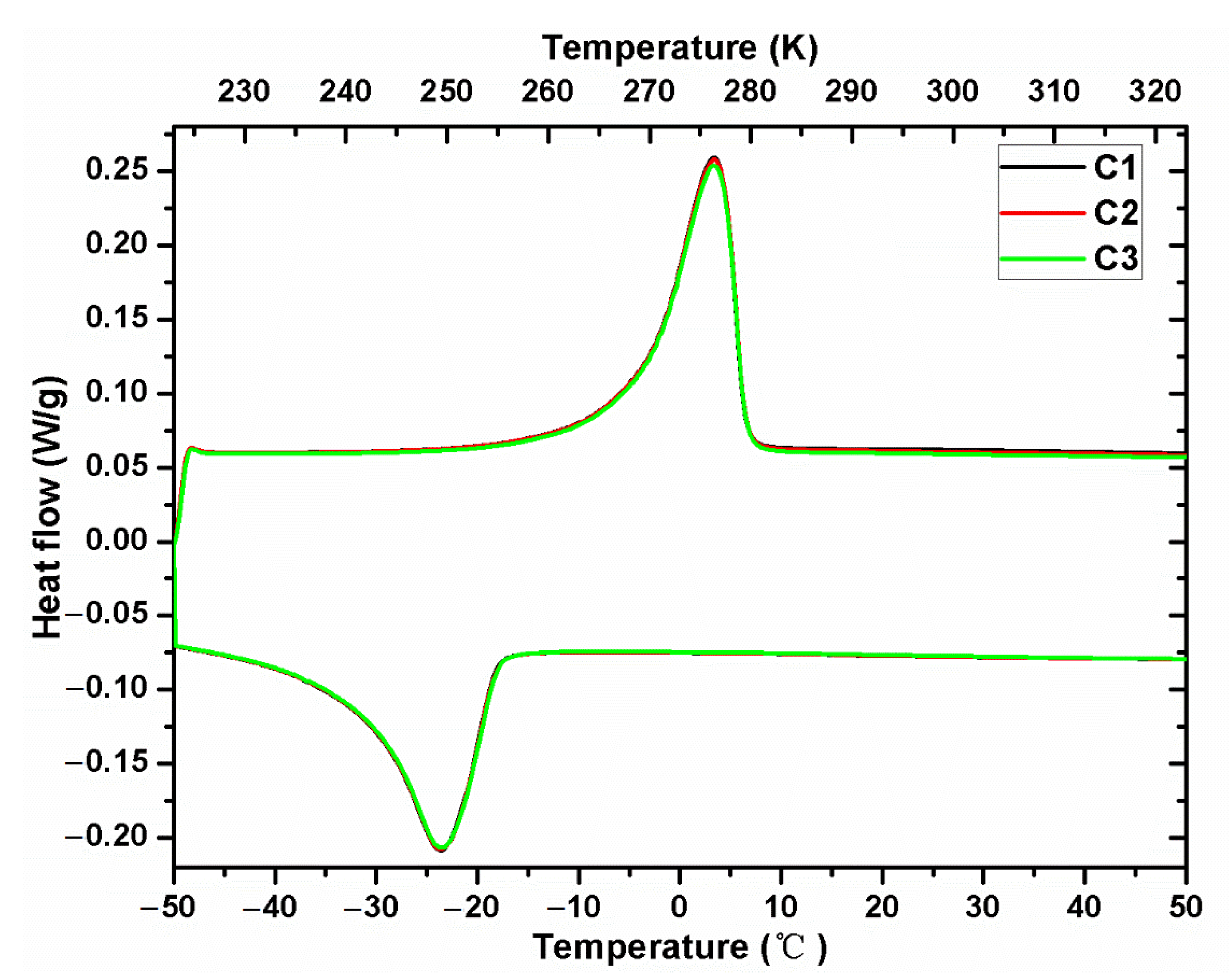

3.3.1. Transformation Temperature of Ti-Ni-Hf-Cu-Nb SMAs

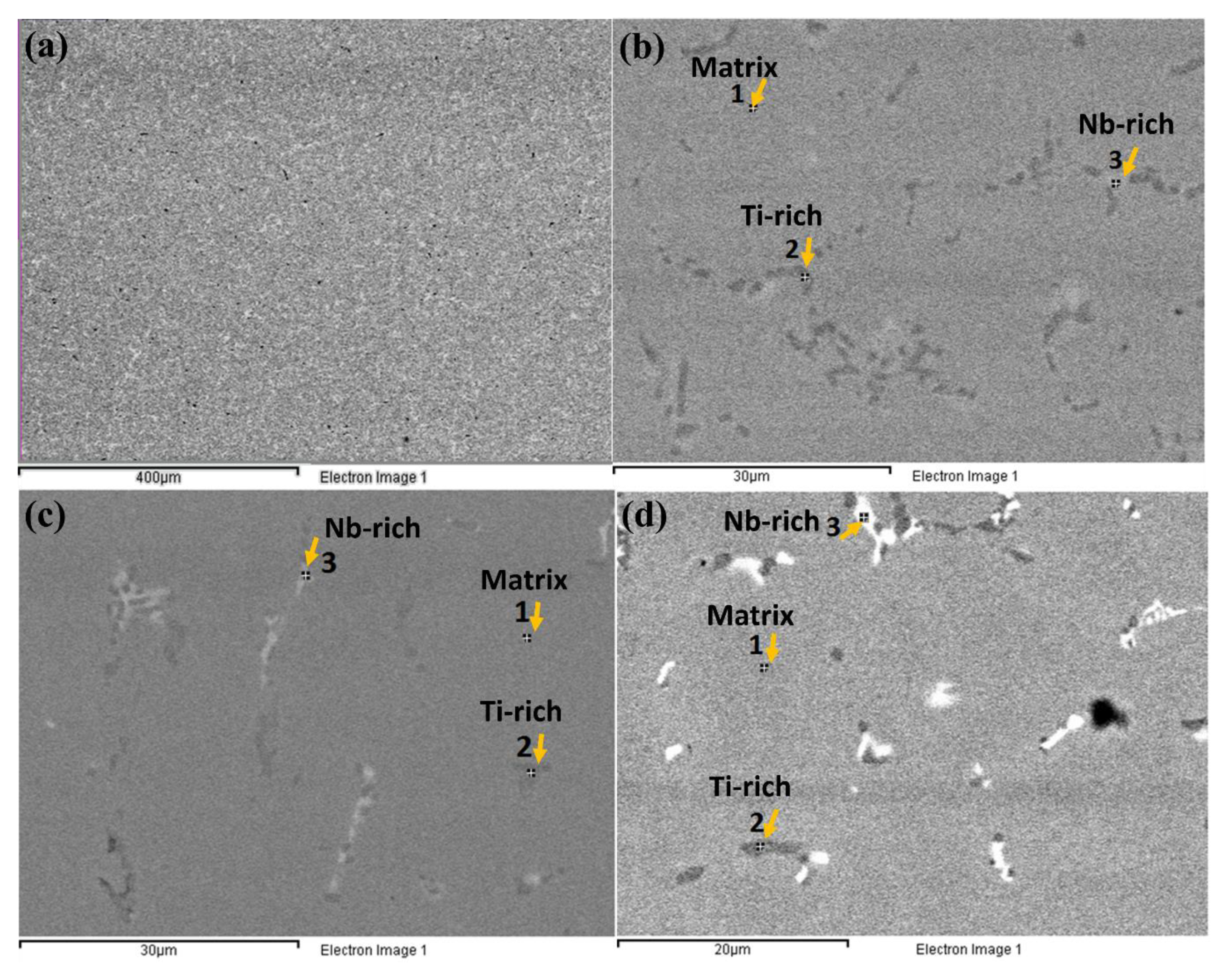

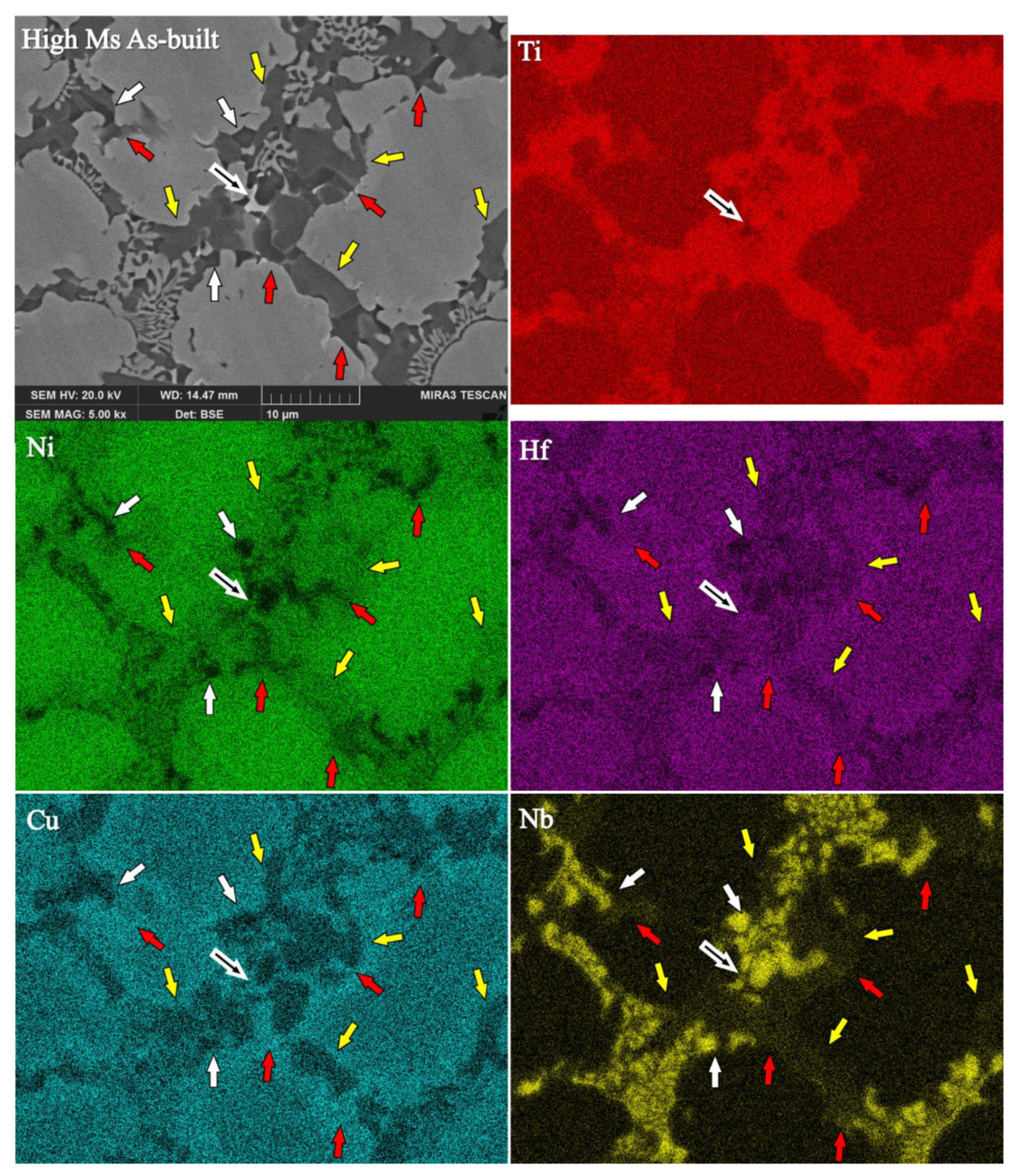

3.3.2. Microstructure of Ti-Ni-Hf-Cu-Nb Alloys

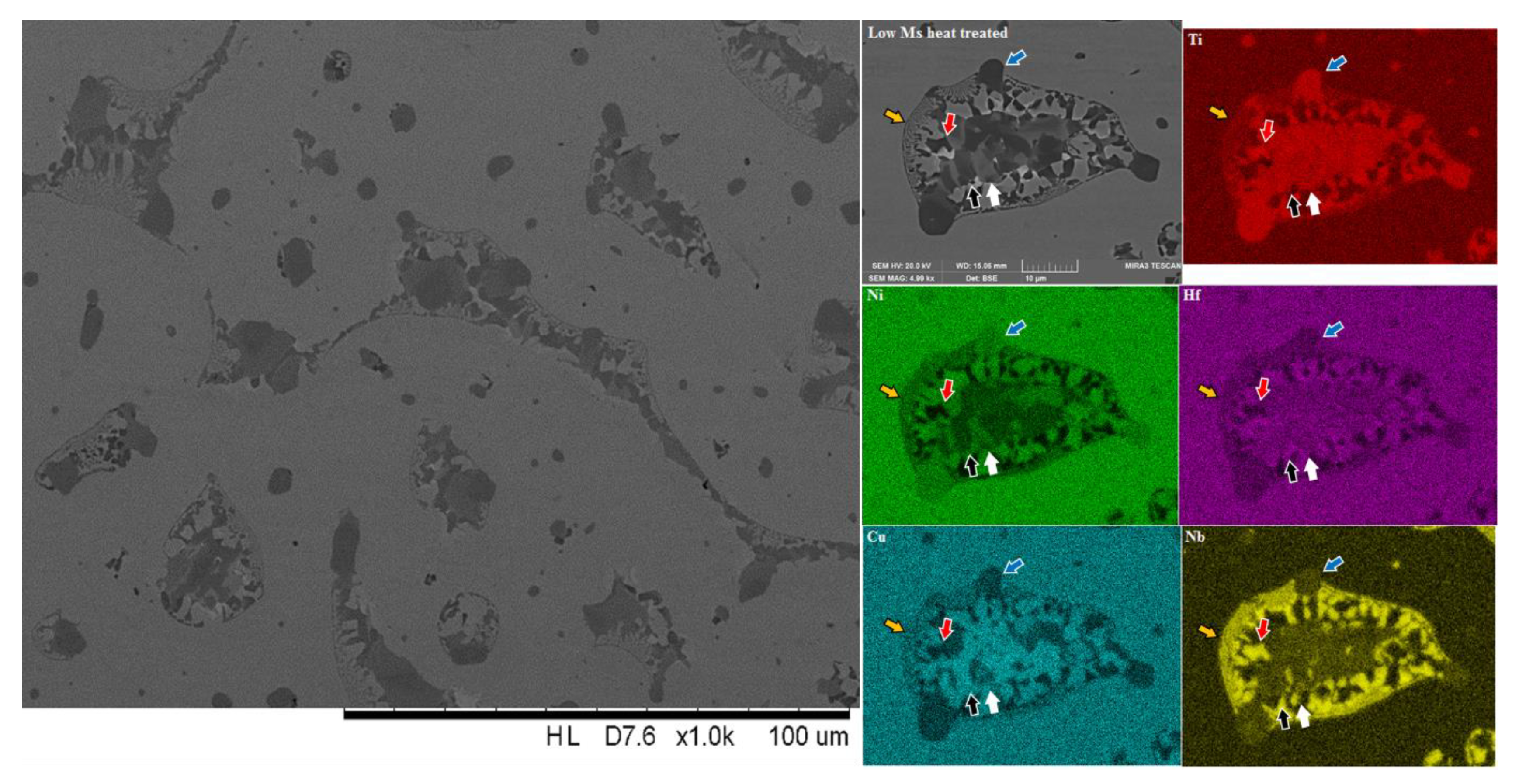

3.3.3. Heat Treatment on Ti-Ni-Hf-Cu-Nb Samples

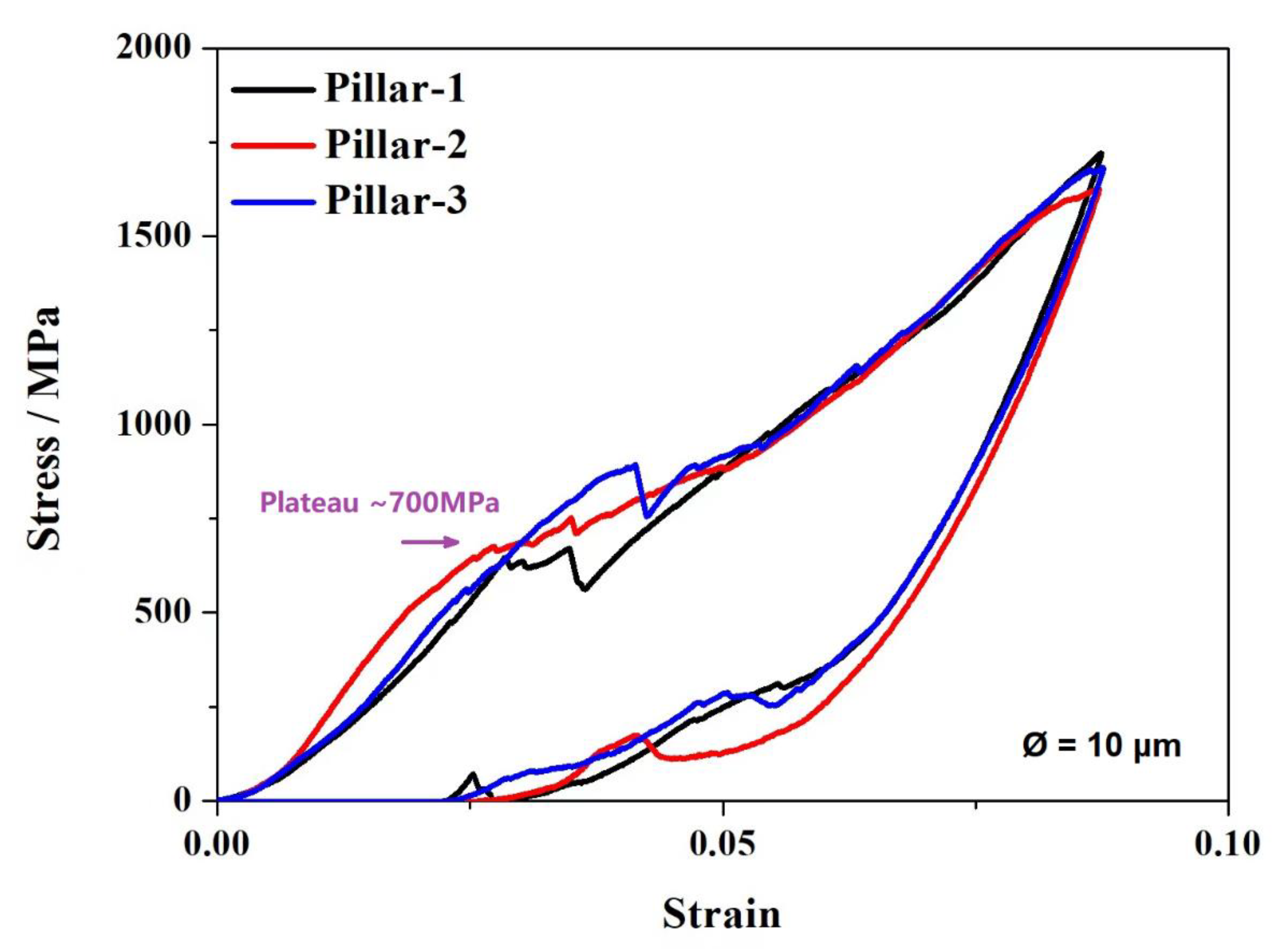

3.3.4. Micromechanical Properties

4. Conclusions

- The addition of Cu in Ti-Ni SMAs slightly decreased the MT temperature by −0.67 K/at.%.

- Cu and Hf have a negative influence on each other on the MT temperature of Ti-Ni-Hf-Cu SMAs. The reduction of Cu on 10 at.% and 15 at.% Hf alloys were −5.1 K/at.% and −5.7 K/at.%, respectively.

- Nb has a stronger influence on the MT temperature of Ti51−xNi39−xCu10Nb2x shape memory alloys (−19 K/at.%) than Ti51−0.5xNi49−0.5xNbx alloys (−6.3 K/at.%). However, the Nb content did not affect the thermal cycle stability of Ti51−xNi39−xCu10Nb2x alloys when the Nb content is lower than 3 at.%.

- Nb content has less influence on MT temperature of Ti41−0.5xNi46−0.5xHf10Cu5Nbx shape memory alloys (−1.5 K/at.%) than Ti41−0.5xNi39−0.5xHf10Cu10Nbx alloys (−12.5 K/at.%). However, the relationship between Nb content and the MT temperature of Ti41−xNi39−xHf10Cu10Nb2x alloys is not linear.

- The Ti41−0.5xNi39−0.5xHf10Cu10Nbx alloys with 1 at.% Nb has the highest transformation temperature but the alloys with 2 at.% Nb has the best thermal cycle stability. The reduction of transformation heat and difference between austenitic transformation and MT increased with higher Nb content.

- The Ti43Ni33Hf10.5Cu11Nb2.5 and Ti44Ni34Hf10Cu10Nb2 alloys showed completely different transformation behaviour due to different matrix composition. Three different precipitates were found in Ti44Ni34Hf10Cu10Nb2 high Ms alloys which may be the reason for unstable transformation and the variation of transformation temperature.

- The homogenised low Ms Ti43Ni33Hf10.5Cu11Nb2.5 alloys has stable narrow transformation peak with no obvious thermal fatigue after a few thermal cycles. Three different types of precipitates were found in heat treated sample.

- The micro-pillar compression test of low Ms showed two-stage deformation. Both the plateau stress and Young’s Modulus are higher than the Ti-Ni shape memory alloys.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Otsuka, K.; Ren, X. Recent developments in the research of shape memory alloys. Intermetallics 1999, 7, 511–528. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1988. [Google Scholar]

- Elahinia, M.H.; Hashemi, M.; Tabesh, M.; Bhaduri, S.B. Manufacturing and processing of NiTi implants: A review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Lin, K.; Wu, S.; Tsai, C.-L. The Effect of Thermal Cycling on B2→B19→B19′ Transformations of Ti50Ni40Cu10 Shape Memory Alloy by Dynamic Mechanical Analyzer. Mater. Trans. 2008, 49, 2776–2780. [Google Scholar] [CrossRef]

- He, X.-M.; Zhao, L.-Z.; Duo, S.-W.; Zhang, R.-F.; Rong, L.-J. Stress-induced martensitic transformation in (Ni47Ti44)100−xNbx shape memory alloys with wide hysteresis. Trans. Nonferrous Met. Soc. China 2006, 16, s42–s46. [Google Scholar] [CrossRef]

- Jiang, P.C.; Zheng, Y.F.; Tong, Y.X.; Chen, F.; Tian, B.; Li, L.; Gunderov, D.V.; Valiev, R.Z. Transformation hysteresis and shape memory effect of an ultrafine-grained TiNiNb shape memory alloy. Intermetallics 2014, 54, 133–135. [Google Scholar] [CrossRef]

- Firstov, G.S.; Van Humbeeck, J.; Koval, Y.N. Comparison of high temperature shape memory behaviour for ZrCu-based, Ti–Ni–Zr and Ti–Ni–Hf alloys. Scr. Mater. 2004, 50, 243–248. [Google Scholar] [CrossRef]

- Potapov, P.L.; Shelyakov, A.V.; Gulyaev, A.A.; Svistunov, E.L.; Matveeva, N.M.; Hodgson, D. Effect of Hf on the structure of Ni-Ti martensitic alloys. Mater. Lett. 1997, 32, 247–250. [Google Scholar] [CrossRef]

- Chluba, C.; Ge, W.; de Miranda, R.L.; Strobel, J.; Kienle, L.; Quandt, E.; Wuttig, M. Ultralow-fatigue shape memory alloy films. Science 2015, 348, 1004–1007. [Google Scholar] [CrossRef] [PubMed]

- Santamarta, R.; Arróyave, R.; Pons, J.; Evirgen, A.; Karaman, I.; Karaca, H.E.; Noebe, R.D. TEM study of structural and microstructural characteristics of a precipitate phase in Ni-rich Ni–Ti–Hf and Ni–Ti–Zr shape memory alloys. Acta Mater. 2013, 61, 6191–6206. [Google Scholar] [CrossRef]

- Vermaut, P.; Lityńska, L.; Portier, R.; Ochin, P.; Dutkiewicz, J. The microstructure of melt spun Ti–Ni–Cu–Zr shape memory alloys. Mater. Chem. Phys. 2003, 81, 380–382. [Google Scholar] [CrossRef]

- Lin, K.-N.; Wu, S.-K.; Wu, L.-M. Martensitic Transformation of Ti50Ni25−xPd25−yCux+y Quaternary Shape Memory Alloys with X, Y ≤ 10 at%. Mater. Trans. 2009, 50, 2384–2390. [Google Scholar] [CrossRef] [Green Version]

- Meng, X.L.; Tong, Y.X.; Lau, K.T.; Cai, W.; Zhou, L.M.; Zhao, L.C. Effect of Cu addition on phase transformation of Ti–Ni–Hf high-temperature shape memory alloys. Mater. Lett. 2002, 57, 452–456. [Google Scholar] [CrossRef]

- Meng, X.L.; Fu, Y.D.; Cai, W.; Li, Q.F.; Zhao, L.C. Cu content and annealing temperature dependence of martensitic transformation of Ti36Ni49−xHf15Cux melt spun ribbons. Intermetallics 2009, 17, 1078–1084. [Google Scholar] [CrossRef]

- Meng, X.L.; Cai, W.; Fu, Y.D.; Zhang, J.X.; Zhao, L.C. Martensite structure in Ti–Ni–Hf–Cu quaternary alloy ribbons containing (Ti,Hf)2Ni precipitates. Acta Mater. 2010, 58, 3751–3763. [Google Scholar] [CrossRef]

- Wang, G.C.; Hu, K.P.; Tong, Y.X.; Tian, B.; Chen, F.; Li, L.; Zheng, Y.F.; Gao, Z.Y. Influence of Nb content on martensitic transformation and mechanical properties of TiNiCuNb shape memory alloys. Intermetallics 2016, 72, 30–35. [Google Scholar] [CrossRef]

- Tong, Y.; Gu, H.; James, R.D.; Qi, W.; Shuitcev, A.V.; Li, L. Novel TiNiCuNb shape memory alloys with excellent thermal cycling stability. J. Alloy. Compd. 2018, 782, 343–347. [Google Scholar] [CrossRef]

- Yi, X.; Pang, G.; Sun, B.; Meng, X.; Cai, W. The microstructure and martensitic transformation behaviors in Ti-Ni-Hf -X (Ag, Sn) high temperature shape memory alloys. J. Alloy. Compd. 2018, 756, 19–25. [Google Scholar] [CrossRef]

- Yi, X.; Gao, W.; Meng, X.; Gao, Z.; Cai, W.; Zhao, L. Martensitic transformation behaviors and mechanical properties of (Ti36Ni49Hf15)100−xYx high temperature shape memory alloys. J. Alloy. Compd. 2017, 705, 98–104. [Google Scholar] [CrossRef]

- Li, J.; Yi, X.; Meng, X.; Qiao, S.; Cai, W.; Zhao, L. Deposition and phase transformation behaviors of Ti–Ni-Hf-Cu quaternary shape memory alloy thin films. J. Alloy. Compd. 2019, 806, 33–39. [Google Scholar] [CrossRef]

- Yi, X.; Sun, K.; Gao, W.; Meng, X.; Cai, W.; Zhao, L. Microstructure design of the excellent shape recovery properties in (Ti,Hf)2Ni/Ti-Ni-Hf high temperature shape memory alloy composite. J. Alloy. Compd. 2017, 729, 758–763. [Google Scholar] [CrossRef]

- Lemke, J.N.; Gallino, F.; Cresci, M.; Coda, A. Achieving improved workability and competitive high temperature shape memory performance by Nb addition to Ni-Ti-Hf alloys. Scr. Mater. 2020, 191, 161–166. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, S.; Zhang, Y.; Zhang, J.; Wen, Y.; Yang, Q.; Huang, S.; Wang, X. A study on the cold workability and shape memory effect of NiTiHf-Nb eutectic high-temperature shape memory alloy. Intermetallics 2020, 127, 106982. [Google Scholar] [CrossRef]

- Li, S.; Adkins, N.J.E.; McCain, S.; Attallah, M.M. Suspended droplet alloying: A new method for combinatorial alloy synthesis; nitinol-based alloys as an example. J. Alloy. Compd. 2018, 768, 392–398. [Google Scholar] [CrossRef] [Green Version]

- Bianchi, M.; Scarpa, F.; Smith, C.W. Shape memory behaviour in auxetic foams: Mechanical properties. Acta Mater. 2010, 58, 858–865. [Google Scholar]

- Gou, L.; Liu, Y.; Ng, T.Y. An investigation on the crystal structures of Ti50Ni50−xCux shape memory alloys based on density functional theory calculations. Intermetallics 2014, 53, 20–25. [Google Scholar] [CrossRef]

- Meng, X.L.; Cai, W.; Zheng, Y.F.; Zhao, L.C. Phase transformation and precipitation in aged Ti–Ni–Hf high-temperature shape memory alloys. Mater. Sci. Eng. A 2006, 438–440, 666–670. [Google Scholar] [CrossRef]

- Frenzel, J.; George, E.P.; Dlouhy, A.; Somsen, C.; Wagner, M.F.-X.; Eggeler, G. Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2010, 58, 3444–3458. [Google Scholar] [CrossRef]

- Thoma, P.E.; Boehm, J.J. Effect of composition on the amount of second phase and transformation temperatures of NixTi90−xHf10 shape memory alloys. Mater. Sci. Eng. A 1999, 273–275, 385–389. [Google Scholar] [CrossRef]

- Sun, Q.P.; He, Y.J. A multiscale continuum model of the grain-size dependence of the stress hysteresis in shape memory alloy polycrystals. Int. J. Solids Struct. 2008, 45, 3868–3896. [Google Scholar] [CrossRef]

- Haenschke, T.; Davis, C.L.; Attallah, M.M. Influence of the microstructural inhomogeneities on the martensite-to-austenite phase transformation temperatures in TiNiCu-based shape-memory alloys. Mater. Chem. Phys. 2013, 141, 272–277. [Google Scholar] [CrossRef]

- Liang, X.L.; Chen, Y.; Shen, H.M.; Zhang, Z.F.; Li, W.; Wang, Y.N. Thermal cycling stability and two-way shape memory effect of Ni–Cu–Ti–Hf alloys. Solid State Commun. 2001, 119, 381–385. [Google Scholar] [CrossRef]

- Meng, X.L.; Cai, W.; Lau, K.T.; Zhao, L.C.; Zhou, L.M. Phase transformation and microstructure of quaternary TiNiHfCu high temperature shape memory alloys. Intermetallics 2005, 13, 197–201. [Google Scholar] [CrossRef]

- Chowdhury, P.; Sehitoglu, H. A revisit to atomistic rationale for slip in shape memory alloys. Prog. Mater. Sci. 2017, 85, 1–42. [Google Scholar] [CrossRef] [Green Version]

- Yi, X.; Meng, X.; Cai, W.; Zhao, L. Multi-stage martensitic transformation behaviors and microstructural characteristics of Ti-Ni-Hf high temperature shape memory alloy powders. J. Alloy. Compd. 2019, 781, 644–656. [Google Scholar] [CrossRef]

- Okamoto, H. Nb-Ni (Niobium–Nickel). J. Phase Equilib. Diffus. 2008, 29, 210. [Google Scholar] [CrossRef]

- Pfetzing-Micklich, J.; Ghisleni, R.; Simon, T.; Somsen, C.; Michler, J.; Eggeler, G. Orientation dependence of stress-induced phase transformation and dislocation plasticity in NiTi shape memory alloys on the micro scale. Mater. Sci. Eng. A 2012, 538, 265–271. [Google Scholar] [CrossRef]

| Sample | Ti50Ni39Cu10Nb1 | Ti50Ni38Cu10Nb2 | Ti50Ni37Cu10Nb3 |

|---|---|---|---|

| 1 (matrix) | Ti50Ni42Cu8 | Ti50Ni42Cu7Nb1 | Ti50Ni41.5Cu7.5Nb1 |

| 2 (Ti-rich) | Ti55Ni32Cu11Nb2 | Ti63Ni28Cu6Nb2 | Ti60Ni28Cu9Nb3 |

| 3 (Nb-rich) | To50Ni38Cu11Nb1 | Ti55Ni14Cu5Nb26 | Ti60Ni28Cu8Nb4 |

| Area analysis | Ti50Ni39Cu10Nb1 | Ti49Ni39Cu10Nb2 | Ti50Ni37Cu10Nb3 |

| Sample | Low Ms, Ti43Ni33Hf10.5Cu11Nb2.5 | High Ms, Ti44Ni34Hf10Cu10Nb2 |

|---|---|---|

| Matrix | Ti39Ni38Hf11Cu11Nb1 | Ti40.3Ni38Hf10.6Cu10.4Nb0.7 |

| Nb-rich (dark) | Ti60.5Ni9Hf5Cu4.5Nb21 | Ti62.6Ni9.3Hf4.1Cu2.7Nb21.3 |

| Ti-rich (bright) | Ti57Ni28Hf8Cu5Nb2 | Ti56.6Ni27.2Hf8.3Cu5.8Nb2.0 |

| (Ti+Cu)-rich (dark) | - | Ti55.5Ni17.0Hf8.1Cu16.3Nb3.1 |

| Area average | Ti43.8Ni34Hf10Cu9.5Nb2.7 | Ti43Ni33Hf10.5Cu11Nb2.5 |

| Sample | Area | Ti | Ni | Cu | Nb | Hf | Ti+Hf | Ni+Cu |

|---|---|---|---|---|---|---|---|---|

| As-built | Top | 39.5 | 36.9 | 11.9 | 1.4 | 10.2 | 49.7 | 48.8 |

| Middle | 40.0 | 36.3 | 12.5 | 1.0 | 10.3 | 50.3 | 48.7 | |

| Bottom | 40.1 | 36.1 | 12.6 | 0.8 | 10.4 | 50.5 | 48.7 | |

| Min | 39.3 | 34.8 | 11.4 | 0.6 | 10.1 | 49.5 | 47.9 | |

| Max | 40.4 | 37.7 | 13.7 | 2.2 | 10.5 | 50.8 | 49.3 | |

| HT3 | Top | 39.8 | 36.5 | 12.3 | 1.1 | 10.4 | 50.1 | 48.8 |

| Middle | 39.7 | 36.6 | 12.3 | 1.0 | 10.3 | 50.0 | 49.0 | |

| Bottom | 40.0 | 36.6 | 12.3 | 1.0 | 10.2 | 50.2 | 48.8 | |

| Min | 39.5 | 36.3 | 11.6 | 0.8 | 10.0 | 49.7 | 48.0 | |

| Max | 40.2 | 37.0 | 12.8 | 1.4 | 10.6 | 50.3 | 49.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Wang, M.; Essa, K.; Gan, C.; Liu, C.; Attallah, M. Effect of Stoichiometry on Shape Memory Properties of Ti-Ni-Hf-Cu-Nb Shape Memory Alloys Manufactured by Suspended Droplet Alloying. Solids 2022, 3, 1-21. https://doi.org/10.3390/solids3010001

Li S, Wang M, Essa K, Gan C, Liu C, Attallah M. Effect of Stoichiometry on Shape Memory Properties of Ti-Ni-Hf-Cu-Nb Shape Memory Alloys Manufactured by Suspended Droplet Alloying. Solids. 2022; 3(1):1-21. https://doi.org/10.3390/solids3010001

Chicago/Turabian StyleLi, Sheng, Minshi Wang, Khamis Essa, Chunlei Gan, Chunyan Liu, and Moataz Attallah. 2022. "Effect of Stoichiometry on Shape Memory Properties of Ti-Ni-Hf-Cu-Nb Shape Memory Alloys Manufactured by Suspended Droplet Alloying" Solids 3, no. 1: 1-21. https://doi.org/10.3390/solids3010001

APA StyleLi, S., Wang, M., Essa, K., Gan, C., Liu, C., & Attallah, M. (2022). Effect of Stoichiometry on Shape Memory Properties of Ti-Ni-Hf-Cu-Nb Shape Memory Alloys Manufactured by Suspended Droplet Alloying. Solids, 3(1), 1-21. https://doi.org/10.3390/solids3010001