Research on Dust Concentration and Migration Mechanisms on Open-Pit Coal Mining Roads: Effects of Meteorological Conditions and Haul Truck Movements

Abstract

1. Introduction

2. Materials and Methods

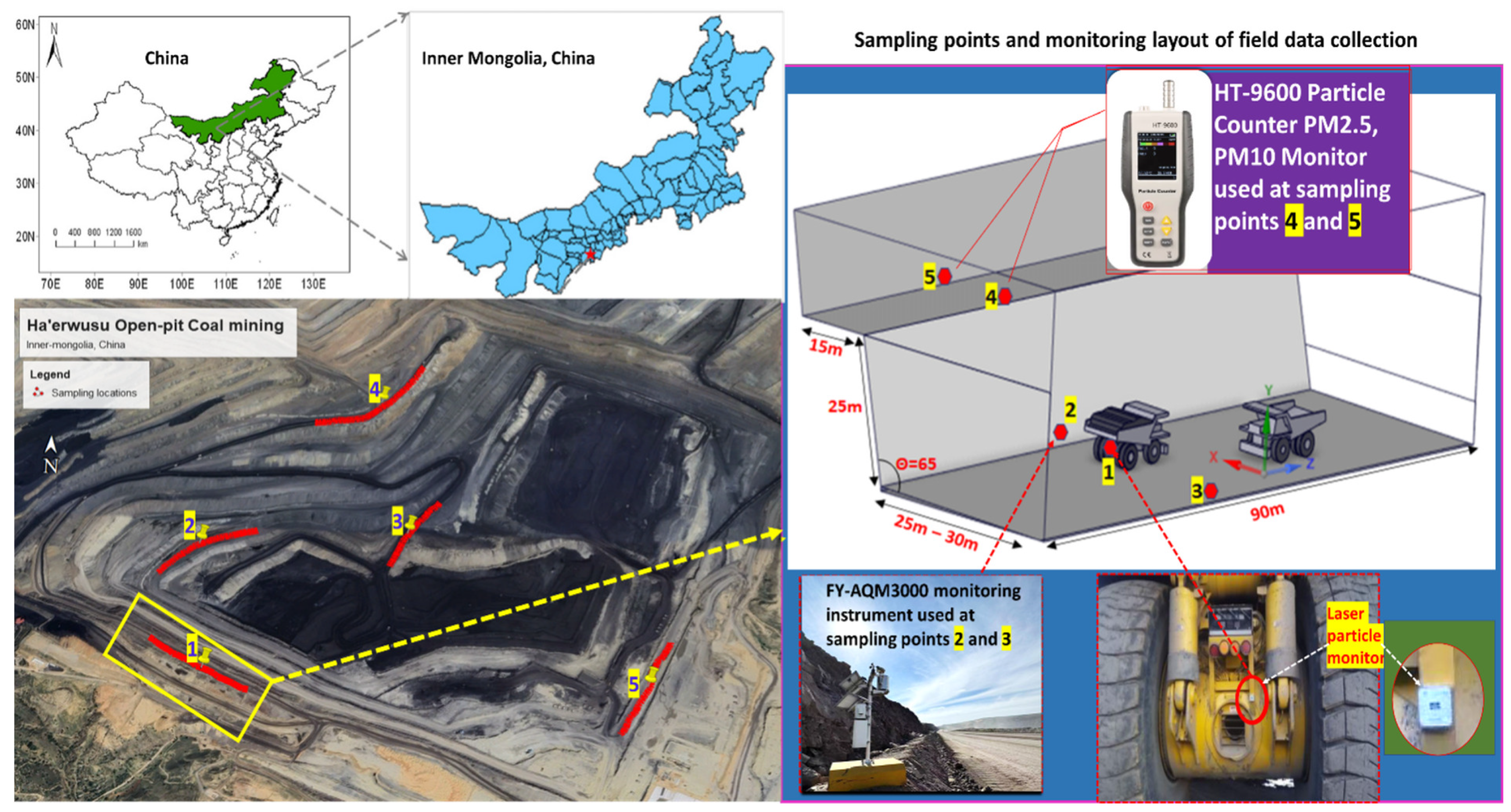

2.1. Study Site and Data Sources

2.2. Field Monitoring Layout and Sampling Design

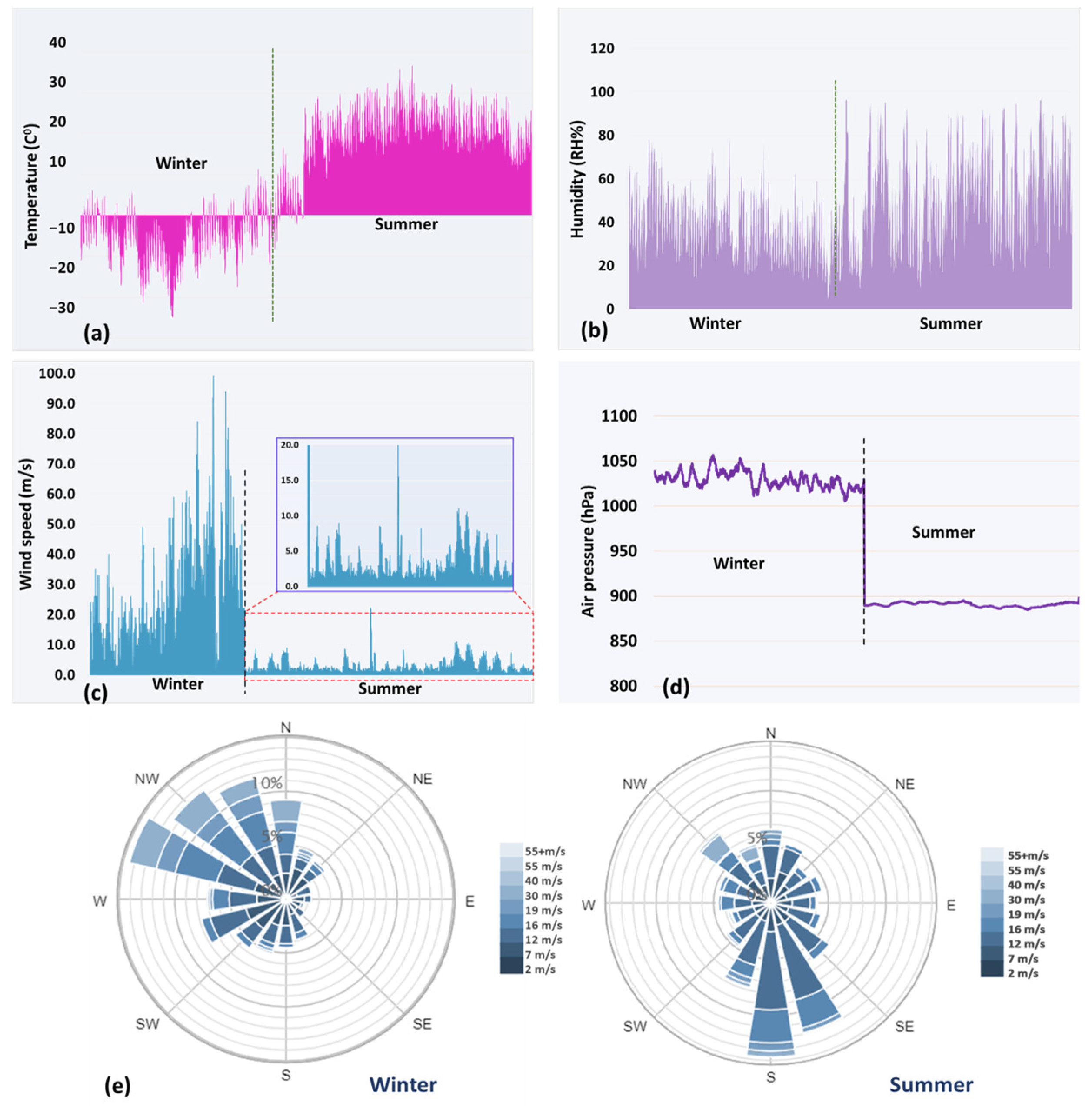

2.3. Meteorological Data Monitoring and Data Analysis

3. Numerical Simulation Settings and Parameters

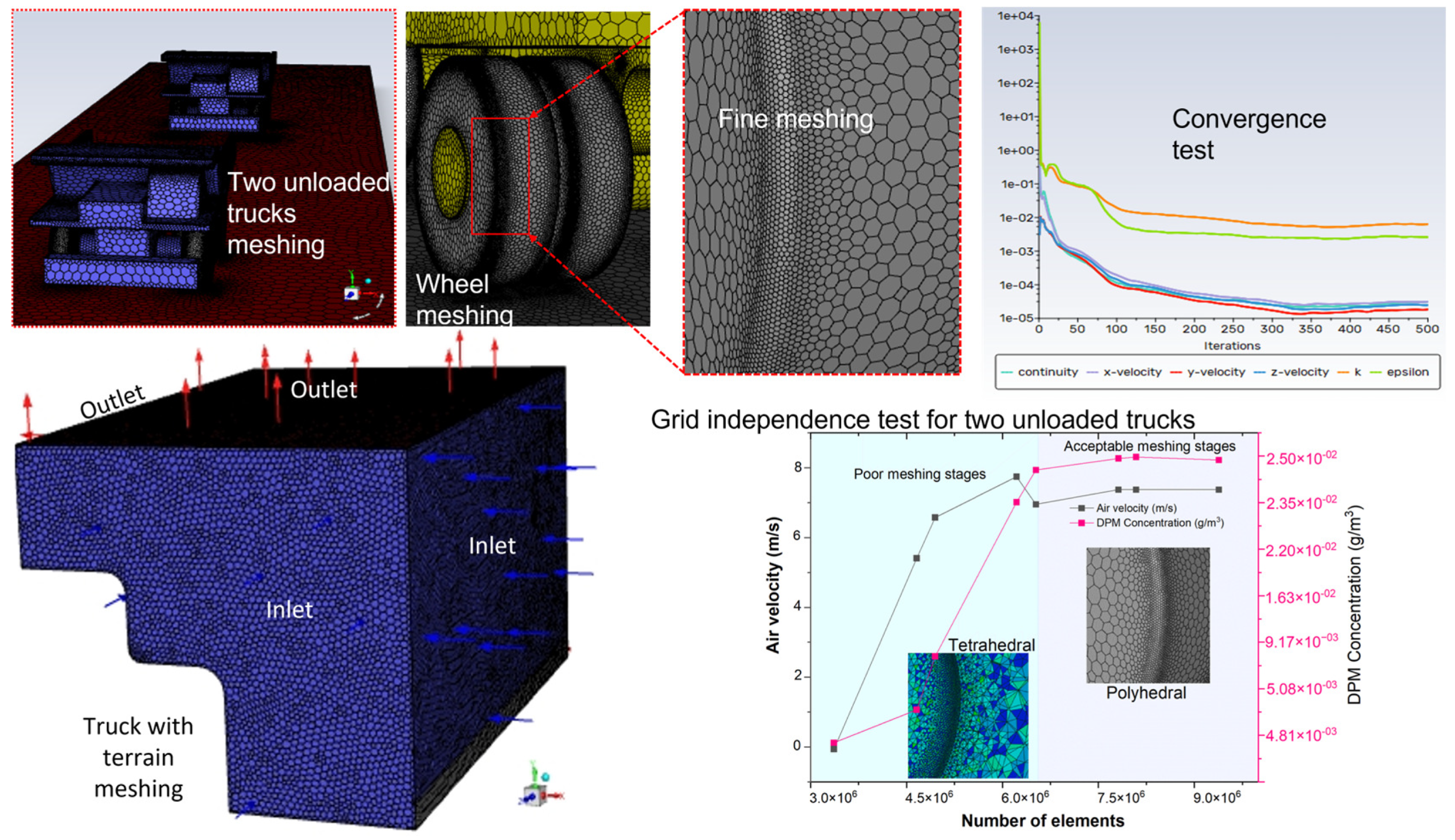

4. Mathematical and Development of Physical Grid Model

4.1. Mathematical Model and Theoretical Basis of Gas-Phase Turbulence

- Turbulent Kinetic Energy (k)

- Dissipation Rate (ε)

4.2. Gas-Solid Two-Phase Flow Models

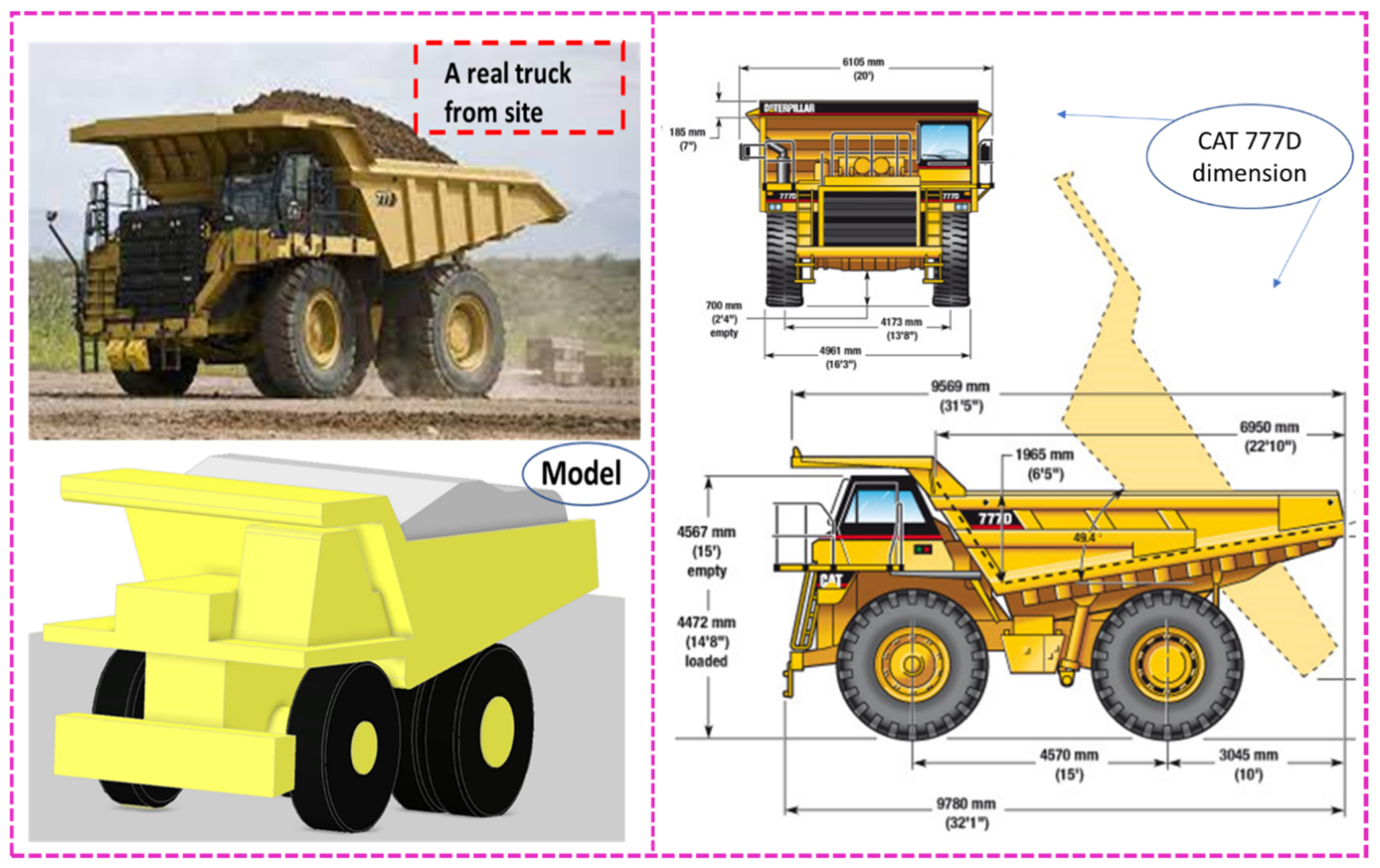

4.3. Development of Physical Grid Model and Mesh Generation

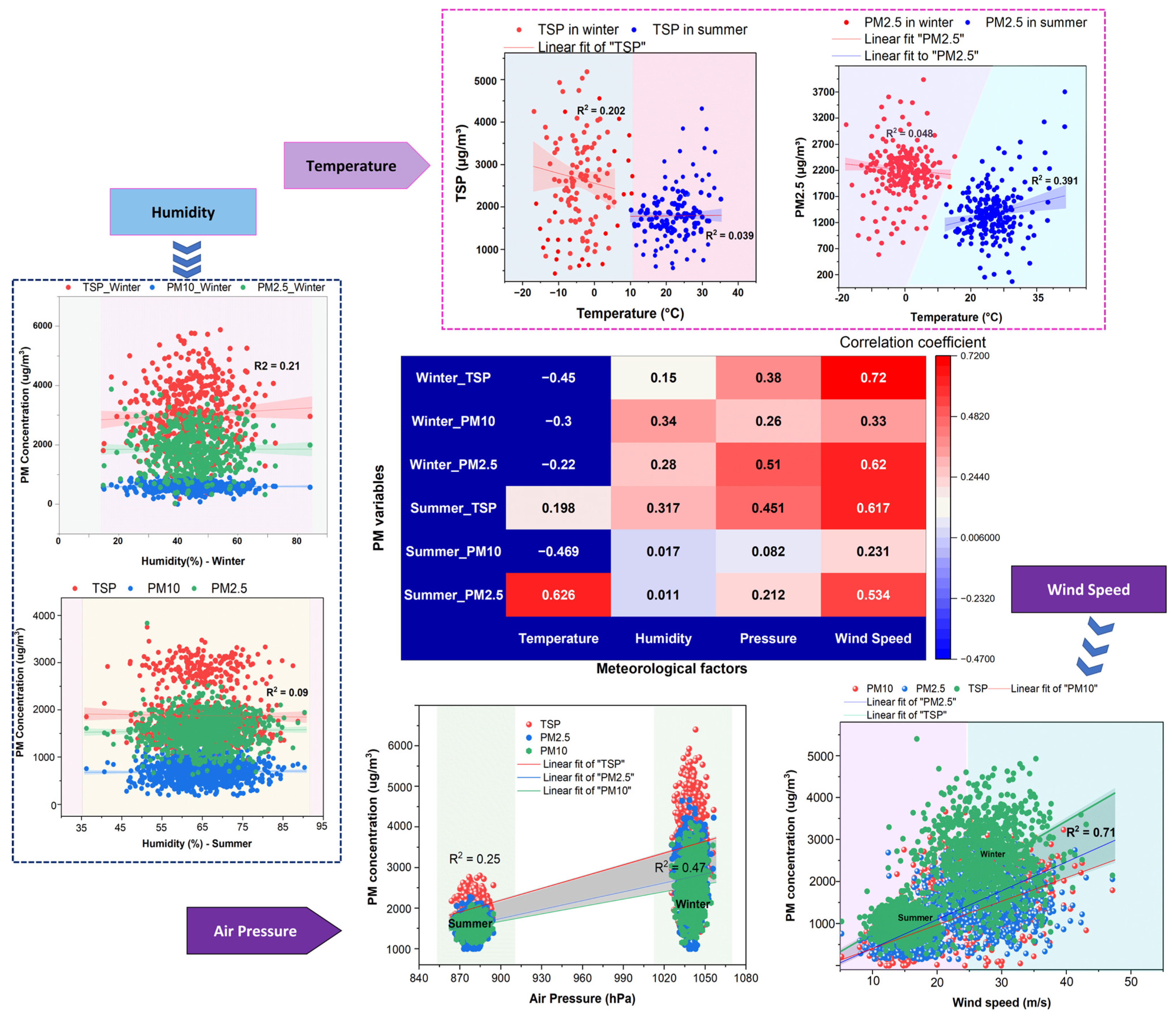

5. Study on the Parameters of Meteorological Factors on Dust Concentration and Dispersion

5.1. Wind Speed and Wind Direction Impacts

5.2. Temperature, Humidity, and Air Pressure Impact on PM Concentration and Dispersion

5.3. Temperature Effects

5.4. Humidity Effects

5.5. Air Pressure Effects

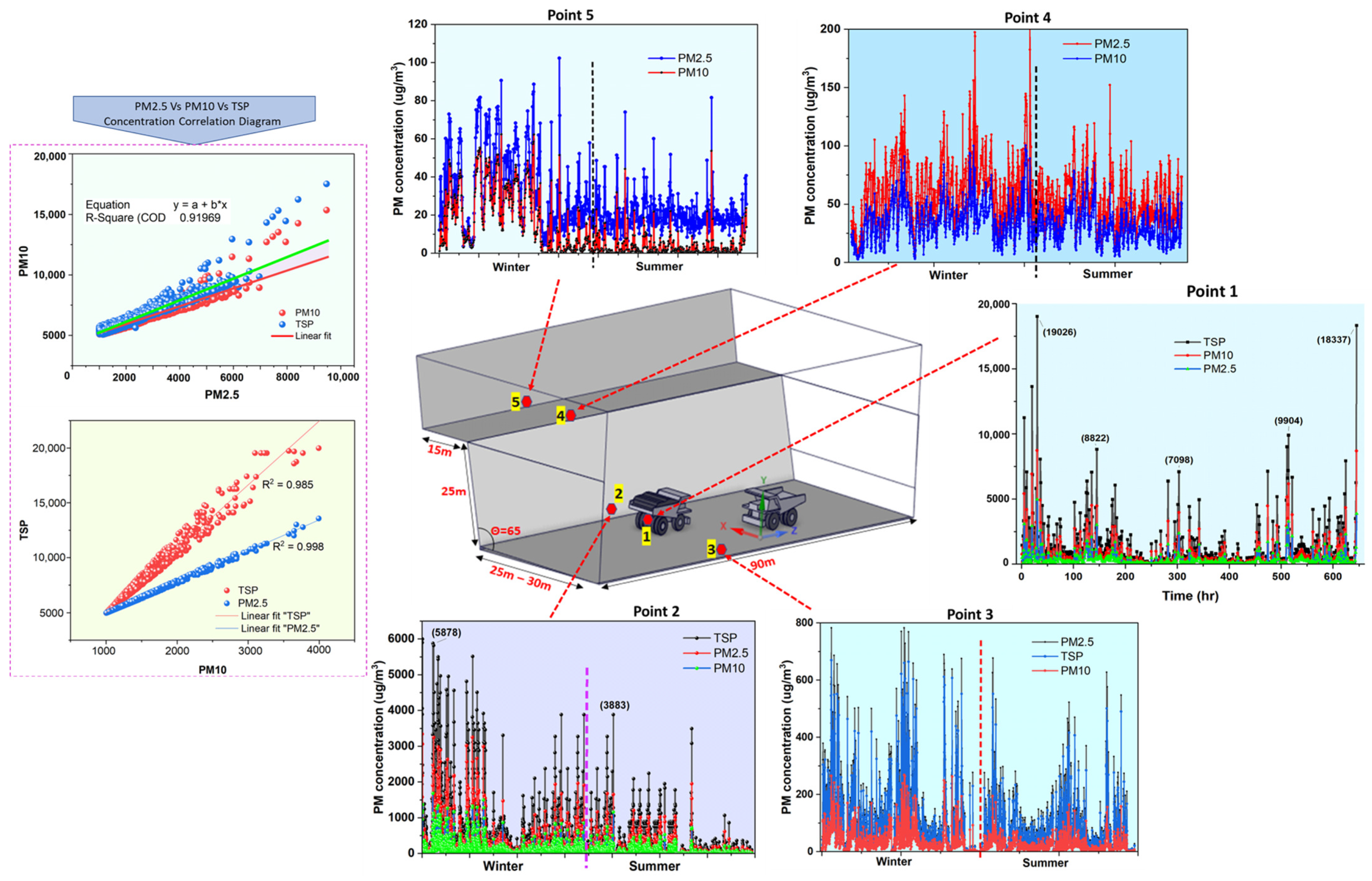

5.6. Spatial Distribution of Dust Concentrations

5.7. Terrain-Influenced Dust Sedimentation and Mitigation Measures

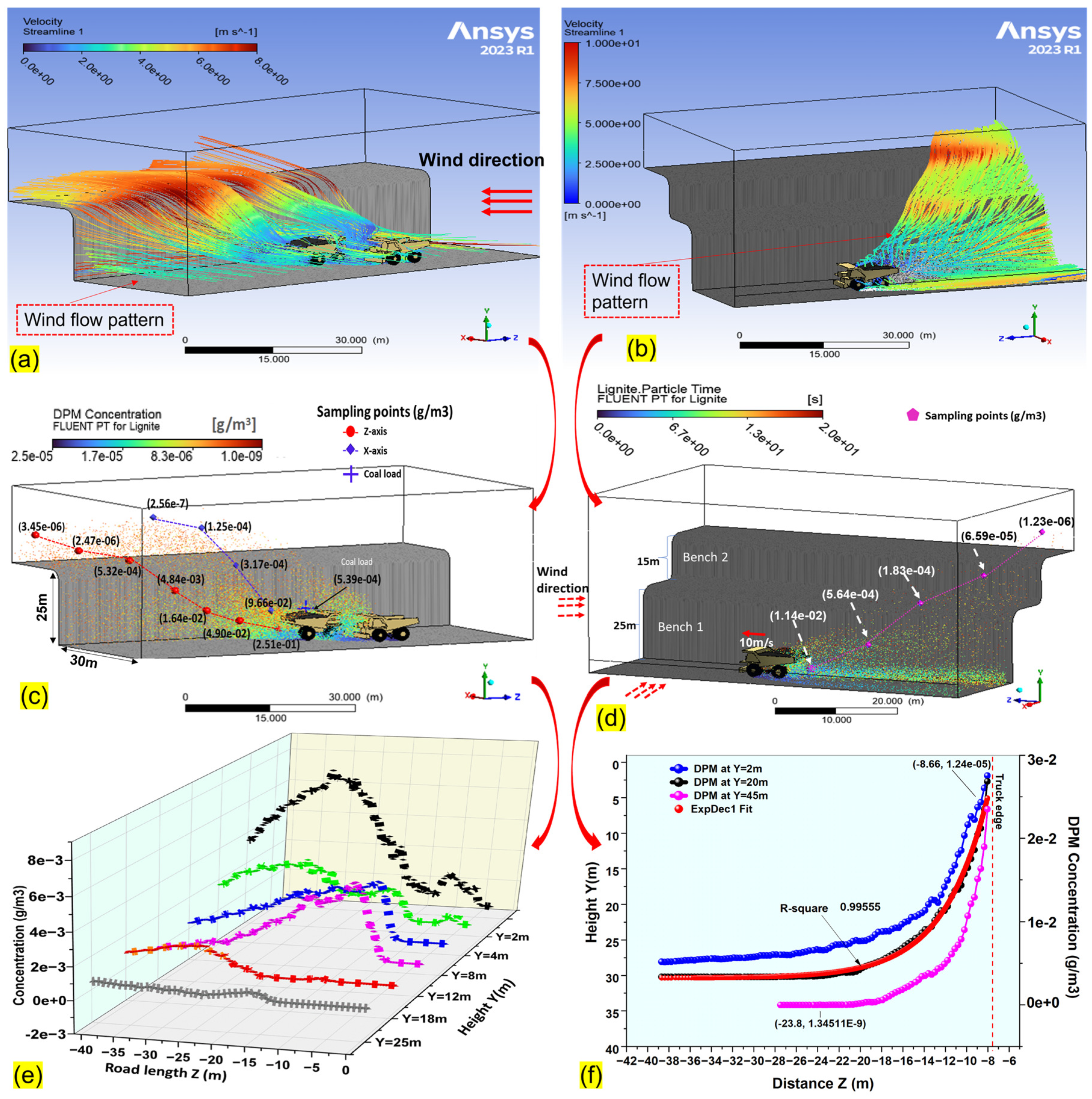

6. Analysis of External Airflow Simulation

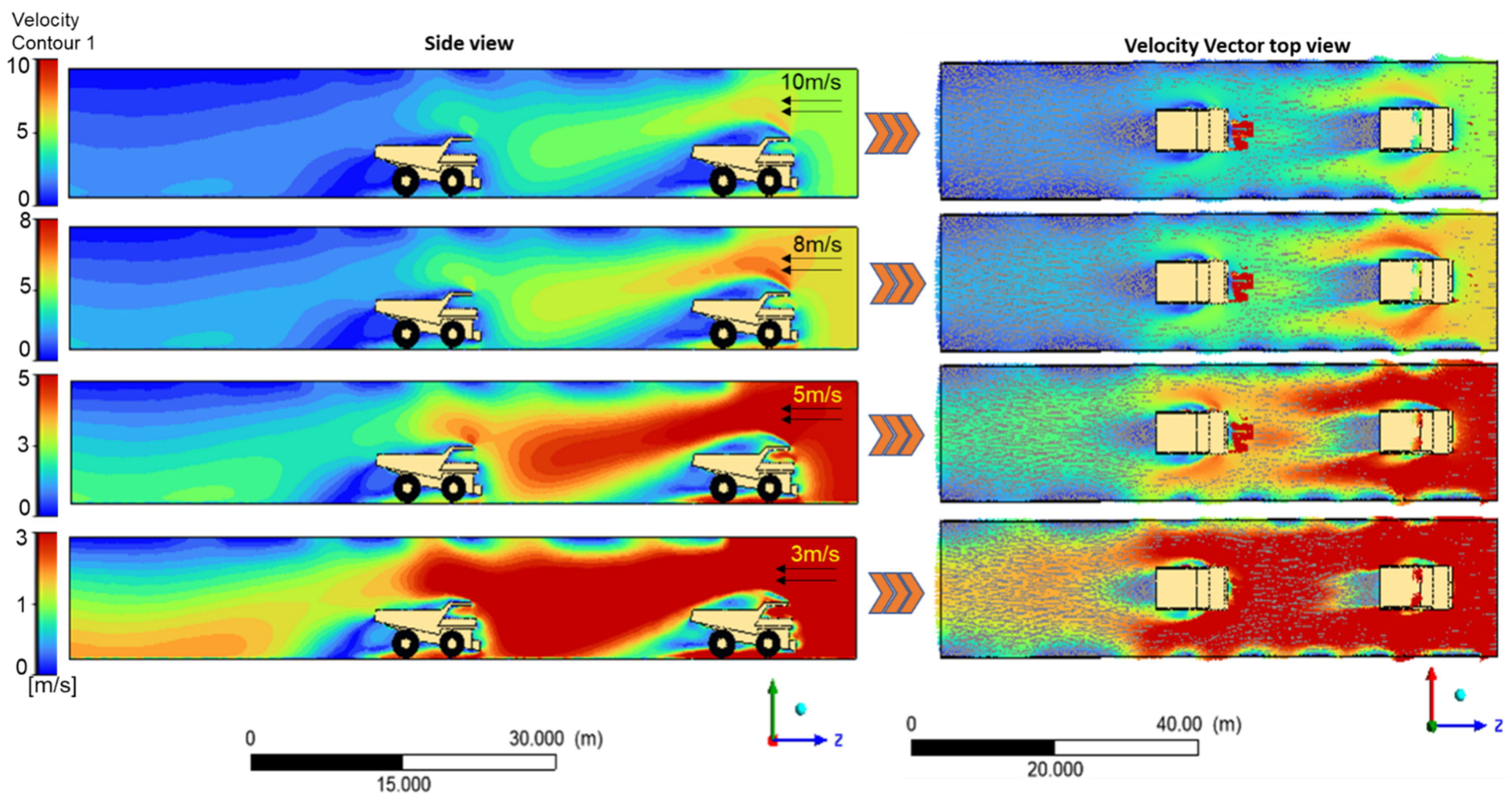

6.1. Airflow Simulation of Vehicle Motion Without Bench-Face Influence

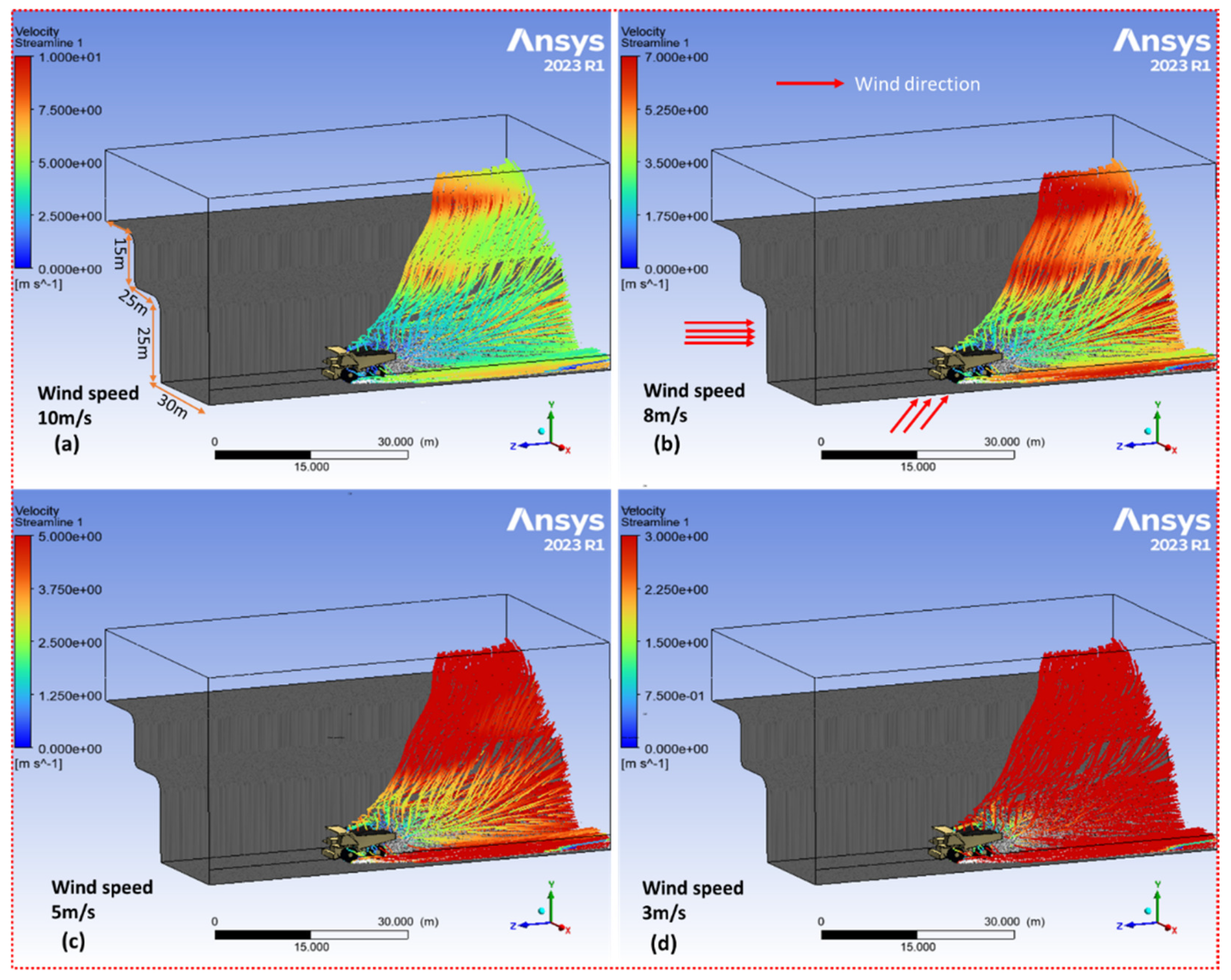

6.2. External Airflow Analysis with Terrain Influence

6.3. Study of Dust Particle Concentration and Migration Mechanism

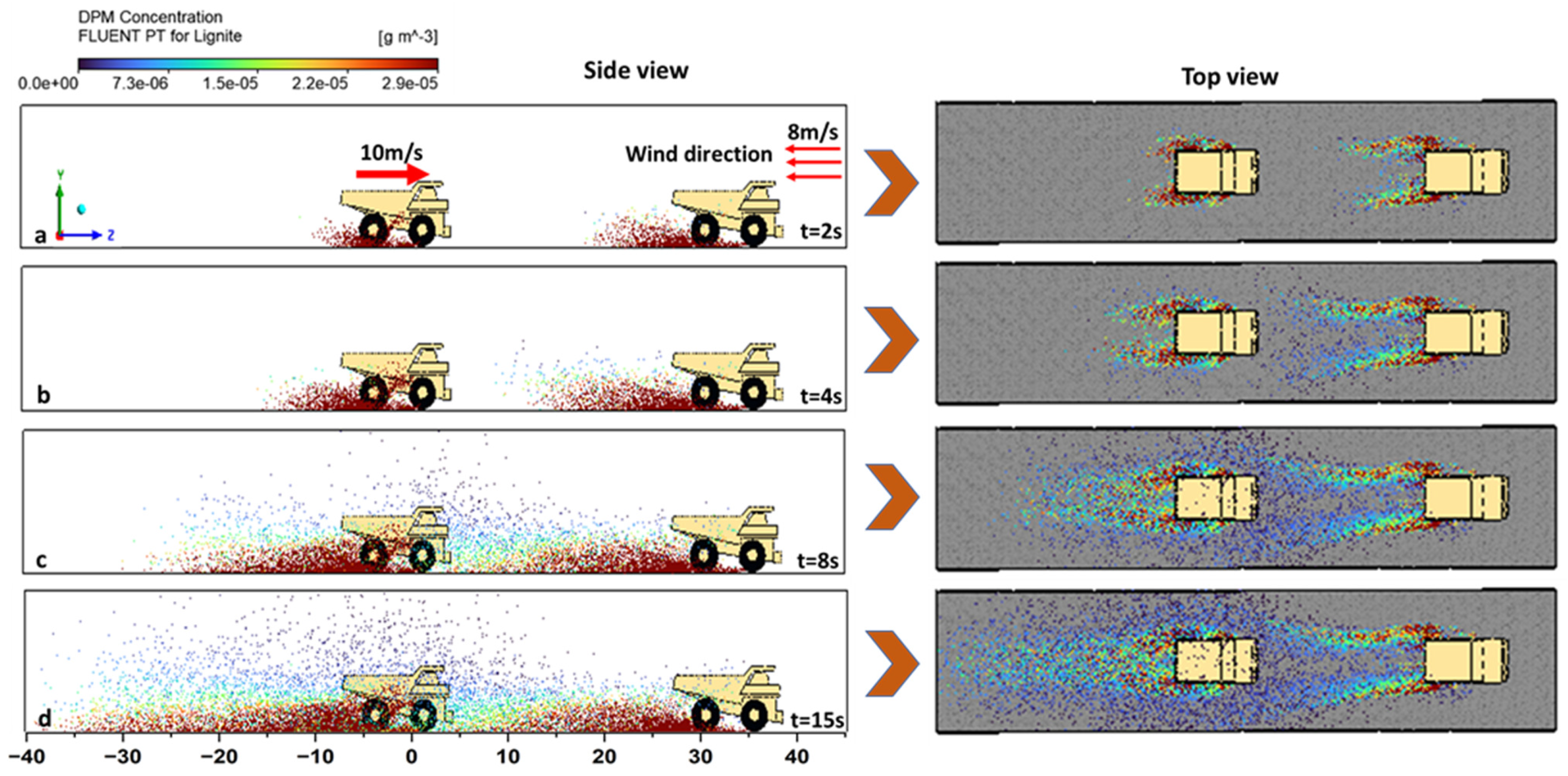

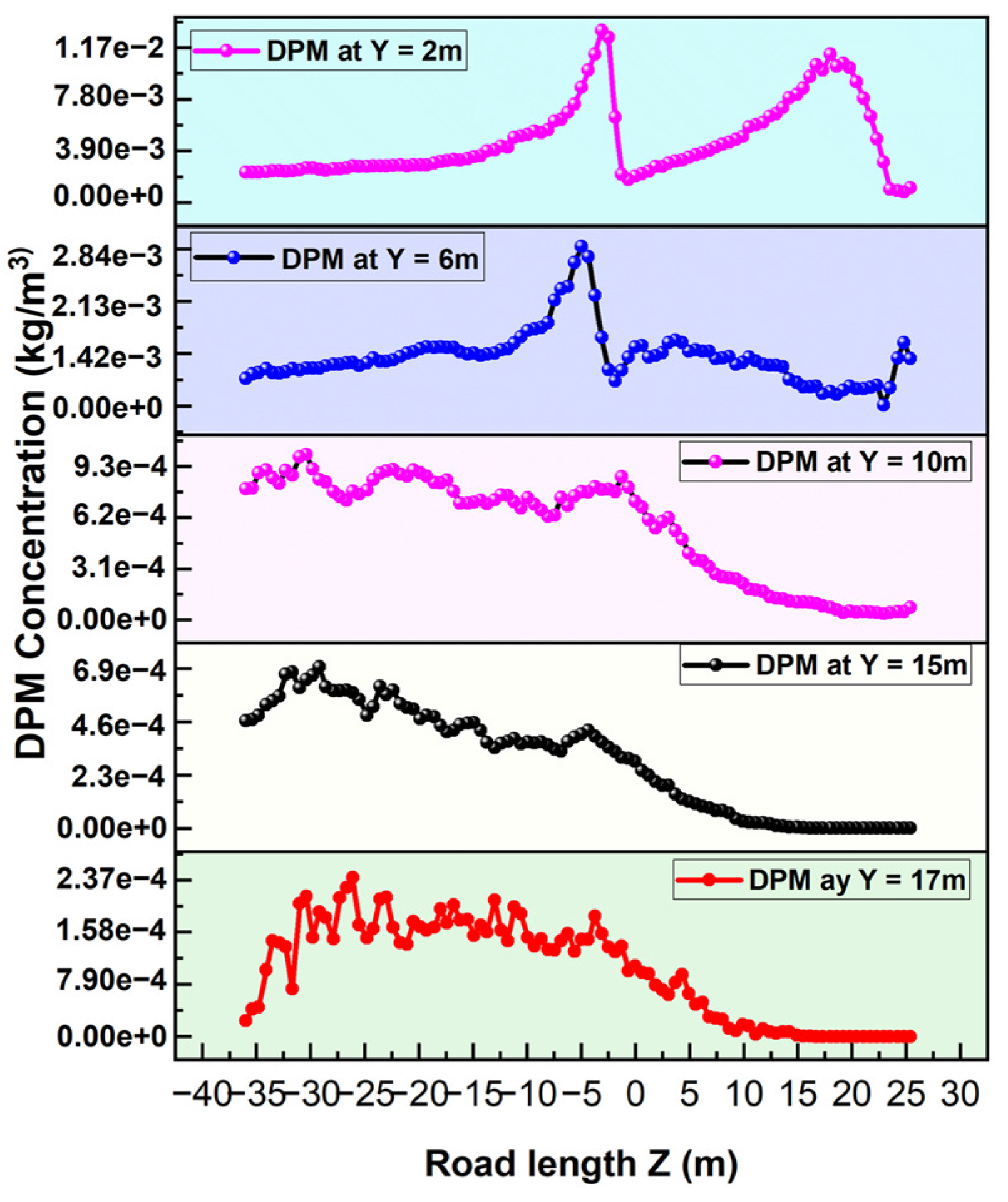

6.4. Examining Dust Profiles from Single and Multiple-Truck Traffic Without Terrain Influence

6.5. Impact of Multiple Trucks on Airborne Dust Concentration and Dispersion Without Terrain Influence

6.6. Analysis of Temporal and Spatial Dust Distribution Considering Terrain and Crosswind Influence

6.7. Evaluation of DPM-Fluent Coupling Effectiveness and Practical Implications

6.7.1. Validation Based on the Spatial Distribution and Concentration of Dust Particles

6.7.2. Practical Implications and Proposed Dust Reduction Measures

7. Conclusions

- Seasonal meteorological influence on PM dispersion: Field data confirmed that meteorological conditions exert season-specific control over dust behavior. In winter, high wind speeds (up to 50 m/s) and elevated air pressure significantly increased PM2.5 and TSP concentrations via mechanical resuspension and surface-layer entrapment. In contrast, summer conditions marked by elevated temperatures (up to 36 °C) and humidity intensified primary dust generation (especially PM2.5) through rapid road surface drying. These findings validate the strong predictive relationships observed in multivariate analysis (R2 = 0.47 for air pressure during winter and R2 = 0.71 for wind speed during both seasons), confirming these parameters as dominant factors of dust concentration and migrations.

- External airflow, turbulence, and terrain Interaction effects: Simulation results revealed that dust plumes form two turbulent wake vortices extending over 70 m downwind of a truck, with turbulent kinetic energy peaking at 5.02 m2/s2. Crosswinds and multi-truck operations amplified these effects, especially on non-watered roads. Terrain features such as benches created flow stagnation zones, resulting in particle stratification, where coarse particles remained near haul roads while fine particles dispersed to upper bench levels. Lateral diffusion reached 45 m, while longitudinal transport extended 55 m from the source within 20 s after initiation.

- Dust generation and concentration mechanism: This study reveals that dust generation in open-pit mining roads is strongly concentrated near haul trucks, with the highest particulate levels observed directly behind moving vehicles on dry, unsprayed roads. Field measurements showed peak total suspended particulate (TSP) concentrations reaching 19,026 µg/m3, while simulation results confirmed similarly intense emission zones with maximum DPM values of 2.62 × 10−2 g/m3. The dust plume rapidly dissipates as particles settle under gravity and disperse with airflow, decreasing sharply within the first 45 m crosswind. These findings emphasized that vehicular motion is the dominant trigger for dust release, and that particle size and atmospheric conditions govern their settling and diffusion mechanisms.

- Dust migration mechanism: based on the simulation approach, the DPM concentrations peaked at 4.34 × 10−2 g/m3 immediately behind a single truck on dry roads and gradually declined to 2.33 × 10−6 g/m3 at 37 m downwind. Under multi-truck scenarios, emissions increased significantly, reaching up to 2.51 × 10−1 g/m3 in the vehicle wake zone and 5.30 × 10−4 g/m3 in adjacent coal loading areas. The spatial profiles revealed that dust migrated downwind longitudinally up to 55 m and crosswind laterally to 45 m from the source within just 20 s, defining the short-term dust migration rate under turbulent conditions. Simulations showed that average settling velocities of particles ranging less than 10 µm and above 10 µm exhibited velocities between 0.035 m/s and 0.218 m/s, respectively, with coarser particles depositing closer to the road surface and finer particles remaining suspended and carried to elevated benches.

- While the CFD-DPM model demonstrated strong agreement with field data, there was a slight underestimation of dust concentrations in the limited number of monitoring stations used for field measurements. Furthermore, the exclusion of spring and autumn monitoring data limits our ability to fully understand seasonal transition mechanisms in dust concentrations. Future studies could address this limitation by incorporating a more extensive network of monitoring points across the downwind direction, validating the model under a wider range of environmental and operational conditions, and collecting four-season data to improve spatial resolution and capture seasonal variability more comprehensively. To minimize computational complexity, the numerical simulations used simplified assumptions, modeling dust particles as uniform-density spheres with a constant mass flow rate, and also did not account for particle-particle interactions. The assumption of steady inlet wind was applied in the CFD simulations. However, in the field, wind speed and direction fluctuate continuously. These temporal variations could lead to different dispersion patterns than those simulated under steady-state assumptions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, M.; Yang, Z.; Tai, C.; Zhang, F.; Zhang, Q.; Shen, K.; Guo, C. Prediction of road dust concentration in open-pit coal mines based on multivariate mixed model. PLoS ONE 2023, 18, e0284815. [Google Scholar] [CrossRef]

- Sinha, S.; Banerjee, S.P. Characterization of haul road dust in an Indian opencast iron ore mine. Atmos. Environ. 1997, 31, 2809–2814. [Google Scholar] [CrossRef]

- Visser, A.T.; Thompson, R. Mine haul road fugitive dust emission and exposure characterisation. Trans. Biomed. Health 2003, 7, 1743–3525. [Google Scholar]

- Piras, L.; Dentoni, V.; Massacci, G.; Lowndes, I.S. Dust dispersion from haul roads in complex terrain: The case of a mineral reclamation site located in Sardinia (Italy). Int. J. Min. Reclam. Environ. 2014, 28, 323–341. [Google Scholar] [CrossRef]

- Silvester, S.; Lowndes, I.; Hargreaves, D. A computational study of particulate emissions from an open pit quarry under neutral atmospheric conditions. Atmos. Environ. 2009, 43, 6415–6424. [Google Scholar] [CrossRef]

- Patra, A.K.; Gautam, S.; Kumar, P. Emissions and human health impact of particulate matter from surface mining operation—A review. Environ. Technol. Innov. 2016, 5, 233–249. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, R.; Li, L.; Liu, Z.; Sun, J.; Kong, L.; Liu, X. Analysis of the Dust-Concentration Distribution Law in an Open-Pit Mine and Its Influencing Factors. ACS Omega 2022, 7, 43609–43620. [Google Scholar] [CrossRef]

- Hui, L. Prediction of Respirable Dust Concentration in Coal Mine Based on Neural Network. In Proceedings of the 2020 IEEE Conference on Telecommunications, Optics and Computer Science (TOCS), Shenyang, China, 11–13 December 2020; pp. 402–406. [Google Scholar]

- Zhang, W.; Xue, S.; Tu, Q.; Shi, G.; Zhu, Y. Study on the distribution characteristics of dust with different particle sizes under forced ventilation in a heading face. Powder Technol. 2022, 406, 117504. [Google Scholar] [CrossRef]

- Dumka, U.C.; Kaskaoutis, D.G.; Francis, D.; Chaboureau, J.; Rashki, A.; Tiwari, S.; Singh, S.; Liakakou, E.; Mihalopoulos, N. The Role of the Intertropical Discontinuity Region and the Heat Low in Dust Emission and Transport Over the Thar Desert, India: A Premonsoon Case Study. J. Geophys. Res. Atmos. 2019, 124, 13197–13219. [Google Scholar] [CrossRef]

- Csavina, J.; Field, J.; Taylor, M.P.; Gao, S.; Landázuri, A.; Betterton, E.A.; Sáez, A.E. A review on the importance of metals and metalloids in atmospheric dust and aerosol from mining operations. Sci. Total Environ. 2012, 433, 58–73. [Google Scholar] [CrossRef]

- Cheng, Y.; Yu, H.; Xie, S.; Zhao, J.; Ye, Y. Study on the coal dust deposition fraction and site in the upper respiratory tract under different particle sizes and labor intensities. Sci. Total Environ. 2023, 868, 161617. [Google Scholar] [CrossRef]

- Shen, Z.; Ao, Z.; Wang, Z.; Yang, Y. Study on Crust-Shaped Dust Suppressant in Non-Disturbance Area of Open-Pit Coal Mine-A Case Study. Int. J. Environ. Res. Public Health 2023, 20, 934. [Google Scholar] [CrossRef]

- Zhao, X.; Han, F.; Song, Z.; Wang, D.; Fan, J.; Jia, Z.; Jiang, G. A research on dust suppression mechanism and application technology in mining and loading process of burnt rock open pit coal mines. J. Air Waste Manag. Assoc. 2021, 71, 1568–1584. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, W.; Wang, Z.; Jiskani, I.M.; Yang, Y. Accurate long-term dust concentration prediction in open-pit mines: A novel machine learning approach integrating meteorological conditions and mine production intensity. J. Clean. Prod. 2023, 436, 140411. [Google Scholar] [CrossRef]

- Wang, L.; Li, F.; Guo, Y.; Li, Q.; Chen, T.; Wu, J. Numerical Simulation Study of Dust Transport of Comprehensive Mining Working Surface. In Proceedings of the Modern Management Based on Big Data III, Seoul, Republic of Korea, 15–18 August 2022; pp. 440–446. [Google Scholar]

- Gautam, S.; Patra, A.K. Dispersion of particulate matter generated at higher depths in opencast mines. Environ. Technol. Innov. 2015, 3, 11–27. [Google Scholar] [CrossRef]

- Luo, H.; Zhou, W.; Jiskani, I.M.; Wang, Z. Analyzing Characteristics of Particulate Matter Pollution in Open-Pit Coal Mines: Implications for Green Mining. Energies 2021, 14, 2680. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, W.; Jiskani, I.M.; Luo, H.; Ao, Z.; Mvula, E.M. Annual dust pollution characteristics and its prevention and control for environmental protection in surface mines. Sci. Total Environ. 2022, 825, 153949. [Google Scholar] [CrossRef]

- Huang, J.; Chan, T. Vehicle queue effect on the characteristics of air flow, and exhaust scalar dispersion and distribution fields in the vehicle wake. Int. J. Heat Mass Transf. 2012, 55, 7981–7990. [Google Scholar] [CrossRef]

- Wang, Y.; Du, C.; Xu, H. Key Factor Analysis and Model Establishment of Blasting Dust Diffusion in a Deep, Sunken Open-Pit Mine. ACS Omega 2021, 6, 448–455. [Google Scholar] [CrossRef]

- Huang, Z. Numerical Simulation of Blasting Dust Pollution in Open-Pit Mines. Appl. Ecol. Environ. Res. 2019, 17, 10313–10333. [Google Scholar] [CrossRef]

- Chen, Z.; Du, C.; Wang, J.; Wang, Y. Influence of Recirculation Flow on the Dispersion Pattern of Blasting Dust in Deep Open-Pit Mines. ACS Omega 2023, 8, 31353–31364. [Google Scholar] [CrossRef]

- Liao, X.; Jiang, Z.; Niu, W.; Yuan, Q. Numerical Simulations of Blasting Dust Migration with the Use of Fluent in Stope. J. Saf. Environ. 2012, 6, 43–46. [Google Scholar]

- Li, L.; Zhang, R.; Sun, J.; He, Q.; Kong, L.; Liu, X. Monitoring and prediction of dust concentration in an open-pit mine using a deep-learning algorithm. J. Environ. Health Sci. Eng. 2021, 19, 401–414. [Google Scholar] [CrossRef]

- Heisler, G.M.; Dewalle, D.R. Effects of windbreak structure on wind flow. Agric. Ecosyst. Environ. 1988, 22–23, 41–69. [Google Scholar] [CrossRef]

- Isley, C.; Kellaghan, R. Tarrawonga Coal Mine -Particulate Matter Control Best Practice Pollution Reduction Program; Whitehaven Coal Limited: Sydney, Australia, 2012; Volume 6680B, pp. 1–45. [Google Scholar]

- Liu, Z.; Ao, Z.; Zhou, W.; Zhang, B.; Niu, J.; Wang, Z.; Liu, L.; Yang, Z.; Xu, K.; Lu, W. Research on the Physical and Chemical Characteristics of Dust in Open Pit Coal Mine Crushing Stations and Closed Dust Reduction Methods. Sustainability 2023, 15, 12202. [Google Scholar] [CrossRef]

- Lu, X.; Tian, Y.; Jiskani, I.M.; Zhou, W.; Zhao, B.; Ding, X.; Ao, Z. Innovate geopolymer synthesis for green mine road construction: Analysis of efflorescence behavior and strength analysis. Constr. Build. Mater. 2023, 401, 132963. [Google Scholar] [CrossRef]

- Kashi, V.K.; Karmakar, N.C.; Krishnamoorthi, S. Study on Opencast Coal Mine Haul Road Dust Suppression using Guargum Grafted Polyacrylamide. J. Mines Met. Fuels 2022, 70, 242–250. [Google Scholar] [CrossRef]

- Ardon-Dryer, K.; Kelley, M.C. Particle size distribution and particulate matter concentrations during synoptic and convective dust events in West Texas. Atmos. Chem. Phys. 2022, 22, 9161–9173. [Google Scholar] [CrossRef]

- Wei, D.; Du, C.; Lin, Y.; Chang, B.; Wang, Y. Temporal-Spatial Distribution of Vehicle Transportation Pavement Dust Migration in an Open-Pit Mine. ACS Omega 2020, 5, 16030–16036. [Google Scholar] [CrossRef]

- Pochwala, S.; Gardecki, A.; Lewandowski, P.; Somogyi, V.; Anweiler, S. Developing of Low-Cost Air Pollution Sensor-Measurements with the Unmanned Aerial Vehicles in Poland. Sensors 2020, 20, 3582. [Google Scholar] [CrossRef]

- Xia, N.; Hai, W.; Song, G.; Tang, M. Identification and monitoring of coal dust pollution in Wucaiwan mining area, Xinjiang (China) using Landsat derived enhanced coal dust index. PLoS ONE 2022, 17, e0266517. [Google Scholar] [CrossRef]

- Patra, A.; Gautam, S.; Majumdar, S.; Kumar, P. Prediction of particulate matter concentration profile in an opencast copper mine in India using an artificial neural network model. Air Qual. Atmos. Health 2015, 9, 697–711. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method, 2nd ed.; Pearson Education Limited: Harlow, UK, 2007; p. 517. [Google Scholar]

- Wang, J.; Levy, E.K. Particle motions and distributions in turbulent boundary layer of air–particle flow past a vertical flat plate. Exp. Therm. Fluid Sci. 2003, 27, 845–853. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, H.; Xiao, J.; Wang, S. Research analysis on the airflow-particle migration and dust disaster impact scope by the moving mining truck in the open-pit mine. Process Saf. Environ. Prot. 2024, 184, 1442–1458. [Google Scholar] [CrossRef]

- Gillies, J.A.; Etyemezian, V.; Kuhns, H.; Nikolic, D.; Gillette, D.A. Effect of vehicle characteristics on unpaved road dust emissions. Atmos. Environ. 2005, 39, 2341–2347. [Google Scholar] [CrossRef]

- Abdullah, S.; Ismail, M.; Fong, S.Y. Multiple Linear Regression (MLR) models for long term Pm10 concentration forecasting during different monsoon seasons. J. Sustain. Sci. Manag. 2017, 12, 60–69. [Google Scholar]

- Ul-Saufie, A.; Yahaya, A.; Nor, Y.; Hazrul, A.; Abdul Hamid, H. Comparison Between Multiple Linear Regression And Feed forward Back propagation Neural Network Models For Predicting PM 10 Concentration Level Based On Gaseous And Meteorological Parameters. Int. J. Appl. Sci. Technol. 2011, 1, 42–49. [Google Scholar]

- Etyemezian, V.; Kuhns, H.; Gillies, J.; Chow, J.; Hendrickson, K.; McGown, M.; Pitchford, M. Vehicle-based road dust emission measurement: I—Methods and calibration. Atmos. Environ. 2003, 37, 4559–4571. [Google Scholar] [CrossRef]

- Jhon, D.; Anderson, J. Computational-Fluid-Dynamics-the-Basics-With-Applications; McGraw-Hill: New York, NY, USA, 1995; 563p. [Google Scholar]

- Li, L.; Zhang, R.; Li, Q.; Zhang, K.; Liu, Z.; Ren, Z. Multidimensional spatial monitoring of open pit mine dust dispersion by unmanned aerial vehicle. Sci. Rep. 2023, 13, 6815. [Google Scholar] [CrossRef]

- Asif, Z.; Chen, Z.; Guo, J. A study of meteorological effects on PM2.5 concentration in mining area. Atmos. Pollut. Res. 2018, 9, 688–696. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, W.; Jiskani, I.; Yan, J.; Luo, H. Optimizing open-pit coal mining operations: Leveraging meteorological conditions for dust removal and diffusion. Int. J. Coal Sci. Technol. 2024, 11, 54. [Google Scholar] [CrossRef]

- Pirsaheb, M.; Bakhshi, S.; Almasi, A.; Mousavi, S.; Rezaei, M.; Sharafi, H.; Saleh, E. Evaluating the effect of meteorological parameters (humidity, temperature, wind speed, and pressure) on the dust phenomenon—Case study: Kermanshah, Iran (2008–2012). Int. J. Pharm. Technol. 2016, 8, 17847–17855. [Google Scholar]

- Laurent, B.; Marticorena, B.; Bergametti, G.; Léon, J.; Mahowald, N. Modeling mineral dust emission from the Sahara desert using new surface properties and soil database. J. Geophys. Res. 2008, 113, D14218. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z.; Wang, R. Characteristics of dust pollution and its influencing factors during cold period of open-pit coal mines in northern China. Front. Earth Sci. 2025, 13, 1458847. [Google Scholar] [CrossRef]

- Wanjun, T.; Qingxiang, C. Dust distribution in open-pit mines based on monitoring data and fluent simulation. Environ. Monit. Assess. 2018, 190, 632. [Google Scholar] [CrossRef]

- Hu, S.; Gao, Y.; Feng, G.; Huang, Y.; Shao, H.; Liao, Q.; Hu, F. Characteristics of dust distributions and dust control measures around road-header drivers in mining excavation roadways. Particuology 2021, 58, 268–275. [Google Scholar] [CrossRef]

- Ham, Y.; Cheriyan, D.; Kim, H.; Han, J.; Kim, Y.; Janani, P.; Choi, J. Particulate matter reduction efficiency analysis of sprinkler system as targeted control measures for construction activity. Heliyon 2024, 10, e27765. [Google Scholar] [CrossRef]

| Parameters | Instruments | |||

|---|---|---|---|---|

| Category | Name | FY-AQM3000 | Laser Particle Counter | HT-9600 Handheld Particle Counter |

| Environmental Quality Monitoring | PM2.5 | 0–5000 μg/m3 | 0–9999.9 μg/m3 | 0–1000 μg/m3 |

| PM10 | 0–5000 μg/m3 | 0–9999.9 μg/m3 | 0–1000 μg/m3 | |

| TSP | 0–20,000 μg/m3 | 0–20,000 μg/m3 | - | |

| Meteorological parameters | Wind speed | 0–70 m/s | - | - |

| Wind direction | 0–360° | - | - | |

| Temperature Humidity Air pressure | −50–80 °C 0–100% RH 500–1100 hpa | 5–45 °C 0–100% RH 70–106 kPa | −20–50 °C 0–100% RH | |

| CFD-Fluent Solver | Operating Conditions | Setting Parameters |

| Solver | Pressure-based | |

| Time | Steady | |

| Gravity | −9.81 m/s2 | |

| Viscous model | k-epsilon-RNG-Enhanced wall | |

| Pressure-velocity Coupling | Simple, Coupled | |

| Turbulent kinetic energy | Second-order upwind | |

| Solution initialization | Standard | |

| Density of lignite coal dust (kg/m3) | 1250 kg/m3 | |

| Air density (kg/m3) | 1.225 kg/m3 | |

| Boundary Conditions | Operating Conditions | Setting Parameters |

| Inlet | Velocity inlet (3, 5, 8, 10 m/s) | |

| Outlet | Pressure outlet | |

| Wall | Haul road (stationary) | |

| Bench face (stationary) | ||

| Trucks (Translational motion, 10 m/s, Z = 1 m) | ||

| Wheel (rotational, 10 m/s = 7.12 rad/s) | ||

| Coal load (stationary) | ||

| Wall roughness | Standard—0 m height |

| Discrete Phase Model (DPM) Solver | Operating Conditions | Setting Parameters |

| Interaction with the continuous phase | On | |

| Saffman lift force | On | |

| Virtual mass flow | On | |

| Pressure gradient force | On | |

| Accuracy control tolerance | 1 × 10−5 | |

| Injection type | Surface (haul road, Coal load) | |

| Material | Lignite coal | |

| Diameter distribution | Rosin-Rammler | |

| Total flow rate | 0.1 kg/s, 0.01 kg/s, 0.001 kg/s | |

| Min. Diameter (μm) | 1 | |

| Max. Diameter (μm) | 100 | |

| Mean Diameter (μm) | 1 × 10−5 | |

| Spread Diameter | 3.5 | |

| Drag law | Spherical | |

| Stochastic tracking | Discrete random walk model |

| Meteorological Variables | PM Variables | p-Value | Variance Inflation Factor (VIF) | |

|---|---|---|---|---|

| Summer | Temperature | PM2.5 | <0.01 ** | 1.7 |

| PM10 | N/A | - | ||

| TSP | 0.004 ** | 2.0 | ||

| Wind speed | PM2.5 | <0.01 ** | 1.8 | |

| PM10 | 0.002 ** | 1.7 | ||

| TSP | <0.01 ** | 1.7 | ||

| Air pressure | PM2.5 | 0.023 * | 2.6 | |

| PM10 | 0.017 * | 2.1 | ||

| TSP | <0.01 ** | 1.5 | ||

| Humidity | PM2.5 | <0.01 ** | 1.7 | |

| PM10 | 0.005 ** | 1.9 | ||

| TSP | 0.002 ** | 1.8 | ||

| Winter | Temperature | PM2.5 | 0.023 * | 2.7 |

| PM10 | N/A | - | ||

| TSP | 0.010 * | 2.3 | ||

| Wind speed | PM2.5 | <0.01 ** | 1.5 | |

| PM10 | <0.001 ** (Ws > 20 m/s) | 1.6 | ||

| TSP | <0.01 ** | 1.5 | ||

| Air pressure | PM2.5 | <0.01 ** | 1.8 | |

| PM10 | 0.010 * | 2.0 | ||

| TSP | <0.01 ** | 1.7 | ||

| Humidity | PM2.5 | 0.038 * | 1.4 | |

| PM10 | 0.012 * | 2.1 | ||

| TSP | 0.027 * | 2.3 |

| Points | PM Concentration and Distribution | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Maximum Baseline PM Concentration Without Transportation (μg/m3) in Both Seasons | Maximum PM Concentration During Active Transportation | |||||||||

| Winter | Summer | Simulation Results | ||||||||

| PM2.5 | PM10 | TSP | PM2.5 | PM10 | TSP | PM2.5 | PM10 | TSP | DPM Concentration (g/m3) | |

| 1 | * | * | * | * | * | * | 5130 | 7086 | 19,026 | 2.62 × 10−2 |

| 2 | 28 | 10 | 43 | 3253 | 1686 | 5878 | 1952 | 1158 | 3883 | 4.33 × 10−3 |

| 3 | 35 | 14 | 52 | 783 | 265 | 670 | 677 | 194 | 552 | * |

| 4 | 32 | 12 | 38 | 200 | 98 | * | 152 | 74 | * | 1.71 × 10−4 |

| 5 | 30 | 11 | 27 | 102 | 62 | * | 81 | 53 | * | 1.09 × 10−5 |

| Particle Size | PM10 (Z = −2 m–(−15 m)) | PM2.5 (Z = −15 m–(−35 m)) |

|---|---|---|

| Time interval | 0 s–6 s | 7 s–15 s |

| Settling velocity | 0.218 | 0.035 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Assefa, F.G.; Xiang, L.; Yang, Z.; Gebretsadik, A.; Wahab, A.; Fissha, Y.; Cheepurupalli, N.R.; Sazid, M. Research on Dust Concentration and Migration Mechanisms on Open-Pit Coal Mining Roads: Effects of Meteorological Conditions and Haul Truck Movements. Mining 2025, 5, 43. https://doi.org/10.3390/mining5030043

Assefa FG, Xiang L, Yang Z, Gebretsadik A, Wahab A, Fissha Y, Cheepurupalli NR, Sazid M. Research on Dust Concentration and Migration Mechanisms on Open-Pit Coal Mining Roads: Effects of Meteorological Conditions and Haul Truck Movements. Mining. 2025; 5(3):43. https://doi.org/10.3390/mining5030043

Chicago/Turabian StyleAssefa, Fisseha Gebreegziabher, Lu Xiang, Zhongao Yang, Angesom Gebretsadik, Abdoul Wahab, Yewuhalashet Fissha, N. Rao Cheepurupalli, and Mohammed Sazid. 2025. "Research on Dust Concentration and Migration Mechanisms on Open-Pit Coal Mining Roads: Effects of Meteorological Conditions and Haul Truck Movements" Mining 5, no. 3: 43. https://doi.org/10.3390/mining5030043

APA StyleAssefa, F. G., Xiang, L., Yang, Z., Gebretsadik, A., Wahab, A., Fissha, Y., Cheepurupalli, N. R., & Sazid, M. (2025). Research on Dust Concentration and Migration Mechanisms on Open-Pit Coal Mining Roads: Effects of Meteorological Conditions and Haul Truck Movements. Mining, 5(3), 43. https://doi.org/10.3390/mining5030043