A Field-Scale Framework for Assessing the Influence of Measure-While-Drilling Variables on Geotechnical Characterization Using a Boruta-SHAP Approach

Abstract

1. Introduction

2. Methods

2.1. Mine Site Geotechnical Data

2.2. Mine Site MWD Systems and Data

2.3. MWD Data Pre-Processing

2.4. Feature Engineering–MWD Variables

2.5. Feature Importance–Boruta-SHAP

2.6. Regression-Based ML Methods

- R2 = coefficient of determination

- RSS = sum of squares of residuals

- TSS = total sum of squares

- N = the number of samples

- = the measured value,

- = the predicted value

- = the mean value.

3. Results

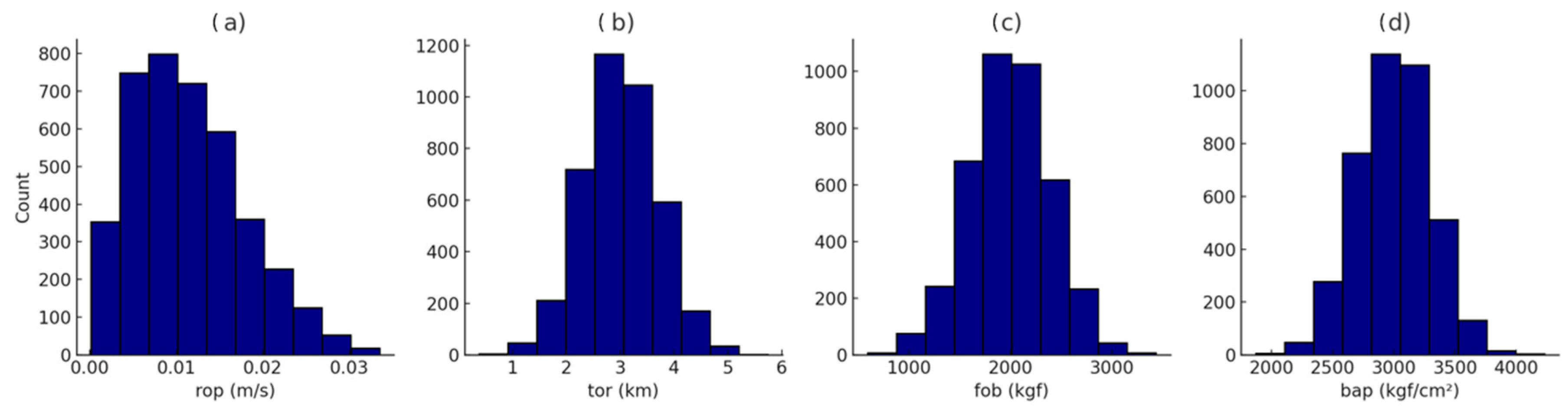

3.1. MWD Exploratory Data Analysis

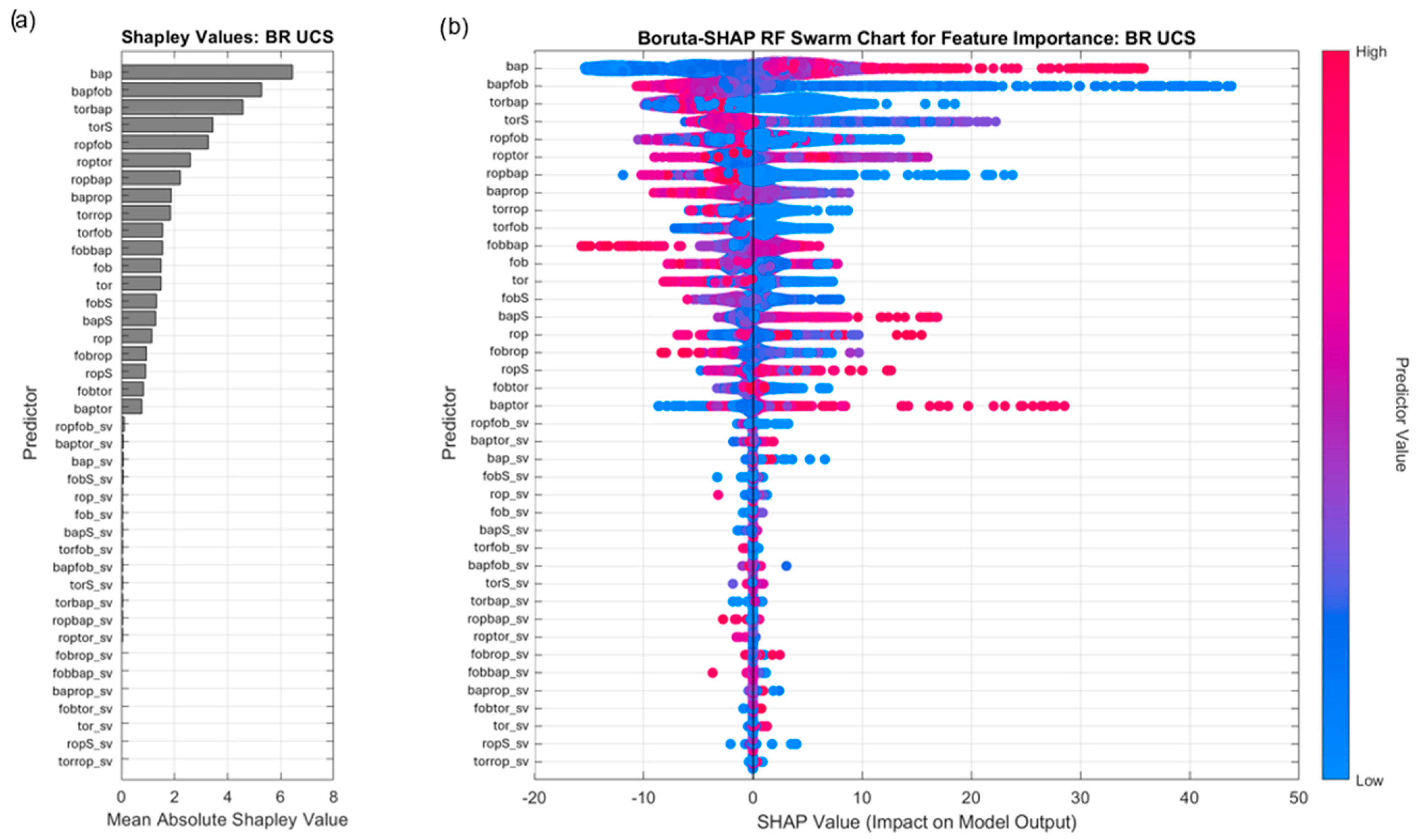

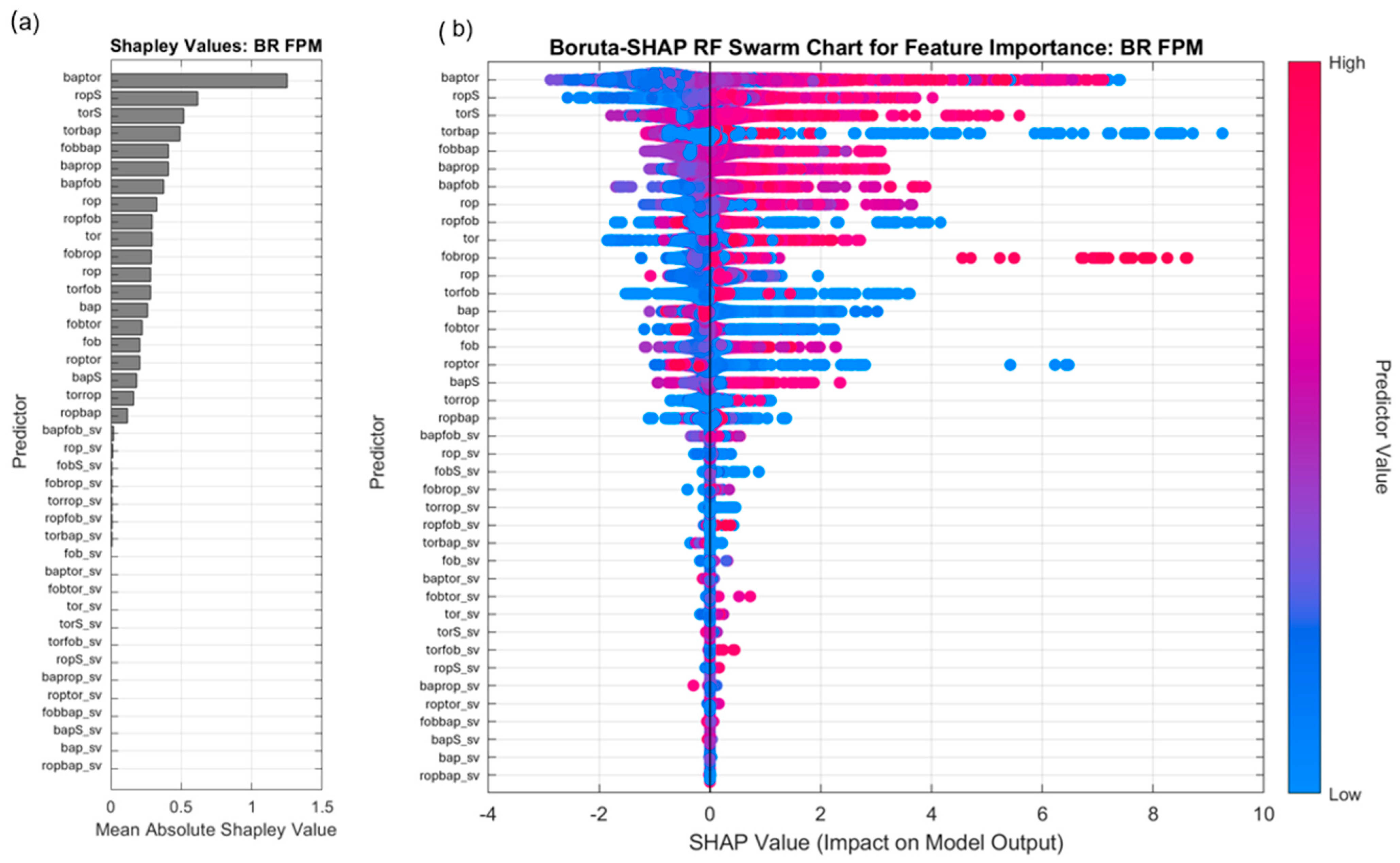

3.2. Feature Importance

- i.

- Ratio-based features (baprop, fobrop, torrop) ranked higher than raw features in UCS and GSI prediction;

- ii.

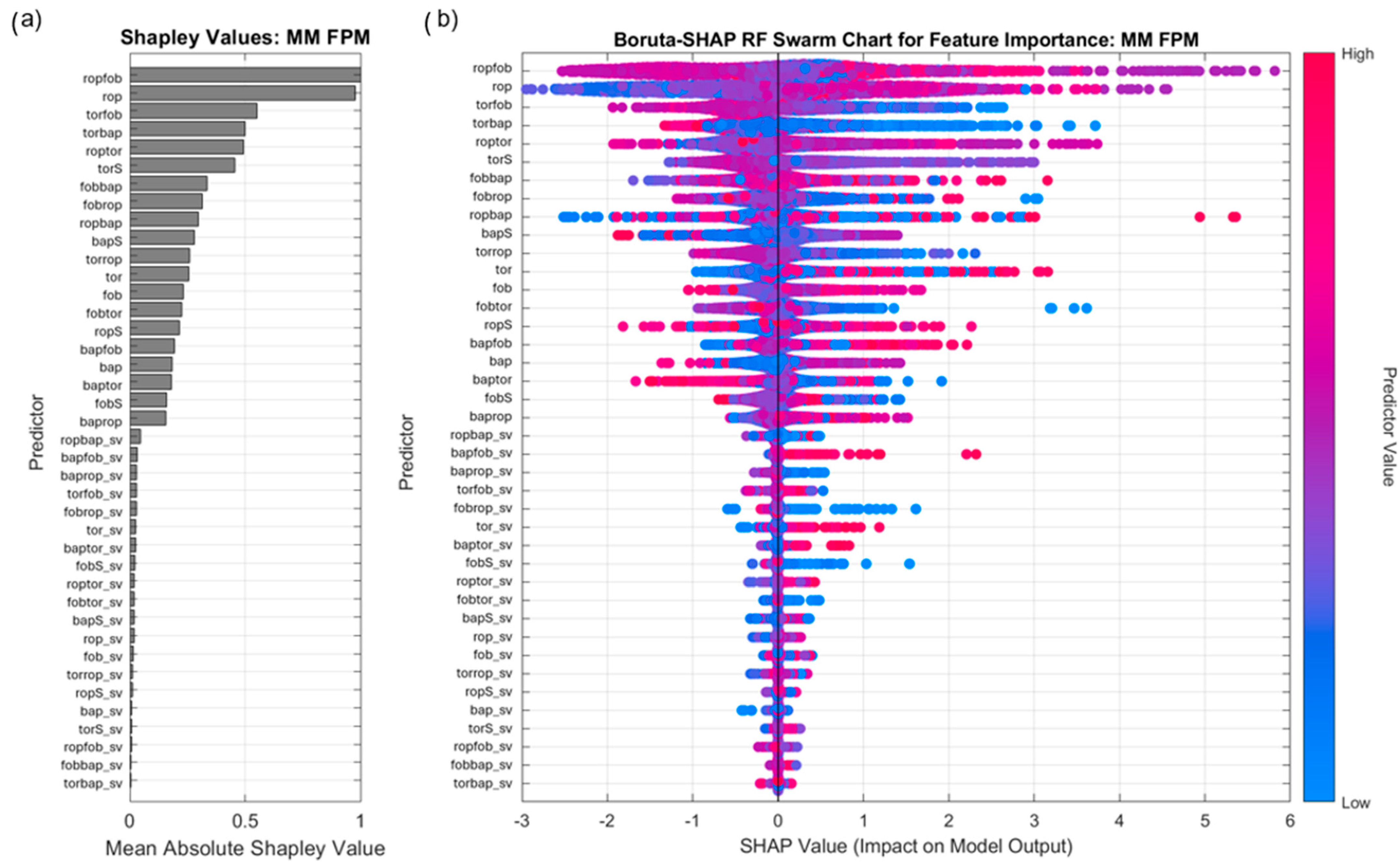

- MSD features (ropS, torS) were critical for FPM, indicating their effectiveness in detecting fracture-related variability;

- iii.

- bap emerged as the most significant raw feature, reinforcing the role of flushing pressure in geotechnical characterization.

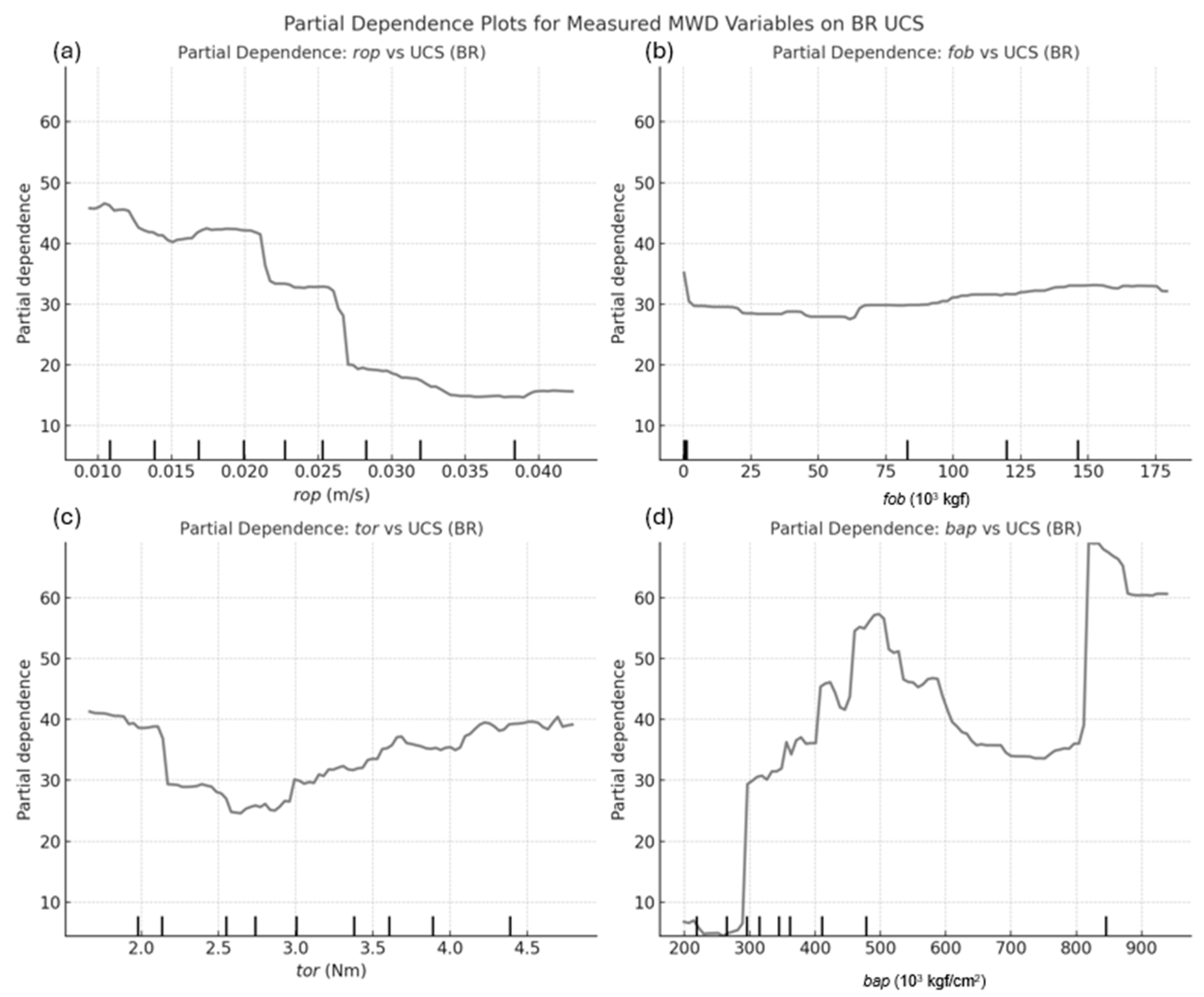

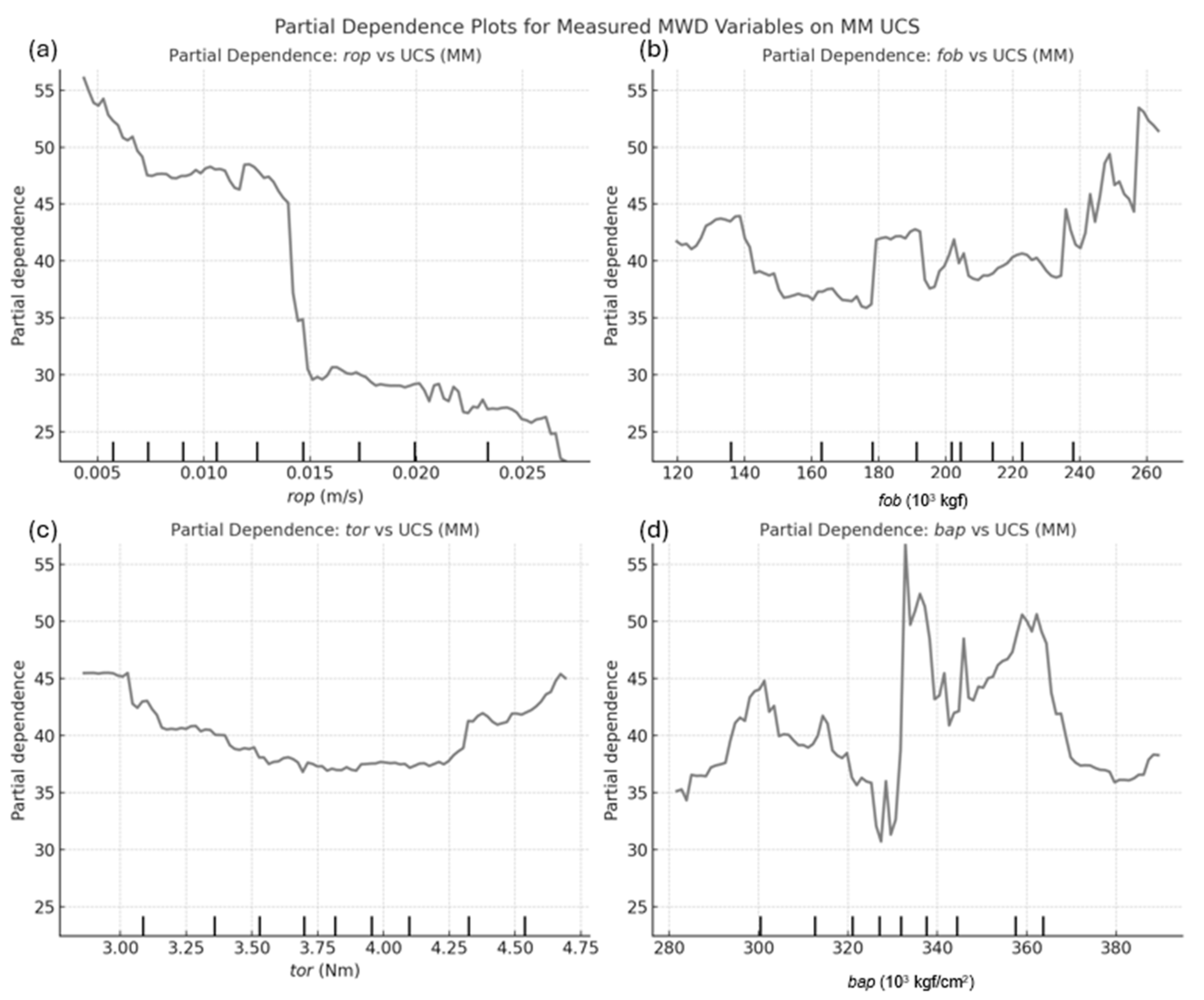

3.2.1. Feature Importance Boruta-SHAP—UCS

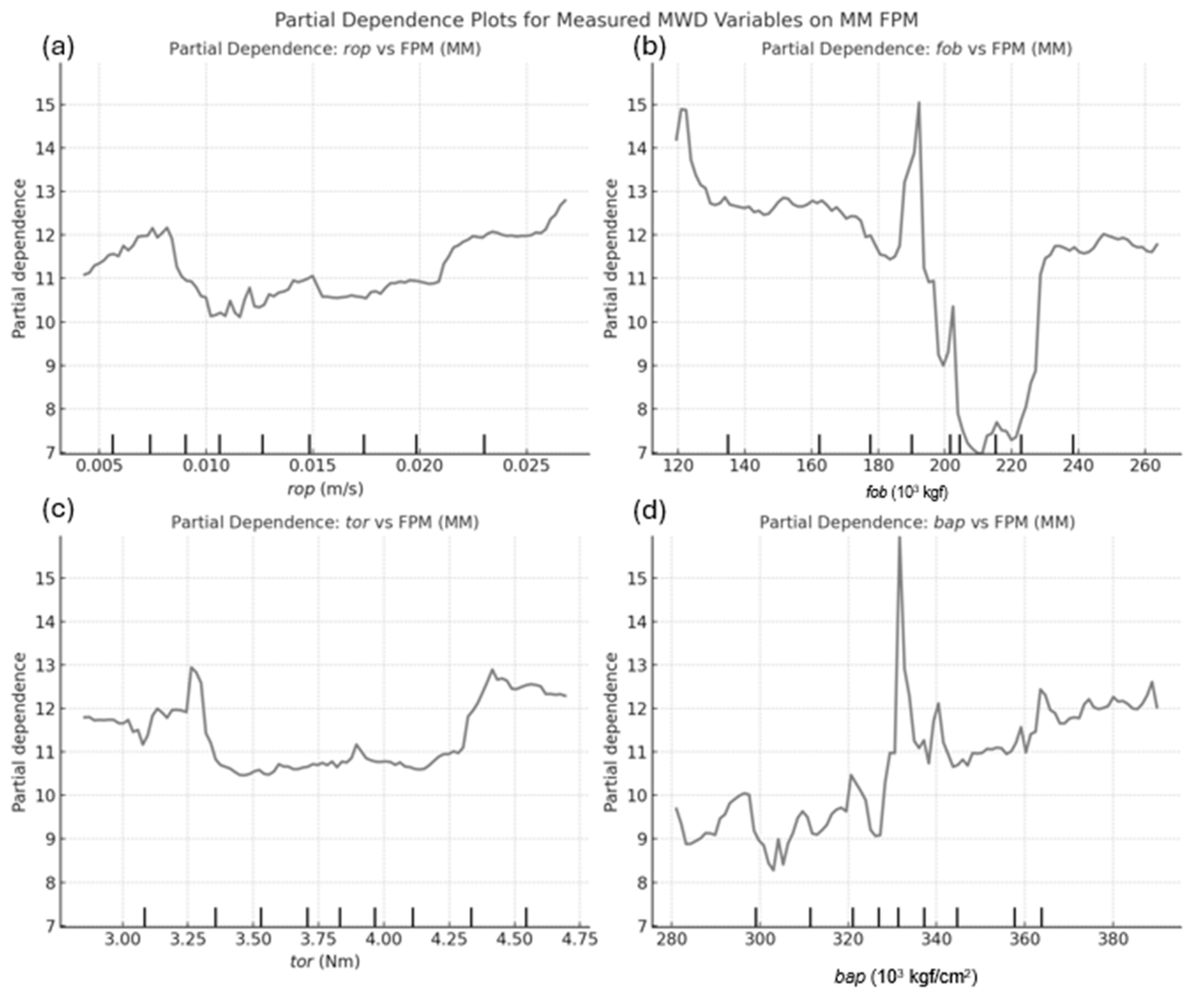

3.2.2. Feature Importance Boruta-SHAP—FPM

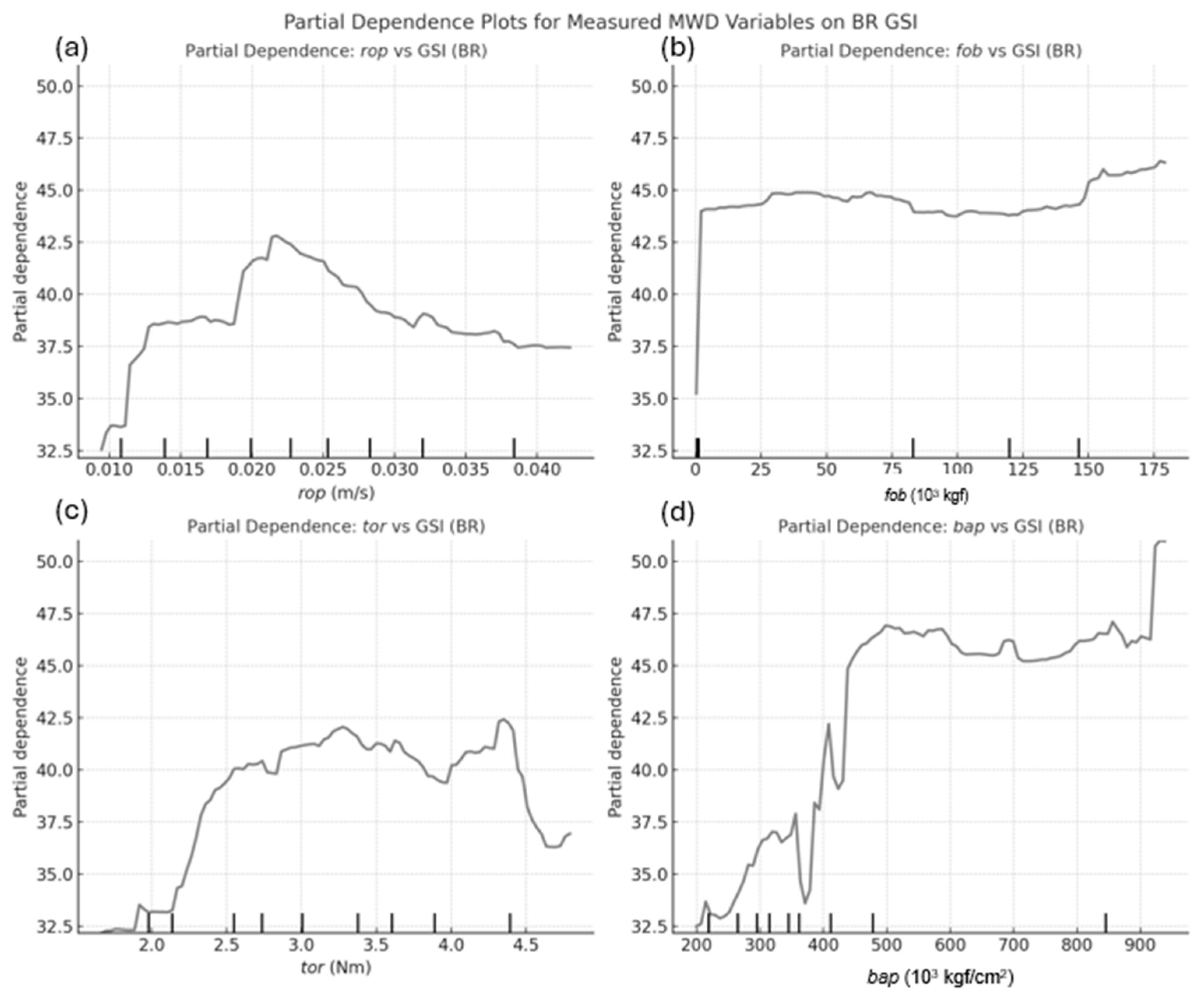

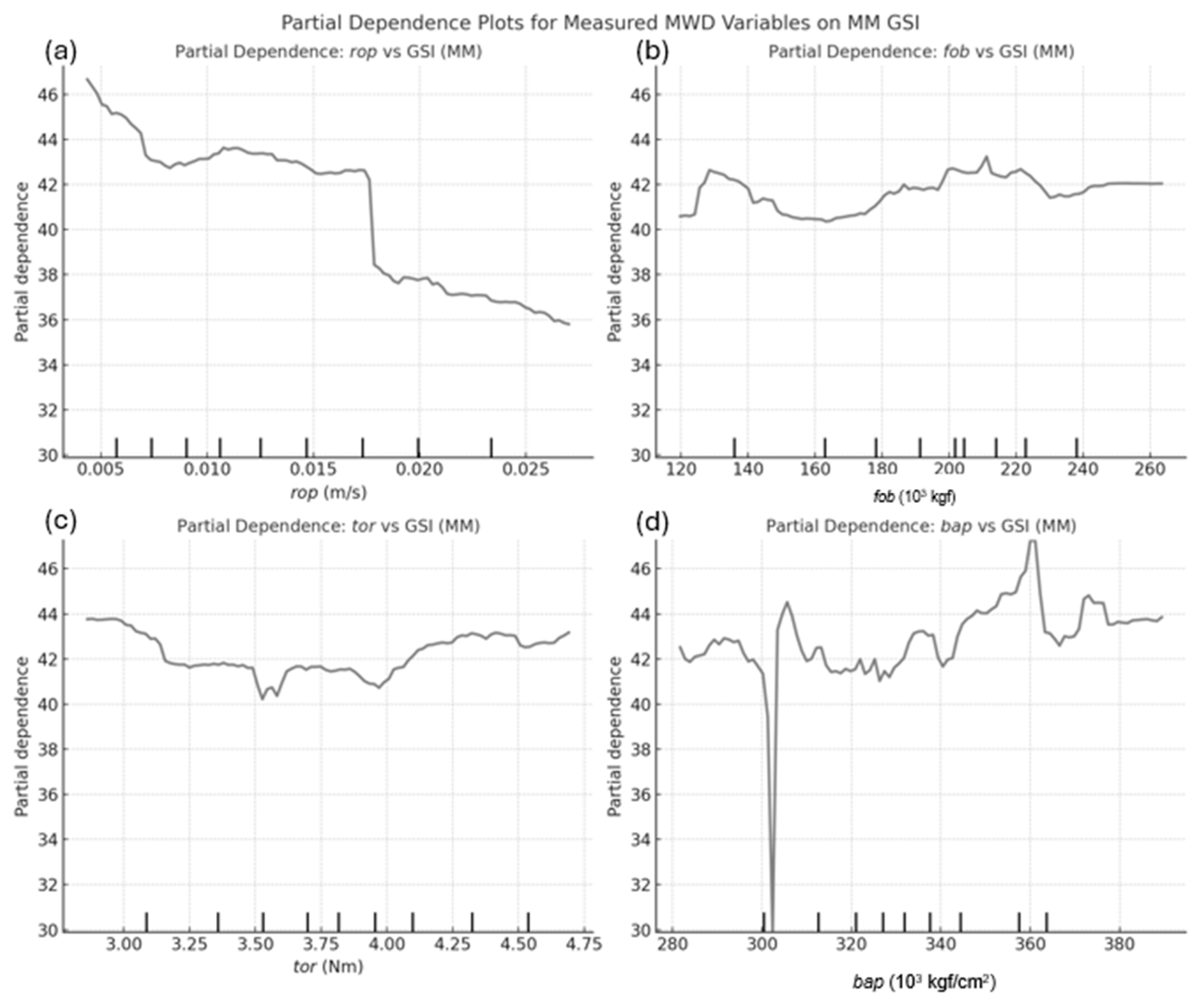

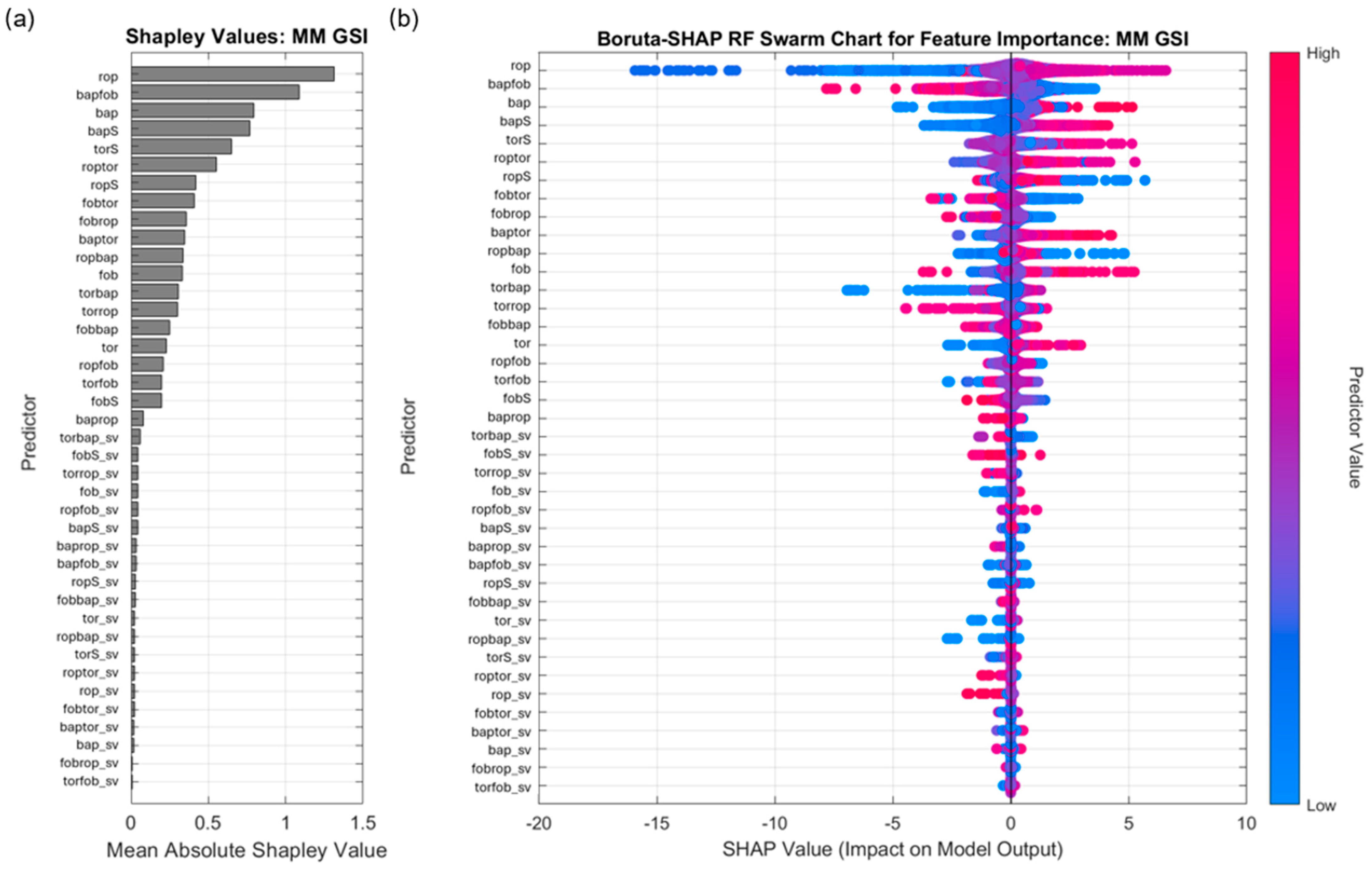

3.2.3. Feature Importance Boruta-SHAP—GSI

3.3. Regression-Based ML Overview

- i.

- DT is prone to overfitting and lacks the ability to capture intricate geomechanical relationships;

- ii.

- SVM relies on a fixed decision boundary, which is not well-suited to continuous, nonlinear geotechnical responses;

- iii.

- GP, while effective in some cases, is computationally expensive and does not generalize well with the large, noisy datasets typical of MWD applications.

3.3.1. UCS Prediction

3.3.2. FPM Prediction

3.3.3. GSI Prediction

4. Discussion

- i.

- Standardizing MWD data processing across different equipment types to improve the transferability of ML models to new operations;

- ii.

- Evaluating the robustness of MWD-based geotechnical predictions across different drill bit designs, rig configurations, and automation levels;

- iii.

- Training models on multi-site, multi-commodity datasets to differentiate universal vs. deposit-specific feature importance;

- iv.

- Developing transfer learning techniques to allow pre-trained ML models to adapt to new sites with minimal re-training;

- v.

- Integrating additional geological context variables (e.g., geophysical wireline logs, lithological logs) to enhance prediction accuracy across different orebody types;

- vi.

- Validating model predictions against real-time operational outcomes, such as blast fragmentation and equipment performance, to ensure practical applicability.

5. Conclusions

- i.

- Comparing MWD-based geotechnical predictions to actual fragmentation results, validating the impact on blast efficiency;

- ii.

- Developing integrated ML models that link MWD data to downstream productivity metrics such as loader efficiency, cycle times, and crusher performance;

- iii.

- Investigating real-time integration of MWD analytics into mine control systems, enabling dynamic adjustments to blast and excavation strategies.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barton, N.; Lien, R.; Lunde, J. Engineering Classification of Rock Masses for the Design of Tunnel Support. Rock Mech. 1974, 6, 189–236. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. Geomechanics Classification (Rock Mass Rating System). In Engineering Rock Mass Classifications: A Complete Manual for Engineers and Geologists in Mining, Civil, and Petroleum Engineering; Wiley-Interscience: New York, NY, USA, 1989. [Google Scholar]

- Deere, D.U. Technical Description of Rock Cores for Engineering Purpose. Rock Mech. Eng. Geol. 1963, 1, 18–22. [Google Scholar]

- Hoek, E. Strength of Jointed Rock Masses. Géotechnique 1983, 33, 187–223. [Google Scholar] [CrossRef]

- Howarth, D.F.; Rowlands, J.C. Quantitative Assessment of Rock Texture and Correlation with Drillability and Strength Properties. Rock Mech. Rock Eng. 1987, 20, 57–85. [Google Scholar] [CrossRef]

- Elbaz, S.; Crawford, D.; Tuck, M. A Method to Assess Rock Strength and Excavability of Diamondiferous Kimberlite Ore through In-Situ Rock Testing In Geotechnical and Geophysical Site Characterisation 5; Springer International Publishing: Sydney, Australia, 2016. [Google Scholar]

- Schunnesson, H. Drill Process Monitoring in Percussive Drilling for Location of Structural Features, Lithological Boundaries and Rock Properties, and for Drill Productivity Evaluation. Ph.D. Thesis, Lulea University of Technology, Lulea, Sweden, 1997. [Google Scholar]

- Palleske, C.; Kalenchuk, K.; Hume, C.; Bawden, W. Strategic Use of Geotechnical Data for Maximised Value Added. In Proceedings of the Eighth International Conference on Deep and High Stress Mining, Australian Centre for Geomechanics, Perth, Australia, 28–30 March 2017; pp. 511–520. [Google Scholar]

- Segui, J.B.; Higgins, M. Blast Design Using Measurement While Drilling Parameters. Int. J. Blasting Fragm. 2001, 6, 28–31. [Google Scholar] [CrossRef]

- Hatherly, P.; Leung, R.; Scheding, S.; Robinson, D. Drill Monitoring Results Reveal Geological Conditions in Blasthole Drilling. Int. J. Rock Mech. Min. Sci. 2015, 78, 144–154. [Google Scholar] [CrossRef]

- Khorzoughi, M.B.; Hall, R.; Apel, D. Rock Fracture Density Characterization Using Measurement While Drilling (MWD) Techniques. Int. J. Min. Sci. Technol. 2018, 28, 859–864. [Google Scholar] [CrossRef]

- Navarro, J.; Sanchidrian, J.A.; Segarra, P.; Castedo, R.; Paredes, C.; Lopez, L.M. On the Mutual Relations of Drill Monitoring Variables and the Drill Control System in Tunneling Operations. Tunn. Undergr. Space Technol. 2018, 72, 294–304. [Google Scholar] [CrossRef]

- Van Eldert, J.; Schunnesson, H.; Johansson, D.; Saiang, D. Application of Measurement While Drilling Technology to Predict Rock Mass Quality and Rock Support for Tunnelling. Rock Mech. Rock Eng. 2020, 53, 1349–1358. [Google Scholar] [CrossRef]

- Kadkhodaie-Ilkhchi, A.; Monteiro, S.T.; Ramos, F.; Hatherly, P. Rock Recognition from MWD Data: A Comparative Study of Boosting, Neural Networks, and Fuzzy Logic. IEEE Geosci. Remote Sens. Lett. 2010, 7, 680–684. [Google Scholar] [CrossRef]

- Goldstein, D.M.; Aldrich, C.; O’Connor, L. A Review of Orebody Knowledge Enhancement Using Machine Learning on Open-Pit Mine Measure-While-Drilling Data. Mach. Learn. Knowl. Extr. 2024, 6, 1343–1360. [Google Scholar] [CrossRef]

- Peck, J.P. Performance Monitoring of Rotary Blasthole Drills. Ph.D. Thesis, McGill University, Montreal, Canada, 1989. [Google Scholar]

- Scoble, M.J.; Peck, J.; Hendricks, C. Correlation between Rotary Drill Performance Parameters and Borehole Geophysical Logging. Min. Sci. Technol. 1989, 8, 301–312. [Google Scholar] [CrossRef]

- Martin, J. Application of Pattern Recognition Techniques to Monitoring-While-Drilling on a Rotary Electric Blasthole Drill at an Open-Pit Coal Mine. Master’s Thesis, Queen’s University, Kingston, Canada, 2007. [Google Scholar]

- Beattie, N. Monitoring-While-Drilling for Open-Pit Mining in a Hard Rock Environment. Master’s Thesis, Queen’s University, Kingston, ON, Canada, 2009. [Google Scholar]

- Khorzoughi, M.B. Use of Measurement While Drilling Techniques for Improved Rock Mass Characterization in Open-Pit Mines. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 2011. [Google Scholar]

- Basarir, H.; Wesseloo, J.; Karrech, A.; Pasternak, E.; Dyskin, A. The Use of Soft Computing Methods for the Prediction of Rock Properties Based on Measurement While Drilling Data. In Deep Mining 2017: Proceedings of the Eighth International Conference on Deep and High Stress Mining; Australian Centre for Geomechanics: Perth, Australia, 2017; pp. 537–551. [Google Scholar] [CrossRef]

- Galende-Hernández, M.; Menéndez, M.; Fuente, M.J.; Sainz-Palmero, G.I. Monitor-While-Drilling-Based Estimation of Rock Mass Rating with Computational Intelligence: The Case of Tunnel Excavation Front. Autom. Constr. 2018, 93, 325–338. [Google Scholar] [CrossRef]

- Klyuchnikov, N.; Zaytsev, A.; Gruzdev, A.; Ovchinnikov, G.; Antipova, K.; Ismailova, L.; Muravleva, E.; Burnaev, E.; Semenikhin, A.; Cherepanov, A.; et al. Data-Driven Model for the Identification of the Rock Type at a Drilling Bit. J. Pet. Sci. Eng. 2019, 178, 506–516. [Google Scholar] [CrossRef]

- Khushaba, R.N.; Melkumyan, A.; Hill, A.J. A Machine Learning Approach for Material Type Logging and Chemical Assaying from Autonomous Measure-While-Drilling (MWD) Data. Math. Geosci. 2021, 54, 285–315. [Google Scholar] [CrossRef]

- Navarro, J.; Seidl, T.; Hartlieb, P.; Sanchidrián, J.A.; Segarra, P.; Couceiro, P.; Schimek, P.; Godoy, C. Blastability and Ore Grade Assessment from Drill Monitoring for Open Pit Applications. Rock Mech. Rock Eng. 2021, 54, 3209–3228. [Google Scholar] [CrossRef]

- Vezhapparambu, V.S.; Eidsvik, J.; Ellefmo, S.L. Rock Classification Using Multivariate Analysis of Measurement While Drilling Data: Towards a Better Sampling Strategy. Minerals 2018, 8, 384. [Google Scholar] [CrossRef]

- Silversides, K.L.; Melkumyan, A. Machine Learning for Classification of Stratified Geology from MWD Data. Ore Geol. Rev. 2022, 142, 104737. [Google Scholar] [CrossRef]

- Goldstein, D.; Aldrich, C.; O’Connor, L. Enhancing Orebody Knowledge Using Measure-While-Drilling Data: A Machine Learning Approach. IFAC Pap. 2024, 58, 72–76. [Google Scholar] [CrossRef]

- Schunnesson, H. Drill Process Monitoring in Percussive Drilling: A Multivariate Approach for Data Analysis. Licentiate Thesis, Lulea University of Technology, Lulea, Sweden, 1990. [Google Scholar]

- Schunnesson, H. RQD Predictions Based on Drill Performance Parameters. Tunn. Undergr. Space Technol. 1996, 11, 345–351. [Google Scholar] [CrossRef]

- Schunnesson, H. Rock Characterisation Using Percussive Drilling. Int. J. Rock Mech. Min. Sci. 1998, 35, 711–725. [Google Scholar] [CrossRef]

- Ghosh, R.; Gustafson, A.; Schunnesson, H. Development of a Geological Model for Chargeability Assessment of Borehole Using Drill Monitoring Technique. Int. J. Rock Mech. Min. Sci. 2018, 109, 9–18. [Google Scholar] [CrossRef]

- Ghosh, R. Assessment of Rock Mass Quality and Its Effects on Chargeability Using Drill Monitoring Technique. Ph.D. Thesis, Lulea University of Technology, Lulea, Sweden, 2017. [Google Scholar]

- Navarro, J.; Schunnesson, H.; Ghosh, R.; Segarra, P.; Johansson, D.; Sanchidrián, J.Á. Application of Drill-Monitoring for Chargeability Assessment in Sublevel Caving. Int. J. Rock Mech. Min. Sci. 2019, 119, 180–192. [Google Scholar] [CrossRef]

- King, R.L.; Hicks, M.A.; Signer, S.P. Using Unsupervised Learning for Feature Detection in a Coal Mine Roof. Eng. Appl. Artif. Intell. 1993, 6, 565–573. [Google Scholar] [CrossRef]

- Finfinger, G.; Peng, S.; Gu, Q.; Wilson, G.; Thomas, B. An Approach to Identifying Geological Properties from Roof Bolter Drilling Parameters. In Proceedings of the 19th Conference on Ground Control in Mining, Morgantown, WV, USA, 8–10 August 2000; pp. 1–12. [Google Scholar]

- Peng, S. Evaluation of Roof Bolting Requirements Based on In-Mine Roof Bolter Drilling. Ph.D. Thesis, West Virgina University, Morgantown, WV, USA, 2004. [Google Scholar]

- Van Eldert, J. Analysis of Excavation Damage, Rock Mass Characterisation and Rock Support Design Using Drilling Monitoring. Licentiate Thesis, Lulea University of Technology, Lulea, Sweden, 2018. [Google Scholar]

- Van Eldert, J. Drill Monitoring for Rock Mass Assessment in Tunnelling. Ph.D. Thesis, Lulea University of Technology, Lulea, Sweden, 2020. [Google Scholar]

- Liu, J. Jiankang Study on Intelligent Prediction Models of Geological Conditions Ahead of Tunnel Face Using Measurement-While-Drilling Data. Ph.D. Thesis, Nagasaki University, Nagasaki, Japan, 2021. [Google Scholar]

- Liu, J.; Jiang, Y.; Han, W.; Sakaguchi, O. Optimized ANN Model for Predicting Rock Mass Quality Ahead of Tunnel Face Using Measure-While-Drilling Data. Bull. Eng. Geol. Environ. 2021, 80, 2283–2305. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, Y.; Ishizu, S.; Sakaguchi, O. Estimation of Tunnel Support Pattern Selection Using Artificial Neural Network. Arab. J. Geosci. 2020, 13, 321. [Google Scholar] [CrossRef]

- Van Eldert, J.; Funehag, J.; Schunnesson, H.; Saiang, D. Drill Monitoring for Rock Mass Grouting: Case Study at the Stockholm Bypass. Rock Mech. Rock Eng. 2021, 54, 501–511. [Google Scholar] [CrossRef]

- Navarro, J.; Sanchidrián, J.A.; Segarra, P.; Castedo, R.; Costamagna, E.; López, L.M. Detection of Potential Overbreak Zones in Tunnel Blasting from MWD Data. Tunn. Undergr. Space Technol. 2018, 82, 504–516. [Google Scholar] [CrossRef]

- Costamagna, E.; Oggeri, C.; Vinai, R. Damage and Contour Quality in Rock Excavations for Quarrying and Tunnelling: Assessment for Properties and Solutions for Stability. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Turin, Italy, 20–25 September 2021. [Google Scholar]

- Zachos, D. Calculation of Penetration Depth of a Support Retaining System Anchored on the Top, for Underground Network and Buried Energy Pipelines. Energy Syst. 2024, 15, 1511–1526. [Google Scholar] [CrossRef]

- Silversides, K.L.; Melkumyan, A. Multivariate Gaussian Process for Distinguishing Geological Units Using Measure While Drilling Data. In Proceedings of the Mining Goes Digitial; Taylor and Francis Group: London, UK, 2019; pp. 94–100. [Google Scholar]

- Silversides, K.L.; Melkumyan, A. Boundary Identification and Surface Updates Using MWD. Math. Geosci. 2020. [Google Scholar] [CrossRef]

- Wold, S.; Esbensen, K.; Geladi, P. Principal Component Analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Lundberg, S.; Lee, S.-I. A Unified Approach to Interpreting Model Predictions. In Proceedings of the Advances in Neural Information Processing Systems 30, Long Beach, CA, USA, 4–9 December 2017; pp. 1–10. [Google Scholar]

- Liu, X.; Aldrich, C. Assessing the Influence of Operational Variables on Process Performance in Metallurgical Plants by Use of Shapley Value Regression. Metals 2022, 12, 1777. [Google Scholar] [CrossRef]

- Goldstein, D.; Aldrich, C.; Shao, Q.; O’Connor, L. A Machine Learning Classification Approach to Geotechnical Characterisation Using Measure-While-Drilling Data. Geosciences 2025, 15, 93. [Google Scholar] [CrossRef]

- Goldstein, D.; Aldrich, C.; Shao, Q.; O’Connor, L. Unlocking Subsurface Geology: A Case Study with Measure-While-Drilling Data and Machine Learning. Minerals 2025, 15, 241. [Google Scholar] [CrossRef]

- Ker, P. Iron Ore Supply Slump as Rio Runs Late on New Mines. Aust. Financ. Rev. 2021. [Google Scholar]

- De-Vitry, C.; Vann, J.; Arvidson, H. Multivariate Iron Ore Deposit Resource Estimation—A Practitioner’s Guide to Selecting Methods. Appl. Earth Sci. 2010, 119, 154–165. [Google Scholar] [CrossRef]

- Jones, H.; Walraven, F.; Knott, G. Natural Gamma Logging as an Aid to Iron Ore Exploration in the Pilbara Region of Western Australia. In Proceedings of the Australasian Institute of Mining and Metallurgy Annual Conference; Australasian Institute of Mining and Metallurgy: Perth, Australia, 1973. [Google Scholar]

- Khorzoughi, B.M.; Hall, R. Processing of Measurement While Drilling Data for Rock Mass Characterization. Int. J. Min. Sci. Technol. 2016, 26, 989–994. [Google Scholar] [CrossRef]

- Van Eldert, J.; Schunnesson, H.; Saiang, D.; Funehag, J. Improved Filtering and Normalizing of Measurement-While-Drilling (MWD) Data in Tunnel Excavation. Tunn. Undergr. Space Technol. 2020, 103, 103467. [Google Scholar] [CrossRef]

- Teale, R. The Concept of Specific Energy in Rock Drilling. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1965, 2, 57–73. [Google Scholar] [CrossRef]

- MATLAB; The MathWorks Inc.: Natick, MA, USA, 2024.

- Kursa, M.B.; Rudnicki, W.R. Feature Selection with the Boruta Package. J. Stat. Softw. 2010, 36. [Google Scholar] [CrossRef]

- Statistics and Machine Learning Toolbox; The MathWorks Inc.: Natick, MA, USA, 2024.

- Zhang, W.; Li, H.; Li, Y.; Liu, H.; Chen, Y.; Ding, X. Application of Deep Learning Algorithms in Geotechnical Engineering: A Short Critical Review. Artif. Intell. Rev. 2021, 54, 5633–5673. [Google Scholar] [CrossRef]

- Kotsiantis, S.B. Decision Trees: A Recent Overview. Artif. Intell. Rev. 2013, 39, 261–283. [Google Scholar] [CrossRef]

- Hearst, M.A.; Dumais, S.T.; Osuna, E.; Platt, J.; Scholkopf, B. Support Vector Machines. IEEE Intell. Syst. Their Appl. 1998, 13, 18–28. [Google Scholar] [CrossRef]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Schulz, E.; Speekenbrink, M.; Krause, A. A Tutorial on Gaussian Process Regression: Modelling, Exploring, and Exploiting Functions. J. Math. Psychol. 2018, 85, 1–16. [Google Scholar] [CrossRef]

- Bishop, C.M. Neural Networks and Their Applications. Rev. Sci. Instrum. 1994, 65, 1803–1832. [Google Scholar] [CrossRef]

- Regression Learner Toolbox; The MathWorks Inc.: Natick, MA, USA, 2024.

- Scoble, M.J.; Peck, J. A Technique for Ground Characterization Using Automated Production Drill Monitoring. Int. J. Surf. Min. Reclam. Environ. 1987, 1, 41–54. [Google Scholar] [CrossRef]

| Type | MWD Features | |||

|---|---|---|---|---|

| Recorded | rop | tor | fob | bap |

| Ratio | roptor ropfob ropbap | torrop torfob torbap | fobrop fobtor fobbap | baprop baptor bapfob |

| Moving Standard Deviation | ropS | torS | fobS | bapS |

| Geotechnical Measurements | BR | MM | ||||||

|---|---|---|---|---|---|---|---|---|

| Measured | Engineered | Measured | Engineered | |||||

| RMSE | R2 | RMSE | R2 | RMSE | R2 | RMSE | R2 | |

| Unconfined Compressive Strength (MPa) | 14.38 | 0.86 | 9.31 | 0.94 | 23.56 | 0.38 | 13.95 | 0.78 |

| Fracture Per Meter | 2.88 | 0.82 | 1.32 | 0.96 | 4.98 | 0.61 | 2.87 | 0.87 |

| Geological Strength Index | 7.96 | 0.79 | 2.56 | 0.98 | 6.78 | 0.43 | 3.23 | 0.87 |

| Regression-Based ML Method | BR | MM | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Train | Test | Train | Test | |||||||

| RMSE | R2 | Time (s) | RMSE | R2 | RMSE | R2 | Time | RMSE | R2 | |

| DT | 13.2 | 0.89 | 8 | 12.4 | 0.90 | 18.5 | 0.61 | 2.3 | 21.88 | 0.46 |

| SVM | 11.9 | 0.91 | 7 | 11.9 | 0.91 | 16.8 | 0.68 | 7.5 | 17.84 | 0.64 |

| RF | 9.7 | 0.94 | 60 | 9.3 | 0.94 | 13.3 | 0.8 | 66.1 | 13.95 | 0.78 |

| GP | 12.2 | 0.91 | 4 | 10.4 | 0.93 | 1.2 | 0.66 | 2.4 | 18.28 | 0.62 |

| NN | 7.7 | 0.96 | 517 | 7.7 | 0.96 | 10.3 | 0.88 | 184 | 11.95 | 0.84 |

| Regression-Based ML Method | BR | MM | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Train | Test | Train | Test | |||||||

| RMSE | R2 | Time (s) | RMSE | R2 | RMSE | R2 | Time | RMSE | R2 | |

| DT | 2.0 | 0.93 | 2 | 1.7 | 0.94 | 4.8 | 0.59 | 2 | 5.5 | 0.53 |

| SVM | 1.8 | 0.94 | 9 | 1.6 | 0.94 | 3.9 | 0.73 | 7 | 3.9 | 0.76 |

| RF | 1.3 | 0.97 | 77 | 1.3 | 0.96 | 3.1 | 0.84 | 59 | 2.9 | 0.87 |

| GP | 1.7 | 0.94 | 4 | 1.8 | 0.93 | 3.1 | 0.84 | 4 | 3.2 | 0.84 |

| NN | 1.0 | 0.98 | 279 | 1.0 | 0.98 | 2.4 | 0.9 | 206 | 2.2 | 0.93 |

| Regression-Based ML Method | BR | MM | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Train | Test | Train | Test | |||||||

| RMSE | R2 | Time (s) | RMSE | R2 | RMSE | R2 | Time (s) | RMSE | R2 | |

| DT | 4.3 | 0.94 | 2 | 4.3 | 0.94 | 5.9 | 0.64 | 2 | 5.1 | 0.68 |

| SVM | 3.7 | 0.95 | 8 | 3.2 | 0.97 | 4.6 | 0.78 | 8 | 3.8 | 0.82 |

| RF | 2.6 | 0.98 | 80 | 2.6 | 0.98 | 3.6 | 0.86 | 60 | 3.2 | 0.87 |

| GP | 3.2 | 0.96 | 5 | 2.9 | 0.97 | 3.6 | 0.86 | 3 | 3.0 | 0.89 |

| NN | 2.0 | 0.99 | 255 | 2.0 | 0.99 | 2.9 | 0.91 | 297 | 2.4 | 0.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goldstein, D.; Aldrich, C.; Shao, Q.; O’Connor, L. A Field-Scale Framework for Assessing the Influence of Measure-While-Drilling Variables on Geotechnical Characterization Using a Boruta-SHAP Approach. Mining 2025, 5, 20. https://doi.org/10.3390/mining5010020

Goldstein D, Aldrich C, Shao Q, O’Connor L. A Field-Scale Framework for Assessing the Influence of Measure-While-Drilling Variables on Geotechnical Characterization Using a Boruta-SHAP Approach. Mining. 2025; 5(1):20. https://doi.org/10.3390/mining5010020

Chicago/Turabian StyleGoldstein, Daniel, Chris Aldrich, Quanxi Shao, and Louisa O’Connor. 2025. "A Field-Scale Framework for Assessing the Influence of Measure-While-Drilling Variables on Geotechnical Characterization Using a Boruta-SHAP Approach" Mining 5, no. 1: 20. https://doi.org/10.3390/mining5010020

APA StyleGoldstein, D., Aldrich, C., Shao, Q., & O’Connor, L. (2025). A Field-Scale Framework for Assessing the Influence of Measure-While-Drilling Variables on Geotechnical Characterization Using a Boruta-SHAP Approach. Mining, 5(1), 20. https://doi.org/10.3390/mining5010020