Use and Recovery of Extractive Waste and Tailings for Sustainable Raw Materials Supply

Abstract

1. Introduction: Raw Material and Critical Raw Materials Supply

- Supply risks, which are the risks connected to the decreases in the production of most of the industrial sectors (in particular, hi-tech and clean technologies) in case any problem occurs in the supply of feeding materials for industries. A high potential of RMs is still available in Europe, but there is a lot of competition among those who want to explore and extract RMs due to strict environmental regulations and different land uses. CRMs are not widely present in the EU, as they are mainly present and exploited in China, Russia, South Africa, Brazil, and the U.S.

- Economic importance, which is closely linked to their importance for the development of modern technologies, especially in cases where no viable substitution possibilities have yet been found and where CRMs drive innovation. For example, an effective alternative technology to Li–ion batteries for electric cars and e-bikes has not yet been clearly identified [4,6].

- Environmental reliability. When dealing with RM/CRM exploitation, it is fundamental to guarantee the environmental preservation of the particular area from extraction and processing activities (https://single-market-economy.ec.europa.eu/sectors/raw-materials/areas-specific-interest/critical-raw-materials_en, accessed on the 15 November 2023).

- Reduce the extraction of natural resources (in line with the EU pillar concerning natural resources preservation).

- Reduce the number and typologies of landfills (including extractive waste facilities).

- Reduce the environmental and human health impacts connected to waste management and landfilling (in line with the EU pillar concerning environmental protection).

- Recover RMs/CRMs from waste (in line with the EU pillar concerning waste recycling).

- Metals, in general, are fundamental for industrial development. Fe, for example, is employed in steel production, paint industry, and magnet production; Al (light and resistant) in car and airplane production; Cu (high electric conductivity) is employed for electric devices and line production; Ti (light and resistant) is used in several applications in airplane production and in medical devices; Au (high conductibility and corrosion resistance) is used not only in the jewelry sector but also in the electrical industry and for airplane windows; Ag (high thermic and electric conductivity) is applied in a range of electrical and electronic applications, including electrical contacts and printed circuit boards, and in medical applications due to its antibacterial properties. Other metals such as Zn and Ni were and still are crucial for the EU economy (Ni is used for Ni–Cd batteries and in super alloys for electric power stations or for airplane turbines), together with some CRMs, which can be associated to those whose importance has increased over the last decades (e.g., PGEs are associated with Ni; Cd, Ge, Ga, and In are associated with Zn–Pb ore deposits). Metals can be exploited from natural ore deposits (still present in the EU countries) and from anthropogenic deposits, such as industrial and urban landfills and extractive waste facilities, which potentially store massive amounts of strategically important materials [10].

- Industrial minerals are crucial for a country’s development across various sectors. They have applications in construction (clay for bricks, calcium carbonate for mortars, and gypsum for plasterboard), industries (feldspar, kaolin, and quartz for ceramics and glass), and environmental uses (clay/bentonite as a waterproof material for landfills). Agriculture benefits from minerals like zeolite for soil pH regulation and a slow nutrient release. In animal feeding, calcium carbonate is utilized as food supplement for skeletal and enzyme system support. It has to be highlighted that, principally due to the present fight between Russia and Ukraine, feldspar in 2023 has been included in the list of CRMs. Further to this, feldspar and kaolin can be associated with REE, which could be exploited as an “associated product” of the principal ones.

- Aggregates are very important for the European industry because of their wide application fields, such as:

- Aggregates for concrete: used in construction, building, and infrastructure sectors.

- Railway ballast used in railway construction.

- Bituminous aggregate for road construction.

- Aggregate for subfloor layers used in railway and road construction.

- Armour stones and rip rap applied for environmental purposes.

2. Extractive Waste Production

2.1. Extractive Waste Facilities: From Site Investigation to EW Characterization (Physical, Geochemical, and Mineralogical Characteristics)

- History of the mining site.

- Depth and extension of the facility bodies.

- Site investigation.

- Typology of EW materials (waste rocks, operating residues, tailings, or mix).

- Waste characterization.

- Geotechnical stability.

- Presence of possible hazardous waste placed in the landfills.

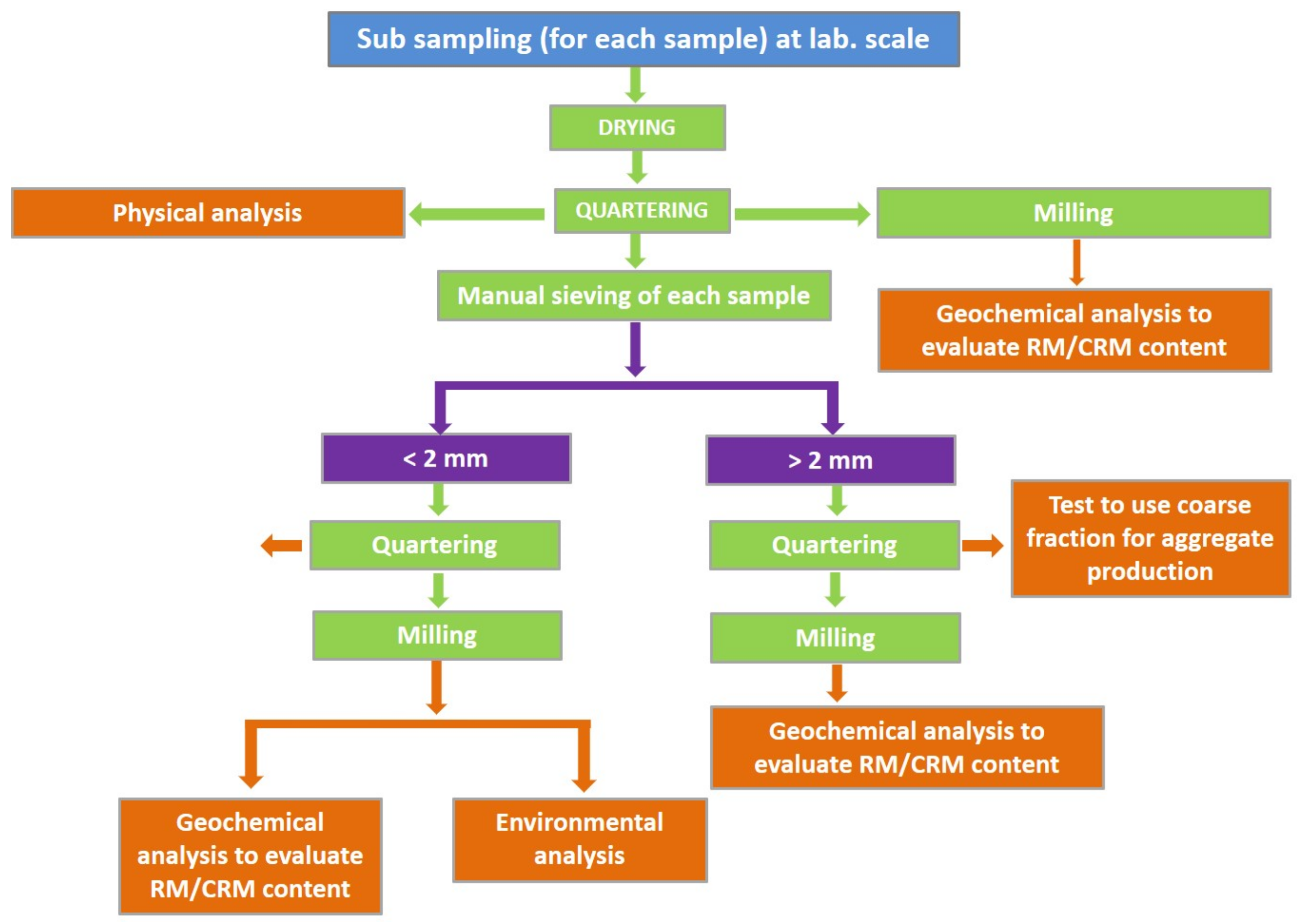

- Physical characterization includes EW basic characteristics, such as humidity (after drying the samples in an oven for about 24 h), bulk density and size distribution (e.g., wet particle-size analysis), and magnetic attitudes. EW characteristics are useful for the construction industry (i.e., for aggregate production), including flat index, shape index, the Los Angeles test, the micro-Deval test, the freeze–thaw test, fine-particle content, Atterberg limits, etc.

- Petrographic characterization to determine the composition and properties of the mineral in the waste fractions. Petrographic observations can be performed by optical (transmitted and reflected-light) microscopy on thin-polished sections. Quantitative volume percentage determinations (i.e., modal analyses) can also be required in some cases.

- Mineralogical characterization is important because the potential exploitation of RMs and CRMs from the rock is strongly linked to its mineralogy (some minerals show a better attitude to be processed for RM/CRM extraction). Thus, only certain minerals are viable for exploitation because they are economically exploitable using existing processing techniques. This analysis can be conducted through scanning electron microscopy (SEM-EDS/WDS) and/or the X-ray powder-diffraction technique (XRPD). Other types of spectroscopic analyses (e.g., micro-Raman spectroscopy) may be required in some cases.

- Geochemical characterization to evaluate RM/CRM content on representative samples (<2 mm) obtained after grinding the original sample. Whole-rock geochemical analysis can be performed with varied spectroscopic techniques, i.e., XRF for major elements, ICP-AES and ICP-MS for minor and trace elements, and electron microscopy (SEM-EDS/WDS) on polished and metalized sections/samples [16,17].

2.2. Extractive Waste Volume Evaluation (New Technologies for EW Facility Investigation)

3. Issues and Potentialities Connected to EW Management

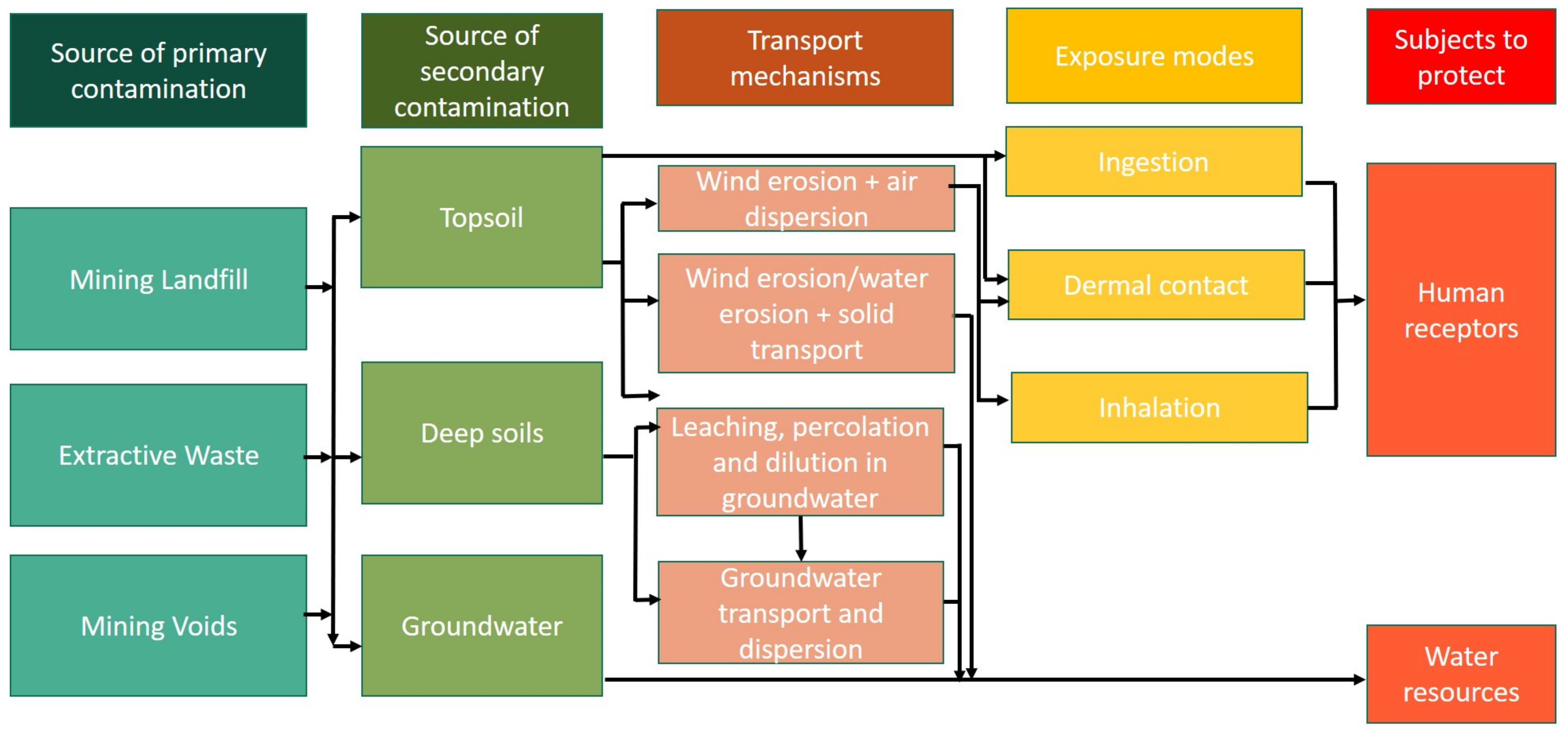

3.1. Environmental Issues

3.2. Raw Materials, Critical Raw Materials, and Secondary Raw Materials (RM/CRM/SRM) Present in EW Facilities, including Tailing Deposits

4. Remarks and Future Perspectives

- First of all, legislative initiatives to reduce the quantity of extractive waste during mining, quarrying, and processing should be adopted.

- Second, there are policy opportunities to provide financial incentives to better improve recovery processes and the reuse of EW.

- Finally, the research funding programs may be used to find suitable alternatives and substitutes for CRM. This is important because they provide an opportunity to explore other options, especially those that may be more sustainable from all social, environmental, and economic points of view.

5. Conclusions

- Importance of Planning and Risk Assessment:

- Proper planning and risk assessment are crucial for sustainable mining waste management, whether in the planning of new mining operations or during the closure phase.

- Risk assessment, verification, and monitoring are essential components for a sustainable approach.

- Value of Extractive Waste:

- Extractive waste facilities represent “anthropogenic ore deposits”, and understanding their contents and characteristics is vital for potential resource recovery.

- Sampling activities and tests on recoverable fractions are necessary to determine the quantity and quality of recoverable resources.

- Challenges in Reuse and Recycling:

- While there is interest in reusing and recycling extractive waste, economic feasibility remains a challenge.

- Legislative initiatives, financial incentives, and research funding are proposed to encourage recovery processes.

- Role of Emerging Technologies:

- Emerging technologies like Artificial Intelligence (AI), machine learning, and autonomous technologies can contribute to economic benefits, cost reduction, efficiency, and improved productivity in the mining sector.

- Circular Economy and Landfill Mining:

- The principles of the circular economy and landfill mining are considered effective approaches to waste management and resource recovery.

- The systematic recovery of resources from extractive waste aligns with sustainable exploitation and integrates resource needs for EU development.

- Best Available Techniques (BAT) and Environmental Management Practices:

- BAT Reference Document for the Management of Waste from Extractive Industries provides guidance for managing extractive waste based on site-specific characteristics and environmental-risk assessments.

- Environmental management practices and guidelines have been developed in various countries to address different environmental and human health aspects.

- Risk Management and Site-Specific Analysis:

- Site-specific risk analysis is essential for proactively managing risks associated with various phases of mining activities.

- Risk-management tools and techniques have evolved over the last 20 years to assess risks related to the construction, operation, and closure of mining facilities.

- Interdisciplinary Approach and Sustainability:

- Real sustainability in the mining sector requires an interdisciplinary approach, considering technical, environmental, social, and economic aspects.

- Actions proposed at both global and European levels emphasize the importance of sustainability reports, corporate social responsibility (CSR), and sustainable finance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jones, B.; Elliott, R.J.R.; Nguyen-Tien, V. The EV revolution: The road ahead for critical raw materials demand. Appl. Energy 2020, 280, 115072. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, M.; Hofmann, H.; Hagelüken, C.; Hool, A. Critical raw materials: A perspective from the materials science community. Sustain. Mater. Technol. 2018, 17, e00074. [Google Scholar] [CrossRef]

- Charalampides, G.; Vatalis, K.I.; Apostoplos, B.; Ploutarch-Nikolas, B. Rare Earth Elements. Industrial Applications and Economic Dependency of Europe. Procedia Econ. Financ. 2015, 24, 126–135. [Google Scholar] [CrossRef]

- Olivetti, E.A.; Ceder, G.; Gaustad, G.G.; Fu, X. Lithium-ion battery supply chain considerations: Analysis of potential bottlenecks in critical metals. Joule 2017, 1, 229–243. [Google Scholar] [CrossRef]

- Grandell, L.; Lehtilä, A.; Kivinen, M.; Koljonen, T.; Kihlman, S.; Lauri, L.S. Role of critical metals in the future markets of clean energy technologies. Renew. Energy 2016, 95, 53–62. [Google Scholar] [CrossRef]

- Glushenkov, A. Recent commentaries on the expected performance, advantages and applications of sodium-ion batteries. Energy Mater. 2023, 3, 300010. [Google Scholar]

- European Commission. Study on the Critical Raw Materials for the EU 2023; Final Report; European Commission: Brussels, Belgium, 2023; p. 160. [Google Scholar] [CrossRef]

- Jones, P.T.; Geysen, D.; Tielemans, Y.; Van Passel, S.; Pontikes, Y.; Blanpain, B.; Quaghebeur, M.; Hoekstra, N. Enhanced Landfill Mining in view of multiple resource recovery: A critical review. J. Clean. Prod. 2013, 55, 45–55. [Google Scholar] [CrossRef]

- Černý, I.; Vaněk, M.; Maruszewska, E.W.; Beneš, F. How economic indicators impact the EU internal demand for critical raw materials. Resour. Policy 2021, 74, 102417. [Google Scholar] [CrossRef]

- Dino, G.A.; Rossetti, P.; Perotti, P.; Alberto, W.; Sarkka, H.; Coulon, F.; Wagland, S.; Griffiths, Z.; Rodeghiero, F. Landfill mining from extractive waste facilities: The importance of a correct site characterization and evaluation of the potentialities. A case study from Italy. Resour. Policy 2018, 59, 564. [Google Scholar] [CrossRef]

- DG Environment, European Commission. BRGM: Management of Mining, Quarrying and Ore-Processing Waste in the European Union; BRGM/RP-50319-FR; DG Environment, European Commission: Brussels, Belgium, 2001; p. 88. [Google Scholar]

- EUROSTAT 2021. Eurostat Statistic Explained—Waste Generation. Waste Statistics—Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics (accessed on 24 April 2023).

- Lottermoser, B. Mine Wastes: Characterization, Treatment, and Environmental Impacts, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- European Commission. Extractive Waste Directive 2006/21/EC. Directive 2006/21/EC of the European Parliament and of the Council of 15 March 2006 on the Management of Waste from Extractive Industries and Amending Directive 2004/35/EC; European Commission: Brussels, Belgium, 2006. [Google Scholar]

- Dino, G.A.; Rossetti, P.; Biglia, G.; Coulon, F.; Gomes, D.; Wagland, S.; Luste, S.; Särkkä, H.; Ver, C.; Delafeld, M.; et al. SMART GROUND Project. Energy Procedia 2016, 97, 15–22. [Google Scholar] [CrossRef]

- Revuelta, M.B. Mineral Resources: From Exploration to Sustainability Assessment; Springer: Cham, Switzerland, 2018; ISBN 978-3-319-58758-5. [Google Scholar]

- Blengini, G.A.; Mathieux, F.; Mancini, L.; Nyberg, M.; Viegas, H.M. Recovery of Critical and Other Raw Materials from Mining Waste and Landfills: State of Play on Existing Practices; Publications Office of the European Union: Luxembourg, 2019; ISBN 978-92-76-08568-3. [Google Scholar]

- Smith, M.V.; Carrivick, J.L.; Quincey, D.J. Structure from motion photogrammetry. Phys. Geogr. 2015, 40, 247–275. [Google Scholar] [CrossRef]

- Blanchette, M.L.; Lund, M.A. Pit lakes are a global legacy of mining: An integrated approach to achieving sustainable ecosystems and value for communities. Curr. Opin. Environ. Sustain. 2016, 23, 28–34. [Google Scholar] [CrossRef]

- Castagna, S.; De Luca, D.A.; Lasagna, M. Eutrophication of Piedmont quarry lakes (north-western Italy): Hydrogeological factors, evaluation of trophic levels and management strategies. J. Environ. Account. Manag. 2015, 17, 1550036. [Google Scholar] [CrossRef]

- McCullough, C.D.; Schultze, M.; Vandenberg, J. Realizing Beneficial End Uses from Abandoned Pit Lakes. Minerals 2020, 10, 133. [Google Scholar] [CrossRef]

- Lim, M.; Han, G.C.; Ahn, J.W.; You, K.S.; Kim, H.S. Leachability of Arsenic and Heavy Metals from Mine Tailings of Abandoned Metal Mines. Int. J. Environ. Res. Public. Health 2009, 6, 2865–2879. [Google Scholar] [CrossRef] [PubMed]

- Heim, S.; Schwarzbauer, J.; Kronimus, A.; Littke, R.; Woda, C.; Mangini, A. Geochronology of Anthropogenic Pollutants in Riparian Wetland Sediments of the Lippe River (Germany). Org. Geochem. 2004, 35, 1409–1425. [Google Scholar] [CrossRef]

- Yolcubal, I.; Demiray, A.D.; Çiftçi, E.; Sanğu, E. Environmental impact of mining activities on surface water and sediment qualities around Murgul copper mine, Northeastern Turkey. Environ. Earth Sci. 2016, 75, 1–25. [Google Scholar] [CrossRef]

- Yalcin, M.G.; Aydin, O.; Elhatip, H. Heavy metal contents and the water quality of Karasu Creek in Nigde, Turkey. Environ. Monit. Assess. 2008, 137, 169–178. [Google Scholar] [CrossRef]

- Çullu, M.; Ertaş, H. Determination of the effect of lead mine waste aggregate on some concrete properties and radiation shielding. Constr. Build. Mater. 2016, 125, 625–631. [Google Scholar] [CrossRef]

- Torres, E.; Lozano, A.; Macías, F.; Gomez-Arias, A.; Castillo, J.; Ayora, C. Passive elimination of sulfate and metals from acid mine drainage using combined limestone and barium carbonate systems. J. Clean. Prod. 2018, 182, 114–123. [Google Scholar] [CrossRef]

- Pat-Espadas, A.M.; Loredo Portales, R.; Amabilis-Sosa, L.E.; Gómez, G.; Vidal, G. Review of Constructed Wetlands for Acid Mine Drainage Treatment. Water 2018, 10, 1685. [Google Scholar] [CrossRef]

- Sapford, D.; Brabham, P.; Crane, R.; Evans, D.; Statford, A.; Wright, A. Mine Waste Resources Assessment and Appraisal of Recovery via Mine Water. In Proceedings of the IMWA 2017-13th International Mine Water Association Congress—Mine Water & Circular Economy, Lappeenranta, Finland, 25–30 June 2017; pp. 956–963. [Google Scholar]

- Wang, Z.; Zhou, W.; Jiskani, I.M.; Luo, H.; Zhongchen Ao Mvula, E.M. Annual dust pollution characteristics and its prevention and control for environmental protection in surface mines. Sci. Total Environ. 2022, 825, 153949. [Google Scholar] [CrossRef]

- Béjaoui, I.; Kolsi-Benzina, N.; Sappin-Didier, V.; Munoz, M. Health Risk Assessment in Calcareous Agricultural Soils Contaminated by Metallic Mining Activity under Mediterranean Climate. CLEAN–Soil Air Water 2016, 44, 1385–1395. [Google Scholar] [CrossRef]

- Silva, D.; Weber, C.; Oliveira, C. Neutralization and uptake of pollutant cations from acid mine drainage (AMD) using limestones and zeolites in a pilot-scale passive treatment system. Miner. Eng. 2021, 170, 107000. [Google Scholar] [CrossRef]

- Masindi, V. Recovery of drinking water and valuable minerals from acid mine drainage using an integration of magnesite, lime, soda ash, CO2 and reverse osmosis treatment processes. J. Environ. Chem. Eng. 2017, 5, 3136–3142. [Google Scholar] [CrossRef]

- Gupta, V.; Courtemanche, J.; Gunn, J.; Mykytczuk, N. Shallow floating treatment wetland capable of sulfate reduction in acid mine drainage impacted waters in a northern climate. J. Environ. Manag. 2020, 263, 110351. [Google Scholar] [CrossRef]

- Öztürk, Y.; Ekmekçi, Z. Removal of sulfate ions from process water by ion exchange resins. Miner. Eng. 2020, 159, 106613. [Google Scholar] [CrossRef]

- Thomas, G.; Sheridan, C.; Holm, P.E. A critical review of phytoremediation for acid mine drainage-impacted environments. Sci. Total Environ. 2022, 811, 152230. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, J.; Li, Z.; Wang, H.; He, X.; Wang, C. A novel method based on membrane distillation for treating acid mine drainage: Recovery of water and utilization of iron. Chemosphere 2021, 279, 130605. [Google Scholar] [CrossRef] [PubMed]

- Foureaux, A.F.S.; Moreira, V.R.; Lebron, Y.A.R.; Santos, L.V.S.; Amaral, M.C.S. Direct contact membrane distillation as an alternative to the conventional methods for value-added compounds recovery from acidic effluents: A review. Sep. Purif. Technol. 2020, 236, 116251. [Google Scholar] [CrossRef]

- Aguiar, A.; Andrade, L.; Grossi, L.; Pires, W.; Amaral, M. Acid mine drainage treatment by nanofiltration: A study of membrane fouling, chemical cleaning, and membrane ageing. Sep. Purif. Technol. 2018, 192, 185–195. [Google Scholar] [CrossRef]

- Mehta, N.; Dino, G.A.; Ajmone-Marsan, F.; Lasagna, M.; Romè, C.; De Luca, D.A. Extractive waste management: A risk analysis approach. Sci. Total Environ. 2018, 622–623, 900–912. [Google Scholar] [CrossRef] [PubMed]

- Tubis, A.; Werbinska-Wojciechowska, S.; Wroblewski, A. Risk Assessment Methods in Mining Industry—A Systematic Review. Appl. Sci. 2020, 10, 5172. [Google Scholar] [CrossRef]

- Zelenakova, M.; Pintilii, R.; Peptenatu, D.; Zvijáková, L. Risk analysis within environmental impact assessment: A review. In Proceedings of the 17th International Multidisciplinary Scientific GeoConference SGEM2017, Albena, Bulgaria, 29 June–5 July 2017. [Google Scholar] [CrossRef]

- Alvarenga, P.; Guerreiro, N.; Simões, I.; Imaginário, M.J.; Palma, P. Assessment of the Environmental Impact of Acid Mine Drainage on Surface Water, Stream Sediments, and Macrophytes Using a Battery of Chemical and Ecotoxicological Indicators. Water 2021, 13, 1436. [Google Scholar] [CrossRef]

- ISPRA. Gerarchizzazione Dei Siti Minerari Censiti. 2012. Available online: https://www.isprambiente.gov.it/files/miniere/gerarchizzazione-siti-minerari-ecologico.pdf (accessed on 18 December 2022).

- APAT. “Criteri Metodologici Per L’applicazione Dell’analisi Assoluta Di Rischio Ai Siti Contaminati”. 2008. Available online: https://www.isprambiente.gov.it/files/temi/siti-contaminati-02marzo08.pdf (accessed on 18 December 2022).

- Whitworth, A.J.; Forbes, E.; Verster, I.; Jokovic, V.; Awatey, B.; Parbhakar-Fox, A. Review on advances in mineral processing technologies suitable for critical metal recovery from mining and processing wastes. Clean. Eng. Technol. 2022, 7, 100451. [Google Scholar] [CrossRef]

- Dino, G.A.; Mehta, N.; Rossetti, P.; Ajmone-Marsan, F.; De Luca, D.A. Sustainable approach towards extractive waste management: Two case studies from Italy. Resour. Policy 2018, 59, 33–43. [Google Scholar] [CrossRef]

- Rendu, J.M. An introduction to cut-off grade estimation. In Mining, Metallurgy and Exploration; Society for Mining Metallurgy: Englewood, CO, USA, 2014. [Google Scholar]

- Rajaram, R.; Melchers, R.E. Chapter 6: Waste Management. In Sustainable Mining Practices—A Global Perspective; Rajaram, V., Dutta, S., Eds.; Taylor & Francis Group: Leiden, The Netherlands, 2005; pp. 193–230. [Google Scholar]

- Valeev, D.; Kondratiev, A.; Pan, J. Advances in Mineral Processing, Waste Recycling and Extractive Metallurgy. Materials 2024, 17, 133. [Google Scholar] [CrossRef]

- Makhathini, T.P.; Bwapwa, J.K.; Mtsweni, S. Various Options for Mining and Metallurgical Waste in the Circular Economy: A Review. Sustainability 2023, 15, 2518. [Google Scholar] [CrossRef]

- Sokratidou, A.; Roumpos, C.; Paraskevis, N.; Servou, A.; Pavloudakis, F. Extractive Waste Management in Coal Surface Mining Projects—A Circular Economy Approach. Mater. Proc. 2023, 15, 13. [Google Scholar] [CrossRef]

- European Commission. Reference Document on Best Available Techniques for Management of Tailings and Waste-Rock in Mining Activities; European Commission: Brussels, Belgium, 2009. [Google Scholar]

- Garbarino, E.; Orveillon, G.; Saveyn, H.G.M.; Barthe, P.; Eder, P. Best Available Techniques (BAT) Reference Document for the Management of Waste from Extractive Industries; JRC Science for Policy Report; European Commission: Brussels, Belgium, 2018; p. 722. [Google Scholar] [CrossRef]

- Gadioli, M.C.B.; de Aguiar, M.C.; Vidal, F.W.H.; Sant’Ana, M.A.K.; de Almeida, K.M.; Giori, A.J.N. Incorporation of Ornamental Stone Waste in the Manufacturing of Red Ceramics. Materials 2022, 15, 5635. [Google Scholar] [CrossRef]

- Prochorov, S. Crushed Stone Waste Use in Building Materials Production. In Fundamental and Applied Scientific Research in the Development of Agriculture in the Far East; E3S Web of Conferences: Tashkent, Uzbekistan, 2023; Volume 371, p. 06015. [Google Scholar] [CrossRef]

- Nega, D.M.; Yifru, B.W.; Taffese, W.Z.; Ayele, Y.K.; Yehualaw, M.D. Impact of Partial Replacement of Cement with a Blend of Marble and Granite Waste Powder on Mortar. Appl. Sci. 2023, 13, 8998. [Google Scholar] [CrossRef]

- El-Hakeem, A.A.; Souaya, E.R.; Ismail Ali, I.M. Utilization of Granite and Limestone Wastes as Aggregates in Concrete. Egypt. J. Geol. 2023, 67, 261–273. [Google Scholar] [CrossRef]

- Dino, G.A.; Cavallo, A.; Rossetti, P.; Garamvölgyi, E.; Sándor, R.; Coulon, F. Towards Sustainable Mining: Exploiting Raw Materials from Extractive Waste Facilities. Sustainability 2020, 12, 2383. [Google Scholar] [CrossRef]

- Menezes, R.R.; Santana, L.N.L.; Neves, G.A.; Ferreira, H.C. Recycling of Mine Wastes as Ceramic Raw Materials: An Alternative to Avoid Environmental Contamination. In Environmental Contamination; IntechOpen: London, UK, 2012; pp. 199–220. [Google Scholar] [CrossRef][Green Version]

- Montero, M.A.; Jordán, M.M.; Almendro-Candel, M.B.; Sanfeliu, M.S.; Hernández-Crespo, M.S. The use of a calcium carbonate residue from the stone industry in manufacturing of ceramic tile bodies. Appl. Clay Sci. 2009, 43, 186–189. [Google Scholar] [CrossRef]

- Dino, G.A.; Cavallo, A.; Faraudello, A.; Rossi, P.; Mancini, S. Raw materials supply: Kaolin and quartz from ore deposits and recycling activities. The example of the Monte Bracco area (Piedmont, Northern Italy). Resour. Policy 2021, 74, 102413. [Google Scholar] [CrossRef]

- André, A.; De Brito, J.; Rosa, A.; Pedro, D. Durability performance of concrete incorporating coarse aggregates from marble industry waste. J. Clean. Prod. 2014, 65, 389–396. [Google Scholar] [CrossRef]

- Careddu, N.; Siotto, G.; Siotto, R.; Tilocca, G. From landfill to water, land and life: The creation of the Centre for stone materials aimed at secondary processing. Resour. Policy 2013, 38, 258–265. [Google Scholar] [CrossRef]

- Gencel, O.; Ozel, C.; Koksal, F.; Erdogmus, E.; Martínez-Barrera, G.; Brostow, W. Properties of concrete paving blocks made with waste marble. J. Clean. Prod. 2012, 21, 62–70. [Google Scholar] [CrossRef]

- Hefni, M.; Ahmed, H.A.M.; Omar, E.S.; Ali, M.A. The Potential Re-Use of Saudi Mine Tailings in Mine Backfill: A Path towards Sustainable Mining in Saudi Arabia. Sustainability 2021, 13, 6204. [Google Scholar] [CrossRef]

- Gorakhki, M.H.; Bareither, C.A. Sustainable Reuse of Mine Tailings and Waste Rock as Water-Balance Covers. Minerals 2017, 7, 128. [Google Scholar] [CrossRef]

- Kinnunen, P.; Ismailov, A.; Solismaa, S.; Sreenivasan, H.; Räisänen, M.; Levänen, E.; Illikainen, M. Recycling mine tailings in chemically bonded ceramics—A review. J. Clean. Prod. 2018, 174, 634–649. [Google Scholar] [CrossRef]

- Mendes, B.; Pedroti, L.G.; Fontes, M.; Ribeiro, J.C.; Vieira, C.M.F.; Pacheco, A.A.; de Azevedo, A.R.G. Technical and environmental assessment of the incorporation of iron ore tailings in construction clay bricks. Constr. Build. Mater. 2019, 227, 116669. [Google Scholar] [CrossRef]

- Scribot, C.; Maherzi, W.; Benzerzour, M.; Mamindy-Pajany, Y.; Abriak, N.E. A laboratory-scale experimental investigation on the reuse of a modified red mud in ceramic materials production. Constr. Build. Mater. 2018, 163, 21–31. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, T.; Lyu, G.; Guo, F.; Zhang, W.; Zhang, Y. Recovery of alkali and alumina from bauxite residue (red mud) and complete reuse of the treated residue. J. Clean. Prod. 2018, 188, 456–465. [Google Scholar] [CrossRef]

- Afonso, P.; Pires, V.; Faria, P.; Azzalini, A.; Lopes, L.; Mourão, P.; Martins, R. A Novel Approach for the Reuse of Waste from the Extractive and Processing Industry of Natural Stone Binders: Development of Stone Composites. Sustainability 2024, 16, 64. [Google Scholar] [CrossRef]

- Afonso, P.; Azzalini, A.; Faria, P.; Lopes, L.; Martins, R.; Mourão, P.; Pires, V. Mortar Based on Sludge from Carbonate Dimension Stone Processing Industry—An Experimental and Feasibility Approach. In Proceedings of the Geo-Resilience Conference; The British Geotechnical Association: London, UK, 2023. [Google Scholar]

- Careddu, N.; Marras, G. Marble processing for future uses of CaCO3-microfine dust: A study on wearing out of tools and consumable materials in stone working factories. Miner. Process. Extr. Metall. 2015, 36, 183–191. [Google Scholar] [CrossRef]

- Mancini, S.; Casale, M.; Rossi, P.; Faraudello, A.; Dino, G.A. Operative instruments to support public authorities and industries for the supply of raw materials: A decision support tool to evaluate the sustainable exploitation of extractive waste facilities. Resour. Policy 2023, 81, 103338. [Google Scholar] [CrossRef]

- Song, X.; Pettersen, J.B.; Pedersen, K.B.; Røberg, S. Comparative life cycle assessment of tailings management and energy scenarios for a copper ore mine: A case study in Northern Norway. J. Clean. Prod. 2017, 64, 892–904. [Google Scholar] [CrossRef]

- Beylot, A.; Bordenan, F.; Guezennec, A.-G.; Muller, S. LCA as a support to more sustainable tailings management: Critical review, lessons learnt and potential way forward. Resour. Conserv. Recycl. 2022, 183, 106347. [Google Scholar] [CrossRef]

- Bellenfant, G.; Guezennec, A.G.; Bodenan, F.; D’Hugues, P.; Cassard, D. Reprocessing of mining waste: Combining environmental management and metal recovery. In Proceedings of the Eighth International Seminar on Mine Closure, Mine Closure; Tibbett, M., Fourie, A.B., Digby, C., Eds.; Australian Centre for Geomechanics: Cornwall, UK, 2013; pp. 571–582. [Google Scholar] [CrossRef]

- Žibret, G.; Lemiere, B.; Mendez, A.-M.; Cormio, C.; Sinnett, D.; Cleall, P.; Szabó, K.; Carvalho, M.T. National Mineral Waste Databases as an Information Source for Assessing Material Recovery Potential from Mine Waste, Tailings and Metallurgical Waste. Minerals 2020, 10, 446. [Google Scholar] [CrossRef]

- Tang, D.; Watkins, A. Ecologies of Gold. Places J. 2011. [Google Scholar] [CrossRef] [PubMed]

- Hyder, Z.; Siau, K.; Nah, F. Artificial Intelligence, Machine Learning, and Autonomous Technologies in Mining Industry. J. Database Manag. 2019, 30, 67–79. [Google Scholar] [CrossRef]

- Maraboutis, P.; Poulimenou, N.I.; Nikolaou, E. How the Proper Management of Extractive Waste Can Support the Circular Economy. Mater. Proc. 2021, 5, 118. [Google Scholar] [CrossRef]

- Garbarino, E.; Orveillon, G.; Saveyn, H.G.M. Management of waste from extractive industries: The new European reference document on the Best Available Techniques. Resour. Policy 2020, 69, 101782. [Google Scholar] [CrossRef]

- Myanmar Mining EIA Guidelines Working Group with the Technical Assistance of ADB TA 8786-MYA: Environmental Safeguard Institutional Strengthening and WWF. Environmental Impact Assessment Guidelines for The Mining Sector. Technical Guidance Environmental Impact Assessment of Mining, 2018, Draft Working Document. Available online: https://www.myanmar-responsiblebusiness.org/pdf/2018-05-25-EIA-Guidelines/MiningEIAGuidelines_18May2018_EN.pdf (accessed on 12 May 2023).

- Franks, D.M.; Brereton, D.; Moran, C.J.; Sarker, T.; Cohen, T. Cumulative Impacts—A Good Practice Guide for the Australian Coal Mining Industry. Centre For Social Responsibility in Mining & Centre for Water in The Minerals Industry, Sustainable Minerals Institute, The University of Queensland. Australian Coal Association Research Program. Brisbane, 2010. Available online: https://www.researchgate.net/publication/49515266 (accessed on 12 May 2023).

- Maraboutis, P.; Poulimenou, N.-I.; Nikolaou, E. Risk Management: An Essential “Tool” for the Extractive Sector. Mater. Proc. 2021, 5, 119. [Google Scholar] [CrossRef]

| Impacts on Water | Main Causes | Mitigation Actions |

|---|---|---|

| Changes in hydrography and hydrogeology of an area (i.e., “pit-lakes” arise during the mining productive and closure phases) | Consumption of water during the exploitation phases (from mining to processing) and interferences between the territory and mining activities. Frequent “pit-lakes” arise during the productive mining and closure phases; such lakes have to be monitored and, if needed, rehabilitated in order not to pollute land and groundwater with potential toxic elements [19,20] | Pit lakes can be reclaimed by creating new end uses, i.e.,: |

| ||

| ||

| ||

| ||

| ||

| ||

| These opportunities largely depend on water quality, slope stability, and safety concerns. | ||

| Overall management of water connected to excavation and processing phases | The excavation and processing phases involve water consumption and treatment and/or the recycling of reagents (e.g., flotation reagents, cyanide, flocculants), water management in tailing facilities, precipitation-related surface-water management, and groundwater management [22] | Recycling of water during the processing phase has significantly increased in recent decades, but 100% recycling is not possible, so some of the water removed from production cycles is present in the waste fraction (i.e., tailings, residual sludge, etc.). |

| In order to limit water consumption and ensure more efficient recycling, various water-treatment technologies have been developed (e.g., filter-press technologies, Dorr decanters, etc.). | ||

| Implementation of appropriate surface-water regulation works and the monitoring of groundwater levels, as well as the quality monitoring of surface and groundwater | ||

| Presence of reagents from mineral processing | Chemical agents and flotation agents that are used in ore dressing and metal-concentrating procedures are released into water resources. The main source of contamination is usually seepage from processing mills and tailings dams | Water treatment after release of processing chemicals and heavy metals through mine spills |

| Vegetation and refurbishment programs at the mine sites applied for mine water contaminated by processing chemicals like polychlorinated biphenyls (PCBs) and tetrachlorobenzyltoluenes (TCBTs) [23]. | ||

| Presence of (heavy) metals due to mineral concentrations in rocks | Heavy metals in mineral concentrations in rocks and an acid (low-pH) environment can be leached and transported downstream as water washes over the rock surface and EW facilities [24,25] | Acidic mine-drainage control systems (to be established in extremely acidic mine water). |

| Reuse/recover the EW or guarantee the proper covering (with impermeable coating) in order to prevent the contamination of the water flow in EW facilities [26]. | ||

| Apply a vegetation cover to prevent water contamination from the surface; this method is more economic and eco-friendly. | ||

| Formation of acid mine drainage (AMD) | Rain or groundwater that filters into the mine’s deposits causes oxidation, hydrolysis, flushing, etc., which results in highly polluted wastewater. The drainage resulting from the natural oxidation of sulfide minerals that occur in ore deposits or extractive waste are exposed to weathering conditions to produce the AMD [16]. AMD can cause serious environment impacts on water (and soil) due to elevated levels of heavy metals and sulfate linked to acid generation. | Use of limestone wastes or fine residues (calcium carbonate) as a neutralizing agent to increase the pH of the water and, thus, reduce its acidity [27]. |

| Formulate technosols for passive/reactive water treatment composed of high percentages of carbonate material and organic matter. | ||

| Controlled oxidation to prevent sulfide formation (i.e., using hydrogen peroxide). | ||

| Design or use of wetlands to favor the precipitation of metals (in the form of sulfides) through the action of sulfate-reducing bacteria, which work under anaerobic conditions or with low oxidation-reduction potential [28]. | ||

| Prevention and covering of materials to reduce exposure to water and oxygen. |

| Impacts on Air | Main Causes | Mitigation Actions |

|---|---|---|

| Production of dust | Production of dust caused by exploitation, processing, transport of rocks and minerals (presence of quartz, asbestos, metals, etc. has to be monitored and faced). Dust is a generic term used to describe fine particles suspended in the atmosphere, produced during mining and processing operations (disturbance of soil and/or rocks) through mechanical action. In particular, the atmospheric dispersion of inorganic fibers and fine particles (PM2.5) can represent a risk to human health both for the workers and for the people living near the mining and processing areas. | Monitoring size, shape, and chemical composition of inorganic particles that can be released in the air. |

| Preventing air dispersion of inorganic particles through irrigation. | ||

| Limiting dust particle inhalation by using appropriate safety devices (i.e., breathing masks). | ||

| Noise and potential odors | Noise and potential odors, connected to transport, in particular, where the mining area is close to residential housing areas | The installation of acoustic barriers or screens can reduce the propagation of sound and, consequently, the noise generated by mining plants and activities. |

| Planning the routes of heavy vehicles to avoid residential areas can reduce the impact of odors on sensitive areas. | ||

| CO2 production | CO2 production due to tracks and machineries | The reduction of CO2 production can be achieved through the adoption of environmentally friendly vehicles and machinery (i.e., electric or hybrid vehicles), regular vehicle maintenance, and the use of vehicles with more energy-efficient engines. |

| Impacts on Soil | Main Causes | Mitigation Actions |

|---|---|---|

| Dust or seepage of liquids that may cause contamination | Dispersion of dust by wind or seepage of liquids into the ground from tailings and/or waste-rock management facilities by the infiltration of rainwater or surface water: i.e., acid mine drainage [29]. | To minimize the aerial dispersion of particles by the wind and the infiltration of liquids into the soil, the following measures are possible: |

| ||

| ||

| ||

| ||

| Contamination of sediments | Chemical agents and flotation agents that are used in ore dressing and metal-concentrating procedures are released into water resources. The main source of contamination is usually seepage from processing mills and tailings dams | Erosion and sedimentation control can be conducted by: |

| ||

| ||

| ||

| The control of sediment contamination can be prevented through water-treatment systems providing unpolluted water. | ||

| Effluents from controlled or uncontrolled EW facilities (tailings and waste rock) | The effluents, which are potentially toxic to humans, animals, and plants [31], can be acidic or alkaline and may contain metals and/or soluble and insoluble complex organic compounds related to mineral processing and mining operations | Acid effluents can be used as: |

| ||

| ||

| Vibration | Vibrations related mainly to the drill-and-blast method and the presence of tracks for the transport of block and tout-venant. Vibrations generated inside the mineral-processing plants are associated with the machinery (in particular, crushers and mills) used in the processing phase | Vibration monitoring is useful for detecting and evaluating the vibration levels generated by equipment, allowing problems to be identified and measures to be taken to reduce the impact of the vibration. |

| Absorbent materials can help absorb and dissipate the energy of vibrations produced by equipment. |

| Main Sectors to Recover/Recycle Waste Rocks and Operating Residues | Recover/Recycle Examples |

|---|---|

| Valuable RM/SRM/CRM | Not known and mined but associated to RM exploited in the past (i.e., PGE associated to Ni deposits; Ga-Ge-In-Cd associated to Zn–Pb deposits, etc. Not mined because only the minerals easier to process were exploited |

| Industrial Minerals | From kaolin process and granite exploitation: production of ceramic materials (ceramic bricks and tiles, roof tiles, mortars, porcelain, mullite bodies, membranes, etc.) [59,60]. Use of EW from marble and limestone to produce calcium carbonate [61]. Quartzite (ornamental stone) EW to produce quartz for glass and ceramic industry [62]. |

| Aggregate and filler | Civil works, road paving, building industry, etc. [63,64,65]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mancini, S.; Casale, M.; Tazzini, A.; Dino, G.A. Use and Recovery of Extractive Waste and Tailings for Sustainable Raw Materials Supply. Mining 2024, 4, 149-167. https://doi.org/10.3390/mining4010010

Mancini S, Casale M, Tazzini A, Dino GA. Use and Recovery of Extractive Waste and Tailings for Sustainable Raw Materials Supply. Mining. 2024; 4(1):149-167. https://doi.org/10.3390/mining4010010

Chicago/Turabian StyleMancini, Susanna, Marco Casale, Antonio Tazzini, and Giovanna Antonella Dino. 2024. "Use and Recovery of Extractive Waste and Tailings for Sustainable Raw Materials Supply" Mining 4, no. 1: 149-167. https://doi.org/10.3390/mining4010010

APA StyleMancini, S., Casale, M., Tazzini, A., & Dino, G. A. (2024). Use and Recovery of Extractive Waste and Tailings for Sustainable Raw Materials Supply. Mining, 4(1), 149-167. https://doi.org/10.3390/mining4010010