Review of Non-Destructive Methods for Rock Bolts Condition Evaluation

Abstract

1. Introduction

- a.

- Friction Bolts: There are two main types of friction bolts. Split set and Swellex bolts. Swellex bolts provide a higher bond strength than the split set rock bolt and the installation is more complex.

- b.

- Mechanical Anchor rock bolts: This type of rock bolt can be differentiated into two types which are slit/wedge rock bolts and expansion shell anchor rock bolts. Mechanical anchor rock bolts are mainly used in hard rocks since they are not highly efficient in soft rocks. Their effectiveness can be reduced in corrosive environments, where the corrosion of the rock bolt is the primary cause of rock bolt failure [3]. Mechanical Anchor bolts are stronger than friction bolts and are capable of being grouted which provides added protection against corrosion.

- c.

- Resin Bolts: Resin bolts are the strongest type of rock bolt. Resin end-anchored rock bolts consist of three parts: the anchored section, the free section, and the faceplate and locking nut. Tensile failure of the bolt rod usually occurs in the free section [4]. Two of the major disadvantages of resin types of bolts are that they are expensive to install, and they have a short shelf life.

- d.

- Grouted dowel: Grouted dowel rock bolts are one of the simpler bolt designs. A dowel is an untensioned steel rod that is drilled into the rock mass, positioned in the borehole, and grouted in place. It does not have an anchor head, is not threaded, and must be activated by ground displacement. The dowels will bear both shear and tensile pressures when joints are put under displacement. The grout type and the composition of the neighboring ground support will determine the ratio of the shear and tensile stresses.

2. Materials and Methods

2.1. NDT Measures for Understanding Corrosion

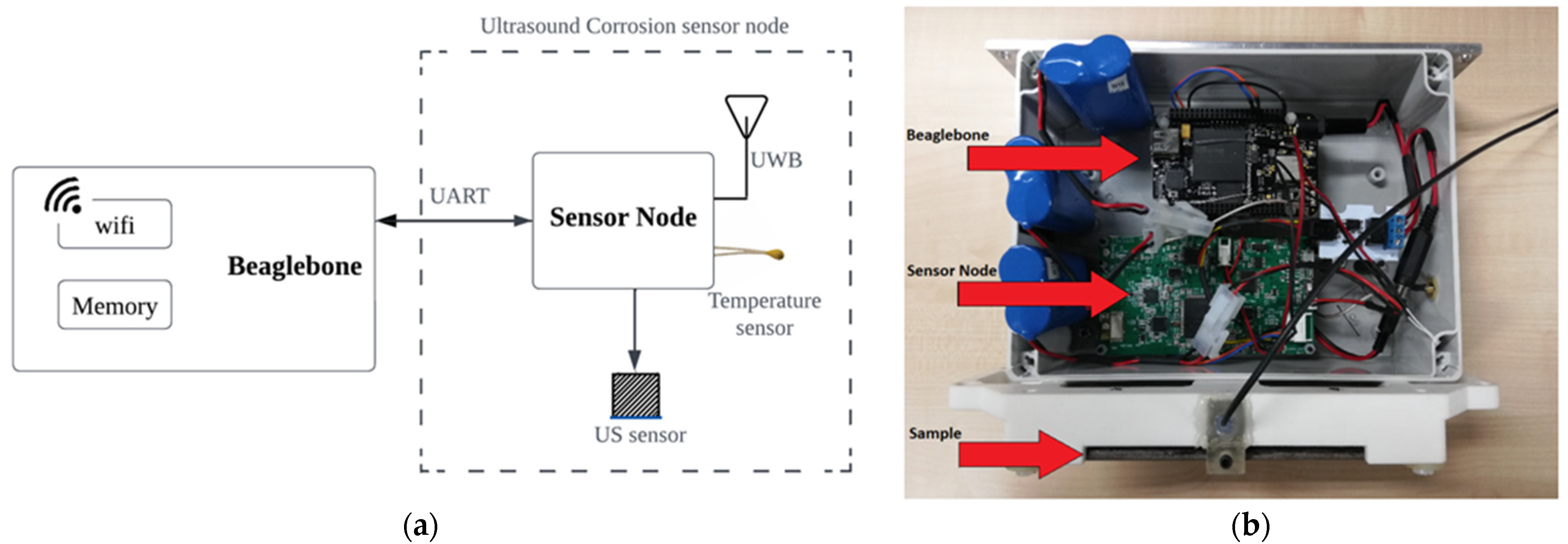

2.1.1. Ultrasonic

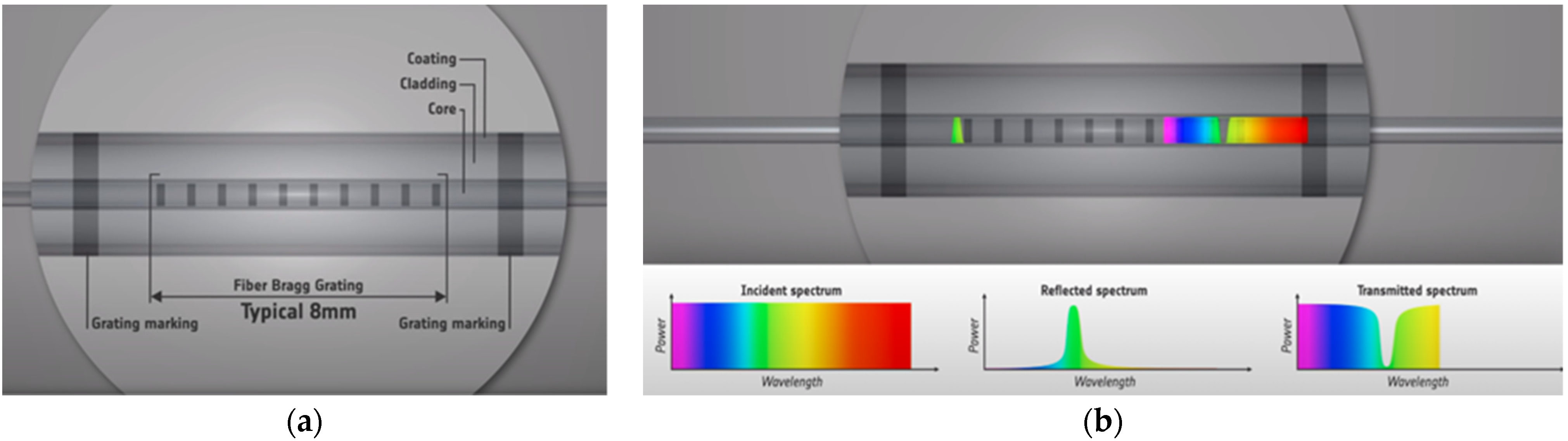

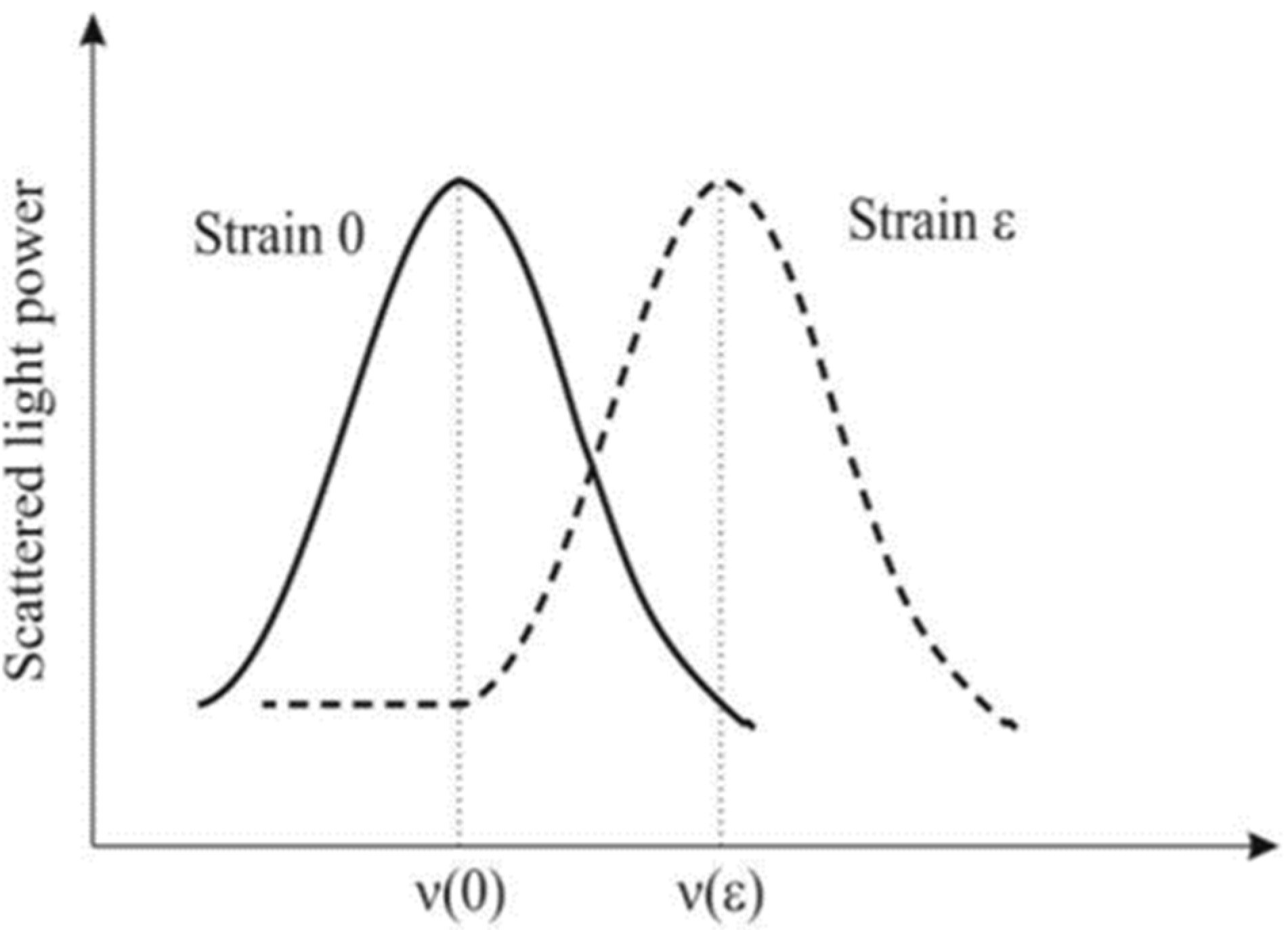

2.1.2. Fiber Optic

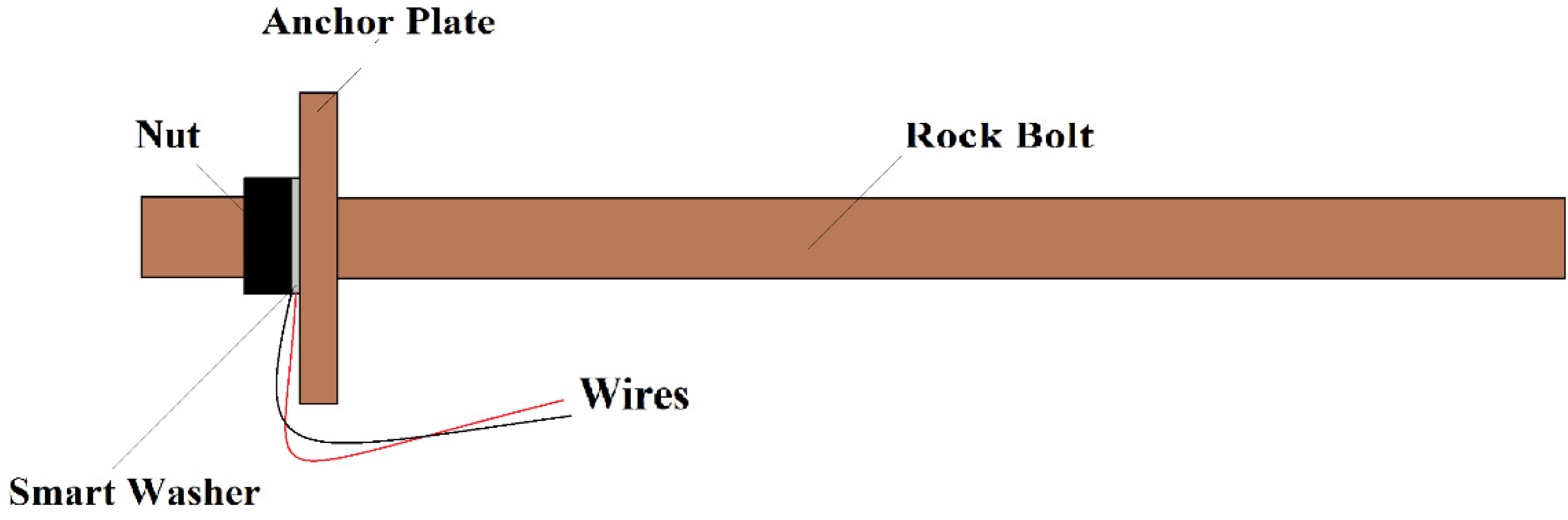

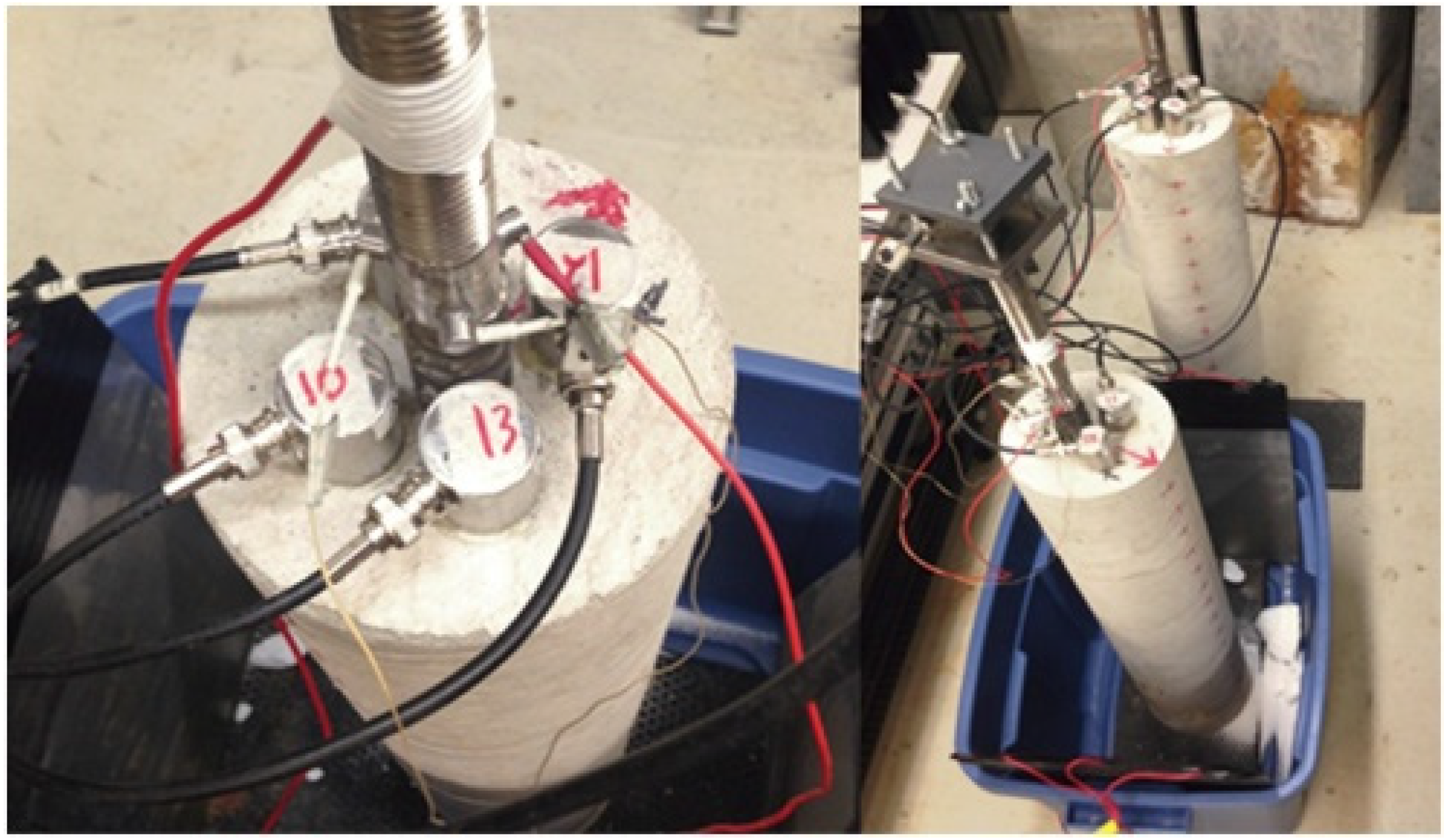

2.1.3. Piezoelectric

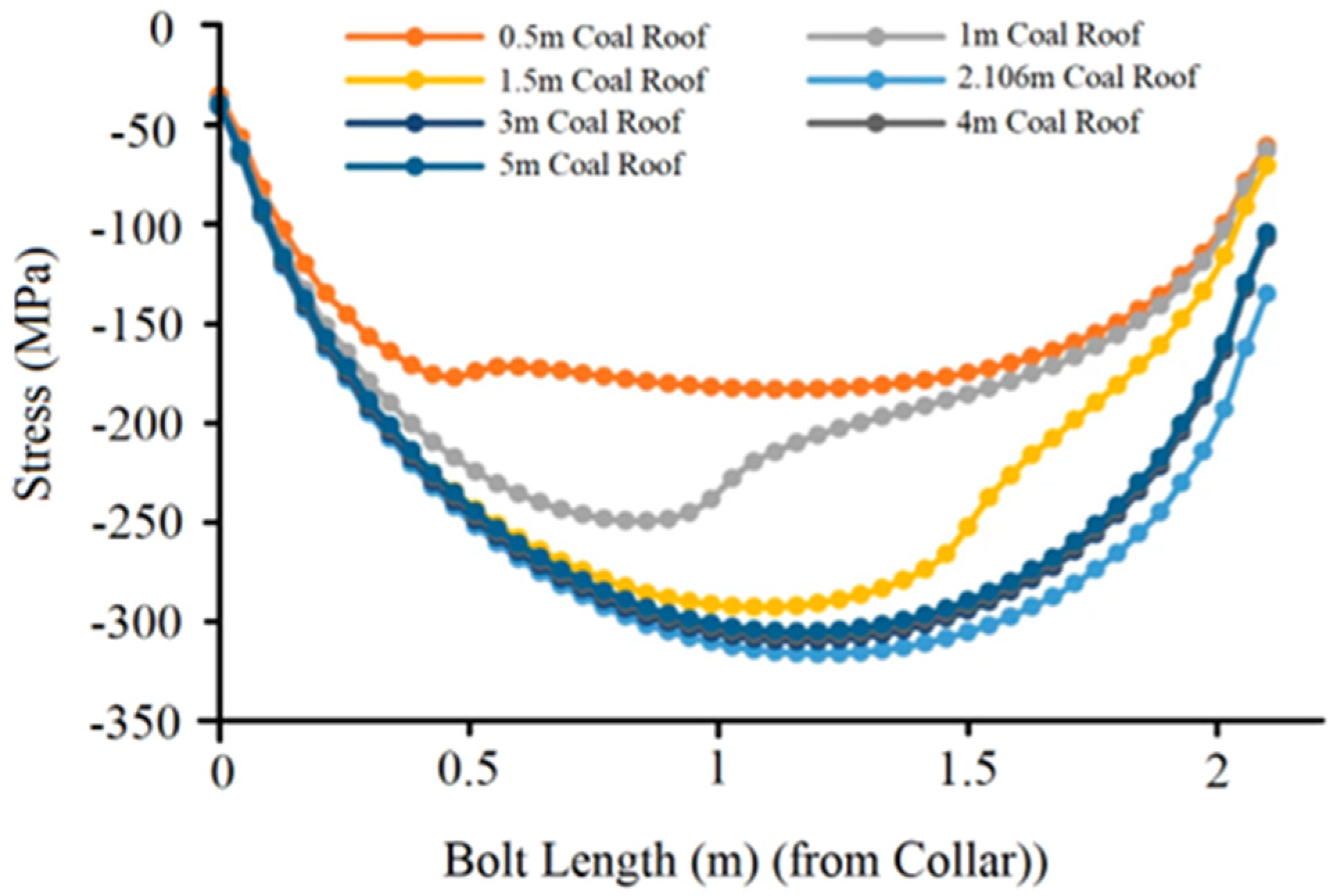

2.1.4. Numerical Methods

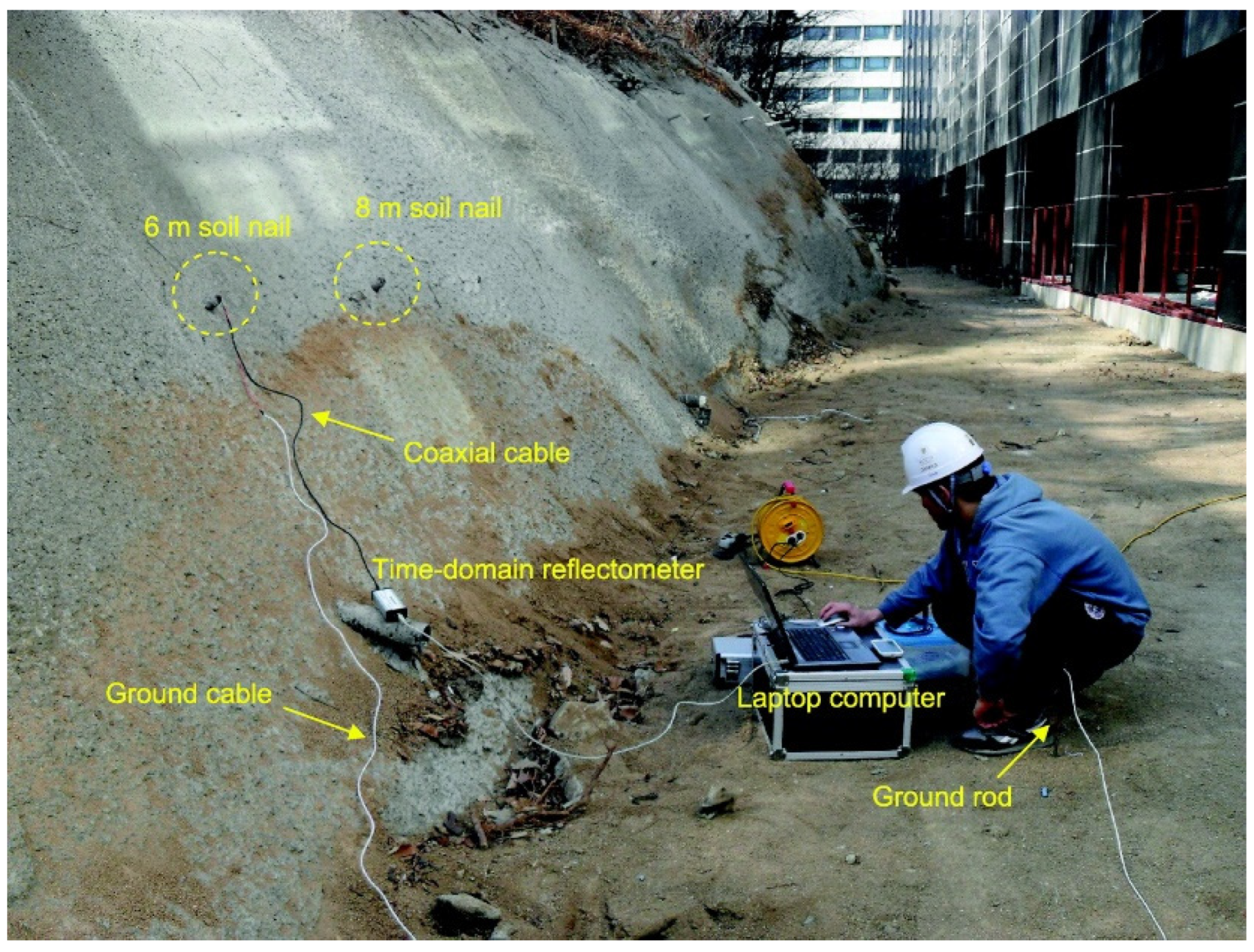

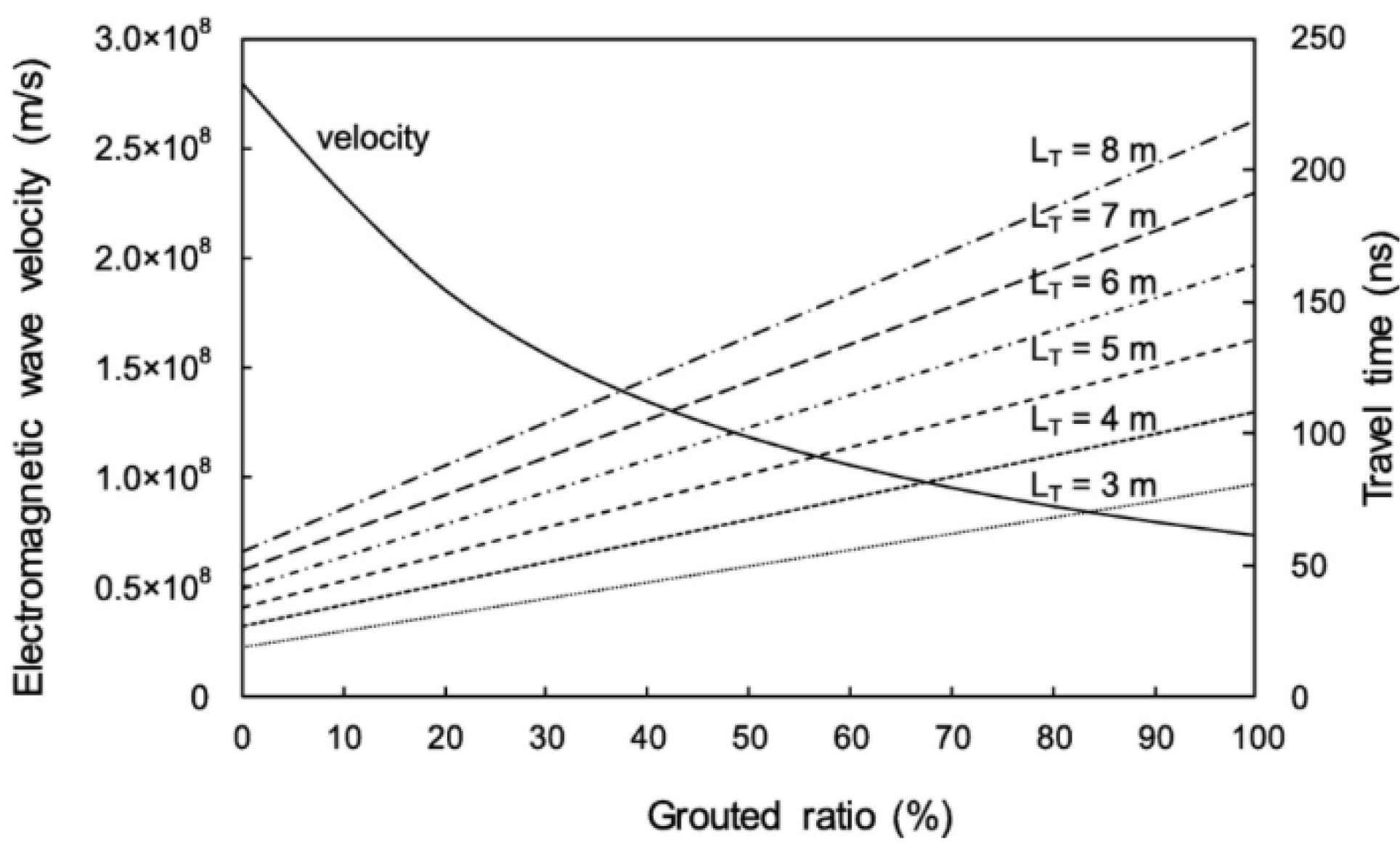

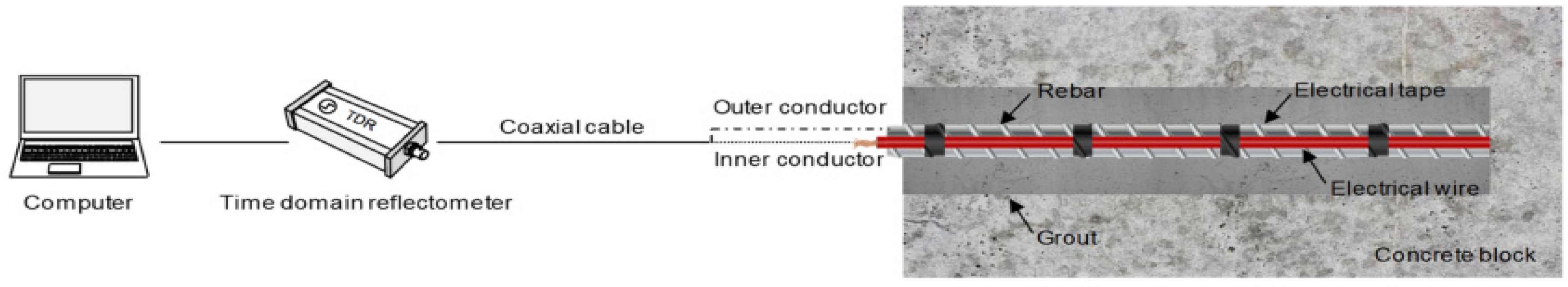

2.1.5. Electromagnetic

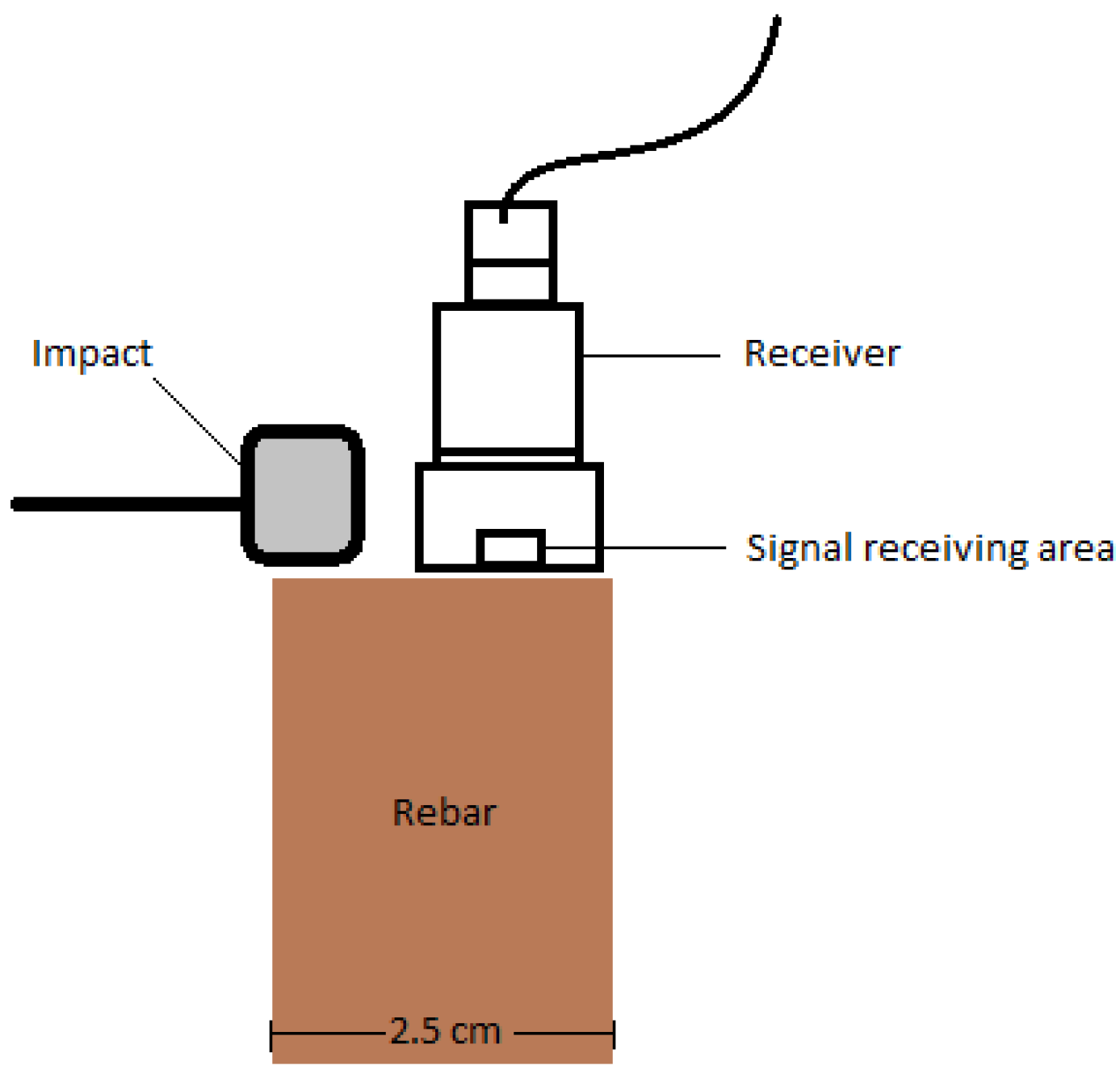

2.1.6. Impact-Echo

2.1.7. Acoustic Emission

3. Discussion

3.1. NDT for the Study of Strain

3.2. NDT for the Study of Corrosion

3.3. NDT for the Study of Grouts

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Luo, M.; Li, W.; Wang, B.; Fu, Q.; Song, G. Measurement of the Length of Installed Rock Bolt Based on Stress Wave Reflection by Using a Giant Magnetostrictive (GMS) Actuator and a PZT Sensor. Sensors 2017, 17, 444. [Google Scholar] [CrossRef]

- Yu, J.-D.; Lee, J.-S. Smart Sensing Using Electromagnetic Waves for Inspection of Defects in Rock Bolts. Sensors 2020, 20, 2821. [Google Scholar] [CrossRef] [PubMed]

- Song, G.; Li, W.; Wang, B.; Ho, S.C. A Review of Rock Bolt Monitoring Using Smart Sensors. Sensors 2017, 17, 776. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Song, Y.; Bai, J.; Elmo, D. A Study on the Failure of Resin End-Anchored Rockbolts Subjected to Tensile Load. Rock Mech. Rock Eng. 2018, 52, 1917–1930. [Google Scholar] [CrossRef]

- Craig, P.; Serkan, S.; Hagan, P.; Hebblewhite, B.; Vandermaat, D.; Crosky, A.; Elias, E. Investigations into the corrosive environments contributing to premature failure of Australian coal mine rock bolts. Int. J. Min. Sci. Technol. 2016, 26, 59–64. [Google Scholar] [CrossRef]

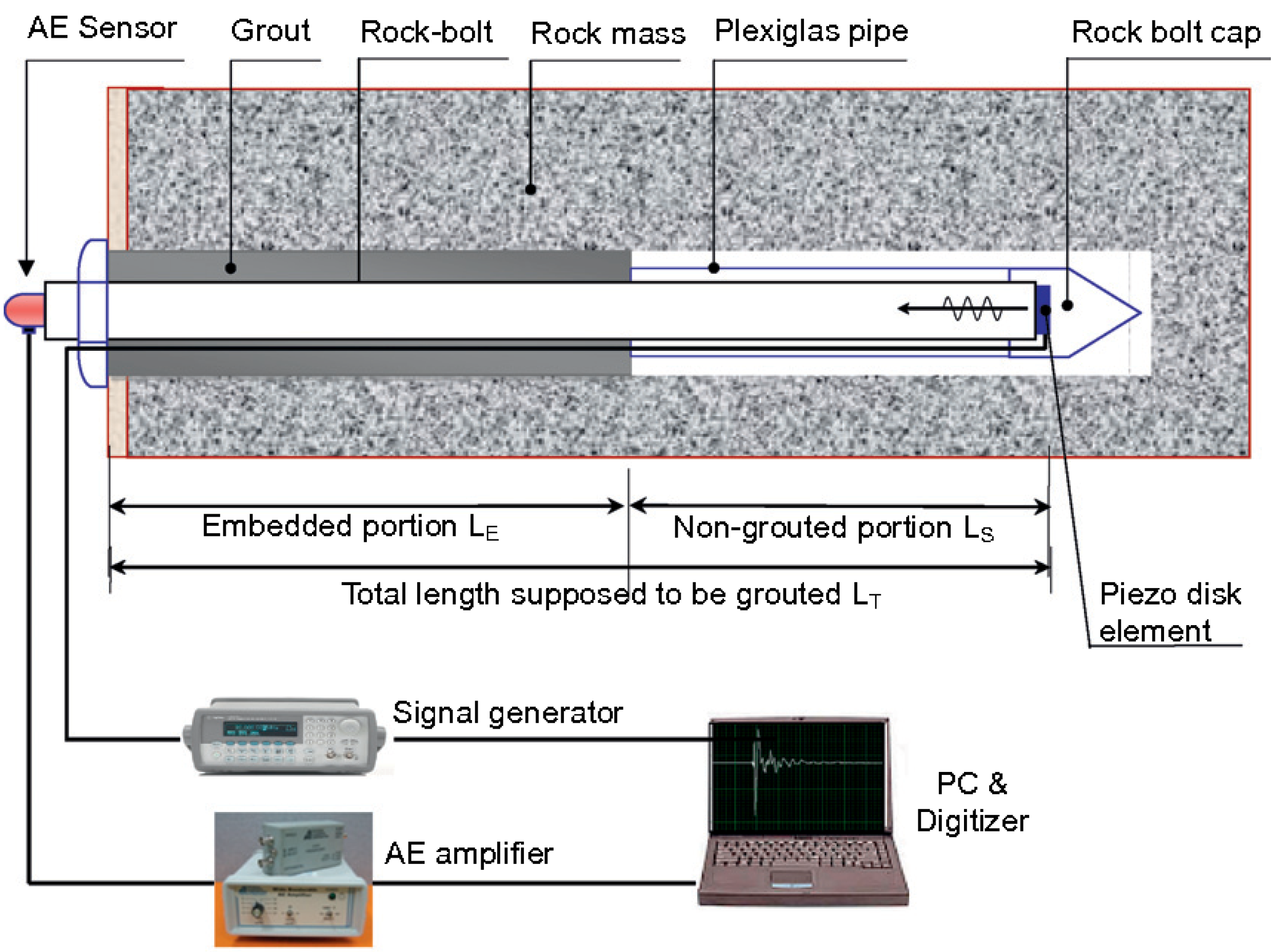

- Zou, D.; Cui, Y. A new approach for field instrumentation in grouted rock bolt monitoring using guided ultrasonicwaves. J. Appl. Geophys. 2011, 75, 506–512. [Google Scholar] [CrossRef]

- Zou, D.S.; Cheng, J.; Yue, R.; Sun, X. Grout quality and its impact on guided ultrasonic waves in grouted rock bolts. J. Appl. Geophys. 2010, 72, 102–106. [Google Scholar] [CrossRef]

- Cui, Y.; Zou, D. Assessing the effects of insufficient rebar and missing grout in grouted rock bolts using guided ultrasonic waves. J. Appl. Geophys. 2012, 79, 64–70. [Google Scholar] [CrossRef]

- Yu, J.-D.; Bae, M.-H.; Lee, I.-M.; Lee, J.-S. Nongrouted ratio evaluation of rock bolts by reflection of guided ultrasonic waves. J. Geotech. Geoenviron. Eng. 2012, 139, 298–307. [Google Scholar] [CrossRef]

- Madenga, V.; Zou, D.; Zhang, C. Effects of curing time and frequency on ultrasonic wave velocity in grouted rock bolts. J. Appl. Geophys. 2006, 59, 79–87. [Google Scholar] [CrossRef]

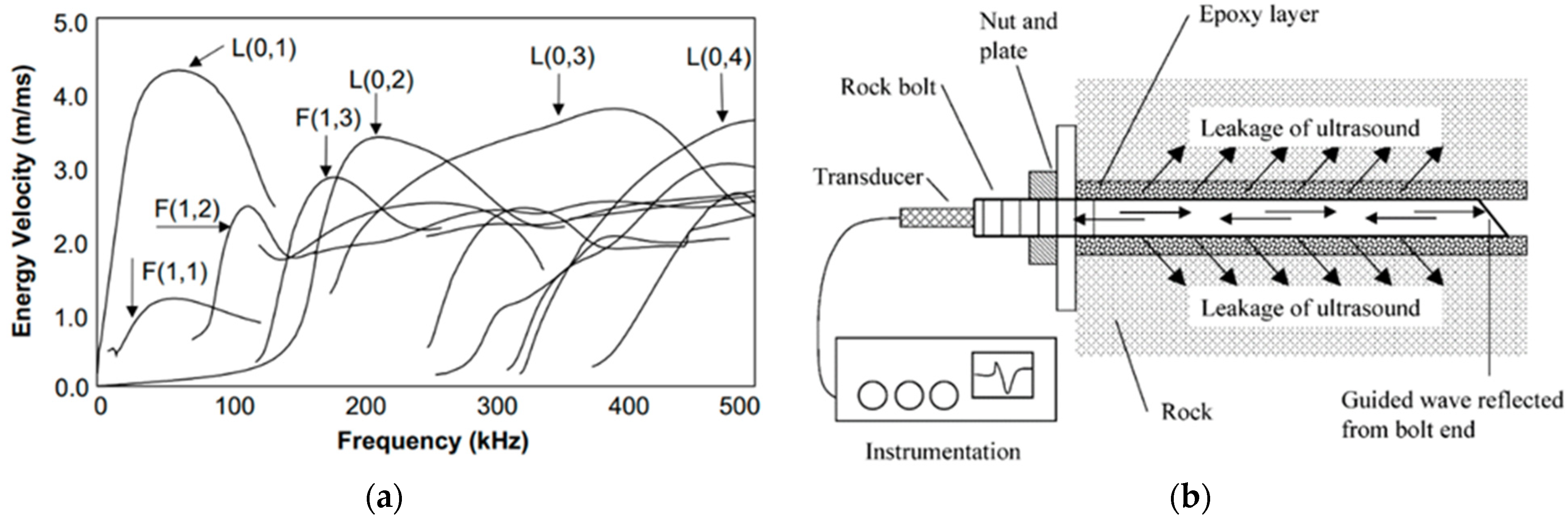

- Wang, C.; He, W.; Ning, J.; Zhang, C. Propagation properties of guided wave in the anchorage structure of rock bolts. J. Appl. Geophys. 2009, 69, 131–139. [Google Scholar] [CrossRef]

- Thibbotuwa, U.C.; Cortés, A.; Irizar, A. Small Ultrasound-Based Corrosion Sensor for Intraday Corrosion Rate Estimation. Sensors 2022, 22, 8451. [Google Scholar] [CrossRef]

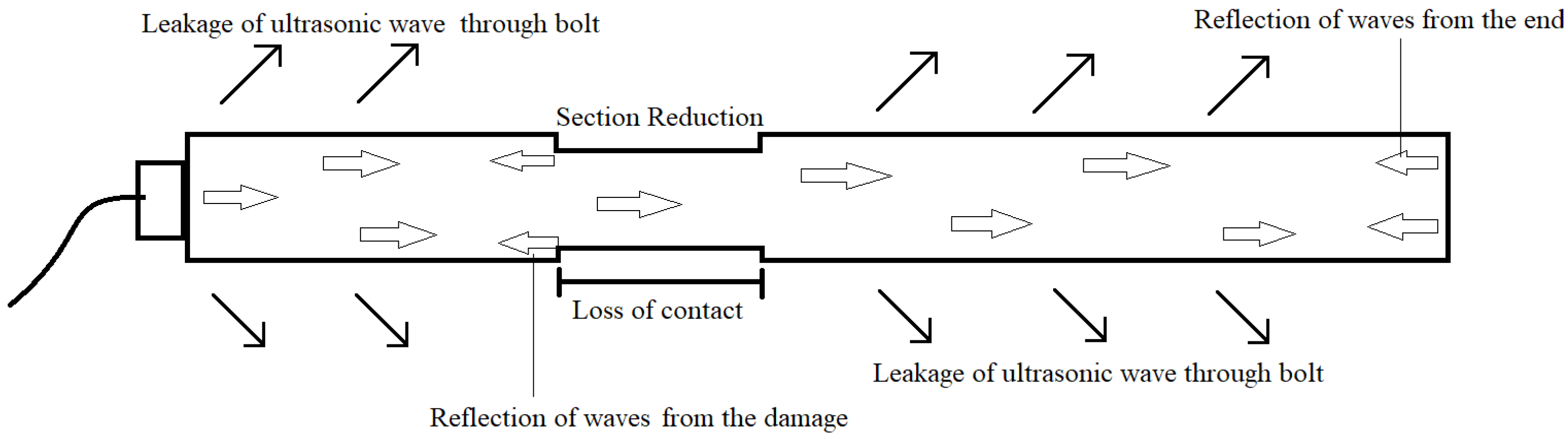

- Lee, I.-M.; Han, S.-I.; Kim, H.-J.; Yu, J.-D.; Min, B.-K.; Lee, J.-S. Evaluation of rock bolt integrity using Fourier and wavelet transforms. Tunn. Undergr. Space Technol. 2012, 28, 304–314. [Google Scholar] [CrossRef]

- Beard, M.; Lowe, M. Non-destructive testing of rock bolts using guided ultrasonic waves. Int. J. Rock Mech. Min. Sci. 2003, 40, 527–536. [Google Scholar] [CrossRef]

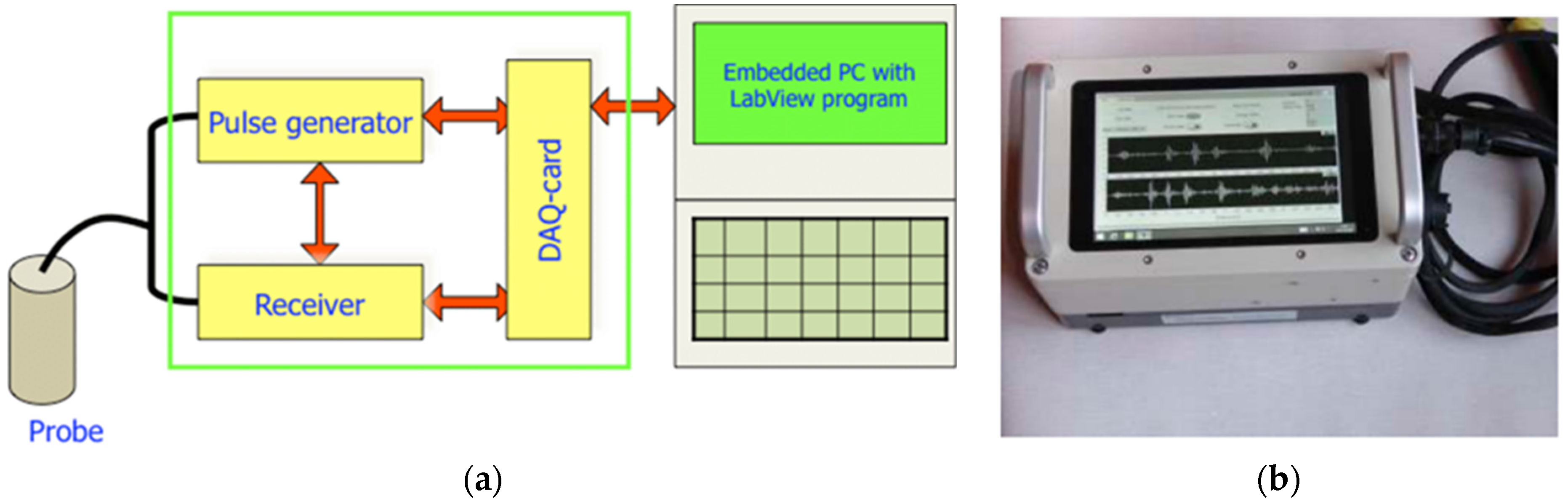

- Stepinski, T.; Matsson, K. Rock Bolt Inspection by Means of RBT Instrument. In Proceedings of the 19th World Conference on Non-Destructive Testing 2016, Munich, Germany, 13–17 June 2016. [Google Scholar]

- Taras, A.; Saleh, K. Non-Destructive Inspection of Corrosion in Rock Bolts Using an Ultrasonic Waveguide Approach. In Proceedings of the 13th International Conference on Damage Assessment of Structures; Lecture Notes in Mechanical Engineering. Wahab, M., Ed.; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Giurgiutiu, V. 17—Structural health monitoring (SHM) of aerospace composites. In Woodhead Publishing Series in Composites Science and Engineering, Polymer Composites in the Aerospace Industry, 2nd ed.; Irving, P., Soutis, C., Eds.; Woodhead Publishing: Sawston, UK, 2020; pp. 491–558. ISBN 9780081026793. [Google Scholar] [CrossRef]

- Bai, Y.; Bai, Q. Chapter 7—Fiber Optic Monitoring System. In Subsea Pipeline Integrity and Risk Management; Bai, Y., Bai, Q., Eds.; Gulf Professional Publishing: Houston, TX, USA, 2014; pp. 145–165. Available online: https://www.sciencedirect.com/science/article/pii/B978012394432000007X (accessed on 10 September 2022). [CrossRef]

- FBGS: FBG Sensor Principle. 2022. Available online: https://fbgs.com/ (accessed on 15 March 2022).

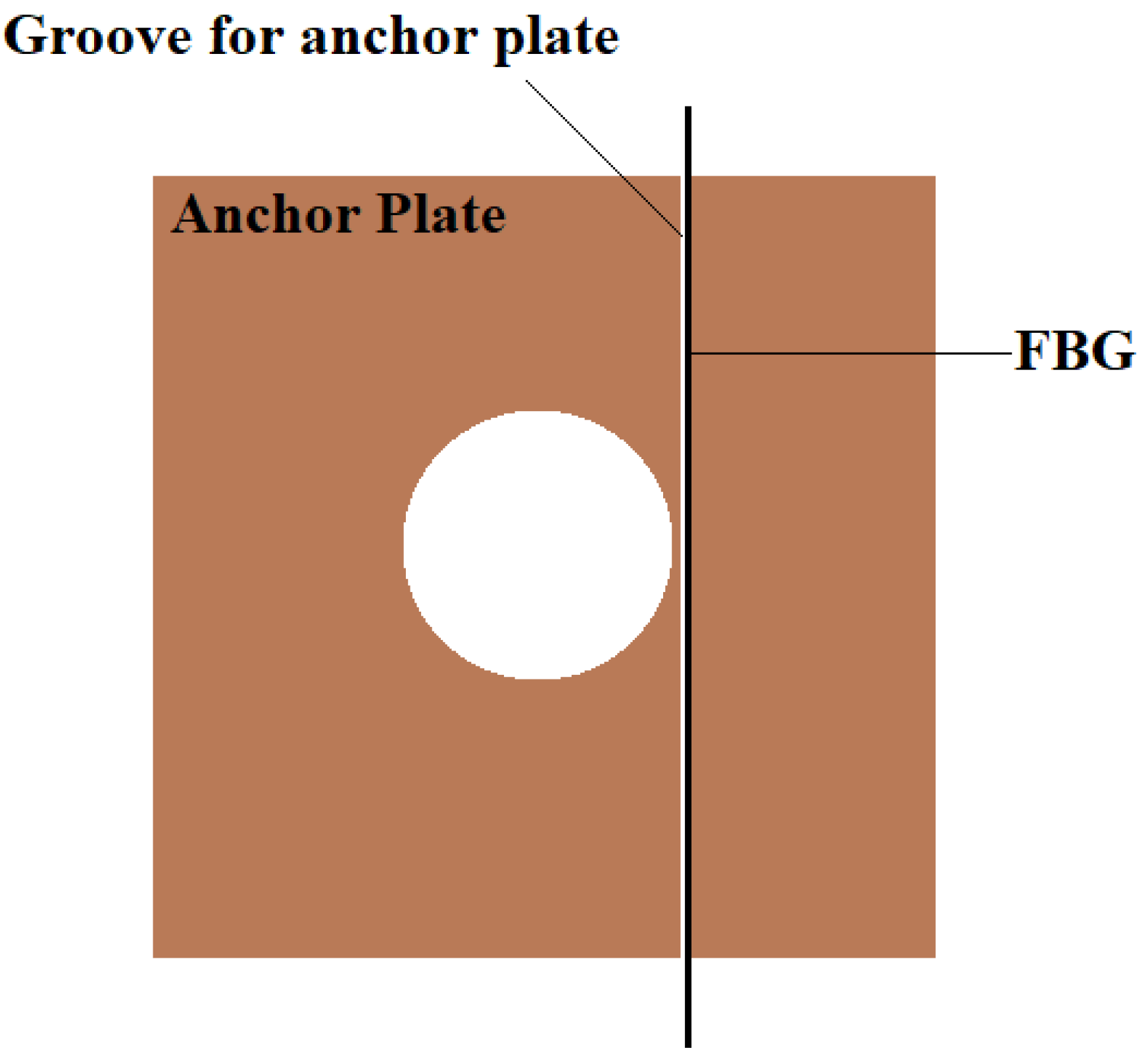

- Ho, S.C.M.; Li, W.; Wang, B.; Song, G. A Load Measuring Anchor Plate for Rock Bolt Using Fiber Optic Sensor. Smart Mater. Struct. 2017, 26, 057003. [Google Scholar] [CrossRef]

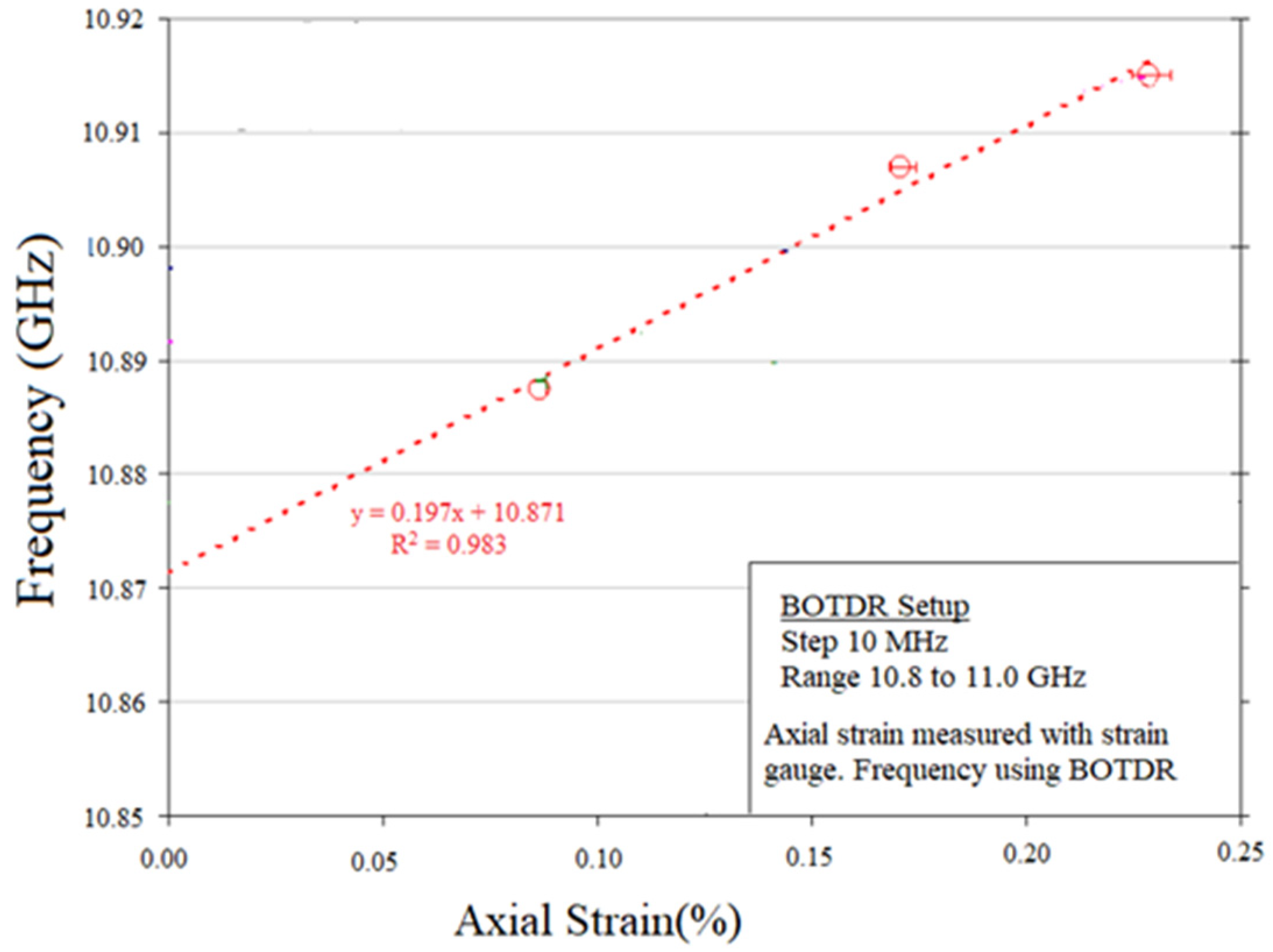

- Moffat, R.A.; Beltran, J.F.; Herrera, R. Applications of BOTDR fiber optics to the monitoring of underground structures. Geo-Mech. Eng. 2015, 9, 397–414. [Google Scholar] [CrossRef]

- Wang, B.; Huo, L.; Chen, D.; Li, W.; Song, G. Impedance-Based Pre-Stress Monitoring of Rock Bolts Using a Piezoceramic-Based Smart Washer—A Feasibility Study. Sensors 2017, 17, 250. [Google Scholar] [CrossRef] [PubMed]

- Craig, P.; Ramandi, H.L.; Chen, H.H.; Vandermaat, D.; Crosky, A.; Hagan, P.; Hebblewhite, B.; Saydam, S. Stress corrosion cracking of rockbolts: An in-situ testing approach. Constr. Build. Mater. 2021, 269, 121275. [Google Scholar] [CrossRef]

- Smith, J.A.; Ramandi, H.L.; Zhang, C.; Timms, W. Analysis of the influence of groundwater and the stress regime on bolt behaviour in underground coal mines. Int. J. Coal Sci. Technol. 2019, 6, 286–300. [Google Scholar] [CrossRef]

- Beard, M.D.; Lowe, M.J.S.; Cawley, P. Inspection of rockbolts using guided ultrasonic waves. AIP Conf. Proc. 2001, 557, 1156–1163. [Google Scholar]

- Yu, J.-D.; Kim, K.-H.; Lee, J.-S. Nondestructive health monitoring of soil nails using electromagnetic waves. Can. Geotech. J. 2018, 55, 79–89. [Google Scholar] [CrossRef]

- Lin, Y.-F.; Ye, J.-W.; Lo, C.-M. Application of impact-echo method for rockbolt length detection. Constr. Build. Mater. 2022, 316, 125904. [Google Scholar] [CrossRef]

- Cole, P.; Watson, J. Acoustic emission for corrosion detection. In Proceedings of the Middle East Nondestructive Testing Conference & Exhibition, Manama, Bahrain, 27–30 November 2005; Available online: https://www.ndt.net/article/mendt2005/pdf/01.pdf (accessed on 3 August 2022).

- Tscheliesnig, P.; Lackner g Jagenbrein, A. Corrosion Detection by means of acoustic emission monitoring. In Proceedings of the 19th World Conference on Non-Destructive Testing 2016, Munich, Germany, 13–17 June 2016; Available online: https://www.ndt.net/article/wcndt2016/papers/th3d2.pdf (accessed on 5 September 2022).

- Light, G. 12—Nondestructive evaluation technologies for monitoring corrosion. In Woodhead Publishing Series in Metals and Surface Engineering, Techniques for Corrosion Monitoring; Yang, L., Ed.; Woodhead Publishing: Sawston, UK, 2008; pp. 293–312. ISBN 9781845691875. [Google Scholar]

- Billeh Ishak Medfouni, E.M.; Kodjo, A.S.; Rivard, P.; Saleh, K.; Quirion, M. Assessment of Corroded Rock Bolts with Pulse Echo Tests. J. Infrastruct. Syst. 2017, 23, 04017007. [Google Scholar] [CrossRef]

| NDT for Strain Measurement | NDT for Detecting Corrosion | NDT for Study of Grouts |

|---|---|---|

| Ultrasonic method | Ultrasonic method | Electromagnetic method |

| Fiberoptic method | Acoustic Emission method | Ultrasonic method |

| Piezoelectric method | Numerical analysis | |

| Impact Echo method | ||

| Electromagnetic wave method |

| Research Progress | Country | Reference No. | Total Ref. |

|---|---|---|---|

| USA | [1,2,3,17,18,22,25,30,31] | 9 |

| China | [1,3,4,7,10,11,20,22] | 8 |

| Canada | [4,6,8,10,16,26] | 6 |

| Korea | [2,8,9,13] | 4 |

| Australia | [5,23,24] | 3 |

| England | [14,28] | 2 |

| Sweden | [15] | 1 |

| Poland | [15] | 1 |

| Germany | [19] | 1 |

| Taiwan | [27] | 1 |

| Austria | [29] | 1 |

| Spain | [12] | 1 |

| Chile | [21] | 1 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lama, B.; Momayez, M. Review of Non-Destructive Methods for Rock Bolts Condition Evaluation. Mining 2023, 3, 106-120. https://doi.org/10.3390/mining3010007

Lama B, Momayez M. Review of Non-Destructive Methods for Rock Bolts Condition Evaluation. Mining. 2023; 3(1):106-120. https://doi.org/10.3390/mining3010007

Chicago/Turabian StyleLama, Biraj, and Moe Momayez. 2023. "Review of Non-Destructive Methods for Rock Bolts Condition Evaluation" Mining 3, no. 1: 106-120. https://doi.org/10.3390/mining3010007

APA StyleLama, B., & Momayez, M. (2023). Review of Non-Destructive Methods for Rock Bolts Condition Evaluation. Mining, 3(1), 106-120. https://doi.org/10.3390/mining3010007