Abstract

The use of the lithium-ion battery (LIB) in both traction and stationary applications has become ubiquitous. It is essential that retired LIBs are wisely treated, with a basis in the concept of the circular economy, to mitigate primary resource use. A closed-loop repurposing and recycling treatment is required. Thus, using the concept of total material requirement as an indicator of natural resource use based on mining activity, a dynamic material flow analysis was executed considering the degradation of the battery, its lifespan, and demand patterns under several scenarios. Then, the effect of circularity on the savings in global natural resource use involved across the entire lifecycles of LIBs was evaluated. It was found that the global resource use for LIBs will increase to between 10 and 48 Gt in 2050. Circularity has the potential to contribute to an 8–44% reduction in the global resource use associated with LIBs in 2050. It was also found that a longer lifespan in the years leading up to 2050 would have a greater impact on the reduction of resource use for LIBs, despite the lower effectiveness of circularity, because it would reduce the demand for LIBs.

Keywords:

lifecycle; mining activity; material footprint; circular economy; repurpose; reuse; mine waste 1. Introduction

Lithium-ion batteries (LIBs) are widely used in traction and stationary applications. The advantages of LIBs include higher energy density, relatively low cost, and a lower environmental impact compared to other types of batteries [1,2]. The demand for traction LIBs is expected to increase remarkably because of the rapid transition from conventional vehicles to electric vehicles [3]. It has been projected that the number of electric vehicles could reach 56 million units per year by 2050 [4]; this would require a massive number of traction LIBs. The demand for stationary LIBs is also expected to increase because of the increasing share of intermittent renewable energy in the distributed generation system. LIBs are often used in such systems to stabilize the electricity quality and secure a continuous supply of electricity.

The extensive number of LIBs adopted across the globe will eventually enter the waste stream. A wise approach to the treatment of retired LIBs based on the concept of the circular economy is essential [5,6]. The concept of the circular economy has emerged over recent decades as a method to gain financial advantage [7], to reduce the environmental impact of production [8], and to improve the supply security of raw material in a given region [9]. In particular, circular economy strategies for LIBs address the issues relevant to natural resource use [10,11]. LIBs contain a large number of critical metals, including cobalt, nickel, copper, and manganese, and the high resource intensity of LIBs accounts for half of the resource intensity of the entire battery electric vehicle [12]. To achieve a closed-loop reuse, repurposing, and recycling system, it is necessary to mitigate primary resource use and improve resource efficiency [13,14].

Among the various actions in the circular process [15], repurposing and recycling are the key stages in the circular treatment of LIBs [16,17]. Repurposing is defined as the reuse of a product differently from the use intended by the original design [18]; in this context, retired traction LIBs are repurposed as stationary energy storage systems as a second-use application [19]. Since batteries degrade through cycles of charging and discharging, the state of health (SOH) of LIBs determines the category of waste management [20]. Even when approaching retirement in the role of a traction battery, the capacity of these retired traction LIBs is still in the range of 60–80% [21], and this SOH matches the battery energy storage system [22]. Repurposing retired traction LIBs for stationary use is an example of industrial symbiosis with the renewable energy industry and has economic and environmental advantages over recycling [23]. When the repurposed LIBs reach their end of life, recycling processes are required as a final treatment to recover resources for further production [24]. Thus, both repurposing and recycling are essential for the circular economy of LIBs.

The resource circularity of LIBs has been analyzed using the material flow analysis approach [10,25,26,27,28,29]. These studies considered the effect of repurposing and recycling on primary resource saving by 2050. However, rather than account for all of the related resources, most of the studies have been focused on specific metals, such as lithium, cobalt, nickel, or manganese. As a future research topic based on their critical literature review, Acerbi and Taisch [30] stressed the importance of considering all of the resources involved in the entire lifecycle of LIBs. For this reason, in this study we consider the effect of repurposing and recycling on the savings in natural resource use involved over the entire lifecycle of LIBs until 2050.

This study employs the concept of total material requirement (TMR) to evaluate the amount of natural resource use. TMR was developed as an indicator for measuring the quantity of resources in a material flow analysis (MFA) [31,32]. Compared to the direct material input and raw material equivalents, TMR is a more inclusive indicator since it covers a wide-ranging system boundary for the resource involved [33]. TMR involves direct and indirect resource inputs, as well as unused resources accompanying them as hidden flows related to overburdening or as mine waste [34]. Since it measures the scale of mining activity for natural resource extraction [35], TMR is also considered one way of expressing the material footprint [36]. In recent years, TMR has been employed to quantify the amount of resource use associated with the concept of circularity for road transportation and electricity [37].

Thus, the objective of this study was to evaluate global circular resource use for LIBs up to 2050 from the perspective of mining activity and with regard to repurposing and recycling for traction and stationary use.

This study is structured as follows: in Section 2, a methodology for estimating the global resource use of LIBs in a projection approach is presented; in Section 3, global circular resource use of LIBs during the period 2010–2050 is illustrated; in Section 4, strategies for the reduction of resource use for LIBs through mining activities up to 2050 are discussed.

2. Materials and Methods

2.1. Total Material Requirement

2.1.1. Calculation Concept

The value of the TMR was calculated based on the direct quantity of material or energy (kg, L, kWh) and the TMR coefficient for material or energy (kg-TMR/kg, L-TMR/L, kWh-TMR/kWh). The relationship is expressed in the following equation:

Based on this concept, the TMR coefficient for the output material and the TMR quantity of the output product are obtained in the following equations:

where is the quantity of input material or product , is the quantity of output material , is the TMR coefficient for the input material or product , is the monetary value of the output material , and is the TMR quantity of the output product.

Considering that the unit of TMR is weight, the law of conservation of mass was applied in the TMR calculation. In addition, the allocation process had to be employed in the calculation, as it is when carrying out a lifecycle assessment and determining a footprint. Since monetary value is a driving force of mining activity, the economic allocation technique was applied. The TMR coefficient for primary resources was taken from previous studies [38,39,40].

2.1.2. Production

The TMR for LIB production has already been reported in a previous study [41] that used a traction LIB, consisting of a cathode of nickel–cobalt–manganese (NMC) and an anode of graphite [42], in the TMR assessment. It was found that the TMR coefficient for traction LIB production per LIB weight was 189 kg-TMR/kg and that of traction LIB production per LIB capacity was 1800 kg-TMR/kWh [41]. These results were used in this study.

2.1.3. Repurposing

Based on the framework of the TMR for urban ore in the context of waste treatment [43], the TMR of a repurposed LIB was calculated. The sum of the weight of a retired vehicle as urban ore and the TMR quantity relevant to its disassembly was allocated to each component (LIB, tires, motor, steel scrap, aluminum scrap, and copper scrap) based on the corresponding monetary value, as shown in Section 2.1.1. The associated data were taken from the authors’ previous studies [12,44].

2.1.4. Recycling

The concept of the circular economy is based on a closed loop of materials and products, with the materials contained in the end-of-life products recycled for use in the new production of an identical type of product [45]. Based on the understanding that the benefit of recycling is higher in a closed loop than in an open loop [46], this study employed the closed loop concept for the circularity of the materials used in LIBs. In the production of recycled LIBs, secondary materials recovered from the end-of-life LIBs are used on a priority basis, and virgin materials from natural ores are used only to compensate for the shortfall between the required quantity of materials and the quantity of secondary materials available. The inventory data for recycling LIBs were taken from a study by Cusenza [22], in which the combination of pyrometallurgical and hydrometallurgical recycling techniques was reported to be the most promising recycling technique for LIBs.

The Monte Carlo simulation, known as a multivariate sensitivity simulation, was employed to determine the TMR of a recycled LIB considering the sensitivity of the copper ore grade, as conducted in a previous study [41].

2.2. Circularity of LIBs

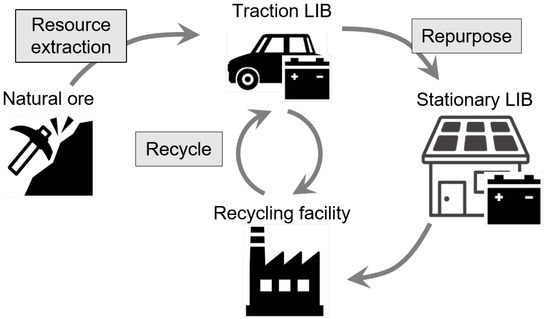

An overview of the LIB circularity considered in this study is shown in Figure 1. Retired traction LIBs are channeled as repurposed stationary LIBs. In the event that the whole capacity of the repurposed LIBs does not meet the demand for stationary LIBs, primary stationary LIBs are used to cover the shortfall. In the event that the demand for stationary LIBs is met by repurposed stationary LIBs, no primary stationary LIBs are produced and the remaining retired traction LIBs are channeled to the recycling stage. When the repurposed stationary LIBs are retired, these are channeled to recycling facilities. To evaluate LIB circularity, a dynamic MFA model, the lifespan of LIBs at each lifecycle stage, and the demand for LIBs for traction and stationary use are the key factors.

Figure 1.

Overview of LIB circularity.

2.2.1. Dynamic Material Flow Analysis

Using an MFA, it is possible to quantify the amount of inflow, outflow, and in-use stock, and a dynamic MFA reflects the dynamic change in mass flow with time [47]. This study employs a dynamic MFA to evaluate the flows of LIBs.

The dynamic MFA is expressed by the following equation:

where is the number of traction and stationary LIBs owned as a stock in year t, is the number of traction and stationary LIBs retired as outflow in year t, and is the demand for traction and stationary LIBs as an inflow in year t.

The number of traction and stationary LIBs retired can be calculated with the following equation:

where is the retiring rate of age i for an LIB that reaches retirement in the role of traction and stationary use in year t and is the survival rate for years i after starting use of traction and stationary LIBs. These parameters are determined based on the lifespan distribution of traction and stationary LIBs. Among the various lifespan distribution models, this study employs the Weibull distribution model, one of the most appropriate simulation models [48]. The accumulative Weibull distribution model is expressed by the following equation:

where is the accumulated retiring rate of age i for an LIB that reaches the retirement moment following traction and stationary use in year t, is the average lifespan for the stage where the LIB is operated for traction and stationary use until it is retired, is a shape parameter, and is a scale parameter. This study used values for the shape parameter and the scale parameter of 2.26 and 23.8, respectively, for traction and stationary LIBs, following the study by Yano et al. [49].

The dynamic MFA simulation for the circularity of LIBs was determined based on contextual factors, including the lifespan and demand of traction and stationary LIBs. This study considered several scenarios to present the potential and conceivable range in global natural resource use for LIBs. These contextual factors are further explained in the following sections.

2.2.2. Lifespan

The state of health (SOH) determines the lifespan of LIBs at each lifecycle stage. The SOH is an indicator for the evaluation of the degree of degradation of battery capacity compared to the cycle number, presented in the form of a percentage (%).

Takata et al. [50] proposed three SOH scenarios of for each of the LIB lifecycle stages, as shown in Table 1. These proposed scenarios were employed in this study by converting the SOH given in the referenced study [50] into years. Based on the driving range for Nissan Leaf battery electric vehicles (BEVs) as a reference (320 km) [51] and the average annual mileage of vehicles (13,700 km) [52], the relationship between SOH and cycle number [53] was converted into that between SOH and duration for traction LIBs. According to Casals et al. [54], the decreasing slope of the SOH with time for stationary LIBs is 0.7-fold gentler than that for traction LIBs. This was applied to the relationship between SOH and year for stationary LIBs.

Table 1.

Three scenarios for LIB lifespan at each lifecycle stage.

The three scenarios are named Lifespan_8, Lifespan_14, and Lifespan_20, according to the different SOH thresholds of traction LIBs. A summary of the three scenarios for the LIB lifespan at each lifecycle stage is presented in Table 1. Similar values were also given in different studies (e.g., DeRousseau et al. [55] stated 8 years as an LIB lifespan and Peters et al. [56] stated 80% of the SOH as a retirement point for traction and stationary LIBs).

2.2.3. Demand

As described in Section 2.2.1, the lifespan used in the Weibull distribution determines the amount of inflow, outflow, and in-use stock. To determine the input data for the demand, this study set two assumptions.

The first assumption is relevant to the relationship between stock and lifespan. The number of future stocks follows the growth trend for durables, reflecting the social landscape in particular [57]. This study assumed that the difference in stock between two successive years would be identical regardless of the lifespan scenario. This is expressed by the following equation:

However, such an assumption cannot be simply applied to the relationship between demand and lifespan, since the production of products with shorter lifespans needs to be higher to fulfill the requirement for the number of stocks, consequently increasing the demand for those products. This highlights the necessity of developing a demand scenario corresponding to each lifespan scenario.

As a starting point for developing the demand scenarios, we referred to the European Commission report from 2018 [58], which included a review of various global growth scenarios (proposed by the BNEF and IEA) for both traction and stationary LIBs in the years leading up to 2040 and categorized these scenarios according to LIB capacity as high, medium, or low. In this study, the predicted increasing trend for LIBs in 2030–2040 was linearly extrapolated from 2040 to 2050. For the demand for stationary LIB capacities, only the high-demand pattern was selected because this demand was nearly zero in the other medium- and low-demand patterns. In forecasting the demand for traction LIB capacities, a number of demand patterns were used in this study: Demand pattern_H, Demand pattern_M, and Demand pattern_L.

In considering the demand for traction LIBs, the referred demand patterns were synthesized from various primary scenarios developed with a different algorithm. Note that it is difficult to assign the appropriate lifespan to each of the categorized demand patterns. As such, this study assumed a 14 year lifespan for traction LIBs, which is the lifespan in the medium scenario (given in Section 2.2.2). This was applied to each of the demand patterns for traction LIBs. Equation (4) was used for the case of a 14 year lifespan, and Equation (5) was used for all lifespan scenarios. Then, the demand for the traction LIBs in the different lifespan scenarios (Lifespan_8 and Lifespan_20) was calculated with the following equations:

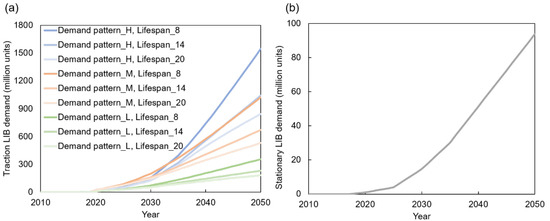

Ultimately, this study analyzed the nine demand scenarios by combining the lifespan scenarios (Lifespan_8, Lifespan_14, and Lifespan_20) and the referenced demand patterns (Demand pattern_H, Demand pattern_M, and Demand pattern_L). The scenarios for the LIB demand are given in Figure 2. The data are given in the Supplementary Materials.

Figure 2.

Scenarios of LIB demand for (a) traction and (b) stationary use.

While it is acknowledged that the assumptions lead to unavoidable uncertainties, the advantage of this approach is that it allows various possibilities in both demand and lifespan to be considered, and the potential and conceivable ranges of global natural resource use can be presented.

2.2.4. Effectiveness of Circularity

The global circular resource use for LIBs based on TMR was estimated with the following equation:

where is the global circular resource use for LIBs, is the TMR for primary LIBs, is the TMR for recycled LIBs, is the TMR for repurposed LIBs, is the inflow of primary traction LIBs, is the inflow of recycled traction LIBs, is the inflow of primary stationary LIBs, is the inflow of repurposed stationary LIBs, is the inflow of traction LIBs, and is the inflow of stationary LIBs.

The effectiveness of LIB circularity was evaluated in the form of the reduction rate by comparing the global circular resource use for LIBs and the global resource use for LIBs without repurposing and recycling. It is expressed by the following equation:

where is the reduction rate for global resource use for LIBs for traction and stationary use through circularity.

3. Results

3.1. TMR for Repurposed and Recycled LIBs

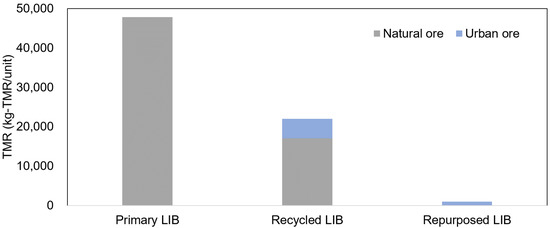

A comparison of the TMR for primary LIBs, recycled LIBs, and repurposed LIBs is presented in Figure 3. While the TMR for primary LIB was 47,800 kg-TMR/unit and the TMR coefficient for primary LIBs per LIB weight was 189 kg-TMR/kg [41], the TMRs for recycled and repurposed LIBs were 22,000 kg-TMR/unit and 1030 kg-TMR/unit and the TMR coefficients for recycled and repurposed LIBs per LIB weight were 87.0 kg-TMR/kg and 4.06 kg-TMR/kg, respectively. These results indicate that the process of repurposing and recycling leads to a significant reduction in resource use from natural ore for the production of primary LIBs. The results also show the benefit of the repurposing stage for the stationary use of LIBs, rather than directly channeling LIBs to the recycling stage, from the perspective of resource use.

Figure 3.

TMR for primary LIBs, recycled LIBs, and repurposed LIBs.

The repurposing of LIBs effectively reduces resource use for primary LIB production by approximately 98%. This low resource use is because just 1630 kg of resources are allocated in the calculation process for repurposing, including 1500 kg of urban ore in the form of obsolete battery electric vehicles. Based on the monetary value, 63% of the total weight of resources can be allocated to repurposed LIBs.

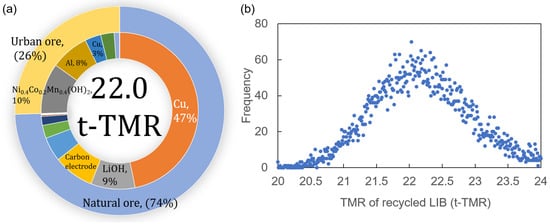

A breakdown for recycled LIBs by composition is presented in Figure 4. The use of recycled LIBs reduces resource use for primary LIB production by more than 50%. This is because of the availability of secondary materials through the recycling process. The TMR coefficient for secondary materials is much lower than that for primary materials, which contributes to the reduction in resource use. According to Figure 3, the TMR for primary materials from natural ores recycled LIBs can be eventually reduced by approximately 64.4% compared to that for primary materials from natural ores the primary LIBs. In particular, the use of secondary copper and NMC would be a major contributor to this reduction. For instance, nearly 50% of copper in spent LIBs can be recycled and used in the production of recycled LIBs, which amounts to a reduction in the TMR coefficient for secondary copper of approximately 90% compared with that for primary copper. Notably, copper extracted from natural ores represented the greatest share (47%) in the TMR, as shown in Figure 4a. Technological innovation for copper recovery from LIBs is a priority to reduce resource use.

Figure 4.

TMR for recycled LIB (a) and from the Monte Carlo simulation (b).

In the Monte Carlo simulation, 22,000 kg-TMR/unit was the most frequent value for the TMR for recycled LIBs, which mostly ranged between 20,000and 24,000 kg-TMR/unit. The use of secondary materials reduces the impact of uncertainties related to the primary materials originating from natural ore.

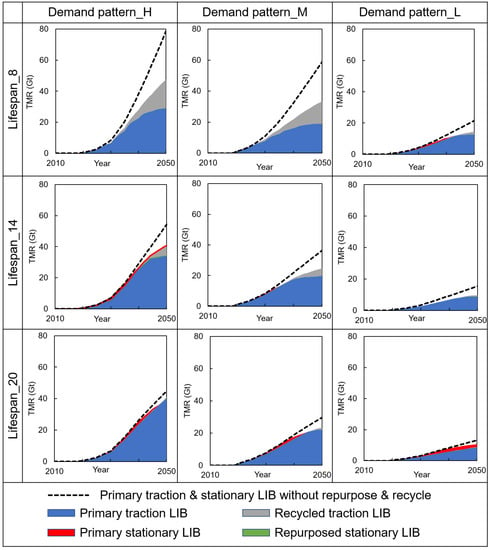

3.2. Global Circular Resource Use

Based on the nine patterns of demand and lifespan presented in Section 2.2.3, a scenario analysis was conducted to estimate the global resource use for LIBs for traction and stationary use. The global circular resource use for LIBs during the 2010–2050 period is presented in Figure 5, and the reduction rate for global resource use for LIBs due to circularity in 2050 is presented in Table 2.

Figure 5.

Global circular resource use for LIBs during the period from 2010 to 2050.

Table 2.

Reduction rate for global resource use for LIBs through circularity in 2050.

Considering the different but promising patterns of demand and lifespan, the TMR of LIBs is expected to increase, reaching 10–48 Gt in 2050. Considering that global mining activities moved over 57 Gt of land every year in the 20th century [59] and that this value is expected to increase because of the expected growth in material use [60,61], it is necessary to calculate TMR value as a representation of the mining footprint when considering the impact of LIB production and to determine the share of the total resource use represented by LIBs.

A shorter lifespan equates to the generation of a greater number of spent LIBs, and this could facilitate the circularity of resources in the shorter term and increase the reduction rate for global resource use for LIBs through circularity in 2050 to up to 44%. On the other hand, a longer lifespan equates to the generation of fewer spent LIBs, and this has a short-term and limited effect on circularity (i.e., an 8% reduction rate in 2050 for a lifespan of 20 years in the case of the high demand pattern).

It must be stressed that the TMR of an LIB with a lifespan of 20 years would be smaller than that of one with a lifespan of 8 years in 2050. This indicates that the increase in LIB demand, rather than the effectiveness of circularity, has a greater impact on resource use. On the other hand, the TMR of an LIB with a lifespan of 20 years would be approximately equivalent to that of one with a lifespan of 14 years in 2050. This is because, in terms of resource use reduction, the lower demand for LIBs with a lifespan of 20 years is compensated for by greater effectiveness in circularity for LIBs with a lifespan of 14 years.

While this study set the lifespan scenario from the perspective of SOH, several automobile companies have announced warranty distances for traction LIBs. Nissan has set a distance of 160,000 km as its warranty distance [62], corresponding to approximately 11.7 years of traction LIB lifespan in this study. Considering the lifespan scenario proposed in this study, this Nissan case would need to rely heavily on closed-loop recycling in the circular system at the early stage.

4. Discussion

4.1. Strategic Implications

This study estimated the global resource use for LIBs for traction and stationary use during the period between 2010 and 2050 and analyzed the effectiveness of resource circularity through repurposing and recycling. In the years leading up to 2050, it was found that a longer lifespan would have a greater impact on the reduction in resource use for LIBs than a shorter lifespan. This is because a longer lifespan is associated with a decrease in the demand (but less effective circularity), whereas a shorter lifespan is associated with an increase in demand (but a higher effectiveness for circularity). Circularity, particularly in terms of closed-loop recycling, will be effective in the longer term, beyond 2050.

Thus, urgent action is required as a mid-term strategy for the reduction of resource use for LIBs for the period up to 2050 to ensure the reuse and repurposing of LIBs and extend their lifespan. Furthermore, ongoing R&D efforts are required to determine methods for improving the rate of recovery from spent LIBs through recycling.

The reuse of spent traction LIBs for traction use is one way of extending the lifespan of LIBs. Since the channeling of spent traction LIBs for traction reuse is limited [63], it is important to identify the demand for traction use that would matche even the deteriorated SOH of retired traction LIBs. For instance, the reuse of spent traction LIBs in fleet vehicles in industry with short driving distances would be an interesting application [64]. The promotion of green purchasing from the demand side in the EV industry [65] and tax credits for reused traction LIBs would serve as financial incentives to improve closed-loop reuse circularity. Specifying the end-user driving behavior and estimating the share of BEVs appropriate for the reuse of spent LIBs in the total demand would allow the effectiveness of circularity to be more precisely evaluated.

Besides efforts directed toward the extension of lifespan, a direct approach to reducing the demand for traction LIBs is also important. As shown in Figure 5, the difference in the estimates among the three promising demand-pattern scenarios proposed by the European Commission [58] was as much as 420%. One of the promising approaches to reducing the demand for EVs is to promote carsharing and ridesharing. Carsharing and ridesharing would contribute to a reduction in the number of personally owned vehicles (e.g., 25–75% [66]), which would contribute to a reduced number of newly produced vehicles [67]. This would eventually lead to lower resource use for LIBs. In addition, under the low-demand-pattern scenario, the effectiveness of recycled traction LIBs would be limited, while the repurposing of spent LIBs for stationary use would be the major contributor to circularity. Cooperation between the stationary energy storage industry and the vehicle service provision industry is important to achieve a circular economy associated with LIBs.

4.2. Limitations and Future Prospective

It should be noted that the effectiveness of circularity for the scenario with a lifespan of 20 years must be observed by extending the period of assessment beyond 2050. A longer duration of assessment (such as up to 2100) would be ideal to show the potential of LIB circularity, despite the unavoidably large uncertainties in the projection. It should be noted that the EC report [58] referred to in this study showed great variances between the three demand pattern scenarios up to 2050. Therefore, the results of this study are just a stepping stone towards a circular economy.

In this study, it was assumed that all of the spent traction LIBs would be channeled toward either the repurposing or recycling stages. A high rate of collection of spent vehicles has been achieved in developed countries (e.g., approximately 100% in Japan [68]). This is because the number of end-of-life vehicles is rigorously managed by the vehicle registration system [69]. On the other hand, in many developing countries, end-of-life vehicles are not properly managed due to an inadequate registration system, and the collection rate is uncertain. This highlights the need for the soft support provided by institutional design for the adequate collection of spent traction LIBs to promote circularity in developing countries, in addition to the physical support of recycling technology for the recovery of resources. From an analytical viewpoint, high spatial resolution is required in future studies to grasp regional characteristics and truly comprehend the global scale of the application of the strategies discussed this study.

Technological innovation with regard to the production of traction LIBs was not considered in this study, and the recovery rate in the recycling stage was assumed to remain steady until 2050. The substitution of currently used resources with lower resource-intensity materials [35] and the achievement of more efficient process of mining and recycling [70] would reduce the specific TMR of LIBs, and the resource use would be lower than that indicated by the results of this study. In particular, a lower value for the specific TMR for recycled LIBs thanks to technological innovation would lead to more effective circularity. In this regard, the results of this study could be considered to represent the worst-case scenario.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/mining2030024/s1.

Author Contributions

Conceptualization, S.K. and E.Y.; methodology, S.K. and E.Y.; software, U.T.; validation, S.K. and E.Y.; formal analysis, S.K. and U.T.; investigation, U.T.; resources, S.K.; data curation, U.T.; writing—original draft preparation, S.K.; writing—review and editing, E.Y.; visualization, U.T.; supervision, E.Y.; project administration, E.Y.; funding acquisition, S.K. and E.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This study was partly supported by research funds from KAKENHI Grants (20K20013 and 22H03805), from the Environment Research and Technology Development Fund (S-16), and from the Ritsumeikan Global Innovation Research Organization(R-GIRO), Ritsumeikan University.

Data Availability Statement

The data presented in this study are available in the Supplementary Materials.

Acknowledgments

The authors would like to thank Genya Murakami for his invaluable comments during the course of this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hu, X.; Murgovski, N.; Johannesson, L.M.; Egardt, B. Comparison of three electrochemical energy buffers applied to a hybrid bus power train with simultaneous optimal sizing and energy management. IEEE Trans. Intell. Transp. Syst. 2014, 15, 1193–1205. [Google Scholar] [CrossRef]

- Hammond, G.P.; Hazeldine, T. Indicative energy technology assessment of advanced rechargeable batteries. Appl. Energy 2015, 138, 559–571. [Google Scholar] [CrossRef]

- International Energy Agency. Energy Technology Perspectives 2020; International Energy Agency: Paris, France, 2020. [Google Scholar]

- International Energy Agency. Global EV Outlook 2017; IEA: Paris, France, 2017. [Google Scholar]

- Hua, Y.; Zhou, S.; Huang, Y.; Liu, X.; Ling, H.; Zhou, X.; Zhang, C.; Yang, S. Sustainable value chain of retired lithium-ion batteries for electric vehicles. J. Power Sources 2020, 478, 228753. [Google Scholar] [CrossRef]

- Velenturf, A.P.; Purnell, P. Principles for a sustainable circular economy. Sustain. Prod. Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

- Ali, H.; Khan, H.A.; Pecht, M.G. Circular economy of Li Batteries: Technologies and trends. J. Energy Storage 2021, 40, 102690. [Google Scholar] [CrossRef]

- Harris, S.; Martin, M.; Diener, D. Circularity for circularity’s sake? Scoping review of assessment methods for environmental performance in the circular economy. Sustain. Prod. Consum. 2020, 26, 172–186. [Google Scholar] [CrossRef]

- Doose, S.; Mayer, J.; Michalowski, P.; Kwade, A. Challenges in Ecofriendly Battery Recycling and Closed Material Cycles: A Perspective on Future Lithium Battery Generations. Metals 2021, 11, 291. [Google Scholar] [CrossRef]

- Baars, J.; Domenech, T.; Bleischwitz, R.; Melin, H.E.; Heidrich, O. Circular economy strategies for electric vehicle batteries reduce reliance on raw materials. Nat. Sustain. 2020, 4, 71–79. [Google Scholar] [CrossRef]

- Xu, C.; Dai, Q.; Gaines, L.; Hu, M.; Tukker, A.; Steubing, B. Future material demand for automotive lithium-based batteries. Commun. Mater. 2020, 1, 99. [Google Scholar] [CrossRef]

- Kosai, S.; Matsui, K.; Matsubae, K.; Yamasue, E.; Nagasaka, T. Natural resource use of gasoline, hybrid, electric and fuel cell vehicles considering land disturbances. Resour. Conserv. Recycl. 2020, 166, 105256. [Google Scholar] [CrossRef]

- van Loon, P.; Diener, D.; Harris, S. Circular products and business models and environmental impact reductions: Current knowledge and knowledge gaps. J. Clean. Prod. 2020, 288, 125627. [Google Scholar] [CrossRef]

- Sommerville, R.; Zhu, P.; Rajaeifar, M.A.; Heidrich, O.; Goodship, V.; Kendrick, E. A qualitative assessment of lithium ion battery recycling processes. Resour. Conserv. Recycl. 2020, 165, 105219. [Google Scholar] [CrossRef]

- Ardente, F.; Peiró, L.T.; Mathieux, F.; Polverini, D. Accounting for the environmental benefits of remanufactured products: Method and application. J. Clean. Prod. 2018, 198, 1545–1558. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G. Reuse and Recycling of Lithium-Ion Power Batteries; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Pagliaro, M.; Meneguzzo, F. Lithium battery reusing and recycling: A circular economy insight. Heliyon 2019, 5, e01866. [Google Scholar] [CrossRef]

- British Standardisation Institute. BS 8887-2-Design for Manufacture, Assembly, Disassembly and End-Of-Life Processing (MADE). Terms and Definitions; BSI: London, UK, 2009. [Google Scholar]

- Bobba, S.; Mathieux, F.; Ardente, F.; Blengini, G.A.; Cusenza, M.A.; Podias, A.; Pfrang, A. Life Cycle Assessment of re-purposed electric vehicles batteries: An adapted method based on modelling of energy flows. J. Energy Storage 2018, 19, 213–225. [Google Scholar] [CrossRef]

- Albertsen, L.; Richter, J.L.; Peck, P.; Dalhammar, C.; Plepys, A. Circular business models for electric vehicle lithium-ion batteries: An analysis of current practices of vehicle manufacturers and policies in the EU. Resour. Conserv. Recycl. 2021, 172, 105658. [Google Scholar] [CrossRef]

- Hein, R.; Kleindorfer, P.R.; Spinler, S. Valuation of electric vehicle batteries in vehicle-to-grid and battery-to-grid systems. Technol. Forecast. Soc. Chang. 2012, 79, 1654–1671. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Guarino, F.; Longo, S.; Mistretta, M.; Cellura, M. Reuse of electric vehicle batteries in buildings: An integrated load match analysis and life cycle assessment approach. Energy Build. 2019, 186, 339–354. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, X.; Zhou, S.; Huang, Y.; Ling, H.; Yang, S. Toward Sustainable Reuse of Retired Lithium-ion Batteries from Electric Vehicles. Resour. Conserv. Recycl. 2020, 168, 105249. [Google Scholar] [CrossRef]

- Mossali, E.; Picone, N.; Gentilini, L.; Rodrìguez, O.; Pérez, J.M.; Colledani, M. Lithium-ion batteries towards circular economy: A literature review of opportunities and issues of recycling treatments. J. Environ. Manag. 2020, 264, 110500. [Google Scholar] [CrossRef]

- Dunn, J.; Slattery, M.; Kendall, A.; Ambrose, H.; Shen, S. Circularity of Lithium-Ion Battery Materials in Electric Vehicles. Environ. Sci. Technol. 2021, 55, 5189–5198. [Google Scholar] [CrossRef] [PubMed]

- Ziemann, S.; Müller, D.B.; Schebek, L.; Weil, M. Modeling the potential impact of lithium recycling from EV batteries on lithium demand: A dynamic MFA approach. Resour. Conserv. Recycl. 2018, 133, 76–85. [Google Scholar] [CrossRef]

- Kamran, M.; Raugei, M.; Hutchinson, A. A dynamic material flow analysis of lithium-ion battery metals for electric vehicles and grid storage in the UK: Assessing the impact of shared mobility and end-of-life strategies. Resour. Conserv. Recycl. 2021, 167, 105412. [Google Scholar] [CrossRef]

- Castro, F.D.; Cutaia, L.; Vaccari, M. End-of-life automotive lithium-ion batteries (LIBs) in Brazil: Prediction of flows and revenues by 2030. Resour. Conserv. Recycl. 2021, 169, 105522. [Google Scholar] [CrossRef]

- Parchomenko, A.; Nelen, D.; Gillabel, J.; Vrancken, K.C.; Rechberger, H. Resource effectiveness of the European automotive sector—A statistical entropy analysis over time. Resour. Conserv. Recycl. 2021, 169, 105558. [Google Scholar] [CrossRef]

- Acerbi, F.; Taisch, M. A literature review on circular economy adoption in the manufacturing sector. J. Clean. Prod. 2020, 273, 123086. [Google Scholar] [CrossRef]

- Fischer-Kowalski, M.; Krausmann, F.; Giljum, S.; Lutter, S.; Mayer, A.; Bringezu, S.; Moriguchi, Y.; Schütz, H.; Schandl, H.; Weisz, H. Methodology and Indicators of Economy-wide Material Flow Accounting: State of the Art and Reliability Across Sources. J. Ind. Ecol. 2011, 15, 855–876. [Google Scholar] [CrossRef]

- Kovanda, J.; Weinzettel, J. Economy-wide Material Flow Indicators on a Sectoral Level and Strategies for Decreasing Material Inputs of Sectors. J. Ind. Ecol. 2016, 21, 26–37. [Google Scholar] [CrossRef]

- Bringezu, S.; Schütz, H.; Steger, S.; Baudisch, J. International comparison of resource use and its relation to economic growth: The development of total material requirement, direct material inputs and hidden flows and the structure of TMR. Ecol. Econ. 2004, 52, 97–124. [Google Scholar] [CrossRef]

- Nakajima, K.; Noda, S.; Nansai, K.; Matsubae, K.; Takayanagi, W.; Tomita, M. Global Distribution of Used and Unused Extracted Materials Induced by Consumption of Iron, Copper, and Nickel. Environ. Sci. Technol. 2019, 53, 1555–1563. [Google Scholar] [CrossRef]

- Kosai, S.; Yamasue, E. Global warming potential and total material requirement in metal production: Identification of changes in environmental impact through metal substitution. Sci. Total Environ. 2018, 651, 1764–1775. [Google Scholar] [CrossRef] [PubMed]

- Södersten, C.-J.; Wood, R.; Wiedmann, T. The capital load of global material footprints. Resour. Conserv. Recycl. 2020, 158, 104811. [Google Scholar] [CrossRef]

- Watari, T.; Nansai, K.; Nakajima, K.; Giurco, D. Sustainable energy transitions require enhanced resource governance. J. Clean. Prod. 2021, 312, 127698. [Google Scholar] [CrossRef]

- Halada, K.; Iijima, K.; N, N.; Okura, T. An Approximate Estimation of Total Material Requirement of Metals. J. Jpn. Inst. Met. Mater 2001, 65, 564–670. [Google Scholar] [CrossRef]

- Nakajima, K.; Halada, K.; Ijima, K.; Nagasaka, T. Estimation of Total Materials Requirement: Energy Resources and Industrial Materials. J. Life Cycle Assess. Jpn. 2006, 2, 152–158. [Google Scholar] [CrossRef][Green Version]

- Wuppertal Institut for Climate, Environment and Energy. Material Intensity of Materials, Fuels, Transport Services, Food; Wuppertal Institute: Wuppertal, Germany, 2011. [Google Scholar]

- Kosai, S.; Takata, U.; Yamasue, E. Natural resource use of a traction lithium-ion battery production based on land dis-turbances through mining activities. J. Clean. Prod. 2021, 280, 124871. [Google Scholar] [CrossRef]

- Ellingsen, L.A.-W.; Majeau-Bettez, G.; Singh, B.; Srivastava, A.K.; Valøen, L.O.; Strømman, A.H. Life Cycle Assessment of a Lithium-Ion Battery Vehicle Pack. J. Ind. Ecol. 2013, 18, 113–124. [Google Scholar] [CrossRef]

- Yamasue, E.; Minamino, R.; Numata, T.; Nakajima, K.; Murakami, S.; Daigo, I.; Hashimoto, S.; Okumura, H.; Ishihara, K. Novel Evaluation Method of Elemental Recyclability from Urban Mine—Concept of Urban Ore TMR—. Mater. Trans. 2009, 50, 1536–1540. [Google Scholar] [CrossRef]

- Yamasue, E.; Matsubae, K.; Nakajima, K.; Daigo, I.; Ishihara, K.N. Total Material Requirement of Scrap Steel from End-of-Life Vehicle. Tetsu Hagane 2014, 100, 778–787. [Google Scholar] [CrossRef]

- Tomić, T.; Schneider, D.R. The role of energy from waste in circular economy and closing the loop concept—Energy analysis approach. Renew. Sustain. Energy Rev. 2018, 98, 268–287. [Google Scholar] [CrossRef]

- Huysman, S.; Debaveye, S.; Schaubroeck, T.; De Meester, S.; Ardente, F.; Mathieux, F.; Dewulf, J. The recyclability benefit rate of closed-loop and open-loop systems: A case study on plastic recycling in Flanders. Resour. Conserv. Recycl. 2015, 101, 53–60. [Google Scholar] [CrossRef]

- Müller, E.; Hilty, L.M.; Widmer, R.; Schluep, M.; Faulstich, M. Modeling metal stocks and flows: A review of dynamic material flow analysis methods. Environ. Sci. Technol. 2014, 48, 2102–2113. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Huisman, J.; Stevels, A.; Baldé, C.P. Enhancing e-waste estimates: Improving data quality by multivariate Input-Output Analysis. Waste Manag. 2013, 33, 2397–2407. [Google Scholar] [CrossRef] [PubMed]

- Yano, J.; Muroi, T.; Sakai, S.-I. Rare earth element recovery potentials from end-of-life hybrid electric vehicle components in 2010. J. Mater. Cycles Waste Manag. 2015, 18, 655–664. [Google Scholar] [CrossRef]

- Takata, S.; Suemasu, K.; Asai, K. Life cycle simulation system as an evaluation platform for multitiered circular manu-facturing systems. CIRP Ann. Manuf. Technol. 2019, 68, 21–24. [Google Scholar] [CrossRef]

- NISSAN. Driving Range. Available online: https://area.nissan.co.jp/fair/ni-aichi/18/11/leaf-for-you/distance/ (accessed on 10 February 2021).

- IEA. Global EV Outlook 2018; IEA: Paris, France, 2018. [Google Scholar]

- Zou, Y.; Hu, X.; Ma, H.; Li, S.E. Combined State of Charge and State of Health estimation over lithium-ion battery cell cycle lifespan for electric vehicles. J. Power Sources 2015, 273, 793–803. [Google Scholar] [CrossRef]

- Casals, L.C.; García, B.A.; Aguesse, F.; Iturrondobeitia, A. Second life of electric vehicle batteries: Relation between materials degradation and environmental impact. Int. J. Life Cycle Assess. 2015, 22, 82–93. [Google Scholar] [CrossRef]

- Derousseau, M.; Gully, B.; Taylor, C.; Apelian, D.; Wang, Y. Repurposing Used Electric Car Batteries: A Review of Options. JOM 2017, 69, 1575–1582. [Google Scholar] [CrossRef]

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters—A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506. [Google Scholar] [CrossRef]

- Tsasaki, T.; Oguchi, M.; Kameya, T.; Urano, K. A Prediction Method for the Number of Waste Durable Goods. J. Jpn. Soc. Waste Manag. Experts 2001, 12, 49–58. (In Japanese) [Google Scholar] [CrossRef]

- Tsiropoulos, I.; Tarvydas, D.; Lebedeva, N. Li-Ion Batteries for Mobility and Stationary Storage Applications—Scenarios for Costs and Market Growth; EUR 29440 EN.; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Douglas, I.; Lawson, N. Material Flows Due to Mining and Urbanization; Edward Elgar Publishing: Cheltenham, UK, 2002. [Google Scholar] [CrossRef]

- Wiedmann, T.; Schandl, H.; Lenzen, M.; Moran, D.; Suh, S.; West, J.; Kanemoto, K. The material footprint of nations. Proc. Natl. Acad. Sci. USA 2015, 112, 6271–6276. [Google Scholar] [CrossRef]

- Wiedenhofer, D.; Fishman, T.; Lauk, C.; Haas, W.; Krausmann, F. Integrating Material Stock Dynamics Into Economy-Wide Material Flow Accounting: Concepts, Modelling, and Global Application for 1900–2050. Ecol. Econ. 2019, 156, 121–133. [Google Scholar] [CrossRef]

- Nissan. Nissan LEAF Range & Charging, Nissan USA. Available online: https://www.nissanusa.com/vehicles/electric-cars/leaf/range-charging.html (accessed on 1 August 2018).

- Martinez-Laserna, E.; Gandiaga, I.; Sarasketa-Zabala, E.; Badeda, J.; Stroe, D.I.; Swierczynski, M.; Goikoetxea, A. Battery second life: Hype, hope or reality? A critical review of the state of the art. Renew. Sustain. Energy Rev. 2018, 93, 701–718. [Google Scholar] [CrossRef]

- Wewer, A.; Bilge, P.; Dietrich, F. Advances of 2nd Life Applications for Lithium Ion Batteries from Electric Vehicles Based on Energy Demand. Sustainability 2021, 13, 5726. [Google Scholar] [CrossRef]

- Shao, J.; Ünal, E. What do consumers value more in green purchasing? Assessing the sustainability practices from demand side of business. J. Clean. Prod. 2018, 209, 1473–1483. [Google Scholar] [CrossRef]

- Yin, B.; Liu, L.; Coulombel, N.; Viguié, V. Appraising the environmental benefits of ride-sharing: The Paris region case study. J. Clean. Prod. 2017, 177, 888–898. [Google Scholar] [CrossRef]

- Pauliuk, S.; Heeren, N.; Berrill, P.; Fishman, T.; Nistad, A.; Tu, Q.; Wolfram, P.; Hertwich, E.G. Global scenarios of resource and emission savings from material efficiency in residential buildings and cars. Nat. Commun. 2021, 12, 1–10. [Google Scholar] [CrossRef]

- Ministry of Economy Trade and Industry. Vehicle Recycling; Ministry of Economy Trade and Industry: Tokyo, Japan, 2020. [Google Scholar]

- Yano, J.; Hirai, Y.; Okamoto, K.; Sakai, S.-I. Dynamic flow analysis of current and future end-of-life vehicles generation and lead content in automobile shredder residue. J. Mater. Cycles Waste Manag. 2013, 16, 52–61. [Google Scholar] [CrossRef]

- Xiang, Y.; Liu, K.; Su, T.; Li, J.; Ouyang, S.; Mao, S.S.; Geimer, M. An Extension of BIM Using AI: A Multi Working-Machines Pathfinding Solution. IEEE Access 2021, 9, 124583–124599. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).