Hyperbolic Representation of Lateral Force–Displacement Relationship for Underground Installed Pipe

Abstract

:1. Introduction

2. Experimental Literature Review

3. Experimental Data

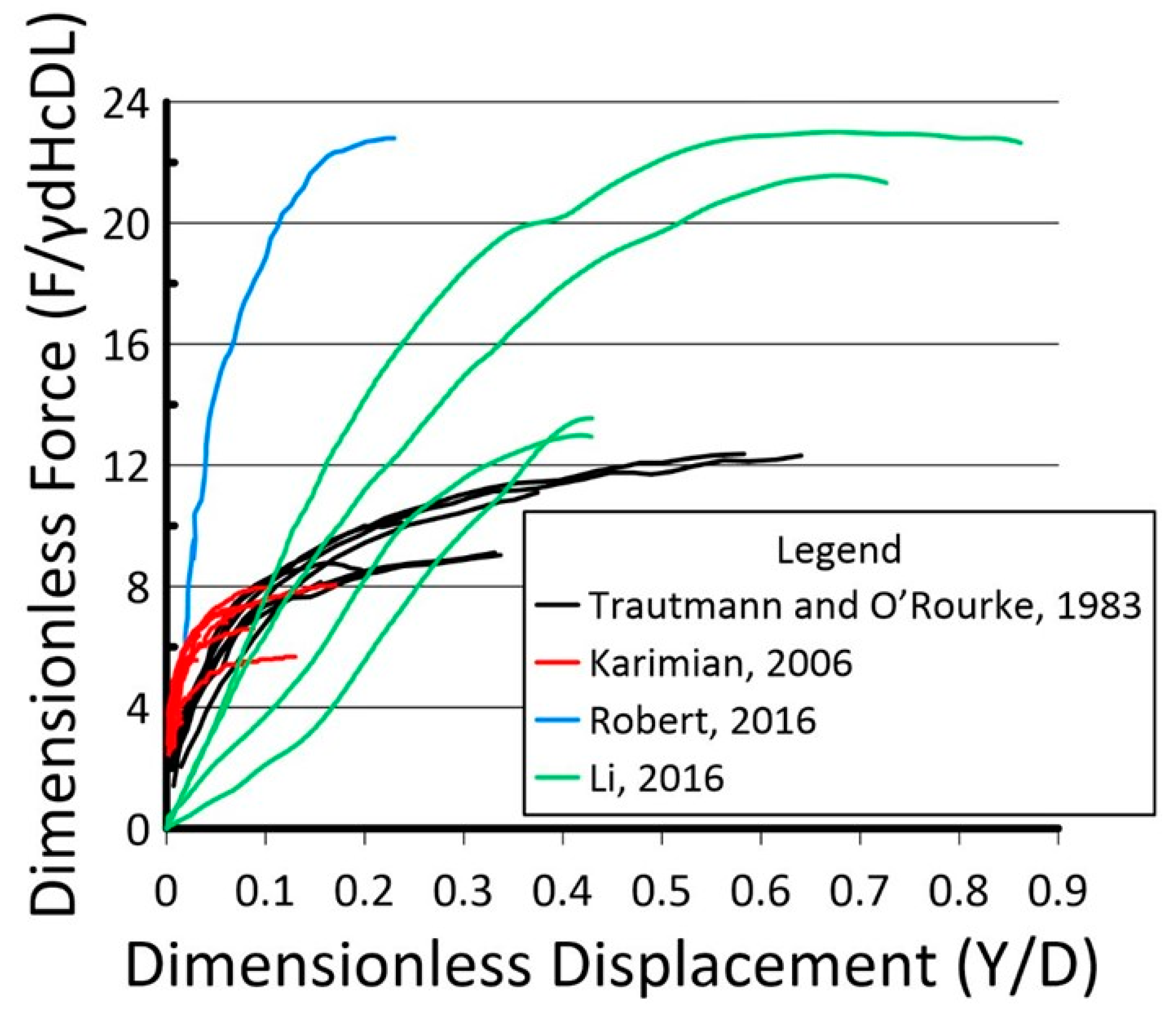

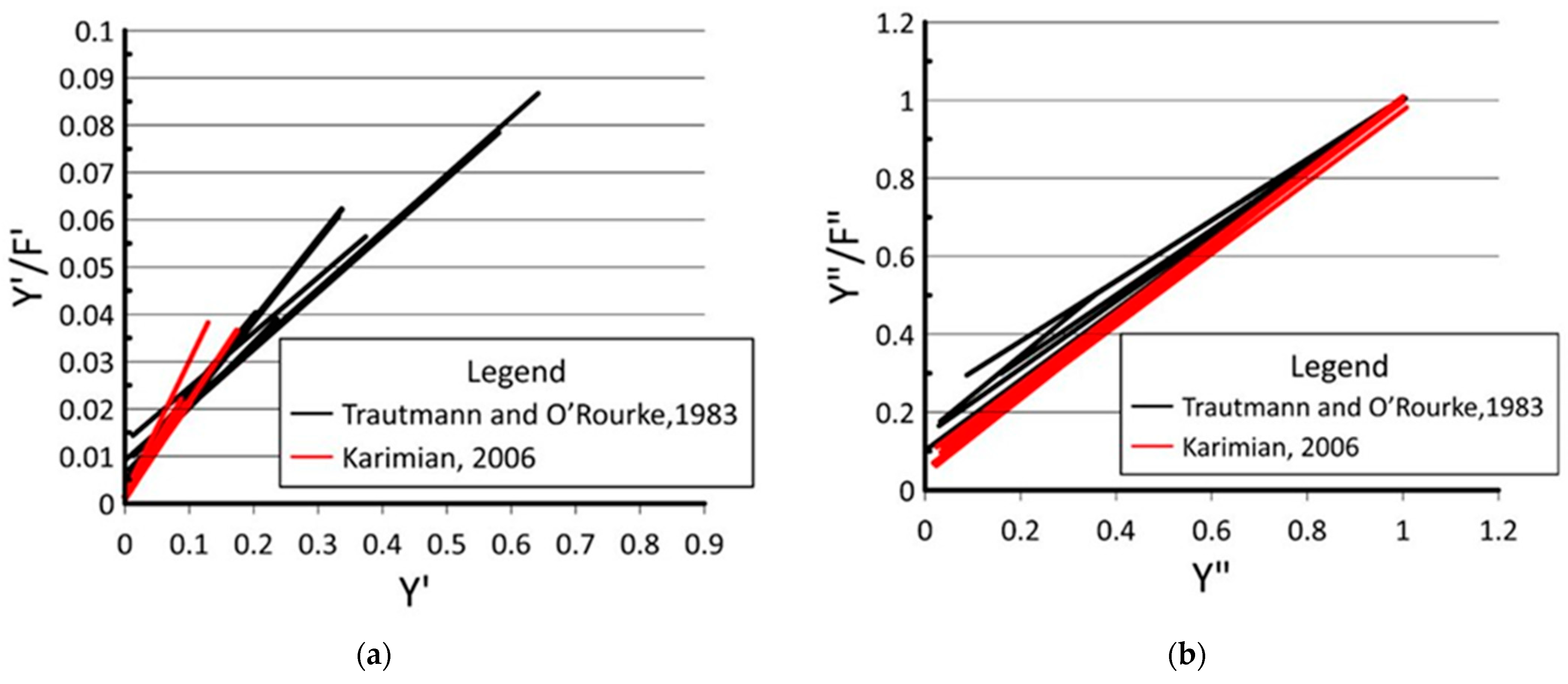

3.1. Medium Sand Experimental Data

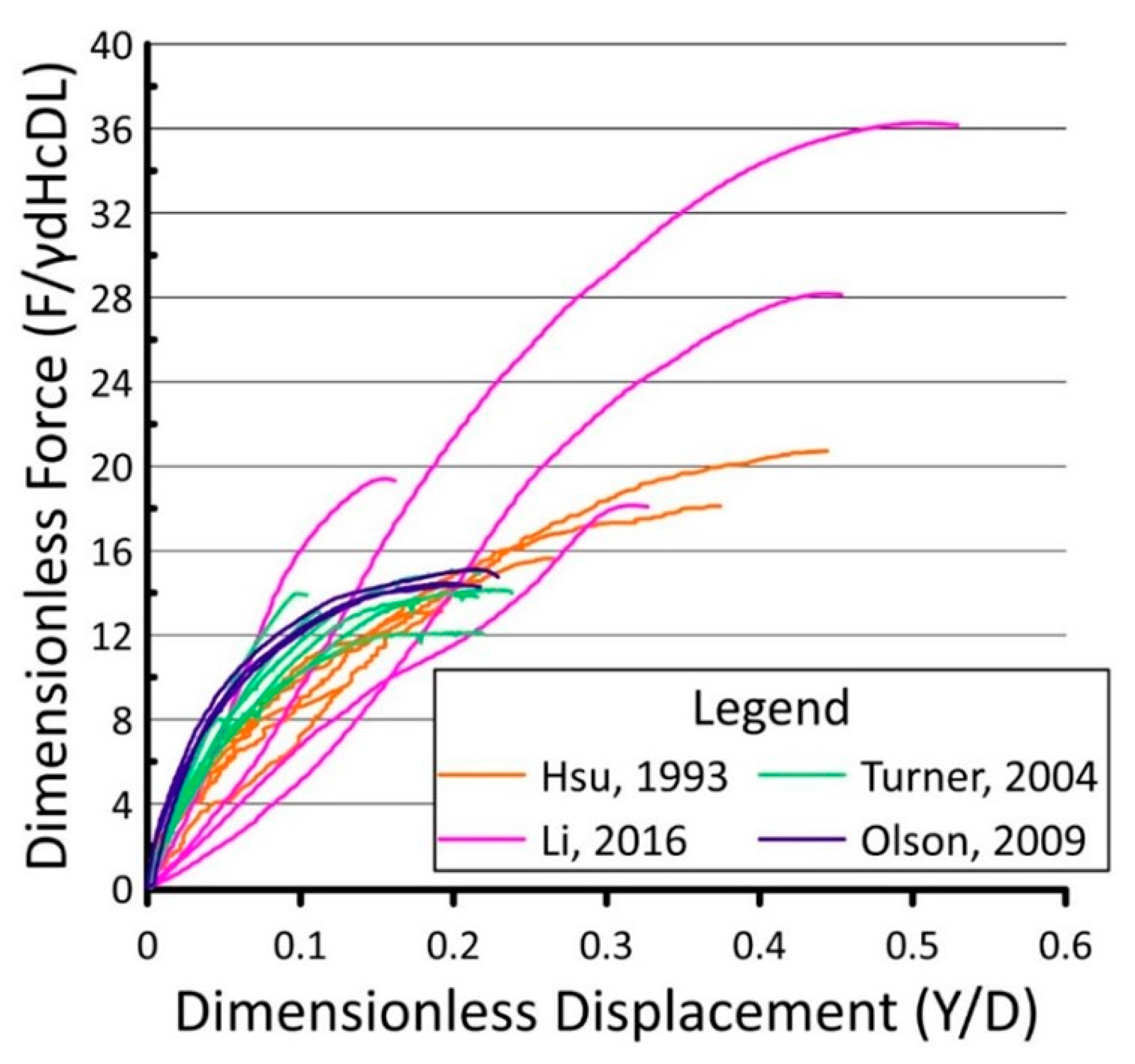

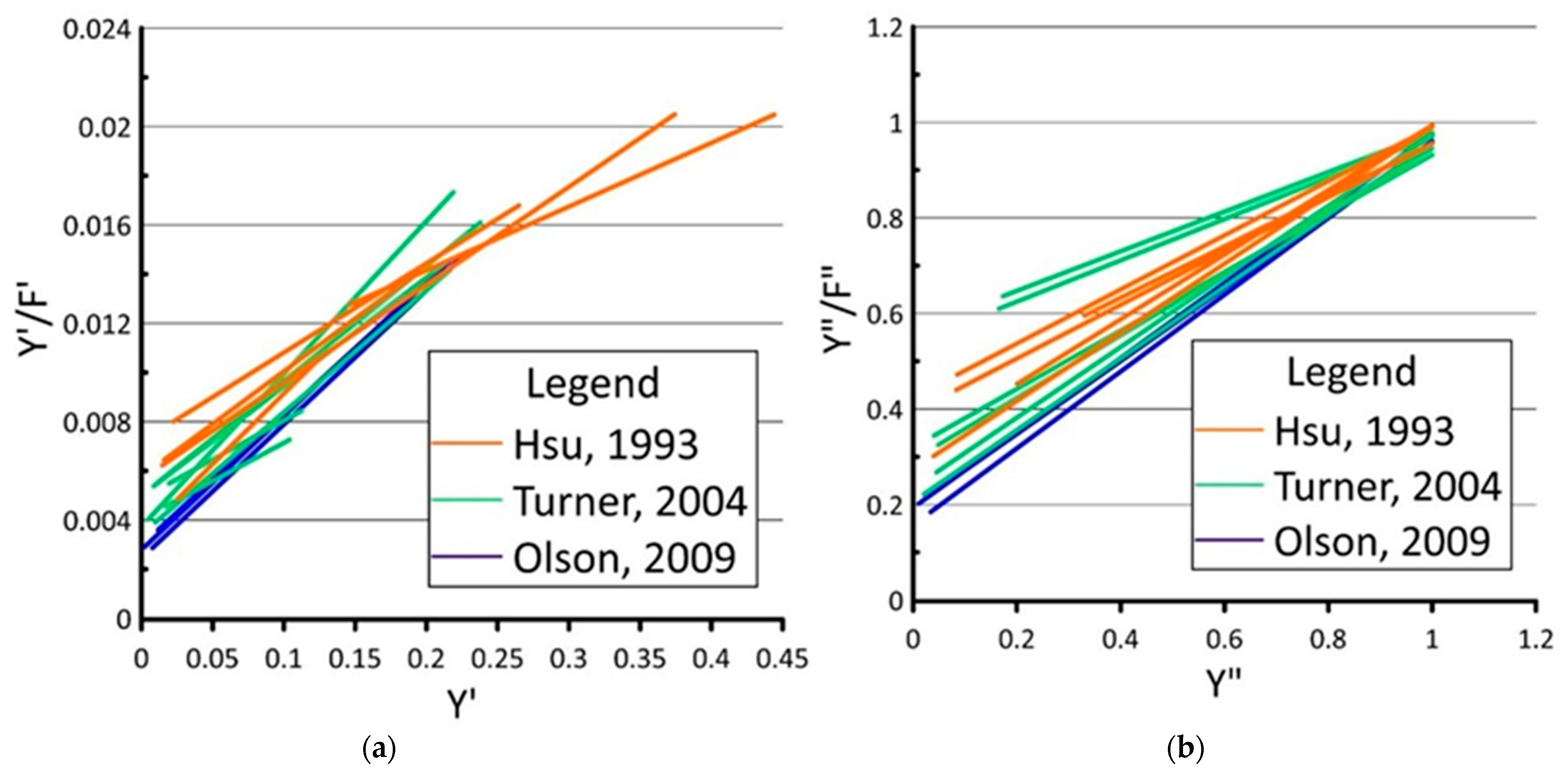

3.2. Dense Sand Experimental Data

3.3. Very Dense Sand Experimental Data

4. Data Analysis

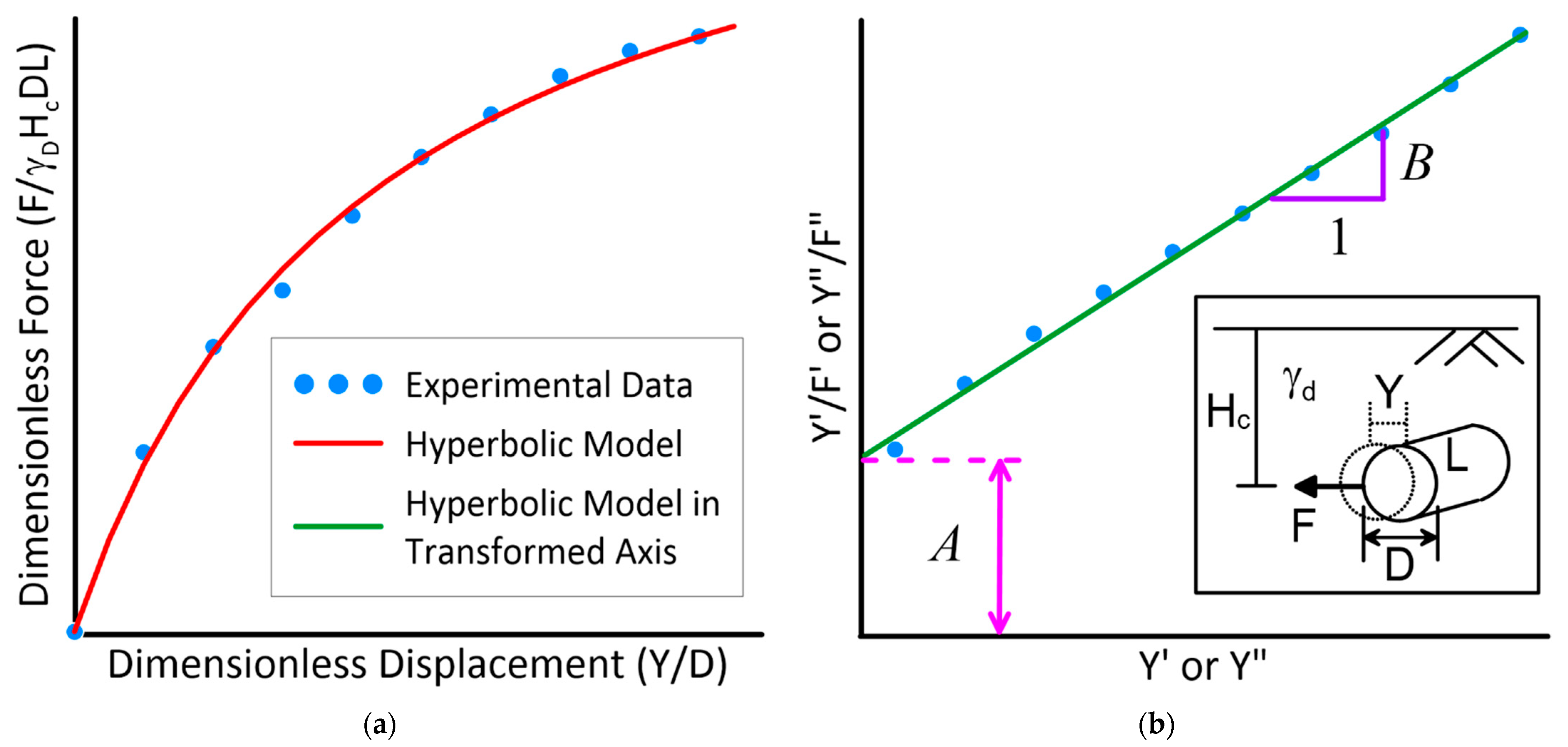

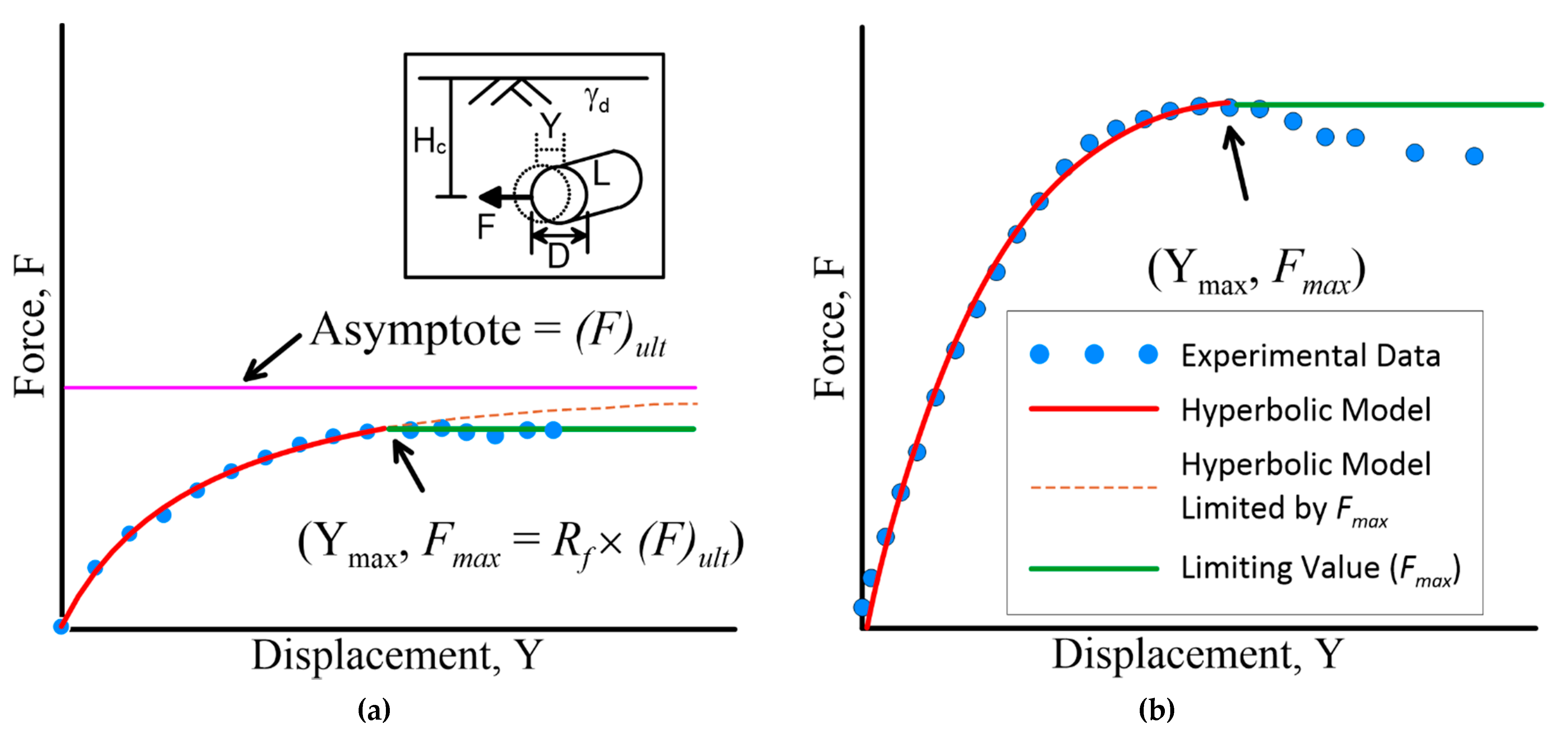

5. Methodology

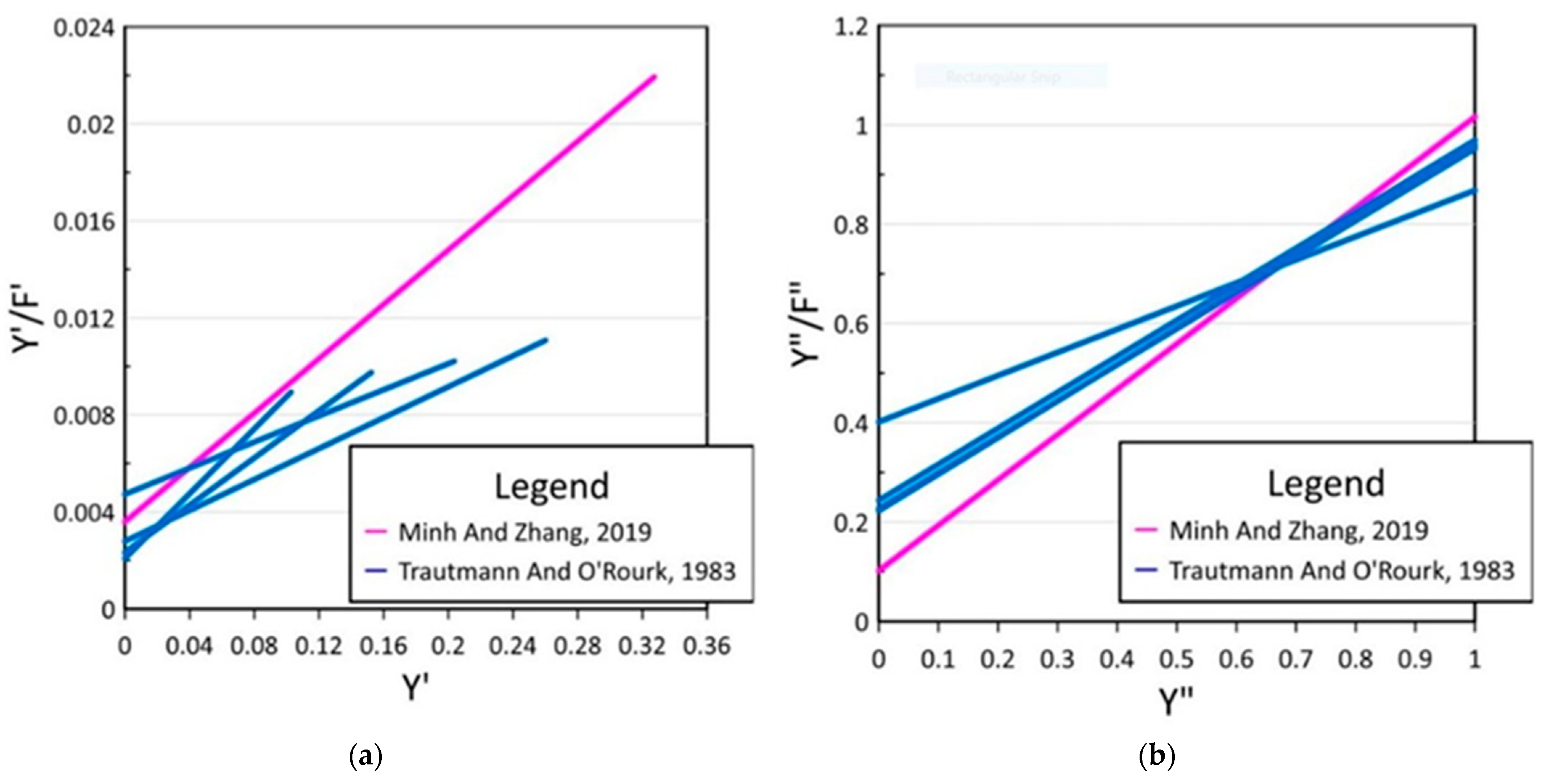

5.1. Single-Normalization

5.2. Double-Normalization

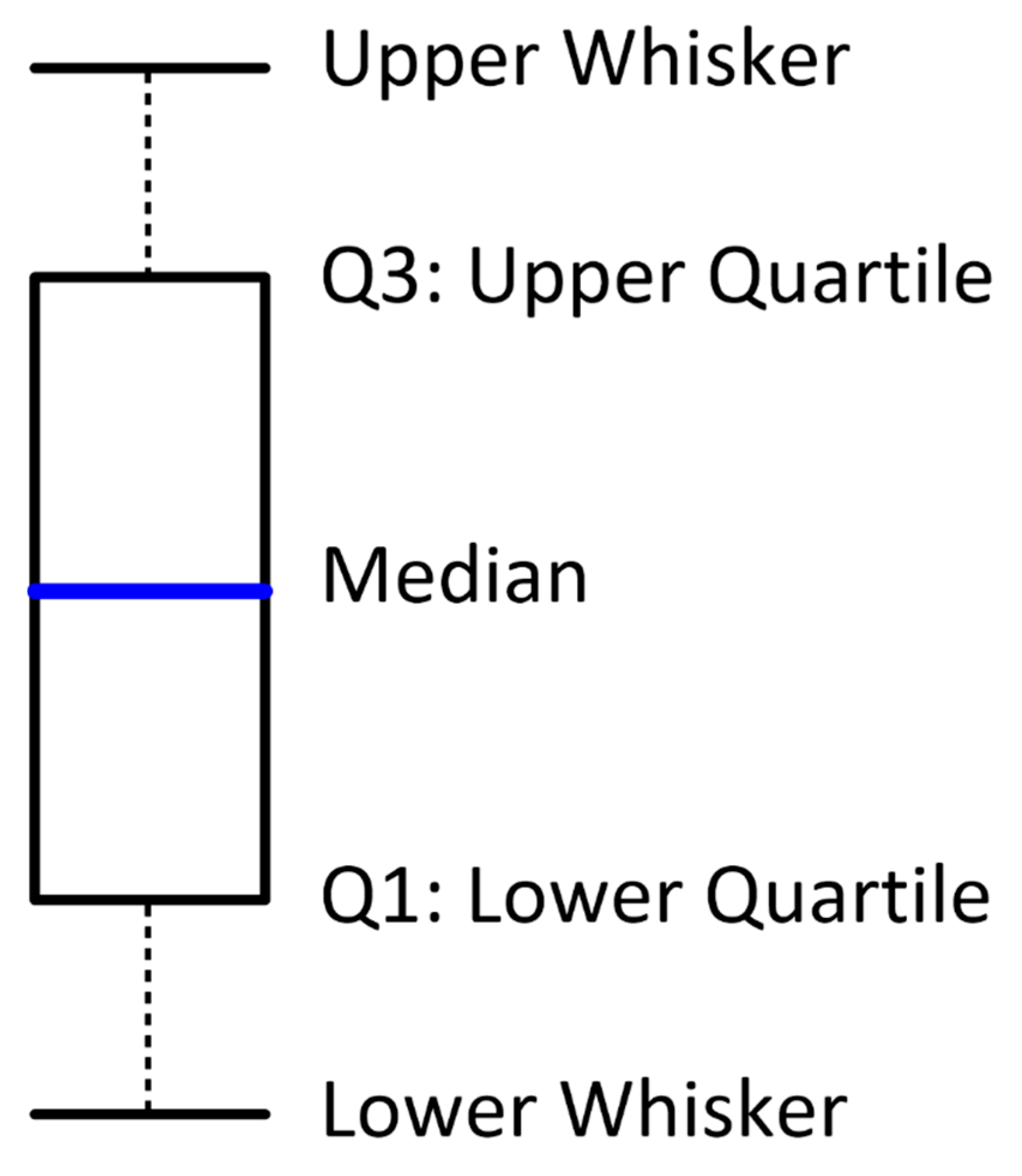

5.3. Outliers

6. Results and Discussion

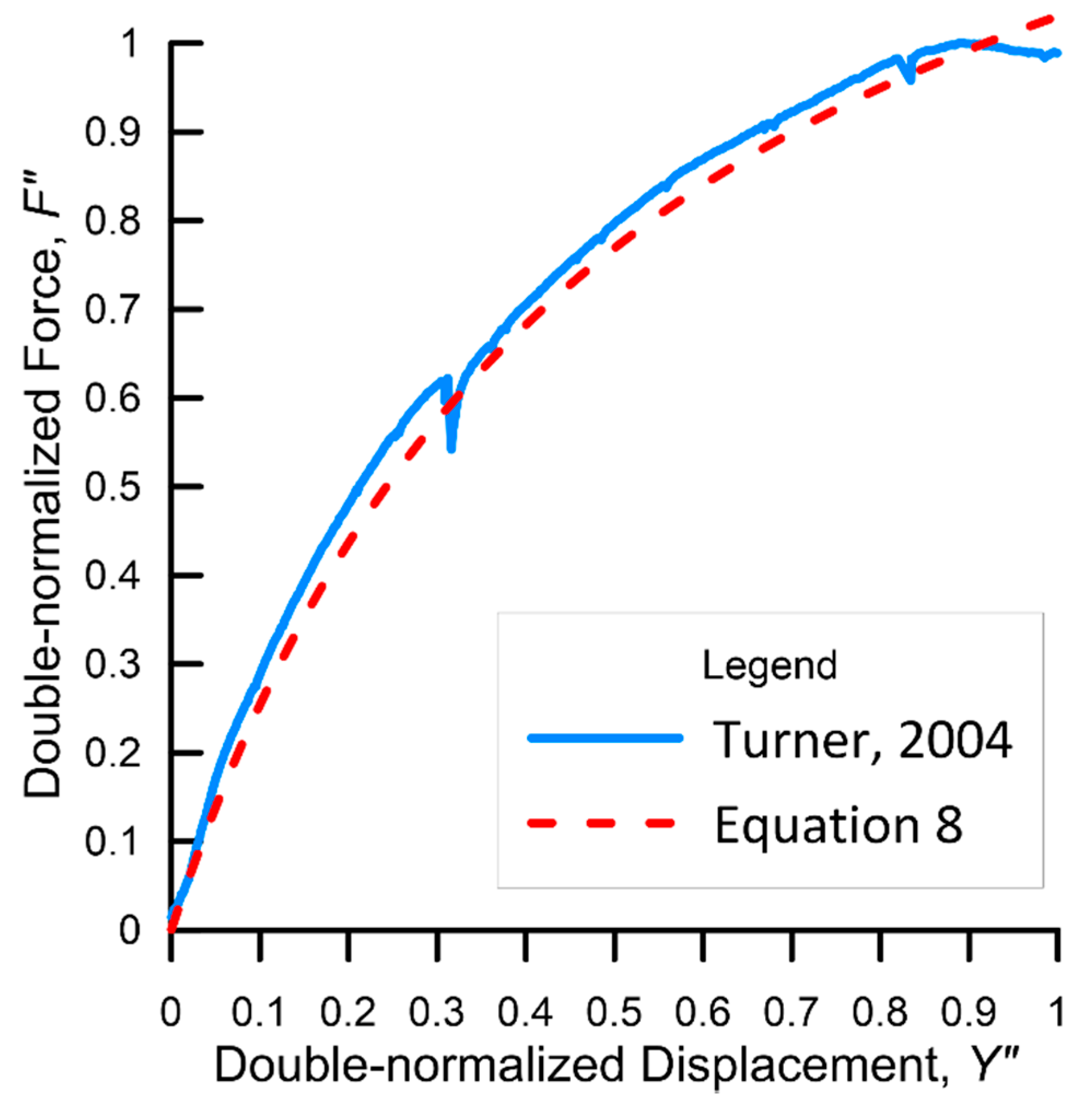

7. Compiled Data and Validation

8. Conclusions

9. Limitations of the Study

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jung, J.K.; O’Rourke, T.D.; Argyrou, C. Multi-directional force-displacement response of underground pipe in sand. Can. Geotech. J. 2016, 53, 1763–1781. [Google Scholar] [CrossRef] [Green Version]

- Soleimani, N.; Davidson, R.A.; Davis, C.; O’Rourke, T.D.; Nozick, L.K. Multihazard Scenarios for Regional Seismic Risk Assessment of Spatially Distributed Infrastructure. J. Infrastruct. Syst. 2021, 27, 04021001. [Google Scholar] [CrossRef]

- O’Rourke, T.D. Geohazards and Large, Geographically Distributed Systems. Geotechnique 2010, 60, 505–543. [Google Scholar] [CrossRef]

- Jung, J.K.; Koo, D.H.D.; Zhang, K. Verification of the pipe depth dependent model using a finite element analysis. Tunn. Undergr. Space Technol. 2014, 39, 34–40. [Google Scholar] [CrossRef]

- Robert, D.J.; Soga, K.; O’Rourke, T.D. Pipelines subjected to fault movement in dry and unsaturated soils. Int. J. Geomech. 2016, 16, C4016001. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Asimaki, D. Smooth nonlinear hysteresis model for coupled biaxial soil-pipe interaction in sandy soils. J. Geotech. Geoenvironmental Eng. 2020, 146, 04020035. [Google Scholar] [CrossRef]

- Trautmann, C.H.; O’Rourke, T.D. Behavior of Pipe in Dry Sand under Lateral and Uplift Loading; Geotechnical Engineering Report 83-7; Cornell University: Ithaca, NY, USA, 1983. [Google Scholar]

- American Society of Civil Engineers. Guidelines for the Seismic Design of Oil and Gas Pipeline Systems; American Society of Civil Engineers: New York, NY, USA, 1984.

- Trautmann, C.H.; O’Rourke, T.D. Lateral force-displacement response of buried pipe. J. Geotech. Eng. 1985, 111, 1077–1092. [Google Scholar] [CrossRef]

- Trautmann, C.H.; O’Rourfce, T.D.; Kulhawy, F.H. Uplift force-displacement response of buried pipe. J. Geotech. Eng. 1985, 111, 1061–1076. [Google Scholar] [CrossRef]

- American Lifelines Alliance. Seismic Design Guidelines for Water Pipelines; American Lifelines Alliance in Partnership with the Federal Emergency Management Agency: Washington, DC, USA, 2005.

- Wijewickreme, D.; Karimian, H.; Honegger, D. Response of buried steel pipelines subjected to relative axial soil movement. Can. Geotech. J. 2009, 46, 735–752. [Google Scholar] [CrossRef]

- Argyrou, C.; O’Rourke, T.D.; Stewart, H.E.; Wham, B.P. Large-scale fault rupture tests on pipelines reinforced with cured-in-place linings. J. Geotech. Geoenviron. Eng. 2019, 145, 04019004. [Google Scholar] [CrossRef]

- Honegger, D.G.; Gailing, R.W.; Nyman, D.J. Guidelines for the seismic design and assessment of natural gas and liquid hydrocarbon pipelines. In Proceedings of the International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2002; Volume 36207, pp. 563–570. [Google Scholar]

- Jung, J.K.; O’Rourke, T.D.; Olson, N.A. Lateral soil-pipe interaction in dry and partially saturated sand. J. Geotech. Geoenviron. Eng. 2013, 139, 2028–2036. [Google Scholar] [CrossRef]

- Ansari, Y.; Kouretzis, G.; Sloan, S.W. Physical modelling of lateral sand–pipe interaction. Géotechnique 2021, 71, 60–75. [Google Scholar] [CrossRef]

- Yimsiri, S.; Soga, K.; Yoshizaki, K.; Dasari, G.R.; O’Rourke, T.D. Lateral and upward soil-pipeline interactions in sand for deep embedment conditions. J. Geotech. Geoenviron. Eng. 2004, 130, 830–842. [Google Scholar] [CrossRef]

- Minh, N.H.; Zhang, D. Soil Responses to Monotonic and Cyclic Lateral Displacement of a Buried Pipe. J. Pipeline Syst. Eng. Pract. 2019, 10, 04019012. [Google Scholar] [CrossRef]

- Morshed, M.A.; Roy, K.; Hawlader, B. Modeling of Buried Pipelines in Dense Sand for Oblique Movement in Vertical–Lateral Plane. J. Pipeline Syst. Eng. Pract. 2020, 11, 04020050. [Google Scholar] [CrossRef]

- Roy, K.; Hawlader, B.; Kenny, S.; Moore, I. A comparative study between lateral and upward anchor-soil and pipe-soil interaction in dense sand. In Proceedings of the International Pipeline Conference, Calgary, AB, Canada, 26–30 September 2016; Volume 50266, p. V002T02A016. [Google Scholar]

- Pike, K.; Kenny, S.; Hawlader, B. Numerical and constitutive model development to aid design against pipeline geohazards. J. Pipeline Eng. 2014, 13, 201–209. [Google Scholar]

- Jung, J.K.; O’Rourke, T.D.; Olson, N.A. Uplift soil–pipe interaction in granular soil. Can. Geotech. J. 2013, 50, 744–753. [Google Scholar] [CrossRef]

- Wong, K.S.; Duncan, J.M. Hyperbolic Stress-Strain Parameters for Nonlinear Finite Element Analyses of Stresses and Movements in Soil Masses; College of Engineering, Office of Research Services, University of California: Berkeley, CA, USA, 1974. [Google Scholar]

- Rowe, R.K.; Davis, E.H. The behaviour of anchor plates in sand. Geotechnique 1982, 32, 25–41. [Google Scholar] [CrossRef]

- Hsu, T.W. Rate effect on lateral soil restraint of pipelines. Soils Found. 1993, 33, 159–169. [Google Scholar] [CrossRef]

- Audibert, J.M.; Nyman, K.J. Soil restraint against horizontal motion of pipes. J. Geotech. Eng. Div. 1977, 103, 1119–1142. [Google Scholar] [CrossRef]

- Turner, J.E. Lateral Force—Displacement Behavior of Pipes in Partially Saturated Sand. Master’s Thesis, Cornell University, Ithaca, NY, USA, 2004. [Google Scholar]

- Karimian, S.A. Response of Buried Steel Pipelines Subjected to Longitudinal and Transverse Ground Movement. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2006. [Google Scholar]

- Das, B.M.; Seeley, G.R. Load-displacement relationship for vertical anchor plates. J. Geotech. Eng. Div. 1975, 101, 711–715. [Google Scholar] [CrossRef]

- Olson, N.A. Soil Performance for Large Scale Soil-Pipeline Tests. Ph.D. Thesis, Cornell University, Ithaca, NY, USA, 2009. [Google Scholar]

- Robert, D.J.; Soga, K.; O’Rourke, T.D.; Sakanoue, T. Lateral load-displacement behavior of pipelines in unsaturated sands. J. Geotech. Geoenviron. Eng. 2016, 142, 04016060. [Google Scholar] [CrossRef]

- Robert, D.J. Soil-Pipeline Interaction in Unsaturated Soils. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2010. [Google Scholar]

- Fern, J.; Soga, K.; Robert, D.J. Shear strength and dilatancy of partially saturated sand in direct shear tests. In Proceedings of the TC105 ISSMGE International Symposium on Geomechanics from Micro to Macro, Cambridge, UK, 1 September–4 September 2014; pp. 1391–1396. [Google Scholar]

- Fern, J.; Soga, K.; Robert, D.J.; Sakanoue, T. Shear strength and dilatancy of unsaturated silica sand in triaxial compression tests. In Proceedings of the 14th International Conference of International Association for Computer Methods and Recent Advances in Geomechanics, Kyoto, Japan, 22–25 September 2014; pp. 535–540. [Google Scholar]

- British Standards Institution (BSI). Methods of Test for Soils for Civil Engineering Purposes; BS 1377-2; BSI: London, UK, 1990.

- Li, J.L. Test Study on Ultimate Soil Bearing Capacity of Buried Pipeline—Sand Lateral Interaction. Master’s Thesis, Beijing University of Technology, Beijing, China, 2016. [Google Scholar]

- Duncan, J.M. Hyperbolic stress-strain relationships. In Limit Equilibrium, Plasticity and General Stress-Strain in Geotechnical Engineering; American Society of Civil Engineers: New York, NY, USA, 1980; pp. 443–460. [Google Scholar]

- Kondner, R.L. Hyperbolic stress-strain response: Cohesive soils. J. Soil Mech. Found. Div. 1963, 89, 115–143. [Google Scholar] [CrossRef]

- Fellenius, B.H. The analysis of results from routine pile load tests. Ground Eng. 1980, 13, 19–31. [Google Scholar]

- Yovichin, R. Hyperbolic Representation of Force Versus Displacement Relationship for Lateral Pipe Movement in Dry Soil. Master’s Thesis, Youngstown State University, Youngstown, OH, USA, 2018. [Google Scholar]

- Duncan, J.M.; Chang, C.Y. Nonlinear analysis of stress and strain in soils. J. Soil Mech. Found. Div. 1970, 96, 1629–1653. [Google Scholar] [CrossRef]

- Larsen, R.D. Box-and-whisker plots. J. Chem. Educ. 1985, 62, 302. [Google Scholar] [CrossRef]

- Massart, D.L.; Smeyers-verbeke, A.J.; Capron, X.; Schlesier, K. Visual presentation of data by means of box plots. LC GC Eur. 2005, 18, 215–218. [Google Scholar]

- Daiyan, N.; Kenny, S.; Phillips, R.; Popescu, R. Investigating pipeline–soil interaction under axial–lateral relative movements in sand. Can. Geotech. J. 2011, 48, 1683–1695. [Google Scholar] [CrossRef] [Green Version]

- Almahakeri, M.; Fam, A.; Moore, I.D. Longitudinal bending and failure of GFRP pipes buried in dense sand under relative ground movement. J. Compos. Constr. 2013, 17, 702–710. [Google Scholar] [CrossRef]

- Burnett, A. Investigation of Full Scale Horizontal Pipe-Soil Interaction and Large Strain Behaviour of Sand. Ph.D. Thesis, Queen’s University, Kingston, ON, Canada, 2015. [Google Scholar]

| γd (kN/m3) | Length (mm) | Diameter (mm) | Hc/D | Experiment | Note |

|---|---|---|---|---|---|

| 16 | 2400 | 457 | 1.92 | Karimian [28] | 2 tests |

| 16 | 2400 | 324 | 1.92 | Karimian [28] | 3 tests |

| 16 | 2400 | 324 | 2.75 | Karimian [28] | |

| 16 | 1000 | 60 | 3 | Li [36] | |

| 16 | 1000 | 60 | 5 | Li [36] | |

| 16 | 1000 | 60 | 8 | Li [36] | |

| 16 | 1000 | 60 | 10 | Li [36] | |

| 16.4 | 1200 | 102 | 3.5 | T & O 1 [7] | 3 tests |

| 16.4 | 1200 | 102 | 3.5 | T & O [7] | |

| 16.4 | 1200 | 102 | 5.5 | T & O [7] | |

| 16.4 | 1200 | 102 | 8 | T & O [7] | |

| 16.4 | 1200 | 102 | 11 | T & O [7] | 2 tests |

| 16.6 | 2400 | 114.6 | 6 | Robert [5] |

| γd (kN/m3) | Length (mm) | Diameter (mm) | Hc/D | Experiment | Note |

|---|---|---|---|---|---|

| 16.9 | 2440 | 120 | 5.47 | Olson [30] | |

| 16.9 | 1200 | 120 | 5.5 | Turner [27] | |

| 17 | 1000 | 60 | 3 | Li [36] | |

| 17 | 1000 | 60 | 5 | Li [36] | |

| 17 | 1000 | 60 | 8 | Li [36] | |

| 17 | 1000 | 60 | 10 | Li [36] | |

| 17 | 1200 | 120 | 5.5 | Turner [27] | |

| 17.1 | 2440 | 124 | 5.29 | Olson [30] | |

| 17.1 | 1210 | 120 | 5.5 | Turner [27] | |

| 17.2 | 1200 | 76.2 | 2.5 | Hsu [25] | |

| 17.2 | 1200 | 76.2 | 4.5 | Hsu [25] | |

| 17.2 | 1200 | 76.2 | 6.5 | Hsu [25]) | |

| 17.2 | 1200 | 76.2 | 8.5 | Hsu [25] | |

| 17.2 | 1200 | 76.2 | 10.5 | Hsu [25] | |

| 17.2 | 2440 | 124 | 5.29 | Olson [30] | |

| 17.2 | 1200 | 120 | 5.5 | Turner [27] | 3 tests |

| γd (kN/m3) | Length (mm) | Diameter (mm) | Hc/D | Experiment |

|---|---|---|---|---|

| 17.7 | 1200 | 120 | 3.5 | T & O 1 [7] |

| 17.7 | 1200 | 120 | 5.5 | T & O [7] |

| 17.7 | 1200 | 120 | 8 | T & O [7] |

| 17.7 | 1200 | 120 | 11 | T & O [7] |

| 20.9 | 1200 | 351 | 4.8 | Minh and Zhang [18] |

| Parameter | Single-Normalized | Double-Normalized | ||

|---|---|---|---|---|

| A | B | A | B | |

| Maximum | 0.0074 | 0.17 | 0.22 | 0.96 |

| Minimum | 0.0005 | 0.07 | 0.05 | 0.78 |

| Parameter | Single-Normalized | Double-Normalized | ||

|---|---|---|---|---|

| A | B | A | B | |

| Maximum | 0.0073 | 0.06 | 0.57 | 0.81 |

| Minimum | 0.0024 | 0.03 | 0.16 | 0.38 |

| Parameter | Single-Normalized | Double-Normalized | ||

|---|---|---|---|---|

| A | B | A | B | |

| Maximum | 0.0038 | 0.11 | 0.30 | 0.91 |

| Minimum | 0.0008 | 0.03 | 0.10 | 0.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yovichin, R.D., III; Jung, J.K.; Lee, W.-J. Hyperbolic Representation of Lateral Force–Displacement Relationship for Underground Installed Pipe. Mining 2022, 2, 170-185. https://doi.org/10.3390/mining2020010

Yovichin RD III, Jung JK, Lee W-J. Hyperbolic Representation of Lateral Force–Displacement Relationship for Underground Installed Pipe. Mining. 2022; 2(2):170-185. https://doi.org/10.3390/mining2020010

Chicago/Turabian StyleYovichin, Richard D., III, Jai K. Jung, and Wei-Ju Lee. 2022. "Hyperbolic Representation of Lateral Force–Displacement Relationship for Underground Installed Pipe" Mining 2, no. 2: 170-185. https://doi.org/10.3390/mining2020010

APA StyleYovichin, R. D., III, Jung, J. K., & Lee, W.-J. (2022). Hyperbolic Representation of Lateral Force–Displacement Relationship for Underground Installed Pipe. Mining, 2(2), 170-185. https://doi.org/10.3390/mining2020010