Artificial Intelligence in Construction Project Management: A Structured Literature Review of Its Evolution in Application and Future Trends

Abstract

1. Introduction

- How has AI application in construction projects evolved?

- What are the main barriers and challenges to AI application in construction projects?

- What is the future outlook for AI application in the construction industry?

2. Research Methods

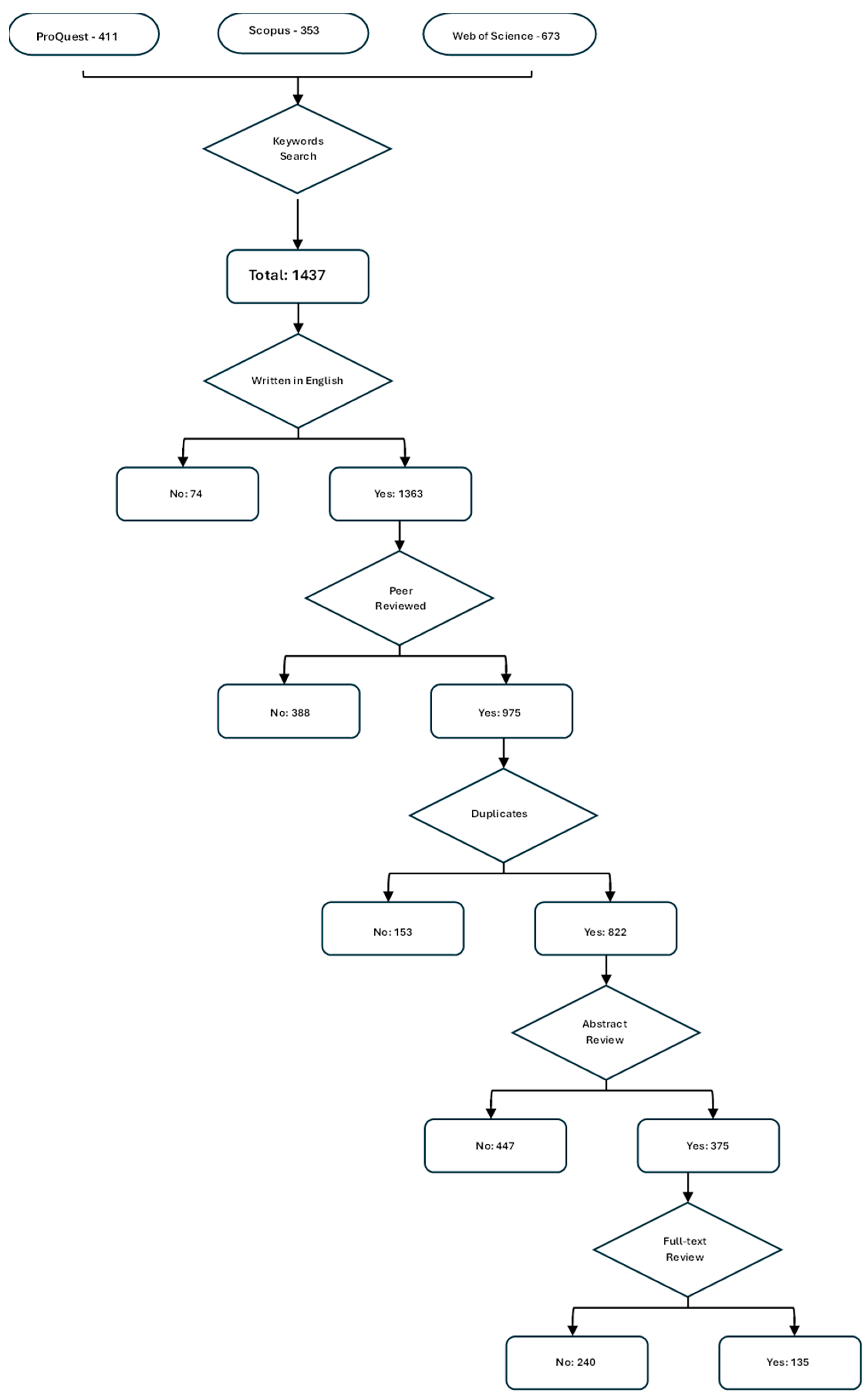

2.1. Material Collection

2.2. Data Analysis

3. AI Application in the Construction Industry

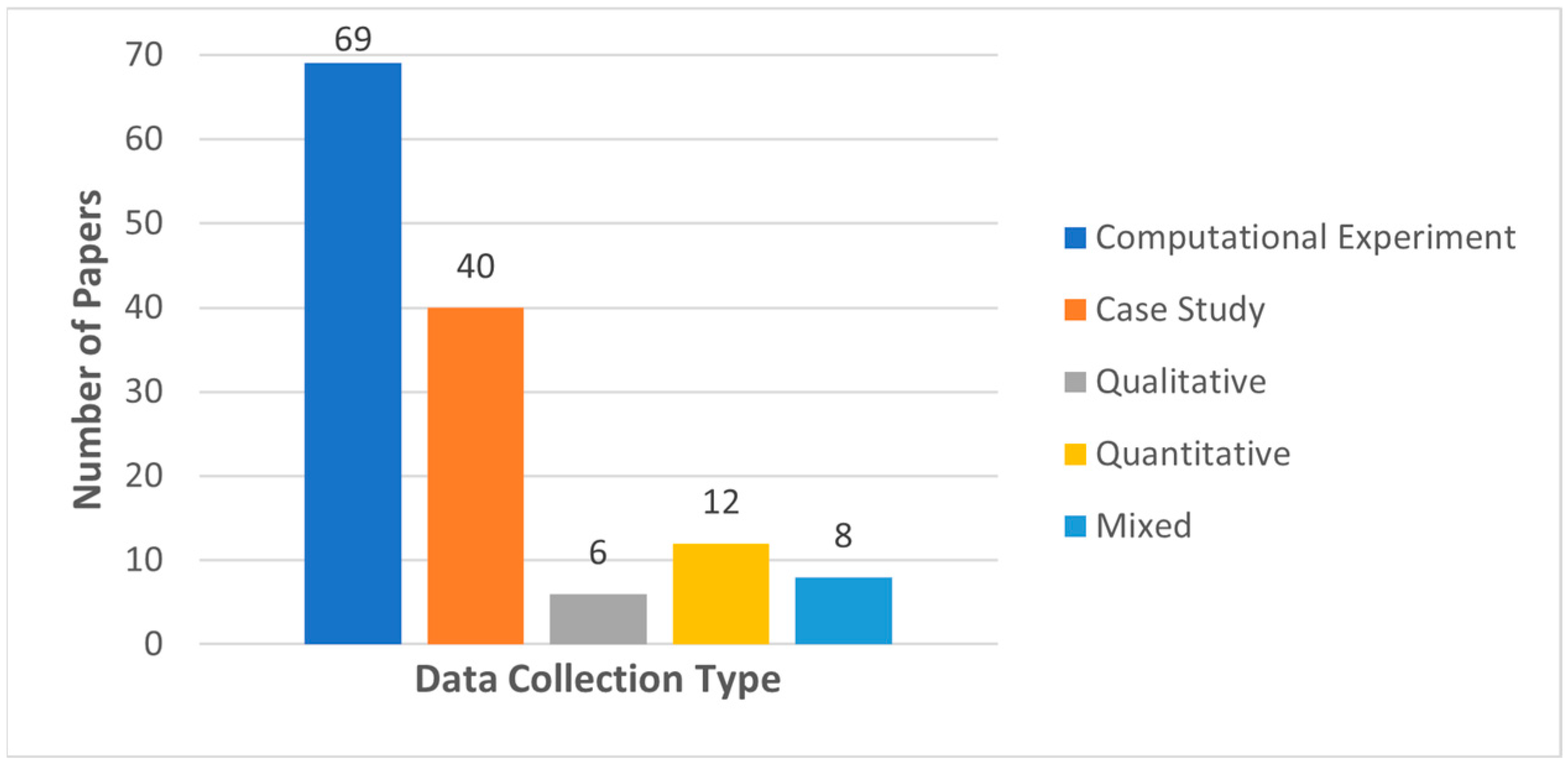

3.1. General Observations

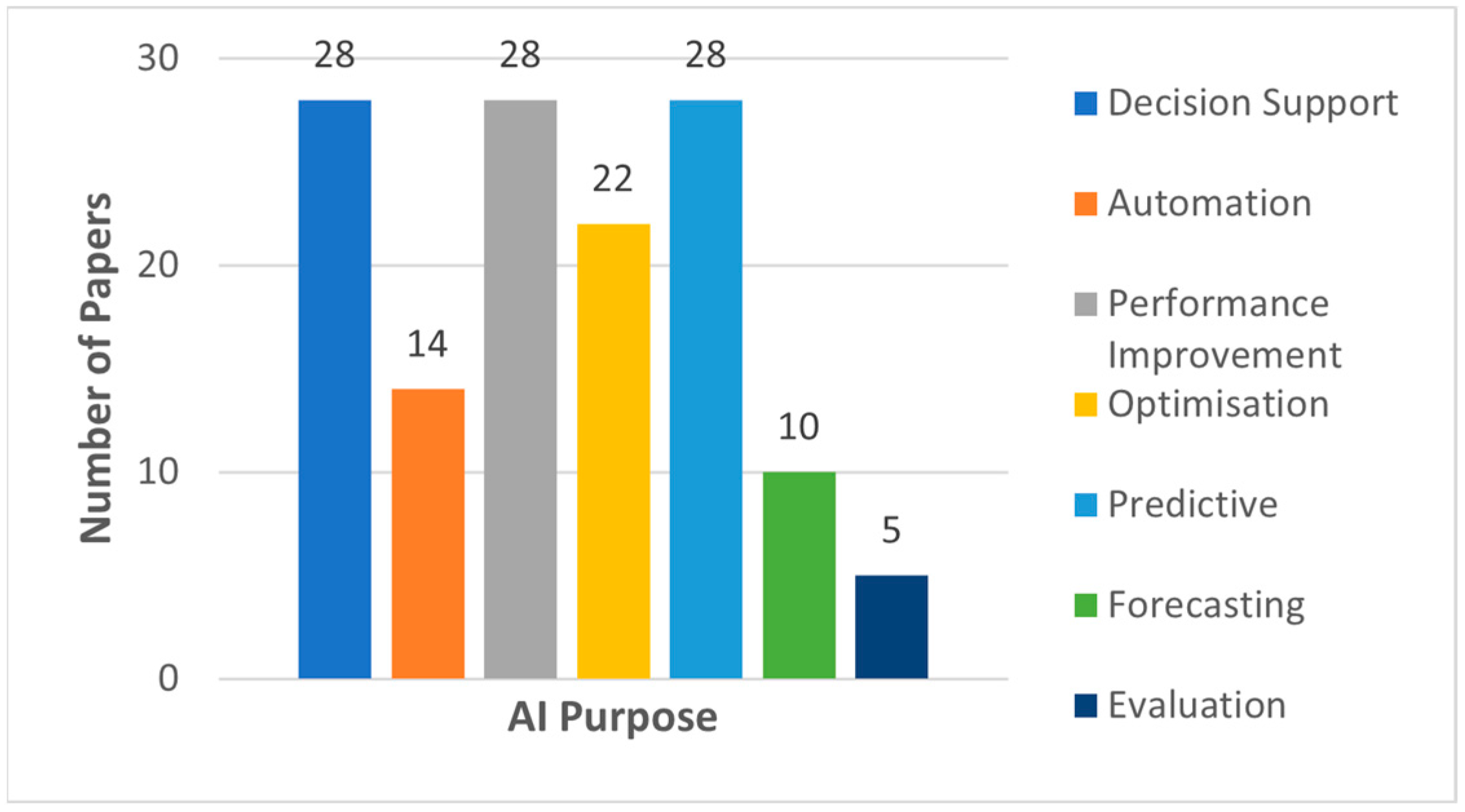

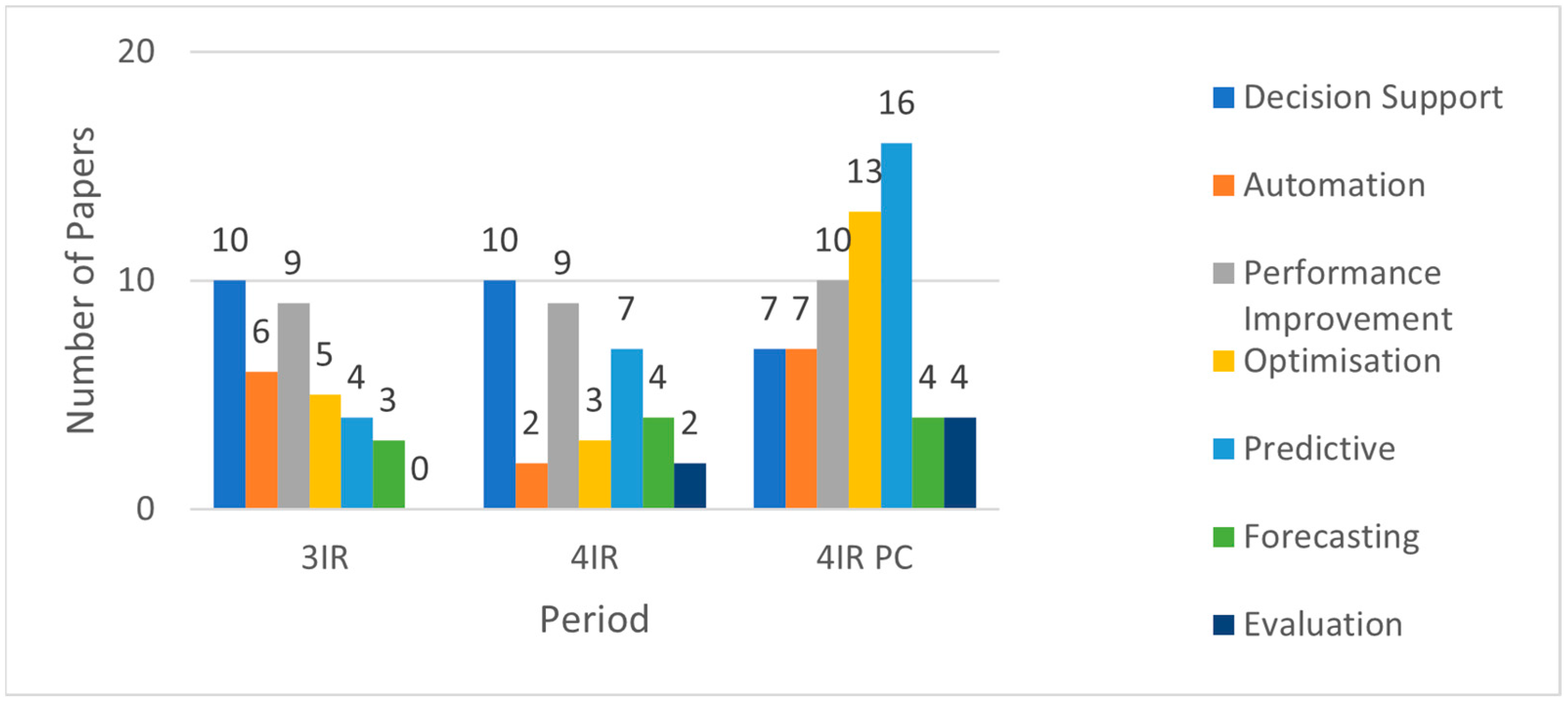

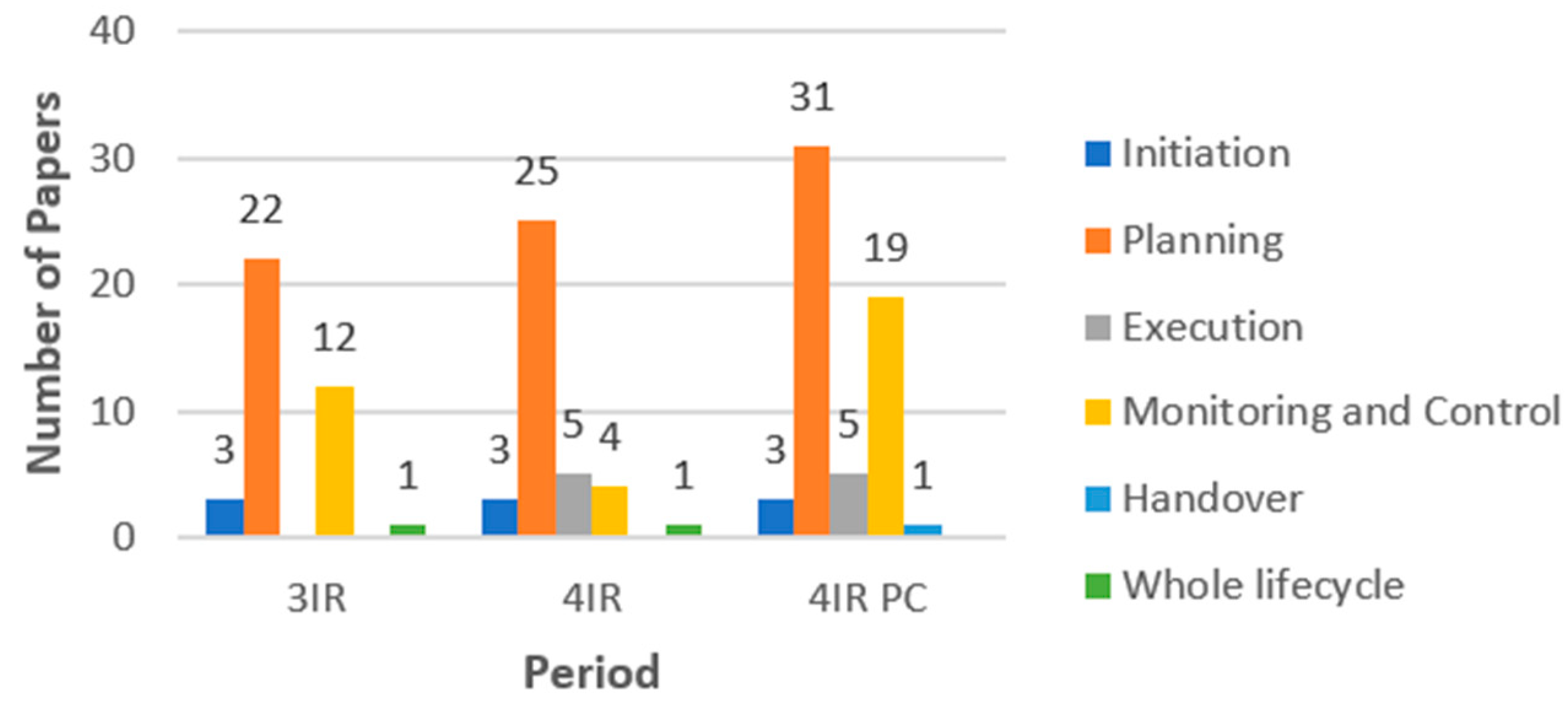

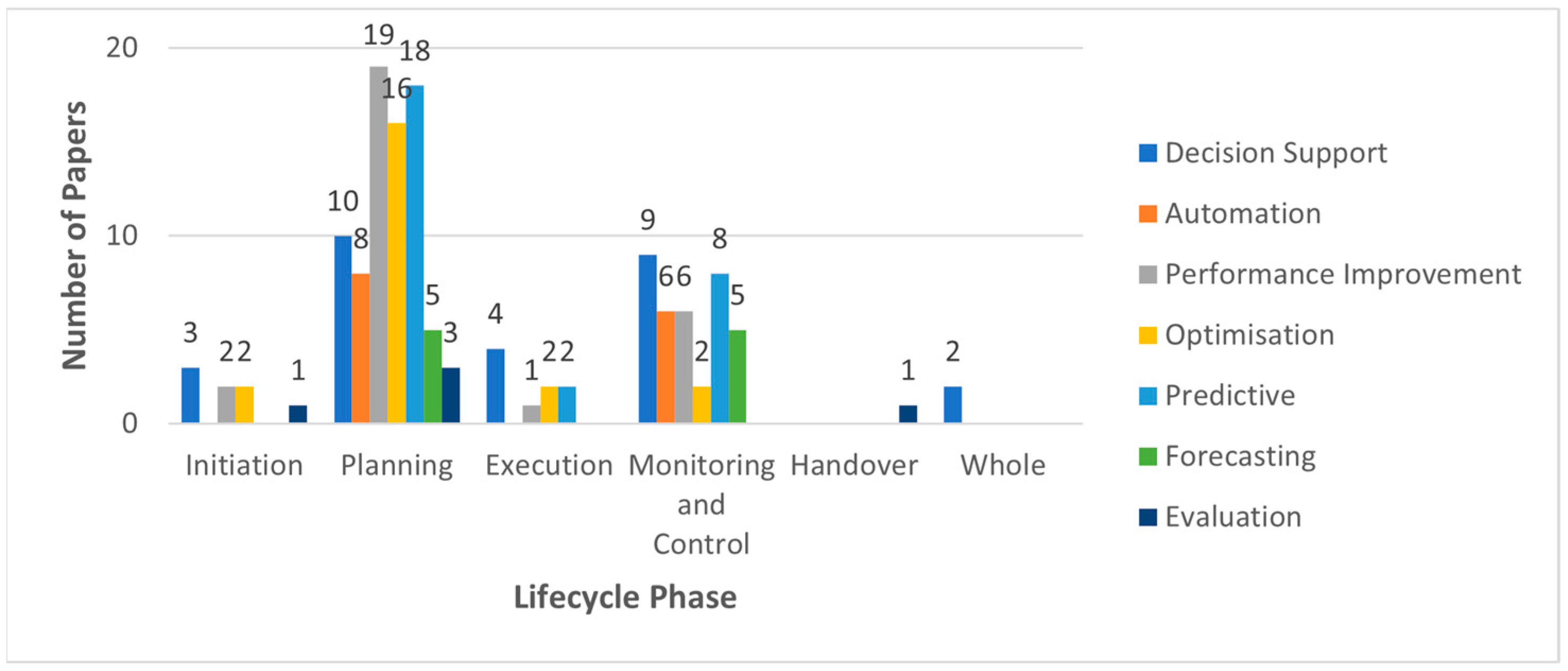

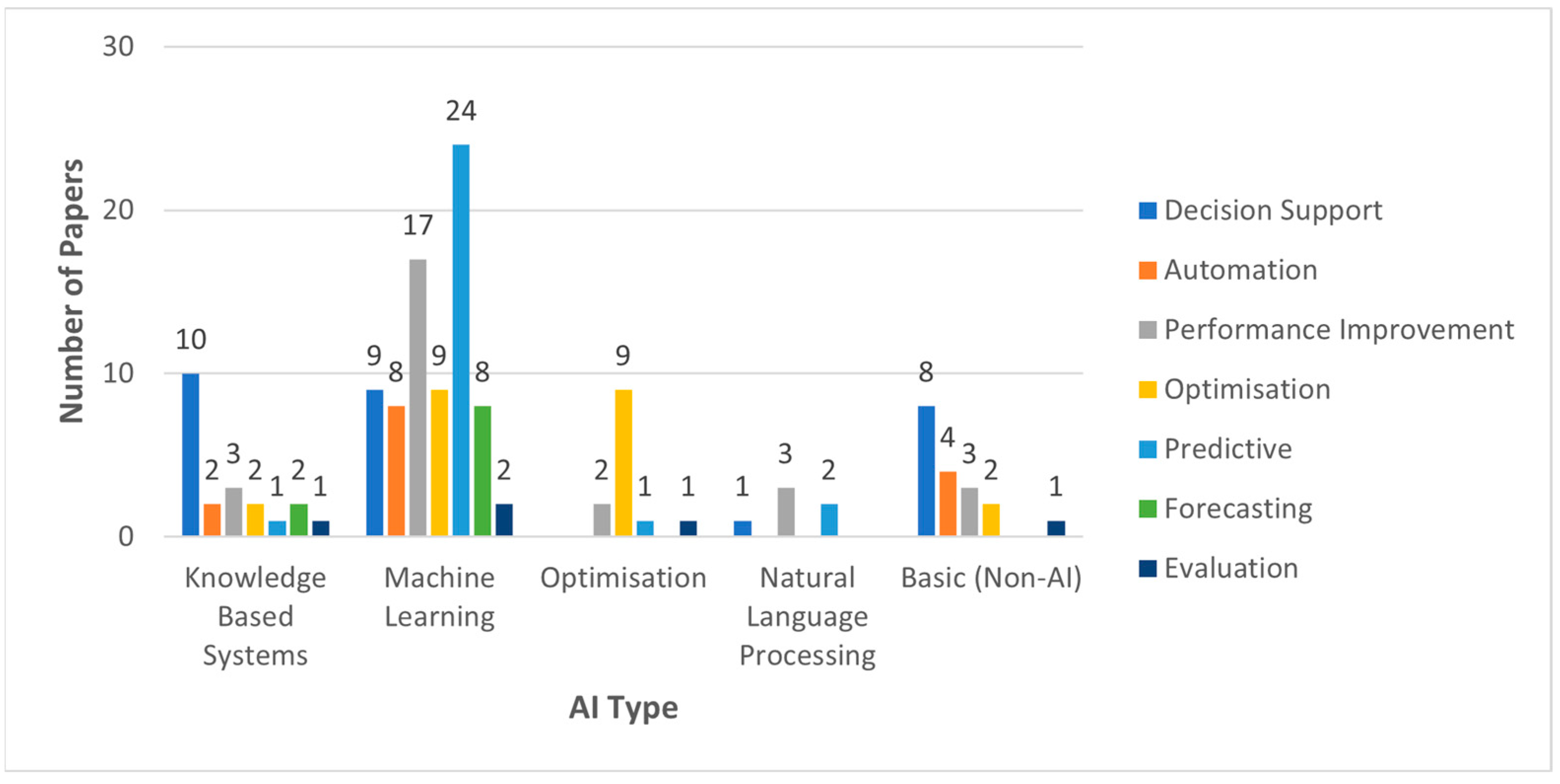

3.2. AI Type and Purpose Under Research in the Construction Industry

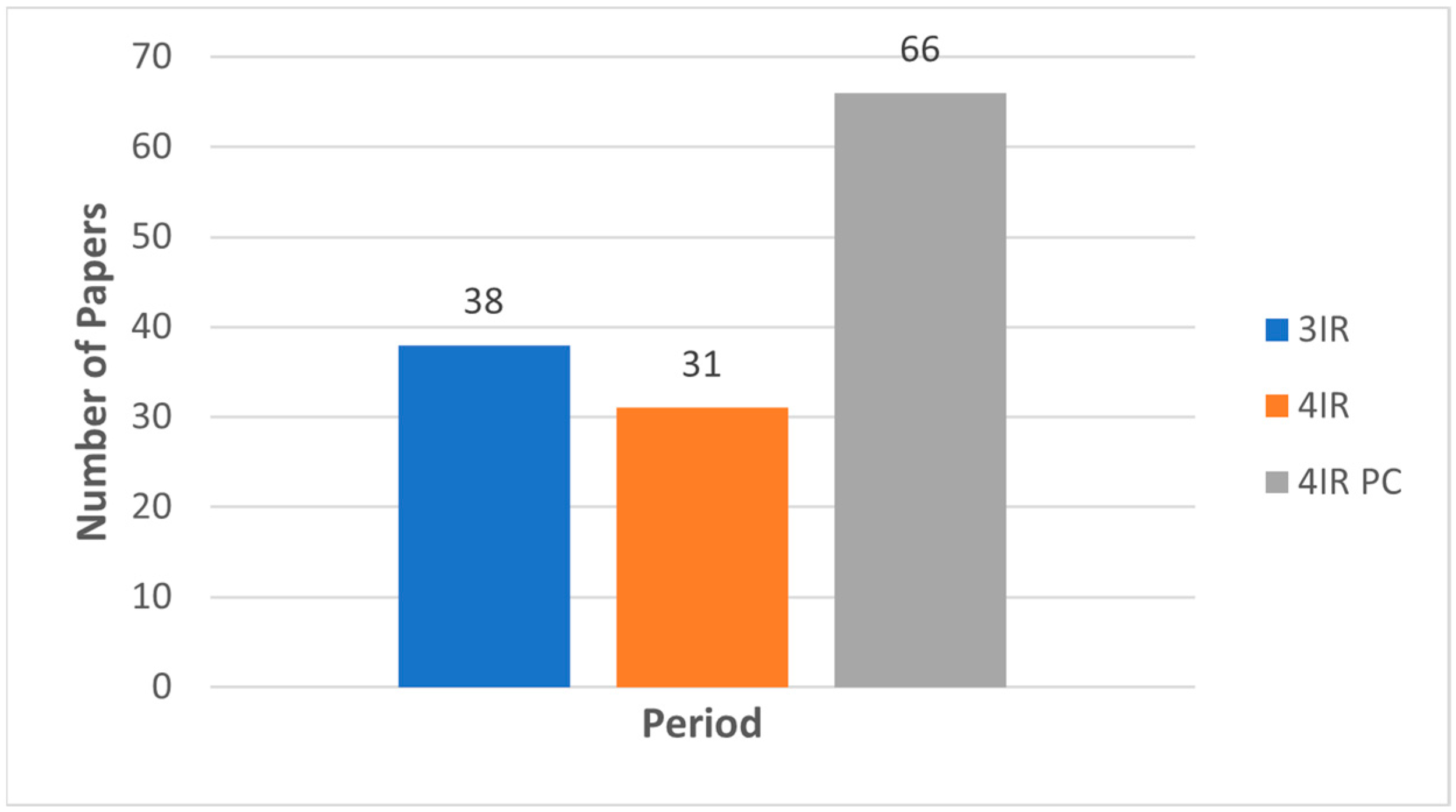

3.3. Analysis of the Progression of AI Research in Construction

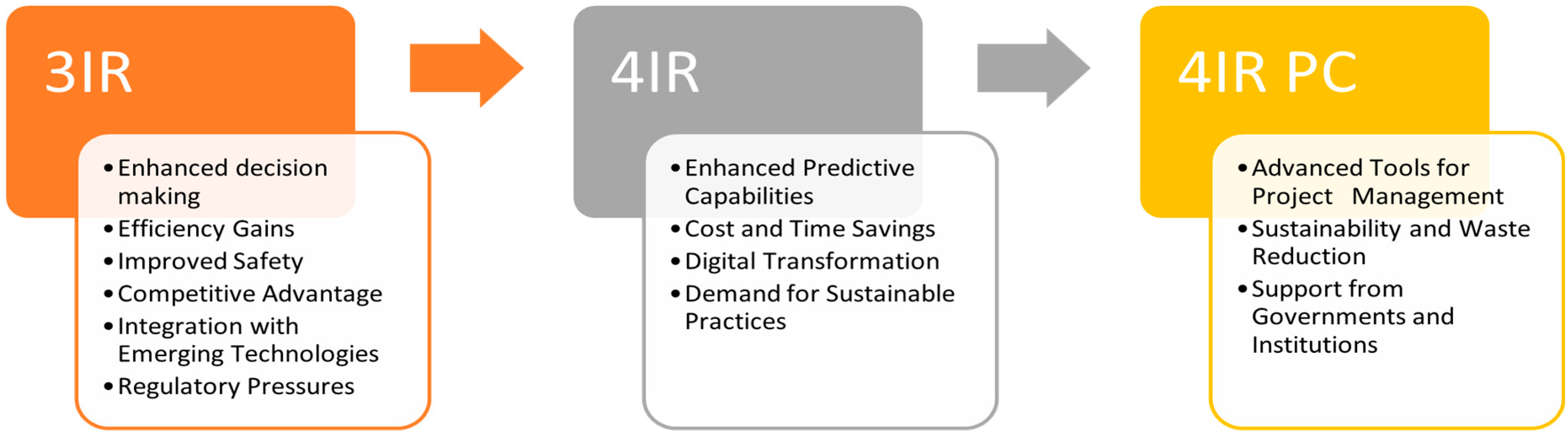

4. Barriers and Drivers of AI Adoption in Construction

4.1. Global Adoption of AI in Construction

4.2. Drivers of the Adoption of AI

4.2.1. Technology Availability

4.2.2. Improved Productivity and Project Outcomes

4.2.3. Competitive Advantage

4.2.4. Growing Emphasis on Sustainability

4.3. Barriers and Limitations to the Adoption of AI

4.3.1. Barrier: Resistance to Technology

4.3.2. Barrier: AI Skills Gap

4.3.3. Barrier: High Implementation Costs

4.3.4. Barrier: Regulatory and Ethical Concerns

4.3.5. Limitation: Data Quality and Quantity Issues

4.3.6. Limitation: Technical Shortcomings

5. The Future of AI in Construction

5.1. Sustainability and Energy Efficiency

5.2. Digital Twins for Predictive Maintenance

5.3. Advanced Robotics and Autonomous Construction

5.4. Optimisation and Enhancements

6. Conclusions and Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- McCarthy, J.; Minsky, M.; Rochester, N.; Shannon, C. A Proposal for the Dartmouth Summer Research Project on Artificial Intelligence. AI Mag. 1955, 27, 12. [Google Scholar]

- Minsky, M.L. Semantic Information Processing; The MIT Press: Cambridge, MA, USA, 1969. [Google Scholar]

- Poole, D.L.; Mackworth, A.K. Artificial Intelligence: Foundations of Computational Agents; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Russell, S.; Norvig, P. Artificial Intelligence: A modern Approach. Pearson Education: Hoboken, NJ, USA, 2022. [Google Scholar]

- Kaplan, A.; Haenlein, M. Siri, Siri, in my hand: Who’s the fairest in the land? On the interpretations, illustrations, and implications of artificial intelligence. Bus. Horiz. 2019, 62, 15–25. [Google Scholar] [CrossRef]

- Wang, P. On defining artificial intelligence. J. Artif. Gen. Intell. 2019, 10, 1–37. [Google Scholar] [CrossRef]

- Dignum, V. Responsible Artificial Intelligence: How to Develop and Use AI in a Responsible Way; Springer: Cham, Germany, 2019; Volume 2156. [Google Scholar]

- Pan, Y.; Zhang, L. Roles of artificial intelligence in construction engineering and management: A critical review and future trends. Autom. Constr. 2021, 122, 103517. [Google Scholar]

- Regona, M.; Yigitcanlar, T.; Xia, B.; Li, R.Y.M. Opportunities and adoption challenges of AI in the construction industry: A PRISMA review. J. Open Innov. Technol. Mark. Complex. 2022, 8, 45. [Google Scholar] [CrossRef]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Xiao, Y.; Watson, M. Guidance on conducting systematic literature review. J. Plan. Educ. Res. 2019, 39, 93–112. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- de Araújo, M.C.B.; Alencar, L.H.; de Miranda Mota, C.M. Project procurement management: A structured literature review. Int. J. Proj. Manag. 2017, 35, 353–377. [Google Scholar] [CrossRef]

- Downe-Wamboldt, B. Content analysis: Method, applications, and issues. Health Care Women Int. 1992, 13, 313–321. [Google Scholar]

- Wang, T.; Chen, H.M. Integration of building information modeling and project management in construction project life cycle. Autom. Constr. 2023, 150, 104832. [Google Scholar]

- Tadayon, A.; Rahmani, F.; Memic, N. A Review of Different Construction Project Lifecycle, Report nr. 1 Oslo, 25.06.2020 prosjektnorge.no; Prosjekt Norge: Oslo, Norway, 2020.

- PMBOK, P. A Guide to the Project Management Body of Knowledge (PMBOK® Guide), 5th ed.; Project Management Institute (PMI): Newtown Square, PA, USA, 2013. [Google Scholar]

- Bennett, F.L. The Management of Construction: A Project Lifecycle Approach; Routledge: London, UK, 2007. [Google Scholar]

- McKendrick, J. AI Adoption Skyrocketed Over the Last 18 Months; Harvard Business Publishing: Brighton, MA, USA, 2021. [Google Scholar]

- Abioye, S.O.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Delgado, J.M.D.; Bilal, M.; Akinade, O.O.; Ahmed, A. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. J. Build. Eng. 2021, 44, 103299. [Google Scholar]

- Ma, Z.; Lu, N.; Gu, W. A decision support system for construction projects based on standardized exchanged documents. Tsinghua Sci. Technol. 2008, 13, 354–361. [Google Scholar]

- Xing, Y.; Song, Z.; Deng, X. Optimizing the schedule of dispatching construction machines through artificial intelligence. Chem. Eng. Trans. 2016, 51, 493–498. [Google Scholar] [CrossRef]

- Hsu, H.; Chang, S.; Chen, C.; Wu, I. Knowledge-based system for resolving design clashes in building information models. Autom. Constr. 2020, 110, 103001. [Google Scholar]

- Lu, M. Enhancing project evaluation and review technique simulation through artificial neural network-based input modeling. J. Constr. Eng. Manag. 2002, 128, 438–445. [Google Scholar]

- Cheng, M.; Peng, H.; Wu, Y.; Chen, T. Estimate at completion for construction projects using evolutionary support vector machine inference model. Autom. Constr. 2010, 19, 619–629. [Google Scholar]

- Kim, J.; Wang, I.; Yu, J. Experimental Study on Using Synthetic Images as a Portion of Training Dataset for Object Recognition in Construction Site. Buildings 2024, 14, 1454. [Google Scholar] [CrossRef]

- Hegazy, T.; Petzold, K. Genetic optimization for dynamic project control. J. Constr. Eng. Manag. 2003, 129, 396–404. [Google Scholar]

- Cheng, M.; Tsai, H.; Liu, C. Artificial intelligence approaches to achieve strategic control over project cash flows. Autom. Constr. 2009, 18, 386–393. [Google Scholar]

- Shi, M.N.; Wang, J.J.; Li, Q.H.; Cui, B.; Guan, S.W.; Zeng, T.C. Accelerated Earth-Rockfill Dam Compaction by Collaborative Operation of Unmanned Roller Fleet. J. Constr. Eng. Manag. 2022, 148, 04022046. [Google Scholar] [CrossRef]

- Ko, T.; Jeong, H.D.; Lee, G. Natural language processing–driven model to extract contract change reasons and altered work items for advanced retrieval of change orders. J. Constr. Eng. Manag. 2021, 147, 04021147. [Google Scholar]

- Chevallier, N.; Russell, A.D. Automated schedule generation. Can. J. Civ. Eng. 1998, 25, 1059–1077. [Google Scholar]

- Bożejko, W.; Hejducki, Z.; Wodecki, M. Applying metaheuristic strategies in construction projects management. J. Civ. Eng. Management. 2012, 18, 621–630. [Google Scholar]

- Karki, S.; Hadikusumo, B. Machine learning for the identification of competent project managers for construction projects in Nepal. Constr. Innov.-Engl. 2023, 23, 1–18. [Google Scholar] [CrossRef]

- McGartland, M.R.; Hendrickson, C.T. Expert systems for construction project monitoring. J. Constr. Eng. Manag. 1985, 111, 293–307. [Google Scholar]

- Elazouni, A.M. Classifying construction contractors using unsupervised-learning neural networks. J. Constr. Eng. Manag. 2006, 132, 1242–1253. [Google Scholar]

- Luo, X.; Shen, G.Q.; Fan, S.; Xue, X. A group decision support system for implementing value management methodology in construction briefing. Int. J. Proj. Manag. 2011, 29, 1003–1017. [Google Scholar] [CrossRef]

- Hanafi, A.G.; Mohd Nawi, M.N.; Abdul Rahim, M.K.I.; Abdul Nifa, F.A.; Omar, M.F.; Mohamed, O. Project managers selection in the construction industry: Towards the integration with artificial emotional intelligence and technology. J. Adv. Res. Appl. Sci. Eng. Technol. 2022, 29, 160–176. [Google Scholar]

- Iranmanesh, H.; Madadi, M. An intelligent system framework for generating activity list of a project using WBS mind map and semantic network. World Acad. Sci. Eng. Technol. Int. J. Comput. Inf. Eng. 2008, 2, 1020–1027. [Google Scholar]

- Oliveira, B.A.S.; De Faria Neto, A.P.; Fernandino, R.M.A.; Carvalho, R.F.; Fernandes, A.L.; Guimaraes, F.G. Automated Monitoring of Construction Sites of Electric Power Substations Using Deep Learning. IEEE Access 2021, 9, 19195–19207. [Google Scholar] [CrossRef]

- Georgy, M.E.; Barsoum, S.H. Artificial neural networks model for parametric estimating of construction project costs. J. Eng. Appl. Sci.-Cairo 2005, 52, 1050. [Google Scholar]

- An, S.H.; Park, U.Y.; Kang, K.I.; Cho, M.Y.; Cho, H.H. Application of support vector machines in assessing conceptual cost estimates. J. Comput. Civ. Eng. 2007, 21, 259–264. [Google Scholar]

- Mirzaei, A.; Nasirzadeh, F.; Parchami Jalal, M.; Zamani, Y. 4D-BIM dynamic time–space conflict detection and quantification system for building construction projects. J. Constr. Eng. Manag. 2018, 144, 04018056. [Google Scholar]

- Sacks, R.; Brilakis, I.; Pikas, E.; Xie, H.S.; Girolami, M. Construction with digital twin information systems. Data-Centric Eng. 2020, 1, e14. [Google Scholar] [CrossRef]

- Pham, V.H.S.; Nguyen Dang, N.T.; Nguyen, V.N. Achieving improved performance in construction projects: Advanced time and cost optimization framework. Evol. Intell. 2024, 17, 2885–2897. [Google Scholar]

- Sklias, G.; Gkelios, S.; Dimitriou, D.; Sartzetaki, M.; Chatzichristofis, S.A. Synergizing Global and Local Strategies for Dynamic Project Management: An Advanced Machine Learning-Enhanced Framework. IEEE Access 2024, 12, 85955–85968. [Google Scholar] [CrossRef]

- Fayek, A.R.; Oduba, A. Predicting industrial construction labor productivity using fuzzy expert systems. J. Constr. Eng. Manag. 2005, 131, 938–941. [Google Scholar]

- Wang, Y.R.; Yu, C.Y.; Chan, H.H. Predicting construction cost and schedule success using artificial neural networks ensemble and support vector machines classification models. Int. J. Proj. Manag. 2012, 30, 470–478. [Google Scholar]

- Koc, K.; Ekmekcioğlu, Ö.; Gurgun, A.P. Accident prediction in construction using hybrid wavelet-machine learning. Autom. Constr. 2022, 133, 103987. [Google Scholar] [CrossRef]

- Kim, J.; Yum, S.; Adhikari, M.D.; Bae, J. A deep-learning approach to leveraging natural hazard indicators for improved safety on construction sites. Saf. Sci. 2024, 177, 106596. [Google Scholar] [CrossRef]

- Al-Tabtabai, H. An expert systems approach for analyzing and forecasting construction project performance. Kuwait J. Sci. Eng. 1997, 24, 264–286. [Google Scholar]

- Poh, C.Q.X.; Ubeynarayana, C.U.; Goh, Y.M. Safety leading indicators for construction sites: A machine learning approach. Autom. Constr. 2018, 93, 375–386. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Cao, M.T.; Herianto, J.G. Symbiotic organisms search-optimized deep learning technique for mapping construction cash flow considering complexity of project. Chaos Solitons Fractals 2020, 138, 109869. [Google Scholar]

- Bai, L.; An, Y.; Sun, Y. Measurement of project portfolio benefits with a GA-BP neural network group. IEEE Trans. Eng. Manag. 2023, 71, 4737–4749. [Google Scholar]

- McKinsey. What is Industry 4.0 and the Fourth Industrial Revolution?|McKinsey. 2022. Available online: https://www.mckinsey.com/featured-insights/mckinsey-explainers/what-are-industry-4-0-the-fourth-industrial-revolution-and-4ir (accessed on 31 August 2024).

- Lu, Y. Artificial intelligence: A survey on evolution, models, applications and future trends. J. Manag. Anal. 2019, 6, 1–29. [Google Scholar] [CrossRef]

- Chen, Q.; Leaman, R.; Allot, A.; Luo, L.; Wei, C.H.; Yan, S.; Lu, Z. Artificial Intelligence in Action: Addressing the COVID-19 Pandemic with Natural Language Processing. Annu. Rev. Biomed. Data Sci. 2021, 4, 313–339. [Google Scholar] [CrossRef] [PubMed]

- Krajewski, L.J.; Malhotra, M.K. Operations Management: Processes and Supply Chains, 14th ed.; UK Pearson: Harlow, UK, 2025. [Google Scholar]

- Kabalisa, R.; Altmann, J. AI Technologies and Motives for AI Adoption by Countries and Firms: A Systematic Literature Review. In Proceedings Economics of Grids, Clouds, Systems, and Services; GECON; Lecture Notes in Computer Science; Springer: Cham, Germany, 2021. [Google Scholar] [CrossRef]

- Precedence Research. Artificial Intelligence (AI) in Construction Market by 2033. 2024. Available online: https://www.precedenceresearch.com/artificial-intelligence-in-construction-market (accessed on 7 September 2024).

- Na, S.; Heo, S.; Choi, W.; Kim, C.; Whang, S.W. Artificial Intelligence (AI)-Based Technology Adoption in the Construction Industry: A Cross National Perspective Using the Technology Acceptance Model. Buildings 2023, 13, 2518. [Google Scholar] [CrossRef]

- Gao, S.; Low, S.P.; Nair, K. Design for manufacturing and assembly (DfMA): A preliminary study of factors influencing its adoption in Singapore. Archit. Eng. Des. Manag. 2018, 14, 440–456. [Google Scholar] [CrossRef]

- Ejohwomu, O.; Adekunle, S.A.; Aigbavboa, C.O.; Bukoye, O.T. Construction Industry and the Fourth Industrial Revolution: Issues and Strategies. In The Construction Industry: Global Trends, Job Burnout and Safety Issues; Nova Science Publishers: New York, NY, USA, 2021. [Google Scholar]

- Zairul, M.; Zaremohzzabieh, Z. Thematic Trends in Industry 4.0 Revolution Potential towards Sustainability in the Construction Industry. Sustainability 2023, 15, 7720. [Google Scholar] [CrossRef]

- Erfani, A.; Cui, Q.B. Predictive risk modeling for major transportation projects using historical data. Autom. Constr. 2022, 139, 104301. [Google Scholar] [CrossRef]

- Wu, C.K.; Li, X.; Jiang, R.; Guo, Y.J.; Wang, J.; Yang, Z.L. Graph-based deep learning model for knowledge base completion in constraint management of construction projects. Comput.-Aided Civ. Infrastruct. Eng. 2023, 38, 702–719. [Google Scholar] [CrossRef]

- Zheng, H.; Moosavi, V.; Akbarzadeh, M. Machine learning assisted evaluations in structural design and construction. Autom. Constr. 2020, 119, 103346. [Google Scholar]

- Zhang, F.; Chan, A.P.C.; Darko, A.; Chen, Z.Y.; Li, D.Z. Integrated applications of building information modeling and artificial intelligence techniques in the AEC/FM industry. Autom. Constr. 2022, 139, 104289. [Google Scholar] [CrossRef]

- Yevu, S.K.; Owusu, E.K.; Chan, A.P.C.; Sepasgozar, S.M.E.; Kamat, V.R. Digital twin-enabled prefabrication supply chain for smart construction and carbon emissions evaluation in building projects. J. Build. Eng. 2023, 78, 107598. [Google Scholar] [CrossRef]

- Piras, G.; Muzi, F.; Tiburcio, V.A. Digital Management Methodology for Building Production Optimization through Digital Twin and Artificial Intelligence Integration. Buildings 2024, 14, 2110. [Google Scholar] [CrossRef]

- Ayhan, M.; Dikmen, I.; Birgonul, M.T. Predicting the Occurrence of Construction Disputes Using Machine Learning Techniques. J. Constr. Eng. Manag. 2021, 147, 04021022. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, S.; Wang, X.Y.; Li, X.C. Novel Unsupervised Machine Learning Method for Identifying Falling from Height Hazards in Building Information Models through Path Simulation Sampling. Adv. Civ. Eng. 2024, 2024, 6333621. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, H.B.; Chen, Z.H.; Wang, L.X.; Zhang, Q.; Guo, L.L. Collision Risk Warning Model for Construction Vehicles Based on YOLO and DeepSORT Algorithms. J. Constr. Eng. Manag. 2024, 150, 04024053. [Google Scholar] [CrossRef]

- Cho, J.; Lee, G.; Song, T.; Jeong, H.D. Chatbot-engaged construction daily work report using mobile messenger. Autom. Constr. 2023, 154, 105007. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Chang, Y.H.; Korir, D. Novel Approach to Estimating Schedule to Completion in Construction Projects Using Sequence and Nonsequence Learning. J. Constr. Eng. Manag. 2019, 145, 04019072. [Google Scholar] [CrossRef]

- Bang, S.; Andersen, B. Utilising Artificial Intelligence in Construction Site Waste Reduction. J. Eng. Proj. Prod. Manag. 2022, 12, 239–249. [Google Scholar] [CrossRef]

- Darko, A.; Glushakova, I.; Boateng, E.B.; Chan, A.P.C. Using Machine Learning to Improve Cost and Duration Prediction Accuracy in Green Building Projects. J. Constr. Eng. Manag. 2023, 149, 04023061. [Google Scholar] [CrossRef]

- Son, P.V.H.; Khoi, L.N.Q. Application of slime mold algorithm to optimize time, cost and quality in construction projects. Int. J. Constr. Manag. 2024, 24, 1375–1386. [Google Scholar] [CrossRef]

- Lung, L.W.; Wang, Y.R. Applying Deep Learning and Single Shot Detection in Construction Site Image Recognition. Buildings 2023, 13, 1074. [Google Scholar] [CrossRef]

- Pal, A.; Lin, J.J.; Hsieh, S.H.; Golparvar-Fard, M. Automated vision-based construction progress monitoring in built environment through digital twin. Dev. Built Environ. 2023, 16, 100247. [Google Scholar] [CrossRef]

- Sousa, A.O.; Veloso, D.T.; Goncalves, H.M.; Faria, J.P.; Mendes-Moreira, J.; Graca, R.; Gomes, D.; Castro, R.N.; Henriques, P.C. Applying Machine Learning to Estimate the Effort and Duration of Individual Tasks in Software Projects. IEEE Access 2023, 11, 89933–89946. [Google Scholar] [CrossRef]

- Doukari, O.; Seck, B.; Greenwood, D. The Creation of Construction Schedules in 4D BIM: A Comparison of Conventional and Automated Approaches. Buildings 2022, 12, 1145. [Google Scholar] [CrossRef]

- Liu, T.Y.; Ma, G.F.; Wang, D.; Pan, X.M. Intelligent green retrofitting of existing buildings based on case-based reasoning and random forest. Autom. Constr. 2024, 162, 105377. [Google Scholar] [CrossRef]

- Xie, X.; Merino, J.; Moretti, N.; Pauwels, P.; Chang, J.Y.; Parlikad, A. Digital twin enabled fault detection and diagnosis process for building HVAC systems. Autom. Constr. 2023, 146, 104695. [Google Scholar] [CrossRef]

- Mahamedi, E.; Wonders, M.; Seresht, N.G.; Woo, W.L.; Kassem, M. A reinforcing transfer learning approach to predict buildings energy performance. Constr. Innov.-Engl. 2024, 24, 242–255. [Google Scholar] [CrossRef]

- Shang, G.; Low, S.P.; Lim, X.Y.V. Prospects, drivers of and barriers to artificial intelligence adoption in project management. Built Environ. Proj. Asset Manag. 2023, 13, 629–645. [Google Scholar] [CrossRef]

- Chen, X.; Chang-Richards, A.Y.; Pelosi, A.; Jia, Y.; Shen, X.; Siddiqui, M.K.; Yang, N. Implementation of technologies in the construction industry: A systematic review. Eng. Constr. Archit. Manag. 2022, 29, 3181–3209. [Google Scholar] [CrossRef]

- Aljawder, A.; Al-Karaghouli, W. The adoption of technology management principles and artificial intelligence for a sustainable lean construction industry in the case of Bahrain. J. Decis. Syst. 2024, 33, 263–292. [Google Scholar] [CrossRef]

- Rafsanjani, H.N.; Nabizadeh, A.H. Towards human-centered artificial intelligence (AI) in architecture, engineering, and construction (AEC) industry. Comput. Hum. Behav. Rep. 2023, 11, 100319. [Google Scholar]

- Momade, M.H.; Durdyev, S.; Dixit, S.; Shahid, S.; Alkali, A.K. Modeling labor costs using artificial intelligence tools. Int. J. Build. Pathol. Adapt. 2022, 42, 1263–1281. [Google Scholar] [CrossRef]

- Waqar, A.; Qureshi, A.H.; Almujibah, H.R.; Tanjung, L.E.; Utami, C. Evaluation of success factors of utilizing AI in digital transformation of health and safety management systems in modern construction projects. Ain Shams Eng. J. 2023, 14, 102551. [Google Scholar] [CrossRef]

- Rashad, A.; Hegazy, H.; Zhang, J.S.; Mahdi, I.; Abdel-Rasheed, I.; Ebid, A. Developing preliminary cost estimates for foundation systems of high-rise buildings. Int. J. Constr. Manag. 2024, 25, 682–698. [Google Scholar] [CrossRef]

- Fridgeirsson, T.V.; Ingason, H.T.; Jonasson, H.I.; Gunnarsdottir, H. A Qualitative Study on Artificial Intelligence and Its Impact on the Project Schedule, Cost and Risk Management Knowledge Areas as Presented in PMBOK®. Appl. Sci. 2023, 13, 11081. [Google Scholar] [CrossRef]

- Elshaboury, N.; Mohammed Abdelkader, E.; Al-Sakkaf, A.; Bagchi, A. A deep convolutional neural network for predicting electricity consumption at Grey Nuns building in Canada. Constr. Innov. 2025, 25, 270–289. [Google Scholar] [CrossRef]

- Naji, K.K.; Gunduz, M.; Mansour, M.M. Development of an Integrated Hybrid Risk Assessment System for Construction Disputes during the Preconstruction Phase Using the Delphi Method. J. Constr. Eng. Manag. 2024, 150, 04024068. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.W.; Xie, Y. Revenue-Sharing Contract Design for Construction Onsite Equipment Sharing. Front. Built Environ. 2022, 8, 909018. [Google Scholar] [CrossRef]

- Tang, L.C.M.; Leung, A.Y.T. An entropy-based financial decision support system (e-FDSS) for project analysis in construction SMEs. Constr. Manag. Econ. 2009, 27, 499–513. [Google Scholar] [CrossRef]

- Mahfouz, T.; Kandil, A. Litigation outcome prediction of differing site condition disputes through machine learning models. J. Comput. Civ. Eng. 2012, 26, 298–308. [Google Scholar] [CrossRef]

- Jung, Y.H.; Cho, I.; Hsu, S.H.; Golparvar-Fard, M. VisualSiteDiary: A detector-free Vision-Language Transformer model for captioning photologs for daily construction reporting and image retrievals. Autom. Constr. 2024, 165, 105483. [Google Scholar] [CrossRef]

- Amer, F.; Jung, Y.; Golparvar-Fard, M. Transformer machine learning language model for auto-alignment of long-term and short-term plans in construction. Autom. Constr. 2021, 132, 103929. [Google Scholar] [CrossRef]

- El-Gohary, N.; El-Diraby, T. Dynamic knowledge-based process integration portal for collaborative construction. J. Constr. Eng. Manag. 2010, 136, 316–328. [Google Scholar] [CrossRef]

- Alexakis, E.; Delegou, E.T.; Mavrepis, P.; Rifios, A.; Kyriazis, D.; Moropoulou, A. A novel application of deep learning approach over IRT images for the automated detection of rising damp on historical masonries. Case Stud. Constr. Mater. 2024, 20, e02889. [Google Scholar] [CrossRef]

- Martínez-Rojas, M.; Marín, N.; Miranda, M.A.V. An intelligent system for the acquisition and management of information from bill of quantities in building projects. Expert Syst. Appl. 2016, 63, 284–294. [Google Scholar] [CrossRef]

- Amini, H.; Alanne, K.; Kosonen, R. Building simulation in adaptive training of machine learning models. Autom. Constr. 2024, 165, 105564. [Google Scholar] [CrossRef]

- Liu, C.; Sepasgozar, S.M.E.; Shirowzhan, S.; Mohammadi, G. Applications of object detection in modular construction based on a comparative evaluation of deep learning algorithms. Constr. Innov.-Engl. 2022, 22, 141–159. [Google Scholar] [CrossRef]

- Maruthi, S.; Dodda, S.B.; Yellu, R.R.; Thuniki, P.; Reddy, S.R.B. Automated Planning and Scheduling in AI: Studying automated planning and scheduling techniques for efficient decision-making in artificial intelligence. Afr. J. Artif. Intell. Sustain. Dev. 2022, 2, 14–25. [Google Scholar]

- Ganiyu, S.A.; Oyedele, L.O.; Akinade, O.; Owolabi, H.; Akanbi, L.; Gbadamosi, A. BIM competencies for delivering waste-efficient building projects in a circular economy. Dev. Built Environ. 2020, 4, 100036. [Google Scholar] [CrossRef]

- Li, Y.; Tong, Z.M.; Tong, S.G.; Westerdahl, D.; Pastoriza, T. A data-driven interval forecasting model for building energy prediction using attention-based LSTM and fuzzy information granulation. Sustain. Cities Soc. 2022, 76, 103481. [Google Scholar] [CrossRef]

- Sun, H.; Liu, Z. Research on Intelligent Dispatching System Management Platform for Construction Projects Based on Digital Twin and BIM Technology. Adv. Civ. Eng. 2022, 2022, 8273451. [Google Scholar] [CrossRef]

- Feng, H.; Song, Q.Y.; Yin, C.B.; Cao, D.H. Adaptive Impedance Control Method for Dynamic Contact Force Tracking of Robotic Excavators. J. Constr. Eng. Manag. 2022, 148, 04022124. [Google Scholar] [CrossRef]

- Dharani, D.L.; Pattnaik, M.; Naveen Kumar, G.N.; Avula, V.A.; Pattanaik, B.; Maheshwari, S. Efficient Project Management in Construction Sites to Monitor and Track the Employees using Multi-Modal Deep Learning Model. Int. J. Intell. Syst. Appl. Eng. 2024, 12, 309–319. [Google Scholar]

- Bakhshi, R.; Moradinia, S.F.; Jani, R.; Poor, R.V. Presenting a Hybrid Scheme of Machine Learning Combined with Metaheuristic Optimizers for Predicting Final Cost and Time of Project. KSCE J. Civ. Eng. 2022, 26, 3188–3203. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Deifalla, A.F. Optimizing compressive strength prediction models for rice husk ash concrete with evolutionary machine intelligence techniques. Case Stud. Constr. Mater. 2023, 18, e02102. [Google Scholar] [CrossRef]

- Chao, Z.M.; Wang, M.Y.; Sun, Y.N.; Xu, X.; Yue, W.H.; Yang, C.X.; Hu, T.X. Predicting stress-dependent gas permeability of cement mortar with different relative moisture contents based on hybrid ensemble artificial intelligence algorithms. Constr. Build. Mater. 2022, 348, 128660. [Google Scholar] [CrossRef]

- Kim, H.; Jang, H. Predicting research projects’ output using machine learning for tailored projects management. Asian J. Technol. Innov. 2023, 32, 346–363. [Google Scholar] [CrossRef]

| Themes | Purpose Category |

|---|---|

| Expert systems for decision making in control and monitoring, financial decisions, scheduling, project control, collaborative project management, project management processes, information analysis, and conflict management Various models for decision making, e.g., computer models for conflict resolution, metaheuristic modelling for scheduling, fuzzy logic for uncertainty and risk management, probabilistic simulation for preconceptual estimates, graph theory and matrix methods for contractor selection, and web-based applications for planning Deep learning for contractor selection and manager selection Natural language processing for risk management | Decision Support |

| Intelligent systems for optimising resources, planning, and scheduling Case-based reasoning for optimising decision making Deep learning for optimising pricing and bidding, time and cost, waste reduction, design, planning and production, resource management, information management, and PM practices Various algorithms for optimization, e.g., genetic algorithm for planning, control and monitoring, structural efficiency, sustainability, evolutionary algorithms for project cash flows, and moth–flame optimisation for time and cost | Optimisation |

| Various models for improvement, e.g., metaheuristic modelling for project duration and Bayesian approach for design process Deep learning systems for improving scheduling critical paths, costing, resources and scheduling, budgeting, conflict resolution improvement, minimisation of delay and waste, and monitoring employees Machine learning for improving estimating at project completion and resource allocation Evolutionary algorithms for improving conceptual phase costing and cost estimating Natural language processing for improving building evaluation | Performance Improvement |

| Expert systems for automating project planning Various tools for automating, e.g., WBS mind map and semantic network for WBS, integrated planning tool for productivity monitoring, and resource management Deep learning for automating project plans, scheduling, monitoring, image recognition and decision support, collision risk warning, and daily construction reporting | Automation |

| Machine learning for predictive conflict resolution Deep learning for predictive costing, scheduling, conflict management, cash flow, risk management, delay estimating, safety management, and waste management Various types of learning, e.g., unsupervised learning for predictive safety management and reinforcement learning for predictive energy performance Natural language processing for predictive risk management | Predictive |

| Deep learning for forecasting performance, schedule, cost, risk, productivity, and pricing | Forecasting |

| Deep learning for evaluation of initiation performance, PM competency, and engineering management Fuzzy logic for evaluating planning performance Genetic algorithms for evaluating investment management | Evaluation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adebayo, Y.; Udoh, P.; Kamudyariwa, X.B.; Osobajo, O.A. Artificial Intelligence in Construction Project Management: A Structured Literature Review of Its Evolution in Application and Future Trends. Digital 2025, 5, 26. https://doi.org/10.3390/digital5030026

Adebayo Y, Udoh P, Kamudyariwa XB, Osobajo OA. Artificial Intelligence in Construction Project Management: A Structured Literature Review of Its Evolution in Application and Future Trends. Digital. 2025; 5(3):26. https://doi.org/10.3390/digital5030026

Chicago/Turabian StyleAdebayo, Yetunde, Paul Udoh, Xebiso Blessing Kamudyariwa, and Oluyomi Abayomi Osobajo. 2025. "Artificial Intelligence in Construction Project Management: A Structured Literature Review of Its Evolution in Application and Future Trends" Digital 5, no. 3: 26. https://doi.org/10.3390/digital5030026

APA StyleAdebayo, Y., Udoh, P., Kamudyariwa, X. B., & Osobajo, O. A. (2025). Artificial Intelligence in Construction Project Management: A Structured Literature Review of Its Evolution in Application and Future Trends. Digital, 5(3), 26. https://doi.org/10.3390/digital5030026