State of the Art and Recent Advances on Ester and Ether Derivatives of Polysaccharides from Lignocellulose: Production and Technological Applications

Abstract

1. Introduction

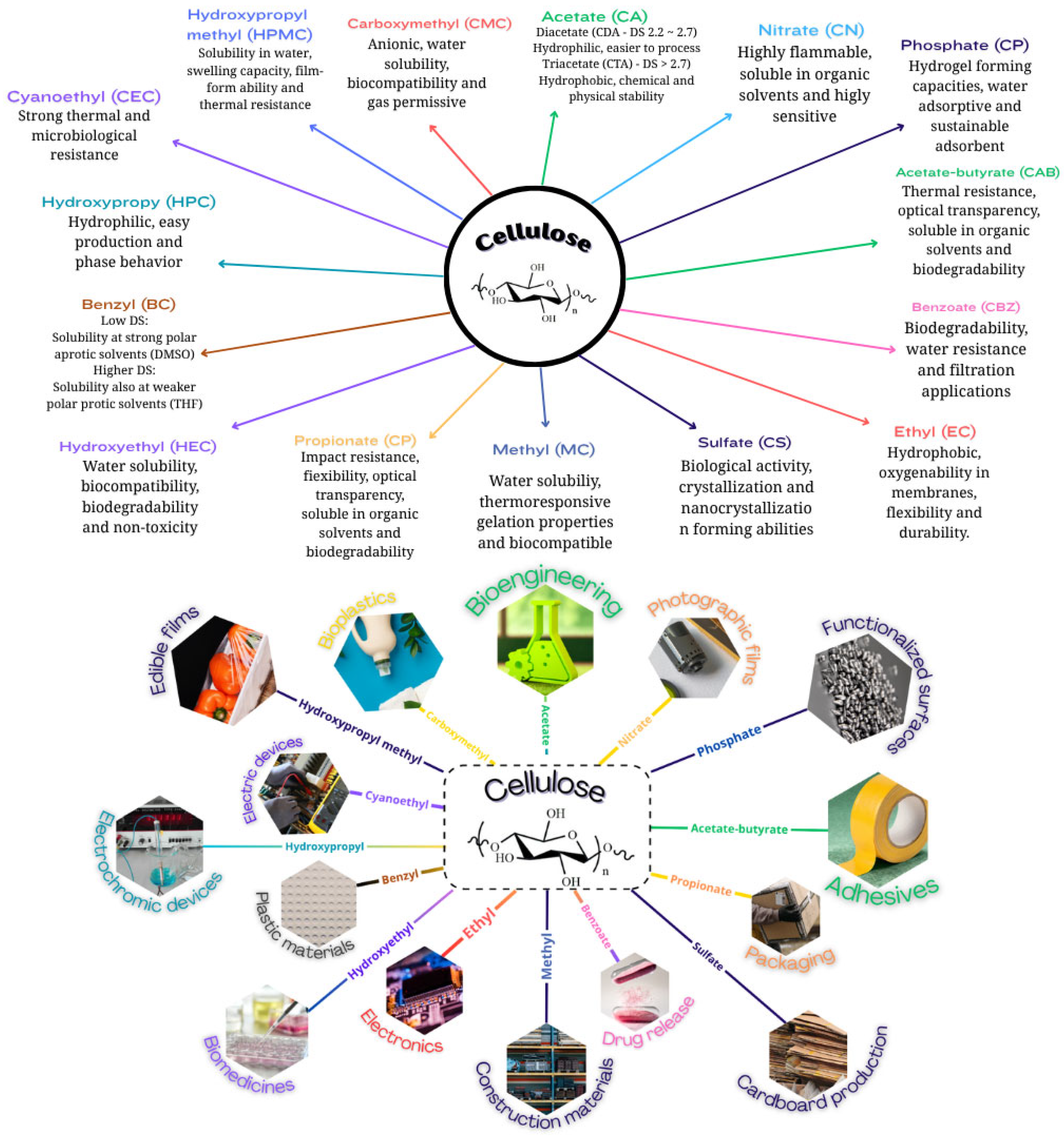

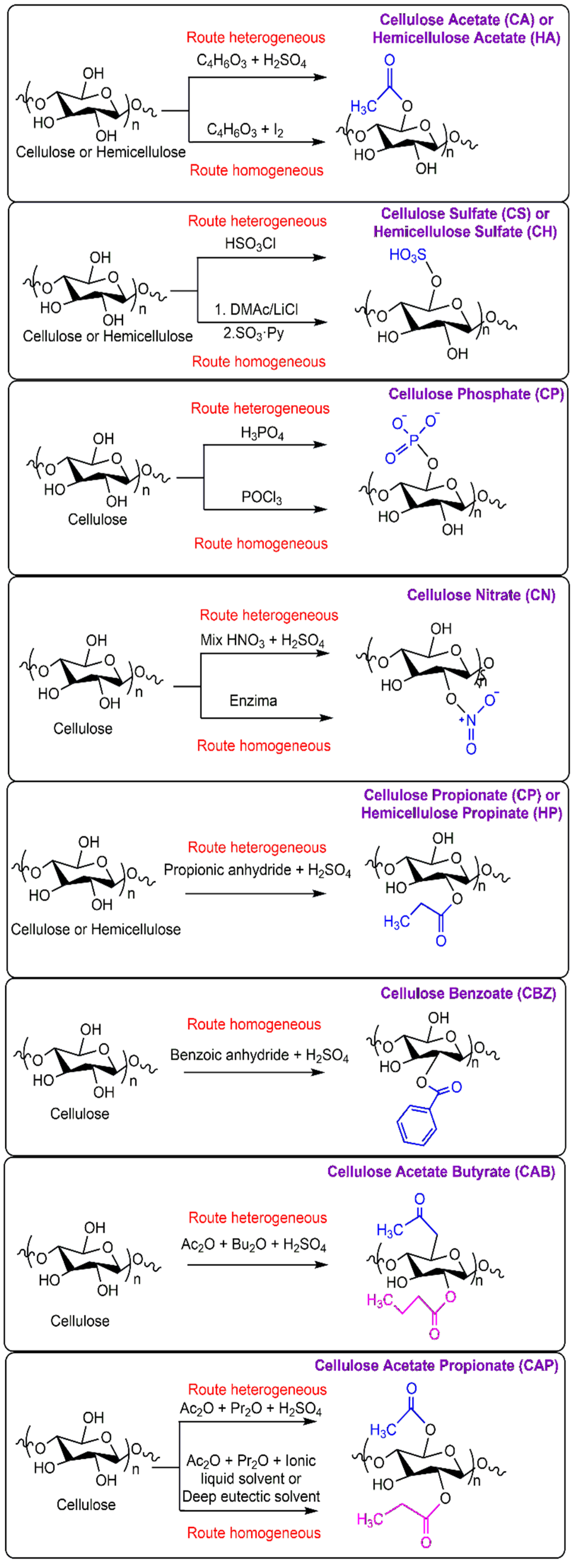

2. Cellulose Esters

2.1. Cellulose Acetate Propionate (CAP)

2.2. Cellulose Sulfate (CS)

2.3. Cellulose Phosphate (CP)

2.4. Cellulose Acetate (CA)

2.5. Cellulose Nitrate (CN)

2.6. Cellulose Benzoate (CB)

2.7. Cellulose Acetate Butyrate (CAB)

2.8. Cellulose Propionate (CP)

3. Cellulose Ethers

3.1. Methyl Cellulose (MC)

3.2. Ethyl Cellulose (EC)

3.3. Hydroxyethyl Cellulose (HEC)

3.4. Hydroxypropyl Cellulose (HPC)

3.5. Hydroxypropyl Methylcellulose (HPMC)

3.6. Carboxymethylcellulose (CMC)

3.7. Benzyl Cellulose (BC)

3.8. Cyanoethyl Cellulose (CEC)

4. Hemicellulose Esters

4.1. Hemicellulose Acetate (HCA)

4.2. Hemicellulose Propionate (HCP)

4.3. Hemicellulose Sulfate (HCS)

5. Hemicellulose Ethers

5.1. Carboxymethyl Hemicellulose (CMH)

5.2. Methyl Hemicellulose (MHC)

5.3. Cyanoethyl Hemicellulose (CEHC)

6. Literature Related to Cellulose Derivatives

7. Conclusions and Research Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muqeet, M.; Mahar, R.B.; Gadhi, T.A.; Ben Halima, N. Insight into Cellulose-Based-Nanomaterials—A Pursuit of Environmental Remedies. Int. J. Biol. Macromol. 2020, 163, 1480–1486. [Google Scholar] [CrossRef]

- Abik, F.; Palasingh, C.; Bhattarai, M.; Leivers, S.; Ström, A.; Westereng, B.; Mikkonen, K.S.; Nypelö, T. Potential of Wood Hemicelluloses and Their Derivates as Food Ingredients. J. Agric. Food Chem. 2023, 71, 2667–2683. [Google Scholar] [CrossRef]

- Arca, H.C.; Mosquera-Giraldo, L.I.; Bi, V.; Xu, D.; Taylor, L.S.; Edgar, K.J. Pharmaceutical Applications of Cellulose Ethers and Cellulose Ether Esters. Biomacromolecules 2018, 19, 2351–2376. [Google Scholar] [CrossRef]

- Nahak, B.K.; Preetam, S.; Sharma, D.; Shukla, S.K.; Syväjärvi, M.; Toncu, D.-C.; Tiwari, A. Advancements in Net-Zero Pertinency of Lignocellulosic Biomass for Climate Neutral Energy Production. Renew. Sustain. Energy Rev. 2022, 161, 112393. [Google Scholar] [CrossRef]

- Kumar, S.; Paritosh, K.; Pareek, N.; Chawade, A.; Vivekanand, V. De-Construction of Major Indian Cereal Crop Residues through Chemical Pretreatment for Improved Biogas Production: An Overview. Renew. Sustain. Energy Rev. 2018, 90, 160–170. [Google Scholar] [CrossRef]

- Rao, J.; Lv, Z.; Chen, G.; Peng, F. Hemicellulose: Structure, Chemical Modification, and Application. Prog. Polym. Sci. 2023, 140, 101675. [Google Scholar] [CrossRef]

- Chen, X.; Shen, M.; Yu, Q.; Chen, Y.; Xie, J. Recent Advance in Chemistry Modified Methods of Natural Polysaccharides and Their Applications. Trends Food Sci. Technol. 2024, 144, 104317. [Google Scholar] [CrossRef]

- Gautam, D.; Rana, V.; Sharma, S.; Kumar Walia, Y.; Kumar, K.; Umar, A.; Ibrahim, A.A.; Baskoutas, S. Hemicelluloses: A Review on Extraction and Modification for Various Applications. ChemistrySelect 2025, 10, e06050. [Google Scholar] [CrossRef]

- Cellulose Esters and Ethers Market Size & Outlook. Available online: https://www.grandviewresearch.com/horizon/outlook/cellulose-esters-and-ethers-market-size/global (accessed on 9 August 2025).

- Moura, H.O.M.A.; Campos, L.M.A.; da Silva, V.L.; de Andrade, J.C.F.; de Assumpção, S.M.N.; Pontes, L.A.M.; de Carvalho, L.S. Investigating Acid/Peroxide-Alkali Pretreatment of Sugarcane Bagasse to Isolate High Accessibility Cellulose Applied in Acetylation Reactions. Cellulose 2018, 25, 5669–5685. [Google Scholar] [CrossRef]

- de Souza, E.C.; Moura, H.O.M.A.; Pereira, A.V.S.; Costa, J.L.B.; Rodríguez-Castellón, E.; Ballesteros-Plata, D.; de Carvalho, L.S. One-Pot Production of Carboxymethyl Holocelluloses from Mango and Pineapple Wastes Optimized via Design of Experiments. Carbohydr. Polym. Technol. Appl. 2025, 10, 100822. [Google Scholar] [CrossRef]

- Abo, B.O.; Gao, M.; Wang, Y.; Wu, C.; Ma, H.; Wang, Q. Lignocellulosic Biomass for Bioethanol: An Overview on Pretreatment, Hydrolysis and Fermentation Processes. Rev. Environ. Health 2019, 34, 57–68. [Google Scholar] [CrossRef]

- Moura, H.O.M.A.; de Souza, E.C.; da Silva, B.R.; Pereira, E.S.; Bicudo, T.d.C.; Rodríguez-Castellón, E.; de Carvalho, L.S. Optimization of Synthesis Method for Carboxymethylcellulose (CMC) from Agro-Food Wastes by Response Surface Methodology (RSM) Using D-Optimal Algorithm. Ind. Crops Prod. 2024, 220, 119413. [Google Scholar] [CrossRef]

- Islam, M.; Sinha, A.S.K.; Prasad, K. Organosolv Delignification of Rice Straw Cellulose Fiber for Functional Food Packaging. Cellulose 2024, 31, 9191–9214. [Google Scholar] [CrossRef]

- Alizadeh, H.-R.; Kansedo, J.; Tan, I.S.; Tan, Y.H.; Suali, E.; Dini, A. Recent Advances on Two-Step and Combined Multi-Step Pretreatment of Lignocellulosic Biomass for Cellulose Extraction. Bioresour. Technol. Rep. 2025, 31, 102243. [Google Scholar] [CrossRef]

- Arce, C.; Kratky, L. Mechanical Pretreatment of Lignocellulosic Biomass toward Enzymatic/Fermentative Valorization. iScience 2022, 25, 104610. [Google Scholar] [CrossRef] [PubMed]

- Banu Jamaldheen, S.; Kurade, M.B.; Basak, B.; Yoo, C.G.; Oh, K.K.; Jeon, B.-H.; Kim, T.H. A Review on Physico-Chemical Delignification as a Pretreatment of Lignocellulosic Biomass for Enhanced Bioconversion. Bioresour. Technol. 2022, 346, 126591. [Google Scholar] [CrossRef]

- Lee, K.M.; Quek, J.D.; Tey, W.Y.; Lim, S.; Kang, H.-S.; Quen, L.K.; Mahmood, W.A.W.; Jamaludin, S.I.S.; Teng, K.H.; Khoo, K.S. Biomass Valorization by Integrating Ultrasonication and Deep Eutectic Solvents: Delignification, Cellulose Digestibility and Solvent Reuse. Biochem. Eng. J. 2022, 187, 108587. [Google Scholar] [CrossRef]

- Al Kamzari, S.M.A.; Nageswara Rao, L.; Lakavat, M.; Gandi, S.; Reddy, P.S.; Kavitha Sri, G. Extraction and Characterization of Cellulose from Agricultural Waste Materials. Mater. Today Proc. 2023, 80, 2740–2743. [Google Scholar] [CrossRef]

- Das, P.; Baruah, J.; Kalita, E. Recent Developments in the Enzymatic and Biocatalytic Pretreatment of Microalgae for Efficient Biofuel Production. In Micro-Algae: Next-Generation Feedstock for Biorefineries; Springer: Singapore, 2022; pp. 193–210. [Google Scholar]

- Kumar, R.; Kim, T.H.; Basak, B.; Patil, S.M.; Kim, H.H.; Ahn, Y.; Yadav, K.K.; Cabral-Pinto, M.M.S.; Jeon, B.-H. Emerging Approaches in Lignocellulosic Biomass Pretreatment and Anaerobic Bioprocesses for Sustainable Biofuels Production. J. Clean. Prod. 2022, 333, 130180. [Google Scholar] [CrossRef]

- Kant Bhatia, S.; Ahuja, V.; Chandel, N.; Gurav, R.; Kant Bhatia, R.; Govarthanan, M.; Kumar Tyagi, V.; Kumar, V.; Pugazendhi, A.; Rajesh Banu, J.; et al. Advances in Algal Biomass Pretreatment and Its Valorisation into Biochemical and Bioenergy by the Microbial Processes. Bioresour. Technol. 2022, 358, 127437. [Google Scholar] [CrossRef]

- Yu, Y.; Wu, J.; Ren, X.; Lau, A.; Rezaei, H.; Takada, M.; Bi, X.; Sokhansanj, S. Steam Explosion of Lignocellulosic Biomass for Multiple Advanced Bioenergy Processes: A Review. Renew. Sustain. Energy Rev. 2022, 154, 111871. [Google Scholar] [CrossRef]

- Zhang, J.; Qi, Y.; Shen, Y.; Li, H. Research Progress on Chemical Modification and Application of Cellulose: A Review. Mater. Sci. 2022, 28, 60–67. [Google Scholar] [CrossRef]

- Lu, Y.; He, Q.; Fan, G.; Cheng, Q.; Song, G. Extraction and Modification of Hemicellulose from Lignocellulosic Biomass: A Review. Green Process. Synth. 2021, 10, 779–804. [Google Scholar] [CrossRef]

- Najjoum, N.; Grimi, N.; Benali, M.; Chadni, M.; Castignolles, P. Extraction and Chemical Features of Wood Hemicelluloses: A Review. Int. J. Biol. Macromol. 2025, 311, 143681. [Google Scholar] [CrossRef]

- Gao, C.; Li, X.; Wei, G.; Wang, S.; Zhao, X.; Kong, F. Cellulose Acetate Propionate Incorporated PVDF-HFP Based Polymer Electrolyte Membrane for Lithium Batteries. Compos. Commun. 2022, 33, 101226. [Google Scholar] [CrossRef]

- Gao, C.; Li, X.; Wei, G.; Wang, S.; Zhao, X.; Kong, F. In-Situ Construction of Cellulose Acetate Propionate-Based Hybrid Gel Polymer Electrolyte for High-Performance Lithium Metal Batteries. Ind. Crops Prod. 2023, 204, 117395. [Google Scholar] [CrossRef]

- Martín-Alfonso, M.A.; Rubio-Valle, J.F.; Hinestroza, J.P.; Martín-Alfonso, J.E.; Franco, J.M. Environmentally Friendly Tailor-Made Oleo-Dispersions of Electrospun Cellulose Acetate Propionate Nanostructures in Castor Oil for Lubricant Applications. Nano Mater. Sci. 2025, 7, 90–104. [Google Scholar] [CrossRef]

- Liu, X.; Xie, J.; Jacquet, N.; Blecker, C. Valorization of Grain and Oil By-Products with Special Focus on Hemicellulose Modification. Polymers 2024, 16, 1750. [Google Scholar] [CrossRef]

- Ebringerová, A. Structural Diversity and Application Potential of Hemicelluloses. Macromol. Symp. 2005, 232, 1–12. [Google Scholar] [CrossRef]

- Heinze, T.; Koschella, A. Solvents Applied in the Field of Cellulose Chemistry: A Mini Review. Polímeros 2005, 15, 84–90. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, K.; Yang, Y.; Kim, M.-S.; Lee, C.-H.; Zhang, R.; Xu, T.; Choi, S.-E.; Si, C. Hemicellulose-Based Hydrogels for Advanced Applications. Front. Bioeng. Biotechnol. 2023, 10, 1110004. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Sun, H.; Yang, B.; Weng, Y. Hemicellulose-Based Film: Potential Green Films for Food Packaging. Polymers 2020, 12, 1775. [Google Scholar] [CrossRef]

- Nechita, P.; Roman, M.; Năstac, S.M. Green Approaches on Modification of Xylan Hemicellulose to Enhance the Functional Properties for Food Packaging Materials—A Review. Polymers 2023, 15, 2088. [Google Scholar] [CrossRef]

- Keldibekova, R.; Suleimenova, S.; Nurgozhina, G.; Kopishev, E. Interpolymer Complexes Based on Cellulose Ethers: Application. Polymers 2023, 15, 3326. [Google Scholar] [CrossRef]

- Wang, C.; Tallian, C.; Su, J.; Vielnascher, R.; Silva, C.; Cavaco-Paulo, A.; Guebitz, G.M.; Fu, J. Ultrasound-Assisted Extraction of Hemicellulose and Phenolic Compounds from Bamboo Bast Fiber Powder. PLoS ONE 2018, 13, e0197537. [Google Scholar] [CrossRef]

- Rhein, F.; Sehn, T.; Meier, M.A.R. Efficient and Accurate Determination of the Degree of Substitution of Cellulose Acetate Using ATR-FTIR Spectroscopy and Machine Learning. Sci. Rep. 2025, 15, 2904. [Google Scholar] [CrossRef]

- Heinze, T.; Liebert, T.F.; Pfeiffer, K.S.; Hussain, M.A. Unconventional Cellulose Esters: Synthesis, Characterization and Structure-Property Relations. Cellulose 2003, 10, 283–296. [Google Scholar] [CrossRef]

- von Schantz, L.; Schagerlöf, H.; Karlsson, E.N.; Ohlin, M. Characterization of the Substitution Pattern of Cellulose Derivatives Using Carbohydrate-Binding Modules. BMC Biotechnol. 2014, 14, 113. [Google Scholar] [CrossRef]

- Yokota, S.; Nishimoto, A.; Kondo, T. Alkali-Activation of Cellulose Nanofibrils to Facilitate Surface Chemical Modification under Aqueous Conditions. J. Wood Sci. 2022, 68, 14. [Google Scholar] [CrossRef]

- Azrak, S.M.E.A.; Gohl, J.A.; Moon, R.J.; Schueneman, G.T.; Davis, C.S.; Youngblood, J.P. Controlled Dispersion and Setting of Cellulose Nanofibril—Carboxymethyl Cellulose Pastes. Cellulose 2021, 28, 9149–9168. [Google Scholar] [CrossRef]

- Verdía Barbará, P.; Choudhary, H.; Nakasu, P.S.; Al-Ghatta, A.; Han, Y.; Hopson, C.; Aravena, R.I.; Mishra, D.K.; Ovejero-Pérez, A.; Simmons, B.A.; et al. Recent Advances in the Use of Ionic Liquids and Deep Eutectic Solvents for Lignocellulosic Biorefineries and Biobased Chemical and Material Production. Chem. Rev. 2025, 125, 5461–5583. [Google Scholar] [CrossRef]

- Yu, J.; Liu, X.; Xu, S.; Shao, P.; Li, J.; Chen, Z.; Wang, X.; Lin, Y.; Renard, C.M.G.C. Advances in Green Solvents for Production of Polysaccharide-based Packaging Films: Insights of Ionic Liquids and Deep Eutectic Solvents. Compr. Rev. Food Sci. Food Saf. 2023, 22, 1030–1057. [Google Scholar] [CrossRef]

- Szabó, L.; Milotskyi, R.; Sharma, G.; Takahashi, K. Cellulose Processing in Ionic Liquids from a Materials Science Perspective: Turning a Versatile Biopolymer into the Cornerstone of Our Sustainable Future. Green. Chem. 2023, 25, 5338–5389. [Google Scholar] [CrossRef]

- Ajayi, S.M.; Olusanya, S.O.; Abimbade, S.F.; Didunyemi, A.E.; Atunde, M.O.; Fapojuwo, D.P.; Olumayede, E.G.; Lawal, O.S.; Akintayo, C.O.; Malomo, D. Preparation and Characterization of Acetate Cellulose Laurate Ester in Sodium Acetate/Zinc Chloride Systems. Biomater. Connect 2024, 1, 1. [Google Scholar] [CrossRef]

- Kostag, M.; Jedvert, K.; Achtel, C.; Heinze, T.; El Seoud, O.A. Recent Advances in Solvents for the Dissolution, Shaping and Derivatization of Cellulose: Quaternary Ammonium Electrolytes and Their Solutions in Water and Molecular Solvents. Molecules 2018, 23, 511. [Google Scholar] [CrossRef] [PubMed]

- He, M.; Lin, Y.; Huang, Y.; Fang, Y.; Xiong, X. Research Progress of the Preparation of Cellulose Ethers and Their Applications: A Short Review. Molecules 2025, 30, 1610. [Google Scholar] [CrossRef] [PubMed]

- Ge, W.; Shuai, J.; Wang, Y.; Zhou, Y.; Wang, X. Progress on Chemical Modification of Cellulose in “Green” Solvents. Polym. Chem. 2022, 13, 359–372. [Google Scholar] [CrossRef]

- Cellulose Acetate Propionate Market Size, Market Outlook & Forecast. Available online: https://www.verifiedmarketreports.com/product/cellulose-acetate-propionate-market/ (accessed on 21 August 2025).

- Wen, Y.; Zhang, H.; Li, J.; An, S.; Chen, W.; Song, Y.F. Core-Shell Assembly of Heteropolyacids and Polymer: Efficient Preparation of Cellulose Acetate Propionate and Its Processed Products. ACS Sustain. Chem. Eng. 2021, 9, 5179–5186. [Google Scholar] [CrossRef]

- Cellulose Acetate Propionate, Eastman—ChemPoint. Available online: https://www.chempoint.com/products/eastman/eastman-cellulose-esters/cellulose-acetate-propionate (accessed on 10 August 2025).

- Géis Superabsorventes de Propionato Acetato de Celulose e Acetato de Celulose: Síntese, Caracterização e Liberação Controlada de Pesticida. Available online: https://repositorio.ufscar.br/items/a9ff097b-8b2b-4abd-b9b9-a2f956f2cd27 (accessed on 10 August 2025).

- Hussain, S.M.S.; Adewunmi, A.A.; Alade, O.S.; Murtaza, M.; Mahboob, A.; Khan, H.J.; Mahmoud, M.; Kamal, M.S. A Review of Ionic Liquids: Recent Synthetic Advances and Oilfield Applications. J. Taiwan Inst. Chem. Eng. 2023, 153, 105195. [Google Scholar] [CrossRef]

- Gao, G.; Cai, L.; Fan, Y.; Aroche Ginarte, R.; Li, Y.; Sun, W.; Jiang, X.; Li, X.; Pi, Y. Effects of Different Hemicellulose Components on Fermentation Kinetics and Microbial Composition in Fecal Inoculum from Suckling Piglets In Vitro. ACS Omega 2025, 15, 45. [Google Scholar] [CrossRef]

- Morozova, O.V.; Vasil’eva, I.S.; Shumakovich, G.P.; Zaitseva, E.A.; Yaropolov, A.I. Deep Eutectic Solvents for Biotechnology Applications. Biochemistry 2023, 88, S150–S175. [Google Scholar] [CrossRef]

- Zhou, S.; Xu, J.; Zhang, Z.; Zhu, S.; Li, J.; Zhang, W.; Zhang, F.; Chen, K. Controlled Preparation of Cellulose Acetate by Deep Eutectic Solvent Homogeneous Catalysis. Carbohydr. Polym. 2025, 349, 122964. [Google Scholar] [CrossRef]

- Tian, C.; Duan, C.; Bie, Y.; Liu, X.; Zhou, B.; Ma, R.; Fan, Q.; Xie, Z.; Ni, Y. A Deep Eutectic Solvent with Bifunctional Acid Sites Treatment to Upgrade a Bamboo Kraft Pulp into a Cellulose-Acetate Grade Dissolving Pulp. Carbohydr. Polym. 2025, 348, 122942. [Google Scholar] [CrossRef]

- Yahaya, S.H.; Muhammad, C.; Zauro, S.A.; Magami, I.M. An In-Depth Review of Sustainable and Environmentally Friendly Pretreatment Techniques for Cellulose Extraction from Lignocellulosic Biomass and Their Uses. Am. J. Appl. Ind. Chem. 2025, 9, 13–33. [Google Scholar] [CrossRef]

- Gao, C.; Li, X.; Song, C.; Wei, G.; Zhao, X.; Wang, S.; Kong, F. Electrospun Polyimide/Cellulose Acetate Propionate Nanofiber Membrane-Based Gel Polymer Electrolyte with Fast Lithium-Ion Transport and High Interface Stability for Lithium Metal Batteries. Cellulose 2023, 30, 9113–9126. [Google Scholar] [CrossRef]

- Kaur, M.; Pal, J. Evaluation of Efficiency of Wheat Straw Nanocellulose as Nanoadsorbent for the Removal of Divalent Copper, Lead and Zinc from Aqueous Solution. Carbohydr. Polym. Technol. Appl. 2023, 6, 100350. [Google Scholar] [CrossRef]

- Zhang, T.; Yuan, Y.; Wu, X.; Yu, P.; Ji, J.; Chai, J.; Kumar Saini, R.; Liu, J.; Shang, X. The Level of Sulfate Substitution of Polysaccharide Regulates Thermal-Induced Egg White Protein Gel Properties: The Characterization of Gel Structure and Intermolecular Forces. Food Res. Int. 2023, 173, 113349. [Google Scholar] [CrossRef]

- Montenegro, R.; Rincón, E.; Rodríguez, A.; González, Z. Manufacturing Sulfated Cellulose Nanofibers Using a Unique Combined DES-Based Pretreatment-Functionalization Protocol for Metal Ion Decontamination through Porous Adsorbents. Carbohydr. Polym. 2025, 349, 122974. [Google Scholar] [CrossRef] [PubMed]

- Su, X.; Fang, H.; Yang, H.; Zou, F.; Li, G.; Wang, L.; Liao, H.; Guan, W.; Hu, X. Cellulose Sulfate Lithium as a Conductive Binder for LiFePO4 Cathode with Long Cycle Life. Carbohydr. Polym. 2023, 313, 120848. [Google Scholar] [CrossRef] [PubMed]

- Johnson, K.I.; Borges, W.; Sharma, P.R.; Sharma, S.K.; Chang, H.Y.; Abou-Krisha, M.M.; Alhamzani, A.G.; Hsiao, B.S. Cellulose Sulfate Nanofibers for Enhanced Ammonium Removal. Nanomaterials 2024, 14, 507. [Google Scholar] [CrossRef] [PubMed]

- Min, K.; Tae, G. Cellular Infiltration in an Injectable Sulfated Cellulose Nanocrystal Hydrogel and Efficient Angiogenesis by VEGF Loading. Biomater. Res. 2023, 27, 28. [Google Scholar] [CrossRef]

- Normakhamatov, N.; Mischnick, P.; Muhitdinov, B.; Mukhamedov, I.; Turaev, A. Sodium Cellulose Sulfate and Its Antimicrobial Activity. React. Funct. Polym. 2023, 191, 105672. [Google Scholar] [CrossRef]

- Long, Y.; Dimde, M.; Adler, J.M.; Vidal, R.M.; Povolotsky, T.L.; Nickl, P.; Achazi, K.; Trimpert, J.; Kaufer, B.B.; Haag, R.; et al. Sulfated Cellulose Nanofiber Hydrogel with Mucus-Like Activities for Virus Inhibition. ACS Appl. Mater. Interfaces 2024, 16, 67504–67513. [Google Scholar] [CrossRef]

- Silva, F.A.G.S.; Branco, S.; Dourado, F.; Neto, B.; Gama, M. Life Cycle Assessment of Bacterial Cellulose and Comparison to Other Cellulosic Sources. J. Clean. Prod. 2025, 493, 144876. [Google Scholar] [CrossRef]

- Wang, X.; Feng, X.; Chen, G.; Lin, B.; Qi, H. Influence of Sulfation Pretreatment on the Structure and Properties of Cellulose Nanofibrils. Ind. Crops Prod. 2022, 187, 115391. [Google Scholar] [CrossRef]

- Tang, C.; Zhao, Z.; Yang, M.; Lu, X.; Fu, L.; Jiang, G. Preparation and Characterization of Sodium Cellulose Sulfate/Chitosan Composite Films Loaded with Curcumin for Monitoring Pork Freshness. Curr. Res. Food Sci. 2022, 5, 1475–1483. [Google Scholar] [CrossRef]

- Almeida, R.; Ramos, A.; Håkonsen, V.; Maloney, T.; Gamelas, J. Functionalized Cellulose Nanofiber Films as Potential Substitutes for Japanese Paper. Carbohydr. Polym. Technol. Appl. 2024, 8, 100573. [Google Scholar] [CrossRef]

- Fernandes, M.; Alves, C.; Melro, L.; Fernandes, R.D.V.; Padrão, J.; Nio, A.; Salgado, J.; Zille, A. Modification of Nanocellulose. In Handbook of Biomass; Springer: Singapore, 2023. [Google Scholar] [CrossRef]

- Jokar, M.; Bidhendi, G.N.; Naeimi, H. Catalytic Chemical Reduction of Cr(VI) from Contaminated Waters by the Production of Hydrogen Radical on the Cellulose Sulfate Microfibers Coated with Palladium Nanocatalyst. Desalination Water Treat 2022, 248, 124–133. [Google Scholar] [CrossRef]

- Li, W.; Wang, Z.; Li, M.; Normakhamatov, N. Cellulose Sulfate/EMIMAc Solution: Rheological Properties and Shaping into Polyelectrolyte Complexes for Protein Adsorption. Cellulose 2021, 28, 2849–2861. [Google Scholar] [CrossRef]

- Romanchenko, A.S.; Levdansky, A.V.; Levdansky, V.A.; Kuznetsov, B.N. Study of Cellulose Sulfates by X-Ray Photoelectron Spectroscopy. Russ. J. Bioorg Chem. 2015, 41, 719–724. [Google Scholar] [CrossRef]

- Wu, Q.X.; Guan, Y.X.; Yao, S.J. Sodium Cellulose Sulfate: A Promising Biomaterial Used for Microcarriers’ Designing. Front. Chem. Sci. Eng. 2019, 13, 46–58. [Google Scholar] [CrossRef]

- Ma, G.; Zhang, Z.; Chen, J.; Yang, G.; He, M. Facile Sulfation of Cellulose via Recyclable Ternary Deep Eutectic Solvents for Low-Cost Cellulose Nanofibril Preparation. Nanoscale Adv. 2023, 5, 356–360. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, Y.; Pan, Y.; Dong, C.; Huang, X.; Zhang, G.; Zhang, K. Sulfated Cellulose Nanocrystal Isolated from Waste Cotton Fabrics by Deep Eutectic Solvent and Its Application in Polymer Nanocomposite Films. J. Vinyl Addit. Technol. 2025, 31, 47–58. [Google Scholar] [CrossRef]

- Live Cell Encapsulation Market Report|Global Forecast from 2025 to 2033. Available online: https://dataintelo.com/report/global-live-cell-encapsulation-market (accessed on 21 August 2025).

- Tang, C.; Zhao, B.; Zhu, J.; Lu, X.; Jiang, G. Preparation and Characterization of Chitosan/Sodium Cellulose Sulfate/Silver Nanoparticles Composite Films for Wound Dressing. Mater. Today Commun. 2022, 33, 104192. [Google Scholar] [CrossRef]

- Li, X.; Ding, W.; Wang, S.; Yang, L.; Yu, Q.; Xiao, C.; Chen, G.; Zhang, L.; Guan, S.; Sun, D. Three-Dimensional Sulfated Bacterial Cellulose/Gelatin Composite Scaffolds for Culturing Hepatocytes. Cyborg Bionic Syst. 2023, 4, 21. [Google Scholar] [CrossRef]

- Li, Z.; Yan, M.; Su, X.; Lei, W.; Han, J.; Huang, Q.; Liao, H.; Hu, X. A Multifunctional Polyelectrolyte Binder to Improve Fast Charging Capability of Graphite Anode in Lithium-Ion Batteries. J. Mater. Sci. Mater. Electron. 2025, 36, 1024. [Google Scholar] [CrossRef]

- Yan, W.; Xian, J.; Huang, S.; Leng, Y.; Liu, Q.; Xiao, T.; Zhao, Y.; Yang, P.; Wu, Y. Scalable and Sustainable Sulfonated Cellulose Separators toward Practical Ah-Level Aqueous Batteries. Energy Storage Mater 2025, 76, 104150. [Google Scholar] [CrossRef]

- Schimper, C.B.; Pachschwöll, P.; Maitz, M.F.; Werner, C.; Rosenau, T.; Liebner, F. Hemocompatibility of Cellulose Phosphate Aerogel Membranes with Potential Use in Bone Tissue Engineering. Front. Bioeng. Biotechnol. 2023, 11, 1152577. [Google Scholar] [CrossRef] [PubMed]

- Suneetha, M.; Kim, H.; Han, S.S. Bone-like Apatite Formation in Biocompatible Phosphate-Crosslinked Bacterial Cellulose-Based Hydrogels for Bone Tissue Engineering Applications. Int. J. Biol. Macromol. 2024, 256, 128364. [Google Scholar] [CrossRef]

- Jeong, D.I.; Kim, S.; Kim, M.-H.; Yoon, I.-S.; Lee, S.-H.; Kim, D.-D.; Cho, H.-J. Donepezil Hydrochloride-Reinforced Cellulose Nanocrystal-Aggregated Gel Structure for Long-Acting Drug Delivery. Carbohydr. Polym. 2022, 296, 119887. [Google Scholar] [CrossRef]

- Garg, T.; Arora, S.; Pahwa, R. Cellulose and Its Derivatives: Structure, Modification, and Application in Controlled Drug Delivery. Future J. Pharm. Sci. 2025, 11, 76. [Google Scholar] [CrossRef]

- Gong, J.; Hou, L.; Ching, Y.C.; Ching, K.Y.; Hai, N.D.; Chuah, C.H. A Review of Recent Advances of Cellulose-Based Intelligent-Responsive Hydrogels as Vehicles for Controllable Drug Delivery System. Int. J. Biol. Macromol. 2024, 264, 130525. [Google Scholar] [CrossRef]

- Hu, T.; Fang, J.; Shen, Y.; Li, M.; Wang, B.; Xu, Z.; Hu, W. Advances of Naturally Derived Biomedical Polymers in Tissue Engineering. Front. Chem. 2024, 12, 1469183. [Google Scholar] [CrossRef]

- Iravani, S.; Varma, R.S. Cellulose-Based Composites as Scaffolds for Tissue Engineering: Recent Advances. Molecules 2022, 27, 8830. [Google Scholar] [CrossRef]

- Li, Z.; Qian, P.; Li, H.; Xiao, H.; Chen, J.; Li, G. Phosphorylated Cellulose Nanofibers Establishing Reliable Ion-Sieving Barriers for Durable Lithium-Sulfur Batteries. J. Energy Chem. 2024, 92, 619–628. [Google Scholar] [CrossRef]

- Aziam, H.; Ouarga, A.; Ettalibi, O.; Shanmukaraj, D.; Noukrati, H.; Sehaqui, H.; Saadoune, I.; Barroug, A.; Ben Youcef, H. Phosphorylated Cellulose Nanofiber as Sustainable Organic Filler and Potential Flame-Retardant for All-Solid-State Lithium Batteries. J. Energy Storage 2023, 62, 106838. [Google Scholar] [CrossRef]

- Rohaizu, R.; Wanrosli, W.D. Production of Cellulose Phosphate from Oil Palm Empty Fruit Bunch: Effect of Chemical Ratio. J. Phys. Conf. Ser. 2015, 622, 012021. [Google Scholar] [CrossRef]

- Abdulhameed, A.; Mbuvi, H.; Changamu, E.; Githinji, I.; Maingi, F. Synthesis and Characterization of Cellulose Phosphate-Based Superabsorbent Hydrogels from Rice Husk under Microwave Heating. Next Mater. 2025, 6, 100400. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, L.; Liu, Y.; Dong, C.; Zhang, K. Production of Flame-Retardant Phosphorylated Cellulose Nanofibrils by Choline Chloride Based Reactive Deep Eutectic Solvent. Carbohydr. Polym. 2025, 348, 122931. [Google Scholar] [CrossRef]

- Gao, Y.; Zhu, J.; Han, S.; Wu, G.; Wu, Q.; Wang, J.; Fu, J.; Shen, S.; Li, Q. One-Step Green Synthesis Durable Flame-Retardant, Antibacterial and Dyeable Cellulose Fabrics with a Recyclable Deep Eutectic Solvent. Int. J. Biol. Macromol. 2025, 299, 140201. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Zhang, L.; Cui, M.; Qi, W.; Lam, H.L.; Huang, R.; Su, R. Integrating Solvent-Free Mechanochemistry and Heat Curing for the Green Production of Highly Charged and Highly Crystalline Phosphorylated Cellulose Nanocrystals. Chem. Eng. J. 2025, 511, 162260. [Google Scholar] [CrossRef]

- Functionalized Cellulose Materials; Springer: Berlin/Heidelberg, Germany, 2025. [CrossRef]

- Catalyzing Commercialization: Converting CO2 into Cellulose with Cell-Free Biocatalysis|AIChE. Available online: https://www.aiche.org/resources/publications/cep/2025/august/catalyzing-commercialization-converting-co2-cellulose-cell-free-biocatalysis (accessed on 9 August 2025).

- Zhao, S.; Li, J.; Wu, L.; Hua, M.; Jiang, C.; Pan, Y.; Yao, L.; Xu, S.; Ge, J.; Pan, G. Synthesis and Characterization of Cellulose Diacetate-Graft-Polylactide via Solvent-Free Melt Ring-Opening Graft Copolymerization. Polymers 2022, 15, 143. [Google Scholar] [CrossRef]

- Raza, A.; Farrukh, S.; Hussain, A.; Khan, I.; Othman, M.H.D.; Ahsan, M. Performance Analysis of Blended Membranes of Cellulose Acetate with Variable Degree of Acetylation for CO2/CH4 Separation. Membranes 2021, 11, 245. [Google Scholar] [CrossRef]

- Oprea, M.; Voicu, S.I. Recent Advances in Composites Based on Cellulose Derivatives for Biomedical Applications. Carbohydr. Polym. 2020, 247, 116683. [Google Scholar] [CrossRef] [PubMed]

- Wsoo, M.A.; Shahir, S.; Mohd Bohari, S.P.; Nayan, N.H.M.; Razak, S.I.A. A Review on the Properties of Electrospun Cellulose Acetate and Its Application in Drug Delivery Systems: A New Perspective. Carbohydr. Res. 2020, 491, 107978. [Google Scholar] [CrossRef] [PubMed]

- Ashter, S.A. Chemistry of Cellulosic Polymers. In Technology and Applications of Polymers Derived from Biomass; Elsevier: Amsterdam, The Netherlands, 2018; pp. 57–74. [Google Scholar]

- Bakri, M.K.B.; Rahman, M.R. Extraction, Types, and Classification of Cellulose. In Fundamentals and Recent Advances in Nanocomposites Based on Polymers and Nanocellulose; Elsevier: Amsterdam, The Netherlands, 2022; pp. 19–40. [Google Scholar]

- Cellulose Diacetate Market Size, Consumer Behavior Insights & Forecast. Available online: https://www.verifiedmarketreports.com/product/cellulose-diacetate-market/ (accessed on 22 July 2025).

- Cellulose Triacetate Market Size, Evaluation, Outlook & Forecast. Available online: https://www.verifiedmarketreports.com/product/cellulose-triacetate-market/ (accessed on 22 July 2025).

- Das, A.M.; Ali, A.A.; Hazarika, M.P. Synthesis and Characterization of Cellulose Acetate from Rice Husk: Eco-Friendly Condition. Carbohydr. Polym. 2014, 112, 342–349. [Google Scholar] [CrossRef] [PubMed]

- Shaikh, H.M.; Anis, A.; Poulose, A.M.; Al-Zahrani, S.M.; Madhar, N.A.; Alhamidi, A.; Aldeligan, S.H.; Alsubaie, F.S. Synthesis and Characterization of Cellulose Triacetate Obtained from Date Palm (Phoenix dactylifera L.) Trunk Mesh-Derived Cellulose. Molecules 2022, 27, 1434. [Google Scholar] [CrossRef]

- Bamba, M.; Assanvo, E.F.; Kouassi, E.K.A.; Soro, D.; Ouattara, L.Y.; Yao, K.B.; Drogui, A.P.; Tyagi, D.R. Preparation and Characterization of Cellulose Triacetate from Cocoa Pod Husk. Bioresources 2023, 18, 1684–1698. [Google Scholar] [CrossRef]

- Esmaeilzadeh, M.; Kaschuk, J.; Nguyen, H.M.; Palo, E.; Al Haj, Y.; Vapaavuori, J.; Miettunen, K. Nano-Imprinted Cellulose Acetate Structures for Light Management of Dye-Sensitized Solar Cells. Front. Mater. Sci. 2025, 19, 250725. [Google Scholar] [CrossRef]

- de Freitas, R.R.M.; Senna, A.M.; Botaro, V.R. Influence of Degree of Substitution on Thermal Dynamic Mechanical and Physicochemical Properties of Cellulose Acetate. Ind. Crops Prod. 2017, 109, 452–458. [Google Scholar] [CrossRef]

- Stiriba, S.-E. Recent Advances in Cellulose Chemistry. Int. J. Mol. Sci. 2024, 25, 8977. [Google Scholar] [CrossRef]

- Wu, C.-S. Mechanical Properties, Biocompatibility, and Biodegradation of Cross-Linked Cellulose Acetate-Reinforced Polyester Composites. Carbohydr. Polym. 2014, 105, 41–48. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Mandal, T.; Goswami, S. Fabrication of Cellulose Acetate Nanocomposite Films with Lignocelluosic Nanofiber Filler for Superior Effect on Thermal, Mechanical and Optical Properties. Nano-Struct. Nano-Objects 2021, 25, 100642. [Google Scholar] [CrossRef]

- Bashir, Z.; Lock, S.S.M.; e Hira, N.; Ilyas, S.U.; Lim, L.G.; Lock, I.S.M.; Yiin, C.L.; Darban, M.A. A Review on Recent Advances of Cellulose Acetate Membranes for Gas Separation. RSC Adv. 2024, 14, 19560–19580. [Google Scholar] [CrossRef]

- Sakellariou, P.; Rowe, R.C.; White, E.F.T. The Solubility Parameters of Some Cellulose Derivatives and Polyethylene Glycols Used in Tablet Film Coating. Int. J. Pharm. 1986, 31, 175–177. [Google Scholar] [CrossRef]

- Bastida, G.A.; Aguado, R.J.; Galván, M.V.; Zanuttini, M.Á.; Delgado-Aguilar, M.; Tarrés, Q. Impact of Cellulose Nanofibers on Cellulose Acetate Membrane Performance. Cellulose 2024, 31, 2221–2238. [Google Scholar] [CrossRef]

- Wang, J.; Abbas, S.C.; Li, L.; Walker, C.C.; Ni, Y.; Cai, Z. Cellulose Membranes: Synthesis and Applications for Water and Gas Separation and Purification. Membranes 2024, 14, 148. [Google Scholar] [CrossRef]

- Rodríguez-Liébana, J.A.; Robles-Solano, E.; Jurado-Contreras, S.; Morillas-Gutiérrez, F.; Moya, A.J.; Mateo, S.; Navas-Martos, F.J.; La Rubia, M.D. Production and Characterization of Cellulose Acetate Using Olive Tree Pruning Biomass as Feedstock. Biofuels Bioprod. Biorefining 2024, 18, 865–882. [Google Scholar] [CrossRef]

- Anwar, M.; Suwanto, A.; Wahono, S.K.; Prasetyo, D.J.; Sugiharto, S.P.; Maryana, R.; Setiyoko, A. Synthesis and Characterization of Cellulose Acetate from Fiber Waste of Sugar Palm Stem (Arenga pinnata sp.). AIP Conf. Proc. 2024, 2957, 060024. [Google Scholar] [CrossRef]

- Jia, X.; Guo, D.; Yan, Q.; Yu, H.; Lyu, Q.; Han, L.; Zhou, C.; Xiao, W. Synthesis and Characterization of Corn Stover-Based Cellulose Triacetate Catalyzed by Ionic Liquid Phosphotungstate. Int. J. Mol. Sci. 2022, 23, 6783. [Google Scholar] [CrossRef] [PubMed]

- Sezali, N.A.A.; Ong, H.L.; Mohd Pisal, M.H.; Jullok, N.; Manzano, M.C.; Villagracia, A.R.; Doong, R.A. Preparation and Characterization of Cellulose Acetate from Rice Straw. In Green Energy and Technology; Springer: Singapore, 2023; pp. 429–436. [Google Scholar] [CrossRef]

- Bae, S.H.; Lee, G.; You, J.B.; Yoo, Y. Fabrication of Cellulose Acetate Membrane Using Deep Eutectic Solvent for Water/Isopropyl Alcohol Pervaporation. Sep. Purif. Technol. 2025, 364, 132406. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, L.; Ain, Q.U.; Tong, Z. Efficient Synthesis of Cellulose Acetate through One-Step Homogeneous Acetylation of Cotton Cellulose in Binary Ionic Liquids. Int. J. Biol. Macromol. 2024, 281, 136306. [Google Scholar] [CrossRef]

- Mofokeng, L.E.; Hlekelele, L.; Moma, J.; Tetana, Z.N.; Chauke, V.P. Energy-Efficient CuO/TiO2@GCN Cellulose Acetate-Based Membrane for Concurrent Filtration and Photodegradation of Ketoprofen in Drinking and Groundwater. Appl. Sci. 2022, 12, 1649. [Google Scholar] [CrossRef]

- An, Y.; Li, F.; Di, Y.; Zhang, X.; Lu, J.; Wang, L.; Yan, Z.; Wang, W.; Liu, M.; Fei, P. Hydrophobic Modification of Cellulose Acetate and Its Application in the Field of Water Treatment: A Review. Molecules 2024, 29, 5127. [Google Scholar] [CrossRef]

- Mottola, S.; Viscusi, G.; Tohamy, H.-A.S.; El-Sakhawy, M.; Gorrasi, G.; De Marco, I. Application of Electrospun N-Doped Carbon Dots Loaded Cellulose Acetate Membranes as Cationic Dyes Adsorbent. J. Environ. Manag. 2024, 370, 122714. [Google Scholar] [CrossRef] [PubMed]

- Ahangari, H.; Ebrahimi, A.; Ehsani, A.; Amjadi, S. Multipurpose Packaging System Based on Intelligent Carboxymethyl Cellulose Film and Activated Cellulose Acetate Electrospun Nanofibers for Seafoods. Int. J. Biol. Macromol. 2025, 298, 140115. [Google Scholar] [CrossRef]

- Marques, C.S.; Silva, R.R.A.; Arruda, T.R.; Ferreira, A.L.V.; de Oliveira, T.V.; Moraes, A.R.F.; Dias, M.V.; Vanetti, M.C.D.; Soares, N.d.F.F. Development and Investigation of Zein and Cellulose Acetate Polymer Blends Incorporated with Garlic Essential Oil and β-Cyclodextrin for Potential Food Packaging Application. Polysaccharides 2022, 3, 277–291. [Google Scholar] [CrossRef]

- Irimia, A.; Grigoraș, V.C.; Popescu, C.M. Active Cellulose-Based Food Packaging and Its Use on Foodstuff. Polymers 2024, 16, 389. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Hu, Q.; Zhang, R.; Ma, W.; Pan, S.; Zhao, Y.; Wang, Q.; Fang, P. Piezoelectric Nanogenerator Based on Electrospinning PVDF/Cellulose Acetate Composite Membranes for Energy Harvesting. Materials 2022, 15, 7026. [Google Scholar] [CrossRef]

- Sharma, M.; Das, P.P.; Sood, T.; Chakraborty, A.; Purkait, M.K. Reduced Graphene Oxide Incorporated Polyvinylidene Fluoride/Cellulose Acetate Proton Exchange Membrane for Energy Extraction Using Microbial Fuel Cells. J. Electroanal. Chem. 2022, 907, 115890. [Google Scholar] [CrossRef]

- Luo, R.; Zhang, F.; Yang, J.H.; Zhang, N.; Wang, Y. Synchronously Enhanced Breakdown Strength and Energy Storage Ability of Cellulose Acetate Flexible Films via Introducing Ultra-Low Content of Carbonized Polymer Dots. Carbohydr. Polym. 2025, 347, 122752. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Tian, X.; Li, X.; Liu, J.; Li, C.; Feng, X.; Shu, C.; Yu, Z.Z. An Environmental Energy-Enhanced Solar Steam Evaporator Derived from MXene-Decorated Cellulose Acetate Cigarette Filter with Ultrahigh Solar Steam Generation Efficiency. J. Colloid. Interface Sci. 2022, 606, 748–757. [Google Scholar] [CrossRef] [PubMed]

- Varghese, H.; Hakkeem, H.M.A.; Chauhan, K.; Thouti, E.; Pillai, S.; Chandran, A. A High-Performance Flexible Triboelectric Nanogenerator Based on Cellulose Acetate Nanofibers and Micropatterned PDMS Films as Mechanical Energy Harvester and Self-Powered Vibrational Sensor. Nano Energy 2022, 98, 107339. [Google Scholar] [CrossRef]

- Wang, M.; Huang, C.; Chen, Y.; Ji, Y.; Yu, D.G.; Bligh, S.W.A. Medicated Tri-Layer Fibers Based on Cellulose Acetate and Polyvinylpyrrolidone for Enhanced Antibacterial and Wound Healing Properties. Carbohydr. Polym. 2025, 348, 122856. [Google Scholar] [CrossRef]

- Ndlovu, S.P.; Alven, S.; Hlalisa, K.; Aderibigbe, B.A. Cellulose Acetate-Based Wound Dressings Loaded with Bioactive Agents: Potential Scaffolds for Wound Dressing and Skin Regeneration. Curr. Drug Deliv. 2023, 21, 1226–1240. [Google Scholar] [CrossRef]

- Lan, X.; Wang, Y.; Yin, M. Enhancing Periodontal Ligament Regeneration via PDLSC Delivery Using Electrospun PCL/Collagen/Cellulose Acetate Scaffolds and Collagen Hydrogel Incorporated with Curcumin-Loaded ZIF-8 Nanoparticles. Int. J. Nanomed. 2025, 20, 887–906. [Google Scholar] [CrossRef]

- Mahalakshmi, M.; Selvanayagam, S.; Selvasekarapandian, S.; Chandra, M.V.L.; Sangeetha, P.; Manjuladevi, R. Magnesium Ion-Conducting Solid Polymer Electrolyte Based on Cellulose Acetate with Magnesium Nitrate (Mg(NO3)2·6H2O) for Electrochemical Studies. Ionics 2020, 26, 4553–4565. [Google Scholar] [CrossRef]

- Mattar, H.; Baz, Z.; Saleh, A.; Shalaby, A.S.; Elsayed Azzazy, A.; Salah, H.; Ismail, I. Nitrocellulose: Structure, Synthesis, Characterization, and Applications. Water Energy Food Environ. J. Int. J. 2020, 1, 1–15. [Google Scholar] [CrossRef]

- Abdul Rahim, K.S.; Samsuri, A.; Jamal, S.H.; Mohd Nor, S.A.; Rusly, S.N.A.; Ariff, H.; Abdul Latif, N.S. Key Attributes of Nitrocellulose-Based Energetic Materials and Recent Developments. Heliyon 2025, 11, e41282. [Google Scholar] [CrossRef]

- Morris, E.; Pulham, C.R.; Morrison, C.A. Structure and Properties of Nitrocellulose: Approaching 200 Years of Research. RSC Adv. 2023, 13, 32321–32333. [Google Scholar] [CrossRef]

- Li, L.; Frey, M. Preparation and Characterization of Cellulose Nitrate-Acetate Mixed Ester Fibers. Polymer 2010, 51, 3774–3783. [Google Scholar] [CrossRef]

- Jamal, S.H.; Roslan, N.J.; Shah, N.A.A.; Noor, S.A.M.; Ong, K.K.; Yunus, W.M.Z.W. Preparation and Characterization of Nitrocellulose from Bacterial Cellulose for Propellant Uses. Mater. Today Proc. 2020, 29, 185–189. [Google Scholar] [CrossRef]

- Sakovich, G.V.; Mikhailov, Y.M.; Budaeva, V.V.; Korchagina, A.A.; Gismatulina, Y.A.; Kozyrev, N.V. Cellulose Nitrates from Unconventional Feedstocks. Dokl. Chem. 2018, 483, 287–291. [Google Scholar] [CrossRef]

- Kashcheyeva, E.I.; Korchagina, A.A.; Gismatulina, Y.A.; Gladysheva, E.K.; Budaeva, V.V.; Sakovich, G.V. Simultaneous Production of Cellulose Nitrates and Bacterial Cellulose from Lignocellulose of Energy Crop. Polymers 2024, 16, 42. [Google Scholar] [CrossRef]

- Muvhiiwa, R.; Mawere, E.; Moyo, L.B.; Tshuma, L. Utilization of Cellulose in Tobacco (Nicotiana tobacum) Stalks for Nitrocellulose Production. Heliyon 2021, 7, e07598. [Google Scholar] [CrossRef] [PubMed]

- binti Abdul Rahim, K.S.; binti Samsuri, A.; binti Jamal, S.H.; binti Mohd Nor, S.A.; binti Rusly, S.N.A.; binti Ariff, H.; binti Abdul Latif, N.S. Redefining Biofuels: Investigating Oil Palm Biomass as a Promising Cellulose Feedstock for Nitrocellulose-Based Propellant Production. Def. Technol. 2024, 37, 111–132. [Google Scholar] [CrossRef]

- Gismatulina, Y.A.; Budaeva, V.V. Cellulose Nitrates-Blended Composites from Bacterial and Plant-Based Celluloses. Polymers 2024, 16, 1183. [Google Scholar] [CrossRef] [PubMed]

- Gismatulina, Y.A.; Budaeva, V.V.; Sakovich, G.V. Nitrocellulose Synthesis from Miscanthus Cellulose. Propellants Explos. Pyrotech. 2018, 43, 96–100. [Google Scholar] [CrossRef]

- Duan, X.; Li, Z.; Wu, B.; Shen, J.; Pei, C. Preparation of Nitrocellulose by Homogeneous Esterification of Cellulose Based on Ionic Liquids. Propellants Explos. Pyrotech. 2023, 48, e202200186. [Google Scholar] [CrossRef]

- Santos, D.; Iop, G.D.; Bizzi, C.A.; Mello, P.A.; Mesko, M.F.; Balbinot, F.P.; Flores, E.M.M. A Single Step Ultrasound-Assisted Nitrocellulose Synthesis from Microcrystalline Cellulose. Ultrason. Sonochem. 2021, 72, 105453. [Google Scholar] [CrossRef] [PubMed]

- Gashtroudkhani, A.K.; Dahmardeh Ghalehno, M.; Abadi, S.S.; Pouyani, M. A Novel, Low-Cost, and High-Efficiency Method for Nitrocellulose Synthesis from Plasma-Modified Cellulose. Sci. Rep. 2025, 15, 6281. [Google Scholar] [CrossRef]

- Han, J.-H.; Wang, M.; Bai, P.; Brushett, F.R.; Bazant, M.Z. Dendrite Suppression by Shock Electrodeposition in Charged Porous Media. Sci. Rep. 2016, 6, 28054. [Google Scholar] [CrossRef]

- Abdelaziz, A.; Trache, D.; Tarchoun, A.F.; Boukeciat, H.; Pal, Y.; Thakur, S.; Pang, W.; Klapötke, T.M. Synergistic Effect of Nitrocellulose Coating on Structural and Reactivity Stabilization of Ammonium Nitrate Oxidizer. Def. Technol. 2025, 43, 35–43. [Google Scholar] [CrossRef]

- Hu, C.S.; Sun, K.; Zhang, Y. Preparation of Nitrocellulose Microspheres Based on Low-Cost High-Throughput Microfluidic Technology. Microfluid. Nanofluid. 2024, 28, 65. [Google Scholar] [CrossRef]

- Dourari, M.; Tarchoun, A.F.; Trache, D.; Abdelaziz, A.; Barkat, T.; Tiliouine, R.; Bekhouche, S.; Bessa, W. Elucidating the Effect of Nitrocellulose-Encapsulated MgAl–CuO on the Thermal Behavior of Double Base Propellant Based on Nitrocellulose and Diethylene Glycol Dinitrate. React. Kinet. Mech. Catal. 2023, 136, 2309–2325. [Google Scholar] [CrossRef]

- Trisnawati, E.W.; Suryanti, V.; Pramono, E. Fabrication and Evaluation of PVDF Membranes Modified with Cellulose and Cellulose Esters from Peanut (Arachis hypogea L.) Shell for Application in Methylene Blue Filtration. JCIS Open 2024, 16, 100123. [Google Scholar] [CrossRef]

- Takao, S.; Rajabzadeh, S.; Shibata, M.; Otsubo, C.; Hamada, T.; Kato, N.; Nakagawa, K.; Kitagawa, T.; Matsuyama, H.; Yoshioka, T. Preparation of Chemically Resistant Cellulose Benzoate Hollow Fiber Membrane via Thermally Induced Phase Separation Method. Membranes 2022, 12, 1199. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Q.; Chen, Z.; Ma, M.; Xie, X.; Weng, H.; Zhang, Y.; Chen, J.; Xiao, A. Synthesis, Characterization, Antibacterial and Emulsifying Properties of Agar Benzoate. Int. J. Biol. Macromol. 2023, 239, 124254. [Google Scholar] [CrossRef] [PubMed]

- Edgar, K.J.; Buchanan, C.M.; Debenham, J.S.; Rundquist, P.A.; Seiler, B.D.; Shelton, M.C.; Tindall, D. Advances in Cellulose Ester Performance and Application. Prog. Polym. Sci. 2001, 26, 1605–1688. [Google Scholar] [CrossRef]

- Trisnawati, E.W.; Cahyani, I.S.; Safriyani, D.; Pramono, E.; Suryanti, V. Cellulose, Cellulose Benzoate and Cellulose Citrate from Screw Pine (Pandanus tectorius) Leaves as PVDF Filler for Improved Permeability and Anti-Fouling Properties. Period. Polytech. Chem. Eng. 2023, 67, 504–515. [Google Scholar] [CrossRef]

- Ci, Y.; Yang, X.; Ma, Y.; Xu, F.; Tang, Y. Cellulose Benzoate Synthesis via Homogeneous Transesterification Catalyzed by Superbase-Derived Ionic Liquids for Advanced Applications. Green Chem. 2025, 27, 3764–3776. [Google Scholar] [CrossRef]

- Liu, S.; Wang, J. Exploring the Potential of Cellulose Benzoate Adsorbents Modified with Carbon Nanotubes and Magnetic Carbon Nanotubes for Microplastic Removal from Water. Chem. Eng. J. 2023, 469, 143910. [Google Scholar] [CrossRef]

- Chen, M.-J.; Li, R.-M.; Zhang, X.-Q.; Feng, J.; Feng, J.; Liu, C.-F.; Shi, Q.-S. Homogeneous Transesterification of Sugar Cane Bagasse toward Sustainable Plastics. ACS Sustain. Chem. Eng. 2017, 5, 360–366. [Google Scholar] [CrossRef]

- Teixeira Polez, R.; Voltarelli Ferracini, T.; Cardoso de Paula, S.F.; Passos de Oliveira Santos, R.; Porto, A.L.M.; Frollini, E. Synthesis of Cellulose Hexanoate, Benzoate, and Mixed Esters: Exploring Their Potential as Enzyme Immobilization Platforms. Macromol. Biosci. 2025, e00221. [Google Scholar] [CrossRef] [PubMed]

- Cellulose Acetate Butyrate: Characteristics, Applications and Selection Guide-Schem.Net. Available online: https://www.schem.net/blog/cellulose-acetate-butyrate-characteristics-applications-and-selection-guide_b143 (accessed on 10 August 2025).

- Cellulose Acetate Butyrate Market Size & Forecast to 2030. Available online: https://www.researchandmarkets.com/report/cellulose-acetate-butyrate?srsltid=AfmBOoqry-QLUHg4s-LXxDidwrtyYwqPeEgtjp-BG78vF6JkkAlaU_Vr (accessed on 21 August 2025).

- Kuang, J.; Wang, J.H.; Bai, Y.; Li, Y. Effects and Mechanism of Cellulose Acetate Butyrate on the Crystallization of Polylactic Acid. Eur. Polym. J. 2019, 121, 109286. [Google Scholar] [CrossRef]

- Ioelovich, M. Adjustment of Hydrophobic Properties of Cellulose Materials. Polymers 2021, 13, 1241. [Google Scholar] [CrossRef]

- Lau, C.C.; Bayazit, M.K.; Knowles, J.C.; Tang, J. Tailoring Degree of Esterification and Branching of Poly(Glycerol Sebacate) by Energy Efficient Microwave Irradiation. Polym. Chem. 2017, 8, 3937–3947. [Google Scholar] [CrossRef]

- Fischer, J.; Thümmler, K.; Zlotnikov, I.; Mikhailova, D.; Fischer, S. Synthesis of Cellulose Acetate Butyrate Microspheres as Precursor for Hard Carbon-Based Electrodes in Symmetric Supercapacitors. Polymers 2024, 16, 2176. [Google Scholar] [CrossRef]

- Huang, A.; Wei, L.; Zhao, Z.; Wei, G.; Zhang, Y.; Huang, Z.; Li, X.; Hu, H.; Qin, X.; Yang, M. A Comparative Analysis of the Preparation of Cellulose Acetate Butyrate and the Characteristics of Applying in Pearlescent Coating Film. Polym. Bull. 2020, 77, 2873–2887. [Google Scholar] [CrossRef]

- Huang, K.; Wang, B.; Cao, Y.; Li, H.; Wang, J.; Lin, W.; Mu, C.; Liao, D. Homogeneous Preparation of Cellulose Acetate Propionate (CAP) and Cellulose Acetate Butyrate (CAB) from Sugarcane Bagasse Cellulose in Ionic Liquid. J. Agric. Food Chem. 2011, 59, 5376–5381. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, J.; Zhang, J.; He, J. 1-Allyl-3-Methylimidazolium Chloride Room Temperature Ionic Liquid: A New and Powerful Nonderivatizing Solvent for Cellulose. Macromolecules 2005, 38, 8272–8277. [Google Scholar] [CrossRef]

- Cao, Y.; Li, H.; Zhang, J. Homogeneous Synthesis and Characterization of Cellulose Acetate Butyrate (CAB) in 1-Allyl-3-Methylimidazolium Chloride (AmimCl) Ionic Liquid. Ind. Eng. Chem. Res. 2011, 50, 7808–7814. [Google Scholar] [CrossRef]

- Abarkan, A.; Achalhi, N.; El Yousfi, R.; El Idrissi, A.; El Barkany, S.; Aqil, M. “Greener” Homogeneous Esterification of Cellulose Isolated from Stipa Tenacissima Plant Located in the Eastern Region of Morocco Using Ionic Liquids as Reaction Medium. Polym. Bull. 2024, 81, 5375–5402. [Google Scholar] [CrossRef]

- Huang, A.; Li, X.; Liang, X.; Zhang, Y.; Hu, H.; Yin, Y.; Huang, Z. Solid-Phase Synthesis of Cellulose Acetate Butyrate as Microsphere Wall Materials for Sustained Release of Emamectin Benzoate. Polymers 2018, 10, 1381. [Google Scholar] [CrossRef]

- Ran, S.; Xue, L.; Wei, X.; Huang, J.; Yan, X.; He, T.-C.; Tang, Z.; Zhang, H.; Gu, M. Recent Advances in Injectable Hydrogel Therapies for Periodontitis. J. Mater. Chem. B 2024, 12, 6005–6032. [Google Scholar] [CrossRef] [PubMed]

- Edgar, K.J. Cellulose Esters in Drug Delivery. Cellulose 2006, 14, 49–64. [Google Scholar] [CrossRef]

- Nejström, M.; Andreasson, B.; Sjölund, J.; Eivazi, A.; Svanedal, I.; Edlund, H.; Norgren, M. On Structural and Molecular Order in Cellulose Acetate Butyrate Films. Polymers 2023, 15, 2205. [Google Scholar] [CrossRef]

- Milotskyi, R.; Serizawa, R.; Yanagisawa, K.; Sharma, G.; Ito, E.R.D.; Fujie, T.; Wada, N.; Takahashi, K. Composite of Cellulose-Nanofiber-Reinforced Cellulose Acetate Butyrate: Improvement of Mechanical Strength by Cross-Linking of Hydroxyl Groups. J. Compos. Sci. 2023, 7, 130. [Google Scholar] [CrossRef]

- Khaing, E.M.; Lertsuphotvanit, N.; Thammasut, W.; Rojviriya, C.; Chansatidkosol, S.; Phattarateera, S.; Pichayakorn, W.; Phaechamud, T. Cellulose Acetate Butyrate-Based In Situ Gel Comprising Doxycycline Hyclate and Metronidazole. Polymers 2024, 16, 3477. [Google Scholar] [CrossRef] [PubMed]

- Tan, H.L.; Kai, D.; Pasbakhsh, P.; Teow, S.Y.; Lim, Y.Y.; Pushpamalar, J. Electrospun Cellulose Acetate Butyrate/Polyethylene Glycol (CAB/PEG) Composite Nanofibers: A Potential Scaffold for Tissue Engineering. Colloids Surf. B Biointerfaces 2020, 188, 110713. [Google Scholar] [CrossRef] [PubMed]

- Tanvir, A.; Ting, V.P.; Eichhorn, S.J. Nanoporous Electrospun Cellulose Acetate Butyrate Nanofibres for Oil Sorption. Mater. Lett. 2020, 261, 127116. [Google Scholar] [CrossRef]

- Dehmen, O.G.; Onen, H.A.; Yildiz, Z.; Gungor, A. Chemical, Mechanical, and Thermal Properties of UV-Curable Cellulose Acetate Butyrate-Based Oligomers and Their Electrospun Fibrous Mats. J. Coat. Technol. Res. 2020, 17, 1043–1052. [Google Scholar] [CrossRef]

- El Nemr, A.; Eleryan, A.; Mashaly, M.; Khaled, A. Rapid Synthesis of Cellulose Propionate and Its Conversion to Cellulose Nitrate Propionate. Polym. Bull. 2021, 78, 4149–4182. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.; Bohn, A. Cellulose: Fascinating Biopolymer and Sustainable Raw Material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef]

- Bednarek, P.S.; Kowalczuk, P.B. Cellulose and Its Derivatives as a Sustainable Reagent in Mineral Flotation: Mechanisms and Applications. Sep. Purif. Technol. 2025, 378, 134690. [Google Scholar] [CrossRef]

- Properties and Applications of Cellulose Propionate (CP). Available online: https://www.azom.com/article.aspx?ArticleID=389 (accessed on 10 August 2025).

- Xu, Z.-M.; Luo, J.-Y.; Huang, Y.-B. Recent Advances in the Chemical Valorization of Cellulose and Its Derivatives into Ester Compounds. Green. Chem. 2022, 24, 3895–3921. [Google Scholar] [CrossRef]

- El Nemr, A.; Eleryan, A.; Mashaly, M.; Khaled, A. Comparative Study of Synthesis of Cellulose Propionate from Different Sources Using NIS as a New Catalyst. Polym. Bull. 2021, 78, 4369–4386. [Google Scholar] [CrossRef]

- Furlan Sandrini, D.M.; Morgado, D.L.; de Oliveira, A.J.A.; de Moraes, D.A.; Varanda, L.C.; Frollini, E. Cellulose Esters: Synthesis for Further Formation of Films with Magnetite Nanoparticles Incorporated. Int. J. Biol. Macromol. 2024, 264, 130594. [Google Scholar] [CrossRef]

- Utrera-Barrios, S.; Pinho Lopes, O.; Mas-Giner, I.; Verdejo, R.; López-Manchado, M.A.; Hernández Santana, M. Sustainable Composites with Self-healing Capability: Epoxidized Natural Rubber and Cellulose Propionate Reinforced with Cellulose Fibers. Polym. Compos. 2024, 45, 7918–7931. [Google Scholar] [CrossRef]

- Lee, C.; Kang, S.W. Derivation of Porous Cellulose Propionate Using Hydrated Hydroxyl Groups and Hydraulic Pressure. Int. J. Biol. Macromol. 2024, 262, 130240. [Google Scholar] [CrossRef] [PubMed]

- Cellulose Propionate Market Size, Industry Outlook & Forecast. Available online: https://www.verifiedmarketreports.com/product/cellulose-propionate-market/ (accessed on 1 October 2025).

- Nasatto, P.L.; Pignon, F.; Silveira, J.L.M.; Duarte, M.E.R.; Noseda, M.D.; Rinaudo, M. Methylcellulose, a Cellulose Derivative with Original Physical Properties and Extended Applications. Polymers 2015, 7, 777–803. [Google Scholar] [CrossRef]

- Xiong, J.; Feng, L.; Liu, B.; Wang, X. Research Progress of Methylcellulose-Based Thermosensitive Hydrogels Applied in Biomedical Field. Sheng Wu Yi Xue Gong Cheng Xue Za Zhi 2024, 41, 199–204. [Google Scholar] [CrossRef]

- Ye, D.; Farriol, X. A Facile Method to Prepare Methylcellulose from Annual Plants and Wood Using Iodomethane. e-Polymers 2005, 5, 040. [Google Scholar] [CrossRef]

- Dimethyl Sulfate|CASRN 77-78-1|DTXSID5024055|IRIS|US EPA, ORD. Available online: https://iris.epa.gov/ChemicalLanding/&substance_nmbr%3D365 (accessed on 21 August 2025).

- Methyl Iodide|CASRN 74-88-4|DTXSID0024187|IRIS|US EPA, ORD. Available online: https://iris.epa.gov/ChemicalLanding/&substance_nmbr%3D650 (accessed on 21 August 2025).

- Oliveira, R.L.; Vieira, J.G.; Barud, H.S.; Assunção, R.M.N.; Rodrigues Filho, G.; Ribeiro, S.J.L.; Messadeqq, Y. Synthesis and Characterization of Methylcellulose Produced from Bacterial Cellulose under Heterogeneous Condition. J. Braz. Chem. Soc. 2015, 26, 1861–1870. [Google Scholar] [CrossRef]

- Viera, R.G.P.; Filho, G.R.; de Assunção, R.M.N.; da Carla, C.; Vieira, J.G.; de Oliveira, G.S. Synthesis and Characterization of Methylcellulose from Sugar Cane Bagasse Cellulose. Carbohydr. Polym. 2007, 67, 182–189. [Google Scholar] [CrossRef]

- Vieira, J.G.; Filho, G.R.; Meireles, C.D.S.; Faria, F.A.C.; Gomide, D.D.; Pasquini, D.; Cruz, S.F.D.; De Assunção, R.M.N.; Motta, L.A.D.C. Synthesis and Characterization of Methylcellulose from Cellulose Extracted from Mango Seeds for Use as a Mortar Additive. Polímeros 2012, 22, 80–87. [Google Scholar] [CrossRef]

- dos Santos, M.A.; Grenha, A. Polysaccharide Nanoparticles for Protein and Peptide Delivery: Exploring Less-Known Materials. Adv. Protein Chem. Struct. Biol. 2015, 98, 223–261. [Google Scholar] [CrossRef]

- Ghorbani, F.; Ghalandari, B.; Liu, Z.; Li, D.; Yu, B. Injectable Light-Assisted Thermo-Responsive Methylcellulose-Sodium Humate Hydrogel Proposed for Photothermal Ablation and Localized Delivery of Cisplatin. Front. Bioeng. Biotechnol. 2022, 10, 967438. [Google Scholar] [CrossRef]

- Ahlfeld, T.; Guduric, V.; Duin, S.; Akkineni, A.R.; Schütz, K.; Kilian, D.; Emmermacher, J.; Cubo-Mateo, N.; Dani, S.; Witzleben, M.V.; et al. Methylcellulose—A Versatile Printing Material That Enables Biofabrication of Tissue Equivalents with High Shape Fidelity. Biomater. Sci. 2020, 8, 2102–2110. [Google Scholar] [CrossRef] [PubMed]

- Methylcellulose Market Report|Global Forecast from 2025 to 2033. Available online: https://dataintelo.com/report/global-methylcellulose-market (accessed on 11 August 2025).

- Nagel, M.C.V.; Koschella, A.; Voiges, K.; Mischnick, P.; Heinze, T. Homogeneous Methylation of Wood Pulp Cellulose Dissolved in LiOH/Urea/H2O. Eur. Polym. J. 2010, 46, 1726–1735. [Google Scholar] [CrossRef]

- Pirsa, S.; Hafezi, K. Hydrocolloids: Structure, Preparation Method, and Application in Food Industry. Food Chem. 2023, 399, 133967. [Google Scholar] [CrossRef]

- Davidovich-Pinhas, M.; Barbut, S.; Marangoni, A.G. The Role of Surfactants on Ethylcellulose Oleogel Structure and Mechanical Properties. Carbohydr. Polym. 2015, 127, 355–362. [Google Scholar] [CrossRef] [PubMed]

- Pratama, J.H.; Lestari, W.W.; Rofida, A.; Putri, A.K.; Widian, R.N.; Gunawan, T.; Hastuti, D.S.; Sulistiono, D.O.; Sari, K.P. Novel Polymer Composite Coated with Ethylcellulose Nanoparticle from Waste Paper as an Alternative Material to Extracorporeal Oxygenation Membrane. J. Polym. Res. 2023, 30, 220. [Google Scholar] [CrossRef]

- Zhou, Y.; Hu, Y.; Tan, Z.; Zhou, T. Cellulose Extraction from Rice Straw Waste for Biodegradable Ethyl Cellulose Films Preparation Using Green Chemical Technology. J. Clean. Prod. 2024, 439, 140839. [Google Scholar] [CrossRef]

- Yavuzturk Gul, B.; Pekgenc, E.; Vatanpour, V.; Koyuncu, I. A Review of Cellulose-Based Derivatives Polymers in Fabrication of Gas Separation Membranes: Recent Developments and Challenges. Carbohydr. Polym. 2023, 321, 121296. [Google Scholar] [CrossRef] [PubMed]

- Li, X.-G.; Kresse, I.; Xu, Z.-K.; Springer, J. Effect of Temperature and Pressure on Gas Transport in Ethyl Cellulose Membrane. Polymer 2001, 42, 6801–6810. [Google Scholar] [CrossRef]

- Gorji, N.; Jahanshahi, M.; Shahavi, M.H.; Ayrilmis, N. Ethylcellulose Microparticles as Green Encapsulation for Slow Release of Microspherical Abamectin Pesticide for Agricultural Applications: Improvement of Process Parameters. Int. J. Biol. Macromol. 2025, 321, 146336. [Google Scholar] [CrossRef]

- Xu, P.; Yu, D.; Wang, S.; Shi, W.; Xing, G.; Wang, A.; Teng, Z.; Hao, D. Thiamethoxam-Loaded Ethyl Cellulose Microspheres for Extending the Efficacy Duration and Reducing the Toxicity on the Growth of Maize (Zea mays L.). Langmuir 2024, 40, 27270–27278. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Li, X.; Huang, B.; Li, N.; Wang, A.; An, C.; Jiang, J.; Shen, Y.; Wang, C.; Zhan, S.; et al. Construction and Characterization of Ethyl Cellulose-Based Nano-Delivery System for Phenamacril. Int. J. Biol. Macromol. 2022, 221, 1251–1258. [Google Scholar] [CrossRef]

- Ji, Y.; Zhao, H.; Liu, H.; Zhao, P.; Yu, D.-G. Electrosprayed Stearic-Acid-Coated Ethylcellulose Microparticles for an Improved Sustained Release of Anticancer Drug. Gels 2023, 9, 700. [Google Scholar] [CrossRef]

- Wildy, M.; Hao, Q.; Wei, W.; Nguyen, D.H.; Xu, K.; Schossig, J.; Hu, X.; Salas-de la Cruz, D.; Hyun, D.C.; Wang, Z.; et al. Tunable Chemotherapy Release Using Biocompatible Fatty Acid-Modified Ethyl Cellulose Nanofibers. Carbohydr. Polym. Technol. Appl. 2025, 9, 100670. [Google Scholar] [CrossRef]

- Li, Z.; Tan, X.; Yarmolenko, M.A.; Keneshbekova, A.; Wang, A.; Liu, X.; Jiang, X. Deposition of Ethyl Cellulose-Based Drug-Carrying Coating by Low-Energy Electron Beam Dispersion and Its Antifungal Properties. Vacuum 2025, 236, 114136. [Google Scholar] [CrossRef]

- Mohamed, R.; Chou, S.F. Physicomechanical Characterizations and in Vitro Release Studies of Electrospun Ethyl Cellulose Fibers, Solvent Cast Carboxymethyl Cellulose Films, and Their Composites. Int. J. Biol. Macromol. 2024, 267, 131374. [Google Scholar] [CrossRef] [PubMed]

- Aboelazayem, S.; Nasra, M.; Ebada, H.; Abdallah, O. Ethyl-Cellulose Nanosponges for Topical Delivery of Simvastatin with Preferential Skin Retention for Wound Healing in a Full-Thickness Wound Rat Model. AAPS PharmSciTech 2025, 26, 126. [Google Scholar] [CrossRef] [PubMed]

- Yao, J.; Zhi, H.; Shi, Q.; Zhang, Y.; Feng, J.; Liu, J.; Huang, H.; Xie, X. Tannic Acid Interfacial Modification of Prochloraz Ethyl Cellulose Nanoparticles for Enhancing the Antimicrobial Effect and Biosafety of Fungicides. ACS Appl. Mater. Interfaces 2023, 15, 41324–41336. [Google Scholar] [CrossRef] [PubMed]

- Soleimanian, Y.; Ghazani, S.M.; Marangoni, A.G. Ethylcellulose Oleogels of Oil Glycerolysis Products as Functional Adipose Tissue Mimetics. Food Hydrocoll. 2024, 151, 109756. [Google Scholar] [CrossRef]

- Horvat, G.; Rožanc, J.; Maver, U.; Finšgar, M.; Knez, Ž.; Novak, Z. Reinforcing Ethyl Cellulose Aerogels with Poly(Lactic Acid) for Enhanced Bone Regeneration. Cellulose 2024, 31, 4421–4439. [Google Scholar] [CrossRef]

- Ghorbani, M.; Ramezani, S.; Rashidi, M.R. Fabrication of Honey-Loaded Ethylcellulose/Gum Tragacanth Nanofibers as an Effective Antibacterial Wound Dressing. Colloids Surf. A Physicochem. Eng. Asp. 2021, 621, 126615. [Google Scholar] [CrossRef]

- Zhang, Z.; Xia, Y.; Gong, W.; Zhou, J.; Yu, D.G.; Xie, Y. feng Electrospun Chitosan//Ethylcellulose-Vitamin E//Ethylcellulose-Curcumin Tri-Chamber Eccentric Janus Nanofibers for a Joint Antibacterial and Antioxidant Performance. Int. J. Biol. Macromol. 2024, 281, 135753. [Google Scholar] [CrossRef]

- Cadena, I.A.; Adhikari, G.; Almer, A.; Jenne, M.; Obasi, N.; Soria Zurita, N.F.; Rochefort, W.E.; Mueller, J.L.; Fogg, K.C.; Robinson, J.; et al. Development of a 3D in Vitro Human-Sized Model of Cervical Dysplasia to Evaluate the Delivery of Ethyl Cellulose-Ethanol Injection. Front. Biomater. Sci. 2024, 3, 1365781. [Google Scholar] [CrossRef]

- Quang, T.T.; Yang, J.; Kaluzienski, M.L.; Parrish, A.; Farooqui, A.; Katz, D.; Crouch, B.; Ramanujam, N.; Mueller, J.L. In Vivo Evaluation of Safety and Efficacy of Ethyl Cellulose-Ethanol Tissue Ablation in a Swine Cervix Model. Bioengineering 2023, 10, 1246. [Google Scholar] [CrossRef]

- Shan, P.; Wang, K.; Sun, F.; Li, Y.; Sun, L.; Li, H.; Peng, L. Humidity-Adjustable Functional Gelatin Hydrogel/Ethyl Cellulose Bilayer Films for Active Food Packaging Application. Food Chem. 2024, 439, 138202. [Google Scholar] [CrossRef] [PubMed]

- Shen, H.; Chen, J.; Tan, K.B. Ethyl Cellulose Matrixed Poly(Sulfur-Co-Sorbic Acid) Composite Films: Regulation of Properties and Application for Food Preservation. Int. J. Biol. Macromol. 2024, 279, 135183. [Google Scholar] [CrossRef]

- Ghiasi, F.; Golmakani, M.T. Fabrication and Characterization of a Novel Biphasic System Based on Starch and Ethylcellulose as an Alternative Fat Replacer in a Model Food System. Innov. Food Sci. Emerg. Technol. 2022, 78, 103028. [Google Scholar] [CrossRef]

- Coelho, A.L.K.; de Andrade Barbosa Guilherme, M.; de Freitas, R.A.; Mafra, M.R.; Mafra, L.I. Tunable Oleogels from Sunflower Oil, Ethylcellulose, and Quillaja Saponin: Synergistic Interactions, Structural Properties, and Oxidative Stability. Food Hydrocoll. 2026, 170, 111744. [Google Scholar] [CrossRef]

- Kanmaz, N.; Buğdaycı, M.; Demirçivi, P. Solvent-Free Mechanochemical Synthesis of TiO2-Ethyl Cellulose Biocomposite for Adsorption of Tetracycline and Organic Dyes. J. Mol. Liq. 2023, 378, 121643. [Google Scholar] [CrossRef]

- Aghaei, F.; Tangestaninejad, S.; Bahadori, M.; Moghadam, M.; Mirkhani, V.; Mohammadpoor−Baltork, I.; Khalaji, M.; Asadi, V. Green Synthesize of Nano-MOF-Ethylcellulose Composite Fibers for Efficient Adsorption of Congo Red from Water. J. Colloid. Interface Sci. 2023, 648, 78–89. [Google Scholar] [CrossRef] [PubMed]

- Karimian, E.; Moslehi, M.; Tangestaninejad, S.; Moghadam, M.; Malekpour, A.; Mohammadpoor-Baltork, I. Highly Efficient Water Desalination via Electrospun Ethyl Cellulose/Polystyrene Composites Integrated with Metal-Organic Frameworks. Sci. Rep. 2025, 15, 27221. [Google Scholar] [CrossRef]

- Palmieri, E.; Cancelliere, R.; Maita, F.; Micheli, L.; Maiolo, L. An Ethyl Cellulose Novel Biodegradable Flexible Substrate Material for Sustainable Screen-Printing. RSC Adv. 2024, 14, 18103–18108. [Google Scholar] [CrossRef]

- Palmieri, E.; Maiolo, L.; Lucarini, I.; Fattorini, A.D.; Tamburri, E.; Orlanducci, S.; Calarco, R.; Maita, F. Toward Sustainable Electronics: Exploiting the Potential of a Biodegradable Cellulose Blend for Photolithographic Processes and Eco-Friendly Devices. Adv. Mater. Technol. 2024, 9, 2301282. [Google Scholar] [CrossRef]

- Ethyl Cellulose Market 2025—Growth, Outlook and Trends 2034. Available online: https://www.thebusinessresearchcompany.com/report/ethyl-cellulose-global-market-report (accessed on 11 August 2025).

- Noreen, A.; Zia, K.M.; Tabasum, S.; Khalid, S.; Shareef, R. A Review on Grafting of Hydroxyethylcellulose for Versatile Applications. Int. J. Biol. Macromol. 2020, 150, 289–303. [Google Scholar] [CrossRef]

- Zia, F.; Nazli, Z.-H.; Zia, K.M.; Aftab, W.; Tabasum, S.; Asrar, M. Synthesis and Characterization of Hydroxyethyl Cellulose Copolymer Modified Polyurethane Bionanocomposites. Int. J. Biol. Macromol. 2021, 179, 345–352. [Google Scholar] [CrossRef]

- Bajaber, M.A.; Anjum, M.N.; Ibrahim, M.; Farooq, T.; Ahmad, M.N.; ul Abideen, Z. Synthesis and Characterization of Hydroxyethyl Cellulose Grafted with Copolymer of Polyaniline and Polypyrrole Biocomposite for Adsorption of Dyes. Molecules 2022, 27, 8238. [Google Scholar] [CrossRef]

- Orhan, B.; Ziba, C.A.; Morcali, M.H.; Dolaz, M. Synthesis of Hydroxyethyl Cellulose from Industrial Waste Using Microwave Irradiation. Sustain. Environ. Res. 2018, 28, 403–411. [Google Scholar] [CrossRef]

- Yin, H.; Song, P.; Chen, X.; Xiao, M.; Tang, L.; Huang, H. Smart PH-Sensitive Hydrogel Based on the Pineapple Peel-Oxidized Hydroxyethyl Cellulose and the Hericium Erinaceus Residue Carboxymethyl Chitosan for Use in Drug Delivery. Biomacromolecules 2022, 23, 253–264. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhang, L.; Li, M.; Wu, X.; Cheng, G. Homogeneous Hydroxyethylation of Cellulose in NaOH/Urea Aqueous Solution. Polym. Bull. 2005, 53, 243–248. [Google Scholar] [CrossRef]

- Zhou, J.; Qin, Y.; Liu, S.; Zhang, L. Homogenous Synthesis of Hydroxyethylcellulose in NaOH/Urea Aqueous Solution. Macromol. Biosci. 2006, 6, 84–89. [Google Scholar] [CrossRef]

- Köhler, S.; Liebert, T.; Heinze, T.; Vollmer, A.; Mischnick, P.; Möllmann, E.; Becker, W. Interactions of Ionic Liquids with Polysaccharides 9. Hydroxyalkylation of Cellulose without Additional Inorganic Bases. Cellulose 2010, 17, 437–448. [Google Scholar] [CrossRef]

- US8541571B2—Homogeneous Synthesis of Cellulose Ethers in Ionic Liquids—Google Patents. Available online: https://patents.google.com/patent/US8541571B2/en (accessed on 11 August 2025).

- Hydroxyethyl Cellulose Market by Application (Detergents & Cleaners, Oil & Gas, Paint & Coatings), Type (High Molecular Weight, Low Molecular Weight, Medium Molecular Weight), Form, Distribution Channel—Global Forecast 2025–2030. Available online: https://www.researchandmarkets.com/reports/5716427/hydroxyethyl-cellulose-market-by-application (accessed on 11 August 2025).

- Murray, J.C.F. 25-Cellulosics. In Handbook of Hydrocolloids: Second Edition; Elsevier: Amsterdam, The Netherlands, 2009; pp. 710–723. [Google Scholar] [CrossRef]

- Chen, B.J.; Liu, G.G.; Wang, X.; Liu, H.R.; Zhang, Y.; Wang, C.F.; Liu, C.X.; Qiao, Y.J. Development and Characterization of an Antioxidant and Antimicrobial Film Composited by Hydroxyethyl Cellulose and Sulfated Rice Bran Polysaccharides for Food Packaging. Foods 2024, 13, 819. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Guo, H.; Luo, W.; Chen, G.; Xiao, N.; Xiao, G.; Liu, C. Development of Functional Hydroxyethyl Cellulose-Based Composite Films for Food Packaging Applications. Front. Bioeng. Biotechnol. 2022, 10, 989893. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Jin, T.; Liu, W.; Hao, W.; Yan, L.; Zheng, L. Effects of Hydroxyethyl Cellulose and Sodium Alginate Edible Coating Containing Asparagus Waste Extract on Postharvest Quality of Strawberry Fruit. LWT 2021, 148, 111770. [Google Scholar] [CrossRef]

- McMullen, R.L.; Ozkan, S.; Gillece, T. Physicochemical Properties of Cellulose Ethers. Cosmetics 2022, 9, 52. [Google Scholar] [CrossRef]

- Mohammad, A.F.; Mourad, A.A.H.I.; Al-Marzouqi, A.H.; Galiwango, E.; Lwisa, E.G.; Mustafa, J. Hydroxyethyl Cellulose as a Multifunctional Agent for Integrated Brine Desalination, CO2 Capture, and Enhanced Oil Recovery. Chem. Eng. Process.-Process Intensif. 2025, 216, 110414. [Google Scholar] [CrossRef]

- Abou Taleb, M.F.; Alzidan, K. Multifunctional Applications of Seaweed Extract-Infused Hydroxyethyl Cellulose-Polyvinylpyrrolidone Aerogels: Antibacterial, and Antibiofilm Proficiency for Water Decontamination. Int. J. Biol. Macromol. 2024, 278, 135021. [Google Scholar] [CrossRef]

- Sun, W.; Yue, D.; Wang, S.; Sun, D.; Yin, L.; Wang, Y. Prewetting Induced Underwater Super Oleophobic Hydroxyethyl Cellulose-SiO2-Graphene Microfiltration Membranes for Emulsion Separation. Sep. Purif. Technol. 2025, 358, 130421. [Google Scholar] [CrossRef]

- Khan, F.; Siddique, A.B.; Irfan, M.I.; Hassan, M.N.U.; Sher, M.; Alhazmi, H.A.; Qramish, A.N.; Amin, H.M.A.; Qadir, R.; Abbas, A. Maleated Hydroxyethyl Cellulose for the Efficient Removal of Cd(II) Ions from an Aqueous Solution: Isothermal, Kinetic and Regeneration Studies. Water Air Soil. Pollut. 2024, 235, 536. [Google Scholar] [CrossRef]

- Ho, H.N.; Le, H.H.; Le, T.G.; Duong, T.H.A.; Ngo, V.Q.T.; Dang, C.T.; Nguyen, V.M.; Tran, T.H.; Nguyen, C.N. Formulation and Characterization of Hydroxyethyl Cellulose-Based Gel Containing Metronidazole-Loaded Solid Lipid Nanoparticles for Buccal Mucosal Drug Delivery. Int. J. Biol. Macromol. 2022, 194, 1010–1018. [Google Scholar] [CrossRef] [PubMed]

- Kafili, G.; Tamjid, E.; Niknejad, H.; Simchi, A. Development of Bioinspired Nanocomposite Bioinks Based on Decellularized Amniotic Membrane and Hydroxyethyl Cellulose for Skin Tissue Engineering. Cellulose 2024, 31, 2989–3013. [Google Scholar] [CrossRef]

- Nam, C.J.; Johari, N.F.I.M.; Khan, S.; Kabeb, S.M.; Zulkifli, F.H. Effect of Crosslinking Agent on the Cellulose Nanocrystals Reinforced Hydroxyethyl Cellulose/Poly(Vinyl Alcohol) Scaffolds. Macromol. Symp. 2025, 414, 2300264. [Google Scholar] [CrossRef]

- Mohammadzadeh, V.; Mahmoudi, E.; Ramezani, S.; Navaeian, M.; Taheri, R.A.; Ghorbani, M. Design of a Novel Tannic Acid Enriched Hemostatic Wound Dressing Based on Electrospun Polyamide-6/Hydroxyethyl Cellulose Nanofibers. J. Drug Deliv. Sci. Technol. 2023, 86, 104625. [Google Scholar] [CrossRef]

- Prasathkumar, M.; George, A.; Sadhasivam, S. Influence of Chitosan and Hydroxyethyl Cellulose Modifications towards the Design of Cross-Linked Double Networks Hydrogel for Diabetic Wound Healing. Int. J. Biol. Macromol. 2024, 265, 130851. [Google Scholar] [CrossRef]

- Fekete, T.; Borsa, J.; Takács, E.; Wojnárovits, L. Synthesis and Characterization of Superabsorbent Hydrogels Based on Hydroxyethylcellulose and Acrylic Acid. Carbohydr. Polym. 2017, 166, 300–308. [Google Scholar] [CrossRef]

- Fratila, D.N.; Virvescu, D.I.; Luchian, I.; Hancianu, M.; Baciu, E.R.; Butnaru, O.; Budala, D.G. Advances and Functional Integration of Hydrogel Composites as Drug Delivery Systems in Contemporary Dentistry. Gels 2024, 10, 661. [Google Scholar] [CrossRef] [PubMed]

- Jaiswal, A.K.; Kumar, V.; Jansson, E.; Huttunen, O.; Yamamoto, A.; Vikman, M.; Khakalo, A.; Hiltunen, J.; Behfar, M.H. Biodegradable Cellulose Nanocomposite Substrate for Recyclable Flexible Printed Electronics. Adv. Electron. Mater. 2023, 9, 2201094. [Google Scholar] [CrossRef]

- Wang, Q.; Pan, X.; Guo, J.; Huang, L.; Chen, L.; Ma, X.; Cao, S.; Ni, Y. Lignin and Cellulose Derivatives-Induced Hydrogel with Asymmetrical Adhesion, Strength, and Electriferous Properties for Wearable Bioelectrodes and Self-Powered Sensors. Chem. Eng. J. 2021, 414, 128903. [Google Scholar] [CrossRef]

- Weißenborn, E.; Braunschweig, B. Hydroxypropyl Cellulose as a Green Polymer for Thermo-Responsive Aqueous Foams. Soft Matter 2019, 15, 2876–2883. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Cheng, X.; Ma, T.; Wang, S.; Yang, S.; Zhu, W.; Song, J.; Han, J.; Jin, Y.; Guo, J. High-Substituted Hydroxypropyl Cellulose Prepared by Homogeneous Method and Its Clouding and Self-Assembly Behaviors. Carbohydr. Polym. 2024, 330, 121822. [Google Scholar] [CrossRef]

- Joshi, G.; Rana, V.; Naithani, S.; Varshney, V.K.; Sharma, A.; Rawat, J.S. Chemical Modification of Waste Paper: An Optimization towards Hydroxypropyl Cellulose Synthesis. Carbohydr. Polym. 2019, 223, 115082. [Google Scholar] [CrossRef]

- Zhong, S.; Xue, Y.; Wang, K.; Wang, L.; Jiang, T. A Sustainable Utilization Approach of Waste Biomass Resources to Smart Materials for Buildings. Mater. Today Commun. 2024, 40, 109506. [Google Scholar] [CrossRef]

- Hydroxypropyl Cellulose Market Size and Statistics—2035. Available online: https://www.factmr.com/report/hydroxypropyl-cellulose-market (accessed on 21 August 2025).

- Okubo, M.; Iohara, D.; Anraku, M.; Higashi, T.; Uekama, K.; Hirayama, F. A Thermoresponsive Hydrophobically Modified Hydroxypropylmethylcellulose/Cyclodextrin Injectable Hydrogel for the Sustained Release of Drugs. Int. J. Pharm. 2020, 575, 118845. [Google Scholar] [CrossRef]

- Xue, H.; Zhu, C.; Wang, Y.; Gu, Q.; Shao, Y.; Jin, A.; Zhang, X.; Lei, L.; Li, Y. Stimulus-Responsive Cellulose Hydrogels in Biomedical Applications and Challenges. Mater. Today Bio 2025, 32, 101814. [Google Scholar] [CrossRef]

- Iqbal, M.A.; Akhter, T.; Faheem, M.; Mahmood, A.; Al-Masry, W.; Nadeem, S.; Hassan, S.U.; Park, C.H. Metal-Free, Visible Light-Mediated Atom Transfer Radical Polymerization of Hydroxypropyl Cellulose-Graft-Poly(Methyl Methacrylate)s: Effect of Polymer Side Chains on Thermo-Responsive Behavior of Hydroxypropyl Cellulose. Cellulose 2023, 30, 7519–7533. [Google Scholar] [CrossRef]

- Kawasaki, R.; Yamana, K.; Shimada, R.; Sugikawa, K.; Ikeda, A. Water Solubilization and Thermal Stimuli-Triggered Release of Porphyrin Derivatives Using Thermoresponsive Polysaccharide Hydroxypropyl Cellulose for Mitochondria-Targeted Photodynamic Therapy. ACS Omega 2021, 6, 3209–3217. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhai, Z.; Yao, Y.; Stant, J.C.; Landrum, S.L.; Bortner, M.J.; Frazier, C.E.; Edgar, K.J. Oxidized Hydroxypropyl Cellulose/Carboxymethyl Chitosan Hydrogels Permit PH-Responsive, Targeted Drug Release. Carbohydr. Polym. 2023, 300, 120213. [Google Scholar] [CrossRef]

- Gunaki, M.N.; Masti, S.P.; D’souza, O.J.; Eelager, M.P.; Kurabetta, L.K.; Chougale, R.B.; Kadapure, A.J.; Praveen Kumar, S.K. Fabrication of CuO Nanoparticles Embedded Novel Chitosan/Hydroxypropyl Cellulose Bio-Nanocomposites for Active Packaging of Jamun Fruit. Food Hydrocoll. 2024, 152, 109937. [Google Scholar] [CrossRef]

- Wardana, A.A.; Wigati, L.P.; Tanaka, F.; Tanaka, F. Functional Enhancement of Hydroxypropyl Cellulose-based Bionanocomposite Films Incorporating Chitosan Nanoparticles. Int. J. Food Sci. Technol. 2023, 58, 907–920. [Google Scholar] [CrossRef]

- Yan, K.; Zhang, X.; Liu, Y.; Cheng, J.; Zhai, C.; Shen, K.; Liang, W.; Fan, W. 3D-Bioprinted Silk Fibroin-Hydroxypropyl Cellulose Methacrylate Porous Scaffold with Optimized Performance for Repairing Articular Cartilage Defects. Mater. Des. 2023, 225, 111531. [Google Scholar] [CrossRef]

- Filip, D.; Macocinschi, D.; Zaltariov, M.-F.; Ciubotaru, B.-I.; Bargan, A.; Varganici, C.-D.; Vasiliu, A.-L.; Peptanariu, D.; Balan-Porcarasu, M.; Timofte-Zorila, M.-M. Hydroxypropyl Cellulose/Pluronic-Based Composite Hydrogels as Biodegradable Mucoadhesive Scaffolds for Tissue Engineering. Gels 2022, 8, 519. [Google Scholar] [CrossRef] [PubMed]

- Tialiou, A.; Athab, Z.H.; Woodward, R.T.; Biegler, V.; Keppler, B.K.; Halbus, A.F.; Reithofer, M.R.; Chin, J.M. Fabrication of Graded Porous Structure of Hydroxypropyl Cellulose Hydrogels via Temperature-Induced Phase Separation. Carbohydr. Polym. 2023, 315, 120984. [Google Scholar] [CrossRef]

- Mohebian, Z.; Tajmohammadi, I.; Yavari Maroufi, L.; Ramezani, S.; Ghorbani, M. A Novel Aloe Vera-Loaded Ethylcellulose/Hydroxypropyl Methylcellulose Nanofibrous Mat Designed for Wound Healing Application. J. Polym. Environ. 2022, 30, 867–877. [Google Scholar] [CrossRef]

- Ding, L.; Qi, Q.; Zhang, S.; Ren, C.; Deng, M.; Sun, Z.; Zhang, R.; Liu, Q.; Duan, S.; Wang, X.; et al. Hydroxypropyl Methylcellulose Reinforced Collagen/PVA Composite Hydrogel Wound Dressing with Self-Adaptive, Hemostasis and Antibacterial Ability for Wound Healing. Int. J. Biol. Macromol. 2025, 304, 140811. [Google Scholar] [CrossRef]

- Liu, S.; Zhao, Y.; Wei, H.; Nie, L.; Ding, P.; Sun, H.; Guo, Y.; Chen, T.; Okoro, O.V.; Shavandi, A.; et al. Injectable Hydrogels Based on Silk Fibroin Peptide Grafted Hydroxypropyl Chitosan and Oxidized Microcrystalline Cellulose for Scarless Wound Healing. Colloids Surf. A Physicochem. Eng. Asp. 2022, 647, 129062. [Google Scholar] [CrossRef]

- Yan, H.; Gu, H.; Lu, S.; Meng, F.; Ma, Q.; Xing, X.; Pan, S.; Che, Y. Bioinspired Multifunctional Conductive Hydrogel Based on Hydroxypropyl Methyl Cellulose for Flexible Sensors. Carbohydr. Polym. 2025, 368, 124192. [Google Scholar] [CrossRef] [PubMed]

- Zhou, B.; Yuan, W. Tunable Thermoresponsive and Stretchable Hydrogel Sensor Based on Hydroxypropyl Cellulose for Human Motion/Health Detection, Visual Signal Transmission and Information Encryption. Carbohydr. Polym. 2024, 343, 122497. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhang, H.; Lv, X.; Xie, T.; Chen, J.; Fang, D.; Yi, S. Construction of Mechanically Robust and Recyclable Catalytic Hydrogel Based on Hydroxypropyl Cellulose-Supported by Montmorillonite/Ionic Liquid with Different Anions for Pollutants(4-NP, MB, CR, Rhb) Degradation. Int. J. Biol. Macromol. 2024, 273, 132788. [Google Scholar] [CrossRef]

- Ledwon, P.; Andrade, J.R.; Lapkowski, M.; Pawlicka, A. Hydroxypropyl Cellulose-Based Gel Electrolyte for Electrochromic Devices. Electrochim. Acta 2015, 159, 227–233. [Google Scholar] [CrossRef]

- Shi, H.; Deng, Y.; Shi, Y. Cellulose-Based Stimuli-Responsive Anisotropic Hydrogel for Sensor Applications. ACS Appl. Nano Mater. 2023, 6, 11524–11530. [Google Scholar] [CrossRef]

- Timmins, P.; Pygall, S.R.; Melia, C.D. Hydrophilic Matrix Dosage Forms: Definitions, General Attributes, and the Evolution of Clinical Utilization. AAPS Adv. Pharm. Sci. Ser. 2014, 16, 1–15. [Google Scholar] [CrossRef]

- Meng, Z.; Qi, K.; Guo, Y.; Wang, Y.; Liu, Y. Macro-Micro Structure Characterization and Molecular Properties of Emulsion-Templated Polysaccharide Oleogels. Food Hydrocoll. 2018, 77, 17–29. [Google Scholar] [CrossRef]

- Sharma, S.; Ansari, T.N.; Handa, S. HPMC: A Biomass-Based Semisynthetic Sustainable Additive Enabling Clean and Fast Chemistry in Water. ACS Sustain. Chem. Eng. 2021, 9, 12719–12728. [Google Scholar] [CrossRef]

- Bahrami, A.; Rezaei Mokarram, R.; Sowti Khiabani, M.; Ghanbarzadeh, B.; Salehi, R. Physico-Mechanical and Antimicrobial Properties of Tragacanth/Hydroxypropyl Methylcellulose/Beeswax Edible Films Reinforced with Silver Nanoparticles. Int. J. Biol. Macromol. 2019, 129, 1103–1112. [Google Scholar] [CrossRef]

- Klangmuang, P.; Sothornvit, R. Barrier Properties, Mechanical Properties and Antimicrobial Activity of Hydroxypropyl Methylcellulose-Based Nanocomposite Films Incorporated with Thai Essential Oils. Food Hydrocoll. 2016, 61, 609–616. [Google Scholar] [CrossRef]

- Larsson, M.; Viridén, A.; Stading, M.; Larsson, A. The Influence of HPMC Substitution Pattern on Solid-State Properties. Carbohydr. Polym. 2010, 82, 1074–1081. [Google Scholar] [CrossRef]

- Jin, C.; Wu, F.; Hong, Y.; Shen, L.; Lin, X.; Zhao, L.; Feng, Y. Updates on Applications of Low-Viscosity Grade Hydroxypropyl Methylcellulose in Coprocessing for Improvement of Physical Properties of Pharmaceutical Powders. Carbohydr. Polym. 2023, 311, 120731. [Google Scholar] [CrossRef]

- Khiste, R.; Bhapkar, N.; Kulkarni, N. A Review on Applications of Hydroxy Propyl Methyl Cellulose and Natural Polymers for the Development of Modified Release Drug Delivery Systems. Res. J. Pharm. Technol. 2021, 14, 1163–1170. [Google Scholar] [CrossRef]

- Ngatirah, N.; Ruswanto, A.; Sunardi, S. Effect of Hydroxypropyl Methylcellulose from Oil Palm Empty Fruit Bunch on Oil Uptake and Physical Properties of French Fries. Food Sci. Technol. 2022, 42, e110421. [Google Scholar] [CrossRef]

- Akbar, M.H.; Harmita; Suryadi, H. Preparation and Characterization of Hydroxypropyl Methylcellulose Produced from A-Cellulose Betung Bamboo (Dendrocalamus asper) and It’s Evaluation on Gel Formulation. Int. J. Pharm. Pharm. Sci. 2020, 12, 156–165. [Google Scholar] [CrossRef]

- Vlad, R.-A.; Pintea, A.; Pintea, C.; Rédai, E.-M.; Antonoaea, P.; Bîrsan, M.; Ciurba, A. Hydroxypropyl Methylcellulose—A Key Excipient in Pharmaceutical Drug Delivery Systems. Pharmaceutics 2025, 17, 784. [Google Scholar] [CrossRef]

- Zheng, M.; Chen, J.; Tan, K.B.; Chen, M.; Zhu, Y. Development of Hydroxypropyl Methylcellulose Film with Xanthan Gum and Its Application as an Excellent Food Packaging Bio-Material in Enhancing the Shelf Life of Banana. Food Chem. 2022, 374, 131794. [Google Scholar] [CrossRef]

- Tundisi, L.L.; Mostaço, G.B.; Carricondo, P.C.; Petri, D.F.S. Hydroxypropyl Methylcellulose: Physicochemical Properties and Ocular Drug Delivery Formulations. Eur. J. Pharm. Sci. 2021, 159, 105736. [Google Scholar] [CrossRef]

- Mady, O.Y.; Dewedar, O.; Abdine, N.; Zaytoon, H.; Haggag, Y. Bioadhesive Behaviors of HPMC E5: Comparative Analysis of Various Techniques, Histological and Human Radiological Evidence. Sci. Rep. 2024, 14, 1–14. [Google Scholar] [CrossRef]