Innovative Cold Processing of PVOH-Based Composites: A Gate-to-Gate Life Cycle Assessment of Environmental Benefits

Abstract

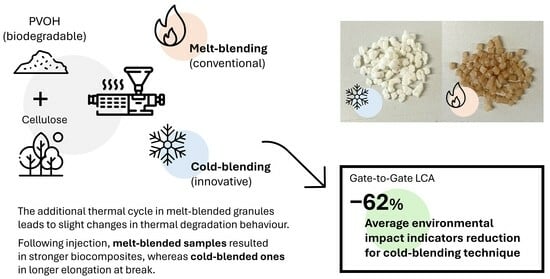

1. Introduction

2. Materials and Methods

2.1. Matrix-Filler Blending

2.1.1. Conventional Melt Blending

2.1.2. Innovative Cold Blending

2.2. Injection Moulding and Tensile Testing

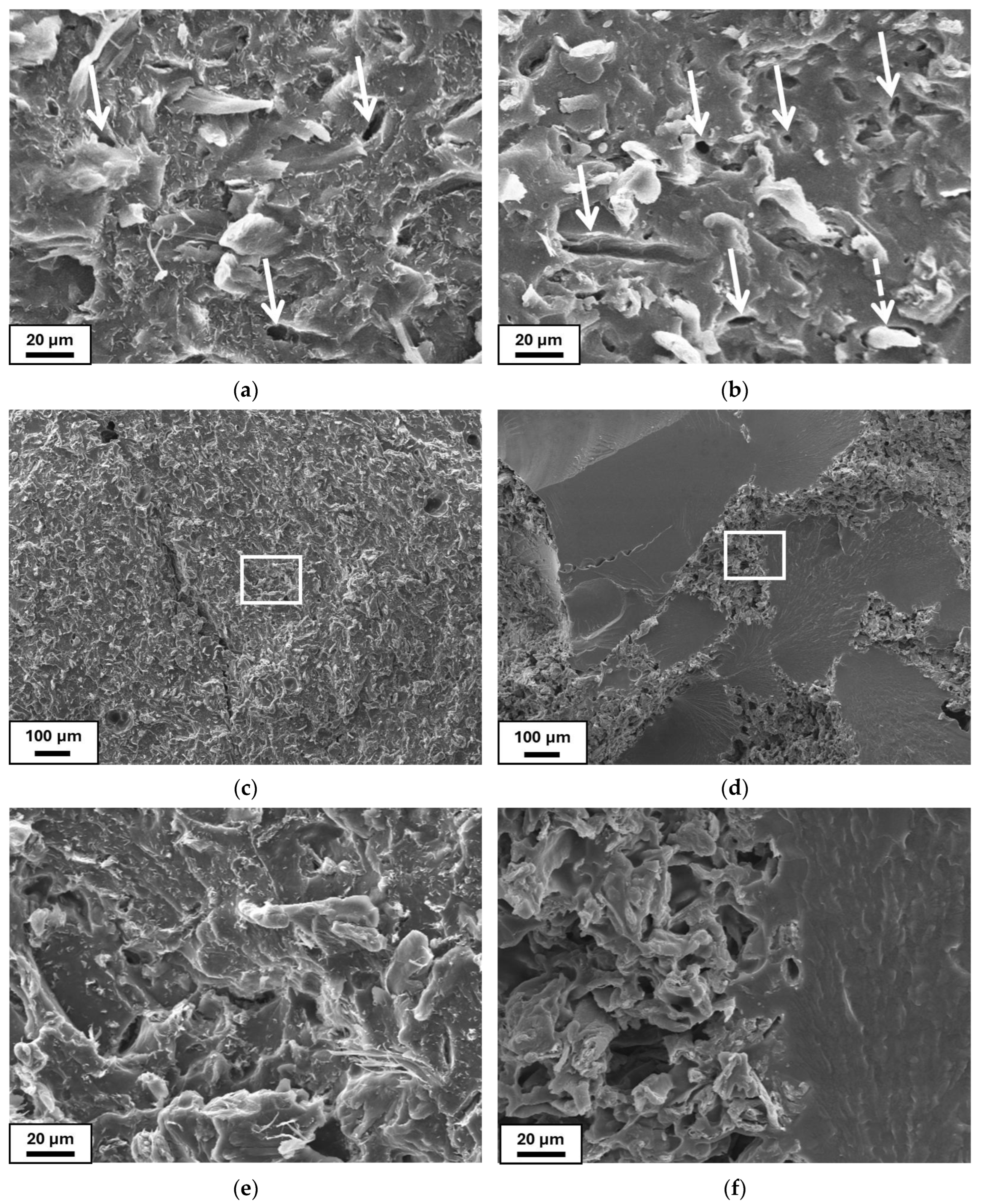

2.3. Scanning Electron Microscopy (SEM)

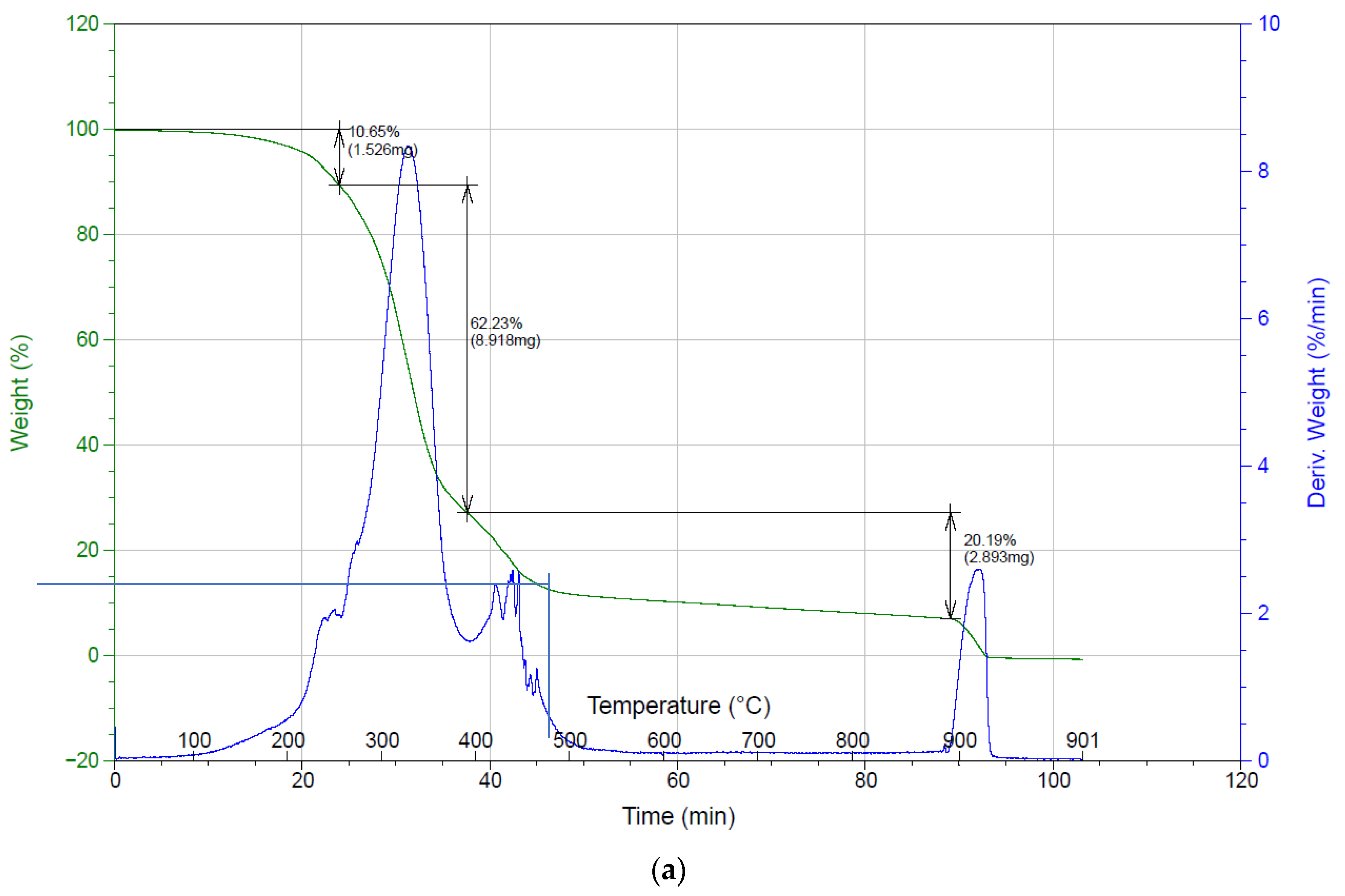

2.4. Thermogravimetric Analysis (TGA)

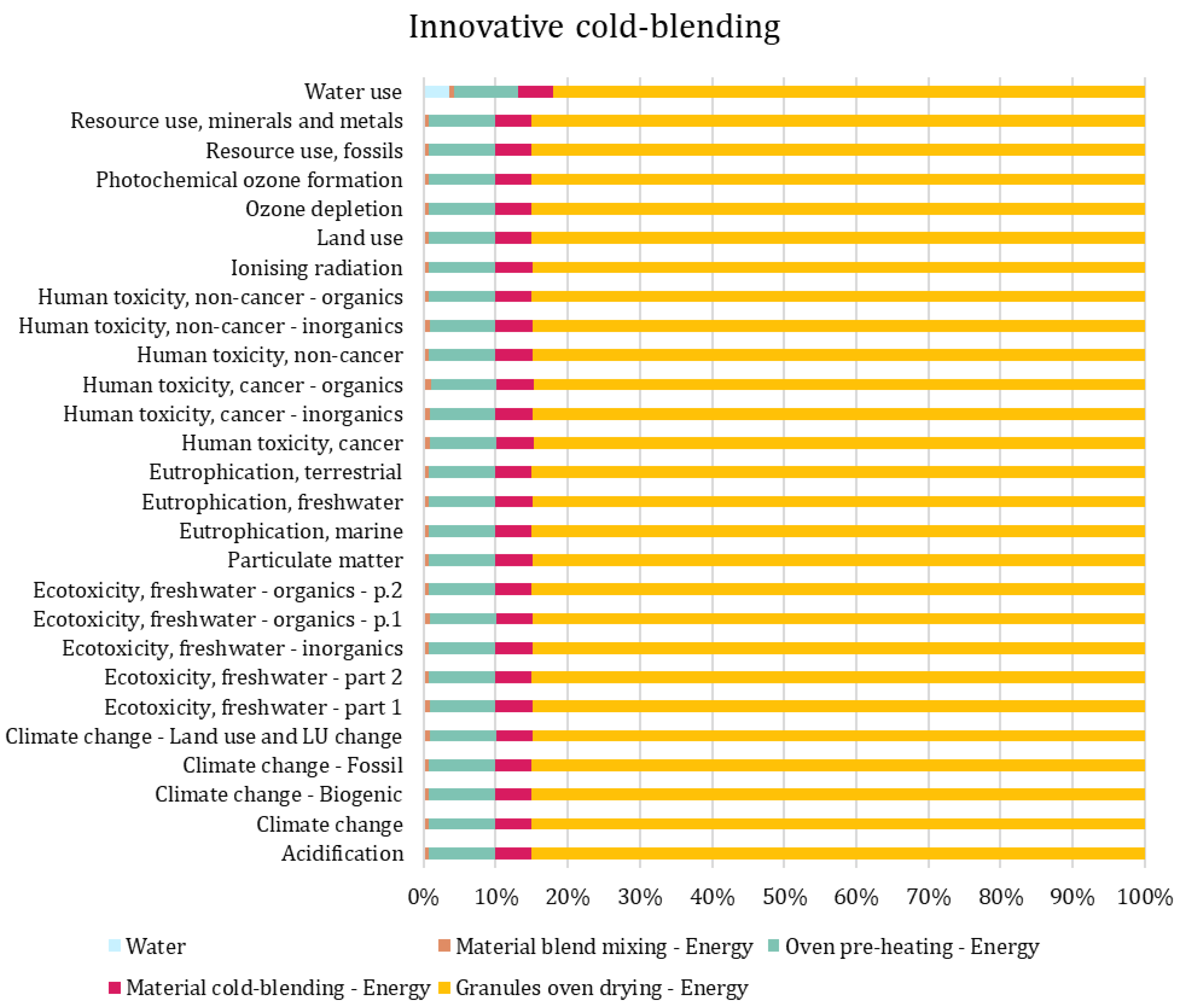

2.5. Life Cycle Assessment

2.5.1. Goal and Scope Definition

2.5.2. Functional Unit

2.5.3. System Boundaries and Life Cycle Stages—Data Quality

2.5.4. Life Cycle Inventory (LCI)

2.5.5. Data and Modelling Assumptions

- The oven has a maximum granule or powder drying batch of 3 kg. Pre-heating was proportionally attributed to one batch as the limit processed amount per working day.

- The drying phase of PVOH and cellulose fibres occurs overnight, i.e., for 16 h.

- The extruder (melt blender) works for one 8 h shift, producing 1.5 kg/h. The pre-heat and working consumption of water and electricity was proportional to the processed amount per shift.

- The oven has a maximum PMC granule drying batch of 3 kg. As per the experimental data, it takes 4.5 h to completely dry one batch. The oven works continuously to process two batches. Therefore, the pre-heating electricity consumption was split proportionally into two dried batches.

2.5.6. Sensitivity Analysis

2.5.7. Life Cycle Impact Assessment (LCIA)

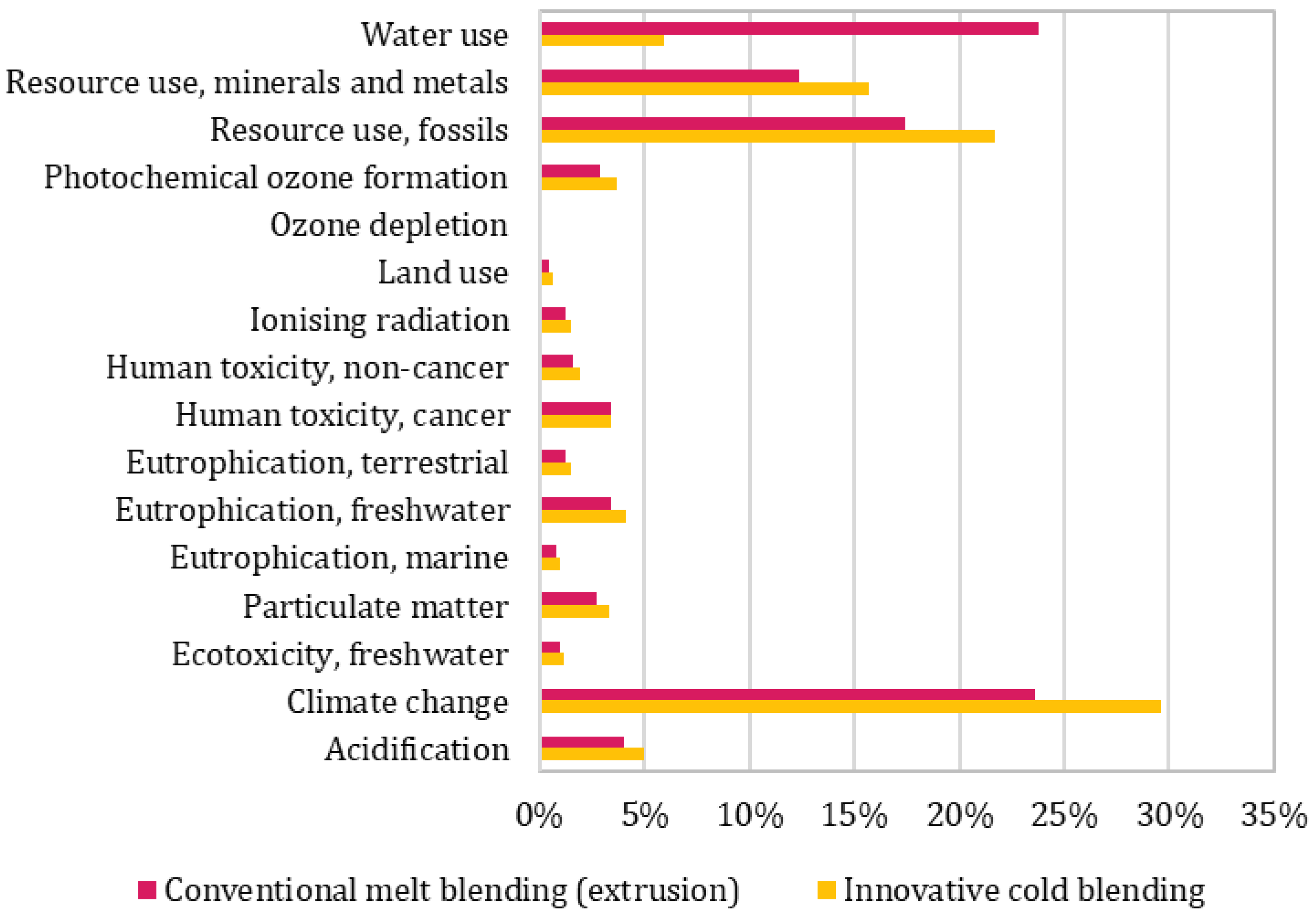

3. Results

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| PMC | Polymeric Matrix Composite |

| PVOH | Polyvinyl alcohol |

| SEM | Scanning Electron Microscopy |

| S1 | Scenario 1 |

| S2 | Scenario 2 |

| TGA | Thermogravimetric Analysis |

Appendix A

Appendix A.1

| Indicator | Unit | Oven Pre-Heating—Energy | Oven Drying—Energy | Extruder Pre-Heating—Water | Extruder Pre-Heating—Energy | Material Melt Blending—Water | Material Melt Blending—Energy | Material Granulation—Energy |

|---|---|---|---|---|---|---|---|---|

| Acidification | mol H+eq | 1 × 10−4 | 2 × 10−3 | 1 × 10−5 | 1 × 10−4 | 1 × 10−4 | 2 × 10−3 | 2 × 10−5 |

| Climate change | kg CO2eq | 3 × 10−2 | 6 × 10−1 | 2 × 10−3 | 3 × 10−2 | 2 × 10−2 | 5 × 10−1 | 5 × 10−3 |

| Climate change—Biogenic | kg CO2eq | 1 × 10−4 | 2 × 10−3 | 4 × 10−6 | 1 × 10−4 | 4 × 10−5 | 2 × 10−3 | 2 × 10−5 |

| Climate change—Fossil | kg CO2eq | 3 × 10−2 | 6 × 10−1 | 2 × 10−3 | 3 × 10−2 | 2 × 10−2 | 5 × 10−1 | 5 × 10−3 |

| Climate change—Land use and LU change | kg CO2eq | 6 × 10−6 | 1 × 10−4 | 4 × 10−6 | 6 × 10−6 | 4 × 10−5 | 9 × 10−5 | 1 × 10−6 |

| Ecotoxicity, freshwater—part 1 | CTUe | 5 × 10−2 | 8 × 10−1 | 2 × 10−2 | 5 × 10−2 | 3 × 10−1 | 7 × 10−1 | 8 × 10−3 |

| Ecotoxicity, freshwater—part 2 | CTUe | 6 × 10−2 | 1 | 4 × 10−3 | 5 × 10−2 | 4 × 10−2 | 8 × 10−1 | 9 × 10−3 |

| Ecotoxicity, freshwater—inorganics | CTUe | 7 × 10−2 | 1 | 1 × 10−2 | 7 × 10−2 | 1 × 10−1 | 1 | 1 × 10−2 |

| Ecotoxicity, freshwater—organics—p.1 | CTUe | 2 × 10−2 | 4 × 10−1 | 2 × 10−2 | 2 × 10−2 | 2 × 10−1 | 3 × 10−1 | 3 × 10−3 |

| Ecotoxicity, freshwater—organics—p.2 | CTUe | 1 × 10−2 | 2 × 10−1 | 9 × 10−4 | 9 × 10−3 | 9 × 10−3 | 1 × 10−1 | 2 × 10−3 |

| Particulate matter | disease inc. | 7 × 10−10 | 1 × 10−8 | 1 × 10−10 | 7 × 10−10 | 1 × 10−9 | 1 × 10−8 | 1 × 10−10 |

| Eutrophication, marine | kg Neq | 2 × 10−5 | 4 × 10−4 | 2 × 10−6 | 2 × 10−5 | 2 × 10−5 | 3 × 10−4 | 3 × 10−6 |

| Eutrophication, freshwater | kg Peq | 7 × 10−6 | 1 × 10−4 | 1 × 10−6 | 7 × 10−6 | 1 × 10−5 | 1 × 10−4 | 1 × 10−6 |

| Eutrophication, terrestrial | mol Neq | 2 × 10−4 | 4 × 10−3 | 2 × 10−5 | 2 × 10−4 | 2 × 10−4 | 3 × 10−3 | 4 × 10−5 |

| Human toxicity, cancer | CTUh | 9 × 10−11 | 2 × 10−9 | 7 × 10−11 | 8 × 10−11 | 8 × 10−10 | 1 × 10−9 | 1 × 10−11 |

| Human toxicity, cancer—inorganics | CTUh | 4 × 10−12 | 8 × 10−11 | 2 × 10−12 | 4 × 10−12 | 2 × 10−11 | 6 × 10−11 | 7 × 10−13 |

| Human toxicity, cancer—organics | CTUh | 8 × 10−11 | 1 × 10−9 | 7 × 10−11 | 8 × 10−11 | 8 × 10−10 | 1 × 10−9 | 1 × 10−11 |

| Human toxicity, non-cancer | CTUh | 4 × 10−10 | 7 × 10−9 | 1 × 10−10 | 4 × 10−10 | 1 × 10−9 | 6 × 10−9 | 7 × 10−11 |

| Human toxicity, non-cancer—inorganics | CTUh | 4 × 10−10 | 7 × 10−9 | 1 × 10−10 | 4 × 10−10 | 1 × 10−9 | 6 × 10−9 | 6 × 10−11 |

| Human toxicity, non-cancer—organics | CTUh | 3 × 10−11 | 4 × 10−10 | 9 × 10−13 | 2 × 10−11 | 9 × 10−12 | 4 × 10−10 | 4 × 10−12 |

| Ionising radiation | kBq U235eq | 4 × 10−3 | 7 × 10−2 | 8 × 10−4 | 4 × 10−3 | 8 × 10−3 | 6 × 10−2 | 6 × 10−4 |

| Land use | Pt | 2 × 10−1 | 3 | 9 × 10−3 | 2 × 10−1 | 1 × 10−1 | 3 | 3 × 10−2 |

| Ozone depletion | kg CFC-11eq | 8 × 10−10 | 1 × 10−8 | 3 × 10−11 | 7 × 10−10 | 3 × 10−10 | 1 × 10−8 | 1 × 10−10 |

| Photochemical ozone formation | kg NMVOCeq | 1 × 10−4 | 2 × 10−3 | 7 × 10−6 | 1 × 10−4 | 8 × 10−5 | 1 × 10−3 | 2 × 10−5 |

| Resource use, fossils | MJ | 5 × 10−1 | 9 | 4 × 10−2 | 5 × 10−1 | 4 × 10−1 | 8 | 9 × 10−2 |

| Resource use, minerals and metals | kg Sbeq | 4 × 10−7 | 7 × 10−6 | 1 × 10−8 | 4 × 10−7 | 1 × 10−7 | 6 × 10−6 | 7 × 10−8 |

| Water use | m3 depriv. | 2 × 10−2 | 4 × 10−1 | 3 × 10−1 | 2 × 10−2 | 3 | 4 × 10−1 | 4 × 10−3 |

| Indicator | Unit | Water | Material Blend Mixing—Energy | Material Cold Blending—Energy | Oven Pre-Heating—Energy | Granules Oven Drying—Energy |

|---|---|---|---|---|---|---|

| Acidification | mol H+eq | 5 × 10−7 | 1 × 10−5 | 1 × 10−4 | 2 × 10−4 | 2 × 10−3 |

| Climate change | kg CO2eq | 9 × 10−5 | 4 × 10−3 | 2 × 10−2 | 4 × 10−2 | 4 × 10−1 |

| Climate change—Biogenic | kg CO2eq | 2 × 10−7 | 1 × 10−5 | 1 × 10−4 | 2 × 10−4 | 2 × 10−3 |

| Climate change—Fossil | kg CO2eq | 9 × 10−5 | 4 × 10−3 | 2 × 10−2 | 4 × 10−2 | 4 × 10−1 |

| Climate change—Land use and LU change | kg CO2eq | 2 × 10−7 | 7 × 10−7 | 5 × 10−6 | 8 × 10−6 | 8 × 10−5 |

| Ecotoxicity, freshwater—part 1 | CTUe | 1 × 10−3 | 5 × 10−3 | 4 × 10−2 | 6 × 10−2 | 6 × 10−1 |

| Ecotoxicity, freshwater—part 2 | CTUe | 2 × 10−4 | 6 × 10−3 | 4 × 10−2 | 7 × 10−2 | 7 × 10−1 |

| Ecotoxicity, freshwater—inorganics | CTUe | 5 × 10−4 | 8 × 10−3 | 5 × 10−2 | 1 × 10−1 | 9 × 10−1 |

| Ecotoxicity, freshwater—organics—p.1 | CTUe | 7 × 10−4 | 2 × 10−3 | 2 × 10−2 | 3 × 10−2 | 3 × 10−1 |

| Ecotoxicity, freshwater—organics—p.2 | CTUe | 4 × 10−5 | 1 × 10−3 | 7 × 10−3 | 1 × 10−2 | 1 × 10−1 |

| Particulate matter | disease inc. | 5 × 10−12 | 7 × 10−11 | 5 × 10−10 | 9 × 10−10 | 9 × 10−9 |

| Eutrophication, marine | kg Neq | 9 × 10−8 | 2 × 10−6 | 2 × 10−5 | 3 × 10−5 | 3 × 10−4 |

| Eutrophication, freshwater | kg Peq | 5 × 10−8 | 8 × 10−7 | 6 × 10−6 | 1 × 10−5 | 9 × 10−5 |

| Eutrophication, terrestrial | mol Neq | 9 × 10−7 | 2 × 10−5 | 2 × 10−4 | 3 × 10−4 | 3 × 10−3 |

| Human toxicity, cancer | CTUh | 3 × 10−12 | 9 × 10−12 | 6 × 10−11 | 1 × 10−10 | 1 × 10−9 |

| Human toxicity, cancer—inorganics | CTUh | 7 × 10−14 | 5 × 10−13 | 3 × 10−12 | 6 × 10−12 | 5 × 10−11 |

| Human toxicity, cancer—organics | CTUh | 3 × 10−12 | 9 × 10−12 | 6 × 10−11 | 1 × 10−10 | 1 × 10−9 |

| Human toxicity, non-cancer | CTUh | 5 × 10−12 | 4 × 10−11 | 3 × 10−10 | 6 × 10−10 | 5 × 10−9 |

| Human toxicity, non-cancer—inorganics | CTUh | 5 × 10−12 | 4 × 10−11 | 3 × 10−10 | 5 × 10−10 | 5 × 10−9 |

| Human toxicity, non-cancer—organics | CTUh | 4 × 10−14 | 3 × 10−12 | 2 × 10−11 | 3 × 10−11 | 3 × 10−10 |

| Ionising radiation | kBq U235eq | 3 × 10−5 | 4 × 10−4 | 3 × 10−3 | 5 × 10−3 | 5 × 10−2 |

| Land use | Pt | 4 × 10−4 | 2 × 10−2 | 1 × 10−1 | 3 × 10−1 | 2 |

| Ozone depletion | kg CFC-11eq | 1 × 10−12 | 8 × 10−11 | 6 × 10−10 | 1 × 10−9 | 9 × 10−9 |

| Photochemical ozone formation | kg NMVOCeq | 3 × 10−7 | 1 × 10−5 | 7 × 10−5 | 1 × 10−4 | 1 × 10−3 |

| Resource use, fossils | MJ | 2 × 10−3 | 6 × 10−2 | 4 × 10−1 | 7 × 10−1 | 7 |

| Resource use, minerals and metals | kg Sbeq | 5 × 10−10 | 4 × 10−8 | 3 × 10−7 | 6 × 10−7 | 5 × 10−6 |

| Water use | m3 depriv. | 1 × 10−2 | 3 × 10−3 | 2 × 10−2 | 3 × 10−2 | 3 × 10−1 |

Appendix A.2

| Indicator | Unit | Oven Pre-Heating—Energy | Oven Drying—Energy | Extruder Pre-Heating—Water | Extruder Pre-Heating—Energy | Material Melt Blending—Water | Material Melt Blending—Energy | Material Granulation—Energy |

|---|---|---|---|---|---|---|---|---|

| Acidification | Pt | 2 × 10−7 | 3 × 10−6 | 1 × 10−8 | 2 × 10−7 | 1 × 10−7 | 2 × 10−6 | 3 × 10−8 |

| Climate change | Pt | 9 × 10−7 | 2 × 10−5 | 6 × 10−8 | 9 × 10−7 | 7 × 10−7 | 1 × 10−5 | 2 × 10−7 |

| Ecotoxicity, freshwater | Pt | 3 × 10−8 | 6 × 10−7 | 1 × 10−8 | 3 × 10−8 | 1 × 10−7 | 5 × 10−7 | 6 × 10−9 |

| Particulate matter | Pt | 1 × 10−7 | 2 × 10−6 | 2 × 10−8 | 1 × 10−7 | 2 × 10−7 | 2 × 10−6 | 2 × 10−8 |

| Eutrophication, marine | Pt | 3 × 10−8 | 6 × 10−7 | 3 × 10−9 | 3 × 10−8 | 4 × 10−8 | 5 × 10−7 | 5 × 10−9 |

| Eutrophication, freshwater | Pt | 1 × 10−7 | 2 × 10−6 | 2 × 10−8 | 1 × 10−7 | 2 × 10−7 | 2 × 10−6 | 2 × 10−8 |

| Eutrophication, terrestrial | Pt | 5 × 10−8 | 8 × 10−7 | 5 × 10−9 | 5 × 10−8 | 5 × 10−8 | 7 × 10−7 | 8 × 10−9 |

| Human toxicity, cancer | Pt | 1 × 10−7 | 2 × 10−6 | 9 × 10−8 | 1 × 10−7 | 1 × 10−6 | 2 × 10−6 | 2 × 10−8 |

| Human toxicity, non-cancer | Pt | 6 × 10−8 | 1 × 10−6 | 2 × 10−8 | 6 × 10−8 | 2 × 10−7 | 9 × 10−7 | 1 × 10−8 |

| Ionising radiation | Pt | 5 × 10−8 | 8 × 10−7 | 9 × 10−9 | 5 × 10−8 | 1 × 10−7 | 7 × 10−7 | 8 × 10−9 |

| Land use | Pt | 2 × 10−8 | 3 × 10−7 | 9 × 10−10 | 2 × 10−8 | 9 × 10−9 | 3 × 10−7 | 3 × 10−9 |

| Ozone depletion | Pt | 9 × 10−10 | 2 × 10−8 | 4 × 10−11 | 9 × 10−10 | 4 × 10−10 | 1 × 10−8 | 2 × 10−10 |

| Photochemical ozone formation | Pt | 1 × 10−7 | 2 × 10−6 | 8 × 10−9 | 1 × 10−7 | 9 × 10−8 | 2 × 10−6 | 2 × 10−8 |

| Resource use, fossils | Pt | 7 × 10−7 | 1 × 10−5 | 5 × 10−8 | 7 × 10−7 | 5 × 10−7 | 1 × 10−5 | 1 × 10−7 |

| Resource use, minerals and metals | Pt | 5 × 10−7 | 9 × 10−6 | 1 × 10−8 | 5 × 10−7 | 2 × 10−7 | 7 × 10−6 | 8 × 10−8 |

| Water use | Pt | 2 × 10−7 | 3 × 10−6 | 2 × 10−6 | 2 × 10−7 | 2 × 10−5 | 3 × 10−6 | 3 × 10−8 |

| Indicator | Unit | Water | Material Blend Mixing—Energy | Material Cold Blending—Energy | Oven Pre-Heating—Energy | Granules Oven Drying—Energy |

|---|---|---|---|---|---|---|

| Acidification | Pt | 5 × 10−10 | 2 × 10−8 | 1 × 10−7 | 2 × 10−7 | 2 × 10−6 |

| Climate change | Pt | 3 × 10−9 | 1 × 10−7 | 7 × 10−7 | 1 × 10−6 | 1 × 10−5 |

| Ecotoxicity, freshwater | Pt | 4 × 10−10 | 4 × 10−9 | 3 × 10−8 | 5 × 10−8 | 4 × 10−7 |

| Particulate matter | Pt | 8 × 10−10 | 1 × 10−8 | 8 × 10−8 | 1 × 10−7 | 1 × 10−6 |

| Eutrophication, marine | Pt | 1 × 10−10 | 3 × 10−9 | 2 × 10−8 | 4 × 10−8 | 4 × 10−7 |

| Eutrophication, freshwater | Pt | 1 × 10−9 | 1 × 10−8 | 1 × 10−7 | 2 × 10−7 | 2 × 10−6 |

| Eutrophication, terrestrial | Pt | 2 × 10−10 | 5 × 10−9 | 4 × 10−8 | 6 × 10−8 | 6 × 10−7 |

| Human toxicity, cancer | Pt | 4 × 10−9 | 1 × 10−8 | 8 × 10−8 | 1 × 10−7 | 1 × 10−6 |

| Human toxicity, non-cancer | Pt | 7 × 10−10 | 6 × 10−9 | 4 × 10−8 | 8 × 10−8 | 7 × 10−7 |

| Ionising radiation | Pt | 4 × 10−10 | 5 × 10−9 | 4 × 10−8 | 6 × 10−8 | 6 × 10−7 |

| Land use | Pt | 4 × 10−11 | 2 × 10−9 | 1 × 10−8 | 3 × 10−8 | 2 × 10−7 |

| Ozone depletion | Pt | 2 × 10−12 | 1 × 10−10 | 7 × 10−10 | 1 × 10−9 | 1 × 10−8 |

| Photochemical ozone formation | Pt | 3 × 10−10 | 1 × 10−8 | 9 × 10−8 | 2 × 10−7 | 1 × 10−6 |

| Resource use, fossils | Pt | 2 × 10−9 | 7 × 10−8 | 5 × 10−7 | 9 × 10−7 | 8 × 10−6 |

| Resource use, minerals and metals | Pt | 6 × 10−10 | 5 × 10−8 | 4 × 10−7 | 7 × 10−7 | 6 × 10−6 |

| Water use | Pt | 1 × 10−7 | 2 × 10−8 | 1 × 10−7 | 2 × 10−7 | 2 × 10−6 |

References

- Circle Economy. In The Circularity Gap Report 2024; Circle Economy Foundation: Amsterdam, The Netherlands, 2025.

- Barbier, E.B. The Concept of Sustainable Economic Development. Environ. Conserv. 1987, 14, 101–110. [Google Scholar] [CrossRef]

- Purvis, B.; Mao, Y.; Robinson, D. Three Pillars of Sustainability: In Search of Conceptual Origins. Sustain. Sci. 2019, 14, 681–695. [Google Scholar] [CrossRef]

- Packaging Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Packaging_waste_statistics (accessed on 14 March 2025).

- Lebreton, L.; Slat, B.; Ferrari, F.; Sainte-Rose, B.; Aitken, J.; Marthouse, R.; Hajbane, S.; Cunsolo, S.; Schwarz, A.; Levivier, A.; et al. Evidence That the Great Pacific Garbage Patch Is Rapidly Accumulating Plastic. Sci. Rep. 2018, 8, 4666. [Google Scholar] [CrossRef]

- Bakir, A.; Desender, M.; Wilkinson, T.; Van Hoytema, N.; Amos, R.; Airahui, S.; Graham, J.; Maes, T. Occurrence and Abundance of Meso and Microplastics in Sediment, Surface Waters, and Marine Biota from the South Pacific Region. Mar. Pollut. Bull. 2020, 160, 111572. [Google Scholar] [CrossRef]

- Roy, P.; Mohanty, A.K.; Misra, M. Microplastics in Ecosystems: Their Implications and Mitigation Pathways. Environ. Sci. Adv. 2022, 1, 9–29. [Google Scholar] [CrossRef]

- Ta, A.T.; Pupuang, P.; Babel, S.; Wang, L.P. Investigation of Microplastic Contamination in Blood Cockles and Green Mussels from Selected Aquaculture Farms and Markets in Thailand. Chemosphere 2022, 303, 134918. [Google Scholar] [CrossRef]

- What Are Bioplastics? Available online: https://www.european-bioplastics.org/bioplastics/ (accessed on 10 November 2019).

- Rotondo, B.; Zych, A.; Marinelli, A.; Santi, R.; Del Curto, B.; Athanassiou, A.; Perotto, G. POMOPLA2: A Bio-Based Material Solution Valorizing Tomato By-Products for Circular Packaging Applications. J. Polym. Sci. 2024, 63, 493–503. [Google Scholar] [CrossRef]

- Sharma, R.; Jafari, S.M.; Sharma, S. Antimicrobial Bio-Nanocomposites and Their Potential Applications in Food Packaging. Food Control 2020, 112, 107086. [Google Scholar] [CrossRef]

- Pei, P.; Sun, Y.; Zou, R.; Wang, X.; Liu, J.; Liu, L.; Deng, X.; Li, X.; Yu, M.; Li, S. Comparing Four Kinds of Lignocellulosic Biomass for the Performance of Fiber/PHB/PBS Bio-Composites. BioResources 2023, 18, 7154–7171. [Google Scholar] [CrossRef]

- Ivorra-Martinez, J.; Verdu, I.; Fenollar, O.; Sanchez-Nacher, L.; Balart, R.; Quiles-Carrillo, L. Manufacturing and Properties of Binary Blend from Bacterial Polyester Poly (3-Hydroxybutyrate-Co-3-Hydroxyhexanoate) and Poly (Caprolactone) with Improved Toughness. Polymers 2020, 12, 1118. [Google Scholar] [CrossRef]

- Qiu, Y.; Fu, J.; Sun, B.; Ma, X. Sustainable Nanocomposite Films Based on SiO2 and Biodegradable Poly (3-Hydroxybutyrate-Co -3-Hydroxyhexanoate) (PHBH) for Food Packaging. e-Polymers 2021, 21, 72–81. [Google Scholar] [CrossRef]

- Lyu, J.S.; Lee, J.-S.; Han, J. Development of a Biodegradable Polycaprolactone Film Incorporated with an Antimicrobial Agent via an Extrusion Process. Sci. Rep. 2019, 9, 20236. [Google Scholar] [CrossRef]

- Lukic, I.; Vulic, J.; Ivanovic, J. Antioxidant Activity of PLA/PCL Films Loaded with Thymol and/or Carvacrol Using ScCO2 for Active Food Packaging. Food Packag. Shelf Life 2020, 26, 100578. [Google Scholar] [CrossRef]

- Santi, R.; Cigada, A.; Del Curto, B.; Farè, S. Modulable Properties of PVA/Cellulose Fiber Composites. J. Appl. Biomater. Funct. Mater. 2019, 17, 2280800019831224. [Google Scholar] [CrossRef]

- Lee, W.J.; Clancy, A.J.; Kontturi, E.; Bismarck, A.; Shaffer, M.S.P. Strong and Stiff: High-Performance Cellulose Nanocrystal/Poly (Vinyl Alcohol) Composite Fibers. ACS Appl. Mater. Interfaces 2016, 8, 31500–31504. [Google Scholar] [CrossRef]

- Cazón, P.; Velazquez, G.; Vázquez, M. Characterization of Mechanical and Barrier Properties of Bacterial Cellulose, Glycerol and Polyvinyl Alcohol (PVOH) Composite Films with Eco-Friendly UV-Protective Properties. Food Hydrocoll. 2020, 99, 105323. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A Review of Natural Fiber Composites: Properties, Modification and Processing Techniques, Characterization, Applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Chiellini, E.; Cinelli, P.; Imam, S.H.; Mao, L. Composite Films Based on Biorelated Agro-Industrial Waste and Poly (Vinyl Alcohol). Preparation and Mechanical Properties Characterization. Biomacromolecules 2001, 2, 1029–1037. [Google Scholar] [CrossRef]

- Arun, R.; Shruthy, R.; Preetha, R.; Sreejit, V. Biodegradable Nano Composite Reinforced with Cellulose Nano Fiber from Coconut Industry Waste for Replacing Synthetic Plastic Food Packaging. Chemosphere 2022, 291, 132786. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and Properties of Natural Fiber Polymer Composites: A Comprehensive Review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Väisänen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of Agricultural and Forest Industry Waste and Residues in Natural Fiber-Polymer Composites: A Review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef]

- Pham, D.H.; Kumar, B.; Kim, J. Environment-Friendly, High-Performance Lignin-Derived and Polyvinyl Alcohol Blended Resin for All-Green Natural Fiber-Reinforced Composite. Int. J. Precis. Eng. Manuf. Technol. 2025, 12, 607–619. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Injection Molded Sustainable Biocomposites from Poly (Butylene Succinate) Bioplastic and Perennial Grass. ACS Sustain. Chem. Eng. 2015, 3, 2767–2776. [Google Scholar] [CrossRef]

- ISO 14040: 2006; Environmental Management—Life Cycle Assessment—Principles and Framework. Available online: https://www.iso.org/standard/37456.html (accessed on 13 June 2024).

- Ramesh, M.; Deepa, C.; Kumar, L.R.; Sanjay, M.; Siengchin, S. Life-Cycle and Environmental Impact Assessments on Processing of Plant Fibres and Its Bio-Composites: A Critical Review. J. Ind. Text. 2022, 51, 5518S–5542S. [Google Scholar] [CrossRef]

- Tadele, D.; Roy, P.; Defersha, F.; Misra, M.; Mohanty, A.K. A Comparative Life-Cycle Assessment of Talc- and Biochar-Reinforced Composites for Lightweight Automotive Parts. Clean Technol. Environ. Policy 2020, 22, 639–649. [Google Scholar] [CrossRef]

- Beigbeder, J.; Soccalingame, L.; Perrin, D.; Bénézet, J.-C.; Bergeret, A. How to Manage Biocomposites Wastes End of Life? A Life Cycle Assessment Approach (LCA) Focused on Polypropylene (PP)/Wood Flour and Polylactic Acid (PLA)/Flax Fibres Biocomposites. Waste Manag. 2019, 83, 184–193. [Google Scholar] [CrossRef]

- Ita-Nagy, D.; Vázquez-Rowe, I.; Kahhat, R.; Quispe, I.; Chinga-Carrasco, G.; Clauser, N.M.; Area, M.C. Life Cycle Assessment of Bagasse Fiber Reinforced Biocomposites. Sci. Total Environ. 2020, 720, 137586. [Google Scholar] [CrossRef]

- Operato, L.; Vitiello, L.; Aprea, P.; Ambrogi, V.; Salzano de Luna, M.; Filippone, G. Life Cycle Assessment of Poly (Lactic Acid)-Based Green Composites Filled with Pine Needles or Kenaf Fibers. J. Clean. Prod. 2023, 387, 135901. [Google Scholar] [CrossRef]

- Miller, S.A.; Lepech, M.D.; Billington, S.L. Application of Multi-Criteria Material Selection Techniques to Constituent Refinement in Biobased Composites. Mater. Des. 2013, 52, 1043–1051. [Google Scholar] [CrossRef]

- Wu, Y.; Xia, C.; Cai, L.; Garcia, A.C.; Shi, S.Q. Development of Natural Fiber-Reinforced Composite with Comparable Mechanical Properties and Reduced Energy Consumption and Environmental Impacts for Replacing Automotive Glass-Fiber Sheet Molding Compound. J. Clean. Prod. 2018, 184, 92–100. [Google Scholar] [CrossRef]

- Bavasso, I.; Sergi, C.; Valente, T.; Tirillò, J.; Sarasini, F. Recycled Multi-Material Packaging Reinforced with Flax Fibres: Thermal and Mechanical Behaviour. Polymers 2022, 14, 4423. [Google Scholar] [CrossRef] [PubMed]

- Uitterhaegen, E.; Parinet, J.; Labonne, L.; Mérian, T.; Ballas, S.; Véronèse, T.; Merah, O.; Talou, T.; Stevens, C.V.; Chabert, F.; et al. Performance, Durability and Recycling of Thermoplastic Biocomposites Reinforced with Coriander Straw. Compos. Part A Appl. Sci. Manuf. 2018, 113, 254–263. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and New Opportunities on Barrier Performance of Biodegradable Polymers for Sustainable Packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Baniasadi, H.; Äkräs, L.; Madani, Z.; Silvenius, F.; Fazeli, M.; Lipponen, S.; Vapaavuori, J.; Seppälä, J. Development and Characterization of Polylactic Acid/Starch Biocomposites—From Melt Blending to Preliminary Life Cycle Assessment. Int. J. Biol. Macromol. 2024, 279, 135173. [Google Scholar] [CrossRef] [PubMed]

- ISO 527-2: 2012; Plastics—Determination of Tensile Properties. Part 2: Test Conditions for Moulding and Extrusion Plastics. Available online: https://www.iso.org/standard/56046.html (accessed on 22 April 2025).

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. Available online: https://store.astm.org/d0638-14.html (accessed on 3 April 2025).

- Aliotta, L.; Gigante, V.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Seggiani, M. Thermo-Mechanical Properties of PLA/Short Flax Fiber Biocomposites. Appl. Sci. 2019, 9, 3797. [Google Scholar] [CrossRef]

- Faludi, G.; Hári, J.; Renner, K.; Móczó, J.; Pukánszky, B. Fiber Association and Network Formation in PLA/Lignocellulosic Fiber Composites. Compos. Sci. Technol. 2013, 77, 67–73. [Google Scholar] [CrossRef]

- Andreasi Bassi, S.; Biganzoli, S.; Ferrara, F.; Amadei, N.; Valente, A.; Sala, A.; Ardente, S. Updated Characterisation and Normalisation Factors for the Environmental Footprint 3.1 Method; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar]

- Zampori, L.; Pant, R. Suggestions for Updating the Organisation Environmental Footprint (OEF) Method; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Developer Environmental Footprint (EF). EF Reference Package 3.1. Available online: https://eplca.jrc.ec.europa.eu/LCDN/developerEF.html (accessed on 2 February 2025).

- Morancho, J.M.; Salla, J.M.; Cadenato, A.; Fernández-Francos, X.; Ramis, X.; Colomer, P.; Calventus, Y.; Ruíz, R. Kinetic Studies of the Degradation of Poly (Vinyl Alcohol)-Based Proton-Conducting Membranes at Low Temperatures. Thermochim. Acta 2011, 521, 139–147. [Google Scholar] [CrossRef]

- Budrugeac, P. Kinetics of the Complex Process of Thermo-Oxidative Degradation of Poly (Vinyl Alcohol). J. Therm. Anal. Calorim. 2008, 92, 291–296. [Google Scholar] [CrossRef]

- Mironova, M.; Makarov, I.; Golova, L.; Vinogradov, M.; Shandryuk, G.; Levin, I. Improvement in Carbonization Efficiency of Cellulosic Fibres Using Silylated Acetylene and Alkoxysilanes. Fibers 2019, 7, 84. [Google Scholar] [CrossRef]

- Capart, R.; Khezami, L.; Burnham, A.K. Assessment of Various Kinetic Models for the Pyrolysis of a Microgranular Cellulose. Thermochim. Acta 2004, 417, 79–89. [Google Scholar] [CrossRef]

- Rosenbaum, R.K.; Bachmann, T.M.; Gold, L.S.; Huijbregts, M.A.J.; Jolliet, O.; Juraske, R.; Koehler, A.; Larsen, H.F.; MacLeod, M.; Margni, M.; et al. USEtox—The UNEP-SETAC Toxicity Model: Recommended Characterisation Factors for Human Toxicity and Freshwater Ecotoxicity in Life Cycle Impact Assessment. Int. J. Life Cycle Assess. 2008, 13, 532–546. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Gibon, T.; Bouman, E.A.; Arvesen, A.; Suh, S.; Heath, G.A.; Bergesen, J.D.; Ramirez, A.; Vega, M.I.; Shi, L. Integrated Life-Cycle Assessment of Electricity-Supply Scenarios Confirms Global Environmental Benefit of Low-Carbon Technologies. Proc. Natl. Acad. Sci. USA 2015, 112, 6277–6282. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Palumbo, E.; Corcione, C.E. Development and Characterization of Sustainable PLA/Olive Wood Waste Composites for Rehabilitation Applications Using Fused Filament Fabrication (FFF). J. Build. Eng. 2022, 56, 104673. [Google Scholar] [CrossRef]

- David, G.; Croxatto Vega, G.; Sohn, J.; Nilsson, A.E.; Hélias, A.; Gontard, N.; Angellier-Coussy, H. Using Life Cycle Assessment to Quantify the Environmental Benefit of Upcycling Vine Shoots as Fillers in Biocomposite Packaging Materials. Int. J. Life Cycle Assess. 2021, 26, 738–752. [Google Scholar] [CrossRef]

- Bianchi, I.; Forcellese, A.; Mancia, T.; Simoncini, M.; Vita, A. Process Parameters Effect on Environmental Sustainability of Composites FFF Technology. Mater. Manuf. Process. 2022, 37, 591–601. [Google Scholar] [CrossRef]

- Cinardi, G.; D’Urso, P.R.; Arcidiacono, C.; Muradin, M.; Ingrao, C. A Systematic Literature Review of Environmental Assessments of Citrus Processing Systems, with a Focus on the Drying Phase. Sci. Total Environ. 2025, 974, 179219. [Google Scholar] [CrossRef]

- Piron, M.; Bovo, E.; Lucchetta, G.; Manzardo, A. Soft-Sensors to Drive Manufacturing toward Clean Production: LCA Based on Digital Twin. J. Clean. Prod. 2025, 498, 145192. [Google Scholar] [CrossRef]

- Naumann, G.; Famiglietti, J.; Schropp, E.; Motta, M.; Gaderer, M. Dynamic Life Cycle Assessment of European Electricity Generation Based on a Retrospective Approach. Energy Convers. Manag. 2024, 311, 118520. [Google Scholar] [CrossRef]

| Formulation | PVOH [w%] | CF [w%] | Water [w%] |

|---|---|---|---|

| Conventional melt blending | 70 | 30 | 0 |

| Innovative cold blending | 54 | 23 | 23 |

| Zone 1 | Zone 2 | Zone 3 | Zone 4 | Zone 5 | Zone 6 | Zone 7 | Zone 8 |

|---|---|---|---|---|---|---|---|

| 155 | 160 | 165 | 175 | 178 | 180 | 180 | 175 |

| Input or Output Flow | Type of Constituent | Quantity of the Constituent (Per Functional Unit) |

|---|---|---|

| Input | PVOH | 0.7 kg |

| Input | Cellulose fibres | 0.3 kg |

| Input | Oven pre-heating—Electricity | 0.09 kWh |

| Input | Oven drying—Electricity | 1.65 kWh |

| Input | Extruder pre-heating—Electricity | 0.09 kWh |

| Input | Extruder pre-heating—Water | 7.23 L |

| Input | Extruder melt blending—Electricity | 1.40 kWh |

| Input | Extruder melt blending—Water | 77.30 L |

| Input | Biocomposite granulation—Electricity | 0.015 kWh |

| Output | PVOH-cellulose fibres PMC granules | 1 kg |

| Output | Wastewaters (untreated) | 84.53 L |

| Input or Output Flow | Type of Constituent | Quantity of the Constituent (Per Functional Unit) |

|---|---|---|

| Input | PVOH | 0.7 kg |

| Input | Cellulose fibres | 0.3 kg |

| Input | Tap water | 0.3 L |

| Input | Dry blending—Electricity | 0.01 kWh |

| Input | Cold blending—Electricity | 0.07 kWh |

| Input | Oven pre-heating—Electricity | 0.125 kWh |

| Input | Oven drying—Electricity | 1.16 kWh |

| Output | PVOH-cellulose fibres PMC granules | 1 kg |

| Production Process | Young’s Modulus (3%) [MPa] | Tensile Strength [MPa] | Elongation at Break [%] |

|---|---|---|---|

| Conventional melt blending | 242 ± 32 | 12.4 ± 1.4 | 13.4 ± 3.8 |

| Innovative cold blending | 137 ± 15 | 9.5 ± 0.3 | 22.5 ± 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marinelli, A.; Seva, F.; Cigada, A.; Paterlini, L.; Pedeferri, M.; Diamanti, M.V.; Del Curto, B. Innovative Cold Processing of PVOH-Based Composites: A Gate-to-Gate Life Cycle Assessment of Environmental Benefits. Macromol 2025, 5, 30. https://doi.org/10.3390/macromol5030030

Marinelli A, Seva F, Cigada A, Paterlini L, Pedeferri M, Diamanti MV, Del Curto B. Innovative Cold Processing of PVOH-Based Composites: A Gate-to-Gate Life Cycle Assessment of Environmental Benefits. Macromol. 2025; 5(3):30. https://doi.org/10.3390/macromol5030030

Chicago/Turabian StyleMarinelli, Andrea, Fulvio Seva, Alberto Cigada, Luca Paterlini, MariaPia Pedeferri, Maria Vittoria Diamanti, and Barbara Del Curto. 2025. "Innovative Cold Processing of PVOH-Based Composites: A Gate-to-Gate Life Cycle Assessment of Environmental Benefits" Macromol 5, no. 3: 30. https://doi.org/10.3390/macromol5030030

APA StyleMarinelli, A., Seva, F., Cigada, A., Paterlini, L., Pedeferri, M., Diamanti, M. V., & Del Curto, B. (2025). Innovative Cold Processing of PVOH-Based Composites: A Gate-to-Gate Life Cycle Assessment of Environmental Benefits. Macromol, 5(3), 30. https://doi.org/10.3390/macromol5030030