Stability Aspects of UV-Curable Prints on Pressure-Sensitive Labels Facestock Made from Agro-Industrial By-Products

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Determination of Roughness

2.3. Rub Resistance Test

2.4. Chemical Resistance Test

2.5. Determination of Lightfastness

2.6. Determination of Color Difference

3. Results and Discussion

3.1. Roughness of the Samples

3.2. Rub Resistance of the Prints

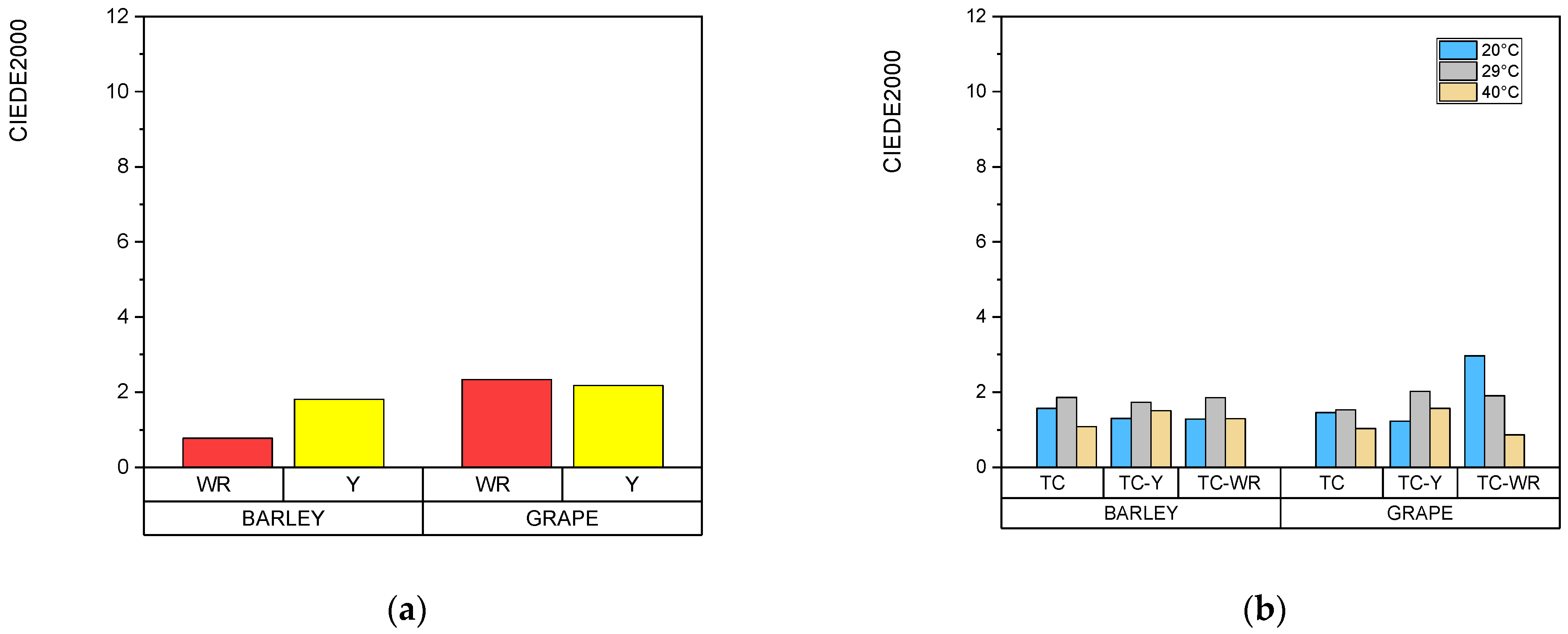

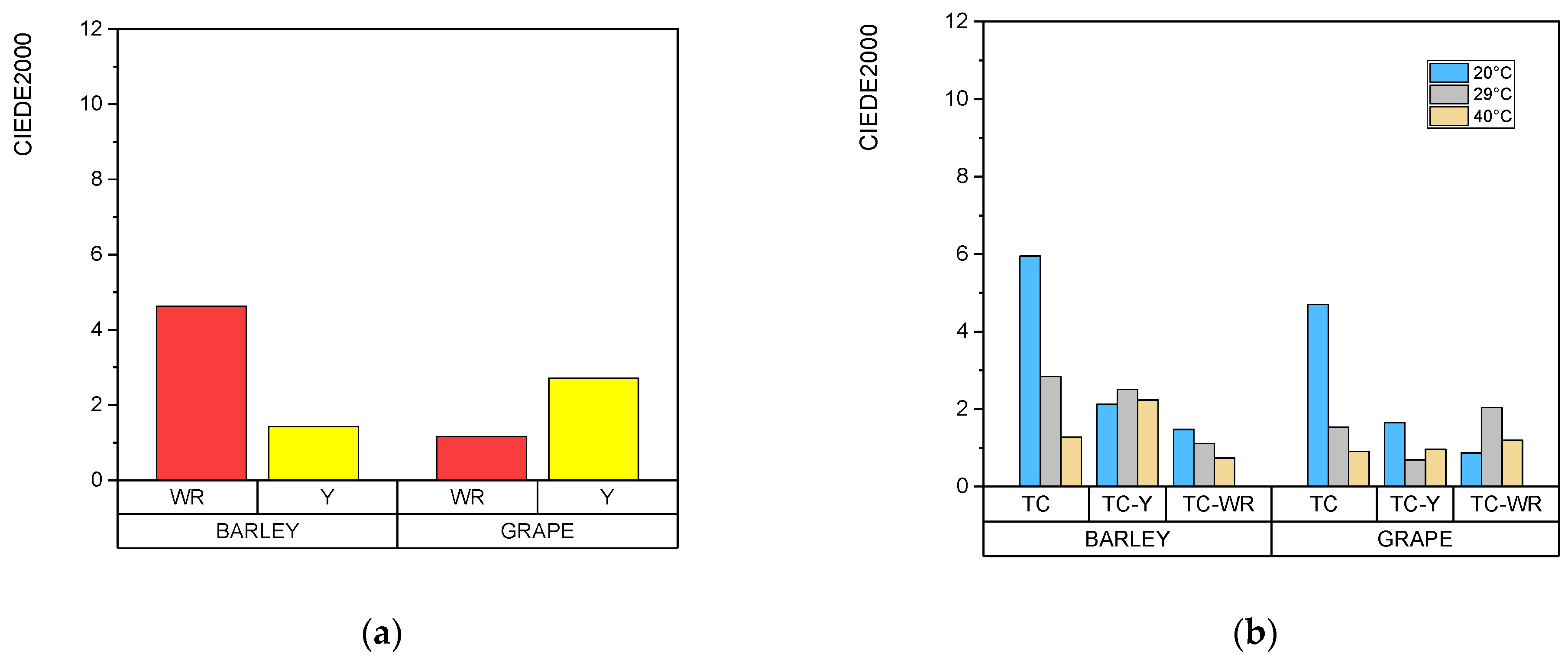

3.3. Chemical Resistance of the Prints

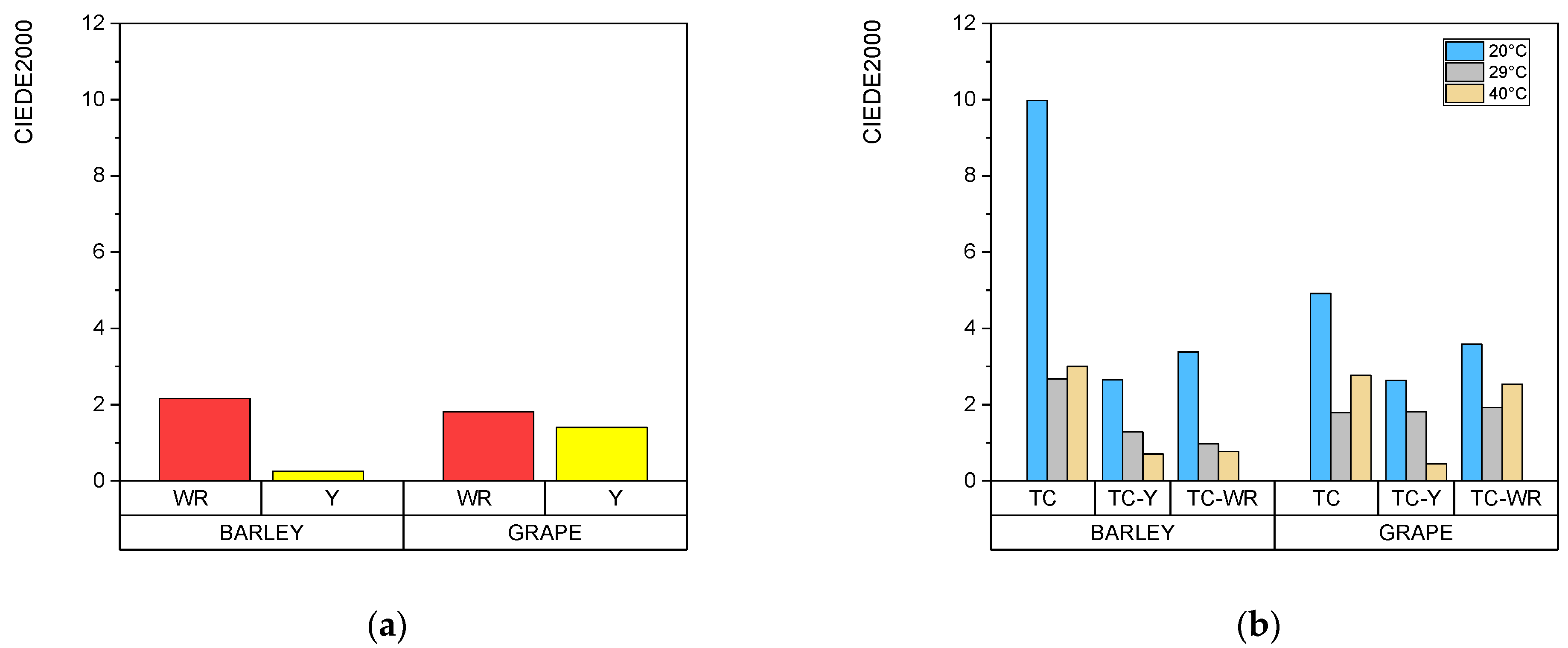

3.4. Light Fastness of Printing Inks

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leach, R.H. The Printing Ink Manual, 5th ed.; Leach, R.H., Pierce, R.J., Hickman, E.P., Mackenzie, M.J., Smith, H.G., Eds.; Springer: Dordrecht, The Netherlands, 2007; ISBN 978-0-948905-81-0. [Google Scholar]

- Robert, T. “Green Ink in All Colors”—Printing Ink from Renewable Resources. Prog. Org. Coat. 2015, 78, 287–292. [Google Scholar] [CrossRef]

- Fischer, A. Deinking—How to Get the Ink Off the Paper. In Inkjet Printing in Industry; Zapka, W., Ed.; Wiley—VCH: Weinheim, Germany, 2022; pp. 449–463. [Google Scholar]

- Yang, S.; Shen, J.; He, T.; Chen, C.; Wang, J.; Tang, Y. Flotation De-Inking for Recycling Paper: Contrasting the Effects of Three Mineral Oil-Free Offset Printing Inks on Its Efficiency. Environ. Sci. Pollut. Res. 2022, 29, 89283–89294. [Google Scholar] [CrossRef] [PubMed]

- Pivnenko, K.; Eriksson, E.; Astrup, T.F. Waste Paper for Recycling: Overview and Identification of Potentially Critical Substances. Waste Manag. 2015, 45, 134–142. [Google Scholar] [CrossRef]

- Jamnicki Hanzer, S.; Kulčar, R.; Vukoje, M.; Marošević Dolovski, A. Assessment of Thermochromic Packaging Prints’ Resistance to UV Radiation and Various Chemical Agents. Polymers 2023, 15, 1208. [Google Scholar] [CrossRef] [PubMed]

- Arman Kandirmaz, E.; Ozcan, A.; Er Ulusoy, D. Production of Thermochromic Microcapsulated Inks for Smart Packaging and Examination of Printability Properties. Pigment Resin Technol. 2020, 49, 273–281. [Google Scholar] [CrossRef]

- Thamrin, E.S.; Warsiki, E.; Bindar, Y.; Kartika, I.A. Thermochromic Ink as a Smart Indicator on Cold Product Packaging—Review. IOP Conf. Ser. Earth Environ. Sci. 2022, 1063, 012021. [Google Scholar] [CrossRef]

- ISO 2836; Graphic Technology—Prints and Printing Inks—Assessment of Resistance of Prints to Various Agents. International Organization for Standardization: Geneva, Switzerland, 2021.

- Medeiros, D.L.; Braghirolli, F.L.; Ramlow, H.; Ferri, G.N.; Kiperstok, A. Environmental Improvement in the Printing Industry: The Case Study of Self-Adhesive Labels. Environ. Sci. Pollut. Res. 2019, 26, 13195–13209. [Google Scholar] [CrossRef]

- Abd El-Sayed, E.S.; El-Sakhawy, M.; El-Sakhawy, M.A.M. Non-Wood Fibers as Raw Material for Pulp and Paper Industry. Nord. Pulp Pap. Res. J. 2020, 35, 215–230. [Google Scholar] [CrossRef]

- AveryDennison Fasson ® RCRUSH GRAPE FSC S2047N-BG45WH IMP FSC 2021. Društvo koloristov Slovenije, Maribor, Slovenia. Available online: https://www.my-muse.com/en/home/materials/eu16-rcrush-grape-fsc.html (accessed on 1 July 2023).

- AveryDennison Fasson ® RCRUSH BARLEY FSC S2030-BG45WH FSC 2021. Društvo koloristov Slovenije, Maribor, Slovenia. Available online: https://www.my-muse.com/en/home/insights/the-graduate-collection/fasson-rcrush-barley-fsc.html (accessed on 1 July 2023).

- Vukoje, M.; Itrić Ivanda, K.; Kulčar, R.; Marošević Dolovski, A. Spectroscopic Stability Studies of Pressure Sensitive Labels Facestock Made from Recycled Post-Consumer Waste and Agro-Industrial By-Products. Forests 2021, 12, 1703. [Google Scholar] [CrossRef]

- ISO 16610; Geometrical Product Specifications (GPS)—Filtration—Part 21: Linear Profile Filters: Gaussian Filters. International Organization for Standardization: Geneva, Switzerland, 2021.

- European Organisation for Tehnical Approval (EOTA). Exposure Procedure for Artificial Weathering—TR 010; European Organisation for Tehnical Approval: Brussels, Belgium, 2004. [Google Scholar]

- ASTM D3424-09; Evaluating the Relative Lightfastness and Weatherability of Printed Mater. ASTM International: West Conshohocken, PA, USA, 2010; Volume 5, pp. 1–5.

- CIE Central Bureau. Colorimetry, 3rd ed.; CIE Central Bureau: Vienna, Austria, 2004; Volume 552. [Google Scholar]

- Schilling, M. Shift Happens… So Measure. Available online: https://inkjetinsight.com/knowledge-base/color-shift-happens-so-measure/ (accessed on 3 February 2023).

- Kumar, M. Barvna Odstopanja v Ofsetnom Tisku. In Interdisciplinarnost Barve 2. del; Jeler, S., Kumar, M., Eds.; Društvo Koloristov Slovenije: Maribor, Slovenia, 2003; pp. 89–100. ISBN 961-90948-0-8. [Google Scholar]

- Eriksen, O.; Johannesen, E.; Gregersen, O.W. The Influence of Paper Surface Roughness on Ink Pigment Distribution. Appita J. 2007, 60, 384–389. [Google Scholar]

- Zhou, W.H.; He, B.H.; Zhang, C.X.; Han, Y. Analysis on Ink Layer Rub Resistance for Coated Paper Prints. Adv. Mater. Res. 2011, 380, 173–178. [Google Scholar] [CrossRef]

- Gajadhur, M.; Stec, A. Improvement of Abrasion Resistance by Over-Varnishing in the Case of Water-Based Flexographic Printing. J. Print Media Technol. Res. 2016, 5, 15–26. [Google Scholar] [CrossRef]

- Rousu, S.; Gustafsson, J.; Preston, J.; Heard, P. Interactions between UV Curing, Hybrid-UV and Sheetfed Offset Inks and Coated Paper—Commercial Print Trials. TAGA J. Tech. Assoc. Graph. Arts 2006, 2, 174–189. [Google Scholar]

- Rožić, M.; Vukoje, M.; Kapović, D.; Marošević, L. Solvents Interactions with Thermochromic Print. J. Graph. Eng. Des. 2017, 8, 19–25. [Google Scholar] [CrossRef]

- Comyn, J. Adhesion Science, 2nd ed.; Royal Society of Chemistry: London, UK, 2021; ISBN 978-1-83916-319-7. [Google Scholar]

- Vukoje, M.; Kulčar, R.; Vrkić, T.; Marošević Dolovski, A. Thermochromic Prints on Beverages Packaging: The Resistance of Printed Labels upon Ethanol. In Proceedings of the The Eleventh International Symposium GRID 2022, Novi Sad, Serbia, 3–5 November 2022; Vladić, G., Ed.; University of Novi Sad: Novi Sad, Serbia, 2022; pp. 123–129. [Google Scholar]

- Plazonić, I.; Barbarić-Mikočević, Ž.; Bates, I.; Malnar, L. Chemical Stability of Prints Made on Hemp Fibre Based Papers. Acta Graph. 2016, 27, 25–30. [Google Scholar]

- Seleš, V.R.; Bates, I.; Plazonić, I.; Rudolf, M.; Zjakić, I. Chemicaland Mechanical Print Stability of Substrates Containing Alternative Non-Wood Fibres. Cellul. Chem. Technol. 2022, 56, 379–389. [Google Scholar] [CrossRef]

- Aydemir, C.; Yenidoğan, S. Light Fastness of Printing Inks: A Review. J. Graph. Eng. Des. 2018, 9, 37–43. [Google Scholar] [CrossRef]

- Nguyen, T.; Gu, X.; Vanlandingham, M.; Byrd, E.; Ryntz, R.; Martin, J.W. Degradation Modes of Crosslinked Coatings Exposed to Photolytic Environment. J. Coat. Technol. Res. 2013, 10, 1–14. [Google Scholar] [CrossRef]

- Groeneveld, I.; Kanelli, M.; Ariese, F.; Van Bommel, M.R. Parameters That Affect the Photodegradation of Dyes and Pigments in Solution and on Substrate—An Overview. Dyes Pigment. 2023, 210, 110999. [Google Scholar] [CrossRef]

| Test Agent | Receptor Surface | Test Duration | Contact Condition |

|---|---|---|---|

| Water (distilled) | filter paper | 24 h | Contact pressure |

| Olive oil | filter paper | 1 h | Contact pressure |

| Ethanol (v/v = 96%) | test tube | 5 min | Immersion |

| Value of Color Difference | Description of Color Difference | Tolerance for Printing Industry |

|---|---|---|

| <0.2 | not visible | Acceptable |

| <0.5 | negligible | |

| 0.2–1.0 | noticeable | |

| 1.0–3.0 | visible, but small | |

| 3.0–6.0 | clearly visible, obvious | Unacceptable |

| 6.0–12.0 | extremely large | |

| >12.0 | unacceptable |

| Substrate | Ra (µm) | Rz (µm) | Rmax (µm) |

|---|---|---|---|

| Grape | 2.860 | 17.725 | 22.918 |

| Barley | 2.853 | 15.782 | 18.930 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malenica, I.; Golik Krizmanić, M.; Vukoje, M.; Kulčar, R.; Itrić Ivanda, K. Stability Aspects of UV-Curable Prints on Pressure-Sensitive Labels Facestock Made from Agro-Industrial By-Products. Macromol 2023, 3, 693-703. https://doi.org/10.3390/macromol3040039

Malenica I, Golik Krizmanić M, Vukoje M, Kulčar R, Itrić Ivanda K. Stability Aspects of UV-Curable Prints on Pressure-Sensitive Labels Facestock Made from Agro-Industrial By-Products. Macromol. 2023; 3(4):693-703. https://doi.org/10.3390/macromol3040039

Chicago/Turabian StyleMalenica, Ivan, Marina Golik Krizmanić, Marina Vukoje, Rahela Kulčar, and Katarina Itrić Ivanda. 2023. "Stability Aspects of UV-Curable Prints on Pressure-Sensitive Labels Facestock Made from Agro-Industrial By-Products" Macromol 3, no. 4: 693-703. https://doi.org/10.3390/macromol3040039

APA StyleMalenica, I., Golik Krizmanić, M., Vukoje, M., Kulčar, R., & Itrić Ivanda, K. (2023). Stability Aspects of UV-Curable Prints on Pressure-Sensitive Labels Facestock Made from Agro-Industrial By-Products. Macromol, 3(4), 693-703. https://doi.org/10.3390/macromol3040039