Abstract

Gasification of residual biomass has emerged as an efficient thermochemical conversion process, applicable to a wide range of uses, such as electricity generation; chemical manufacturing; and the production of liquid biofuels, BioSNG (biomass-based synthetic natural gas), and hydrogen. Thus, gasification of biomass residues not only constitutes an important contribution toward decarbonizing the economy but also promotes the efficient utilization of renewable resources. Although a variety of gasification technologies are available, there are no clear guidelines for selecting the type of gasifier appropriate depending on the feedstock and the desired downstream products. Herein, we propose a gasifier classification model based on an extensive literature review, combined with a multi-criteria decision-making approach. A comprehensive and up-to-date literature review was conducted to gain a thorough understanding of the current state of knowledge in biomass gasification. The different features of the different types of gasifiers, in the context of biomass gasification, are presented and compared. The gasifiers were reviewed and evaluated considering criteria such as processing capacity, syngas quality, process performance, feedstock flexibility, operational and capital costs, environmental impact, and specific equipment features. A multi-criteria classification methodology was evaluated for assessing biomass gasifiers. A case study of such methodology was a applied to determine the best gasifiers for BioSNG inclusion in the natural gas distribution system in a small-scale scenario. Validation was conducted by comparing the matrix findings with commercially implemented gasification projects worldwide.

1. Introduction

Residual biomass, derived from agroindustrial and forestry activities, is a promising alternative to address both the challenge of increasing energy demand and the negative environmental impacts associated with energy consumption [1]. The growing global population has led to increased biomass generation from agriculture, urbanization, and related waste, driving the expansion of the biomass gasification market. This greater biomass availability supports the adoption of gasification technologies as a renewable energy and waste management solution [2]. Moreover, governments and policymakers in various countries are actively providing financial incentives and subsidies to encourage the adoption of renewable energy sources, with a particular focus on waste management [3].

Gasification corresponds to the conversion of any carbonaceous feedstock into a gaseous product mainly consisting of syngas, a mixture of hydrogen and carbon monoxide [4]. The utilization of syngas is anticipated to witness significant growth across diverse applications, encompassing electricity generation, chemical manufacturing, fertilizer production, liquid biofuels, biomass-based synthetic natural gas (BioSNG), and hydrogen production [2]. In general, chemical synthesis does not depend on the source of the syngas. Therefore, advances from coal syngas methanation can usually be transferred to syngas made from biomass. However, coal and biomass differ in composition and mineral matter, which often requires adjustments in the gasification techniques [5]. Thus, the choice of the type of gasifier has a large effect on the syngas composition and consequently on the processes involved in the BioSNG production [4,6].

The need for careful selection of gasification technologies arises from the growing interest in renewable energies and the revalorization of organic waste. However, this is an intricated task due to the variability in the syngas composition, influenced by the gasifying agent and the diversity of available biomass. Distinct types of biomasses and H/C or O/C ratios generate distinct syngas compositions [7]. Although the gasifying agent plays a fundamental role in determining the process thermodynamics and final syngas composition, the influence of the biomass feedstock remains a significant factor that should not be overlooked. Biomass variability, particularly in terms of elemental composition and proximate properties, has a direct impact on syngas yield and quality, introducing technical and economic challenges for scale-up. Therefore, choosing the appropriate gasification technology becomes essential not only to maximize process efficiency, but also to adapt to the specific characteristics of the feedstock and to tailor the syngas composition according to production goals, such as providing the feedstock for fuels and chemicals.

Therefore, choosing the appropriate gasification technology becomes essential to maximize efficiency and adjust the syngas composition according to production goals, such as obtaining BioSNG. Effectively implementing gasification for the production of specific fuels or chemicals comes with challenges, such as a large range of (i) operational conditions, (ii) biomass variability and availability, (iii) scale of the process and (iv) gasification technologies. Furthermore, accounting for gas post-treatments and raw material pre-treatments becomes crucial to ensure the efficiency and sustainability of the gasification process. Given the numerous alternatives and evaluation criteria associated with biomass gasification technologies, a decision-making tool can facilitate the selection process for the production of BioSNG and other related products. Herein, first we present a review of the available gasification technologies in the context of biomass gasification and syngas conversion to BioSNG. Finally, we propose a methodology for the selection of the most adequate gasifiers for BioSNG generation.

2. Biomass Gasification for BioSNG Production

Natural gas is an essential component of the world’s energy supply. Its versatility as a source of electricity and industrial heating and its important role in supporting the energy transition have spiked the demand for this non-renewable resource [8]. However, there is a constraint in its long-term viability as a source of electricity and industrial heating due to its non-renewable nature and the environmental repercussions linked to its consumption [9]. A carbon neutral source of electricity and industrial heating would require that the emissions associated with the combustion were offset by the capture of carbon dioxide during the synthesis of the fuel. One of the alternatives to achieve this carbon neutral fuel is the development of biomass-based synthetic natural gas (BioSNG) [4,10]. BioSNG is methane produced via biomass gasification followed by a methanation reaction [11]. Thus, it is a potential substitute for natural gas, with similar chemical composition, which could benefit from the use of existing facilities for transportation, storage and use. That is, the existing infrastructure for the generation of electricity and heat from natural gas and its transportation could still be used without any additional investments.

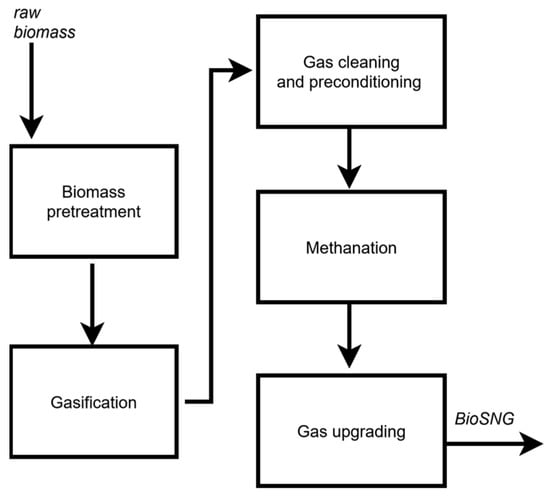

A gasification plant for the production of BioSNG contains five main sections (i) biomass pretreatment; (ii) gasification; (iii) gas cleaning and preconditioning; (iv) methanation and (v) upgrading [12], as shown in Figure 1.

Figure 1.

Block diagram representation of the basic sections required for the production of BioSNG from biomass.

Residual biomass is usually composed of large particle size and low-density materials. These characteristics are a significant limitation for their use in gasification processes. Thus, the biomass pretreatment section involves the initial drying of the biomass feedstock and particle size reduction [13]. The latter requires breaking down the biomass using mechanical processes like shredding, milling and grinding. This increases the surface area of the material, enhancing its reactivity, flowability, and suitability for further processing in the gasification section.

Once the biomass pretreatment is completed the biomass can be taken to the gasification section. The biomass gasification process involves the conversion of solid or liquid organic compounds into gas/vapor phase and a solid phase [6,14,15]. The resulting gas phase, commonly referred to as “syngas,” is an important building block in the chemical industry. The solid phase, known as “char,” consists of the unconverted organic fraction and the inert materials present in the treated biomass. Additional byproducts are also generated during the gasification process, such as tar and ashes. Tar can cause operational problems if not properly controlled, while ashes must be properly managed to prevent environmental impacts and ensure the reliable operation of the system. Chemical reactions in the gasification process lead to partial oxidation of carbon in the feedstock, facilitated by a gasifying carrier such as oxygen, air, steam, or carbon dioxide. In the gasifier, biomass undergoes reaction steps, including drying, pyrolysis, partial oxidation, and reduction [6,15]:

- (1)

- Heating and drying involves the removal of moisture from the biomass through heating, and many gasification systems utilize biomass with a moisture range of 10 to 20% to produce a high-calorific-value gas [6,16,17]. Drying is considered complete when the process temperature exceeds 150 °C [6,18]. The steam released during moisture evaporation can contribute to additional chemical reactions, significantly impacting gasification efficiency and product composition.

- (2)

- Pyrolysis is the thermochemical decomposition of the carbonaceous materials matrix, promoting the formation of molecules with lower molecular weight. This occurs at temperatures ranging from 200 to 700 °C in the absence of an oxidizing agent [6,17,18]. The process yields solid, liquid, and gaseous fractions. The solid fraction, high in carbon content and heating value, consists of inert materials like ash and char. The liquid fraction, known as tars, comprises complex organic substances condensable at relatively low temperatures. The gaseous fraction, called pyrolysis gas, mainly consists of hydrogen, carbon monoxide, carbon dioxide, and light hydrocarbons [19].

- (3)

- The partial oxidation step is essential to generate the thermal energy required for endothermic processes, maintaining the operating temperature at the necessary level. Executed under low oxygen supply, this step oxidizes a small portion of the carbonaceous species. Primary reactions in this phase include char combustion, partial oxidation, and hydrogen combustion, resulting in a gas mixture of carbon monoxide, carbon dioxide, and water [17].

- (4)

- The reduction phase involves products from the pyrolysis and oxidation stages, where gas mixtures and char react to form the final syngas [6]. Key reactions in this step include shift conversion, Boudouard reaction, water-gas shift (WGS) and methanation [15,20]. The temperature during the reduction step significantly influences the syngas composition and properties [21]. Additionally, char’s reactivity, controlled by factors such as heating rate, pyrolysis temperature, inorganic components, and pyrolysis pressure, determines the pace of the reduction reaction and the residence time of the gasification process [22].

In some gasifier types, such as fluidized bed and plasma, there is no clear spatially distinguishable reaction zones. In this sense, although the individual reaction zones are not spatially separated, the key phenomena pyrolysis, oxidation, and reduction still occur, albeit in a dispersed and simultaneous manner within the fluidized medium. Therefore, their modeling and analysis require approaches, based on multiphase kinetics and reactor hydrodynamics rather than on spatial stratification. Nevertheless, it is important to clarify that while the type of reactor significantly influences the rate at which the gasification processes occur, it does not fundamentally alter the nature of the chemical reactions themselves. This principle is consistent with classical reaction engineering fundamentals, where reactor design primarily affects conversion, residence time, and heat/mass transfer efficiencies, but not the stoichiometry or pathway of the chemical reactions involved.

The outlet of the gasification is a mixture of hydrogen, carbon monoxide, light hydrocarbons, carbon dioxide, and undesired byproducts such as particulate matter, inorganic pollutants, organic pollutants (tars), and ash are also produced. The composition, tar content, and dust content in the raw gas before gas cleaning can be adjusted by factors such as temperature, moisture, gasification agent, gasifier geometry, and others. Tars or undesirable byproducts after gasification must be removed in the cleaning and preconditioning section to produce high-quality syngas. Partial oxidation, tar cracking, and steam reforming are potential mechanisms for transforming these byproducts [6,22]. The sensible heat of the raw syngas can be utilized for this reaction by integrating the process as the gas exits the gasifier.

Thus, the subsequent step after gasification involves syngas cleaning. The cleaning methods include filtration, quenching/scrubbing and different adsorption technologies, that depend on the feedstock used in the gasification process and the syngas application requirements [23,24,25,26,27]. Tar reforming technologies use thermal and/or catalytic methods to break down tars and heavy hydrocarbons into H2 and CO [28,29]. An integrated multisystem approach for the removal of various contaminants has been deemed essential for effective syngas cleaning [23]. For a gasification plant aiming to produce BioSNG, achieving the right concentrations of reactants (H2 and CO) in the methanation reaction is crucial. Thus, preconditioning requires adjusting the H2/CO molar ratio for BioSNG production, which should be ~3 [30,31]. The adjustment of this ratio can be done via the WGS reaction (CO + H2O ↔ H2 + CO2), aided by a catalyst [30,32].

BioSNG can be produced through methanation, where carbon monoxide and hydrogen from the cleaned and preconditioned syngas are converted into methane in an exothermic reaction [30,33]. Nickel is a typical catalyst for methanation due to its selectivity, activity, and cost-effectiveness, although other metals like Ru, Rh, Pt, Fe, and Co can also be used [34,35]. Note that these catalysts are vulnerable to poisons such as sulfur and chlorine species. Following the methanation process, a final upgrade of the raw synthetic natural gas is necessary. This upgrade involves the removal of carbon dioxide and water to meet regulatory quality specifications [30,35].

3. Gasification Technologies

In recent decades, there has been notable development in gasifier reactors, catering to various applications. Current commercial gasification technologies are categorized based on factors such as heat supply method, supplied gasifying agent, and reactor type [24,36]. Gasifiers typically belong to three primary categories: fixed bed (downdraft, updraft and cross-draft) [37,38], fluidized bed (bubbling and circulating) [39,40], and entrained fluidized bed [6,41]. Moreover, plasma [42] and rotary kiln gasifiers [43] are also commercialized. Each type serves specific scales of operation, aligning with the characteristics of biomass and the intended application of synthesis gas.

There are several works highlighting the advantages and disadvantages of different types of gasifier [6,43,44,45], such as conventional gasifiers (fixed-bed, fluidized-bed, entrained-flow, rotary kiln, and plasma reactors) and emerging technologies (catalytic, microwave, ionic, and supercritical water gasifiers). Herein, we summarize the available gasifier technologies, focusing on the relevant characteristics for production of BioSNG.

3.1. Fixed-Bed Gasifiers

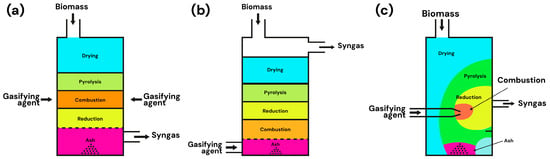

Fixed-bed gasifiers are a technology that uses a slow-movement system [24,44]. They can be classified as (i) updraft, (ii) downdraft, or (iii) cross draft (see Figure 2). In conventional updraft gasifiers, biomass is introduced at the top of the gasifier, while gasifying agents are introduced at the side or at the bottom of the reactor. The synthesis gas moves upward through the reactor and is delivered at an upper level of the bed, while ashes fall at the bottom [46]. In the downdraft reactor, the raw material enters at the top of the reactor, the gasification agents enter from the side or the top of the gasifier, and the synthesis gas moves downward to the bottom of the bed [47]. In cross draft gasifiers, both the biomass feed and ash removal occur vertically, while the gasifying agent is introduced horizontally from the side. Cross-draft reactors represent a less common configuration among fixed-bed gasifier designs and are characterized by a lateral injection of the gasifying agent that flows horizontally across the biomass bed [48]. This geometry promotes rapid combustion of the feedstock, which can enable a faster thermal response and generate high-temperature syngas. These gasifiers can achieve reasonable thermal efficiencies in small-scale cogeneration applications; however, their commercial deployment has been limited due to challenges in controlling tar content and syngas heterogeneity, especially when using residual biomass. As such, their operation requires tightly controlled conditions and uniform fuel composition to maintain stable performance. In this kind of fixed-bed gasifier, the combustion and reduction zones are concentrated near the air inlet, and the syngas is extracted from the opposite side of the reactor (Figure 2c). This configuration allows for rapid response and high-temperature operation but often leads to incomplete tar cracking due to the short gas residence time in the high temperature zone [49].

Figure 2.

Schematics of Fixed-Bed Gasifiers: (a) Updraft, (b) Downdraft, and (c) Cross draft configurations.

Fixed-bed gasifiers operate within a temperature range of 900 to 1200 °C and at pressures ranging from 1 to 100 bar [44]. This technology stands out for its extended residence time, which typically ranges from 5 to 30 min, depending on the reactor configuration and operating conditions [15]. This prolonged residence time is a key feature that differentiates fixed-bed gasifiers from other types, such as fluidized-bed and entrained-flow gasifiers. This plays a crucial role in the operational process by facilitating a more efficient breakdown of the feed materials [6,45]. This contributes to waste minimization, thereby optimizing the conversion of inputs into energy products or synthesis gas. The updraft gasifier typically produces syngas with a lower heating value and higher tar content compared to other gasification technologies. Thus, in order to improve the quality of the syngas, particularly its composition and heating value, it is necessary to operate at higher temperatures and to optimize the airflow rate to enhance partial oxidation reactions [50].

Fixed-bed gasifiers are flexible concerning the biomass feedstock, allowing for high variability in the particle size and moisture contents ranging from 5% to 55% [50]. However, it is essential to note that, unlike other types of gasifiers, fixed-bed gasifiers may require some form of pretreatment (e.g., torrefaction and pelletization) to adapt the feedstock [51].

These technologies have reached an advanced level of maturity in terms of technology readiness levels (TRL). Most fixed-bed gasifiers are at TRL level 9 [52], suggesting that these facilities have successfully passed the stages of experimental and demonstrative development, having achieved full validation in real operational environments. Whether in updraft or downdraft configurations, fixed-bed gasifiers are renowned for their simple construction and operation. They offer high carbon conversion, extended solid residence times, and low ash and tar carryover [53]. In particular, the updraft process stands out for its high thermal efficiency, albeit with the drawbacks of producing tar-rich gas and a higher cost of electricity due to higher capital investment and production costs, whereas the downdraft fixed-bed system economic performance is strongly linked to its size, with larger installations showing overall better economic performance [24,44].

3.2. Fluidized-Bed Gasifiers

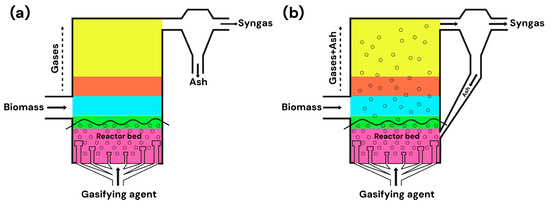

A fluidized bed gasifier is a well-stirred type of reactor, where a bed of solid biomass particles are suspended and agitated by a gas flowing upwards through it, as shown in Figure 3. This continuous mixing process promotes uniform temperatures throughout the bed [6,44,54]. The gas inlet into the reactor, which may contain oxygen, steam, and recycled syngas, must be sufficient to keep the particles suspended in the bed but not so high as to carry them out of the reactor. As the particles are gasified, they become smaller and lighter, which can lead to their entrainment out of the reactor. It is essential that the temperatures within the bed remain below the initial ash fusion temperature of the biomass to prevent particle agglomeration [6,55]. A cyclone is typically employed downstream of various gasifier types to remove larger entrained particles from the product gas stream. In circulating fluidized-bed gasifiers (CFB), the cyclone captures solid particles, such as unconverted char and bed material, which are then recirculated back into the reactor to enhance conversion efficiency and maintain the biomass load inside the gasifier. In contrast, in bubbling fluidized-bed gasifiers (BFB), the cyclone primarily functions to separate particulate matter from the syngas, as these systems do not involve continuous solids recirculation [54,56].

Figure 3.

Schematics of Fluidized-Bed Gasifiers: (a) Bubbling fluidized bed, and (b) Circulating fluidized bed configurations.

In fluidized bed gasifiers, beds are composed of materials such as sand, olivine, limestone, dolomite, or alumina fluidized with air, oxygen, and/or steam [6,55]. Fluidized bed gasifiers exhibit improved mixing capabilities and higher heat transfer rates compared to fixed-bed gasifiers, resulting in a more uniform bed and ultimately higher reaction rates and conversions. Furthermore, fluidized bed gasifiers show higher mass flow rates, feeding flexibility, scalability, and moderate tar and particulate production compared to updraft gasifiers [6,57]. Fluidized bed gasifiers offer significant advantages in terms of biomass flexibility and raw material specifications, with various types of reactors that can accommodate different needs and production scales.

Small particle size for the biomass (<40 mm) is highly recommended in fluidized bed gasification because the smaller the biomass particles introduced into the reactor, the greater their specific surface area. This reduces the time required for heat transfer from the particle walls to the center, resulting in higher chemical reaction rates. Additionally, the use of small particles contributes to achieving higher overall gas yields (higher H2 concentrations), and lower carbon and tar yields [58]. A moisture content of around 15% by weight in the feedstock is recommended [6]. The syngas improvement process in fluidized bed gasification involves the removal of tar from the syngas using mechanical, thermal, and catalytic methods.

Biomass fluidized bed gasifiers are highly scalable due to several key advantages: (i) they can process a wide range of biomass types, which is essential to adapt to environments with variations in fuel availability; (ii) they can also handle biomass with small particles, providing flexibility in choosing the raw material; (iii) they produce moderate amounts of tar and particles, making byproduct management easier in different production scales; and (iv) they can operate in bubbling (BFB) or circulating modes (CFB), thus adapting to various applications and production scales. This versatility and flexibility contribute to their scalability [6,45].

3.3. Entrained Flow Gasifier

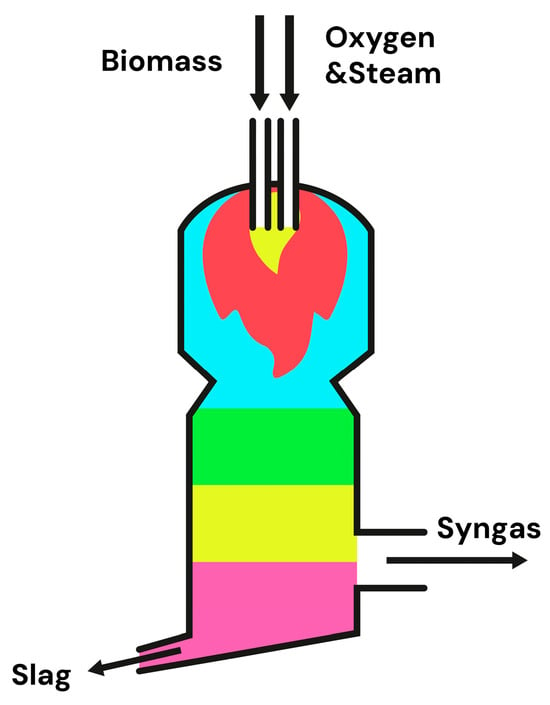

In entrained-flow gasifiers, finely ground biomass is injected into the reactor along with a gasifying agent (typically steam and oxygen) in a co-current flow configuration. Unlike air-blown systems, these gasifiers commonly use oxygen as the oxidant to improve energy efficiency [50]. As illustrated in Figure 4, the fuel and gasifying agents enter the reactor simultaneously and in the same direction, promoting rapid reactions due to high operating temperatures and fine particle sizes [44,45].

Figure 4.

Schematics of Entrained flow gasifier.

This process results in a rapid increase in the temperature of the solid fuel and its reaction with the oxidant. What sets apart entrained flow gasifiers is the short residence time of the material in the gasifier, typically of the order of seconds. Due to this short residence time, entrained flow gasifiers must operate at high temperatures to achieve high carbon conversion. Therefore, most of these gasifiers use oxygen instead of air and operate above the slagging temperature [59,60]. Entrained flow gasification of coal has commercial use in integrated gasification combined cycle (IGCC) plants and the chemical industry [61], however commercial implementation for biomass is still pending.

The high-temperature operation leads to slag formation and entrainment of some molten slag in the raw syngas [45]. Syngas upgrading is achieved by maintaining a uniform temperature in biomass particles, which allows for a more complete reaction and improves the quality of the produced gas. In general, temperature and residence time influence gas composition and gasification efficiency, while particle size has a minimal effect on the H2/CO ratio [6]. Due to the high operating temperatures and the relatively large amount of oxidant required, the raw syngas produced contain a significant amount of sensible heat. Additionally, entrained-flow gasifiers offer the flexibility to process a wide range of biomasses, regardless of their agglomeration behavior or fine particle content [50]. This technology requires a reduced particle size of the biomass, ideally up to 2 mm, and low moisture content, preferably below 5% [60]. It is worth noting that, although a low moisture content is preferred, this gasifier still allows for working with slightly higher percentages, providing operational flexibility in terms of biomass composition.

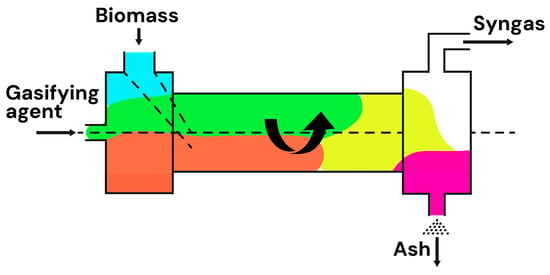

3.4. Rotary Kiln Gasifier

The slow rotation of the rotary bed gasifier or rotary kiln reactor ensures a uniform heat distribution, favoring high efficiency in converting materials into syngas [60]. The inclination of the rotating bed toward the exit end facilitates the movement of the fed material along the reactor, allowing for prolonged exposure to gasification conditions. As shown in Figure 5 the injection of gasifying agents at the bottom of the furnace promotes an effective chemical reaction with the fed material, thus generating the desired syngas [50].

Figure 5.

Schematics of Rotary kiln gasifier.

This type of gasifier stands out for its remarkable flexibility in working with a wide range of types and sizes of biomass particles. It can process extremely small biomass particles, even less than 1 mm, allowing for efficient management of finely crushed biomass [62]. Moreover, it allows the use of larger particles, up to 50 mm, opening possibilities for handling biomass with diverse particle size distributions. This versatility is not limited only to particle size, as the rotary bed gasifier can process different types of biomasses [50].

The rotary kiln reactor operates over a wide range of temperatures, from low temperatures around 450 °C to reaching up to 1000 °C [60,63]. This temperature variability allows adaptation to different processing requirements, either to maximize gasification efficiency or to meet specific production goals. In terms of pressure, the rotary kiln reactor also offers flexibility, operating in a pressure range of 20 to 80 bar [60]. This technology uses prolonged residence times, which contributes to obtaining high-quality syngas.

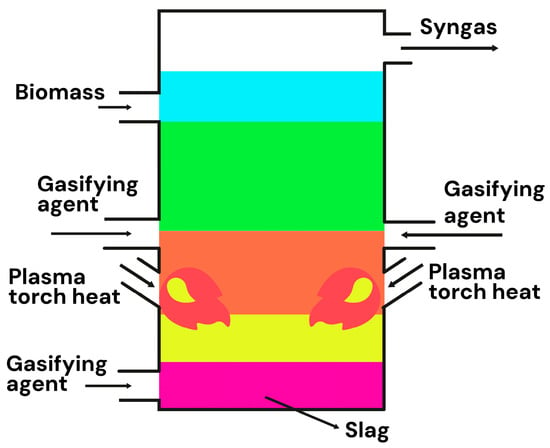

3.5. Plasma Gasifier

Plasma gasification is an innovative technology that uses electrically ionized gas at temperatures of up to 10,000 °C through plasma torches at pressures ranging from 1 to 30 bars to break down feedstock into synthesis gas and form slag [6,50,60]. A schematic of a plasma reactor is shown in Figure 6. The feedstock is introduced at the top of the chamber, while the gasifying agent is introduced at the side of the reactor to activate the reactions. Plasmas create a superheated column of electrical conductivity that results in a high temperature in the reactor, allowing for the vaporization and ionization of the biomass. Compared to conventional gasification, this technology uses energy more efficiently to generate free radicals that initiate gasification reactions, accelerating the conversion of carbon in fuel particles [6,64].

Figure 6.

Schematics of Plasma gasifier.

Plasma gasification enhances flexibility in biomass feedstock, as it allows working with almost any type of feedstock and particle sizes, typically in the range of 6 mm. This technology can be used to break down hazardous and non-hazardous waste such as municipal solid waste, biomass, tires, and refuse derived fuels into gas phase products [6,38]. Biomass feed becomes more versatile and efficient with plasma-assisted gasification, expanding the range of usable biomass options and improving the conversion into synthesis gas. Additionally, it can handle biomasses with different moisture percentages, due to the application of high temperatures [65]. The residence time in plasma gasification is extremely short due to the very rapid reaction kinetics enabled by the intensely high temperatures generated by the plasma torch. As a result, the gasification process occurs in milliseconds to a few seconds [38,50].

The scalability of the plasma gasifier presents some challenges, especially in terms of the high energy input required by thermal plasmas [66]. Plasma gasification technology is classified as moderate to high TRL (around 8) [67]. Although it has progressed in terms of TRL, it has not yet reached all levels, indicating that there is still room for ongoing developments and improvements [6]. The technology has reached prototype demonstrations and validations in relevant operational environments [65]; however, commercial maturity goes beyond TRLs and focuses on practical and economic considerations. It is emphasized that the high energy demand, approximately between 1200 and 2500 MJ per ton of municipal solid waste [38], could be a significant challenge from both operational and economic perspectives. The costs associated with electricity generation to power plasma reactors can influence the commercial viability of this technology.

3.6. Emerging Technologies

Four emerging technologies for gasifiers are under development [68]: (i) catalytic [69], (ii) microwave [70], (iii) ionic [71], and (iv) supercritical water gasifiers [72]. According to the IEA these technologies have achieved a TRL above 5, indicating successful testing in relevant environments and potential for near-future deployment [68]. The catalytic biomass gasification technology involves a two-stage process where a primary gasification step is followed by a catalytic reforming or cleaning stage. Catalysts such as nickel-based or dolomite materials are used to enhance tar reforming and increase hydrogen yield, improving syngas quality and reducing downstream cleaning requirements [67]. Microwave-assisted gasification is a variation in plasma gasification in which microwave radiation serves as the heating source, generating localized, high-temperature plasma zones [70,73]. The ionic gasifiers use ionized gases (plasma arcs) to reach temperatures over 3000 °C, allowing an almost complete conversion of organic matter into value-added products [71]. The supercritical water gasifier can operate under supercritical water conditions (374 °C and 22.1 MPa). It is advantageous when the biomass being used has a high moisture content, since this solvent is in direct contact with the biomass and the supercritical conditions improve solubility during the process [72].

3.7. Comparison of Gasification Technologies

In this review, the gasifiers considered for the production of syngas suitable for synthesizing BioSNG were downdraft, updraft and cross draft fixed-bed, bubbling and circulating fluidized-bed, entrained flow, plasma and rotary kiln, this selection was made based on the biomass gasification background found for these equipment [6,72,73]. A summary of the main advantages of these gasification technologies is presented in Table 1. Fixed-bed gasifiers are suitable for small-scale operations due to their low cost, but as the scale increases, fluidized bed gasifiers become more efficient, because of their scalability and lower costs compared to entrained flow and plasma gasifiers. Nevertheless, there are two main strategies for increasing the production capacity of a gasifier: scaling-up and numbering-up. Scale-up consists of enlarging the physical dimensions and capacity of a single unit, which generally requires redesigning components and adapting operating parameters to handle larger volumes. In contrast, numbering-up involves installing and operating multiple units in parallel while maintaining the original size and design of each unit. This latter approach is common in modular technologies, as it allows for increasing the total production capacity without facing the technical and economic limitations often associated with scale-up. The use of numbering-up makes it possible to achieve overall production scales greater than what a single unit could deliver, even when the individual capacity of the technology is limited. This means that the nominal scale of a unit should not be taken as the only reason to exclude technology from the analysis, particularly if the technology offers significant advantages in areas such as gas quality, feedstock flexibility, or regulatory compliance.

Table 1.

Summary of the main advantages and disadvantages of conventional gasification technologies.

As shown in Table 1 rotary kiln and plasma gasifiers can handle high-moisture biomass and larger particles, offering greater versatility, while entrained flow gasifiers are less flexible in terms of biomass. Higher operating temperatures enhance gasification reactions, leading to higher H2 and CO yields and less tar [74]. Plasma and entrained flow gasifiers, operating at high temperatures, can yield high-quality syngas. However, lower outlet gas temperatures are ideal for downstream processes, with updraft gasifiers showing the best performance in this area. Syngas yield is higher in downdraft gasifiers compared to updraft types. Bubbling bed gasifiers achieve the highest yields, making them highly efficient for biomass gasification. Circulating fluidized bed and plasma gasifiers also perform well, while rotary kilns produce lower yields due to their lower temperatures. Entrained flow gasifiers, with their low biomass compatibility, show the poorest syngas yields.

Although cross-draft gasifiers offer specific advantages in terms of compact design and fast thermal response, they were not included in the multi-criteria analysis due to their limited representation in commercial applications using residual biomass as feedstock (See Table S4). The available literature on their technical, economic, and environmental performance in BioSNG production contexts is scarce and fragmented. This lack of comparable data regarding gas quality, conversion efficiency, and operating costs prevented their objective evaluation within the framework proposed in this study. Nevertheless, the potential of cross-draft gasifiers in specific niches is acknowledged, and their inclusion could be considered in future studies.

The selection of the best type of gasifier is application and context specific. This must account for multiple criteria, including economic viability, operational flexibility in handling feedstock variability, maintenance demands, production throughput, energy efficiency, syngas composition and quality, as well as environmental performance. Table 2 presents a quantitative and qualitative comparison of different parameters in the gasifiers that can have an influence in the selection of the best type of gasifier for a given application.

Table 2.

Comparative performance of gasifier types. Quantitative and qualitative data from the literature were synthesized to evaluate the advantages of different gasifiers, the data collected is provided in Supplementary Materials (Table S1).

For the production of BioSNG it is suggested that the H2/CO ratio of the syngas should be adjusted to approximately three [23]. For methanation, moderate to high CO concentrations are ideal. Moreover, if the H2/CO ratio falls below three, it can be adjusted through the water-gas shift reaction [25]. On the other hand, reducing CO2 production is crucial for syngas intended for methanation [76]. Downdraft, bubbling bed, and rotary kiln gasifiers can produce syngas with low CO2 concentrations. Plasma, updraft, and entrained flow gasifiers can also achieve low CO2 levels, but their typical concentration ranges are broader. Circulating bed gasifiers similarly exhibit a wide range of CO2 concentrations, but their lower limit is higher compared to other gasifier types.

The challenge of tar production manifests mainly in updraft gasifiers, where an increased generation is observed. On the contrary, plasma gasifiers produce little to no tar, while downdraft and rotary kilns also have low tar generation. Entrained flow and fluidized bed gasifiers have wider tar ranges but can produce low concentrations. The data in Table 2 provides general guidance for selecting gasification equipment.

Various gasification technologies are currently implemented in demonstration or commercial-scale projects in several countries. Documented examples in Europe and North America include plants utilizing fixed-bed, fluidized-bed, and entrained-flow gasifiers. These facilities are applied in combined heat and power (CHP) generation, industrial boiler operation, Fischer–Tropsch synthesis for liquid fuels, and the production of BioSNG. Examples of such implementations include plants located in Skive (Denmark), Güssing and Oberwart (Austria), and the BioSNG production projects developed by Goteborg Energi and E.On in Sweden (see Table S4). These developments represent significant progress towards the commercial deployment of biomass gasification as a viable option for the production of sustainable energy carriers.

4. Gasifier Selection for BioSNG

Multicriteria decision making (MCDM) approaches have been applied extensively in the chemical engineering field [116,117,118,119]. Herein, the gasifier selection matrix was developed in line to the approach proposed by Kaneesamkandi et al. [120] and it was complemented with the Analytic Hierarchy Process (AHP) weighting method for the selection of chemical engineering equipment [116]. The Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) method was employed to normalize the values for the performance attributes and analyze the results of the selection matrix.

Multiple MCDM techniques have been employed to support the selection of energy technologies, particularly in gasification contexts. However, there are significant differences in the ability of these techniques to represent specific contexts or incorporate technical/regulatory constraints. AHP–TOPSIS has been one of the most widely used approaches due to its ease of implementation and its ability to discriminate between alternatives based on their closeness to the ideal solution. However, previous studies have applied this technique without incorporating regulatory parameters that are critical for the real-world feasibility of BioSNG projects [116,119], which limits the direct applicability of their results in contexts where strict gas quality standards exist.

Other approaches, such as AHP–VIKOR or ANP–TOPSIS, offer advantages in handling interdependencies between criteria or managing conflicts among them. Nevertheless, these methods also require greater data input and present higher methodological complexity, which can hinder their practical application especially when working across multiple production scales or when expert input is not available for all technical dimensions involved.

The proposed decision-making approach is mainly focused on technical criteria rather than cost-related criteria. Capital investment estimates were obtained from some of the leading gasifier manufacturers worldwide, while operational costs were based on values reported in the literature [60,121,122,123,124,125]. The decision matrix accounted for different categories including (i) economic viability, (ii) operational flexibility, (iii) equipment features, (iv) production throughput, (v) process performance, (vi) syngas quality and (vii) environmental performance. Table 3 presents the selected criteria in each category or subgroup and the units of measurement used for each criterion. The decision matrix seeks to optimize each of these criteria to their optimal levels. For instance, the feedstock flexibility was maximized to avoid biomass preprocessing [76,126]. The capacity-related criteria were evaluated based on target syngas production rates defined according to the specific need and production constraints of the specific scenario under analysis; the technical complexity was minimized due to its impact on equipment operation, process control and investment, operational and maintenance costs [119,126]. Tar yield was minimized, because it is undesirable and costly for the syngas upgrading process [74]. CO2 concentration was minimized, because it can reduce the CH4 productivity in the methanation reaction; CO and H2 concentrations were maximized due to their importance as reactants in the methanation reaction [87,126]. The target H2/CO molar ratio was set at 3, as dictated by the methanation reaction [78,127,128]. Gas yield and carbon conversion were maximized to fully utilize the biomass input; and cold gas efficiency was maximized to preserve as much of the biomass’s calorific value as possible in the produced syngas.

Table 3.

Clustering of performance criteria into subgroups as considered in the selection matrix, and the corresponding units for the values in the database.

The criteria marked as scored corresponds to either qualitative variables converted to quantitative data or quantitative data that was normalized to avoid artifacts in the optimization procedure (see Table S1). Operating cost, technical complexity and biomass flexibility were rated on a discrete scale from 1 to 4 according to the range of values reported in the literature. Logarithmic normalization was applied to capital cost and tar yield, which had highly skewed distributions and/or wide ranges of values. For the remaining quantitative variables, a Euclidean normalization approach was used. This tailored approach ensured more balanced scoring across criteria and minimized the influence of outliers in the decision-making process [129,130,131,132].

The entropy weight method [120,132] was used to calculate the relative weights of each criterion clustered in a subgroup (see Table 3). The AHP method [116,133] was implemented to estimate the weight of each subgroup, and was carried out in a decision matrix, where the relative importance of each subgroup was evaluated through pairwise comparisons. The linear judgement scale was selected due to its balance between consistency and allocation of priority [116,134]. The scale ranges from 1 to 9, with 1 corresponding to criteria of equal importance and 9 for criteria of extreme importance [134].

Table 4 presents a pairwise comparison matrix to evaluate the relative importance of the evaluation groups using the AHP method. For the selection of gasifiers for BioSNG production, this evaluation was based on the need to ensure compliance with regulatory requirements for the injection of BioSNG into the natural gas transmission network. In particular, standards for BioSNG injection such as EN 16723-1 and EN 16723-2, which establish quality specifications for gas injection into the network [135,136]. In this context, priority was given to the criteria most directly related to regulatory compliance, namely syngas quality and process performance, which received the highest relative importance in the AHP matrix. The values in the matrix were defined through expert judgment using the Saaty fundamental scale, which is commonly used in AHP evaluations. In this study, the evaluation was conducted by experts with experience in thermochemical processes and renewable gas production, considering the specific application of BioSNG for injection into the natural gas grid. The assigned weights reflect regulatory compliance priorities, particularly focusing on syngas quality and process performance, which are critical to meeting specifications such as methane content, contaminant removal, and energy content. For instance, the “Economical” criterion was rated significantly higher than others (8 over feedstock flexibility and equipment features), reflecting the cost-driven nature of industrial implementation; “Process performance” and “Syngas quality” were rated as more important than most criteria (for example, 4 to 6 times more important than capacity or environmental factors), since achieving stable conversion efficiency and a clean, high-quality syngas is essential for BioSNG projects targeting grid injection; and “Environmental” aspects, while relevant, were rated lower when compared to the technical feasibility and compliance-driven factors. For the environmental factors instead of using comprehensive methods, such as life cycle analysis (LCA), only the greenhouse gas and particulate matter emissions were considered given the limited availability of reliable and comparable studies using LCA for biomass gasification in different gasifiers. This structured judgment process ensures transparency and alignment with technical and regulatory priorities in the context of renewable gas deployment.

Table 4.

Pairwise comparison matrix of the evaluation groups using the AHP method.

Monte Carlo simulations were used to estimate the confidence intervals of the results. In this study, 200,000 simulations were produced by randomly changing the parameters by ±10%, when under the upper limit for the parameter. The resulting consistency ratio was between 0.02 and 0.05, indicating a satisfactory level of coherence in the pairwise evaluation of the criteria and the tolerance to fluctuations in the AHP matrix.

The model organizes the selection problem into the seven subgroups presented in Table 3. Each group is composed of specific criteria that reflect the key attributes influencing gasifier selection, and these are connected to the seven gasification technologies considered in this study. This structure was used to implement the methodology [137,138,139]. Details on the implementations of the methodology are presented in the Supplementary Materials.

According to the pairwise comparison matrix and the individual criteria, the weights of each criterion in the technology selection process were calculated, showing that: gas quality emerged as the most influential evaluation subgroup, highlighting the importance of syngas composition for downstream applications such as methanation and grid injection. Within this subgroup, CO2 concentration in syngas received the highest weight of all individual criteria, indicating the need to minimize CO2 to ensure methane synthesis efficiency and regulatory compliance. Tar yield and H2/CO molar ratio also showed significant weights, confirming their importance for gas purity and compatibility with catalytic upgrading processes. Process performance was the second most relevant subgroup, indicating the importance of energy efficiency indicators. Syngas yield held a notable weight, emphasizing the advantage of technologies that maximize the gas output per unit of biomass. Cold gas efficiency followed, as a reflection of how effectively energy content is preserved through the gasification process. Economic criteria represented the third most influential subgroup. Operating cost contributed a significantly higher weight than capital costs, suggesting that long-term operating expenses are more decisive in technology selection than initial investment costs. Environmental criteria received a moderate overall weight. While environmental impact is acknowledged as an important factor in the adoption of these technologies, it has lower variability across technologies compared to performance and gas quality indicators. Capacity received a relatively low combined weight, not due to low variability in the data across technologies, but rather because it was assigned lower relative importance within the context defined for this study. This is attributed to the fact that capacity is not a parameter constrained by regulatory requirements for BioSNG injection into the natural gas grid, and therefore, it was considered a secondary factor in the decision-making process. Equipment features and feedstock flexibility showed the lowest overall influence. This may indicate lower variation among gasifiers in these aspects or limited impact on the final decision under the defined context.

In summary, this entropy-based analysis highlights gas quality, process efficiency, and operating costs as the most critical factors in evaluating gasification technologies for BioSNG production. These weights served as the foundation for the scenario-based TOPSIS analysis.

The results of the TOPSIS analysis provide the ranking of gasification technologies and the confidence intervals (see Table S3). The ranking of the technologies for BioSNG production was, on average, as follows: (1) downdraft, (2) fluidized bed, (3) updraft, (4) plasma, (5) circulating bed, (7) rotary kiln, and (8) entrained flow. From the Monte Carlo simulations, downdraft and bubbling fluidized bed gasifiers consistently ranked as the most favorable options, as they combine high thermal efficiency, low levels of syngas impurities, and moderate operating costs. Under the context analyzed, these characteristics would allow these gasifiers to meet the requirements established by regulations for the injection of BioSNG into the natural gas network, without compromising the technical or economic viability of the project. In contrast, entrained flow and rotary kiln technologies consistently ranked lowest due to their lower compatibility with residual biomass, greater technical complexity, and higher operational demands. It is important to highlight that there are at least twelve commercial or pre-commercial plants (see Table S4) that employ downdraft or bubbling fluidized bed gasification technologies, with the specific purpose of producing liquid or gaseous fuels. Among them, seven correspond to downdraft gasifiers, and five use fluidized bed gasification, thus, validating the results of the MCDM approach.

Moreover, the variation in syngas production capacity across the three production scale scenarios (small, medium, and large) had little to no effect on the ranking of technologies (see Table S3). This is because, as previously explained, the capacity criterion holds low relative importance within the defined context, since it is not a parameter constrained by regulatory requirements for BioSNG injection into the natural gas network unlike syngas quality and process performance, which are key determinants.

Note in passing that the specific values of a relative importance matrix can be subjective and represent the opinion of individuals in a specific context. The influence of the decision matrix in the results was assessed by an additional simulation using (i) a homogeneous weight vector, i.e., all criteria were assigned equal importance, and (ii) a homogeneous pairwise comparison matrix, i.e., an equal relative importance among all the criteria. This sensitivity analysis serves to evaluate the robustness of the previously obtained rankings and to determine whether the model outcomes are significantly influenced by expert judgment or remain stable due to the intrinsic performance differences among the technologies. The use of a homogeneous weighting scheme results in rankings where technologies such as updraft and rotary kiln appear more favorable than under the expert-based approach. This occurs because the homogeneous model dilutes the influence of critical criteria such as gas quality and process performance while unintentionally amplifying the role of secondary or low-impact criteria, such as capacity or less variable environmental indicators. In this scenario, technologies tend to be ranked based on their average performance, rather than their alignment with regulatory and operational priorities. In contrast, the expert-based model prioritized the criteria of gas quality, process performance, and economic viability, recognizing that regulatory compliance is a non-negotiable requirement, while financial feasibility is crucial for project sustainability. As a result, technologies like bubbling fluidized bed and downdraft consistently ranked as top performers, combining energy efficiency, low impurity levels, and reasonable operating costs key attributes for a compliant and financially viable BioSNG project. On the other hand, entrained flow technology ranked the lowest under both weighting schemes, reflecting its persistent shortcomings in terms of biomass compatibility and technical complexity, which negatively affect both performance and costs.

The sensitivity analysis shows that the relative importance matrix using homogeneous weights may lead to selection outcomes that do not fully reflect the regulatory demands or strategic objectives of the project. The expert-driven approach, by assigning weights consistent with the case study priorities, supports a more accurate and robust technology selection process aligned with both compliance and feasibility. Nevertheless, it should be considered that the ranking given by the MCDM only provide initial guidelines for selecting process equipment, however the final selection should be performed by a more thorough evaluation of the process economics constrained by the environmental and product quality requirements.

5. Conclusions and Future Outlook

The selection of an appropriate gasification technology for biomass valorization is inherently context-dependent and must consider a range of criteria, including economic feasibility, feedstock flexibility, operational complexity, syngas quality, energy efficiency, and environmental impact. Each gasifier type presents distinct advantages and limitations, which must be weighed carefully against the specific requirements of the intended application. For instance, rotary kiln and plasma gasifiers offer notable versatility, as they can process high-moisture and coarse biomass, in contrast to lower cost options such as fixed-bed and fluidized-bed gasifiers.

High temperature gasifiers, such as plasma and entrained flow, typically produce syngas with elevated H2 and CO concentrations and minimal tar content, which is favorable for downstream applications. However, these benefits often imply higher energy demands and larger infrastructure costs. In contrast, gasifiers with lower outlet temperatures, such as updraft designs, are advantageous for thermal integration with downstream processes. Downdraft gasifiers generally yield higher syngas output than updraft types, while bubbling fluidized beds stand out for their high syngas production efficiency.

Looking forward, the optimization of gasifier design and operation must be guided by the intended end-use of the syngas and the characteristics of available biomass resources. Future research should focus on improving process adaptability, enhancing tar cracking mechanisms, and reducing CO2 emissions across all gasifier types. Integrating advanced control strategies and hybrid systems may offer promising pathways to further improve performance and sustainability in biomass gasification technologies.

From an integrative perspective, the results showed that downdraft and bubbling fluidized bed gasifiers are ideal for production of BioSNG due to their high thermal efficiency, low tar production, reduced CO2 concentrations, and H2/CO ratios close to the ideal range for methanation processes. These features position them as viable options both technically and in terms of regulatory compliance for BioSNG projects. Moreover, expanding the AHP–Entropy–TOPSIS model toward more holistic assessments that include life cycle assessment would allow for the evaluation of environmental impacts beyond regulatory compliance, considering the overall impact of the different processes and technologies.

The integration of MCDM models with geographic information systems would allow the focus in decision-making to shift from the technological level to a territorial one. This integration not only would provide the optimal location of biomass valorization plants but also would enable the development of more comprehensive models incorporating geospatial variables such as transportation routes, consumption nodes, environmental restrictions, and protected areas. By linking MCDM with logistics optimization modules, it might be possible to design deployment strategies aligned with public policy, maximizing regional biomass utilization and minimizing transportation and handling costs.

An emerging research avenue with great potential is the application of artificial intelligence tools to enhance technology selection processes. Supervised learning algorithms, such as random forests or support vector machines, could be trained using previous decisions generated by the MCDM model, leading to adaptive expert systems capable of recommending optimal alternatives under new technical or regulatory conditions. In parallel, the use of genetic algorithms and neural networks would allow for dynamic sensitivity analysis by automatically exploring thousands of combinations of criteria and weights to assess the robustness of technology rankings under uncertainty. Moreover, integrating these approaches with recommendation engines based on historical project databases or national energy policies would enable the development of hybrid decision support systems that are smarter and more customizable to specific application contexts.

Moreover, hybrid gasification systems or co-gasification configurations, which allow for the combination of different feedstocks or the integration of gasification with complementary processes (such as anaerobic digestion or electrolysis) are promising alternatives for the production of fuels and feedstocks. These configurations can improve overall energy efficiency, broaden the spectrum of usable biomass, and generate operational synergies.

Looking ahead, BioSNG production via gasification is projected as a strategic solution in the energy transition, particularly for countries with strong potential in residual biomass and existing natural gas infrastructure. This technology can contribute to the decarbonization of the transport sector and to achieving carbon neutrality targets. In this context, evaluation tools such as the one proposed here are essential to guide investment and public policy decisions based on technically sound, economically viable, and environmentally informed criteria.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/gases5040022/s1, Table S1. Attribute values for each gasifier in each criterion considered in the selection matrix; Table S2. Consistency metrics for the AHP pairwise comparison matrix; Table S3. TOPSIS results and rankings of gasification technologies under three syngas production capacity scenarios; Table S4. Inventory of Biomass Gasification Plants around the World.

Author Contributions

J.C.-G.: Conceptualization, writing—original draft preparation, Methodology, Formal analysis, Data curation. L.C.G.V.: Conceptualization, writing—original draft preparation, Visualization. D.M.: Conceptualization, writing—original draft preparation, Data curation. A.A. (Alejandro Argel): Conceptualization, writing—original draft preparation, Data curation. S.G.-F.: Conceptualization, Writing—Review & Editing. D.A.: Conceptualization, Writing—Review & Editing. M.S.: Writing—Review & Editing. A.A. (Adriana Aristizabal): Conceptualization, Methodology, Supervision, Formal analysis. M.L.B.: Conceptualization, Formal analysis, Methodology, Project administration, Supervision, Writing—review and editing. S.B.: Conceptualization, Methodology, Formal analysis, Supervision, Writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to acknowledge the financial support from the GreenGas Alliance between EAFIT University, Promigas S.A and its subsidiary Transmetano S.A. (agreement P2.0.002-2022).

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Abbreviations

The following abbreviations are used in this manuscript:

| AHP | Analytic Hierarchy Process |

| BioSNG | Bio-based Synthetic Natural Gas |

| CH4 | Methane |

| CO2 | Carbon Dioxide |

| EN | European Norm (Standard) |

| CO2eq | CO2 Equivalent Emissions |

| GIS | Geographic Information Systems |

| H2 | Hydrogen gas |

| H2/CO | Hydrogen to Carbon Monoxide Ratio |

| LCA | Life Cycle Assessment |

| MCDM | Multi-Criteria Decision Making |

| Nm3 | Normal Cubic Meter |

| TOPSIS | Technique for Order Preference by Similarity to Ideal Solution |

| %w/w | Percent Weight by Weight |

| %v/v | Percent Volume by Volume |

References

- Millinger, M.; Hedenus, F.; Zeyen, E.; Neumann, F.; Reichenberg, L.; Berndes, G. Diversity of Biomass Usage Pathways to Achieve Emissions Targets in the European Energy System. Nat. Energy 2025, 10, 226–242. [Google Scholar] [CrossRef]

- MarketsandMarkets. Biomass Gasification Market Growth, Drivers, & Opportunities. Available online: https://www.marketsandmarkets.com/Market-Reports/biomass-gasification-market-105152418.html (accessed on 13 June 2025).

- Research and Marckets, Ltd. Biomass Gasifier Market Size, Competitors, Trends & Forecast. Available online: https://www.researchandmarkets.com/reports/5867942/biomass-gasifier-market-size-market-share (accessed on 13 June 2025).

- Sikarwar, V.S.; Zhao, M.; Clough, P.; Yao, J.; Zhong, X.; Memon, M.Z.; Shah, N.; Anthony, E.J.; Fennell, P.S. An Overview of Advances in Biomass Gasification. Energy Environ. Sci. 2016, 9, 2939–2977. [Google Scholar] [CrossRef]

- Higman, C.; Tam, S. Advances in coal gasification, hydrogenation, and gas treating for the production of chemicals and fuels. Chem. Rev. 2014, 114, 1673–1708. [Google Scholar] [CrossRef] [PubMed]

- Tezer, Ö.; Karabağ, N.; Öngen, A.; Çolpan, C.Ö.; Ayol, A. Biomass Gasification for Sustainable Energy Production: A Review. Int. J. Hydrogen Energy 2022, 47, 15419–15433. [Google Scholar] [CrossRef]

- Ravikiran, A.; Renganathan, T.; Pushpavanam, S.; Voolapalli, R.K.; Cho, Y.S. Generalized Analysis of Gasifier Performance Using Equilibrium Modeling. Ind. Eng. Chem. Res. 2012, 51, 1601–1611. [Google Scholar] [CrossRef]

- Chengzao, J.; Yongfeng, Z.; Xia, Z. Prospects of and Challenges to Natural Gas Industry Development in China. Nat. Gas Ind. B 2014, 1, 1–13. [Google Scholar] [CrossRef]

- Yaman, C. A Review on the Process of Greenhouse Gas Inventory Preparation and Proposed Mitigation Measures for Reducing Carbon Footprint. Gases 2024, 4, 18–40. [Google Scholar] [CrossRef]

- Radosits, F.K.; Ajanovic, A.; Harasek, M. The Relevance of Biomass-Based Gases as Energy Carriers: A Review. WIREs Energy Environ. 2024, 13, e527. [Google Scholar] [CrossRef]

- Kohl, T.; Laukkanen, T.; Tuomaala, M.; Niskanen, T.; Siitonen, S.; Järvinen, M.P.; Ahtila, P. Comparison of Energy Efficiency Assessment Methods: Case Bio-SNG Process. Energy 2014, 74, 88–98. [Google Scholar] [CrossRef]

- IEA Bioenergy Task 33, Gasification of Waste for Energy Carriers, IEA Bioenergy. Available online: https://www.ieabioenergy.com/wp-content/uploads/2019/01/IEA-Bioenergy-Task-33-Gasification-of-waste-for-energy-carriers-20181205-1.pdf (accessed on 8 August 2025).

- van der Meijden, C.M.; Veringa, H.J.; Rabou, L.P.L.M. The Production of Synthetic Natural Gas (SNG): A Comparison of Three Wood Gasification Systems for Energy Balance and Overall Efficiency. Biomass Bioenergy 2010, 34, 302–311. [Google Scholar] [CrossRef]

- Pollex, A.; Ortwein, A.; Kaltschmitt, M. Thermo-Chemical Conversion of Solid Biofuels. Biomass Convers. Biorefinery 2012, 2, 21–39. [Google Scholar] [CrossRef]

- Basu, P. Chapter 1—Introduction. In Biomass Gasification, Pyrolysis and Torrefaction, 3rd ed.; Basu, P., Ed.; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar] [CrossRef]

- Kalita, P.; Baruah, D. Investigation of Biomass Gasifier Product Gas Composition and Its Characterization. In Coal and Biomass Gasification: Recent Advances and Future Challenges; De, S., Agarwal, A.K., Moholkar, V.S., Thallada, B., Eds.; Springer: Singapore, 2018. [Google Scholar] [CrossRef]

- Dogru, M.; Howarth, C.R.; Akay, G.; Keskinler, B.; Malik, A.A. Gasification of Hazelnut Shells in a Downdraft Gasifier. Energy 2002, 27, 415–427. [Google Scholar] [CrossRef]

- Paiva, M.; Vieira, A.; Gomes, H.T.; Brito, P. Simulation of a Downdraft Gasifier for Production of Syngas from Different Biomass Feedstocks. ChemEngineering 2021, 5, 20. [Google Scholar] [CrossRef]

- Fortunato, B.; Brunetti, G.; Camporeale, S.M.; Torresi, M.; Fornarelli, F. Thermodynamic Model of a Downdraft Gasifier. Energy Convers. Manag. 2017, 140, 281–294. [Google Scholar] [CrossRef]

- Basu, P. Chapter 7—Gasification Theory. In Biomass Gasification, Pyrolysis and Torrefaction, 3rd ed.; Basu, P., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 211–262. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, M.; Raheem, A.; Wang, F.; Wei, J.; Xu, D.; Song, X.; Bao, W.; Huang, A.; Zhang, S.; et al. Syngas Production from Biomass Gasification: Influences of Feedstock Properties, Reactor Type, and Reaction Parameters. ACS Omega 2023, 8, 31620–31631. [Google Scholar] [CrossRef]

- Kushwah, A.; Reina, T.R.; Short, M. Modelling Approaches for Biomass Gasifiers: A Comprehensive Overview. Sci. Total Environ. 2022, 834, 155243. [Google Scholar] [CrossRef] [PubMed]

- Jordan, C.A.; Weatherby, J.; Barclay, A. Advanced Gasification Technologies—Review and Benchmarking: Review of Current Status of Advanced Gasification Technologies, Task Report 2; BEIS Research Paper Number 2021/038; AECOM & Fichtner Consulting Engineers: London, UK, 2021; pp. 1–196. [Google Scholar]

- Santos, S.M.; Assis, A.C.; Gomes, L.; Nobre, C.; Brito, P. Waste Gasification Technologies: A Brief Overview. Waste 2023, 1, 140–165. [Google Scholar] [CrossRef]

- Rey, J.R.C.; Longo, A.; Rijo, B.; Pedrero, C.M.; Tarelho, L.A.C.; Brito, P.S.D.; Nobre, C. A Review of Cleaning Technologies for Biomass-Derived Syngas. Fuel 2024, 377, 132776. [Google Scholar] [CrossRef]

- Abdoulmoumine, N.; Adhikari, S.; Kulkarni, A.; Chattanathan, S. A Review on Biomass Gasification Syngas Cleanup. Appl. Energy 2015, 155, 294–307. [Google Scholar] [CrossRef]

- Mondal, P.; Dang, G.S.; Garg, M.O. Syngas Production through Gasification and Cleanup for Downstream Applications—Recent Developments. Fuel Process. Technol. 2011, 92, 1395–1410. [Google Scholar] [CrossRef]

- Lotfi, S. Technologies for Tar Removal from Biomass-Derived Syngas. Pet. Petrochem. Eng. J. 2021, 5, 1–35. [Google Scholar] [CrossRef]

- Worley, M.; Yale, J. Biomass Gasification Technology Assessment: Consolidated Report; NREL/SR--5100-57085, 1059145, LFA-2-22480-01; NREL: Golden, CO, USA, 2012. [Google Scholar] [CrossRef]

- Wu, Y.; Ye, X.; Wang, Y.; Wang, L. Methane Production from Biomass by Thermochemical Conversion: A Review. Catalysts 2023, 13, 771. [Google Scholar] [CrossRef]

- González-Vázquez, M.P.; García, R.; Gil, M.V.; Pevida, C.; Rubiera, F. Comparison of the Gasification Performance of Multiple Biomass Types in a Bubbling Fluidized Bed. Energy Convers. Manag. 2018, 176, 309–323. [Google Scholar] [CrossRef]

- Kambolis, A.; Schildhauer, T.J.; Kröcher, O. CO Methanation for Synthetic Natural Gas Production. Chimia 2015, 69, 608–613. [Google Scholar] [CrossRef] [PubMed]

- Materazzi, M.; Grimaldi, F.; Foscolo, P.U.; Cozens, P.; Taylor, R.; Chapman, C. Analysis of Syngas Methanation for Bio-SNG Production from Wastes: Kinetic Model Development and Pilot Scale Validation. Fuel Process. Technol. 2017, 167, 292–305. [Google Scholar] [CrossRef]

- Kopyscinski, J.; Schildhauer, T.J.; Biollaz, S.M.A. Production of Synthetic Natural Gas (SNG) from Coal and Dry Biomass—A Technology Review from 1950 to 2009. Fuel 2010, 89, 1763–1783. [Google Scholar] [CrossRef]

- Gröbl, T.; Walter, H.; Haider, M. Biomass Steam Gasification for Production of SNG—Process Design and Sensitivity Analysis. Appl. Energy 2012, 97, 451–461. [Google Scholar] [CrossRef]

- Kumar, A.; Jones, D.D.; Hanna, M.A. Thermochemical Biomass Gasification: A Review of the Current Status of the Technology. Energies 2009, 2, 556–581. [Google Scholar] [CrossRef]

- Patra, T.K.; Sheth, P.N. Biomass Gasification Models for Downdraft Gasifier: A State-of-the-Art Review. Renew. Sustain. Energy Rev. 2015, 50, 583–593. [Google Scholar] [CrossRef]

- Martínez, J.D.; Mahkamov, K.; Andrade, R.V.; Silva Lora, E.E. Syngas Production in Downdraft Biomass Gasifiers and Its Application Using Internal Combustion Engines. Renew. Energy 2012, 38, 1–9. [Google Scholar] [CrossRef]

- Alauddin, Z.A.B.Z.; Lahijani, P.; Mohammadi, M.; Mohamed, A.R. Gasification of Lignocellulosic Biomass in Fluidized Beds for Renewable Energy Development: A Review. Renew. Sustain. Energy Rev. 2010, 14, 2852–2862. [Google Scholar] [CrossRef]

- Gómez-Barea, A.; Leckner, B. Modeling of Biomass Gasification in Fluidized Bed. Prog. Energy Combust. Sci. 2010, 36, 444–509. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, Q.; Zhao, H.; Cao, X.; Mei, Q.; Luo, Z.; Cen, K. Biomass–Oxygen Gasification in a High-Temperature Entrained-Flow Gasifier. Biotechnol. Adv. 2009, 27, 606–611. [Google Scholar] [CrossRef]

- Oliveira, M.; Ramos, A.; Ismail, T.M.; Monteiro, E.; Rouboa, A. A Review on Plasma Gasification of Solid Residues: Recent Advances and Developments. Energies 2022, 15, 1475. [Google Scholar] [CrossRef]

- Shi, H.; Si, W.; Li, X. The Concept, Design and Performance of a Novel Rotary Kiln Type Air-Staged Biomass Gasifier. Energies 2016, 9, 67. [Google Scholar] [CrossRef]

- Mishra, S.; Upadhyay, R.K. Review on Biomass Gasification: Gasifiers, Gasifying Mediums, and Operational Parameters. Mater. Sci. Energy Technol. 2021, 4, 329–340. [Google Scholar] [CrossRef]

- Puig-Arnavat, M.; Bruno, J.C.; Coronas, A. Review and Analysis of Biomass Gasification Models. Renew. Sustain. Energy Rev. 2010, 14, 2841–2851. [Google Scholar] [CrossRef]

- Ismail, T.M.; El-Salam, M.A. Parametric Studies on Biomass Gasification Process on Updraft Gasifier High Temperature Air Gasification. Appl. Therm. Eng. 2017, 112, 1460–1473. [Google Scholar] [CrossRef]

- Kuo, P.-C.; Wu, W.; Chen, W.-H. Gasification Performances of Raw and Torrefied Biomass in a Downdraft Fixed Bed Gasifier Using Thermodynamic Analysis. Fuel 2014, 117, 1231–1241. [Google Scholar] [CrossRef]

- Monteiro, E.; Ramos, A.; Rouboa, A. Fundamental Designs of Gasification Plants for Combined Heat and Power. Renew. Sustain. Energy Rev. 2024, 196, 114305. [Google Scholar] [CrossRef]

- Nwakaire, J.N.; Ugwuishiwu, B.O. Development of a Natural Cross Draft Gasifier Stove for Application in Rural Communities in Sub-Saharan Africa. J. Appl. Sci. 2015, 15, 1149–1157. [Google Scholar] [CrossRef]

- Ren, J.; Cao, J.-P.; Zhao, X.-Y.; Yang, F.-L.; Wei, X.-Y. Recent Advances in Syngas Production from Biomass Catalytic Gasification: A Critical Review on Reactors, Catalysts, Catalytic Mechanisms and Mathematical Models. Renew. Sustain. Energy Rev. 2019, 116, 109426. [Google Scholar] [CrossRef]

- Couhert, C.; Salvador, S.; Commandré, J.-M. Impact of Torrefaction on Syngas Production from Wood. Fuel 2009, 88, 2286–2290. [Google Scholar] [CrossRef]

- Hrbek, J. Status Report on Thermal Gasification of Biomass and Waste 2021, IEA Bioenergy Task 33; IEA Bioenergy: Paris, France, 2022; pp. 1–69. [Google Scholar]

- Sheth, P.N.; Babu, B.V. Experimental Studies on Producer Gas Generation from Wood Waste in a Downdraft Biomass Gasifier. Bioresour. Technol. 2009, 100, 3127–3133. [Google Scholar] [CrossRef]

- Siedlecki, M.; De Jong, W.; Verkooijen, A.H.M. Fluidized Bed Gasification as a Mature and Reliable Technology for the Production of Bio-Syngas and Applied in the Production of Liquid Transportation Fuels—A Review. Energies 2011, 4, 389–434. [Google Scholar] [CrossRef]

- Morris, J.D.; Daood, S.S.; Chilton, S.; Nimmo, W. Mechanisms and Mitigation of Agglomeration during Fluidized Bed Combustion of Biomass: A Review. Fuel 2018, 230, 452–473. [Google Scholar] [CrossRef]

- Gray, D. Chapter 8—Major Gasifiers for IGCC Systems. In Integrated Gasification Combined Cycle (IGCC) Technologies; Wang, T., Stiegel, G., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 305–355. [Google Scholar] [CrossRef]

- Corella, J.; Toledo, J.M.; Molina, G. A Review on Dual Fluidized-Bed Biomass Gasifiers. Ind. Eng. Chem. Res. 2007, 46, 6831–6839. [Google Scholar] [CrossRef]

- Latif, A. A Study of the Design of Fluidized Bed Reactors for Biomass Gasification. Doctoral Thesis, University of London, London, UK, 1999. Available online: https://discovery.ucl.ac.uk/id/eprint/1349342/ (accessed on 19 June 2025).

- Zhao, Y.; Sun, S.; Zhou, H.; Sun, R.; Tian, H.; Luan, J.; Qian, J. Experimental Study on Sawdust Air Gasification in an Entrained-Flow Reactor. Fuel Process. Technol. 2010, 91, 910–914. [Google Scholar] [CrossRef]

- Chanthakett, A.; Arif, M.T.; Khan, M.M.K.; Oo, A.M.T. Performance Assessment of Gasification Reactors for Sustainable Management of Municipal Solid Waste. J. Environ. Manag. 2021, 291, 112661. [Google Scholar] [CrossRef]

- Guo, X.; Dai, Z.; Gong, X.; Chen, X.; Liu, H.; Wang, F.; Yu, Z. Performance of an Entrained-Flow Gasification Technology of Pulverized Coal in Pilot-Scale Plant. Fuel Process. Technol. 2007, 88, 451–459. [Google Scholar] [CrossRef]

- Babler, M.U.; Phounglamcheik, A.; Amovic, M.; Ljunggren, R.; Engvall, K. Modeling and Pilot Plant Runs of Slow Biomass Pyrolysis in a Rotary Kiln. Appl. Energy 2017, 207, 123–133. [Google Scholar] [CrossRef]

- Molino, A.; Iovane, P.; Donatelli, A.; Braccio, G.; Chianese, S.; Musmarra, D. Steam gasification of refuse-derived fuel in a rotary kiln pilot plant: Experimental tests. Chem. Eng. Trans. 2013, 32, 337–342. [Google Scholar] [CrossRef]

- Willis, K.P.; Osada, S.; Willerton, K.L. Plasma Gasification: Lessons Learned at Eco-Valley WTE Facility. In Proceedings of the 18th Annual North American Waste-to-Energy Conference, Orlando, FL, USA, 11–13 May 2010. [Google Scholar] [CrossRef]

- Pang, Y.; Bahr, L.; Fendt, P.; Zigan, L.; Will, S.; Hammer, T.; Baldauf, M.; Fleck, R.; Müller, D.; Karl, J. Plasma-Assisted Biomass Gasification with Focus on Carbon Conversion and Reaction Kinetics Compared to Thermal Gasification. Energies 2018, 11, 1302. [Google Scholar] [CrossRef]

- Rueda, Y.G.; Helsen, L. The Role of Plasma in Syngas Tar Cracking. Biomass Convers. Biorefinery 2020, 10, 857–871. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Yin, X.L.; Wu, C.Z. A Review on the Development and Commercialization of Biomass Gasification Technologies in China. Renew. Sustain. Energy Rev. 2004, 8, 565–580. [Google Scholar] [CrossRef]

- Jafri, Y.; Waldheim, L.; Lundgren, J. Emerging Gasification Technologies for Waste & Biomass; IEA Bioenergy: Paris, France, 2020; pp. 3–80. [Google Scholar]

- Devi, L.; Ptasinski, K.J.; Janssen, F.J.J.G.; van Paasen, S.V.B.; Bergman, P.C.A.; Kiel, J.H.A. Catalytic Decomposition of Biomass Tars: Use of Dolomite and Untreated Olivine. Renew. Energy 2005, 30, 565–587. [Google Scholar] [CrossRef]

- Arpia, A.A.; Nguyen, T.-B.; Chen, W.-H.; Dong, C.-D.; Ok, Y.S. Microwave-Assisted Gasification of Biomass for Sustainable and Energy-Efficient Biohydrogen and Biosyngas Production: A State-of-the-Art Review. Chemosphere 2022, 287, 132014. [Google Scholar] [CrossRef] [PubMed]

- HelioStorm. Heartland. Available online: https://www.oneheartland.com/heliostorm/ (accessed on 20 June 2025).

- Guo, L.; Cao, C.; Lu, Y.; Guo, L.; Cao, C.; Lu, Y. Chapter 9. Supercritical Water Gasification of Biomass and Organic Wastes. In Biomass; IntechOpen: London, UK, 2010. [Google Scholar] [CrossRef]

- Murugan, P.C.; Joseph Sekhar, S. Investigation on the Yield of Producer Gas from Tamarind Shell (Tamarindus indica) as Feedstock in an Imbert Type Biomass Gasifier. Fuel 2021, 292, 120310. [Google Scholar] [CrossRef]

- Havilah, P.R.; Sharma, A.K.; Govindasamy, G.; Matsakas, L.; Patel, A. Biomass Gasification in Downdraft Gasifiers: A Technical Review on Production, Up-Gradation and Application of Synthesis Gas. Energies 2022, 15, 3938. [Google Scholar] [CrossRef]

- Manali, A.; Pothoulaki, A.; Gikas, P. The State of the Art in Biosolids Gasification. J. Environ. Manag. 2024, 364, 121385. [Google Scholar] [CrossRef]

- Thomson, R.; Kwong, P.; Ahmad, E.; Nigam, K.D.P. Clean Syngas from Small Commercial Biomass Gasifiers; a Review of Gasifier Development, Recent Advances and Performance Evaluation. Int. J. Hydrogen Energy 2020, 45, 21087–21111. [Google Scholar] [CrossRef]

- Ahrenfeldt, J.; Thomsen, T.P.; Henriksen, U.; Clausen, L.R. Biomass Gasification Cogeneration—A Review of State of the Art Technology and Near Future Perspectives. Applied thermal engineering 2013, 50, 1407–1417. [Google Scholar] [CrossRef]

- Crouse, D.; Gangwal, S.; Knudsen, S.; Munson, C.; Shilling, N.; Slettehaugh, B.; Sorensen, J.; Turk, B.; Ramezan, M.; Lyons, D.; et al. Guidelines/Handbook for the Design of Modular Gasification Systems; U.S. Department of Energy: Washington, DC, USA, 2022.