Abstract

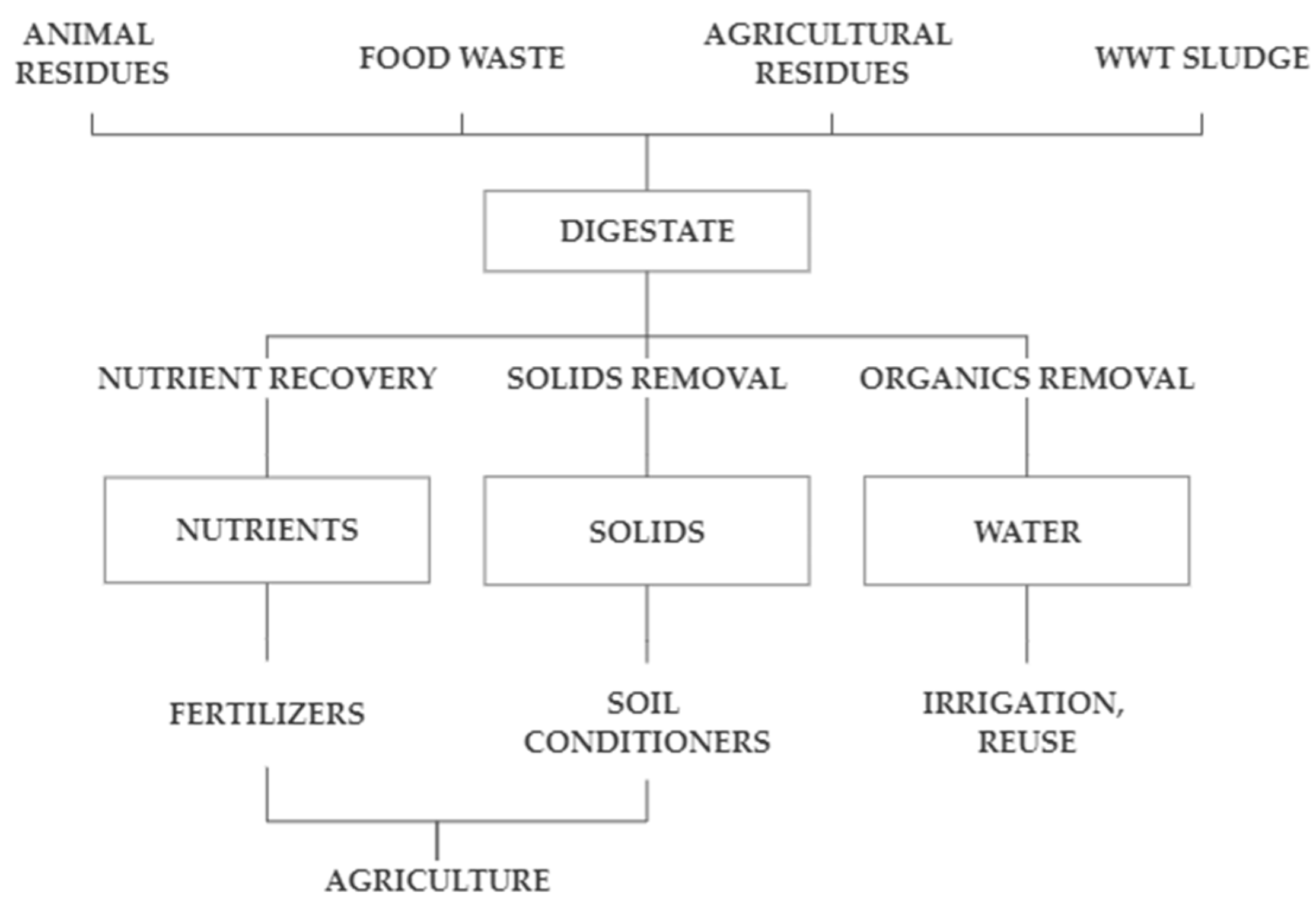

The reuse of nutrient-rich waste in order to create green fertilizers in a sustainable and efficient way is a new strategy for the transition to a circular economy. Digestate is produced as a by-product from anaerobic digestion plants in large amounts creating a major management issue both for storage, utilization or disposal. The current work focuses on the development of an innovative, small-scale technology for the processing of digestate from anaerobic digestion plants that use food, animal, agricultural and sludge waste. The technology targets the recovery of fibres and nutrients for the production of high-performance bio-fertiliser products and clean water from digestate.

1. Introduction

Synthetic fertilizers’ manufacture and use are highly associated with the depletion of mineral resources, greenhouse gas emissions and energy-intensive production methods with high environmental impact. The reuse of nutrient-rich waste in order to create green fertilizers in a sustainable and efficient way is a new strategy for the transition to a circular economy. Digestate, anaerobic digestion’s residue, is frequently used as fertilizer or soil amender without any pre-treatment substituting synthetic fertilizers [1].

However, the fluctuating content of inorganics, solids and organic matter in digestate depending on its origin, along with the high volumes produced due to high water content suggest difficulties in handling and processing [2,3]. Direct application of digestate without complying with the soil carrying capacities results in the uncontrolled leaching of nutrients (nitrogen, phosphorus and potassium) in the surface and groundwater causing environmental pollution [4]. Digestate may as well contain high-risk compounds, such as antibiotics and increased microbial load making its direct disposal dangerous to public health [5,6].

The constant need for environmental protection and establishing stricter rules regarding fertilizer and soil conditioner application results in the necessity to pursue more cost-effective and eco-friendly digestate treatment methods in order to comply with the rules.

Currently, it is not economically feasible for the majority of small anaerobic digestion plants to convert digestate to bio-fertiliser products due to the excessive on-site processing and end of waste costs. Therefore, the development of technologies that can process digestate, reduce its overall volume and recover nutrients that can be further used for the production of fertilizers is of high importance.

The present study aims to investigate a system of simultaneous selective separation and recovery of nutrient ions (PO43−, NH4+, K+, Ca2+, Mg2+) using selective electrodialysis (SED) from digested residue with different origins from anaerobic digestion plants after pasteurization and separation. By mixing the different products of the SED in specific proportions, it is possible to produce high-value products to broadly meet the needs of the agricultural industry. Calculations in order to estimate the potential nutrient availability of achievable products as well as to quantify the composition of the recovered fibre are presented.

2. Materials and Methods

2.1. Process Description

The current work focuses on a process for the recovery of valuable products derived from digestate which is arranged in two steps.

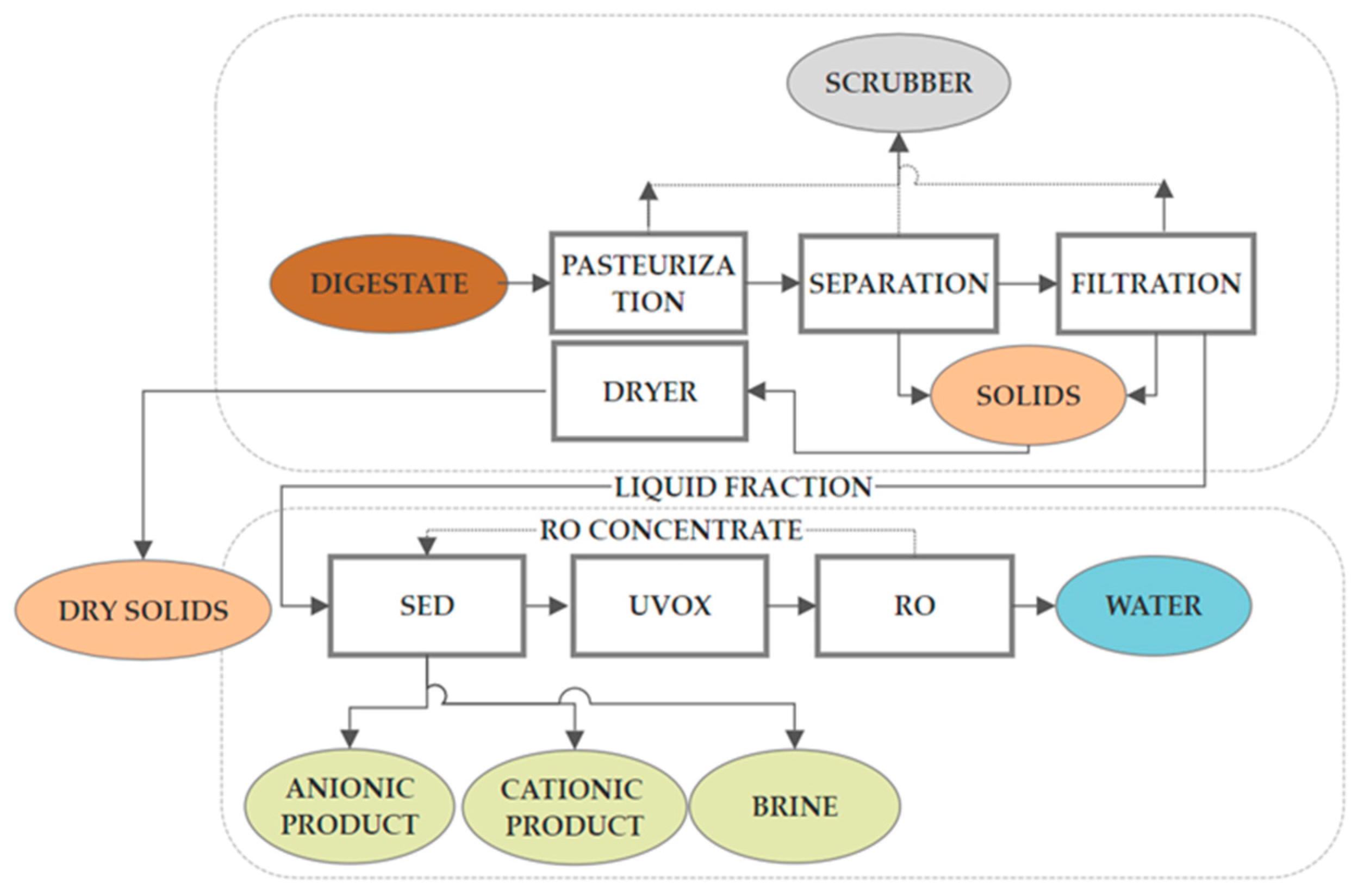

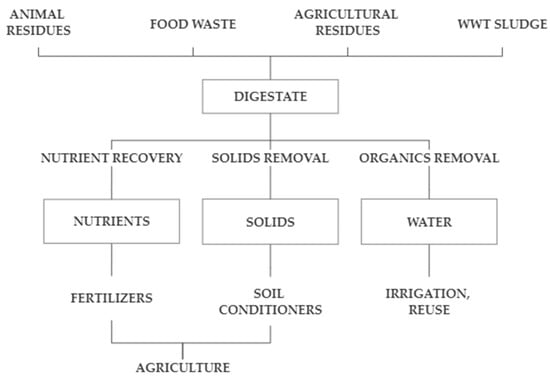

Step 1 includes the mechanical, thermal and separation processes, i.e., maceration, pasteurization, drying and solids separation via filtration producing a solid and a liquid fraction, while Step 2 includes the nutrient recovery and antibiotics removal (Figure 1) from the liquid fraction for fertilizer production and water recovery.

Figure 1.

Main process components and potential products.

The integration of the different components creates an innovative small-scale digestate processing technology which enables effective digestate management and nutrient recovery from different anaerobic digestion plants, treating variable waste and producing valuable products (fertilizers, soil amenders tailored to farmers’ soil and crop requirements, antibiotics free water) (Figure 2).

Figure 2.

Proposed technological approach.

2.1.1. Raw Digestate Treatment

The raw digestate from the anaerobic digestion tank is macerated and filtered to remove larger particles and then pasteurized via heating up to 71 °C for 1 h.

The pasteurized digestate is fed to the screw press to separate the solid and liquid fractions. The solids are collected for further treatment. The liquid fraction is filtered through a series of filters for further solid removal.

Potential emissions from pasteurization and drying steps are vented to a packed bed water scrubber before exiting to the atmosphere. The wash-water is collected for further processing.

2.1.2. Solid Fraction Treatment

The fibre fraction of the digestate collected from the separation process is moved to the dryer for further water content and volume reduction using hot air. The dry solid fraction along with the sludge derived from the filtration steps is composted, with the addition of woodchips or ash.

2.1.3. Liquid Fraction Treatment

The cooled liquid fraction is fed to rotary filters for filtration down to 75 μm and then pumped through a set of cascade filters. Then, the liquid containing particles with mean size <1 μm is led to an ultrafiltration unit (UF) for further particle and organic matter removal to avoid fouling and the creation and interruption of nutrient ion separation during the nutrient recovery process with the electrochemical-driven membrane process.

The liquid fraction after the UF treatment is then fed to a selective electrodialysis (SED) unit for the recovery of nutrient ions (PO43−, NH4+, K+, Ca2+, Mg2+) using monovalent cationic and anionic membranes. The SED process produces four streams: anionic product stream (PO43− and SO42−), cationic product stream (Mg2+ and Ca2+), brine product stream (K+ and NH4+) and a stream free of nutrients for further treatment [7]. The concentrate fractions are led to a tank for further treatment and the production of fertilizers (e.g., struvite, ammonium sulphate, calcium phosphate, magnesium phosphate and potassium chloride). The ion-free liquid is pumped to the advanced oxidation processing (UVOX) unit for the removal of antibiotics and organic matter reduction. Then, the liquid fraction is led to reverse osmosis (RO) unit for purification and clean water production. The RO concentrate is returned to the SED for desalinization and the recovery of ions that were not separated. Depending on the quality of the RO discharge, potable water or grey water are produced that can be reused at the biogas plant or for irrigation purposes.

2.2. Materials

2.2.1. Biogas Plants’ Digestate

There are a range of parameters that are characteristic of digestate depending on its origin. To identify the characteristics that are relevant to the variety of biogas plant’s feedstock and may affect both quality and quantity of products produced, characterization of samples that were received from biogas plants with diverse digestate types and different capacity was conducted. Biogas plants’ feedstock included food waste, used vegetable oil, residues from agricultural and livestock activities and sludge from wastewater treatment plants.

A summary of the information related to the sites and the anaerobic digestion processes deployed in each plant is presented in Table 1.

Table 1.

Biogas plants operation and specifications.

2.2.2. Analysis

Digestate characterization was performed by the determination of pH, dry matter (DM), total nitrogen (TN), total Kjeldahl nitrogen (TKN), ammonium (NH4+), chemical oxygen demand (COD), total phosphorus (TP) and the ions: PO43-, K+, Ca2+, Mg2+ and results are presented in Table 2 and Table 3. Analysis of the digestates were conducted by the IHE Delft Institute for Water Education following the Standard Methods for Wastewater characterization [8].

Table 2.

Average digestates’ nutrients and dry matter composition.

Table 3.

Fibre, nutrients and water recovery from 1 t digestate treatment.

3. Results and Discussion

3.1. Digestate Characterization

Feedstock pH values ranged from 7.6 to 8.8, with wastewater treatment plant sludge digestate (WWTPD) appearing to have the lowest value and food waste digestate (FWD) the highest (Table 2). Crop residues digestate (CRD) presented with elevated dry matter content due to the low digestibility of lignin, a structural plant polymer. On contrary, animal residues digestate (ARD) that is derived from highly biodegradable substrates presented with lower dry matter content [9]. VOD and FWD had a higher content of total nitrogen compared to other digestates, 149 and 145 gN/kg DM, respectively, and the WWTPD total nitrogen content was the one third of VOD. Furthermore, in all cases the Kjeldahl nitrogen content was equal to the total nitrogen content of the digestates, indicating that nitrogen was present in organic bonds and as ammonium nitrogen. Potassium and phosphorus content was lower than nitrogen content with a range of values between 18–118 gK/kg DM and 8–27 gPO4/kg DM, respectively. WWTPD seemed to be less loaded compared to the other digestates, indicating that it would be easier to be treat. CRD contained high amounts of nitrogen and potassium but poor amounts of phosphorus and organic matter. Nevertheless, ARD and FWD were rich in nutrients and organic matter.

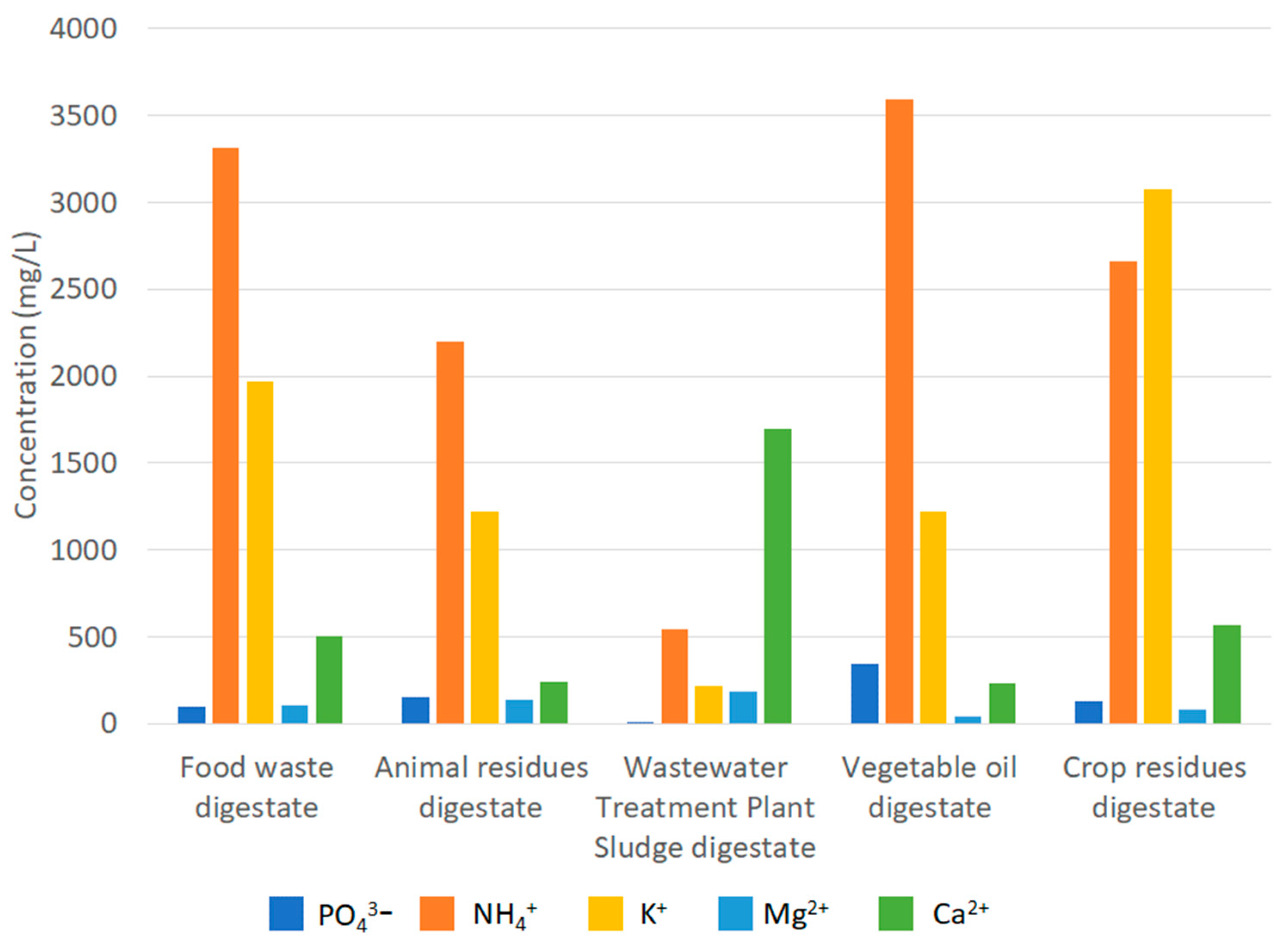

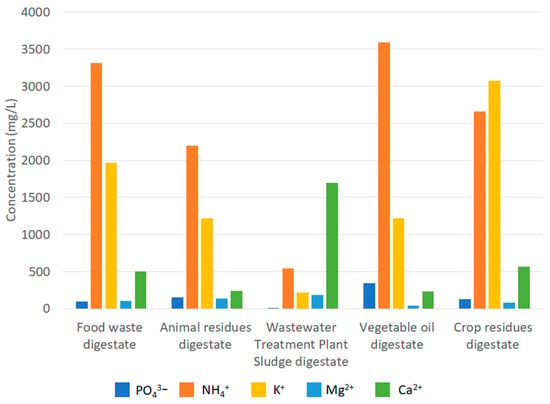

Characterization was also performed in the liquid fraction of the digestates after being filtered down to 0.1 μm in order to replicate the SED inlet. Filtration turned out to be an effective process in terms of the removal of phosphorus and various metals; however, organic matter and nitrogen remained in high concentrations in the liquid fraction. Generally, the liquid fraction was enriched with nitrogen and potassium and the solid fraction was characterized by a high content of nitrogen and phosphorus. Figure 3 illustrates the nutrient ion availability in the filtered digestates in relation to their origin.

Figure 3.

Nutrient ion availability in the filtered digestates in relation to their origin.

3.2. Products Availability

From the preliminary design assessment there are various potential recoverable materials from anaerobic digestate, including soil conditioners, liquid and solid fertilizer products and water. Calculations according to the digestate characterization results (i.e., density, total solids (TS), total nitrogen (TN) and total Kjeldahl nitrogen (TKN)) and the literature have been developed in order to estimate the potential nutrient availability in the derived products. The results of the potential products (i.e., fibre, nutrients and water) after treating 1 t digestate with the proposed technology are presented in Table 3.

The key assumptions made for the calculations were the following:

- Percentage of water loss during pasteurization (2%).

- Moisture content of recovered solids (70%) [10].

- Percentage of ammonium loss during pasteurization (43%) [11,12].

- 100% recovery of nutrient ions during SED.

- 50% water recovery during UF–RO systems [13,14].

Results indicate that higher fibre recovery was achieved in the case of CRD as expected due to the high solids content in the raw CRD and lower fibre recovery in the cases of ARD and UWSD with low solid content. CRD and VOD fibre was richer in TN suggesting that the predominant form in these cases is the organically bound nitrogen, in contract with FWD fibre that even though raw FWD appeared to be high in TN, soluble nitrogen (NH4+) was the predominant form resulting in high concentrations in the liquid fraction [15]. Consequently, higher NH4+ recovery with SED resulted in FWD and VOD. As phosphorus is almost exclusively a particulate, the recovery from the liquid fraction was lower than of the other nutrients [9]. Potassium recovery appeared higher in CRD due to its higher concentration in both the liquid fraction and raw CRD.

4. Conclusions

The proposed technology seems very promising in terms of treating diverse digestate and producing a variation of valuable products (i.e., soil conditioners, compost, liquid and solid fertilizers and water). Every fraction of digestate is processed and utilized with respect to the circular economy and an environmentally friendly manner, through the enhancement of circular resource management (e.g., reduction of fertiliser, soil amender and water costs, by recovering them as by-products from waste) and sustainable agricultural practices (e.g., elimination of the negative environmental and climate impacts of digestate use on land).

The current technology could be key in reducing the overall cost, complexity and footprint of small biogas plants, reducing the risks and challenges associated with digestate (e.g., reduction of pasteurization cost, reduction of digestate storage and disposal needs), creating new revenue streams and improving their economic viability.

Future work will focus on the recovery of nutrients and the production of fertilizers from the wide variety of digestates via the SED, the integration of the SED in the overall process and the demonstration of its operation under realistic conditions. In all cases the products (fertilizers, soil amenders, water) produced will be field tested and assessed against regional requirements.

Author Contributions

Conceptualization, K.P. (Konstantinos Plakas) and R.Y.; methodology, K.P. (Konstantinos Plakas), R.Y., B.H., F.J.R.R. and V.P.; formal analysis, V.P.; investigation, K.P. (Konstantinos Plakas), R.Y., B.H., F.J.R.R., S.L. and V.P.; resources, K.P. (Konstantinos Plakas), B.H. and F.J.R.R.; writ-ing—original draft preparation, V.P.; writing—review and editing, S.L. and K.P. (Kyriakos Panopoulos); visualization, V.P.; supervision, K.P. (Kyriakos Panopoulos), P.K. and A.Z.; project administration, K.P. (Konstantinos Plakas); funding acquisition, K.P. (Konstantinos Plakas). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Horizon 2020 EU grant number GA 863000.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

This research was funded by the project NOMAD/Horizon 2020 EU grant number GA 863000. The authors would like to thank the laboratory staff (Moradi Nazanin) at the IHE Delft Institute for Water Education for their work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Katarzyna, C.; Moustakas, K.; Witek-Krowiak, A. Bio-Based Fertilizers: A Practical Approach towards Circular Economy. Bioresour. Technol. 2020, 295, 122223. [Google Scholar] [CrossRef]

- Li, Y.; Manandhar, A.; Li, G.; Shah, A. Life Cycle Assessment of Integrated Solid State Anaerobic Digestion and Composting for On-Farm Organic Residues Treatment. J. Waste Manag. 2018, 76, 294–305. [Google Scholar] [CrossRef] [PubMed]

- Rehl, T.; Müller, J. Life Cycle Assessment of Biogas Digestate Processing Technologies. Resour. Conserv. Recycl. 2011, 56, 92–104. [Google Scholar] [CrossRef]

- Huang, J.; Xu, C.C.; Ridoutt, B.G.; Wang, X.; Ren, P. Nitrogen and Phosphorus Losses and Eutrophication Potential Associated with Fertilizer Application to Cropland in China. J. Clean. Prod. 2017, 159, 171–179. [Google Scholar] [CrossRef]

- Gurmessa, B.; Pedretti, E.F.; Cocco, S.; Cardelli, V.; Corti, G. Manure Anaerobic Digestion Effects and the Role of Pre- and Post-Treatments on Veterinary Antibiotics and Antibiotic Resistance Genes Removal Efficiency. Sci. Total Environ. 2020, 721, 137532. [Google Scholar] [CrossRef] [PubMed]

- Logan, M.; Chettiyappan, V. Management Strategies for Anaerobic Digestate of Organic Fraction of Municipal Solid Waste: Current Status and Future Prospects. Waste Manag. Res. 2019, 37 (Suppl. 1), 27–39. [Google Scholar] [CrossRef] [PubMed]

- Baird, R.; Bridgewater, L. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar]

- Ye, Z.L.; Ghyselbrecht, K.; Monballiu, A.; Pinoy, L.; Meesschaert, B. Fractionating various nutrient ions for resource recovery from swine wastewater using simultaneous anionic and cationic selective-electrodialysis. Water Res. 2019, 60, 424–434. [Google Scholar] [CrossRef] [PubMed]

- Gienau, T.; Brüß, U.; Kraume, M.; Rosenberger, S. Nutrient Recovery from Biogas Digestate by Optimised Membrane Treatment. Waste Biomass Valorization 2018, 9, 2337–2347. [Google Scholar] [CrossRef]

- Tambone, F.; Orzi, V.; D’Imporzano, G.; Adani, F. Solid and Liquid Fractionation of Digestate: Mass Balance, Chemical Characterization, and Agronomic and Environmental Value. Bioresour. Technol. 2017, 243, 1251–1256. [Google Scholar] [CrossRef] [PubMed]

- Rincón, C.A.; De Guardia, A.; Couvert, A.; Le Roux, S.; Soutrel, I.; Daumoin, M.; Benoist, J.C. Chemical and Odor Characterization of Gas Emissions Released during Composting of Solid Wastes and Digestates. J. Environ. Manag. 2019, 233, 39–53. [Google Scholar] [CrossRef] [PubMed]

- Awiszus, S.; Meissner, K.; Reyer, S.; Müller, J. Ammonia and Methane Emissions during Drying of Dewatered Biogas Digestate in a Two-Belt Conveyor Dryer. Bioresour. Technol. 2018, 247, 419–425. [Google Scholar] [CrossRef] [PubMed]

- Chiumenti, A.; Da Borso, F.; Teri, F.; Chiumenti, R.; Piaia, B. Full-Scale Membrane Filtration System for the Treatment of Digestate from a Co-Digestion Plant. Appl. Eng. Agric. 2013, 29, 985–990. [Google Scholar] [CrossRef]

- Światczak, P.; Cydzik-Kwiatkowska, A.; Zielińska, M. Treatment of Liquid Phase of Digestate from Agricultural Biogas Plant in a System with Aerobic Granules and Ultrafiltration. Water 2019, 11, 104. [Google Scholar] [CrossRef]

- Masse, L.; Beaudette, V.; Muir, M. Size Distribution and Composition of Particles. J. Aerosol. Sci. 2005, 48, 1943–1950. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).