1. Introduction

Engineering surface properties to control wettability is key for optimising material performances in applications such as microfluidics, self-cleaning coatings, and biosensing. Polydimethylsiloxane (PDMS) is particularly valued for its flexibility, optical transparency, and biocompatibility [

1]. Among the various surface wettability modification methods, moulding and replication represent an effective strategy to tailor PDMS surface properties, ensuring high reproducibility, uniformity, and scalability while avoiding complex post-processing or hazardous chemicals [

2]. However, this approach requires the fabrication of structured moulds, which can be time-consuming and resource-intensive when produced through conventional methods such as soft lithography [

3]. To overcome these drawbacks, femtosecond laser (fs-laser) micromachining offers a clean, flexible, and high-precision technique for micro- and nanostructuring of a wide range of materials, including metals [

4,

5], polymers [

6,

7], and crystalline materials [

8,

9,

10]. In this work, aluminium moulds with controlled textures were fabricated by femtosecond laser texturing and replicated on PDMS. The fabricated surfaces were analysed using scanning electron microscopy (SEM) and profilometry to evaluate the reproducibility efficiency, while wettability was assessed via static contact angle measurements to study the influence of surface geometry parameters. Finally, the long-term stability of the surfaces was analysed over a 4-month period.

2. Materials and Methods

AA2024 aluminium sheets (5 × 5 × 0.1 cm3) were used as mould substrates, cleaned in isopropyl alcohol before processing. Surface texturing was carried out using a TruMicro Femto laser system Trumpf GmbH, Ditzingen, Germany (1030 nm, 900 fs, 200 kHz, 0.8 µJ), equipped with a galvanometric scanner and a 100 mm telecentric lens. Grid patterns were fabricated by varying the hatch distance (dₕ = 5–1500 µm) and the number of scans (Ns = 1, 5, 30, 40), while laser-induced periodic surface structures (LIPSSs) were generated under parallel line hatch, one scan and fixed hatch distance (30 µm).

PDMS replicas were produced using the Sylgard 184 kit (10:1 ratio), degassed, poured onto the laser-textured aluminium moulds, and cured at 60 °C for 3 h before demoulding. Surface morphology was characterised by SEM (ZEISS GeminiSEM 480, Carl Zeiss Microscopy Deutschland GmbH (ZEISS), Oberkochen, Germany) and profilometry (Bruker Contour x100, Bruker Corporation Billerica (MA), USA).

Replication efficiency was evaluated by comparing the key geometrical parameters between the aluminium moulds and the corresponding PDMS replicas. For grid structures, it was quantified by comparing the lateral feature dimensions measured at half-depth on the mould and half-height on the replica. For uniformly textured surfaces, replication was assessed through roughness analysis, while for LIPSS-patterned samples, the surface period was used as the reference parameter. Relative replication errors were obtained by repeating each measurement three times at different locations on the same surface. The reported error bars correspond to the weighted standard deviation derived from this measurement set.

Wettability was assessed via static contact angle measurements using a DataPhysics OCA25 goniometer (DataPhysics Instruments GmbH, Filderstadt, Germany) with 3 µL and 6 µL of water droplets. For each surface, three identical droplets were deposited at different positions to assess surface homogeneity. The contact angle was extracted for both sides of each droplet, resulting in six measurements per sample. The mean CA values and standard deviations were calculated from this dataset.

A long-term stability study was also conducted by periodically remeasuring contact angles over 4 months after surface cleaning and storage in a dry environment.

3. Results

3.1. Surface Characterisation

SEM and profilometric analyses were performed on the femtosecond laser-textured aluminium moulds and their corresponding PDMS replicas to evaluate replication accuracy. A representative case is shown in

Figure 1, where (a) displays the SEM image of the aluminium mould and (b) shows the corresponding PDMS replica (

dₕ = 200 µm, N

s = 30). The mould’s engraved microstructure is clearly reproduced as a raised pattern on the PDMS surface.

For the grid geometries, an average relative replication error of 2.0 ± 0.4% was found.

For fully textured surfaces, a relative error of 1.2 ± 0.01% was found. For fully textured surfaces, a relative replication error of 1.2 ± 0.01% was obtained, while for LIPSS-patterned samples, the error was 6.0 ± 1.3%.

3.2. Wettability Characterisation

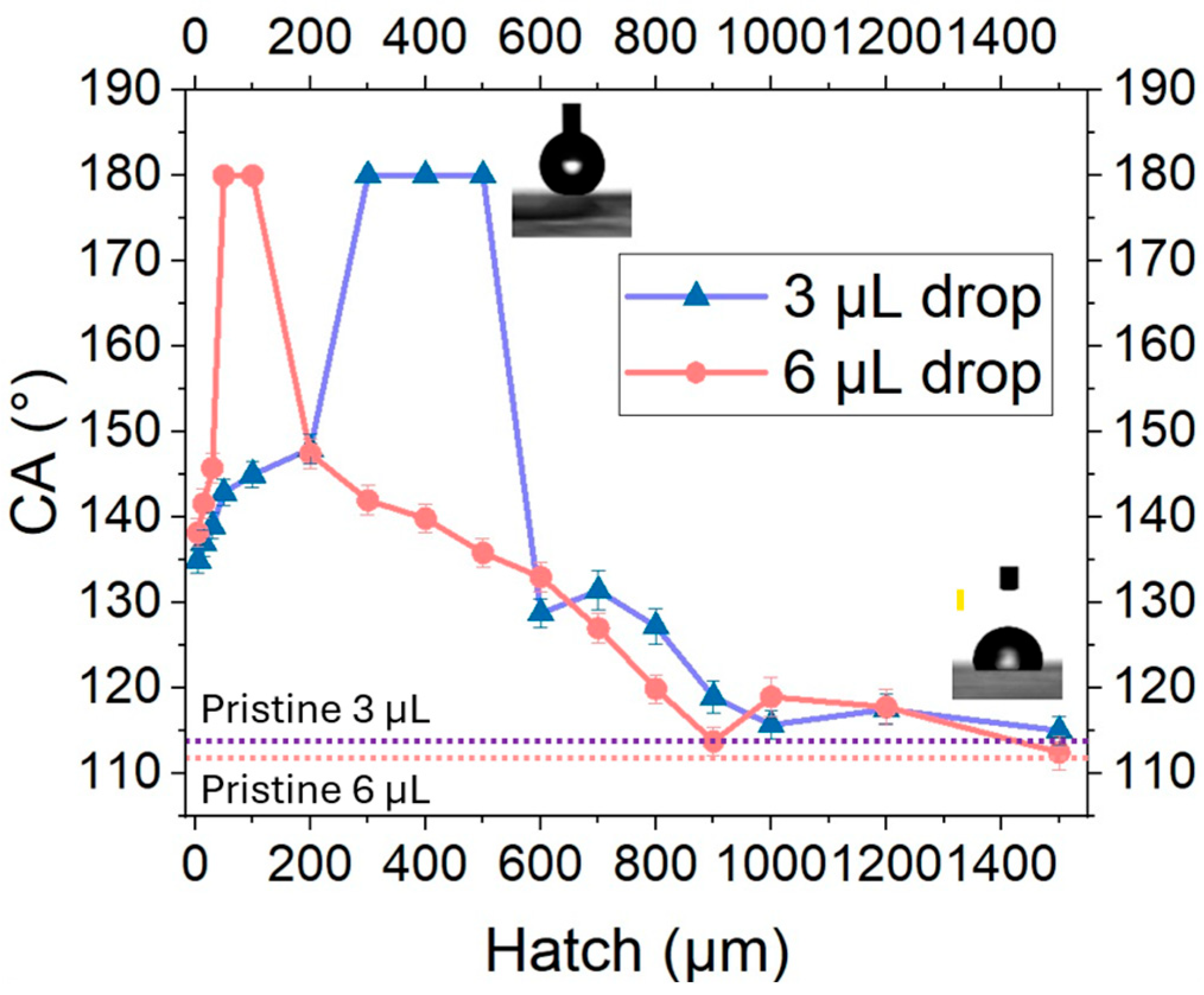

CA measurements on the PDMS replicas for the 3 µL and 6 µL droplets are reported in

Figure 2.

LIPSS-textured surfaces exhibited enhanced wettability, though the improvement was less pronounced than that achieved with the grid structures.

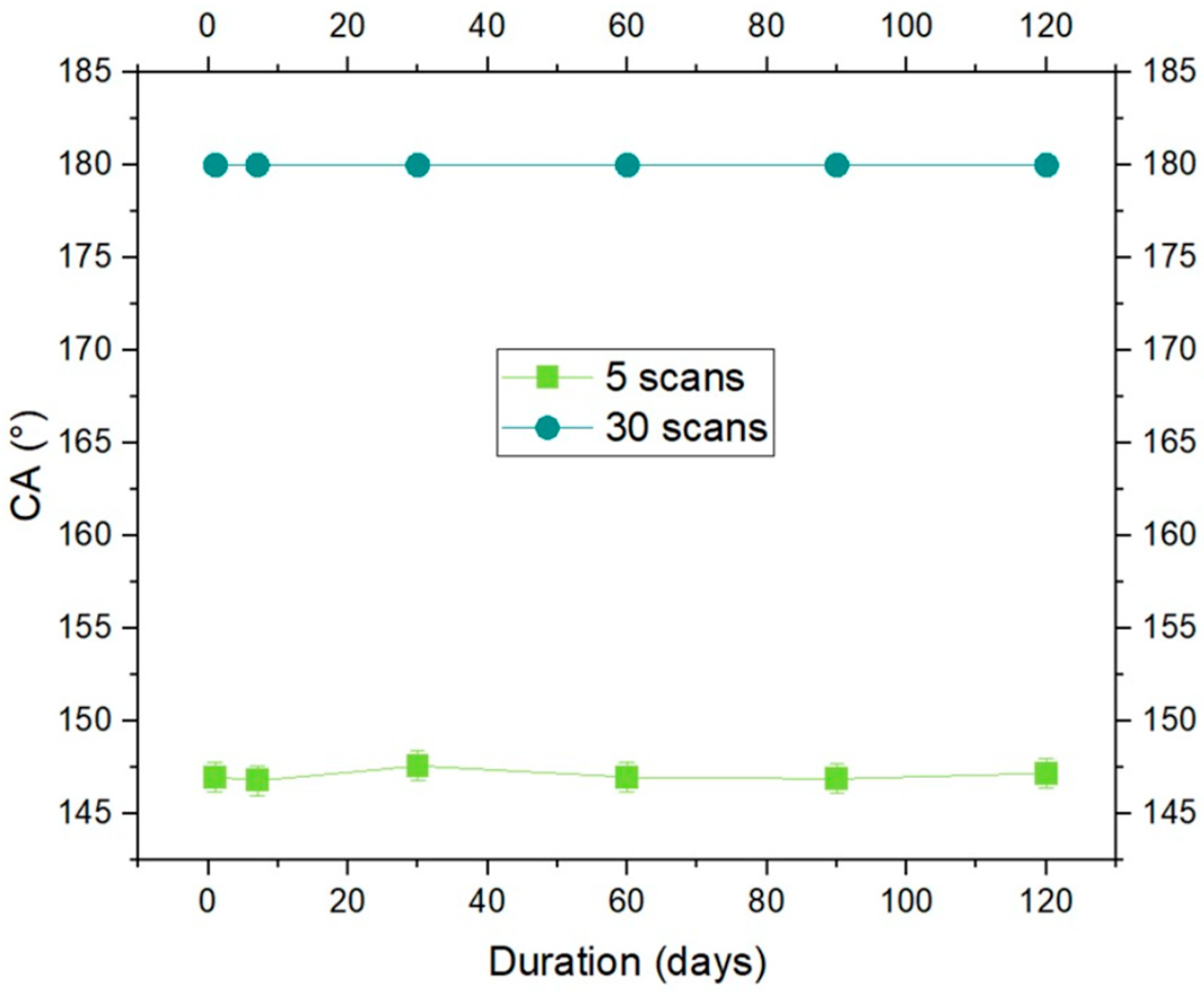

All samples maintained stable hydrophobicity over four months without degradation, as shown in

Figure 3.

4. Discussion

The results showed that femtosecond laser micromachining enabled precise control of aluminium mould morphology, allowing for systematic tuning of PDMS wettability after replication. The strong correlation between laser parameters (dₕ, Ns) and the resulting CA confirmed the key role played by both the lateral spacing and height of the surface morphologies in determining surface wetting behaviour.

As can be seen from

Figure 2, at small hatch distances (

dₕ < 30 µm), surfaces were fully textured, resulting in uniform hydrophobicity independently from the number of laser scans. As

dₕ increased, grid geometries formed cavities that trapped air beneath droplets, consistent with the Cassie–Baxter model, leading to higher CAs and superhydrophobicity for

Ns = 30–40 and

dₕ = 300–500 µm. Beyond this range, larger cavities failed to sustain air pockets, causing a transition toward the Wenzel regime and a decrease in CA.

The wettability curves confirmed this trend, showing a CA maximum followed by decreasing and position-dependent values when

dₕ became comparable to the droplet diameter, as the droplet contact area matched the grid cell size. Further increases in

dₕ led the CA to return toward that of pristine PDMS. Larger droplets (6 µL) reached their maximum CA at smaller

dₕ values compared to 3 µL droplets, as the contact area depends on droplet volume (

Figure 2). Larger droplets cover a wider surface, interacting with more surface cavities and trapping greater amounts of air, thus achieving the superhydrophobic state earlier for the same laser parameters

dₕ and

Ns.

LIPSS-textured samples exhibited enhanced hydrophobicity compared to pristine PDMS but did not achieve the superhydrophobic regime due to their submicron-scale features, which were insufficient for stable air trapping. Nonetheless, the faithful replication of these nanostructures confirmed the precision of the laser-based moulding process and suggested that combining LIPSSs with microscale grids could yield hierarchical surfaces with improved performance.

Finally, the long-term stability of both hydrophobic and superhydrophobic states over four months demonstrated the durability and robustness of this coating-free surface modification approach.

5. Conclusions

Femtosecond laser texturing enabled the precise fabrication of aluminium moulds with well-defined micro- and nanostructures. The subsequent PDMS replication demonstrated excellent morphological fidelity and allowed for the fine-tuning of surface wettability through controlled variation in hatch distance and number of laser scans. Wettability tests confirmed that both micro- and nanoscale features effectively influenced the hydrophobic response of the replicated surfaces. Moreover, the long-term stability of the hydrophobic and superhydrophobic state over four months validated the durability and reliability of this coating-free fabrication strategy. Overall, the proposed method provided a scalable and robust route for engineering functional PDMS surfaces with tailored wetting behaviour. This durability, together with the scalability and reproducibility of femtosecond laser processing, highlighted the potential of this method for the industrial fabrication of functional PDMS surfaces in applications requiring controlled wettability, such as microfluidics, self-cleaning coatings, and biomedical devices.

Author Contributions

Conceptualization, S.C., C.G., F.P.M., A.A., P.P. and A.V.; Methodology, R.D.P., F.A.S., A.A., P.P., A.V. and A.V.; Software, S.C.; Validation, S.C.; Formal Analysis, S.C.; Investigation, S.C.; Resources, A.A., P.P. and A.V.; Data Curation, S.C.; Writing—Original Draft Preparation, S.C. and A.V.; Writing—Review and Editing, R.D.P., F.A.S., C.G., F.P.M., A.A., P.P. and A.V.; Supervision, R.D.P., C.G., F.P.M., A.A., P.P. and A.V.; Project Administration, A.A., A.V. and A.V.; Funding Acquisition, A.A. and A.V. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by MUR in the framework of the PRIN 2022 PNRR Project “Surface and Interface acoustic wave-driven Microfluidic devices BAsed on fs-laser technology for particle sorting (SIMBA)” (grant number: Prot. P2022LMRKB), and by the project “Quantum Sensing and Modeling for One-Health (QuaSiModO)” (CUP: H97G23000100001).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

Author Pietro Patimisco was employed by the company Polysense Innovations srl. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Neves, L.B.; Afonso, I.S.; Nóbrega, G.; Barbosa, L.G.; Lima, R.A.; Ribeiro, J.E. A Review of Methods to Modify the PDMS Surface Wettability and Their Applications. Micromachines 2024, 15, 670. [Google Scholar] [CrossRef] [PubMed]

- Tony, A.; Samadian, S.; Fathi, M.; Hatamie, A. The Additive Manufacturing Approach to Polydimethylsiloxane (PDMS) Microfluidic Devices: Review and Future Directions. Polymers 2023, 15, 1926. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Mehl, B.T.; Munshi, A.S.; Townsend, A.D.; Spence, D.M.; Martin, R.S. 3D-Printed Microfluidic Devices: Fabrication, Advantages and Limitations—A Mini Review. Anal. Methods 2016, 8, 6005–6012. [Google Scholar] [CrossRef] [PubMed]

- Ahmmed, K.M.T.; Grambow, C.; Kietzig, A.-M. Fabrication of Micro/Nano Structures on Metals by Femtosecond Laser Micromachining. Micromachines 2014, 5, 1219–1253. [Google Scholar] [CrossRef]

- Caragnano, S.; De Palo, R.; Sfregola, F.A.; Gaudiuso, C.; Mezzapesa, F.P.; Patimisco, P.; Ancona, A.; Volpe, A. Femtosecond Laser-Engineered Molds for Long-Term Stable Superhydrophobic Polydimethylsiloxane (PDMS) Surfaces. Adv. Mater. Interfaces 2025, 12, e202500808. [Google Scholar] [CrossRef]

- Caragnano, S.; Petruzzellis, I.; Rodriguez Villarreal, A.I.; Casals Terré, J.; Ancona, A.; Osellame, R.; Martínez Vázquez, R.; Volpe, A. Femtosecond Laser-Driven Fabrication of a Polymeric Lab-on-a-Chip for Efficient Size-Based Particle Sorting in a Spiral Microchannel. Macromol. Mater. Eng. 2025, 310, e00158. [Google Scholar] [CrossRef]

- Obilor, A.F.; Daramola, M.O.; Aruna, S.T.; Aigbodion, V.S. Micro-Texturing of Polymer Surfaces Using Lasers: A Review. Int. J. Adv. Manuf. Technol. 2022, 119, 1503–1534. [Google Scholar] [CrossRef]

- Bogatyrev, A.; Liao, Z.; Axinte, D.; Norton, A. Femtosecond Laser Ablation of Zirconia-Based Ceramic Materials: From Ablation Mechanism to Modelling of Large-Scale Processing. J. Mater. Process. Technol. 2025, 335, 118668. [Google Scholar] [CrossRef]

- Hirooka, Y.; Tanaka, K.; Takahashi, K.; Yamamoto, Y. Femtosecond Laser-Ablation Processing of Optical Grade Quartz Crystal. Jpn. J. Appl. Phys. 2006, 45, 792–796. [Google Scholar] [CrossRef]

- Bonse, J.; Baudach, S.; Krüger, J.; Kautek, W.; Lenzner, M. Femtosecond Laser Ablation of Silicon—Modification Thresholds and Morphology. Appl. Phys. A 2002, 74, 19–25. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).