Abstract

Access to clean cooking remains a major challenge in rural and off-grid areas where traditional fuels are costly, harmful, or scarce. Solar cooking offers a sustainable solution, but many existing systems suffer from fixed positioning and low efficiency. This study presents a low-cost, dual-axis solar tracking parabolic dish cooker designed for such regions, featuring adjustable pot holder height and portability for ease of use. The system uses an Arduino UNO, LDR sensors, and a DC gear motor to automate sun tracking, ensuring optimal alignment throughout the day. A 0.61 m parabolic dish with ≥97% reflective silver-coated mirrors concentrates sunlight to temperatures exceeding 300 °C. Performance tests in April, June, and November showed boiling times as low as 3.37 min in high-irradiance conditions (7.66 kWh/m2/day) and 6.63 min under lower-irradiance conditions (3.86 kWh/m2/day). Compared to fixed or single-axis systems, this design achieved higher thermal efficiency and reliability, even under partially cloudy skies. Built with locally available materials, the system offers an affordable, clean, and effective cooking solution that supports energy access, health, and sustainability in underserved communities.

1. Introduction

The world’s energy needs are still largely met through petroleum-based fuels, but this dependence is becoming increasingly unsustainable. While energy usage is growing at a rate of about 1% annually in developed countries and 5% in developing countries [1], one of the most energy-intensive activities remains cooking, which accounts for nearly 30–40% of global household energy consumption [2]. Different types of fuels such as firewood, fossil fuels, and charcoal are being used as sources of energy for cooking as well as in other processes. This has created a significant shortage of fossil fuels. This shortage, along with the intensifying impacts of climate change, has made it necessary to find clean and sustainable energy alternatives [3]. Among the various renewable energy sources, solar energy holds a distinct advantage due to its abundance, accessibility, and zero-emission nature [4]. Earth receives around 173,000 terawatts of solar energy at a time, which is more than 10,000 times the total global energy demand. But the key question is how to catch, concentrate, and convert this energy at reasonable prices.

CSP technology is one of the most promising. CSP systems concentrate sunlight on a small surface using mirrors or lenses and produce heat that may reach 100 °C or more than 750 °C, depending on the setup [5]. Concentrated heat can be employed for cooking and hot water generation. Sun Belt countries like Pakistan are highly benefited by CSP because they have high solar insolation. Pakistan has about 5.5 to 6.5 kWh/m2/day of solar radiation for over 300 days in a year, which is suitable for solar-based applications, particularly in off-grid or remote areas. In these areas, CSP is a cost-effective and feasible alternative to conventional sources of power supply.

Among the various applications of Concentrated Solar Power (CSP) technology, solar cooking stands out as one of the most practical, efficient, and cost-effective solutions. Cooking still relies on firewood and coal or is biomass-based in most rural communities worldwide, resulting in deforestation, indoor air pollution, and growing carbon emissions [6]. With more than 2.6 billion people worldwide continuing to use such fuels, the environmental and health costs are staggering. The World Health Organization attributes the estimate of roughly 4 million premature deaths annually to indoor air pollution, mainly to women and children. Solar cookers using CSP, if universal, would minimize such risks as well as time and labor expenses regarding collecting firewood.

Over the past two decades, significant advancements have been made in CSP cooking technologies, reflecting a growing recognition of their potential to promote clean and sustainable energy solutions. Researchers have explored a wide range of designs, materials, and configurations to enhance both thermal efficiency and economic viability. Among the earliest contributions, Sonune and Philip [7] designed a compact, Fresnel-type solar concentrator capable of handling daily cooking tasks like frying and baking for a small family, marking an important step toward practical domestic solar cookers. Building on the foundation of affordability and reuse, Muhammad [8] introduced a manually tracked system with a basic absorber tube, achieving thermal efficiencies between 52% and 56%. As the focus expanded toward durability and precision, Villamil et al. [9] employed AISI 430 stainless steel for its strength and corrosion resistance, recommending laser or waterjet cutting for accurate fabrication. Zanganeh et al. [10] addressed portability and ease of assembly by using lightweight polyester mirror membranes with up to 92% reflectivity, reducing both system weight and cost, an ideal setup for remote applications. Recognizing regional differences in solar exposure, Yosra et al. [11] optimized concentrator design for Tunisia’s climate by tailoring the dish diameter, focal length, and receiver size to local solar data.

Expanding beyond household cooking applications, Poullikkas et al. [12] explored the potential of parabolic dish concentrators for decentralized electricity generation in the Mediterranean, where solar irradiance ranges from 4.5 to 7.0 kWh/m2/day. Their findings showed that with optimized tracking and reflectors, CSP systems could achieve over 20% overall efficiency, highlighting their dual-use potential for both thermal and electrical energy generation. Further innovations focused on maximizing thermal output, such as the work performed by Loni et al. [13], who investigated the role of nanofluids and cavity receiver geometries in parabolic dish systems. Their study revealed that the cavity shape—whether hemispherical, cylindrical, or conical—significantly affected heat absorption and temperature uniformity, stressing the importance of careful receiver design in enhancing performance.

This study aims to design and experimentally evaluate CSP-based solar cookers for rural and off-grid areas, particularly in regions like Pakistan with high solar insolation. We focus on improving thermal efficiency, material selection, and portability while ensuring cost-effectiveness. By experimenting with various concentrator designs and absorber configurations, we aim to enhance performance and make solar cooking a sustainable, accessible alternative to traditional fuels, reducing health and environmental risks.

2. System Model

2.1. Objective

Building on these developments and existing studies, this study shows the design, development, and testing of a smart, low-cost solar stove based on a parabolic dish for off-grid and rural areas. The intention is to provide a clean and low-cost solution to traditional cooking, which is still dependent on firewood or fossil fuels and causes health problems and pollution.

2.2. Design and Functionality

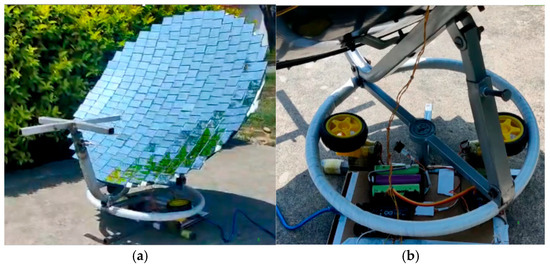

The solar stove employs a dual-axis tracking system to track the sun during the day. The east–west axis is controlled automatically using an Arduino microcontroller, LDR sensors, and DC gear motors. The north–south tilt is manually controlled to adjust to seasonal changes in the sun’s position. The prototype is as shown in Figure 1: it has a special spiral rotation mechanism, is motor-driven, and it provides smooth and continuous movement of the dish. An adjustable pot holder is included to shift the cooking vessel for improved focus and flexibility while cooking.

Figure 1.

(a) Solar stove; (b) rotation mechanism.

The parabolic dish has a diameter of 2 feet (0.61 m) and a depth of 0.125 m, providing a focal length of approximately 18.6 cm. Focused sunlight at this focal point can generate temperatures in excess of 300 °C, which is adequate for frying, boiling, and baking.

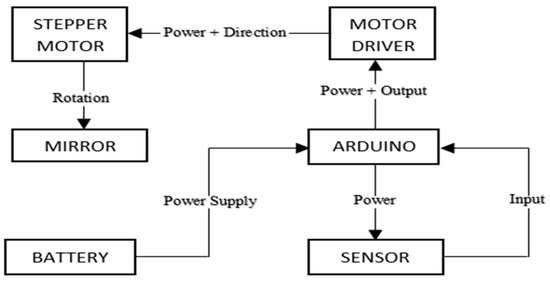

The block diagram shown in Figure 2 explains the electronic control architecture of the solar tracking mechanism. It displays the interactions between the sensor, Arduino microcontroller, motor driver, stepper motor, battery, and the parabolic mirror for effective and automatic solar tracking.

Figure 2.

Solar stove control system.

2.3. Materials and Construction

For the reflective surface, silver-coated glass mirrors were employed due to their high reflectivity (≥97%), which provides the effective concentration of sunlight. These were preferred over lighter materials such as Mylar film, acrylic sheets, or polished aluminum, which are less reflective (85–92%), more prone to damage, and may degrade under UV exposure and heat. Although heavier, glass mirrors do not change shape, are resistant to UV degradation, and provide long-term performance.

The frame is constructed from mild steel, which is very strong, inexpensive, and readily available locally. As it is rust-prone, the frame was coated with anti-rust primer and weather-resistant paint. It was chosen in place of lighter but pricey options such as aluminum or galvanized iron due to its optimal combination of strength, price, and local manufacture as shown in Table 1. It also held up under the weight of the mirrors without bending out of shape or losing alignment.

Table 1.

Comparison of different materials for construction.

It provides an efficient, portable, and energy-saving cooking option that can be easily replicated in remote locations using simple equipment.

Overall, this research integrates intelligent automation, hot cooking, local material use, and effective monitoring in a compact and portable product. It closes the gap between expensive solar technology and actual world community requirements and enables sustainable development and experiential engineering education.

3. Methodology

3.1. System Overview

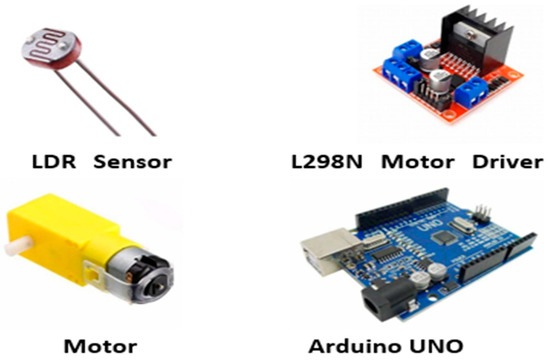

The solar tracking system was developed for increasing the efficiency of solar energy collection by adjusting the position of a frame with reference to the position of the sun. Similar components included a motor, an Arduino UNO microcontroller, a motor driver (L298N), and photosensitive resistors (LDR sensors) (Manufacturer: Electronics Pro, Lahore, Pakistan), which are also shown in Figure 3. The approach used for the project involved a systematic approach in the identification of the hardware, software, and system integration. The solar stove and motor handling stand were made using aluminum; this was to provide strength and adjustments to achieve correct positioning.

Figure 3.

Components used in solar stove.

3.2. Hardware Setup

In the setup, the Arduino UNO was connected with the motor driver, LDR sensors, and power supply. Two LDR sensors were used to measure changes in light intensity, and both of them were positioned at the left and right sides of the frame. These sensors were interfaced to analog interfaces A0 (left sensor) and A1 (right sensor) of the Arduino through connections. The conditions for these sensors are listed in Table 2. The motor driver L298N was applied to control the motors, and its terminals were connected to the Arduino board’s digital pins 8 and 9 with code names MOTOR_INPUT1 and MOTOR_INPUT2 correspondingly. Stepper motors were installed to adjust the panel’s angle according to the light measured by the sensors. A solderless breadboard along with jumper wires helped to make the connections easy, and all the connections were made modular so that in the case of a fault finding process, any connection could easily be isolated.

Table 2.

Conditions on the sensors feedback.

3.3. Software and Control Logic

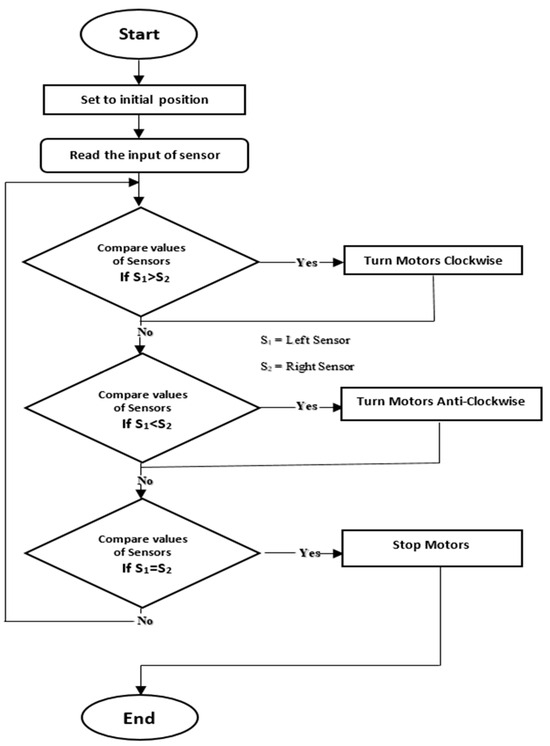

The Arduino code was created for the purpose of initially reading the LDR sensor, comparing light intensities, and controlling the motor. Should one sensor observe a higher light intensity than the other, the motor adjusted the orientation of the panel in the direction of the brighter light source. If both sensors register the same intensity, no motor is activated, and the panel maintains its position. The flowchart of the code is outlined in Figure 4.

Figure 4.

Flowchart of the logic control.

3.4. Testing and Calibration

Possible impairments of the code: The code was designed to consume minimal power so as to achieve constant effective motor operation. A series of trial-and-error tests were performed. Under low-light conditions, changes were made to the threshold values of the sensors as well as the logic controlling the motors to test the speed and accuracy of the system.

3.5. System Validation

After the assembly and electronic interconnection, the system was calibrated to ensure proper operation. In an attempt to overcome these problems, the LDR sensors were set to equalize prevailing ambient light conditions, while the range of motion of the motors was limited to avoid over-rotation of the panel and stand, which would exert mechanical stress on the structures. After calibrating the color dictionary, the system was tested in both indoor and outdoor environments under varying light conditions. The heat produced by the reflecting mirrors was measured with the tracking system and without it. This experiment showed an increase in energy harvesting with the functioning of the tracking mechanism.

4. Thermal Performance Analysis

To assess the capability of the solar parabolic dish to boil water, we calculated the energy required to heat 1 L of water and then determined the time needed using the power collected from solar irradiance.

4.1. Energy Required to Boil Water

The required energy for raising the temperature of 1 L (1 kg) of water from 25 °C to 100 °C is calculated using the following formula:

where

Q = mcΔT = 1 × 4186 × (100 − 25) = 313,950 J

- m = 1 kg (mass of water);

- c = 4186 J/kg·°C (specific heat of water);

- ΔT = 75 °C (temperature difference).

4.2. Collector Area and Power Calculation

The parabolic dish has a diameter of 24 inches (0.61 m), giving a surface area of

The useful power collected from solar irradiance is calculated using

where

P = A × I × η

- A = 0.292 m2 (collector area);

- I = solar irradiance in W/m2 (converted from kWh/m2/day);

- η = 70% efficiency (0.7), accounting for reflection and other losses.

4.3. Boiling Time Estimation

The boiling time for 1 L of water is then

This equation is applied to each month’s irradiance values.

4.4. Seasonal Variation in Performance

- April: At 6.65 kWh/m2/day solar irradiance, the system generates 1.35 kW and boils 1 L of water in 3.87 min.

- June: Higher irradiance (7.66 kWh/m2/day) increases power to 1.56 kW, reducing boiling time to 3.36 min.

- November: Lower irradiance (3.86 kWh/m2/day) results in 0.79 kW, extending the boiling time to 6.63 min.

5. Results and Discussion

5.1. Performance Evaluation Across Months

The solar tracking parabolic stove was experimentally evaluated during April, June, and November to represent different solar irradiance conditions. The active tracking system demonstrated clear improvements in thermal performance across all three months.

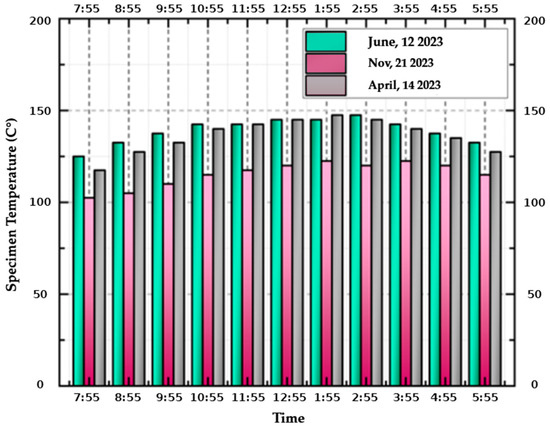

Figure 5 illustrates the temperature trends throughout the day, showing steady increases in each month. June recorded the highest temperatures, followed by April, while November showed the lowest. This variation corresponds directly to differences in solar irradiance.

Figure 5.

Comparison of water temperature achieved by the solar stove in different months.

The following Table 3 summarizes the monthly performance based on solar irradiance, usable power, boiling time, and peak temperature:

Table 3.

Monthly performance based on solar irradiance.

These data confirm the impact of seasonal variations in solar irradiance on the thermal performance of the solar tracking stove.

5.2. Impact of Solar Tracking

Experiments involving the integration of dual LDR sensors, an Arduino UNO, and a stepper motor enabled accurate real-time sun tracking. This precise alignment consistently focused sunlight on the stove’s focal point, resulting in

- Enhanced thermal energy capture;

- Faster boiling times;

- Stable heat performance throughout the day.

5.3. Comparison with Previous Research

Compared to the manually tracked PV system presented by Saeed et al. [14], which achieved an annual electrical output of 3984 kWh and a daily production of 11.412 kWh under semi-arid conditions, our system demonstrates superior performance in thermal applications. While their study focused on optimizing photovoltaic efficiency through manual solar tracking, our parabolic solar cooker with active dual-axis tracking achieved a usable thermal power output of up to 1550 W and was able to boil 1 L of water in just 3.37 min during peak summer irradiance (7.66 kWh/m2/day). Even under moderate conditions (6.65 kWh/m2/day), it delivered 1350 W and boiled water in 3.85 min. These findings highlight that although both systems leverage sun tracking, our approach offers a more rapid and direct thermal response—especially valuable for off-grid cooking and heating applications—thus extending the utility of solar tracking beyond electricity generation to efficient, high-temperature thermal use.

5.4. System Limitations

Despite its advantages, the system showed reduced efficiency under cloudy or diffused sunlight conditions, which impaired LDR sensor accuracy. The winter months also showed diminished performance, suggesting the potential need for

- Improved sensor technologies;

- Hybrid or predictive tracking algorithms for better alignment in low-light scenarios.

6. Conclusions

This research presented the design and testing of a low-cost, dual-axis parabolic dish solar cooker using automated sun tracking. The system effectively employed silver-coated glass mirrors (≥97% reflectivity) and a motorized spiral base for optimal solar alignment, reaching temperatures above 300 °C. It was able to cook different types of food and boil water under typical summer conditions, showing high thermal performance.

Made with locally accessible materials, the cooker offers affordability, mobility, and user-friendliness. Value addition through the facility to boil water and pasteurize fluids provides an advantage, particularly to off-grid populations. This initiative presents a consistent, low-maintenance, and environmentally friendly alternative to conventional cooking fuels, contributing to access to clean energy in disadvantaged areas.

Author Contributions

Conceptualization, H.A.K. and M.O.G.; methodology, H.A.K., M.H.N., and M.O.G.; software, H.A.K.; validation, H.A.K., M.H.N., and M.O.G.; formal analysis, H.A.K. and M.O.G.; investigation, M.H.N.; resources, H.A.K.; data curation, H.A.K. and M.O.G.; writing—original draft preparation, H.A.K. and M.O.G.; writing—review and editing, M.O.G.; visualization, H.A.K.; supervision, M.J.; project administration, M.J.; proof reading, M.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

The authors would like to thank the Ghulam Ishaq Khan Institute of Engineering Sciences and Technology for providing the necessary facilities and support during the project.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| CSP | Concentrated Solar Power |

| LDR | Light Dependent Resistor |

| UNO | Universal Numbering Object (Arduino UNO board) |

References

- Devan, P.; Bibin, C.; Gowtham, S.; Hariharan, G.; Hariharan, R. A comprehensive review on solar cooker with sun tracking system. Mater. Today Proc. 2020, 33, 771–777. [Google Scholar] [CrossRef]

- Gorjian, A.; Rahmati, E.; Gorjian, S.; Anand, A.; Jathar, L.D. A comprehensive study of research and development in concentrating solar cookers (CSCs): Design considerations, recent advancements, and economics. Sol. Energy 2022, 245, 80–107. [Google Scholar] [CrossRef]

- Höök, M.; Tang, X. Depletion of fossil fuels and anthropogenic climate change—A review. Energy Policy 2013, 52, 797–809. [Google Scholar] [CrossRef]

- Maka, A.O.; Alabid, J.M. Solar energy technology and its roles in sustainable development. Clean Energy 2022, 6, 476–483. [Google Scholar] [CrossRef]

- Jaiswal, K.K.; Chowdhury, C.R.; Yadav, D.; Verma, R.; Dutta, S.; Jaiswal, K.S.; Karuppasamy, K.S.K. Renewable and sustainable clean energy development and impact on social, economic, and environmental health. Energy Nexus 2022, 7, 100118. [Google Scholar] [CrossRef]

- Gonzalo, A.P.; Marugán, A.P.; Márquez, F.P.G. A review of the application performances of concentrated solar power systems. Appl. Energy 2019, 255, 113893. [Google Scholar] [CrossRef]

- Sonune, A.; Philip, S. Development of a domestic concentrating cooker. Renew. Energy 2003, 28, 1225–1234. [Google Scholar] [CrossRef]

- Mohammed, I.L. Design and development of a parabolic dish solar thermal cooker. Int. J. Eng. Res. Appl. 2013, 3, 1179–1186. [Google Scholar]

- Villamil, J.A.A.; Hortúa, J.E.; López, A. Design and construction of a solar collector parabolic dish for rural zones in Colombia. Tecciencia 2013, 7, 14–22. [Google Scholar]

- Zanganeh, G.; Bader, R.; Pedretti, A.; Pedretti, M.; Steinfeld, A. A solar dish concentrator based on ellipsoidal polyester membrane facets. Sol. Energy 2012, 86, 40–47. [Google Scholar] [CrossRef]

- Yosra, K.; Nizar, D.; Houssem, B.A.; Hsan, H.A. Design of a solar dish concentrator according to the needed energy for a given application. In Proceedings of the 14th International Conference on Sciences and Techniques of Automatic Control & Computer Engineering—STA’2013, Sousse, Tunisia, 20–22 December 2013; pp. 425–431. [Google Scholar]

- Poullikkas, A.; Kourtis, G.; Hadjipaschalis, I. Parametric analysis for the installation of solar dish technologies in Mediterranean regions. Renew. Sustain. Energy Rev. 2010, 14, 2772–2783. [Google Scholar] [CrossRef]

- Loni, R.; Asli-Areh, E.A.; Ghobadian, B.; Kasaeian, A.; Gorjian, S.; Najafi, G.; Bellos, E. Research and review study of solar dish concentrators with different nanofluids and different shapes of cavity receiver: Experimental tests. Renew. Energy 2020, 145, 783–804. [Google Scholar] [CrossRef]

- Saeed, F.; Ghafoor, A.; Hussain, M.I.; Ikram, K.; Faheem, M.; Shahzad, M.; Amjad, W.; Omar, M.M.; Lee, G.H. Empirical and numerical-based predictive analysis of a single-axis PV system under semi-arid climate conditions of Pakistan. Front. Energy Res. 2024, 11, 1293615. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).