Abstract

Sulfur recovery units are integral to the oil and gas industry, addressing the release of hazardous gases, particularly hydrogen sulfide. These units facilitate the conversion of H2S into elemental sulfur, aligning with stringent environmental regulations. This study employs a machine learning algorithm to predict sulfur recovery efficiency under uncertain conditions. An industrial sulfur recovery unit was simulated in Aspen HYSYS and validated using real-world industrial data. The simulation incorporated artificial uncertainties (±5%) in key process parameters, including acid gas flow rate, acid gas temperature, air flow rate, air temperature, and Claus reactor inlet temperature. The generated data were utilized to train a Gaussian process regression model, assessed through R2 and RMSE values during validation, achieving a high predictive accuracy with an R2 value of 0.993 and RMSE value of 0.0709. In the next step, the Gaussian process regression model served as a surrogate for fitness function evaluations within a particle swarm optimization framework. The application of a hybrid optimization methodology resulted in the optimal parameter values, leading to a notable 3% increase in sulfur recovery efficiency. This study establishes the foundation for applying industry 4.0 principles to augment predictive capabilities in sulfur recovery units, thereby laying the groundwork for the development of digital twins.

1. Introduction

The stringent regulation of hydrogen sulfide (H2S) emissions emphasizes the critical need for effective sulfur recovery units (SRUs). The management of sulfur contaminants emission poses significant challenges, bearing environmental and economic implications. Consequently, even modest improvements in efficiency, operational costs, and energy management within SRUs hold considerable value.

Numerous studies have been carried out to maximize sulfur production while minimizing the adverse effects on the environment. Flavio et al. used a multiscale optimization approach to enhance sulfur production and steam generation in an industrial SRU. They employed the study aimed to maximize sulfur production and steam generation, revealing a potential 6% improvement in steam generation while maintaining optimal sulfur production [1]. Kazempour et al. study optimized the thermal section of the Claus process, using a kinetic model. Sensitivity analysis explored the impact of various factors on sulfur recovery efficiency, steam production, and the H2S/SO2 ratio. Multi-objective optimization, employing response surface methodology, revealed that a slight decrease in sulfur recovery efficiency enhances steam production, while a significant improvement in the H2S/SO2 ratio compensates for reduced efficiency [2]. Ghahraloud et al. optimized an industrial-modified Claus process for maximum sulfur recovery using a Genetic Algorithm. Key decision variables include inlet temperatures, feed distribution, and airflow rate. The optimized process demonstrates a significant 4.63% improvement in sulfur recovery compared to conventional methods [3].

Ramees K et al. focused on optimizing SRU for heightened efficiency in minimizing sulfur emissions. The research developed a multi-objective optimization model with a detailed reaction mechanism validated using SRU plant data. The thermal and catalytic sections were simulated using Chemkin Pro and Aspen HYSYS, respectively, and integrated and optimized using MATLAB with genetic algorithm and artificial neural network techniques. The optimized SRU operation achieves a 98% reduction in fuel gas consumption, along with decreased temperatures of air and acid gas, and maintains low aromatics emissions (<1 ppm) [4]. Thameem et al. investigated emissions from an SRU. Artificial intelligence-based models were tested and optimized, revealing that the CNN-LSTM autoencoder model outperforms others [5]. Efforts in emission control, contaminant destruction, and sulfur production optimization still leave a gap in predictive modeling for Sulfur Recovery Efficiency (SRE) [2,5]. Previous studies, while advancing sulfur production, prioritized optimization over holistic SRE predictive modeling, often overlooking the potential benefits of advanced machine learning techniques. Our study addresses these gaps by introducing novel contributions:

- Predictive modeling with machine learning by introducing Gaussian process regression (GPR) for forecasting SRE. It enhances our understanding of sulfur recovery efficiency under varying and uncertain conditions.

- Surrogate-assisted particle swarm optimization modeling, integrating predictive modeling for more efficient SRU parameter optimization. The synergy between the surrogate model and PSO enhances overall sulfur recovery efficiency.

2. Process Description

The SRU employs a modified Claus process featuring two key sections. In the initial thermal phase, consisting of a furnace reactor and Waste Heat Boiler (WHB), one-third of H2S oxidizes to produce SO2, with the furnace reactor operating at an outlet temperature of 1053 °C. Downstream of the WHB, two catalytic reactors function at temperatures between 250 and 200 °C, facilitating the conversion of SO2, H2S, and other sulfur-containing compounds [6]. Rigorous temperature control ensures that outlet stream temperatures from the furnace and each converter remain below the dew point of sulfur, preventing sulfur deposition. Alumina is used as the catalyst in these reactors [7]. Due to the equilibrium nature of the chemical reaction, achieving complete conversion of incoming sulfur compounds to elemental sulfur is unattainable in a single Claus plant stage.

Consequently, multiple stages operate in series, with each catalytic stage recovering half to two-thirds of the incoming sulfur. The WHB, integrated with the furnace, cools the outlet stream, and a subsequent condenser further lowers the temperature, facilitating the formation of liquid elemental sulfur. The collected liquid sulfur is stored in a designated tank, while the gas stream undergoes reheating before entering the catalytic section. This preheating step prevents liquid sulfur formation, ensuring catalyst integrity.

3. Methodology

First-Principle Model: A first-principle model for SRU was developed using Aspen Hysys, ensuring accuracy and real-world relevance through the incorporation of literature data and validation against industrial data.

Data Generation and Dynamic Simulation: Transitioning the Aspen Hysys model into dynamic mode, an interface between MATLAB and Aspen Hysys was established to introduce ±5% uncertainty in critical process conditions. This dynamic mode created a dataset of 1000 samples, simulating real-world variability.

GPR Model Development: A GPR model was developed using MATLAB. The evaluation criteria for the model are RMSE and R2 values shown in Equations (1) and (2), respectively.

PSO-Based Evolutionary Optimization: The developed GPR model was used to evaluate fitness function in the PSO framework.

4. Results and Discussion

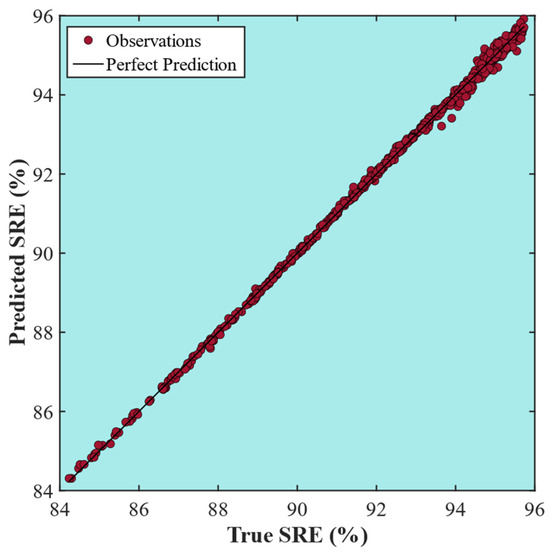

The GPR model was formulated, trained, and assessed using MATLAB 2023b. A dataset comprising 1000 data points was generated, incorporating artificial uncertainties in six operating conditions. For model development, 70% of the data points were randomly selected for training, while the remaining 30% were reserved for testing. Figure 1 displays the R2 graph, illustrating the correlation between actual SRE values and predictions from the proposed GPR model. The figure visually communicates a robust correlation between the predicted and actual SRE values.

Figure 1.

Actual vs Predicted SRE.

The model’s reliability and accuracy are reinforced by reported performance metrics, including a low Root Mean Squared Error (RMSE) of 0.0709 and a high R-squared value of 0.994.

The R2 graph serves as a crucial visualization tool, showcasing the GPR model’s proficiency in capturing underlying patterns and variations in the dataset. The near 1 R-squared value indicates the model’s capability to explain a substantial proportion of variability in the observed data. This capability is particularly essential in an industrial setting, where correct predictions of SRE values are paramount for assessing and optimizing sulfur recovery units. Furthermore, the accurate prediction of SRE values positions the GPR model as a trustworthy surrogate model in optimization networks.

The optimized parameter values of SRU are shown in Table 1. The sulfur recovery unit’s performance significantly improved using a PSO-based hybrid framework compared to straight run conditions, resulting in a 3% increase in Sulfur Recovery Efficiency. The shift from 93.29 SRE in a straight run to 96.01 highlights the effectiveness of the optimization process. Notably, our achieved SRE surpasses the reported 95.10 in a comparable optimization study in the literature, showcasing the superior performance of our approach [4].

Table 1.

Comparison of straight run and GPR-PSO framework.

5. Conclusions

This research addresses critical challenges in sulfur recovery units by employing advanced modeling techniques. The first-principle model, developed using Aspen Hysys and validated with industrial data, lays the groundwork for predicting SRE under uncertain conditions. The integration of a GPR model, trained on a dynamic dataset with ±5% uncertainty, exhibits high predictive accuracy, having an R2 value of 0.989. Furthermore, the GPR model, serving as a surrogate in a PSO framework, leads to a notable 3% increase in sulfur recovery efficiency. This study not only contributes to predictive modeling in the context of SRUs but also establishes a foundation for Industry 4.0 application, paving the way for enhanced sustainability and compliance in the oil and gas industry.

Author Contributions

Conceptualization, M.A.; methodology and visualization, I.K.; investigation, I.K. and H.S.; resources and validation, M.A. and I.K.; writing—original draft preparation, I.K.; writing—review and editing and supervision, M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Manenti, F.; Papasidero, D.; Bozzano, G.; Ranzi, E. Model-based optimization of sulfur recovery units. Comput. Chem. Eng. 2014, 66, 244–251. [Google Scholar] [CrossRef]

- Kazempour, H.; Pourfayaz, F.; Mehrpooya, M. Modeling and multi-optimization of thermal section of Claus process based on kinetic model. J. Nat. Gas Sci. Eng. 2017, 38, 235–244. [Google Scholar] [CrossRef]

- Ghahraloud, H.; Farsi, M.; Rahimpour, M. Modeling and optimization of an industrial Claus process: Thermal and catalytic section. J. Taiwan Inst. Chem. Eng. 2017, 76, 1–9. [Google Scholar] [CrossRef]

- Rahman, R.K.; Ibrahim, S.; Raj, A. Multi-objective optimization of sulfur recovery units using a detailed reaction mechanism to reduce energy consumption and destruct feed contaminants. Comput. Chem. Eng. 2019, 128, 21–34. [Google Scholar] [CrossRef]

- Thameem, M.; Raj, A.; Berrouk, A.; Jaoude, M.A.; AlHammadi, A.A. Artificial Intelligence-Based Forecasting Model for Incinerator in Sulfur Recovery Units to Predict So2 Emissions. Environ. Res. 2024, 249, 118329. [Google Scholar] [CrossRef]

- Ibrahim, S.; Rahman, R.K.; Raj, A. Dual-stage acid gas combustion to increase sulfur recovery and decrease the number of catalytic units in sulfur recovery units. Appl. Therm. Eng. 2019, 156, 576–586. [Google Scholar] [CrossRef]

- Hashemi, M.; Pourfayaz, F.; Mehrpooya, M. Energy, exergy, exergoeconomic and sensitivity analyses of modified Claus process in a gas refinery sulfur recovery unit. J. Clean. Prod. 2019, 220, 1071–1087. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).