Experimental and Numerical Investigation of Jute Fibre-Reinforced Composite, a Sustainable Material for Green Energy †

Abstract

1. Introduction

2. Method of Fabrication and Materials

2.1. Materials Obtained from Different Sources

2.2. Fabrication of NFRC Using the VARTM Process

2.3. Numerical Analysis of NFRC by FEA Software

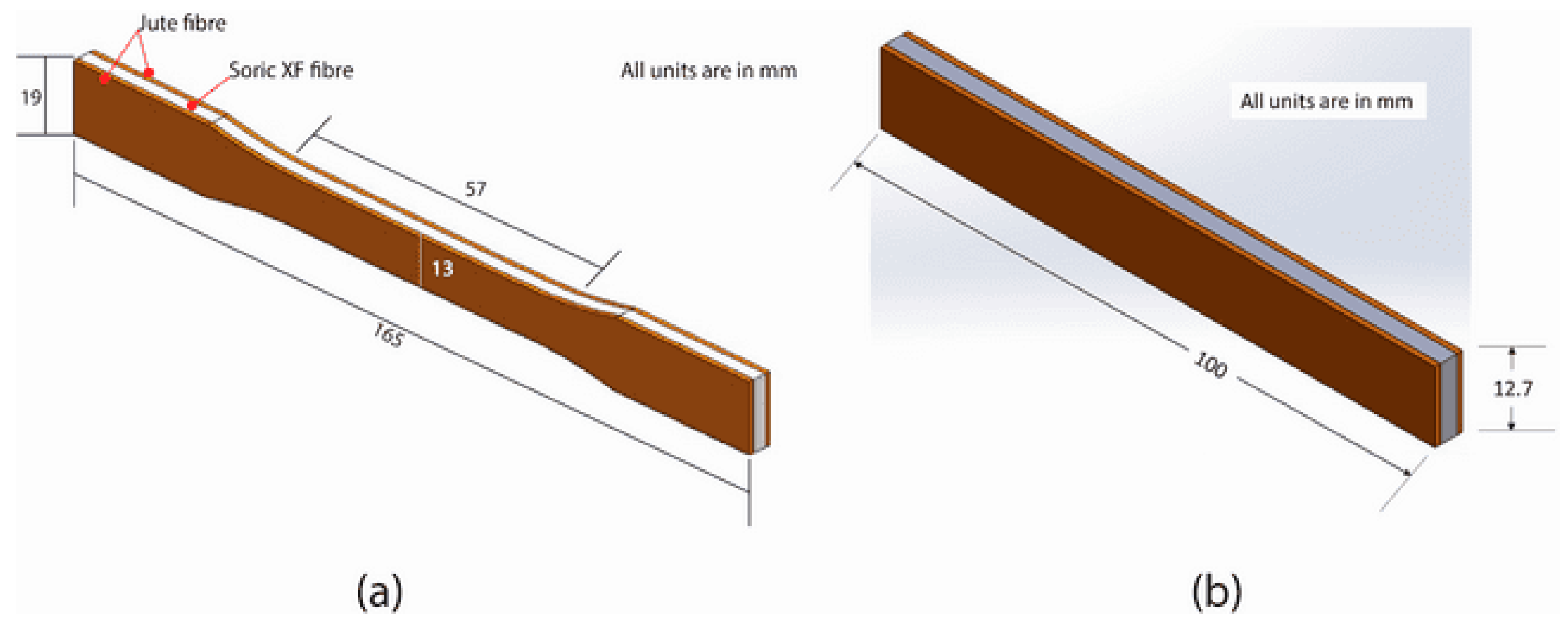

2.3.1. Three-Dimensional Modelling of the ASTM D638-03 and ASTM D790 NFRC Structure

2.3.2. Boundary Conditions

3. Results and Discussion

3.1. Tensile Test

3.1.1. An Experimental Test of an ASTM D638 Tensile Specimen

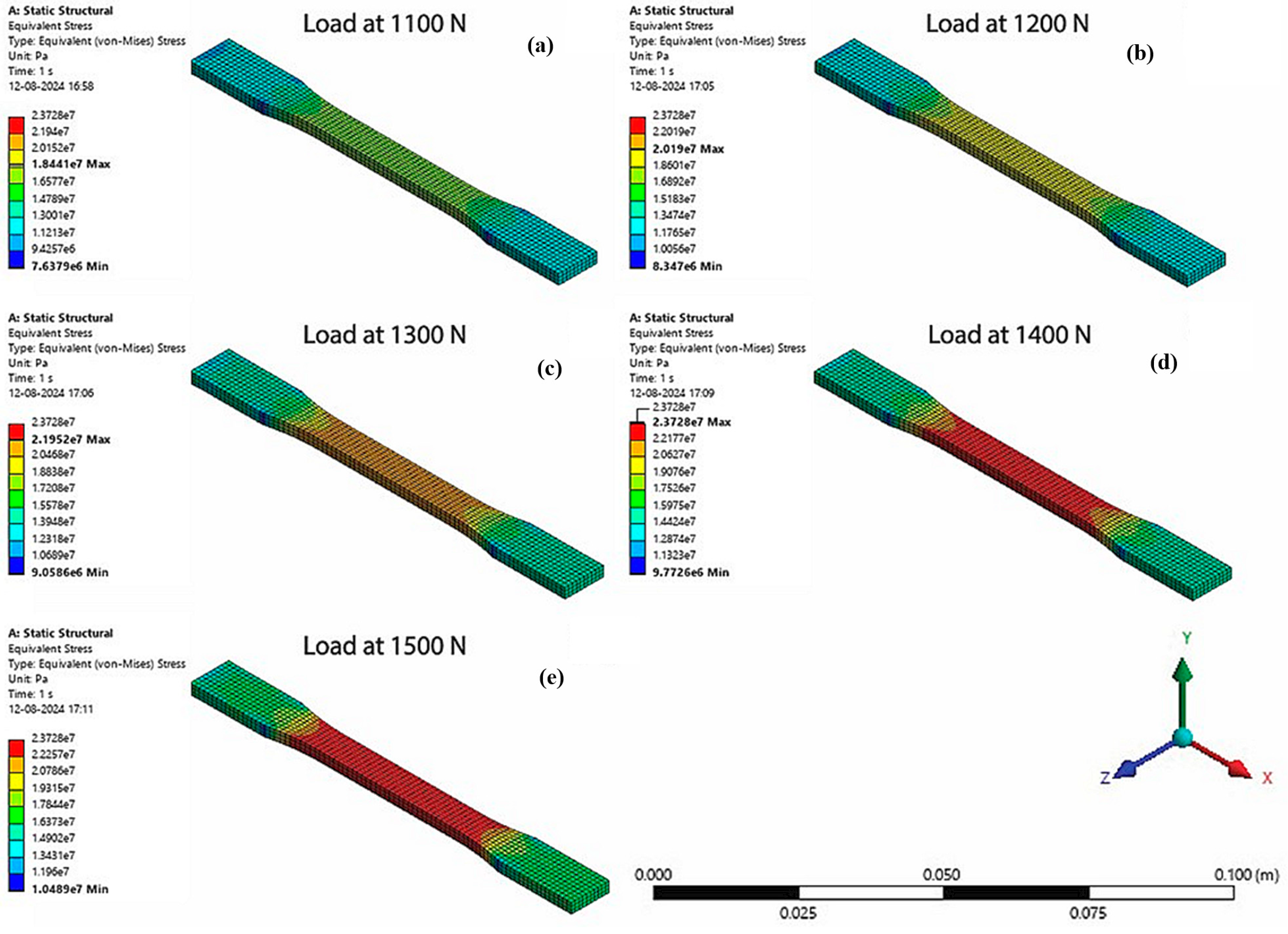

3.1.2. A Computational Test of an ASTM D638-03 Tensile Structure

3.1.3. Comparative Results of the Experimental and Computational Test on an ASTM D638-03 Tensile Structure

3.2. Flexural Test

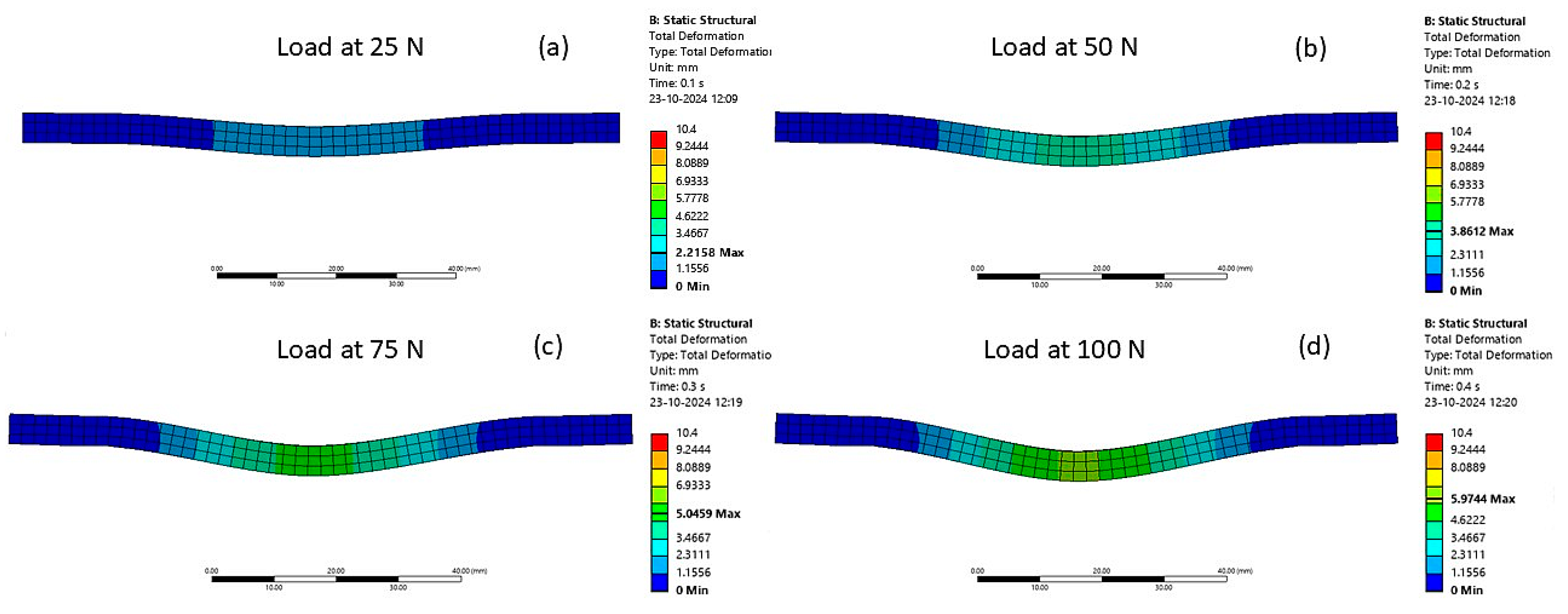

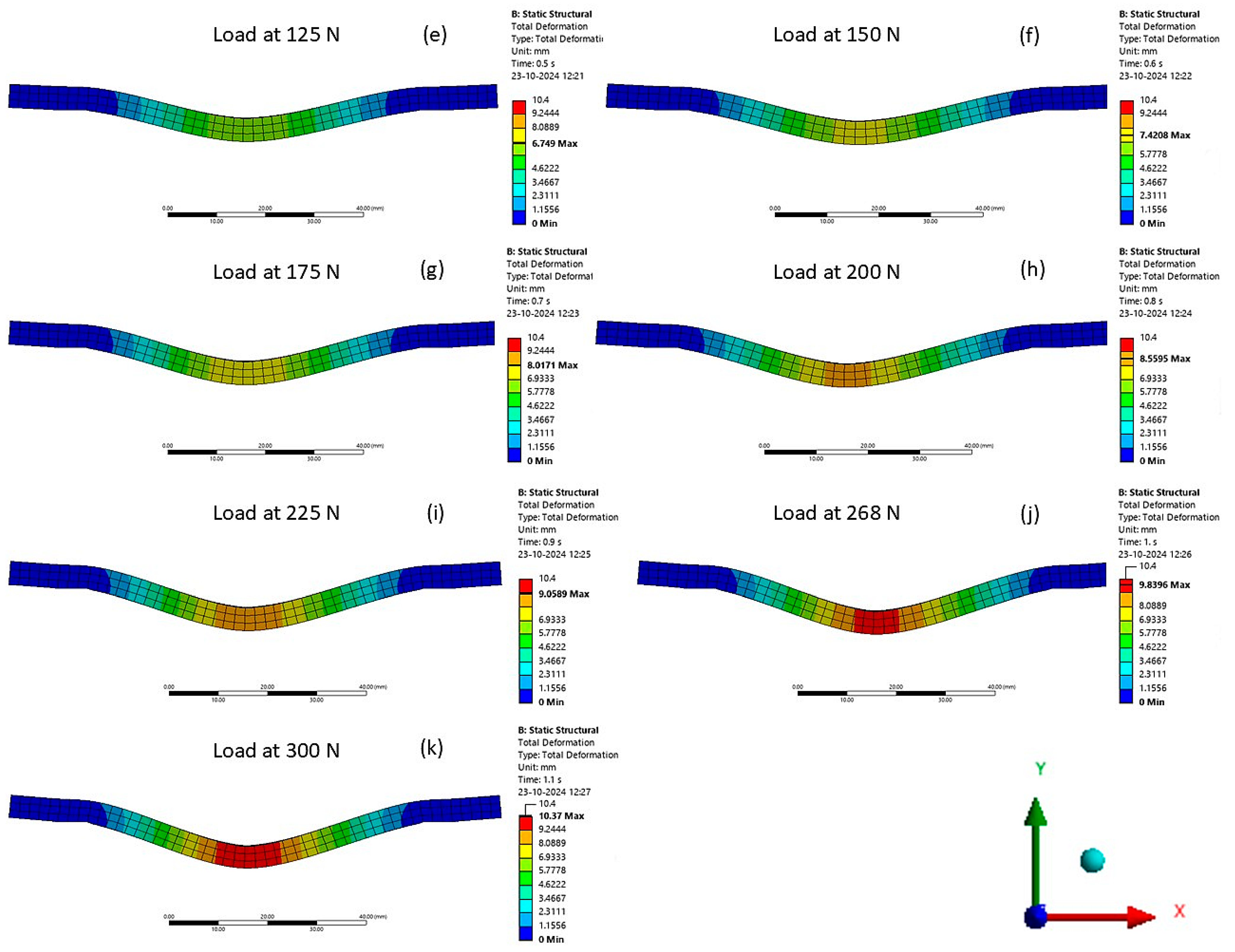

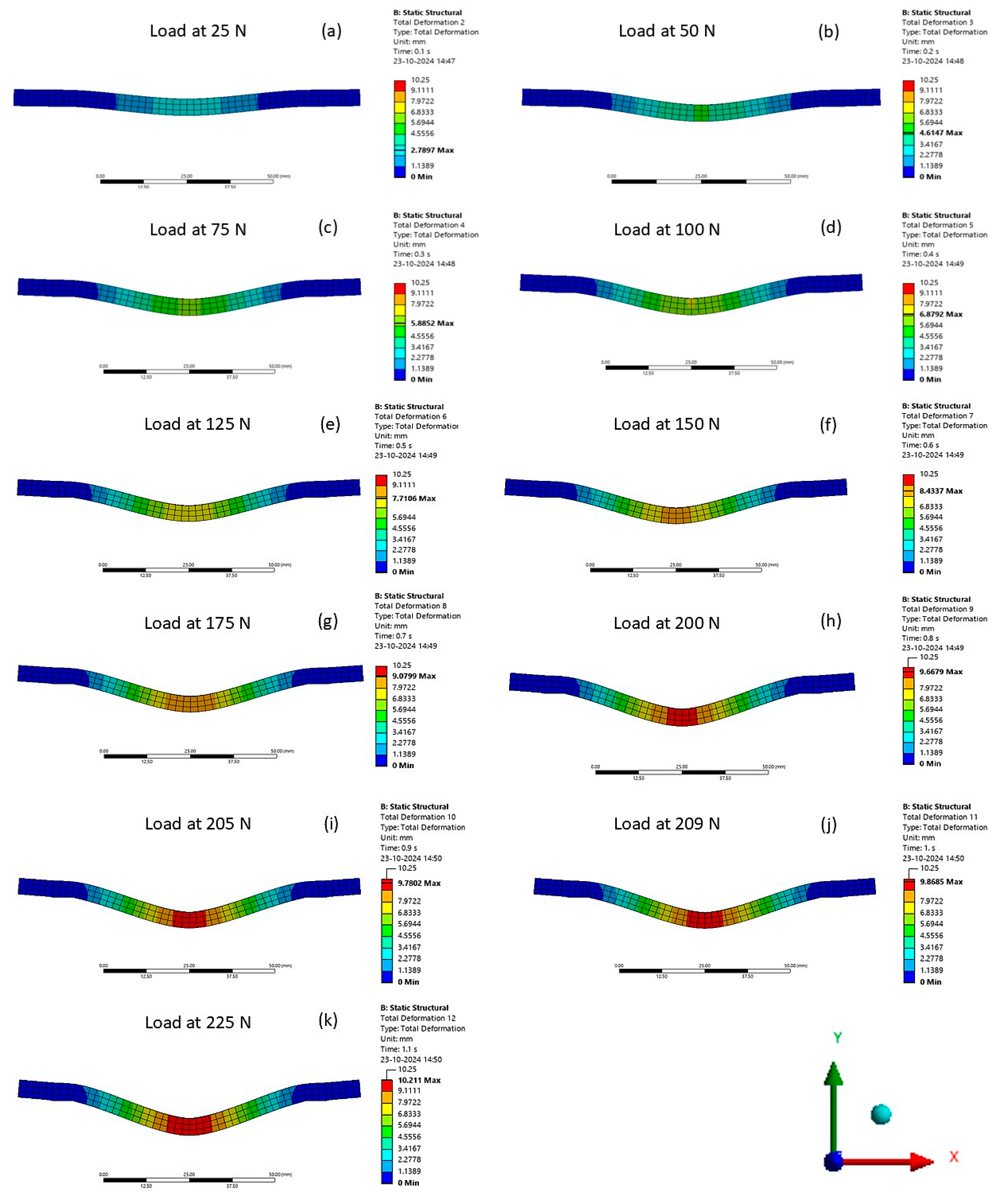

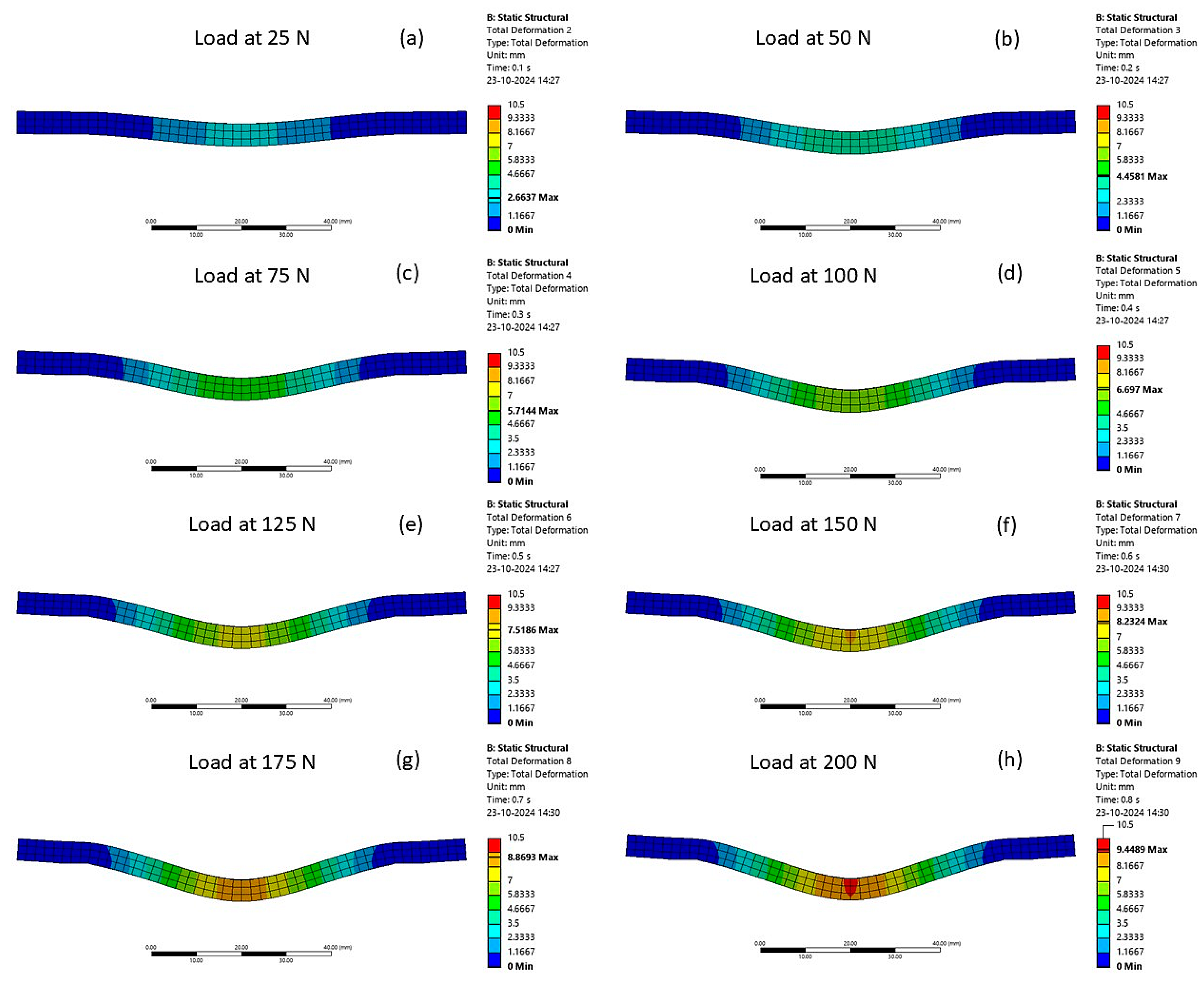

3.2.1. A Computational Test of an ASTM D790 Flexural Structure

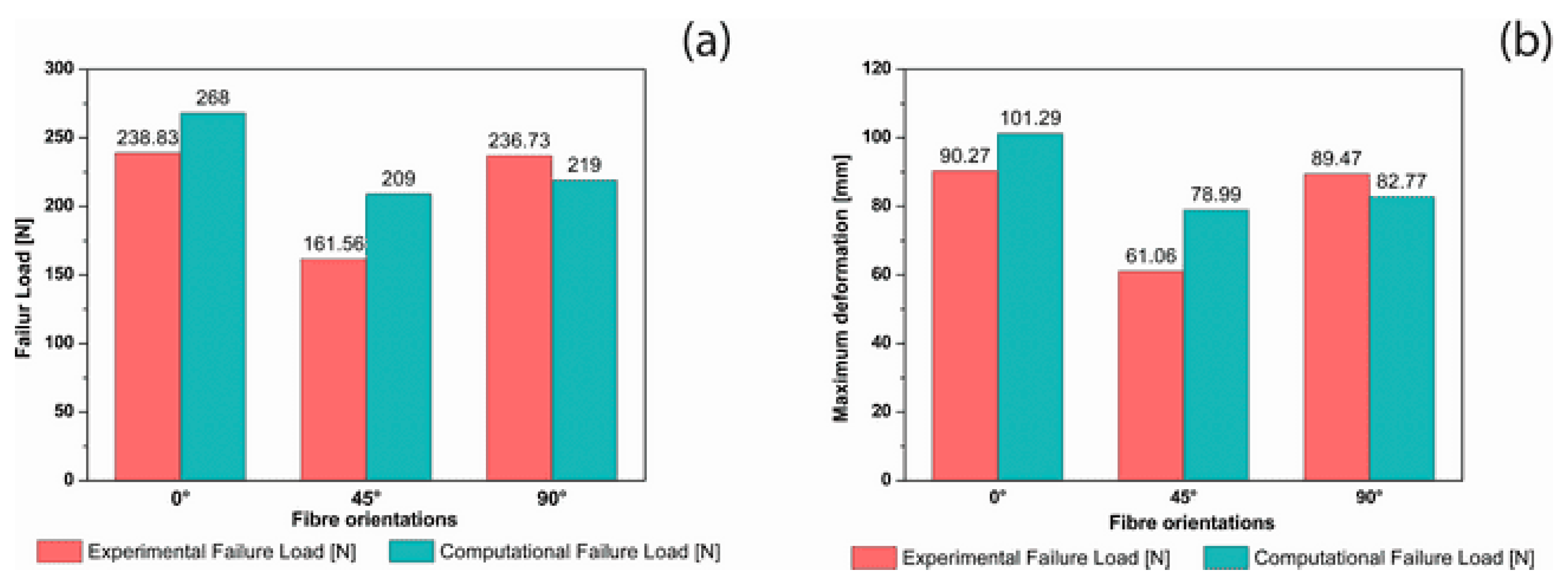

3.2.2. Comparative Results of the Experimental and Computational Test of an ASTM D638-03 Tensile Structure

4. Conclusions

4.1. Summary of the Tensile Test

- Fibre orientation of 0°

- Fibre orientation of 45°

- Fibre orientation of 90°

4.2. Summary of the Flexural Test

- Fibre orientation of 0°

- Fibre orientation of 45°

- Fibre orientation of 90°

- Experimental and Computational study

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ekundayo, G.; Gong, H.; Abeykoon, C. Jute Fibre Reinforced Polymer Composites in Structural Applications: A Review. J. Mater. Polym. Sci. 2024, 4, 1–13. [Google Scholar] [CrossRef]

- Sarker, F.; Karim, N.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Potluri, P. High-Performance Graphene-Based Natural Fiber Composites. ACS Appl. Mater. Interfaces 2018, 10, 34502–34512. [Google Scholar] [CrossRef] [PubMed]

- Sangmesh, B.; Patil, N.; Jaiswal, K.K.; Gowrishankar, T.; Selvakumar, K.K.; Jyothi, M.; Jyothilakshmi, R.; Kumar, S. Development of sustainable alternative materials for the construction of green buildings using agricultural residues: A review. Constr. Build. Mater. 2023, 368, 130457. [Google Scholar] [CrossRef]

- Jaiswal, K.K.; Chowdhury, C.R.; Yadav, D.; Verma, R.; Dutta, S.; Jaiswal, K.S.; B, S.; Karuppasamy, K.S.K. Renewable and sustainable clean energy development and impact on social, economic, and environmental health. Energy Nexus 2022, 7, 100118. [Google Scholar] [CrossRef]

- Karaçor, B.; Özcanlı, M.; Serin, H. The influence of hybridization and different manufacturing methods on the mechanical properties of the composites reinforced with basalt, jute, and flax fibers. Iran. Polym. J. 2024, 33, 289–304. [Google Scholar] [CrossRef]

- Arya, M.; Malmek, E.-M.; Ecoist, T.K.; Pettersson, J.; Skrifvars, M.; Khalili, P. Enhancing Sustainability: Jute Fiber-Reinforced Bio-Based Sandwich Composites for Use in Battery Boxes. Polymers 2023, 15, 3842. [Google Scholar] [CrossRef]

- Mahesh, V.; Mahesh, V. Development and Mechanical Characterization of Light Weight Fiber Metal Laminate using Jute, Kenaf and Aluminium. Mech. Adv. Compos. Struct. 2024, 11, 259–270. [Google Scholar] [CrossRef]

- Farooq, U.; Ahmad, M.S.; Rakha, S.A.; Ali, N.; Khurram, A.A.; Subhani, T. Interfacial Mechanical Performance of Composite Honeycomb Sandwich Panels for Aerospace Applications. Arab. J. Sci. Eng. 2017, 42, 1775–1782. [Google Scholar] [CrossRef]

- Tamakuwala, V.R. Manufacturing of fiber reinforced polymer by using VARTM process: A review. Mater. Today Proc. 2021, 44, 987–993. [Google Scholar] [CrossRef]

- Kurien, R.A.; Arshad, A.; Joseph, A.; Sunil, A.; Cherian, B.T.; Rangappa, S.M.; Suttiruengwong, S.; Kannan, G.; Siengchin, S. Agave-jute fiber–reinforced hybrid composite for lightweight applications: Effect of hybridization. Biomass Convers. Biorefinery 2025, 15, 12241–12254. [Google Scholar] [CrossRef]

- Srikanth, R.; Vali, S.K.; Saraswathamma, K.; Sadaq, S.I. Investigation of optimum stacking sequence of pineapple leaf fiber composite laminate using numerical approach. Interactions 2024, 245, 188. [Google Scholar] [CrossRef]

- Suman, S.; Balaji, P.S.; Selvakumar, K.; Kumaraswamidhas, L.A. Nonlinear Vibration Control Device for a Vehicle Suspension Using Negative Stiffness Mechanism. J. Vib. Eng. Technol. 2021, 9, 957–966. [Google Scholar] [CrossRef]

- Sinha, A.K.; Narang, H.K.; Bhattacharya, S. Mechanical properties of natural fibre polymer composites. J. Polym. Eng. 2017, 37, 879–895. [Google Scholar] [CrossRef]

- Mostafa, N.H.; Hunain, M.B.; Jassim, A. Mechanical properties of the Jute fibers-activated carbon filled reinforced polyester composites. Mater. Res. Express 2019, 6, 125104. [Google Scholar] [CrossRef]

- Sanivada, U.K.; Mármol, G.; Brito, F.P.; Fangueiro, R. PLA Composites Reinforced with Flax and Jute Fibers—A Review of Recent Trends, Processing Parameters and Mechanical Properties. Polymers 2020, 12, 2373. [Google Scholar] [CrossRef]

- Al-Shammri, M.A.; Abdullah, S.E. Experimental and Numerical Investigation of Hyper Composite Plate Structure Under Thermal and Mechanical Loadings. J. Eng. 2017, 23, 56–69. [Google Scholar] [CrossRef]

- Trindade, D.; Habiba, R.; Fernandes, C.; Costa, A.A.; Silva, R.; Alves, N.; Martins, R.; Malça, C.; Branco, R.; Moura, C. Material Performance Evaluation for Customized Orthoses: Compression, Flexural, and Tensile Tests Combined with Finite Element Analysis. Polymers 2024, 16, 2553. [Google Scholar] [CrossRef]

- Venkatesan, K.; Bhaskar, G.B. Evaluation and Comparison of Mechanical Properties of Natural Fiber Abaca-sisal Composite. Fibers Polym. 2020, 21, 1523–1534. [Google Scholar] [CrossRef]

- Feng, L.; Wang, D.; Yan, J. Reliability Study of Wood–Plastic Composites Based on Probabilistic Finite Elements. Polymers 2023, 15, 312. [Google Scholar] [CrossRef]

- G, P.C.; Reddy, M.S.; Rajendrachari, S.; Mahale, R.S.; Mahesh, V.; Pandith, A. The Behavior of Banyan (B)/Banana (Ba) Fibers Reinforced Hybrid Composites Influenced by Chemical Treatment on Tensile, Bending and Water Absorption Behavior: An Experimental and FEA Investigation. J. Compos. Sci. 2024, 8, 31. [Google Scholar] [CrossRef]

- Kumar, K.K.S.; Kumaraswamidhas, L.A. Investigation on Stability of an Elastically Mounted Circular Tube under Cross-Flow in Inline Square Arrangement. Iran. J. Sci. Technol. Trans. Mech. Eng. 2020, 44, 313–325. [Google Scholar] [CrossRef]

- Sujita, S.; Sutanto, R. Influence of drying methods on tensile strength of polyester composites reinforced apus bamboo. World J. Adv. Eng. Technol. Sci. 2024, 12, 245–249. [Google Scholar] [CrossRef]

- Nagarajaiah, M.; Mahadevaiah, R.R.; Parshuram, K.R.B.; Hiremath, P. A Numerical Study on Coconut Inflorescence Stem-Fiber-Reinforced Panels Subjected to Tensile Load, Compressive Load, and Flexural Load. Eng. Proc. 2024, 59, 233. [Google Scholar] [CrossRef]

- Habib, A.; Rajoni, H.; Sayeed, A.; Islam, M.; Sajedujjaman, A.T.M.; Saifullah, A.; Sarker, F. Sustainable Jute Fiber Sandwich Composites with Hybridization of Short Fiber and Woven Fabric Structures in Core and Skin Layers. Macromol. Mater. Eng. 2024, 309, 2400138. [Google Scholar] [CrossRef]

| Properties/Fibre Orientations | 0° | 45° | 90° |

|---|---|---|---|

| Young’s Modulus [MPa] | 170.3588 | 130.4588 | 138.2963 |

| Poisson’s Ratio | 0.219231 | 0.164423 | 0.191827 |

| Ultimate Tensile Strength [MPa] | 23.91 | 18.31 | 19.41 |

| Tensile Yield Strength [MPa] | 23.91 | 18.35 | 19.41 |

| Fibre Orientations | Ultimate Tensile Strength (MPa) | Ultimate Load (N) | Breaking Load (N) | Maximum Displacement (mm) |

|---|---|---|---|---|

| 0° | 23.91 | 1570.69 | 1570.69 | 1570.69 |

| 45° | 18.31 | 1229.29 | 1195.58 | 1195.58 |

| 90° | 19.41 | 1463.21 | 1463.21 | 1463.21 |

| Load [N] | Maximum Deformation [mm] | Deformation Along Gauge Length [mm] | Minimum von Mises Stress [MPa] | Maximum von Mises Stress [Mpa] | Safety Factor |

|---|---|---|---|---|---|

| 1100 N | 15.09 | 10.663 | 7.6379 | 18.441 | 1.2966 |

| 1200 N | 16.596 | 11.732 | 8.347 | 20.19 | 1.1843 |

| 1300 N | 18.128 | 12.819 | 9.0586 | 21.952 | 1.0892 |

| 1400 N | 19.684 | 13.926 | 9.7726 | 23.728 | 1.0077 |

| 1500 N | 21.267 | 15.052 | 10.489 | 25.517 | 0.93704 |

| Load [N] | Maximum Deformation [mm] | Deformation Along Gauge Length [mm] | Minimum von Mises Stress [MPa] | Maximum von Mises Stress [Mpa] | Safety Factor |

|---|---|---|---|---|---|

| 800 N | 14.13 | 9.9792 | 5.5073 | 13.234 | 1.3835 |

| 900 N | 16.041 | 11.334 | 6.242 | 14.936 | 1.2259 |

| 1000 N | 17.989 | 12.716 | 6.9868 | 16.648 | 1.0998 |

| 1095 N | 19.872 | 14.052 | 7.7039 | 18.285 | 1.0014 |

| 1200 N | 21.992 | 15.559 | 8.507 | 20.105 | 0.9107 |

| Load [N] | Maximum Deformation [mm] | Deformation Along Gauge Length [mm] | Minimum von Mises Stress [MPa] | Maximum von Mises Stress [Mpa] | Safety Factor |

|---|---|---|---|---|---|

| 800 N | 14.233 | 10.054 | 5.8773 | 14.142 | 1.3726 |

| 900 N | 16.056 | 11.346 | 6.6178 | 15.864 | 1.2235 |

| 1050 N | 17.913 | 12.664 | 7.3688 | 17.599 | 1.1029 |

| 1200 N | 19.806 | 13.119 | 7.7703 | 19.371 | 1.002 |

| 1350 N | 20.965 | 14.759 | 8.7416 | 21.792 | 0.8907 |

| Fibre Orientations | Ultimate Flexural Strength (MPa) | Ultimate Load (N) | Ultimate Stress (N/mm2) | Breaking Load (N) | Maximum Displacement (mm) |

|---|---|---|---|---|---|

| 0° | 44.265 | 238.83 | 3.44 | 158.75 | 3.11 |

| 45° | 29.943 | 161.56 | 2.64 | 161.56 | 3.43 |

| 90° | 43.876 | 236.73 | 3.45 | 221.27 | 2.77 |

| Load [N] | Deformation [mm] | Minimum von Mises Stress [MPa] | Maximum von Mises Stress [Mpa] | Safety Factor |

|---|---|---|---|---|

| 25 | 2.2158 | 2.82 × 10−4 | 4.0419 | 5.9155 |

| 50 | 3.8612 | 5.55 × 10−4 | 7.4825 | 3.1955 |

| 75 | 5.0459 | 7.63 × 10−4 | 10.235 | 2.336 |

| 100 | 5.9744 | 9.65 × 10−4 | 12.568 | 1.9024 |

| 125 | 6.749 | 1.13 × 10−3 | 14.632 | 1.6341 |

| 150 | 7.4208 | 1.26 × 10−3 | 16.511 | 1.4481 |

| 175 | 8.0171 | 1.40 × 10−3 | 18.244 | 1.3106 |

| 200 | 8.5595 | 1.52 × 10−3 | 19.869 | 1.2034 |

| 225 | 9.0589 | 1.64 × 10−3 | 21.406 | 1.117 |

| 268 | 9.8396 | 1.82 × 10−3 | 23.884 | 1.0011 |

| 300 | 10.37 | 1.93 × 10−3 | 25.622 | 0.93319 |

| Load [N] | Deformation [mm] | Minimum von Mises Stress [MPa] | Maximum von Mises Stress [Mpa] | Safety Factor |

|---|---|---|---|---|

| 25 | 2.7897 | 1.96 × 10−4 | 3.982 | 4.6083 |

| 50 | 4.6147 | 4.32 × 10−4 | 7.0466 | 2.6041 |

| 75 | 5.8852 | 5.92 × 10−4 | 9.4325 | 1.9454 |

| 100 | 6.8792 | 7.74 × 10−4 | 11.452 | 1.6024 |

| 125 | 7.7106 | 9.23 × 10−4 | 13.241 | 1.3859 |

| 150 | 8.4337 | 1.02 × 10−3 | 14.872 | 1.2338 |

| 175 | 9.0799 | 1.12 × 10−3 | 16.382 | 1.1201 |

| 200 | 9.6679 | 1.23 × 10−3 | 17.799 | 1.0309 |

| 205 | 9.7802 | 1.33 × 10−3 | 18.074 | 1.0153 |

| 209 | 9.8685 | 1.35 × 10−3 | 18.288 | 1.0034 |

| 225 | 10.211 | 1.43 × 10−3 | 19.139 | 0.95876 |

| Load [N] | Deformation [mm] | Minimum von Mises Stress [MPa] | Maximum von Mises Stress [Mpa] | Safety Factor |

|---|---|---|---|---|

| 25 | 2.6637 | 2.27 × 10−4 | 4.0078 | 4.8431 |

| 50 | 4.4581 | 4.43 × 10−4 | 7.1675 | 2.708 |

| 75 | 5.7144 | 5.92 × 10−4 | 9.6383 | 2.0138 |

| 100 | 6.697 | 7.62 × 10−4 | 11.729 | 1.6549 |

| 125 | 7.5186 | 8.95 × 10−4 | 13.581 | 1.4292 |

| 150 | 8.2324 | 9.97 × 10−4 | 15.269 | 1.2712 |

| 175 | 8.8693 | 1.11 × 10−3 | 16.83 | 1.1533 |

| 200 | 9.4489 | 1.22 × 10−3 | 18.296 | 1.0609 |

| 219 | 9.8602 | 1.30 × 10−3 | 19.357 | 1.0027 |

| 225 | 9.9848 | 1.32 × 10−3 | 19.685 | 0.98603 |

| 250 | 10.482 | 1.41 × 10−3 | 21.004 | 0.9241 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Covallane, K.; Johan, D.; Singh, R.K.; Sinha, R.; Boodala, D.; Jaiswal, K.K.; Kumar, K.S. Experimental and Numerical Investigation of Jute Fibre-Reinforced Composite, a Sustainable Material for Green Energy. Eng. Proc. 2025, 95, 17. https://doi.org/10.3390/engproc2025095017

Covallane K, Johan D, Singh RK, Sinha R, Boodala D, Jaiswal KK, Kumar KS. Experimental and Numerical Investigation of Jute Fibre-Reinforced Composite, a Sustainable Material for Green Energy. Engineering Proceedings. 2025; 95(1):17. https://doi.org/10.3390/engproc2025095017

Chicago/Turabian StyleCovallane, Kirubakaran, Daryl Johan, Rakesh Kumar Singh, Rahul Sinha, Digvijay Boodala, Krishna Kumar Jaiswal, and Karthik Selva Kumar. 2025. "Experimental and Numerical Investigation of Jute Fibre-Reinforced Composite, a Sustainable Material for Green Energy" Engineering Proceedings 95, no. 1: 17. https://doi.org/10.3390/engproc2025095017

APA StyleCovallane, K., Johan, D., Singh, R. K., Sinha, R., Boodala, D., Jaiswal, K. K., & Kumar, K. S. (2025). Experimental and Numerical Investigation of Jute Fibre-Reinforced Composite, a Sustainable Material for Green Energy. Engineering Proceedings, 95(1), 17. https://doi.org/10.3390/engproc2025095017