Abstract

Advanced engineering materials are in high demand for a combination of tailored properties in a single material. Titanium with aluminum alloys is widely used to prepare pistons and knee joints due to its high strength and abundant availability. The primary focus of the study was to utilize an eco-friendly composite material with low cost and a simple production process. Ti–48Al–2Cr–2Nb with molybdenum disulfide was added as reinforcement in varying percentages, fabricated using the squeeze casting production technique. The dry sliding wear test was performed. Adding 4% molybdenum disulfide to Ti–48Al–2Cr–2Nb enhanced its mechanical properties and wear resistance by 57%.

1. Introduction

Using traditional monolithic materials has some ability in accomplishing stiffness and strength. Composite materials are gaining attention for surmounting the shortcomings of monolithic materials, and meet the ever-escalating demands of modern technology. The potential pay-off for the composites is so high that they have become one of the fastest-evolving research and development areas [1]. Due to their enhanced properties and potential for weight reduction, there has been a growing interest in Ti–Al-based metal matrix composites reinforced with discontinuous particles as alternatives to solid materials in several sectors [2]. Combining titanium with niobium-based materials can lead to significantly enhanced strength in composite that exhibit better strength. The high cost of production limits the manufacturing of composite materials. However, squeeze casting employs a uniform mixture during the fabrication process to address challenges.

The mechanical and tribological properties of Ti–Nb composites were investigated by Johannsen et al. [3], on both heat-treated and untreated specimens. The aluminum oxide (Al2O3) and MoS2 reinforcement particles significantly changed mechanical and wear properties. Abrasive and adhesive wear, along with plastic deformation in dry sliding conditions, were the dominant phenomena in the tribological conditions of the composites. The tensile strength improved, while reinforced particles increased. It was found that the proper dispersion of the particulates in the matrix determined the property improvement of the composite material. The reinforced particles’ distribution was uniform at low percentages, but agglomeration and sedimentation were formed as the reinforcement percentage increased. MoS2 was added to avoid this problem [4].

The wear resistance of the composite improved up to 2% of the SiC and MoS2, but beyond this, the wear rate started to increase. The coefficient of friction (COF) value also reduced with the increase of the reinforcement. Sathish et al. [5] reported that adding MoS2 with Ti and V as alloying elements can replace steel, improving corrosion resistance. The Co–Nb and Ti–Al alloys are the materials used for implant applications. Despite their excellent strength, stiffness, and high density, these materials are subject to failure after prolonged usage. Hence, there is a need to develop implants with a longer lifetime and excellent biocompatibility [6]. Ti–Al/MoS2 has an inherent affinity with oxygen and nitrogen to form strong nitrides and oxides as residues, which are potential sites for more nucleation of grains, resulting in fine-grain structures and improved mechanical properties. The cost-effective, high-strength chromium (Cr) and niobium (Nb) alloys used in most industries have some poor performance in certain aspects, which can be overcome by adding titanium (Ti) and aluminum (Al) materials. The required performance can be enhanced by reinforcing the molybdenum disulfide (MoS2) and its alloy metal with desirable particulate reinforcement. Therefore, Ti, Al, Nb, and Cr are chosen in this research due to their exceptional characteristics, including low weight, superior corrosion resistance, and impressive strength-to-weight ratios. These properties make these elements well-suited for various industrial applications. The objectives of the present study are:

- To develop a Ti–Al–Cr–Nb composite material with appropriate proportions of the constituents, which will be advantageous in applications related to aeronautical industries and scale down the usage of the monolithic element with enhanced properties, life expectancy, and better performance.

- Fabrication of Ti–48Al–2Cr–2Nb with MoS2 composites varying by 2% to 6% using the squeeze casting technique and analyzing their microstructure.

- To evaluate the mechanical properties of Ti-48Al-2Cr-2Nb/MoS2 composites.

2. Experimental Studies

2.1. Matrix

2.1.1. Titanium Alloy (Ti) and Aluminum Alloy (Al)

The aluminum and titanium matrices are frequently employed due to their superior mechanical properties. Aluminum is a versatile material used across numerous industries. This material was chosen because of its advantageous properties, such as its ease of machining, corrosion resistance, and lightweight nature. The titanium metal matrix composites replace the automobile parts to reduce the components’ weight and achieve the material’s required properties. The physical and mechanical properties of titanium and aluminum alloys are represented in Table 1 [7]. This study obtained aluminum and titanium materials from Manhar Metal Supply Corporation, Chennai, India.

Table 1.

Physical and mechanical properties of titanium and aluminum alloys.

2.1.2. Chromium (Cr) and Niobium (Nb)

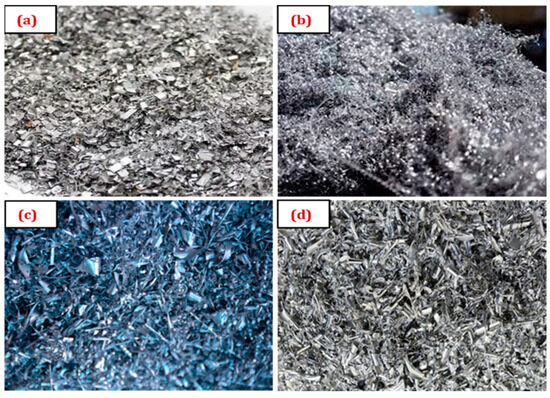

Chromium is a compound of Cr and niobium with the chemical formula of Nb. The Nb has high hardness and low density. Because of that, it is used in various applications, including military armor, nozzles, pump seals, and control rods in nuclear plants. The chromium and niobium materials were procured from Shubham Industrial Pvt. Ltd. Mumbai, India. Table 2 illustrates the physical and mechanical characteristics of chromium and niobium alloys. [8]. The initial raw materials of pure Ti, Al, Nb, and Cr are shown in Figure 1a–d.

Table 2.

Physical and mechanical properties of chromium and niobium alloys.

Figure 1.

Raw materials (chips) of (a) Ti, (b) Al, (c) Cr, and (d) Nb alloys.

2.2. Reinforcement Material

The MoS2 particles in the metal matrices provide better strength and stiffness to the composites and good thermal and electrical conductivity. Joseph et al. [9] explained that machining characteristics, such as improved surface roughness and reduced cutting forces, were enhanced to improve the wear resistance. To avoid self-ignition issues, it is essential to have a solid lubricant like molybdenum disulfide as reinforcement. In this study, MoS2 was obtained from Royal Industrial Traders, Mumbai, India, as shown in Figure 2.

Figure 2.

Raw material of molybdenum disulfide (MoS2) particles.

2.3. Fabrication Process of Squeeze Casting

- (a)

- Experimental Setup

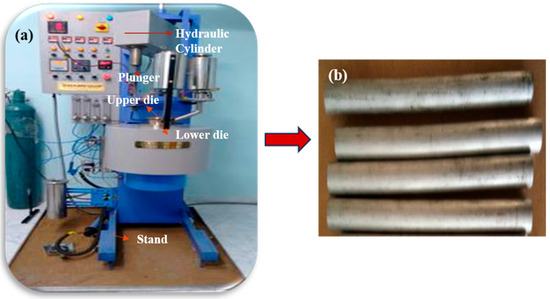

A separate pre-heater was used to retain the melt’s pouring temperature inside the die cavity. If the temperature of the die was lower than the prescribed range, it caused premature cooling and cold laps in the casting. The die surface defects were induced when the die temperature reached a higher range. The die pre-heater was employed to maintain the die internal temperature of 500 °C. A switch provision in the squeeze casting setup’s panel controlled the die’s temperature. Then, the molten metal was transferred from the furnace to the metal mold cavity through the pathway unit, which was integrated with the furnace pouring spot and mold top surface. A pre-heater kept the pathway temperature at approximately 600 °C, preventing early solidification within the passage. According to the casting material, the preheater temperature was maintained by the controller in the panel board of the squeeze casting setup, and the equipment is shown in Figure 3. The bottom pouring electric induction furnace with a 2 kg capacity can melt the metals up to 1200 °C. A pit was made near the furnace with a concrete bed to accommodate the metal die unit. The split die with a cylindrical cavity made from H13 die steel was placed inside the pit during casting. The hydraulic pressure unit capacity of 100 tons can deliver up to 500 MPa pressure and was placed above the metal die at the center of the pit by clamping devices to maintain rigidity during load delivery [10]. The punch was firmly fitted with the hydraulic cylinder to pressure the molten metal during solidification. The panel board with control knobs was mounted behind the furnace to control the process and other accessories. Adjacent to the furnace stand, an argon gas cylinder with a capacity of 100 L was used to supply argon gas to the molten metal to ensure purification and removal of the burned gases from the molten metal. The bottom metal pouring spot of the furnace was related to a portable metal die through a pathway runner; it transferred the molten metal from the furnace to the die cavity in a negligible duration without the turbulent flow of the molten metal. The thin graphite coating eliminated the adhesiveness of the molten metal with the metal die. Hence, the casting could be easily removed from the mold after solidification without casting surface damage.

Figure 3.

Schematic representation of (a) squeeze casting equipment and (b) casting samples.

- (b)

- Process parameters of casting

The squeezing pressure, pouring temperature, and dwell time (loading duration) affected responses significantly. Hence, it is noted from the literature that a minimum of 50 MPa pressure is required to eliminate the porosity [11]. Pressures from 75 MPa showed better results, and pressures above 125 MPa did not affect the mechanical properties of Ti-Al alloys. Thus, the pressure range was fixed at 75 MPa to 125 MPa. The solidification time for light metal alloys is in the range of 30 to 60 s. Complete solidification occurs when it exceeds 60 secs, and there is no significant improvement in mechanical properties. Hence, the dwell time was fixed to 60 s. Pouring temperatures higher than 800 °C lead to the development of a coarse dendritic structure due to impediments in the solidification period. In contrast, temperatures less than 650 °C led to early solidification in the castings. They may cause cold shut, shrinkage, pinholes, etc., in the castings. Hence, the experimental investigation considers the pouring temperature in the range of 720 °C to 840 °C. Premature solidification occurs when the die’s preheating temperature is below 220 °C, and there is a loss in the die’s life period if the die’s temperature is above 300 °C. To avoid the above setbacks, this work adopts a die-preheating temperature of 270 °C.

2.4. Mechanical Properties

2.4.1. Brinell Hardness Test

The ASTM E9 standard was used for performing the Brinell hardness test [12] at three different locations per composite with the specimens cast according to the dimension of Ø30 mm × 15 mm, and the mean value is considered. The Brinell hardness of the composites and matrix alloy is measured using Brinell testing equipment. The procedure involves applying a 200 N test force for 10 to 15 s at various points on the composite surface, using a 5 mm diameter ball indenter.

2.4.2. Tensile Test

Three samples per composite designation were subjected to the tensile test by ASTM E8-04. The mean value was measured with an overall length of 50 mm and a diameter of the grip section of 10 mm [13]. A computerized system connected to the tensile test machine notes the output of load vs. deflection and stress vs. strain.

2.4.3. Density

The density of the composite materials and the matrix alloy was calculated using the theoretical method and measured using experimental methods. For each experiment to measure the density of the composites, three specimens were considered for variability. The theoretical density for single reinforcement composite material was calculated using the rule of mixture principle using Equation (1) [14] and compared with the mean density.

3. Results and Discussion

3.1. Initial Microstructure

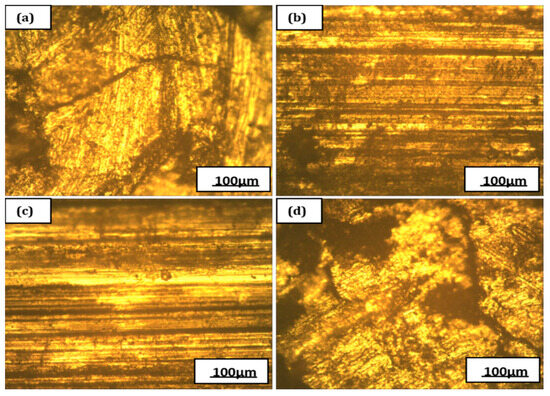

Figure 4a–d displays the optical microstructure images of the unreinforced alloy and hybrid composites. Figure 4a illustrates the fissures and more prominent channels present on the surface of the base alloy. Initially, the MoS2 particles have a much higher melting point than the material. As a result, they become partly embedded in the base material and appear as small plate-shaped structures. When the wt.% of reinforcing particles increases, and later, it decreases, the presence of surface grooves, which serve as lubricants to enhance the mechanical properties. The matrix phase is characterized by an Al/Ti/Cr composition and contains Nb particles with a small, plate-like shape. In contrast, the secondary phase consists of MoS2 particles with a spherical shape. The grain size has decreased, resulting in a significant improvement in mechanical properties. However, no MoS2 particle clustering was observed in the combination, as revealed by backscattered electron microscopy. Zang et al. [15] prepared a hybrid composite material through a squeeze casting process using Ti–Al alloy as the matrix with Al2O3 and MoS2 as reinforcements. However, the material strength of the composite improved due to the presence of MoS2, whereas the smooth surface appears up to 3% of reinforcement particles. Figure 4c reveals a uniform mixture in addition to 4% MoS2 particles to the base alloy, which tends to have a smooth surface. However, small cracks are identified, increasing 6% MoS2 particles, as shown in Figure 4d.

Figure 4.

OM of (a) Ti-48Al-2Cr-2Nb alloy, (b) Ti-48Al-2Cr-2Nb/2%MoS2, (c) Ti-48Al-2Cr-2Nb/4%MoS2 and (d) Ti-48Al-2Cr-2Nb/6%MoS2 mixtures.

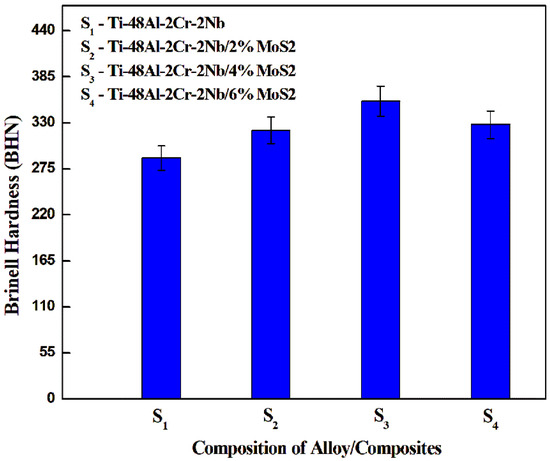

3.2. Evaluation of Brinell Hardness

Figure 5 shows the Brinell hardness values of base alloy and hybrid composites with varying reinforcement content. Due to the thermal mismatch during the solidification of the molten metal, the hardness values of the Ti-48Al-2Cr-2Nb composite increased with the addition of MoS2 particles. Reinforcement particles in molten metal provide nucleation sites, resulting in finer grain sizes and composite grain boundary strengthening. Because the moving dislocation must change its orientation across the grain boundary and the slip system changes, grain boundaries impede dislocation motion [16]. Thus, a larger grain boundary area in composites leads to significant strengthening. Because of MoS2 particles in the matrix, the Ti–48Al–2Cr–2Nb/4% MoS2 specimen exhibits high hardness (356 BHN) over the as-cast alloy. Due to the addition of a high weight percentage of MoS2 particles in the matrix, the hardness values of Ti-48Al-2Cr-2Nb/6% MoS2 are lower than those of other composites (Figure 5). The inclusion of reinforcements in composite materials can significantly impact their hardness. The composite’s hardness exhibits an upward trend as the concentration of reinforcement particles, like MoS2, increases, but only to a specific limit. The hardness gradually rises until it reaches 4 wt.% of MoS2; however, it declines when the particle content is elevated to 6% (328 MPa). However, the strain value of the composite specimens continues to increase with the addition of MoS2. This suggests that the optimal percentage of reinforcement particles for achieving maximum hardness varies depending on the material type and size [17]. The particles incorporated into the material are responsible for its lubricating properties. The presence of MoS2 particles enables swift grain motion along the slip planes, resulting in the effortless deformation of the sample under the indenter.

Figure 5.

Histogram of Brinell hardness of hybrid composites.

3.3. Evaluation of Split Tensile Test

Table 3 presents the results of tensile tests conducted on Ti–48Al–2Cr–2Nb alloy and its hybrid composites. The hybrid composites exhibited superior tensile strength compared to the base Ti–48Al–2Cr–2Nb alloy, which can be attributed to the fine-grained structure developed during the solidification process of these composite materials. The reinforcing particles in the liquid metal served as nucleation sites for grain formation, decreasing grain size. Particles of hard reinforcement, such as molybdenum disulfide, impeded the movement of dislocations [18]. The tensile strength of the as-cast alloy is 1032 MPa. The UTS is increased to 1365 MPa due to an increase of 2% in MoS2 particles, as represented in Table 3. The maximum tensile strength (1473 MPa) was obtained for the 4wt%MoS2 hybrid composite; meanwhile, the percentage elongation was also reduced from 12.89% to 8.62%, respectively. The study reveals that adding MoS2 particles to a base alloy enhances the tensile strength of the resulting hybrid composites, with the improvement being directly proportional to the weight percentage of MoS2 particles incorporated. Scanning electron microscopy analysis shows that the binding strength between larger particles with longer, shallower craters is more significant than between smaller particles. This is attributed to the formation of more shallow craters and sliding grooves, reducing the elastic modulus of the hybrid composites, ultimately resulting in a higher tensile strength than the base alloy.

Table 3.

Tensile properties of Ti–48Al–2Cr–2Nb hybrid composites.

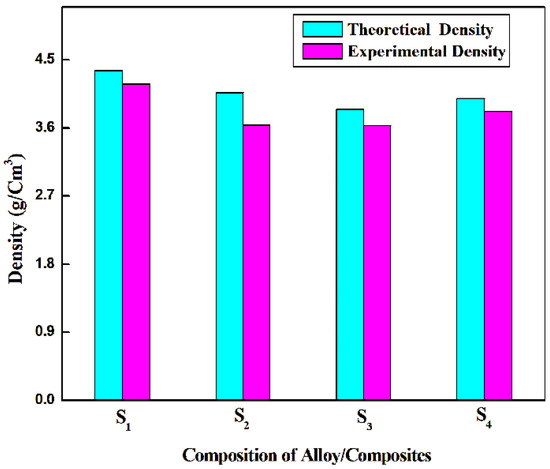

3.4. Assessment of Density

The theoretical density of the composites was determined using the law of mixtures from Equation (1). Figure 6 displays the comparison between theoretical and measured density. The theoretical densities of the base alloy are higher (4.36 g/cm3) than the density of the hybrid composites. The density value of the sample (S2) is 3.85 g/cm3, and adding the MoS2 reinforcement in the matrix phase decreased the experimental density of composites by up to 4% (3.70 g/cm3) due to uniform distribution between particles [19]. As the concentration of particles increases, the matrix–particle interface strengthens, which enhances the particles’ tendency to aggregate. Incorporating 6% MoS2 particles deteriorates their bonding abilities, resulting in a lower measured density of 3.82 g/cm3 compared to the theoretical density.

Figure 6.

Graphical representation of the density of hybrid composites.

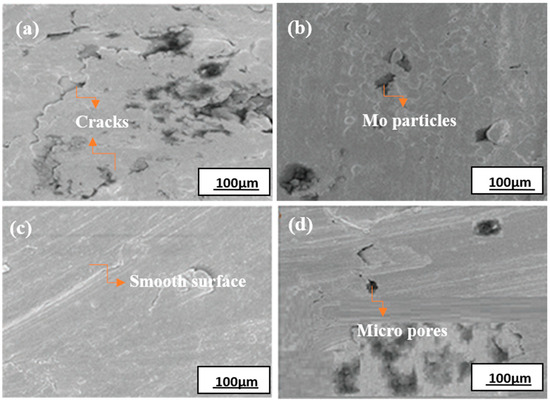

3.5. Surface Morphology

Figure 7a depicts a mechanically alloyed Ti–48Al–2Cr–2Nb matrix that exhibits cracks and pores on the material surface. Comparing the base alloy (S1) with other increased weight percentages of MoS2 reinforced and mechanically alloyed cast samples, SEM morphology exemplified a smaller size and was found to lower the cracks. Adding a 4% MoS2 specimen represents the dense and homogenous morphology that enhances tensile behavior and produces a smooth surface (Figure 7c). Further addition of 6% reinforcement, the decohesion of MoS2 from the matrix alloy resulted in the formation of dimple structures, which reduced the material strength, as shown in Figure 7d. Ismail et al. [20] confirmed ductile behavior in the matrix alloy, which led to necking and plastic deformation before failure occurred. Therefore, the Ti–48Al–2Cr–2Nb/4% hybrid composite possesses high strength and better surface conditions than the other composites. It is used widely in making pistons, bolts, flying wheels, etc.

Figure 7.

SEM images of (a) Ti–48Al–2Cr–2Nb alloy, (b) Ti–48Al–2Cr–2Nb/2%MoS2, (c) Ti–48Al–2Cr–2Nb/4%MoS2 and (d) Ti–48Al–2Cr–2Nb/6%MoS2 mixtures.

4. Conclusions

- The squeeze casting method successfully produced Ti–48Al–2Cr–2Nb alloy samples by varying amounts of MoS2 by weight.

- SEM micrograph analysis has verified the even distribution of MoS2 particles throughout the Ti–48Al–2Cr–2Nb matrix.

- The Brinell hardness of the composite was improved in addition of S3 composite compared to other samples. The hardness enhancement was 36% higher than that of the parent as-cast sample.

- Among the composite samples tested, the 4% MoS2 hybrid composite exhibited superior tensile strength compared to the other compositions. The improved tensile strength was 42% more than that of the parent as-cast sample. The enhanced strength can be attributed to the even distribution of reinforcement particles throughout the matrix.

- An examination of the surface morphology reveals that MoS2 particles are uniformly dispersed throughout the matrix material. Analysis of the Ti–Al structure with varying weight percentages of reinforcement filler demonstrated prominent adjustments. Adding 4% MoS2 with Ti–Al–Cr–Nb exhibits a smooth surface.

- Therefore, the Ti–48Al–2Cr–2Nb/4% hybrid composite exhibits enhanced density and superior mechanical characteristics.

Author Contributions

B.M.R.: Data curation, Investigation, Formal analysis, experimentation, writing original draft, Validation, Visualization, and Funding acquisition. S.S.K.R. and B.V.: Conceptualization, Resources Management, Writing & editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not Applicable for studies not involving humans or animals.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Data sharing is not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Freitas, L.R.; Gelamo, R.V.; Marino, C.E.; Nascimento, J.P.; Figueiredo, J.M.; Fernandes, J.C.; Moreto, J.A. Corrosion behaviour of reactive sputtering deposition niobium oxide based coating on the 2198-T851 aluminium alloy. Surf. Coat. Technol. 2022, 434, 128197. [Google Scholar] [CrossRef]

- Ai, Y.; Wang, Y.; Yan, Y.; Han, S.; Huang, Y. The evolution characteristics of solidification microstructure in laser welding of Ti-6Al-4V titanium alloy by considering transient flow field. Optics Laser Technol. 2024, 170, 110195. [Google Scholar] [CrossRef]

- Johannsen, J.; Lauhoff, C.; Stenzel, M.; Schnitter, C.; Niendorf, T.; Weinmann, M. Laser beam powder bed fusion of novel biomedical Titanium/Niobium/Tantalum alloys: Powder synthesis, microstructure evolution and mechanical properties. Mater. Design 2023, 233, 112265. [Google Scholar] [CrossRef]

- Narayana, T.; Saleem, S.S. Enhancing Fretting Wear Behavior of Ti64 Alloy: The Impact of Surface Textures and CrN-MoS2-Ag Composite Coating. Tribol. Int. 2024, 193, 109346. [Google Scholar] [CrossRef]

- Sathish, T.; Saravanan, R.; Kumar, A.; Prakash, C.; Shahazad, M.; Gupta, M.; Senthilkumar, N.; Pandit, B.; Ubaidullah, M.; Smirnov, V.A. Influence of synthesizing parameters on surface qualities of aluminium alloy AA5083/CNT/MoS2 nanocomposite in powder metallurgy technique. J. Mater. Res. Technol. 2023, 27, 1611–1629. [Google Scholar] [CrossRef]

- Mathew, R.; Ajayan, J. Material processing, performance and reliability of MoS2 field effect transistor (FET) technology-A critical review. Mater. Sci. Semicond. Proc. 2023, 160, 107397. [Google Scholar] [CrossRef]

- Ramanathan, S.; Vinod, B.; Narayanasamy, P.; Anandajothi, M. Dry sliding wear mechanism maps of Al-7Si-0.3Mg hybrid composite: Novel approach of agro-industrial waste particles to reduce cost of material. J. Bio- Tribo-Corros. 2019, 5, 32. [Google Scholar] [CrossRef]

- Safavi, M.S.; Walsh, F.C.; Visai, L.; Khalil-Allafi, J. Progress in niobium oxide-containing coatings for biomedical applications: A critical review. ACS Omega 2022, 7, 9088–9107. [Google Scholar] [CrossRef] [PubMed]

- Joseph, J.D.; Kumaragurubaran, B.; Sathish, S. Effect of MoS2 on the wear behavior of aluminium (AlMg0.5Si) composite. Silicon 2020, 12, 1481–1489. [Google Scholar] [CrossRef]

- Pragathi, P.; Elansezhian, R. Mechanical and microstructure behaviour of aluminum nanocomposite fabricated by squeeze casting and ultrasonic aided squeeze casting: A comparative study. J. Alloys Comp. 2023, 956, 170203. [Google Scholar] [CrossRef]

- Srinivasan, R.; Shrinivasan, B.H.; Prasath, K.J.; Saleth, R.J.; Anandhan, R.D. Experimental investigation of aluminium hybrid metal matrix composites processed through squeeze casting process. Mater. Today Proc. 2020, 27, 1821–1826. [Google Scholar] [CrossRef]

- Rockenhäuser, C.; von Hartrott, P.; Skrotzki, B. Brinell-Hardness data (HBW 2.5/62.5) of aluminum alloy EN AW-2618A after different aging times and temperatures. Data Brief 2023, 46, 108830. [Google Scholar] [CrossRef] [PubMed]

- Vinod, B.; Sonagiri, S. Hot deformation and fatigue behaviour of a zinc base doped biocompatible material: Characterization of plasma spray coating on surface. Surf. Topogr. Metrol. Prop. 2023, 11, 035015. [Google Scholar] [CrossRef]

- Ebenezer, N.S.; Vinod, B.; Jagadesh, H.S. Effect of Heat Treatment on the Corrosion Behaviour of Nickel Surface-Deposited Agro-Reinforced Metal Matrix Composites. J. Inst. Eng. (India) Ser. D 2021, 102, 345–354. [Google Scholar] [CrossRef]

- Zhang, C.; Liao, W.; Shan, Z.; Song, W.; Dong, X. Squeeze casting of 4032 aluminum alloy and the synergetic enhancement of strength and ductility via Al-Ti-Nb-B grain refiner. Mater. Sci. Eng. A 2024, 896, 146233. [Google Scholar] [CrossRef]

- Baskaran, P.; Saravanan, R.; Vignesh, M.; Prasanna, N.; Gnanavel, C.; Nagarathi, D.K.; Gopalakrishnan, T. Influence of molybdenum disulfide particles’ concentration on waste cooking oil nano fluid coolant in cutting force reduction on machining SAE 1144 steel. Mater. Today Proc. 2022, 62, 1969–1972. [Google Scholar] [CrossRef]

- Ma, Z.Q.; Wang, Y.H.; Peng, Y.; Guo, X.; Meng, Z. A novel molybdenum disulfide nanosheet loaded Titanium/Zirconium bimetal oxide affinity probe for efficient enrichment of phosphopeptides in A549 cells. J. Chromatogr. B 2022, 1199, 123235. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, P.; Krishnan, G.S.; Kumar, J.P.; Bakkiyaraj, M.; Pradhan, R. A critical investigation on viscosity and tribological properties of molybdenum disulfide nano particles on diesel oil. Mater. Today Proc. 2021, 43, 1830–1833. [Google Scholar] [CrossRef]

- Faudzi, S.M.; Khalil, A.N.; Azmi, A.I.; Sowi, S.A. Thermophysical Properties of Molybdenum Disulfide (MoS2) and Aluminium Oxide (Al2O3) in Bio-based Coconut Oil Hybrid Nanolubricant for Cleaner Metalworking Cutting Fluid Applications. Tribol. Ind. 2023, 44, 247. [Google Scholar] [CrossRef]

- Ismail, K.B.; Arun Kumar, M.; Mahalingam, S.; Kim, J.; Atchudan, R. Recent Advances in Molybdenum Disulfide and Its Nanocomposites for Energy Applications: Challenges and Development. Materials 2023, 16, 4471. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).